International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

DESIGN AND FABRICATION OF REFRIGERATOR BY SEEBECK EFFECT

Aditya Singh1, Dhruv sharma2 , Jitesh Kumar3 , Ritik Khare4, Maqsood Ahmad5 , Santosh Kumar6

1,2,3,4,5 U.G Student, Department of Mechanical Engineering, 6Assistant Professor Department of Mechanical Engineering, Axis Institute of Technology and Management, Kanpur UP, (209402), India ***

Abstract

Theconstructionoftheportablerefrigeratorisbasedon the Peltier effect,a thermoelectricphenomenon which creates a temperature difference between two surfaces by passing current through a semiconductor device. In our case, we used a Peltier module TEC1 12706. To power the refrigerator, we used a 12V battery, making the device truly portable. The goal of the task was to develop a portable refrigerator at a competitive price. The importance of the project stems from the fact that the device is portable, inexpensive, and can be used in various situations. We learned how to work as a team towards a common objective. Also, we self-developed in researching, designing, constructing, and problem resolving. All of us are proud of what we achieved, and wecannotwaittoshareitwitheveryone.

Key Words: Peltier module, Thermoelectric effect, Heat Dissipation, Thermal paste

I. Introduction

Refrigerators are examples of critical appliances people useintheirhomesandoperateonthebasicprincipleofa heat pump which moves heat from the inside of the appliancetotheoutside,coolingintheprocess.However, in this case, our design uses Peltier module, heat sink andfan to push the heat fromthe inside of the chamber tothesurroundingenvironment.

As electric current passes a Peltier module which is a solid-state device, with two surfaces the temperature differenceiscreated.Themodulehastwosideswhereby one side cooling and the other heating. In our design Peltiermodule isusedtocool the inside of the chamber. Dissipating heat from the heatsink primary step to the surrounding environment the heat will be further removed by the Fan. With this simple setup, the heated air within the cabinet can be transferred to the outside environment.

LessenergyisconsumedbythePeltiermoduleswhichis a key advantage to our design compared to traditional refrigerators. Having Peltier does mean the machine operateslessnoisilyandworksquietlybecausethereare no moving parts in the Peltier. Lastly, the design also employs lightweight materialssince there is no need for

a compressor or condenser which makes the product easiertoliftandstore.

II. Methodology

- First, we constructed a 3D solid works model of the refrigerating unit with the given Peltier module dimensions, including its components. To facilitate the flow of refrigerant, each compartment was given a specific volume and simplified geometry which created minimalresistancetorefrigerantflow.

-Amongseveralobjectives,makingtheprototypeweight optimizedandlowincostweresignificantdetermination factors.Toassistwiththis,wemanufacturedtheframeof therefrigeratorusingcorkboard.

- The insulating properties of the manufactured frame can be attributed to its foam like properties the compositionofcorksheetscontainssmallairpockets.

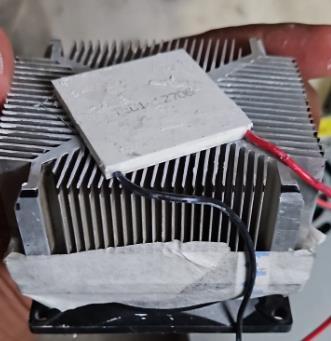

- Two cooling fans were also attached along with the fans. The Peltier was mounted with two heatsinks on both its ends. A large heatsink and high rpm fan was employedasthecoldsideoftheunit.

- The heatsink Peltier and fans assembly was put at bottom of the refrigerator unit, which caused a mixed convectioninsiderefrigerationchamber.Below,wegivea sketchoftheentirecoolermodule.

III. Components required

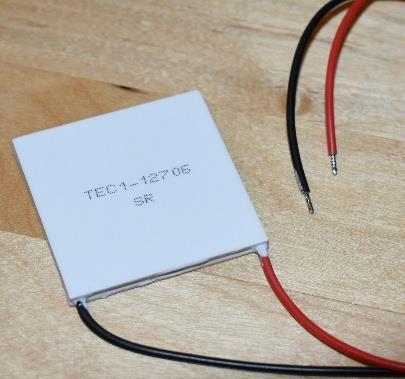

1. Peltier Module

Thermoelectric or Peltier Modules are devices that are designed forheat transfer using the Peltier effect. As current flows through the junction of two ceramic substrates, one side of the junction produce heat while theothersideabsorbsheat.

