International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Altab Patel1 , Shripad Navshinde2 , Ganesh Nangude3, Dipak S. Patil4

1Student, Mechanical Dept., G H Raisoni College of Engineering and Management, Pune, India

2Student, Mechanical Dept., G H Raisoni College of Engineering and Management, Pune, India

3Student, Mechanical Dept., G H Raisoni College of Engineering and Management, Pune, India

4Assistant Professor, Mechanical Dept., G H Raisoni College of Engineering and Management, Pune, India

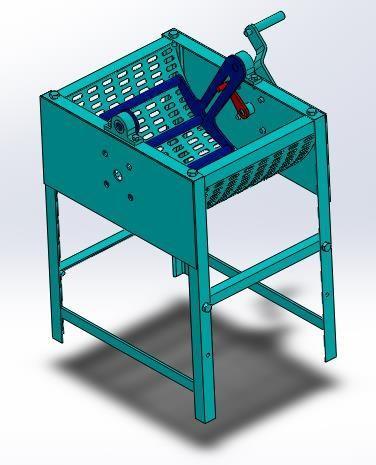

Abstract - The Design and Fabrication of a Modified Groundnut Peeler Machine aims to provide a cost-effective, manually operated solution to meet the needs of small-scale farmers and businesses. Existing groundnut peeling machines are often expensive, reliant on electricity, and unsuitable for use in remote areas. This project introduces an innovative design incorporating a handwheel and Crank and Slotted Lever Mechanism, which effectively reduces humaneffort and minimizes operator fatigue.The machine features an adjustable peeling mechanism to accommodate various groundnut sizes, ensuring flexibility and efficiency across different varieties. Its compact and portable design makes it easy to transport, assemble, and use, providing an affordable alternative to traditional motorized peelers. The simplicity of the design also ensures low maintenance and accessibility for rural andsmall-scaleoperations.Futureenhancementsinclude integrating a chain and sprocket mechanism for smoother operation or motorization to further reduce manual effort. The machine can even be adapted as an exercise device, offering multifunctionality.

Key Words: Groundnut, pee Machine, Efficiency, Design, Calculations, Fabrication, Assembling, Evaluation, Modification.

Groundnut peeling is a critical stage in post-harvest processing, particularly for small-scale farmers and rural communities.Efficientpeelingnotonlyimpactsproductivity but also determines the overall profitability of groundnut cultivation. However, existing peeling machines are often expensive,heavilyreliantonelectricity,andunsuitablefor small-scale applications due to their bulky designs and operationalcomplexity[1].Theselimitationsareparticularly challenging for farmers in remote areas where access to electricityandhigh-endmachineryisrestricted.Thisstudy focuses on addressing these issues by designing and fabricatingamanuallyoperatedgroundnutpeelermachine that is cost-effective, portable, and easy to operate. The proposedmachineisspecificallytailoredtomeettheneeds of small-scale farmers, providing a practical solution that eliminates the dependency on electricity while improving productivity. By incorporating a handwheel-driven

mechanism, the machine simplifies operation, reduces physicalstrain,andensuresefficientpeeling.Thecompact and lightweight design, combined with the use of locally available raw materials, further enhances its affordability andadaptability.Theprimaryobjectiveofthisprojectisto develop an innovative groundnut peeling solution that integratesmechanicalefficiency,portability,andeaseofuse. Themachine'sdesignaimstobridgethegapbetweenhighend, motorized solutions and manual methods, thereby empowering farmers to optimize their post-harvest processes[2].Throughthisresearch,weaimtocontributeto the advancement of agricultural technologies that cater specifically to the needs of small-scale farmers and rural communities.

Developaconceptualdesignforahand-operatedgroundnut peelingmachinethatincludesahandwheelandacrankand slotted lever mechanism [3]. The design will emphasize simplicity,compactnessandeaseofuse,makingitidealfor small businessesandfarmers.Themachinewill beeasyto assemble and disassemble, allowing convenient transportation,storageandmaintenance.

To accommodate different sized ground nuts, the peeling mechanism will be adjustable, ensuring optimum performancefordifferenttypesofgroundnuts.Thedesign will also focus on reducing human effort and reducing unnecessary movements to avoid user fatigue, ensuring comfortableandefficientoperationforlongperiodsoftime. CrankandSlottedLeverQuickReturnMechanismismostly used in shaping machines, slotting machinesand in rotary internalcombustionengines[4] Usingthismechanismwe canincreaseeffectiveworkingtime[5]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

The modified groundnut peeler machine operates using a combinationofa handwheel anda crank andslottedlever quickreturnmechanism.Thissetupisdesignedtoefficiently peelgroundnutswithminimaleffort.

