COMMERCIAL VEHICLE WORKSHOP

TROUBLESHOOTER

Diagnosing a commercial vehicle engine cut-out due to the demands on modern trucks

Diagnosing a commercial vehicle engine cut-out due to the demands on modern trucks

Guidance on the replacement of hydraulic working cylinders

22 Sampa’s precision-engineered axle, steering, and suspension systems deliver OE-surpassing durability, helping fleets maximise uptime, cut costs, and keep every load moving safely and smoothly.

25 ZF Aftermarket showcases how it’s strengthening commercial repair capabilities with advanced electric drive and suspension solutions.

28 Everything you need to know about shock absorbers and what can go wrong from suspension specialist febi.

30 Diesel Technic shares some practical advice on leaf springs and air springs.

32 BPW shares how its suspension systems are a good choice for your workshop, offering efficiency and reliability for commercial vehicles.

35 Using PicoScope J1939 decoding, Pico Technology’s Ben Martins diagnosis a commercial vehicle engine cut-out.

39 Texa explores the future of vehicle diagnostics and how garages can best get ready for it.

41 Opus IVS addresses a common issue causing lack of power and an illuminated EML on Renault Models.

42 Prometeon Tyre Group UK highlights five key ways workshop tyre expertise can boost customers’ profitability while strengthening long-term loyalty.

AutoSock presents its traction aid solution to the hidden cost of winter downtime for UK fleets.

Everything you need to know about how retread tyres could give workshops and fleets a smart way to cut waste AND running cost from Continental.

How Sandback Tyre Service Ltd has been able to improve its LCV services and operations with the help of Davanti Tyres.

51 Vaculug is championing the importance of regular tyre checks in its new safety drive.

53 Read about how Bridgestone and its dealer network use data, performance insights, and follow-ups to turn tyre work into ongoing service opportunities.

Editor

FREYA COLEMAN

cvw@hamerville.co.uk

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

JOE CLARKE

Senior Account Manager

MATTHEW BOASE

Group Manager

ALEX DILLEIGH

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates:

UK £30 post paid

Airmail £99 post paid

Europe £70 post paid

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by

Stephens and George

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2025

Irecently moved house and, let me tell you, it was a whole lot of effort. Between lugging boxes upstairs, building furniture, and forking out for a new dresser just so I didn’t have to live out of boxes for weeks, it’s safe to say both my back and my bank account have taken a hit. But what’s building flatpack furniture compared to transporting a HGV lift?

All of this got me thinking about a few conversations I’ve had in garages over the past year about the struggles of moving to a new premises. Earlier this year, for example, I spoke with Commercial Motors in Watford, just up the road from our office. I was told about the difficulties they’d faced trying to find a suitable new site. They eventually ended up on a farm-type property very much off the beaten track and now have to move all of the vehicles they’re working on inside every night for security.

AJ Fleetcare had similar challenges when it came to expanding. So did PW Auto Repair – both had to convince their landlords that they weren’t “Phil Mitchell”–type mechanics up to no good, but genuine, hardworking business owners running respectable, well-kept garages. It’s frustrating to think that in 2025, these kinds of outdated perceptions still hang over the industry.

What this all boils down to, in my view, is a persistent misconception about what garages and technicians represent, particularly within the commercial sector. Too often, garages are still associated with oil-stained overalls, cluttered forecourts, and loud machinery, rather than with the modern, skilled, and professional environments that most now are.

This misconception doesn’t just make it harder for workshops to find or expand premises – it ripples across the entire industry. It affects recruitment, with fewer young people seeing the trade as a career worth pursuing. It affects how customers perceive value when labour rates rise to reflect the increasing skills and technology required in today’s vehicles. And it affects how the industry is respected more broadly, despite the fact that it keeps Britain quite literally moving.

If there’s one thing my move has reminded me of, it’s that location matters, but reputation matters even more. Maybe it’s time we do more to shout about the professionalism and precision that go into keeping fleets on the road, and to change the narrative around what a commercial “garage” really looks like today.

Editor

■ VLS launches investigation and issues warning about engine oils making claims against Stellantis specification. The independent and impartial body which investigates lubricant product complaints, has launched a widespread market investigation and issued a caution over engine oils making claims against the Stellantis FPW 9.55535/03 specification.

■ TIP opens new branch in Shepshed with spacious 8-bay workshop. The provider of trailer rental, leasing, maintenance, repair and associated services, has opened a new branch in Shepshed, Leicestershire, complete with a purpose-built trailer and truck maintenance and repair workshop.

■ Fleet expectations of operating electric vans are falling. The 2025 Arval Mobility Barameter shows that, when asked to predict the percentage of battery electric vans on their fleet in 2028, the response was 14 per cent - a fall from 15 per cent in 2024 and 18 per cent in 2023.

■ Tyre manufacturer of the year named. Prometeon Tyre Group UK & Ireland is celebrating after winning the award at the 2025 National Tyre Distributors Association Annual Dinner and Awards.

■ Structure-flex are celebrating 55 years since two new innovations sparked the company’s birth. The lorry tension curtain experts were established just one year after the lorry tension curtain was introduced as a new solution for securing and accessing goods on lorries and trucks.

TRA recommends new measure on engine oils and hydraulic fluids.

The Trade Remedies Authority (TRA) has recently proposed a new anti-dumping measure to protect UK producers of engine oils and hydraulic fluids. The TRA opened its investigation into imports of certain engine oils and hydraulic fluids from Lithuania and the UAE in response to an application from UK manufacturer Aztec Oils last June. The investigation covered certain engine oils and hydraulic fluids, including passenger car motor oils, heavy-duty commercial vehicle oils and hydraulic oils.

According to the TRA’s estimates, UKproduced engine oils and hydraulic fluids resulted in sales exceeding £285 million during the investigation period (April 2023 to March 2024).

However, the TRA found that the UK engine oil industry has been suffering material injury due to the dumped goods from Lithuania and the UAE and determined that there would be further injury if a measure was not recommended. Most UK producers are small businesses employing fewer than 100 people. In April, provisional measures were put in place based on the TRA’s recommendation to protect the UK industry while completing the full investigation.

The TRA has now published its initial findings in a Statement of Essential Facts (SEF), proposing anti-dumping duties of up to 84.72 per cent for individual participating companies and countrywide rates of 95.36 per cent for Lithuania and 34.55 per cent for the UAE, for a period of five years.

The Institute of the Motor Industry (IMI) is set to engage with the new consultation to ensure V Levels and Level 2 pathways reflect the realities of modern automotive training.

The IMI welcomes the Government’s publication of the Post-16 Education and Skills White Paper and the launch of the consultation on Level 3 and below qualifications. Nick Connor, CEO of the

IMI, said: “These reforms are a pivotal opportunity to ensure technical education meets the real needs of modern industries. For automotive, it is vital that Government engages directly with industry bodies like the IMI and with employers, so V Levels reflect the skills required today and in the future, from EVs and ADAS to advanced diagnostics, and prepare the workforce for the next generation of mobility.

of UK van fleets are expecting growth in the next three years, according to the new Arval Mobility Observatory Barometer. This compares to 55 per cent who believe numbers will remain stable and 13 per cent who are predicting a decrease.

£70,000

the amount four firms and a haulier have been fined after allowing thousands of lorries to move waste from housing developments and dump it in Suffolk. The Environment Agency said the mismanagement of the waste, which amounted to 121,000 tonnes, was “completely off the scale” and that it was crystal clear the firms involved should have known the rules.

of dealers are using artificial intelligence within their business, according to October's Startline Used Car Tracker. The technology is offered by 38 per cent to help buyers find the right vehicle and 31 per cent to help with initial customer contact. It also revealed, however, that 16 per cent are yet to be convinved as to how AI could help them.

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

The government should consider a “Plan B” for the electric van market in the likely event that sales figures stay well below official targets, says FleetCheck.

Peter Golding, CEO of FleetCheck, points out that year-to-date sales penetration of 9 per cent is far short of the Zero Emissions Vehicle Mandate objective of 16 per cent, and that the figure rachets up to 24 per cent in 2026.

“Fleet resistance to electric vans remains high for reasons of range, payload, charging speed and charger availability

that are not easily solved. It's not like the electric car market where lower prices and higher incentives can be used to overcome consumer resistance – electric vans are simply not fit for purpose for many operators.

“There is no step change improvement in electric van technology on the horizon to remove these inherent problems and we hear from many of our fleet customers that as new diesel van availability decreases, they are simply planning to keep their old vehicles on the road as long as possible.”