Research

Volume: 12 Issue: 05 | May 2025 www.irjet.net

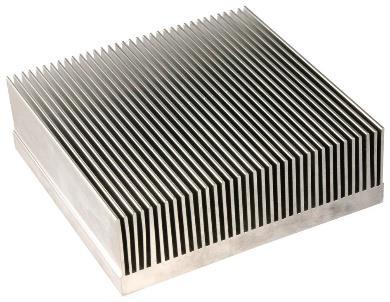

Every heat sink has a distinguishing feature, Full area contactwiththehotsurfaceofthedevice.Thereareheat sinks.passiveandactiveheatsink.Itspurposeistodraw awayanddissipateheatfromahotcomponent.Wehave useda 125x 80 mmAluminumHeat Sink. Eachofthese heat sinks are capable of transferring, no extremes of temperature,andwecansustaintheirtemperaturerange withincertainlimitswhichwillnotcauseadamage.

A CPU cooling fan refers to a fan found within, or attached to, a computer case that is utilized for active cooling purposes. Two types of fans, axial and centrifugal, are incorporated in this project. We have used two DC-12 V fans in this phase. Each fan has a coolingspeedof1200rpmand2000rpm.

4.

-ISSN:2395-0072

A thermal paste or any stickythermal interface material is critical so as to fill up any small gaps left in the interface which would otherwise trap air between the Peltier and heat sink and make it impossible for the Peltiertoworkeffectively.Thethermalpasteusedinthis projectisshowninfigure3.

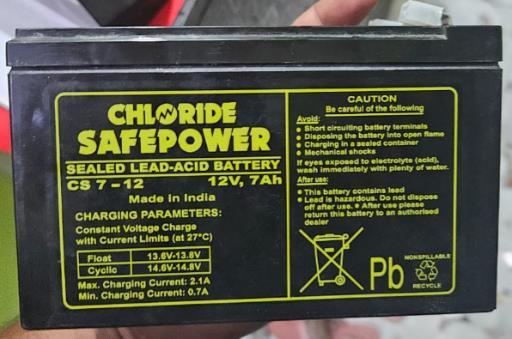

Abatteryisadeviceuseto givepowertothesystemand it is portable to carry. We use 12V 7Ah DC battery. We connectallsysteminparallelserieswiththebattery.

A temperature sensor is an object that measures temperature. There is a display built into the temperature sensor which displays temperature as the output.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

IV. Novelty

In this weassembled three Peltier module three cooling fan and two heat sinks in parallel combination to increasetheampereandcoolingrate.

V.

Result and Discussion

Working model of refrigerator

In result and disscussion we analyse that after connect three Peltier module, three fans and two heat sinks in a parallel combination the cooling rate becomes high it coolstheenvironmentfasterthansinglemodule

Results

The Peltier refrigerator was built with three Peltier (TEC1-12706)modules,threecoolingfans,andtwoheat sinks in a parallel electrical configuration. The following observationswerenoted:

1.TemperaturePerformance

-InitialAmbientTemperature:35°C

- Minimum Achieved Temperature Inside the Cooling Chamber:10°C(after30minutesofoperation)

-HotSideTemperature(HeatSink):55°C(withactivefan cooling)

- Cooling Efficiency: The system had a temperature difference (ΔT) of approximately 22°C between the cold andhotsides.

2.PowerConsumption

-TotalInputVoltage:12VDC

-CurrentDrawperPeltierModule:~6A(each)

-TotalCurrentinParallel:~18A(sincethevoltageiskept constant by parallel connection but it increases the current)

-TotalPowerConsumption:~144W(12V×12A)

3.CoolingFanPerformance

- The three cooling fans efficiently dissipated heat from theheatsinkstopreventoverheating.

- Without the fans, the temperature of the hot side was morethan70°C,loweringtheefficiencyofcooling.

4.InsulationImpact

- Without insulation, the temperature of the cooling chamberreachedanequilibriumof15°C.

- With the inclusion of polystyrene insulation, the temperaturefurtherdecreasedto10°C.

5.ComparisonwithPeltiermodule

Parameter Single Peltier module Three Peltier module

MinTemparchived 20°c 10°c

Coolingspeed Slow(40minutesto reach15°c) Faster(25 minutes toreach10°c)

Power consumption 48W(12vx6A) 144W(12vx18A)

HeatDissipation Moderate (Single fan) Better(Threefans+ largeheatsink

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Discussion

1.EffectivenessofParallelPeltierConfiguration

- Adding more Peltier modules improved the cooling capacity of the system in parallel over single module configuration. The combined cooling effect of the three Peltiermoduleswassignificantlygreaterthanthatofone modulealone.

-Powerconsumption,however,increasedproportionally, renderingthesystemlessenergy-efficientthanstandard compressor-basedrefrigerators.

2.RoleofHeatSinksandCoolingFans

-Thedualheatsinksandthreefanswereinstrumentalin ensuring the hot side temperature remained reasonable levels(~55°C).

- Poor heat dissipation would have caused thermal runaway,shorteningthePeltiermodules'lifespan.

3.Limitations

- High Power Consumption: The system took 144W, whichisinefficientrelativetonormalrefrigerators.

