International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Rahul Chandel1, Sayantan Ghosh2

1Master's Degree Scholar, Department of Civil Engineering, Maharaja Agrasen University, Baddi (Himachal Pradesh)

2 Assistant Professor Department of Civil Engineering, Maharaja Agrasen University, Baddi (Himachal Pradesh)

Abstract - Powder obtained from the recycling process of concrete waste is consideredanessentialproductforattaining complete recycling of concretewaste.Powder withasize< 150 μm is considered in the categories withanomenclatureasRCP (recycled concrete powder). However, various studies show that the RCP integrated with cement reducestheperformance. Thus, this study aims to investigate the performance of thermally treated RCP at 650 0C, 700 0C, and 7500C for 2h and also investigate the properties of untreated RCP, at 10% and 15% replacement with the addition of 1% nano CaCO3 Various properties of mortar, such as flow ability, SAI (Strength Activity index) at28days, andcompressivestrength, were tested, besides determining the flow ability, affected by an increase in dosage of replacement, an increase in treated temperature, and on addition of Nano CaCO3.TheSAIvaluesof mortar mixes 650TR10N, 700TR10, 700TR10N, 700TR15and 700TR15N are 76.8%, 75%, 84.3%, 77.9% and 88% respectively. Thermally treated RCP at 700oC at 15% replacement with 1% nano CaCO3 shows 7% increment at 7days and 11.9% reduction in compressivestrengthat28days as compared to standard mortar (Rf). The effective range of activation of RCP in this study ranges from 6500C to 7000C.This study provides a way to utilize RCP and contribute to sustainable construction practices.

Key Words: Construction and demolition waste, nano Calcium carbonate, Recycled Concrete Powder, thermally treated Concrete Powder.

Theconsumptionofconcreteworldwideisabout25billion tonsannually,anditsdemandrisesdramatically.Production rateofconcretepredictedtobemorethan18billiontonsper year,andcementwillbe5.5billiontonsby2050[1].

Construction industries are promising to take steps to achievenet-zeroemissionsby2050.Variousstudiesshow, the construction industry contributes approximately 20% CO2 emissions globally.Mostly,7%to8% comesfrom the cementindustryalone[2].Datafromvariousenvironmental and concrete associations shows that the production of cementintheyearof2023was4.1billiontonnesglobally.

On the other hand, the problem of C&DW arises, approximately, 3 billion tonnes of C&DW are generated annually and grow constantly [3] and [1]. India is the second-largest country behind China, which produces approximately100to400MTC&DWperyearreportedby Building Material and Technology Promotion Council (BMTPC).MostofC&DWisinertandnon-hazardous,other than this minority of C&DW containing environmental unfriendlysubstanceslikeasbestos, organicpollutantand heavy metals especially, zinc which is responsible for soil andairpollution,secondissueswiththat,itrequireslandfor its dumping which increase its dumping cost as well as coveredusefulland,[1]

Various studies are available and still ongoing to find the solutionstotheaboveproblem.TheRCPparticleshavean irregular shape, a rough surface, and micro pores, which increasewaterdemandandadverselyaffecttherheological properties[1].Incontrast,thesharpangleandroughsurface improvethehydrationprocessbyprovidingnucleationsites, varioushydratedproductslikeC-S-Hgel,Aft,andCHform duetoinitialhydration,andCaCO3 duetocarbonation,and SiO2 from sand, chemical composition almost similar to cement[1].StudiesfoundthatCaOandSiO2oxidesaremajor oxidesinRCPinwhichSiO2ispresentinmajorityandAl2O3, which are obtained from hydration products, unhydrated cement,andCaCO3,[4]

Rocha,J.H.,&Filho,R.D.reportedthatthestrengthActivity Index of RCP is enhanced by the particle size of RCP and reportedthat87.2%AIat28dayscomesatD50 of8.22μm, and AI comes 15% at D50 of 22.7 μm, and comes approximately100%atD50of2.34μm.Thermaltreatmentis oneoftheeffectivemethodstoenhancethereactivityofRCP. Several studies found that the effective range of thermal activationofRCPrangesfrom6500Cto700°C,providingAI of >75% and also reported that, with temperature and replacementdosageincrease,therheologicalpropertiesare affected,andfoundthatreplacementdosageshouldbe<30% tobeanadequatereplacement[4] Thepreviousstudieson nanoCaCO3foundtheoptimumdosagerangeofnanoCaCO3 asanadditiveis1%to3%;furtherincrementsinitsdosage cause agglomeration of particles, resulting in improper hydration[5][6].

