Full offering

- Full range vehicles with the most advanced technologies

- Highly customized product driven by market needs and optimized Total Cost of Ownership

High capillarity of aftersales

- Repair and Maintenance contracts and competitive warranty conditions

- Origin 100% IVECO Parts and a widespread network coverage

European technology

- High quality complete line-up in terms of tonnage, power, torque, safety, ergonomics

- High performance and robust trucks for extreme Off-road conditions

Customer centricity

- Comfort, ergonomics and the latest safety technology to make on board easier

- Driver Style Evaluation tool on Heavy ON-road range and optimized vehicle design to improve customer profitability

SIGNATURE MEDIA FZ LLE

P. O. Box 49784, Dubai, UAE

Tel: 04 3795678

Email: info@signaturemediame.com

Exclusive Sales Agent Signature Media LLC

P.O. Box 49784, Dubai, UAE

Publisher: Jason Verhoven jason@signaturemediame.com

Editor: Abigail Mathias abigail@signaturemediame.com

Art Director: Johnson Machado johnson@signaturemediame.com

Printed and Distributed by Masar Printing and Publishing L.L.C., Part of Dubai Media Incorporated Dubai, UAE

Contributor’s opinions do not necessarily reflect those of the publisher or editor and while every precaution has been taken to ensure that the information contained in this magazine is accurate and timely, no liability is accepted by them for errors or omissions, however caused. Articles and information contained in this publication are the copyright of Signature Media FZ LLE & SIGNATURE MEDIA LLC and cannot be reproduced in any form without written permission.

The logistics industry stands at a defining crossroads—where inno vation is no longer optional, resil ience is a strategic imperative, and leadership is being re‑written in real time. This month’s issue cap tures that transformation with a lens on the companies, technolo gies, and visionaries shaping the next era of global movement.

Automation continues to acceler ate the sector’s evolution, and our coverage of HWArobotics high lights how intelligent systems are empowering efficiency at an un precedented scale.

We also explore the rise of new global networks, with J&T Express building a logistics ecosystem that transcends borders and redefines speed and connectivity. In aviation, Turkish Airlines’ 2033 vision and IATA’s latest air cargo insights reveal how the skies are becoming a battleground for innovation, sustainability, and long‑term strategic planning.

Leadership remains at the heart of progress, and our CEO Special ex amines what truly sets standout leaders apart in an industry defined by complexity and constant change. Complementing this, ECS offers a for ward‑looking perspective on the future of air cargo.

Sustainability also takes centre stage. Polygreen’s partnership with Again Please showcases how environmental responsibility is becom ing embedded in logistics operations, not added on. Meanwhile, Safe Logistics’ new JAFZA facility and the debut of Deliver – Middle East underscore the region’s growing role as a global logistics powerhouse.

On the mobility front, the launch of E Canter and UD Trucks’ Kuzer light duty range signals a new frontier for the UAE’s transport land scape.

As the industry continues to navigate disruption and opportunity in equal measure, this issue aims to equip you with insights that matter— and perspectives that inspire.

Let innovation lead the way.

Abigail Mathias Editor

abigail@signaturemediame.com www.globalsupplychainme.com

1500+

150+

HWArobotics is a global leader in warehouse automation, especially renowned for its automated storage and retrieval systems (ASRS) and shuttle-robot solutions. Founded with a vision to transform traditional warehousing into intelligent, highthroughput operations, the company began its journey in 2003 with the development of its first shuttle robot system — an ambition that would define its future standing in logistics automation.

From the outset, HWArobotics focused sharply on shuttle technology, designed to move goods efficiently within dense racking systems using autonomous robotic vehicles. The company’s early commitment to innovation was underlined in 2007 when it was among the first manufacturers to obtain a patent for a complete tote-handling shuttle system — a key milestone that positioned it as a true innovator in goods-to-person and ASRS solutions.

Over the following decade, HWArobotics expanded its capabilities and its footprint. In 2017 and 2018 it marked significant advances in both product implementation and international market reach, including entry into European and American markets. By this stage, its shuttle systems were being deployed across diverse sectors — from e-commerce and publishing to automotive and retail.

Headquartered in Singapore, HWArobotics has grown into an international enterprise with regional bases in the Dubai - Middle East & Africa, United States, Europe, LATAM and APAC, as well as manufacturing bases in Thailand and China. Its multinational leadership and R&D teams have driven the development of a broad portfolio: from pallet and tote shuttle systems to mini shuttles, split-case picking systems, and advanced control software.

By the mid-2020s, HWArobotics had delivered tens of thousands of shuttle units worldwide, serving major global customers

including Bosch UAES, SONY, Shein, and JD.com. Its solutions have been implemented across continents — from Asia-Pacific to North America — reflecting not only deep technical expertise but also a scalable, modular approach to automation.

