International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 12 Issue: 05 | May 2025 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 12 Issue: 05 | May 2025 www.irjet.net

Amarjeet Mohture, Sandesh Bansod , Ajay Mahawadiwar*

B.Tech, Department of Mechanical Engineering, G.H Raisoni University, Saikheda M.P.

*Asstt. Professor, Department of Mechanical Engineering, G.H Raisoni University, Saikheda M.P.

Abstract - The Swinging Cow Grooming Brush is a distinctive and enjoyable tool crafted to simplify grooming for both pets and their owners. Its unique swingingmotion,inspiredbythenaturalmovementof acow'stail,allowsthebrushtoglidegentlythroughthe fur,effectivelycleaninganddetanglingwithoutcausing anydiscomfort.WhatsetstheSwingingCowGrooming Brush apart from traditional grooming tools is its playful and eye-catching design. The swinging action transformsgroomingintoasoothingritualratherthan amundanetask.Itisthoughtfullydesignedtoaccessall areas of the animal's fur, loosening dirt and tangles whileremaininggentleontheskin.Thebrushfeatures an abstract and whimsical design, often showcasing curved lines and soft shapes that deviate from the conventional appearance of grooming tools. It serves notonlyasa groominginstrument butalsoasa piece of art, elevating an everyday task into something visuallyappealing.TheSwingingCowGroomingBrush beautifully merges aesthetics with functionality, providing a creative approach to animal care this grooming tool is ideal for those looking to infuse a sense of fun into the grooming process while maintainingpracticality.Itsuniqueblendofmovement, design, and purpose offers a truly exceptional experience, transforming grooming into a more enjoyableandartisticendeavor.

Key Words: Grooming Cow brush, Swinging motion, Animal care, Abstract design, Animal comfort

1. INTRODUCTION

TheSwingingCowGroomingBrushisadelightfuland innovative tool crafted to simplify the grooming process for your animals while making it a more enjoyable experience. Drawing inspiration from the natural swinging motion of a cow's tail, this brush incorporates a gentle, rhythmic movement that effectivelyloosensdirtandtanglesinthefurwithout causinganydiscomforttotheanimal.

Whatsetsthis brushapart isitsuniquedesign, which not only enhances the effectiveness of grooming but also transforms it into a soothing and almost playful

activity for both the animal and the owner. Whether you're tending to a cow, horse, or other types of livestock, the Swinging Cow Grooming Brush merges practicalitywithcreativedesign,providingarefreshing approachtoanimalcare.

Enhance Grooming Efficiency: Utilizes a swinging motionthateffectivelyeliminatesdirtandtanglesfrom thefur.

Prioritize Comfort: Softly brushes the animal's coat, ensuring a gentle experience that mimics a natural, soothingmotion.

Transform Grooming into Enjoyment: Makes the grooming process a fun and calming experience for bothpetsandtheirowners.

Encourage Consistent Use: Inspires pet owners to groom morefrequentlybyturningitintoanengaging andenjoyableactivity.

Merge Functionality with Aesthetics: Integrates practicalgroomingfeatureswithanattractive,abstract designthatcatchestheeye.

Adaptable for Various Animals: Designed to be effectiveforarangeofanimals,includingcows,horses, andotherlivestock.

BuiltforDurability:Constructedtoendureregularuse, ensuring reliability over the long term. Foster Innovation:Providesa fresh andcreativeapproachto traditionalgroomingtools.

A literature study on the Swinging Cow Grooming Brush delves into the evolution of grooming tools for animals, emphasizing both functionality and design. Historically,traditionalgroomingtoolshavefocusedon efficiency and comfort, but recent innovations are introducingmorecreativeandinteractiveelementsto enhancethegroomingexperience.

TheSwingingCowGroomingBrushexemplifiesthis trend by featuring a swinging motion that mimics the naturalmovementsofanimals,particularlycows.This

Volume: 12 Issue: 05 | May 2025 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

gentle motion effectively loosens dirt and tangles, makingthegroomingprocessmorecomfortableforthe animal. Research in animal behavior indicates that rhythmicmotionscanhavecalmingeffectsonlivestock, therebycontributingtoapositivegroomingroutine.