International Research

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

Based on findings from previous studies, this study investigatesthefeasibilityofthermal-treatedanduntreated RCPhavingasize<75μmasanSCMwiththeadditionof1% nano CaCO3, which has not been investigated yet. In this study,RCParethermallytreatedat6500C,7000Cand7500C for 2h in muffle furnace and leave it for 24h for cooling insidefurnace,andpreparemortarsampleof10%and15% replacementbycementandinvestigatesomepropertieslike AIat7daysand28days,mechanicalpropertiesat7daysand 28daysandrheologicalpropertiesatfreshstate.

In this study, ordinary Portland cement of grade 43, river sand,portablewater,nanoCaCO3havingpropertiessuchas: molecular weight of 100g/mol, melting point 1339oC, densityof2.71g/cm3,purityof99%,whitecolorandhaving particlesize(APS)of<100nm,wereusedasadditive.Inthis study,approximately3%weightpercentageofthefraction of <75 μm, size RCP generated from concrete waste by performingsieveanalysis.

2.1

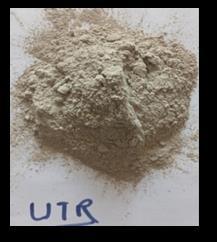

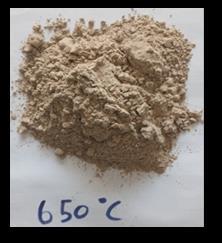

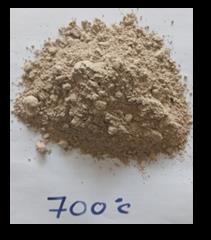

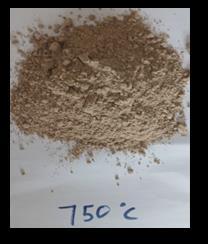

ThermaltreatmentofRCPat6500C,7000Cand750°Cfor2h withaheatingrateof10°C/minute,inamufflefurnace,and leaveitfor24hforcoolinginsidethefurnace,showninFig. 1,andhaveLOIof13.5%.

2.2 Mixing Composition and Specimen Preparation of Mortar

UsingASTMC109forcompressivestrengthandASTMC311 standard for sampling and testing fly ash or natural pozzolana for use in Portland cement concrete, and a specimensizeof50x50x50mmasperASTMspecification. Prepare 108 specimens of 18 samples shown in Table 1, havingabinder-to-sandratioof1:2.75andwatertowaterto-binderratioof0.5. InTable1,Rfwasareferencesample, and RfN composition same as the (Rf) reference sample, exceptadditional1%nanoCaCO3.UTR10untreatedRPCwith 10% replacement, UTR15: untreated RPC with 15% replacement.UTR10N-untreatedRPCwith10%replacement with 1% nano CaCO3, UTR15N- untreated RPC with 15% replacement. 650TR10- thermal treated at 650 de gree Celsiuswith10%replacement,650TR15-thermaltreatedat 650 degrees Celsius with 15% replacement.700TR10thermal treated at 700 degree Celsius with 10% replacement, 700TR15- thermal treated at 700 degree Celsiuswith15%replacement.750TR10-thermaltreatedat 750 degree Celsius with 10% replacement, 750TR15thermal treated at 750 degree Celsius with 15% replacement.

ToinvestigatethefeasibilityoftreatedanduntreatedRCPas an SCM with 1% nano CaCO3 as an additive, certain test methods are adopted in this study and emphasizing on to determine the AI and, 7days and 28 days compressive strength according to ASTM C 311 and ASTM C 109 respectively, andflowabilitybehavior byusingflow table testfollowingASTMC1437.

Fig-1:(a)untreatedRCP,(b)thermallytreatedRCPat 650oC,(c)thermallytreatedRCPat700oC,(d)thermally treatedRCPat750°C

Table-1: SamplecompositionofRCPmortar

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net

fig.4.(d).Thedescendingorderofcompressivestrengthof mixessameasSAI,discussedinSection3.2.