MAHA UK is delighted to announce that the (DVSA) has approved its commercial brake tester with rising roller bed option for annual testing in Authorised Testing Facilities.

The MBT 7250 EUROSYSTEM’s rising roller design has an option to lift rollers by up to 250mm, simulating axle loads of up to 10 tonnes. Using a hydraulic system to apply weight onto the axle – by simply raising the vehicle – it delivers accurate, real-world brake performance testing and provides a compliant alternative to external loading.

According to the DVSA, a vehicle tested must be appropriately laden (at least 65 per cent of its design axle weight) to ensure accurate, real-world results for the safety inspection – MAHA UK’s MBT 7250 commercial brake tester with rising roller bed option can facilitate this parameter.

Krone Trailer UK has supplied another consignment of Mega Dry Liner trailers to FCL, as the event logistics specialist responds to surging demand in the live entertainment, sport, and exhibition sectors. The additional trailers will support FCL’s expanding operations across the UK and mainland Europe, where, says the company, reliability, payload efficiency and flexibility are crucial.

MAHA UK’s rising roller brake testers have been incredibly popular over the last 12 months. This follows the DVSA’s Guide to Maintaining Roadworthiness, putting the spotlight on brake performance. Safety inspections are now expected to include a brake performance assessment that is carried either by a laden roller brake test, a suitable electronic braking performance monitoring system or a decelerometer with temperature readings.

Always observe the following when replacing the working cylinders:

● For all work on the hydraulic steering system, extreme cleanliness must be ensured. The smallest contaminations could cause a failure of the steering support.

Hydraulic working cylinders are key components in the steering systems of commercial vehicles, ensuring smooth and stable handling. While they’re designed for a long service life, replacement may be necessary after damage or malfunction. Bosch provides workshops with expert guidance.

Working cylinders support the hydraulic steering system in commercial vehicles. For example, this might take place on multiple steered front axles or rear-axle steering systems. They provide the necessary hydraulic assistance that makes it easier for the wheels to turn and improves the vehicle’s directional stability. Working cylinders are mostly maintenance-free and designed to last for the complete vehicle life cycle. Replacement is necessary if the

steering function is impaired, for example due to mechanical overload or an accident.

Visual inspection and functional tests first

When working on steering systems, comprehensive visual and functional inspections are always the first step. For this purpose, operating forces, resetting, clearances, noises and the warning lamp are checked. Workshops using the software ESI[tronic] for Truck/OHW will find comprehensive service and installation instructions included within the SIS module. They provide information concerning troubleshooting on electrical and mechanical systems. Afterwards, an additional in-depth diagnosis is performed to determine what action is required. If the working cylinder is affected, it may be necessary to replace the entire working cylinder or its ball joints.

● When removing the working cylinder, the hydraulic oil should be drained without leaving any residue and the hydraulic steering system should be flushed.

● Threads and contact surfaces of parts to be screwed should be checked by sight. They must be free of deformation, damage and dirt.

● All self-locking screws and nuts as well as seals and locking elements must be replaced.

● All screw connections must be tightened with the tightening torque according to the manufacturer’s instructions.

● No force! Damaged sealing ring seats or sealing surfaces can lead to failure of the working cylinder.

● After replacement, the system must be properly filled with hydraulic oil, bled and, if necessary, adjusted. Only hydraulic oils approved by the manufacturer should be used.

● Last but not least, the system’s proper functioning must be checked during a test ride on non-public grounds.

To ensure your axles consistently perform at their peak, regular yet straightforward maintenance is essential, urges SAF Holland.

When removing the SAF Holland hub nut for the first time (this is identified by the silicone still being shown in place - see image) there is a first-time removal warranty on the SAF hub nut. SAF Holland Intra 9-ton Axles is six years for first time removal and the SAF Holland Modul 9-ton Axles is nine years for first time removal.

Before you attempt to remove the hub nut for the first time, always take a picture of the silicone intact to prove this. A photo of this will be asked for evidence when processing a warranty claim. Again, if the hub unit refuses to come off for the first, as proven by the evidence of the silicone, there is a first-time removal warranty.

WANT TO KNOW MORE? Make sure to scan the QR code!

SAF Holland Intra Axles, six years for first time removal and the SAF Holland Modul Axles, three years for first time removal. If you come across any issues on first time removal, please contact our SAF Holland customer services department.

Delco Remy showcases how 48V systems are transforming vehicle power management, delivering faster charging, greater efficiency, reduced weight, and longer battery life.

48V systems fill the need for increasing power requirements from DC battery systems. The new Delco Remy 48V high output alternator replaces the conventional alternator to charge the lithium ion batteries at very high rates and at the same time it provides power for the electric DC air conditioning and the electric water pump.

Further benefits of a 48V system include much more efficient components such as chargers and inverters, reduction of excessive cable and harnessing costs, eliminating the need for liquid cooling and of course higher output alternators inreasonable package sizes.

Volt will be an essential large part of the future automotive architecture. Not only in heavy commercial vehicles like trucks and in passenger cars but this technology is finding its way into agricultural and marine applications as well.

All electrical appliances work on wattage. Wattage is a simple formula: amperage times voltage. The higher the voltage, the lower the amperage. Batteries store amperage, they have a certain voltage but they're storing amperage. The less amperage you draw out of a battery, the

longer it lasts in the cycle. The higher the voltage, the smaller the components can become to accomplish the same result and the less heat they produce, prolonging the lifetime of the component.

A 48V water pump or air-conditioning compressor would be about 25 per cent the size of a 12V electric water pump and it would draw approximately a quarter of the amperage. This means the same battery bank would last much longer in a 48V system, as it would in a 12V system. That's less weight for the vehicle which improves fuel efficiency.

Although some might question the validity of the belt-in-oil concept, several VMs, including Ford, PSA and VAG, have embraced the technology, but why? Here, Dayco explains how it developed the oil pump belt in the 1.6 litre TDI engine used in millions of VAG vehicles.

With emissions reduction and weight saving as key goals in vehicle manufacturing, vehicle manufacturers’ attention turned to the oil pump, which has historically been chain driven. The aim was to retain the same layout with fixed centre distances, delivering the same function, but without using a tensioner.

The new solution had to meet several key requirements:

● No redesign of the drive.

● No change to the assembly line.

● Maintain or improve performance.

● Meet lifetime targets.

● Offer a cost advantage.

Using the original chain layout and surrounding geometry, the belt system was developed to match. The driver pulley was a sintered part, press fitted onto the crankshaft without flanges. The driven pulley, also sintered, was fitted to the pump shaft with two flanges. The system worked without a tensioner, reducing complexity and potential points of failure.

Before the design could be approved, Dayco carried out feasibility studies on both the layout and the belt.

The layout: The oil pump is secured to the lower engine block by screws and located with reference bushings. Axial tolerances on both the camshaft and oil pump were analysed. A belt width of

9.4mm was chosen, and parts were manufactured to test extreme tolerances through fitting and validation. Radial tolerances were then assessed, and a nominal belt length was defined.

The belt: Conventional timing belts are designed to operate in dry conditions. For belt-in-oil (BIO)applications, the belt had to function in a chemically aggressive environment throughout the engine’s entire service life and across various global climates. This demanded a new material strategy.

“With the support of oil manufacturers and VMs, Dayco created a test matrix that included even extreme cases.”

Experience from sealing components cannot be transferred, as belts are exposed to dynamic mechanical stress. The development phase involved extensive variables, including more than 100 different engine oils diluted with fuel, water, acids and cleaning fluids, at varying temperatures and levels of ageing.

Accurately defining real world conditions was essential. With the support of oil manufacturers and VMs, Dayco created a test matrix that included even extreme cases, such as acidified oil capable of corroding the sump.

To validate performance, Dayco developed a focused testing procedure to simulate contamination and evaluate key belt parameters. Samples were soaked in oil

and fuel to track degradation. Time and temperature of exposure produced a damage factor for each tested parameter. Controlled measurements included:

● Elongation, tensile strength and modulus.

● Dimensional variation/delta weight.

● Adhesion, cord pull out and hardness.

● Tooth stiffness under static and dynamic loads.

Using these metrics, engineers could calculate the number of hours equivalent to full service life. To accelerate testing, oil temperatures were raised. For example, 800 hours at 140°C was found to represent a worst-case ageing cycle.

The test programme

In addition to passing the standard VM validation process, Dayco created bespoke tests to assess chemical and mechanical wear. These included:

● Running engines to generate expected fuel contamination.

● Engine cycles to reach peak oil temperatures.

● Rig testing with artificially acidified aged oils up to 150°C.

● Simulations of coolant or cleaning fluid ingress.