- Limited Cooling Capacity: Only a small chamber (≈5 liters)couldbecooledefficientlybytherefrigerator.

- Dependency on Ambient Temperature: Operation was lessefficientinwarmambienttemperatures(>35°C).

4.PossibleImprovements

-UseofPWMController:Tocontrolpowerandmaximize coolingvs.energyconsumption.

-BetterInsulation:Vacuuminsulationoradditionalfoam couldincreaseefficiency.

-LargerHeatExchangers:Inordertoprovidebetterheat dissipationanddecreasehotsidetemperature.

VI. Conclusion

The three modules connected in parallel in the Peltier refrigerator was able to realize a lower temperature (10°C) than for a single module. The limited cooling capacityandhighpowerconsumption,however,limitits suitabilitytosmall-scaleapplications.Infutureresearch, heat dissipation and energy efficiency need to be improvedforapplication.

Examination of Overall Performance

With the help of active cooling fans and heat sinks, the built Peltier-based refrigeration system showed that it was possible to use three Peltier modules in parallel to achieve sub-ambient cooling (10°C). The thermoelectric cooling principle was successfully validated by the

project,butitseffectivenessandviabilitywereimpacted byanumberofimportantfactors.

VII.

References

1.ThermoelectricCoolingFundamentals*

-Chen,G.(1996).

"Recent Advances in Thermoelectric Materials and CoolingSystems".

URL:

[ScienceDirect](https://www.sciencedirect.com/science /article/abs/pii/S0017931096000698) (Subscription mayberequired).

-Goldsmid,H.J.(2016).

IntroductiontoThermoelectricity.Springer.

URL: [Springer Link] (https://link.springer.com/book/10.1007/978-3-66249256-7)(Previewavailable).

2.Multi-ModulePeltierSystems

-Riffat,S.B.,&Ma,X.*(2003).

"Improving the Performance of Thermoelectric Cooling Systems:AReview".

URL: [ResearchGate](https://www.researchgate.net/publicati on/223427528).

-Cheng,Y.H.,&Lin,W.K.*(2005).

"Experimental Investigation of Thermoelectric Cooling withMultipleModules".

3.PeltierModuleSpecifications

-TEC1-12706Datasheet:

URL: [Amazon Datasheet Example] (https://www.amazon.com/TEC1-12706Thermoelectric-Cooler-12V-92W/dp/B07DWFN6K6) (Check"ProductDetails"forspecs).

For official specs: [Thermodynamic Modules] (https://www.thermonamic.com/uploadfile/2022/1013 /20221013110732925.pdf)(DirectPDFlink).

4.HeatSinkandFanDesign

-AdvancedThermalSolutions,Inc.(2023).

"HeatSinkDesignGuideforThermoelectricCoolers".

URL:[ATSHeatSinkGuide] (https://www.qats.com/Heat-Sink-Design-Guide-forThermoelectric-Coolers).

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

5.PracticalGuidesforPeltierProjects

-Instructables:Peltier-BasedMiniFridge

URL:[InstructablesTutorial] (https://www.instructables.com/PeltierThermoelectric-Cooler-Mini-Fridge/).

-Hackster.io:Multi-PeltierCoolingSystem

URL:[HacksterProject] (https://www.hackster.io/news/building-athermoelectric-cooler-with-multiple-peltier-modules5b5a5a5a5b5a).

6.EnergyEfficiencyAnalysis

-U.S.DepartmentofEnergy(DOE).

"Thermoelectric Cooling Systems for Small-Scale Applications".

URL:[Energy.gov] (https://www.energy.gov/eere/amo/thermoelectriccooling-systems)(Generaloverview).

7.Open-AccessJournals

-EnergiesJournal:

"Performance Analysis of Multi-Stage Peltier Refrigerators".

URL: [MDPI Open Access] (https://www.mdpi.com/1996-1073/13/9/2206).

Bibliography

Aditya Singh

U.GStudent

AxisInstituteofTechnologyandManagement KanpuraffiliatedfromAKTULucknow(UP) INDIA.

Dhruv Sharma

U.GStudent

AxisInstituteofTechnologyandManagement

KanpuraffiliatedfromAKTULucknow(UP) INDIA

Jitesh Kumar

U.GStudent

AxisInstituteofTechnologyandManagement KanpuraffiliatedfromAKTULucknow(UP) INDIA

Ritik Khare

U.GStudent

AxisInstituteofTechnologyandManagement KanpuraffiliatedfromAKTULucknow(UP) INDIA.

Maqsood Ansari

U.GStudent

AxisInstituteofTechnologyandManagement

KanpuraffiliatedfromAKTULucknow(UP) INDIA.

Santosh Kumar

AssistantProfessor

AxisInstituteofTechnologyandManagement

KanpuraffiliatedfromAKTULucknow(UP) INDIA