3.1

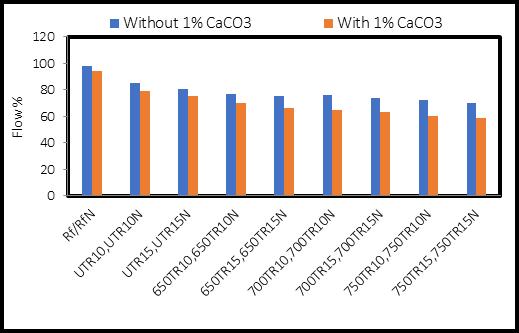

The flow table outcomes of fresh mortar are shown in Fig.2.Rfshowsmaximumflowabilityofabout98%.Itclearly shows in Figure 2, the flow of mortar decreases with an increase in replacement dosage, with an increase in activationtemperature,andwiththeadditionofnanoCaCO3, [4],[5],and[6] Inthisstudy,650TR10and650TR15show flowof77%and75%;similarly,650TR10Nand650TR15N showflowof70%and66%.700TR10and700TR15havea flow of 76% and 74% and in the case of 700TR10N and 700TR15N, show a flow of 65% and 63%.750TR10 and 750TR15 have a flow of 72% and 70% and in the case of 700TR10Nand700TR15N,showaflowof60%and59%.

At 28 days strength activity index, only few mix samples achievestandardSAIvalueasperASTMC311standardsuch as: 650TR10N,700TR10, 700TR10N, 700TR15and 700TR15NhavingSAIvalue76.8%,75%,84.3%,77.9%and 88% respectively, show in Fig.3.And follows descending order of SAI value such as: 700TR15N>700TR10N>700TR15>650TR10N>700TR10.

Thisstudyfoundthat700°Cisaneffectivetemperaturefor activation of RCP if nano CaCO3 was not added. On the additionof1%nanoCaCO3, resultsfurtherenhancementin compressivestrengthandalsoprovidegoodresultsat650o apartfrom700°C.Thus,onadditionof1%nanoCaCO3the effective range of thermal treatment temperature varies from650oCto700oC.

Compressive strength results, show in Fig.5, RfN shows increment of 3.9% and decrement of 4% in compressive strengthat7daysandat28days,showninfig.4.(a).650TR10 hasdecrementof9.3%and28.8%at7and28daysandin caseof650TR10Nshowsdecrementof2.3%and25%at7 days and 28 days, shown in fig.4.(b).700TR10 and 700TR10N, shows small decrement of 14% and 16.4% at 7days and has 15.7% and 25% at 28 days, shown in fig.4.(c).700TR15showsverylowerdecrementof3.9%and 25%at7and28days.700TR15Nshowsincrementof7%at 7daysandleastdecrementof11.9%at28days,shownin

Fig-2:FlowabilityofuntreatedandtreatedRCP,withand without1%nanoCaCO3

Fig-3:StrengthActivityIndexat28days

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

increasingthehydrationproduct.VariousStudiesonnano CaCO3found,nanoCaCO3onlyprovidenucleationsitewhen itisinertandnotreactwithcementandshowpresenceof weaken spot on contact place between nano CaCO3 and siliconrichlayer,duetodisturbancecreatedonthesilicon rich layer on surface of cement and also provide the nucleation site outside the silicon rich layer that leads to acceleratetherateofhydrationandshortentheinduction periodasaresultprovidingearlyagestrength,[6] Duetothe highsurfaceenergyofnanocalciumcarbonateadsorbsCa2+ andOH-ionsgeneratedbyC3Sandacceleratesthehydration by providing acceleration to ion migration, and provides nucleation sites leading to the production of a denser structure of C-S-H gel. Due to the large consumption of water,resultingreductionininductiontimeandrheological propertiesisaffected,Fig.2,[7]and[6].

RCPhasalargeporosityandangularshape,causingalarge specific surface area, hence, water demand increases. Similarly,specific surface area increases with increases in replacementandthermaltreatment(largespecificsurface area due todecomposition ofcompoundandformation of activecompounds)rheologicalpropertiesareaffected,Fig. 2,[4]and[5]

At 700 °C treatment to RCP gives a satisfactory result. Literature found, at 500 0C thermal treatment to RCP dehydrationoffreewaterandboundwateroccurs,at6006500C,CHdecomposesandpartialdecarbonationofcalcite, at800-1000 0C,calcitedecarbonationandCaO,C2S,andC3S found,andat12000CamorphousSiO2 found,[4] At650 0C, CHdecomposesintoCaOandOHandpartialdecarbonation of calcite (CaCO3 decompose into CaO and CO2 and less formationofactivecompounds,thermaltreatmentat7000C contributefurtherdecompositionofcalciteandotheractive compoundshavinglargespecificsurfaceareaandpartially formation ofC2Sand C3Scompounds occurs thatpromote secondary hydration and other finer compounds provide nucleationsite,insteadofitpresenceofbothcrystallineand amorphous silica act as filler and pozzolonic material. A studyfoundthat,withfurtherincreaseintemperatureupto 7500C resulting compound decomposes and forms finer particles, which increase the specific surface area and finenessofparticles,leadingtoagglomeration.Asaresult, waterdemandincreased,leadingtoareductioninstrength [4]and[5]

5. Conclusion

Fig-4:Compressivestrengthat7and28days,(a)Rfand RfN.(b)650TR10and650TR10N(c)700TR10and 700TR10N.(d)700TR15and700TR15N.