Switching from a chain to a belt reduced the power required to drive the oil pump, particularly at lower oil temperatures. Testing and modelling confirmed this was mainly due to reduced internal friction and the removal of sliding tensioning components, providing improved engine performance and reduced emissions. This early development of BIO technology enabled Dayco to expand the solution to other engine platforms and demonstrate it as a cost effective alternative to chain drives.

Working closely with VMs and oil suppliers helped define realistic operating conditions, where chemical exposure was added to existing thermal and mechanical stresses. The result was a system that offered lower friction, improved acoustics and reduced weight.

Workshops repairing BIO equipped vehicles must ensure technicians are aware of the potential challenges, know what to look for, and are trained in the correct replacement procedures. That investment in training can generate a reliable revenue stream and ensure long term customer confidence.

“Workshops repairing BIO equipped vehicles must ensure technicians are aware of the potential challenges.”

Febi explores a common fault found in clutch servos and interior fan assemblies with motors.

Function

Due to the high vehicle weight and the underlying engine power, clutches in heavy commercial vehicles must be dimensioned accordingly. However, this also requires high forces to operate the clutch, which would overstrain the driver in the long run. Therefore, clutch servos are used in heavy commercial vehicles. They are hydraulic slave cylinders that are combined with a compressed air cylinder as an amplifier. The pneumatic assistance reduces the force for the driver to operate the clutch pedal by about 80 per cent and enables a sensitive and precise clutch operation.

Cause of failure

Since clutch servos consist of various mechanical components such as springs and valves with small bores, mechanical defects, leaks or blockage of bores are common causes of failure. In addition to the compressed air system, clutch servos are also connected to a closed hydraulic system, which is filled with either brake fluid or hydraulic oil based on mineral base oils. It repeatedly happens that the wrong fluid is used, which destroys sealing rings inside within a short

Function

WANT TO KNOW MORE? Make sure to scan the QR code!

Interior fans usually consist of a plastic housing with an integrated radial fan motor. As an important component of the heating, ventilation or air conditioning system, it draws in fresh air from outside and blows it through the vents into the vehicle interior.

Cause of failure

Since the fan motor is an electric motor, contact problems at plug connections and defective electric components are often the cause of failure. But wear of the bearings, commutator ring, the slide ring or the carbon brushes in the motor also occur after years of use. Since these components are not intended for regular replacement, repair is not economical and often the only option is to replace the entire interior fan assembly together with the motor.

We spoke with Matt Wiggington,director of growth and development at the automotive charity Ben, on supporting the commercial vehicle community.

QCould you start by introducing yourself and your role at Ben?

A: I’m Matt and I’ve been at Ben for about ten years and lead our income-generating teams, the people who build relationships with employers and partners across the industry. My current focus is to help double our income over the next five years so that we can reach more people, especially within the commercial vehicle world.

Q What’s your background and how did you end up at Ben?

A: I spent around 20 years in the travel industry before moving into the charity sector. I led corporate partnerships at the Royal Horticultural Society, managing sponsorship of the Chelsea Flower Show, quite a contrast to the motor trade! Then, a contact told me about Ben, and it instantly felt right. Ten years later, I still love it.

Q What’s your biggest takeaway from working with the automotive and CV sectors?

A: The people. No two businesses are the same, but the issues affecting their teams often are. Everyone genuinely wants to look after their staff, but it’s hard to find the time or resources to make that a real priority. That’s where Ben helps –turning goodwill into real, practical support.

QDo you find that garage owners often put their team before themselves?

A: All the time. In smaller garages especially, the owner will always look after the team first, it’s that family-business mindset. But even leaders need help. Whether you’re running a workshop, managing a fleet, or turning spanners, Ben is here for everyone in the industry.

Q How is Ben reaching further into the CV community?

A: Historically, we’ve been well-known in passenger car retail, but the CV world is huge and vital. We’re doing more to engage directly with operators, workshops, and suppliers –building awareness, attending shows, and listening to what people in the sector really need. The goal is simple: that everyone in CV knows Ben is there for them.

Q Fundraising is a big part of your role, how does that connect with CV businesses?

A: We’re moving toward sustainable fundraising that fits naturally into the sector. Volume-based schemes work really well, small donations linked to every vehicle serviced, part sold, or job completed. Those pennies add up to predictable income that allows us to keep

WANT TO KNOW MORE? Make sure to scan the QR code!

providing help where it’s needed. And we always make sure businesses get value too –through initiatives like BenLife, our wellbeing programme that offers counselling, advice and digital health tools for employees.

Q What about garages on the outskirts of the industry, how can they get involved?

A: We know smaller independents are often focused on simply keeping the doors open. That’s why we focus first on awareness and support rather than fundraising. If a garage owner knows they or a team member can turn to us in confidence, that’s the most important thing. Once they see the impact, they often want to give back –whether that’s hosting a Ben’s Big Breakfast, joining BenLife, or spreading the word.

Q If you could send one message to the CV sector, what would it be?

A: You might not know us yet, but you can trust us to help. Whether you’re an owner, a technician or a driver, you’re never alone. Ben has been supporting the automotive community for over 120 years, and we’ll keep doing it for many more. Whatever’s going on in your life or business, don’t hesitate to pick up the phone –that’s what we’re here for.

The automotive sector is evolving at an incredible pace and is being driven by new technologies, electrification, and changing consumer needs. Yet, alongside this growth lies a pressing challenge, which is the shortage of skilled workers. To combat this is Repairify has invested in its apprenticeship programme.

At Repairify, the investment in apprenticeships goes beyond simply offering training. The company sees its programme as a longterm sustainable strategy that nurtures the next generation of talent, equips them with in-demand skills, and ensures the business, and the wider industry continue to thrive well into the future. With this in mind, let’s explore some of the key benefits apprenticeship programmes deliver alongside insights from apprentices who are part of the programme.

Apprenticeships help build skills the industry needs, and this is especially important in a sector where technologies are rapidly evolving. Repairify apprentice Rosie Nicholson explains that her aim for the apprenticeship is to gain a broad range of practical technical skills and knowledge, particularly in automotive diagnostics, fault troubleshooting, and IT systems related to vehicle diagnostics. “The type of skills I have gained as part of the Repairify apprenticeship programme makes apprentices job-ready and futureproofed at

the point of entry because we have the knowledge to adapt to new technologies that are coming into the workshop.”

From a business perspective, providing apprenticeship opportunities for the likes of Rosie and her peers means the skills gap is being slowly bridged.

“This collaborative culture within the programme helps individual development.”

Another benefit of apprenticeship programmes that is important but is often overlooked is peer to peer support. Rosie states, “I’ve received valuable support from other apprentices who have been a great source of guidance and shared learning. They’ve helped me adapt to the work environment by offering insights into the tasks and processes I’m still getting familiar with. Whether it’s through tips on using diagnostic tools or advice on managing workloads, they’ve made the learning

process smoother. The collaborative atmosphere has encouraged me to ask questions and learn from their experiences, making me feel more confident in my role.”

This sentiment is also echoed by another Repairify apprentice Madison Leigh who highlights, “Since starting this apprenticeship, I have received nothing but positive support throughout and because we are all doing the same course, we are here to support each other.”

This collaborative culture within the programme helps individual development as well as embracing knowledge-sharing habits that the apprentices will use down the line with peers or apprentices they might work with.

Apprenticeships also benefit the industry because they widen the talent pool. In an industry that is seen to be male-dominated, both Rosie and Madison feel that their experience has been inclusive and supportive. Rosie explains that from day one, her gender has not been a barrier. “The emphasis has always been on the work and my growth as a professional, rather than

my gender. While the industry may traditionally be male-dominated, I’ve been able to find a place where my contributions are valued based on my abilities and dedication to the work.”

Madison’s experience also echoes this as she describes her workplace as “like having a big, crazy, loud family all in one place.” This has allowed her to fit right in and help her settle into the programme, while also growing in confidence. This positive culture within Repairify’s programme helps improve engagement because a happy apprentice is an engaged apprentice, and an engaged apprentice is an apprentice who is learning and growing as a person.

Looking ahead, it is important to see apprenticeships as part of the journey and

“Apprenticeships are not charitable initiatives but strategic investments by businesses.”

these two young apprentices seem to know where they are going. Rosie has her eye on mastering diagnostics and emerging technologies such as EVs and autonomous systems, with the potential to move into leadership. Madison, meanwhile, is focused on progressing in her role while pursuing personal goals such as her motorbike test and, one day, owning her dream car, which is a Chevrolet Camaro SS.