Operation steps:

• The operator turns the handwheel, which initiates the motionofthecrank.

• Asthehandwheelturns,thecrankrotates,andtheslotted levermechanismconvertsthis rotational motionintoa linearback-and-forth(reciprocating)motion.

• Thereciprocatingmotiondrivesthepeelingmechanism withintheshellingchamber.Thegroundnutsarefedinto the machine, and the pods are broken by the shelling mechanism.

• The machine includes an adjustment mechanism that allowstheoperatortosetthepeelinggapaccordingtothe sizeofthegroundnuts.Thisensureseffectivepeelingfor variousgroundnuts.

• Asthepeelingoccurs,theshellsareseparatedfromthe nuts. The peeled nuts are then collected in a separate chamber,whilethediscardedshellsareejected.

• The peeled groundnuts are collected in a separate chamber, ready for furtherprocessing orconsumption. Thequickreturnmechanismensuresthattheprocessis efficient,witharapidcycleofpeelingandseparation.

ForceandTorqueCalculations:Determinetherequired forcetooperatethehandwheeleffectively.Calculatethe torque needed to convert the rotary motion into oscillating motion using the Crank and Slotted Lever Mechanism [4]. These calculations will ensure that the machine is easy to operate while maintaining high efficiency.

MaterialStressAnalysis:Performstressanalysisonthe selected materials to ensure they can withstand the

operational loads. This will include calculations for the mechanical properties of the materials, such as tensile strength,yieldstrength,andfatiguelimits[5].

Efficiency and Output Rate Calculations: Estimate the peeling efficiency and output rate of the machine. This willinvolvecalculatingthenumberofgroundnutsthat canbeprocessedperunitoftime,consideringthespeed of operation and the effectiveness of the peeling mechanism.

Todeterminethestresses,forces,shearforcediagram(SFD), andbendingmomentdiagram(BMD)forthedescribedrotary lever mechanism, we can break the system into key components:

a) Handwheel(Handle)

b) Shaft

c) Pin

d) Slotted-levermechanism

e) Crank

Here’showwecanapproachtheproblemstepbystep: Determine the required force to operate the handwheel effectively.Calculatethetorqueneededtoconverttherotary motionintooscillatingmotionusingtheCrankandSlotted LeverMechanism.

a) Forces Acting on the Hand wheel (Handle)

Ahumanappliesaforce(F)=250Natthehandle.[6]

Thedistancefromthecenteraxisofthelevertothecenter axisoftheshaftisnowR=150mm=0.15m.

[7]

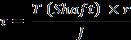

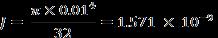

b) Handwheel Shaft Forces and Stresses

Diameteroftheshaft=20mm

Thesametorqueappliedbytheleveristransferredtothe crankthroughtheshaft.

TShaft=37.5Nm

Wecalculatetheshearstressusingthetorsionformula [10]

Where:

τ=ShearStress

r=Shaftradius=10mm=0.01m

J=Polarmomentofinertia

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

c) Pin Forces

• ConsideredPindiameter=10mm.

• Stressesdevelopedinpin

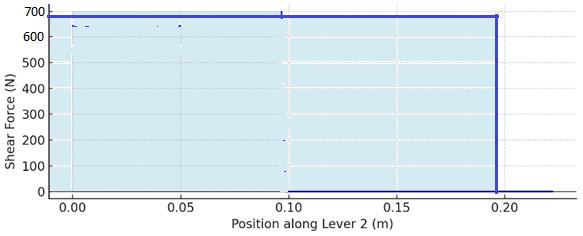

d) Stresses slotted leaver (Shear Force in the Slot) [7]

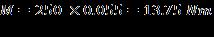

Figure 4.1: ShearForceDiagram(SFD)

e) Crank Forces and Stresses (BendingMomentonthe crank)[7]

Figure 4.2: BendingMomentDiagram(BMD

• ShearForceDiagram(SFD):Theshearforcestartsatits

maximumvalue(545.45N)atthepivotpointofLever2 anddecreasestozeroaswemovetowardstheslotwhere thecrankpinslides.

• BendingMomentDiagram(BMD):Thebendingmoment ishighestnearthepivotpointofLever2(52.91Nm)and decreasestozerotowardstheslotwherethecrankpin acts.