Additionally, the integration of art and function in grooming tools is gaining traction. Numerous studies suggest that visually appealing tools can enhance the user experience, making grooming tasks more enjoyable and encouraging regular use. The Swinging Cow Grooming Brush embraces this concept with its unique, abstract design that not only challenges traditionalgroomingaestheticsbutalsoofferspractical benefits.

Furthermore, the tool's adaptability for various animals, including cows, horses, and other livestock, underscores a growing trend toward multipurpose groomingdevices.Literatureonanimalcarehighlights the significance of using tools that can accommodate differentspecies,ensuringamoreefficientandstressfree grooming process for both the animal and the caretaker.

Literature Review and Conceptualization: The project begins with a thorough examination of existing grooming tools and methods utilized in animal care. This involves analyzing animal grooming behaviors, particularly how natural actions, like a cow’s tail swishing, can be integrated into a grooming tool. The literature review also investigates user needs and preferences, ensuring that the design prioritizes comfort,efficiency, and ease of use.

Design and Prototyping: Drawing from the insights obtainedduringtheliteraturereview,theinitialdesign of the Swinging Cow Grooming Brush is developed. This stage includes creating concept sketches and 3D models that incorporate the swinging motion mechanism.Designersaimtocraftabrushthatdelivers a gentle, rhythmic movement while effectively removing dirt and tangles. A prototype is constructed using selected materials that are durable, lightweight, and safe for the animals, with bristles tested for softnesstoguaranteeanimalcomfort.

Material Selection and Testing: The selection of materials is approached with a focus on both

functionality and safety. The bristles are crafted from either synthetic or natural fibers that are gentle yet effective,whilethebrush'sbodyismadefromarobust, lightweight material that facilitates the swinging motion. During this phase, various materials are subjectedtotestsfordurability,flexibility,andeaseof cleaning,ensuringcompliancewithindustrystandards foranimalcaretools.

Prototype Evaluation: The prototype undergoes multiple rounds of testing to assess its performance. These evaluations focus on the effectiveness of the swinging action in loosening dirt and detangling fur. Additionally, the comfort and safety of the brush are closelymonitoredbyobservingtheanimals'reactions during the grooming process. Feedback is collected from a select group of animal caretakers, including farmers and groomers, who use the prototype on various animals such as cows, horses, and goats. The objective is to confirm that the brush performs well acrossdifferentfurtypesandthattheswingingmotion isbothsafeandefficient.

User Feedback and Refinement: After the prototype testing, feedback is solicited from animal caretakers regarding the brush's usability, design, and comfort. This information is crucial for identifying any design flawsorareasneedingimprovement.Adjustmentsare made to the brush’s swinging mechanism, handle ergonomics, and overall appearance based on the feedbackreceived.

Final Product Development: Once the design and functionalityhavebeenrefined,preparationsformass production of the final product commence. Detailed manufacturingspecificationsareestablishedtoensure consistency and quality.The productismanufactured using high-quality,durablematerialsandistestedforscalabilityin themassmarket.

Post-LaunchMonitoringandEvaluation:Followingthe product's market release, ongoing monitoring is conducted to assess its long-term performance. Customer reviews and feedback are collected to pinpointanyareasthatmayneedfurtherenhancement oradjustmentsinfutureiterationsoftheproduct.

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 05 | May 2025 www.irjet.net