If there’s one thing these apprentices want others to know, is that the leap is worth it. Rosie’s advice is clear, “Go for it without hesitation. Stay confident in your abilities and embrace the challenges.”

Madison echoes this sentiment: “Honestly, if it’s something you want to do, then do it –it’s the best thing I’ve pushed myself to do.”

Overall, apprenticeships are not charitable initiatives but strategic investments by businesses. These schemes have been developed to build a pipeline of fresh perspectives, diverse talent and future-ready skills that enable businesses to remain competitive in a rapidly evolving industry.

CVW recently spoke to an up-and-coming vehicle technician working at PW Auto Repairs, who has faced an uphill battle getting accepted into his local colleges.

Despite automotive vacancies still sitting at 2.3 per cent, the eleventh highest sector in the UK, according to the latest figures from the IMI, many prospective automotive learners are facing great difficulties entering the official college system. This was highlighted during a recent visit to one Nottinghamshire garage by the CVW editorial team.

“The college said his GCSE grades were not good enough to get on the course, but with autism and ADHD there should be consideration.”

Diana Whetton, PW Auto Repair.

PW Auto Repairs, a family garage run by Diana and Paul Whetton, has been supporting one of their employees in his struggle to get the full education he is entitled to. 17-year-old Lewis’ difficulties with Maths and English – stemming from his autism and ADHD – have resulted in Newark College initially refusing to accept him on to their automotive repair courses beyond Level One.

His employer, Diana Whetton, played a crucial role in fighting his case with the college, spending “hundreds of hours, phoning and emailing people”, reaching out to a range of third party organisations to ask for help, including Apprenticeship Central. She told CVW: “The college said his GCSE grades were not good enough to get on the course, but with autism and ADHD there should be consideration.” And, in fact, she discovered there was a way around the requirement for GCSEs in special cases.

It’s a start!

Newark College accepted him on a Level One course and had agreed provisionally to allow him to undergo a Functional Skills qualification instead of the more stringent GCSEs. As it transpired, however, the college had in fact enrolled him into GCSE qualifications: “He'd been working really hard on his GCSEs at college and successfully completed his Level One course. Then, in a meeting with the college, they told me he wouldn’t be going into the next year for the Level Three, due to failing his English and Maths GCSEs. I said, I don't understand because he's kept his end of the bargain and you haven’t. He was never going to move the needle far enough on his grades to pass, due to his autism and ADHD. That’s why he was supposed to be on a Functional Skills qualification,” Diana told CVW. “Their response was, it’s funding and not our fault”.

“Not many bosses or workplaces would put so much effort into helping and pushing so much through to get the help needed. I just feel so grateful towards her and towards the company. I’ve been here for 18 months now, and I think I’ll miss it when I’m at college!” Lewis, apprentice.

Even though Diana had presented Newark College with a recent Government paper outlining that funding wouldn’t be affected in cases like Lewis’. It was to no avail. In fact, the college even suggested that Lewis switch course to take on bricklaying or plastering instead. A suggestion which found no favour with Lewis or Diana: “Lewis is the most passionate person about this industry that I've ever met. To suggest he change course when he has no interest in doing something else was quite frankly offensive.”

“I asked the head of automotive,” Diana explained. “If you take English and Maths out of the equation, could Lewis successfully

complete the course in three years time? He said yes, with the right support…"

Diana then spent months talking to colleges, training providers, organisations and even other garages, to gain as much information as she possibly could to fight Lewis’ corner. "We wanted him on the three year course and I was just furious with the college.”

Other colleges offered options, however it wouldn’t be on a straight three-year Level Three course. Instead, he would have to go through another six years of training, after already completing a year on the Level One – making it seven years, to get to the same place his peers would in three years total.

The man himself Lewis told CVW that he was supremely grateful for the effort Diana has gone to in his case: “Not many bosses or workplaces would put so much effort into helping and pushing so much through to get the help needed. I just feel so grateful towards her and towards the company. I’ve been here for 18 months now, and I think I’ll miss it when I’m at college!”

Diana added: “Lewis hates even having a day off, he learns a lot at work and he is determined to complete the course. He has our full support”

Update from Diana: “Newark College have now signed Lewis up! The college eventually back-pedalled and said they would take Lewis on, despite there being no change in circumstances.”

“Lewis is the most passionate person about this industry that I've ever met. To suggest he change course when he has no interest in doing something else was quite frankly offensive.”

Diana Whetton, PW Auto Repair.

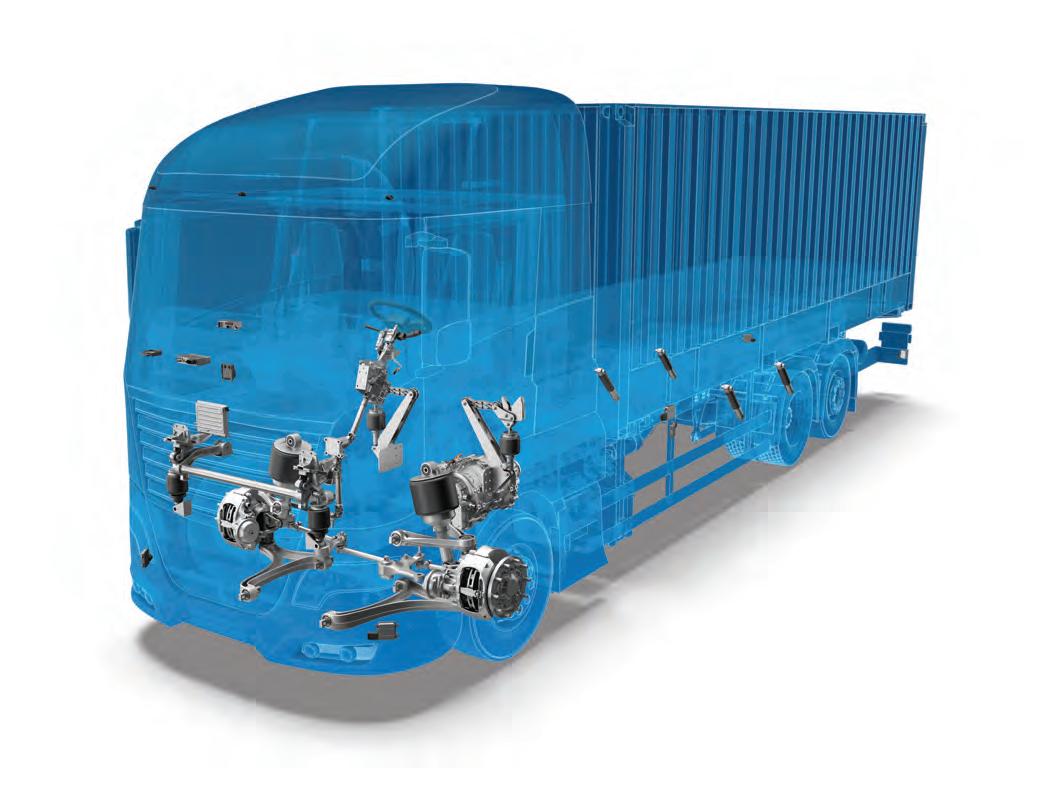

From bonded bushes to robot-welded axles, every Sampa suspension component is designed for endurance. The result: less tyre scrub, lower fuel bills and no more costly unplanned stops to keep your business moving.

When a deep pothole sends a shudder through your trailer, Sampa’s axle, steering and suspension solutions take the impact by smoothing out jolts, increasing braking reserves and eliminating wind-up. Results mean drivers keep going, cargo stays secure, and unplanned stops become a thing of the past.

Key features

● Rugged trailing arm and solid axle connection – a no-wiggle link from chassis to road.

● Large-diameter shocks and premium seals – soak up impact, keep out grit.

● Bonded bushes and ABS-monitored assembly – minimise wear, maximise safety.

● Thicker double-stud top plates – extra metal on your air-spring connection.

Every product in the Sampa axle and suspension range is engineered to exceed OE specifications, robot-welded for pinpoint consistency and tested in the CAMP R&D centre against standards twice as demanding as standard OEM. The product is a chassis protector that prevents wind-up, water ingress and bushing fatigue. Modern commercial vehicle suspension systems are much more than mechanical linkages. They are finely tuned ecosystems balancing load, stability and ride comfort in the toughest conditions. Independent tests show that improved suspension geometry can cut tyre scrub by up to 15 per cent, translating directly into lower rolling resistance and better fuel economy. Axle alignment accuracy plays a major part too: even a halfdegree deviation can increase tyre wear by around 10 per cent, which is why solid trailing arms and precisely machined axle beams are vital for long-term fleet efficiency.