4. Discussion

In this study, with 1% nano CaCO3 as an additive, the influence on the compressive strength of RCP mortar at 7 and 28 days. This is due to nanoCaCO3 improving the hydrationrateofcementbyprovidinganucleationsiteand

Thisstudyinvestigatesthefeasibilityofthermal-treatedand untreated RCP as an SCM with the addition of 1 % nano CaCO3 Thefollowingconclusionsweredrawn

1) Strength Activity Index of sample 650TR10N, 700TR10,700TR10N,700TR15and700TR15Nare equivalentandabovethestandardSAIvalue,hence, havingalotofpossibilityasSCM.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

2) The maximum strength activity index and compressive strength of RCP were found 700oC thermaltreatment.

3) Thestudyshows,decreaseincompressivestrength with the dosage of replacement, going from 10 to 15%. In contrast, 700°C-treated RCP shows high strengthat15%replacement.

4) NanoCaCO3,enhancesthecompressivestrengthof thermallytreatedRCP,andonadditionof1%nano CaCO3 it can also shows satisfactory results were alsoobtainedattemperaturesof650°C,apartfrom 700oC. Hence, the effective range of thermal treatmentis650oCto700oC.

5) Studyshows that,flowability ofmortar decreases withincreasesincalcinations(treated)temperature andwithreplacementdosageofRCP.

6) Nano CaCO3 shows an adverse effect on the flowabilityofmortars.

References

[1] S. S. Trivedi, K. Snehal, B. Das, and S. Barbhuiya, "A comprehensivereviewtowardssustainableapproaches on the processing and treatment of construction and demolition waste," 2023. [Online]. Available: www.elsevier.com/locate/conbuildmat.

[2] A.Adesina,"Recentadvancesintheconcreteindustry toreduceitscarbondioxideemissions,"2020.[Online]. Available:www.elsevier.com/locate/envc.

[3] p. Jagadesh, S. Oyebisi, A. H. Muthu, A. Sarulatha, K. Supikshaa,V.V. Laxmy,N.A.Sor,andM.A. O.Mydin, "Recycledconcretepowderoncementmortar:Physicomechanicaleffectsandlifecycleassessments,"[Online]. Available:www.elsevier.com/locate/jobe.

[4] J. H. A. Rocha and R. D. T. Filho, "The utilization of recycled concrete powder as supplementary cementitious material in cement-based materials: A systematicliteraturereview,"2023.[Online].Available: www.elsevier.com/locate/jobe.

[5] J. Kim and A. Ubysz, "Thermal activation of multirecycled concrete powder as supplementary cementitious material for repeated and waste-free recycling,"2024.[Online].Available:JournalofBuilding Engineering.

[6] H.SharmaandD.K.Ashish,"NanoCaCO3forenhancing propertiesofcement-basedmaterials:acomprehensive review," 2023. [Online]. Available: www.tandfonline.com/journals/tscm20.

[8] J. Tang, C. Yu, and J. Yu, "Viability of using recycled powder from CDW to produce ternary cement type LC3," [Online]. Available: www.elsevier.com/locate/cscm.

[9] C.Meyer,"Thegreeningoftheconcreteindustry,"2009. [Online]. Available: www.elsevier.com/locate/cemconcomp.

[10] (. E. I. Saraya), “Stopping of cement hydration by variousmethods,” HBRC, 2010.

[11] D.-C. Park, E.-H. Kwon, and J.-c. Ahn, "Analysis on CalcinationofCementitiousPowderofWasteConcrete for Raw Cement," 2014. [Online]. Available: www.jkibc.org.

[12] Karen Scrivener, Ruben Snellings, and Barbara Lothenbatch, A Practical Guide to Microstructural AnalysisofCementitiousMaterials,CRCPress,2016.

[7] Q. Fu, Z. Zhang, X. Zhao, W. Xu, and D. Niu, "Effect of nano calcium carbonate on hydration characteristics and microstructure of cement-based materials: A review," 2022. [Online]. Available: www.elsevier.com/locate/jobe.