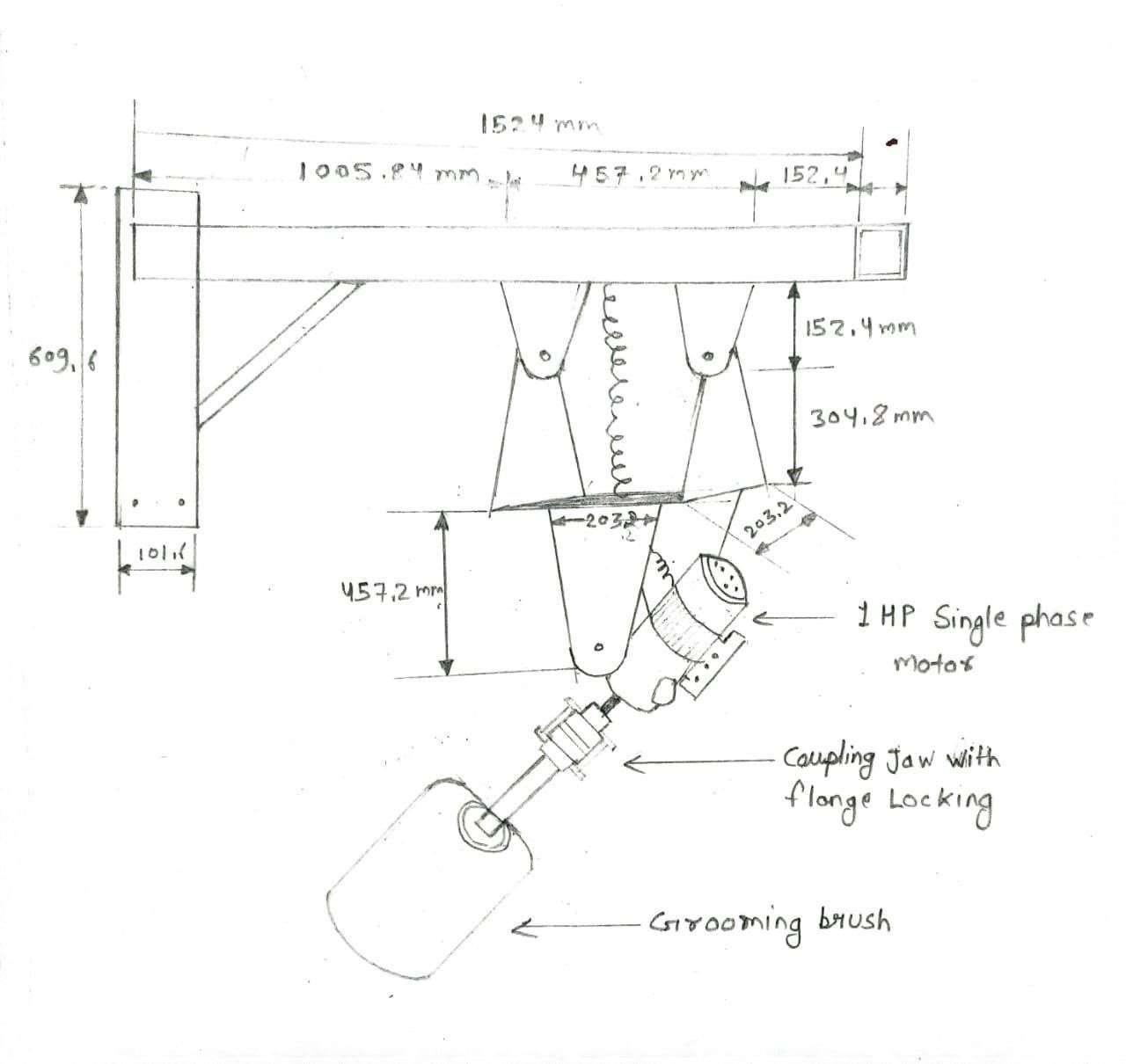

V. DESIGNING OF THE MODEL

Thedesigningofthemodelwasdoneinboth2D

Firstthe2Dmodeldiagramsweremadetounderstand the basic principles needed to be implemented while fabricatingthemachine. Frontviewinframebodyinswingingmotioninshow.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 12 Issue: 05 | May 2025 www.irjet.net

Thecowbrush conforms to the scientific design of Ithasswingingpartsuchasmotionsystemin the cow's body structure andbehavioralhabits.It mechanismintherottedinmotorandshaftcoupling useshigh-wear-resistantmaterialgaskets inJointinaflangesysteminlocked

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 12 Issue: 05 | May 2025 www.irjet.net

During the fabrication stage of the project model, variousprocessessuchassheetcutting,welding,lathe working assembly of parts and study of the materials tobeusedwasdoneduringitscourse.