Thermal management and material science are advancing rapidly across the industry. High-tensile spring steels, treated through quenching and tempering, now maintain elasticity over millions of load cycles without cracking or fatigue. Modern elastomer bushes are formulated to resist ozone damage and micro-tearing, particularly under the heavy torsional loads seen in long-haul transport across the UK. Likewise, corrosion-resistant coatings and sealed bearing designs extend component life, even when facing salt spray, standing water and grit from Britain’s winter roads.

performance

Thanks to optimised spring rates, highcapacity air springs running at lower pressures and exacting rubber-to-metal injection points for perfect heat distribution, Sampa parts deliver long-distance motorway-cruising comfort. And with direct-from-factory pricing plus proven total-cost-of-ownership savings, you can now swap frequent pit-stops for maximum uptime on the road. For your business this means fewer repair bills on the workshop docket. For operators, uptime isn’t just a slogan –

WANT TO KNOW MORE? Make sure to scan the QR code!

it’s measurable value. Fleet data shows that well-maintained suspension systems can cut unplanned maintenance by up to 30 per cent. Air-suspension setups, when paired with adaptive damping technology, help maintain consistent ride height under changing loads, improving aerodynamics and driver comfort. As payloads shift and temperatures vary, Sampa precision-engineered valves and seals prevent air loss, maintaining steady pressure and reducing compressor cycling to keeping running costs down.

Local service with nationwide coverage

With a 215,000 m² integrated 17-factory campus, internationally accredited quality systems (including Ford Q1) and distribution right across the UK and Ireland, Sampa has the parts you need in stock and engineers ready for rapid-fit replacements. All axle and suspension solutions carry UK/EU ISO certification and bolt straight onto any HGV trailer make or model.

Beyond the parts themselves, the real value lies in lifecycle management. Predictive maintenance, powered by sensor data and wear analytics, is changing how fleets plan reliability. Integration of axleload sensors allows continuous monitoring of stress patterns, helping you schedule replacements before failures occur. Coupled with modular component design, this forward-looking approach reduces downtime, simplifies servicing and ensures interchangeability across fleet models.

Join hundreds of UK haulage operators who have upgraded to SAMPA. Discover more about our market-leading axles, steering and suspension solutions. We engineer our parts to keep your fleet on the move, working tirelessly to complete and repeat every job.

ZF Aftermarket details how its enhancing commercial repair capabilities with new electric drive and suspension solutions.

As commercial vehicle fleets transition toward cleaner and more intelligent transport systems, ZF Aftermarket continues to lead the way by bridging original equipment technology with real-world workshop support. At the heart of this evolution are three key product and service developments from ZF that are engineered to maximise uptime, increase efficiency, and equip the independent aftermarket with future-ready repair capabilities: new CeTrax electric drive repair kits, the intelligent iEBS trailer braking platform, and SACHS premium comfort valve (PCV) shock absorbers for buses and coaches. Each innovation demonstrates ZF’s dual focus: providing high-end technological components and ensuring aftermarket support with the training, kits, and tools needed for fast, safe, and confident repairs in the workshop environment.

The introduction of twelve new repair kits for the CeTrax electric central drive system marks a milestone for aftermarket readiness in commercial electric vehicles (e-CVs). CeTrax is ZF’s fully integrated, allelectric central drive designed for medium and heavy-duty applications such as urban buses and last-mile delivery trucks. It offers a compact and modular layout that fits within the space traditionally occupied by internal combustion powertrains, making it ideal for OEMs shifting toward zero-emissions propulsion.

Installed in battery-electric vehicles, CeTrax aims enable smooth, efficient operation with zero local emissions. However, servicing these systems has historically been limited to the OEM network due to the complexity of electric drivetrains and limited aftermarket access to parts and diagnostic knowledge.

ZF Aftermarket’s new repair kits tackle these barriers directly. Each kit is purposebuilt for specific service scenarios and includes all relevant components for safe, effective repairs. This includes seals, fasteners, bearings, and selected electronic modules depending on the kit version. By standardising components into clear, application-specific kits, ZF removes the guesswork and procurement delays often associated with EV repair.

For workshop technicians, the benefits are clear: quicker part identification, simplified ordering, and a safe and efficient repair workflow that aligns with ZF’s OEM-grade procedures. Most importantly, ZF is opening up its e-mobility ecosystem to the independent aftermarket –a key enabler for fleet operators looking to service electric vehicles without relying exclusively on OEM service networks.

Technical support, including comprehensive repair instructions, torque specifications, and safety guidelines for working with high-voltage systems, is also integrated into ZF Aftermarket’s training and support platforms, including ZF [pro]Academy and its [pro]Service partner network.

Beyond electric propulsion, ZF is also reshaping trailer technology with the launch of its intelligent electronic braking system (iEBS) platform. Released to the aftermarket in the fourth quarter of 2024, the new iEBS system aims to combine traditional braking control with advanced data integration and diagnostics for greater trailer efficiency and uptime.

The iEBS platform is offered in standard and premium configurations, both of which provide modular, scalable functionality designed to meet the evolving demands of logistics operators. For example, integrated tyre pressure monitoring system (TPMS) functionality is now part of the iEBS ecosystem, allowing fleet operators and service providers to track tire health in realtime and proactively address safety or efficiency issues.

From an aftermarket perspective, the key advantage lies in the diagnostic transparency and serviceability of the new iEBS. The system’s embedded connectivity allows for advanced condition monitoring, which can be accessed and interpreted by ZF-trained service partners. This enables predictive maintenance strategies that reduce unplanned downtime, increase vehicle safety, and extend component life.

ZF Aftermarket is also preparing its [pro]Service workshops for the rollout of iEBS. This includes tailored technical training on system architecture, fault finding, installation best practices, and software updates. Shorter installation and training times mean workshops can offer smarter braking solutions without lengthy onboarding, helping fleets meet compliance and performance standards with minimal disruption. For fleet operators navigating the growing complexity of modern trailer systems, iEBS represents a significant step forward in cost control, roadworthiness assurance, and real-time operational insights.

Comfort and control are critical components in commercial vehicle operation –especially in passenger transport segments such as intercity coaches and urban buses. As powertrains electrify and chassis layouts shift, suspension systems must adapt to new vehicle dynamics, including different weight distributions and noise, vibration, and harshness (NVH) profiles.

SACHS premium comfort valve (PCV) shock absorbers, developed by ZF, address these challenges withReplacing springs without addressing worn mounts is a false

economy that can shorten the life of the new component valve technology that ensures superior ride quality and chassis control under varying loads and road conditions. The PCV units are available for bus applications from manufacturers such as MAN and Daimler Buses.

What sets PCV shocks apart is their ability to maintain optimal damping force across a wide range of inputs, adjusting to both driver manoeuvres and passenger load. This results in smoother rides, less vehicle sway, and improved control –critical for electric buses that operate in stop-start city environments where comfort and handling are constantly tested.

For the aftermarket, the benefit is twofold. First, the PCV range offers a direct replacement solution that enhances vehicle dynamics while simplifying fitment. Second, ZF’s catalogue and training support make identification and installation straightforward, ensuring compatibility and proper function in even the most advanced electric chassis configurations.

As electrification redefines the weight balance and operating characteristics of buses, PCV technology becomes not just a luxury, but a necessary adaptation to keep pace with OEM advancements.

This illustrate ZF Aftermarket’s commitment to enabling independent workshops and fleet service providers to compete and thrive in a rapidly changing commercial vehicle landscape.

By launching electric drive repair kits, intelligent trailer braking platforms, and premium suspension systems designed for modern drive configurations, ZF ensures that the aftermarket can keep pace with the complexity at the OE level.

More importantly, ZF’s integrated training, cataloguing, and partner support systems –especially through the ZF [pro]Service and [pro]Academy –transform advanced technology into real-world serviceability. This support structure is essential for the independent aftermarket as it prepares for a wave of battery-electric trucks, nextgeneration braking systems, and digitally integrated components. The focus must be on repair efficiency, component reliability, and technical training –not just for parts but for systems.

ZF Aftermarket’s recent product launches are not simply new parts –they are an infrastructure for change. As the commercial vehicle sector transitions to lower emissions and smarter fleet management, ZF is helping ensure that the aftermarket is not left behind.

From scalable EV repair to smarter trailer controls and adaptive suspension systems, ZF’s approach is practical, modular, and grounded in decades of OE expertise. For independent workshops, it signals a future of opportunity rather than disruption –provided they have the right tools, training, and support in place.

Suspension specialist febi tells us everything you need to know about shock absorbers, and what can go wrong in them.