Table -1: Forcerequiredforpeeling

Table 2: ForceGeneratedbyMachine

theHandwheel

Inonemin.ourmachinecancrush

OurMachinecanPeeldryGroundnutsin Hr 15to20Kg

The force appliedbythe handwheel(250N)combinedwith the crank mechanism generates a force of 681.82 N at the peeling point, sufficient to peel 10 ground nuts simultaneously.

These calculations will ensure that the machine is easy to operate while maintaining high efficiency.

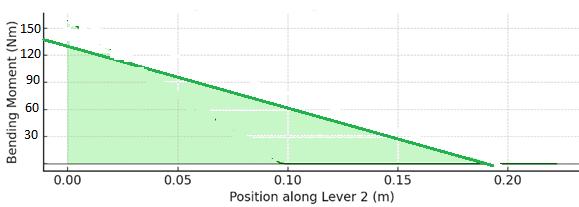

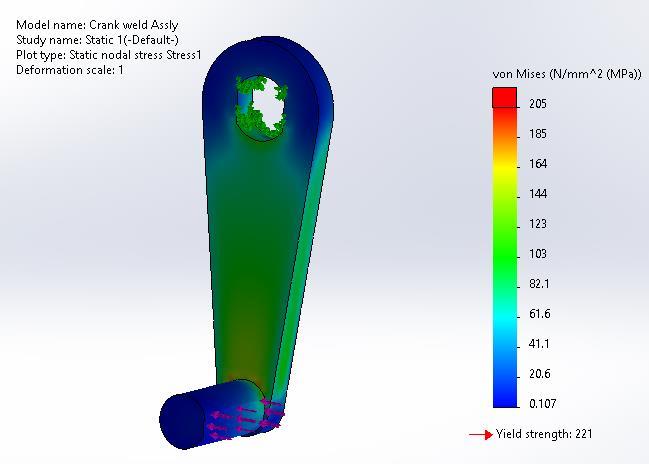

Performstressanalysisontheselectedmaterialstoensure theycanwithstandtheoperationalloads.Thiswill include calculationsforthemechanicalpropertiesofthematerials, suchastensilestrength,yieldstrength,andfatiguelimits.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Aspergotresultsourcrankassemblywillwithstandforthe

-5.1:StressesdevelopedinCrank

-5.2:Displacement

6. CONCLUSIONS

TheDesignandFabricationofaModifiedGroundnutPeeler Machine successfully addresses the challenges associated with traditional groundnut peeling methods and existing machines. The manually operated machine, utilizing a handwheelandCrankandSlottedLeverMechanism,offersa cost-effective, compact, and efficient solution tailored for small-scale farmers and businesses. Its design focuses on reducing hu-man effort, increasing portability, and eliminating the need for electricity, making it ideal for remotelocations.

[1] Liao,Xuan,etal."Peanut-ShellingTechnologiesand Equipment: A Review of Recent Developments." Agriculture14.7(2024):1178.

[2] Damtie,EneywGardie,andHabtamuDubale."Finite element analysis of crank and slotted lever quick returnmechanismforshapermachineapplication." ResultsinMaterials14(2022):100288.

[3] Shelare, S. D., P. S. Thakare, and C. C. Handa. "Computeraidedmodellingandpositionanalysisof crank and slotted lever mechanism." International Journal of Mechanical Engineering and Robotics Research2.2(2012):47-52.

[4] Bautista, Emilio, ed. Theory of Machines and MechanismsI.NiraliPrakashan,1987.

[5] Grodzinski,Paul.APracticalTheoryofMechanisms: ClassificationandDescriptionofMechanismsApplied InMachinesandInstruments.2021.

[6] McMulkin,MarkL.,andJeffreyC.Woldstad."Effects ofwheeldesignonthetorquesappliedtolargehand wheels." International Journal of Industrial Ergonomics15.3(1995):205-213.

[7] Ambekar,AshokG.Mechanismandmachinetheory. PHILearningPvt.Ltd.,2007.

[8] Krishnappa. "Engineering properties of selected groundnut Varieties." International Journal of AgriculturalScienceandResearch7.4(2017):203216.

Altab Ekabal Patel, final year B.Tech.MechanicalStudentofGH RaisoniCollegeofEngineeringand Management,Wagholi,Pune,India.

Shripad Navshinde, final year B.Tech.MechanicalStudentofGH RaisoniCollegeofEngineeringand Management,Wagholi,Pune,India.

GaneshNangude,finalyearB.Tech. MechanicalStudentofGHRaisoni College of Engineering and Management,Wagholi,Pune,India.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Dr. Dipak S. Patil, Faculty, Mechanical Department of G H RaisoniCollegeofEngineeringand Management,Wagholi,Pune,India.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page350