Material identification and collection is the first step takenwhilefabricatingthemodel.

Materials such as mild steel sheet, square arm are chosen to build the outer body structure of the machine.

Sheet & Square Pipe cutting operation:

Thetypeofsheetusedinswingingmotiontheouter body is mild steel sheet. And square arm pipe in structureareouterbodyinlordafford.

Firstly cutting the beat as per drawing length1.5* 4’’*belowandupperincuttinginaplatesin4noes anddrawingaccording

Lathe Working :

Inlathemachinewedokeywaycuttingbymovingthe shaft.

Andinthiscaseofcoupling no110,a holeof20mmis madefromonesidewithkeywayandinthedia.Ofthe other side a hole of 38.1mm with key way is made as theymakeit.

And to locking the coupling a flange is made, around whicha12mmdrillholeinmade.

Welding work :

Weweldtheplatesmentionedinthesquarearmpipe andfromthestructurebyjoiningalltheothersplates jointinwelding.

Operations:

Firstofallweconnectthesquarearmpipeinweldedin aplate.andweldedplateincenterinconnectedin1hp singlephasemotorinHTboltandbrushinconnectin helpofcouplinginshaftandflangeinalock.

And rotted in a motor and then grooming bush in a rotted.

In summary, a swinging cow grooming brush representsagroundbreakingtoolaimedatenhancing the health and comfort of livestock, especially dairy cows.Thisinnovativebrushoffersamoreeffectiveand comprehensive cleaning experience, efficiently removing dirt, debris, and loose hair. As a result, it promotesbetterhygieneandminimizestheriskofskin infections.

Theuniqueswingingmotionofthebrushallowscows to groom themselves in a natural and relaxed way, which can significantly boost their overall well-being

Volume: 12 Issue: 05 | May 2025 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

and help alleviate stress. Furthermore, by enhancing thecomfortofthecows,thisgroomingtoolcanleadto increasedmilkproductionandimprovedproductivity withintheherd.

ACKNOWLEDGEMENT

We would like to express our heartfelt gratitude to everyone who played a role in the development and successoftheswingingcowgroomingbrush.Aspecial acknowledgmentgoestotheengineers,designers,and livestock experts whose knowledge and dedication have brought this innovative solution to life. Their unwaveringcommitmenttoenhancinganimalwelfare and advancing farming practices has been truly invaluable.

Furthermore, we extend our appreciation to the farmers and dairy producers who have shared their feedback and support throughout this journey. Their insights have been crucial in helping us refine and improve the product.Thiscollaborative effort hasled tothecreationofatoolthatnotonlybenefitslivestock but also enhances agricultural operations, ultimately resulting in healthier animals and more efficient farmingpractices.

1) Ewing, S. A., Lay, D. C., and Von Borell, E. 1999. Farm Animal Well Being. Upper Saddle River, NJ: Prentice Hall.

2) DeVries, J. J., Vankova, M., Veira, D. M., and von Keyserlingk, M. A. G. 2007. “Short Communication: of Mechanical Brushes by Lactating Dairy Cows.”T. DairySci.90: 2241-5. doi:10.3168/jds.2006648.

3) Georg, H., and Totschek, K. 2001. “Examining anAutomatic Cow brush for Dairy Cows.” Landtechnik56:260-1.K.Elissa,“Titleofpaperif known,”unpublished.

4) Yousef, R. T., and Tawil, G. G. 1980. “Antimicrobial of Volatile Oils.” Pharmazia 35: 698-701.

5) Fraser,A.F.,andBroom,D.M.1990.FarmAnimal BehaviourandWelfare.London:BaillièreTindall.

NAME:AJAYMAHAWADIWAR Asst. Prof. Department of Mechanicalengineering GHRaisoniUniversity,Saikheda

NAME:AMARJEETMOHTURE B.Tech Mechanical Engineering Is a student GH Raisoni University,Saikheda

NAME:SANDESHBANSOD Diploma Mechanical EngineeringIsastudent GH RaisoniUniversity,Saikheda