Since springs have the capacity to oscillate when the vehicle is travelling over uneven ground, the vehicle can start moving excessively, which can lead to a loss of road contact with the tyres. To prevent spring oscillation, shock absorbers are required to dampen the oscillation to a minimum and to keep the tyres in contact with the road for a comfortable and safe ride.

Function

Conventional shock absorbers are mainly produced as hydraulic telescopic shock absorbers in a single or twin tube design. In the heavy commercial vehicle sector, mainly twin-tube gas pressure shock absorbers are used.

The shock absorbers are filled with special shock absorber oil and a small amount of gas, which is usually nitrogen. The gas is needed because of its property to be compressible. When the piston rod is pushed into the shock absorber, it displaces the oil into the outer tube.

The increase of volume of the push rod inside the shock absorber is compensated by the compressible gas, which decreases its volume.

dampening characteristics

As vehicles are constructed in various configurations and have different weights, every shock absorber must have specific dampening characteristics according to the vehicle it is applicable for. Chassis shock absorbers work hydraulically and the moving of the chassis is compensated by transferring the moving energy into friction energy. The friction is created by pressing the oil through the piston valves and

bottom valves while the piston is moving.

The different dampening characteristics can be achieved by the construction of the piston and the bottom valves where the oil is being pressed through. Their principle is based on the fact that the resistance to the flow of the displaced shock absorber oil depends on the flow velocity. It is not linear, but rather progressive, i.e., it increases with the flow velocity.

“If there is any doubt about the condition of the shock absorbers, a professional workshop should be visited immediately.”

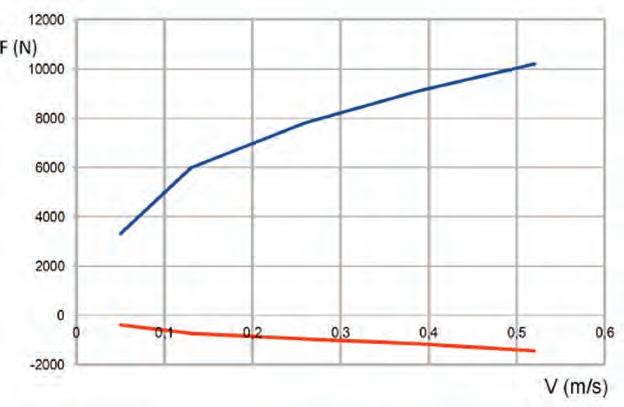

The push and pull forces are measured in comparison to the speed the piston rod moves in and out of the shock absorber. Only shock absorbers with suitable dampening characteristics can bring optimal dampening performance required for road safety and comfort.

The wear and its consequences

Shock absorbers are subject to wear. Various aspects influence service life and wear and tear, such as mileage, road condition, and the weight of the vehicle. Over time, the dampening performance decreases. This is a slow process, which the driver often does not recognise. For example, a loss of 50 per cent of the dampening performance can result in a 20 per cent extended braking distance when the optimal road contact cannot be achieved. The driver assistance systems are also very dependent on shock absorbers and a perfect chassis suspension.

Bake distance comparison:

Besides the longer braking distance, a vehicle with a poor shock absorber performance may break away in road bends and crosswind sensitivity may increase. This is particularly dangerous for heavy trucks because of their high centre of gravity and large wind-exposed area. In addition, the truck may dive under braking, making the vehicle unstable. Tyres wear out faster and driving comfort decreases.

Are the shock absorbers still okay?

Truck drivers should ask themselves this question regularly. But not every driver is able to answer this question sufficiently. The fact that the shock absorbers are worn out or defective can be noticed, above all, by significantly poorer driving comfort and in changed steering behaviour. If the tyre

tread is not worn evenly, but varies in depth or is uneven over the tyre circumference, this also indicates defective shock absorbers. When the piston rod seal is leaking and the shock absorber is losing a significant amount of oil, which is easily visible on the outside, it should be replaced as soon as possible.

If there is any doubt about the condition of the shock absorbers, a professional workshop should be visited immediately. Trained specialists can detect defective shock absorbers and replace them professionally. The driver, any passengers, or even sensitive freight will be grateful for a perfect suspension and the resulting driving comfort. In heavy commercial vehicles or buses, safety should always be the focus to not endanger other road users and to avoid dangerous driving situations and accidents.

Rely on tested, OE matching quality replacement parts from febi. The entire range of shock absorbers can be found at WWW.RDR.LINK/VBZ011

The febi brand is part of the bilstein group, the umbrella organisation for several other strong brands.

Diesel Technic parts specialist, Lee Harris, gives practical advice on leaf springs and air springs.

When it comes to axles and suspension, reliability is everything. For commercial vehicles, suspension components such as leaf springs and air springs are vital in keeping loads stable, axles aligned, and drivers safe. Yet, as every workshop knows, these parts face punishing conditions and are often overlooked until a failure occurs.

At Diesel Technic, our parts specialists regularly support workshops worldwide with practical advice on suspension components. Drawing on their expertise, here are some key insights into diagnosis, replacement, and best practice for workshops handling these critical parts.

Leaf springs remain a trusted workhorse of suspension systems, particularly for construction vehicles, vans, and older trucks. Their design may appear simple, but precision matters when it comes to maintenance and replacement.

● Different designs, different demands: Leaf springs come in various assemblies – from heavy-duty stacks connected with heart bolts and spring clips, to lighter versions fitted with pressed-in rubber bushes for noise and vibration damping. Workshops should always identify the correct design for the application before sourcing replacements.

● Critical role in axle alignment: The centre bolt within a leaf spring doesn’t just hold the assembly together – it helps align the axle. U-bolts are equally important, providing lateral guidance and securing the spring to the axle. Any compromise here risks misalignment, uneven tyre wear, and instability.

● Replace like-for-like: One of the most common mistakes in spring replacement is fitting the wrong specification. Always ensure the replacement matches the original spring rate, number of

Air springs deliver superior ride comfort and adaptability, particularly for long-haul and heavy-duty vehicles. However, they introduce their own maintenance challenges.

leaves, and design. Deviating from specification can disrupt load-dependent braking systems, which rely on predictable suspension compression under load. A mismatch can compromise braking efficiency and vehicle safety.

● Workshop tip: When replacing, inspect all fixing points, bushes, and bolts for wear. Replacing springs without addressing worn mounts is a false economy that can shorten the life of the new component

● Error patterns to watch for: Common causes of failure include chafing from foreign objects between the piston and rubber, thermal overload from overheated brakes, or simple material fatigue leading to porosity. Technicians should be aware that not all visible damage is a product defect – often, it’s the result of external conditions.

● Torque matters: Over-tightening mounting bolts is a frequent workshop error. Diesel Technic’s parts specialists stress the importance of observing the specified torque values marked on the part. Excess torque can deform plates and compromise sealing – leading to premature failure.

● Testing for leaks: Ideally, workshops should use a test basin to check for air loss. But a practical alternative is leak

detection spray or even soapy water, applied to suspect areas while the system is pressurised. Small air bubbles will quickly reveal problem points.

● Correct fitment is crucial: An air spring that is too short or incorrectly specified can cause top plates to distort or pistons to slip out of position. As with leaf springs, correct part selection is non-negotiable.

● Level control systems: Air springs often operate in tandem with level sensors and valves. If a vehicle is exhibiting uneven ride height or erroneous readings, don’t immediately assume a sensor failure. Follow the diagnostic chain: check wiring, linkages, and connectors before replacing electronic components.

“Replacing springs without addressing worn mounts is a false economy.”

Prevention over cure

Suspension failures don’t just cause downtime – they can compromise safety and shorten the life of other connected components. Workshops can add real value to customers by adopting a preventative approach:

● Inspect suspension parts at every service, not just when faults are reported.

● Emphasise to fleet operators the importance of replacing in pairs (springs, airbags, and sensors).

● Use manufacturer data and online portals, such as Diesel Technic’s partner portal, to ensure correct part identification and availability.

Whether it’s the traditional strength of leaf springs or the adaptive comfort of air springs, suspension components demand precision and care. For workshops, the advice is clear: replace like-for-like, respect torque values, and never underestimate the importance of correct diagnosis. By doing so, you not only keep vehicles safe and roadworthy but also build long-term trust with fleet operators.

WANT TO KNOW MORE?

Make sure to scan the QR code!

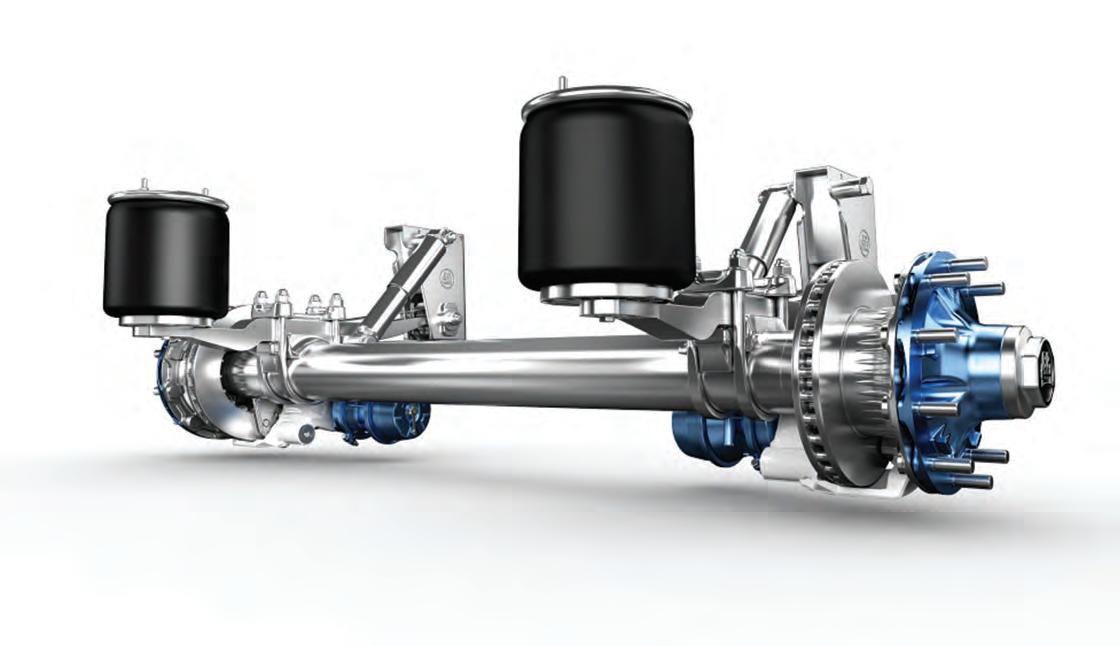

Leading suspension specialist BPW details how its suspension systems are a smart choice for workshops, aiming to deliver efficiency and reliability for commercial vehicles.

High performance, low maintenance, and reduced wholelife costs define BPW suspension systems, making them a top choice for fleet operators who demand reliability and efficiency. BPW aims to set industry standards by delivering innovations that maximise vehicle uptime without compromising safety or durability.

BPW offers a wide range of air suspension systems, for different transport needs. For long-haul or heavy-duty operations, BPW delivers solutions that keep trailers performing optimally and maintain low maintenance costs.

For 9-tonne axles, the company offers three suspension types. The latest Airlight II Round (AL II-R), an advancement of the proven Airlight II (AL-II), features a conventional sprung steel trailing arm for reliable trailer performance. The ECO Air, with its cast trailing arm design, offers the same properties as the Airlight II and accommodates a variety of trailer designs and operating conditions. For more demanding requirements, the Airlight Heavy Duty (AL-HD) incorporates reinforced components to withstand higher stresses. For even greater loads, the SL suspension supports up to 14 tonnes.

“A lighter unladen weight meanslowerfuel consumption and larger payloads.”

These solutions aim to ensure maximum strength, stability, and efficiency across various operational applications.

The Airlight II Round (AL II-R) suspension is among the lightest axle and suspension systems on the market. It delivers outstanding performance and reliability for trailers with axle loads up to nine tonnes. Its modular design uses a round-axle beam manufactured with state-of-the-art laser processing technology. This design enhances stability and significantly reduces overall weight.

The design of the trailing arms, hanger brackets, and axle clamping can reduce the weight of a tri-axle trailer by up to 93kg, thereby improving efficiency. A lighter unladen weight means lower fuel consumption and larger payloads, resulting in increased revenue.

The suspension’s modular design allows for easy, low-cost replacement of individual parts and components, reducing repair costs by only needing to replace damaged or worn-out parts. The Airlight II Round also features flexible trailing arm technology, which can be precisely adapted to a particular vehicle and its application. The sprung steel trailing arm absorbs the

strongest vibrations from the running gear and uneven road surfaces, reducing stress on the tyres, frame, vehicle body, and the load itself, which extends the lifespan of the trailer.

Building on the lightweight efficiency of the AL II-R, the BPW LightTube is among the lightest 9-tonne chassis solutions on the market, with a total module weight under 370kg. Designed for Airlight II running gear, its high-strength, hollow-section leaf spring connects chassis and axle in a robust, lightweight configuration.

The result is increased payload capacity and reduced fuel consumption. Lower CO2 emissions drive both environmental and operational savings, as well as long-term sustainability. Its clamped spring seat arrangement also prevents cracking risks often found in welded alternatives. This ensures a long service life with reduced maintenance.

By combining a lightweight design with performance and reliability, LightTube underscores BPW’s promise to deliver efficiency and durability.

ECO Air is a robust and modular air suspension system that aims to performs well across multiple road conditions. Its two-part cast trailing arm, combined with BPW’s precision-engineered steel rubber bush, ensures long-term durability and ease of maintenance. Unlike welded alternatives, the modular design says to allow quick replacement of individual components. This reduces downtime and lowers repair costs.

“By minimising maintenance time and costs, the AL-HD ensures continuous fleet productivity.”

A key feature of ECO Air is BPW’s patented high-tech laser production process. It combines BPW’s typical clamped modular air suspension mounting with round-axle beams. By integrating the threedimensional laser profile, etched on the bottom of the casting interface, the system creates a positive location with less clamping force. This technology ensures a secure fit with minimal clamping force, improving overall durability and stability.

The asymmetrical steel-rubber bush enhances load absorption and guidance while reducing tyre wear and improving ride comfort. With its optimised design, ECO Air offers a cost-effective option for fleet operators needing efficient air suspension.

For transport operations requiring higher load capacity, the Airlight Heavy Duty (ALHD) suspension system is engineered to handle axle loads of up to 12 tonnes. It includes reinforced components, such as thicker springs, welded spring seats, and robust M24 U-bolts. The AL-HD delivers superior strength and stability in the most demanding conditions.

This system also features clamped connections, letting you replace individual components as needed without requiring complete axle replacements. By minimising maintenance time and costs, the AL-HD ensures continuous fleet productivity. It also provides the durability required for demanding applications such as heavy haulage, construction logistics, and logging.

Designed for the heaviest loads and extreme conditions, the SL suspension system supports axle loads up to 14 tonnes. Featuring a low-maintenance U-bolt clamping arrangement, it allows for straightforward component replacement, helping to minimise operational downtime. With a 100mm-wide spring steel trailing arm, available in single or twin-leaf configurations, BPW SL suspension aims to deliver durability for off-road or specialist transport applications. The combination of axle, connection, and trailing arm forms a robust unit that can handle the toughest loads while remaining stable.

BPW suspension systems are said to give operators the flexibility to select solutions tailored to their transport requirements. Whether prioritising lightweight efficiency, modular maintenance, or heavy-duty strength, BPW delivers technology that reduces costs and maximises vehicle lifetime.

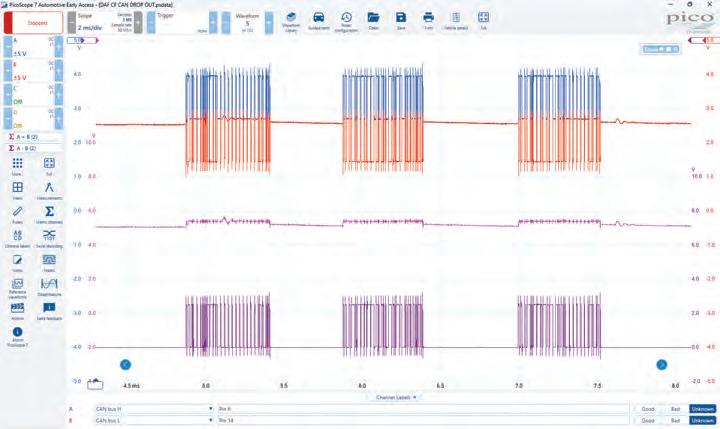

Ben Martins, automotive application specialist at Pico Technology diagnosis a commercial vehicle engine cut-out with PicoScope J1939 decoding.

In the world of commercial vehicle maintenance, electrical and communication faults are becoming the primary diagnostic challenge. Modern trucks and off-highway machinery rely on complex networked systems, and a complete breakdown, like a sudden engine cut-out, often screams CAN bus communication failure. While many communication fault codes can trigger panic, a structured approach, starting with the fundamentals of voltage and network integrity, coupled with advanced tools like the PicoScope’s J1939 decoder, provides the clarity needed to pinpoint the true culprit.

Before touching a tool, talking to the customer is critical. Their experience holds the key to the puzzle. In this instance, the complaint was: the vehicle suddenly cut out and wouldn’t restart. Through openended questions, about the weather, driving duration and prior warnings, a crucial detail emerged: the vehicle ran fine from cold but cut out after driving for some time. Following the initial recovery attempt, it restarted, only to cut out again shortly after. This pattern immediately suggested a temperature-related fault.

Initial checks: serial data and network health

When the vehicle arrived, it was cool, allowing us to replicate the initial operating conditions. A quick serial diagnostic scan confirmed our suspicions. We found 12 active diagnostic trouble codes (DTCs), 11 of which were reporting CAN communication faults, with four specifically pointing to the engine electronic control unit (ECU). This clearly directed our focus toward the Engine ECU’s network connection.

To ensure network integrity, a resistance check is the first step, performed when the network is inactive. Observing the breakout box LEDs confirmed the network had shut down. A quick resistance measurement across CAN High and CAN Low yielded 60 Ω, confirming the expected value for two 120 Ω resistors in parallel and establishing the physical network integrity.

Capturing the fault with the oscilloscope

With the physical integrity confirmed, the next step was to catch the fault in action. We connected the PicoScope and used its ability to capture data over an extended period. To analyse the signal, we utilised Math Channels, a powerful PicoScope feature. By using the built-in A+B and A−B functions (where A is CAN High and B is CAN Low), we can view the network signals with more detail. The A−B channel provides a differential view of the data, which is crucial for proving CAN's inherent fault tolerance by eliminating interference that occurs in both CAN H and CAN L, showing you what the ECU is seeing. The resulting A−B trace was perfectly clean and ready for decoding.

After running the vehicle until it reached operating temperature, the engine hesitated and then abruptly cut out, precisely as the customer described. Critically, we left the PicoScope running to capture both pre-fault and post-fault data.

Looking at the trace, the scope showed a complete network silence for two buffers, totalling 40ms. This was followed by a significant reduction in CAN traffic.

To move from raw voltage data to actionable diagnostic information, we needed to know which ECUs were still communicating and, more importantly, which ones had dropped out. Commercial vehicles simplify this task by often using the SAE J1939 protocol, which is more standardised than passenger car networks.

We deployed the PicoScope's J1939 Serial Decode feature, creating a new decoder for CAN. The J1939 decoder splits the ID into three sections, Priority, PGN (parameter group number) and Source Address. The input channel was set to our clean A−B Math Channel. After setting the

voltage threshold (crossing point) to 1 V and determining the Baud Rate using the time rulers (which showed 250 kHz), the scope converted the raw waveform data into a table of hexadecimal (HEX) values.

As the J1939 protocol standardises ECU address IDs, with the PGN and source

address, we can use the decode table to identify who is on or offline quickly.

Using the ISOBUS.net website, we can get a generic list of source address IDs where looking at our decode table, 0 is very busy. Looking source address 0 up on the isobus list, it refers to Engine ECU.

This is where the power of the PicoScope’s analysis features becomes evident. Instead of just looking at raw hex codes, we can use the software's Link File feature to translate these IDs. By creating a CSV file and inputting the HEX ID0 and its description (e.g., "Engine Controller 1"), we instructed PicoScope to replace the obscure code with a language we could easily understand.

With the Engine ECU's ID known, we extended the serial decoder to analyse All Buffers in the capture. We then used the decode table's Filter option to display only messages from the Engine Controller 1.

Our search began at the point the fault occurred: buffer 96. The analysis was conclusive: the Engine Controller 1 message was no longer present after buffer 96, yet

there are still other source addresses present after this, indicating the network is still awake with messaging taking place. This ID, which had been extremely active in every previous buffer, had completely vanished.

This finding provided the evidence we needed: the Engine ECU had dropped off the network following the engine cut-out. Since the network was physically intact and the fault was temperature-dependent, the logical conclusion was an internal failure within the ECU.

The Engine ECU was removed for testing and confirmed faulty. A new unit was fitted, coded and the vehicle returned to service, fault-free. This case demonstrates how a strategic diagnostic approach, leveraging the fundamental principle of voltage measurement combined with the advanced J1939 decoding capability of the PicoScope, can turn a complex communication failure into a clear, evidence-based repair decision, avoiding costly guesswork. The possibilities are only limited by your imagination - and time, of course! WANT TO

examines what the future of diagnostics could look like, and how garages can best prepare for this.

Walk into any workshop today and the first thing you’ll notice isn’t the smell of oil or the clatter of impact wrenches –it’s the laptop on the bench. What used to be a mechanical job has evolved into something far more complex. Today’s vehicles are rolling networks of sensors, control units and encrypted gateways, and diagnosing faults has become as much about understanding systems as it is about tools.

Welcome to the new era of diagnostics–where success isn’t about turning a bolt but turning data into answers.

From under the bonnet to behind the screen

For years, diagnostics was seen as a side task, something you did after the “real” mechanical work, but as vehicles became more sophisticated, that model quietly broke down.

Now, it’s not unusual for a relatively simple issue, such as an airbag warning light, to require access to secure onboard systems, coding procedures, or even online authentication. The workshop that isn’t prepared for that reality risks falling behind, not just technically but commercially. Modern diagnostics isn’t just another step in the process. It is the process.

Security is the new standard

In the past, accessing a vehicle’s fault codes was straightforward. If you had the right plug, you were in. But manufacturers, understandably wary of cybersecurity and theft, have tightened access over the last decade.

Secure gateways, encrypted ECUs and limited-function OBD access are now standard on many post-2018 vehicles. For independent garages, this can feel like a locked door with no key unless your diagnostic tool has secure access protocols built in. This isn’t about convenience anymore it’s about survival. If your workshop can’t handle secure access, you’re not just slower than the competition, you’re out of the game entirely.

The EV challenge isn’t coming, it’s already here

Electric vehicles once felt like tomorrow’s problem. But for many workshops, they’re already today’s reality, and they don’t play by the old rules.

Gone are fuel trims, EGR valves and turbochargers. In their place: inverter control units, thermal management systems and complex battery monitoring software. Diagnostics becomes more than scanning for codes –it’s about understanding how a 400V system behaves under load, or why a battery’s state-of-health reading might mean replacement, not repair.

“A tool that can handle a wide range of vehicles give workshops a single source of truth.”

Crucially, EVs introduce new safety challenges. High-voltage components can’t be approached with trial and error. You need procedures, you need training and you need tools built with this environment in mind. For workshops still waiting to “see more EVs” before investing in the right gear, the risk is becoming clear: by the time the volume arrives, you may already be behind.

Advanced Driver Assistance Systems –the silent force behind lane-keeping, adaptive cruise control and emergency braking. These systems are precise, sensitive and often disrupted by the most mundane repairs.

A new windshield? That camera needs recalibration. Suspension work? The radar may now be misaligned.

It’s not just about doing the job right –it’s about liability. If a customer drives away with a poorly calibrated ADAS system and something goes wrong, the consequences aren’t just technical, they could indeed be legal.

Calibrating ADAS systems isn’t like fitting a clutch. It requires space, proper lighting, floor flatness, target boards, or laser-guided tools. It’s a process as close to optical engineering as it is to car repair and yet, it’s increasingly part of everyday workshop life.

Most garages don’t work on one brand or even one type of vehicle. A compact hybrid in the morning, a diesel van in the afternoon, maybe a motorcycle or a boat engine before closing.

Juggling three or four different diagnostic tools to cover your bases isn’t just inefficient but it’s expensive, confusing and slow. That’s why multi-brand, multi-environment platforms are becoming essential.

A tool that can handle a wide range of vehicles give workshops a single source of truth. One interface. One update process. One support number to call when something goes wrong.

It also means fewer subscriptions, fewer compatibility headaches and a shorter learning curve for new techs.

“If your workshop can’t handle secure access, you’re not just slower than the competition, you’re out of the game entirely.”

Even with the most powerful diagnostic platform, you’ll hit walls. A strange fault, a vague DTC, a vehicle behaving in ways the manual doesn’t explain. This is where real support separates good tools from great ones.

Workshops need more than a tool –they need a partner. That means live technical assistance, software updates that reflect real workshop needs, not just marketing checklists, and access to training, not just as an upsell, but as part of the experience.