In 2025 the company’s impact was recognised with industry accolades such as the “Best Newcomer in Logistics Technology” award at the Transport & Logistics Middle East Achievement Awards, further cementing its reputation as a forward-looking force in intralogistics.

Today, HWArobotics continues to evolve its shuttle and robotic systems, combining two decades of product experience with global reach. Its history illustrates not just technological progression but a sustained commitment to redefining how materials are stored, moved and retrieved in the warehouses of the future.

GSC: How is HWArobotics integrating AI-driven robotics and autonomous systems into warehouse automation?

Umer Saleem: At HWArobotics, AI is not a bolt-on; it is embedded at the core of our robotics and software architecture. We apply machine learning to optimise slotting strategies, predict demand patterns, and dynamically balance workloads across shuttles, lifts, and workstations. Our autonomous systems continuously learn from operational data, allowing the warehouse to self-adjust in real time, improving throughput, energy efficiency, and system resilience without manual intervention.

GSC: What differentiates your shuttle systems from competitors in terms of speed and accuracy?

US: Our shuttle systems are designed around consistent, real-world performance rather than headline speeds. We achieve high throughput through intelligent task sequencing, congestion-free routing, and precise motion control, ensuring stable cycle

times even at peak demand. Accuracy is driven by high-resolution positioning, robust mechanical tolerances, and AI-enabled software that continuously optimises shuttle movements. The result is a system that delivers reliable speed and repeatable accuracy at scale, not just in controlled test conditions.

GSC: How do you see shuttle ASRS (Automated Storage and Retrieval Systems) evolving in the next five years?

US: Over the next five years, shuttle ASRS will evolve from high-density storage solutions into intelligent, modular platforms. We will see greater standardisation, faster deployment times, and deeper integration with upstream and downstream automation. AI-driven orchestration will enable mixed SKU profiles, variable carton sizes, and seamless scalability. The shuttle will no longer be viewed as a subsystem, but as the backbone of the automated warehouse.

GSC: What regions or industries are driving the highest demand for smart warehousing in 2026?

US: In 2026, the strongest demand for smart warehousing is being driven by the Middle East, Asia-Pacific, and parts of Central Europe, alongside continued momentum in North America. Industry-wise, e-commerce, omni-channel retail, pharmaceuticals, food and beverage, and 3PLs are leading adoption. Labour constraints, servicelevel expectations, and the need for rapid fulfilment are accelerating automation decisions across these sectors.

GSC: How is HWArobotics positioning itself against global competitors in the automation and robotics sector?

US: HWArobotics positions itself through engineering depth, cost-performance balance, and flexibility. Unlike some global competitors who offer rigid, one-size-fits-all solutions, we work closely with integrators and end users to tailor systems to operational

By 2030, Robots will handle repetitive, high-speed, and physically demanding tasks, while humans focus on supervision and valueadded activities.

realities. Our strength lies in robust hardware, intelligent software, and a pragmatic approach to ROI, ensuring automation delivers measurable business value rather than complexity.

GSC: Are you exploring partnerships with e-commerce giants or logistics providers to scale adoption?

US: Yes, partnerships are a key pillar of our growth strategy. We actively engage with e-commerce platforms, logistics providers, and system integrators to accelerate adoption across multiple markets. These collaborations allow us to align our technology roadmaps with real operational challenges, while enabling partners to scale quickly using proven, industrial-grade automation solutions.

GSC: How do you envision human-robot collaboration evolving in warehouses by 2030?

US: By 2030, human-robot collaboration will be defined by augmentation rather than replacement. Robots will handle repetitive, high-speed, and physically demanding tasks, while humans focus on supervision, exception handling, and value-added activities. Improved interfaces, safer collaborative designs, and AI-driven decision support will make warehouses more productive, safer, and more attractive places to work.

GSC: What trends in logistics and supply chain resilience do you believe will dominate the next decade?

US: Over the next decade, supply chain resilience, localisation, and digital visibility will dominate logistics strategy. Companies will invest in flexible automation, diversified sourcing, and data-driven decision-making to mitigate disruption. Automation will no longer be viewed purely as a costsaving tool, but as a strategic enabler of continuity, responsiveness, and long-term competitiveness.

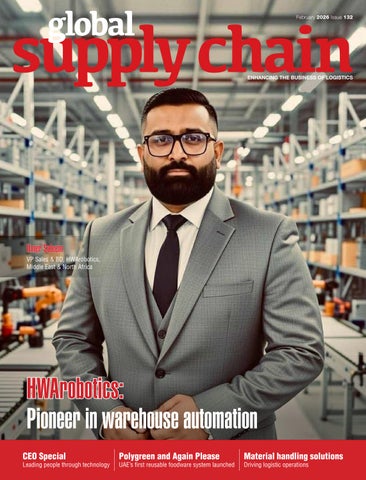

Umer Saleem, VP Sales & BD, Middle East & North Africa

By Umer Saleem, VP Sales & BD, Middle East & North Africa

quiet revolution

Across the world’s most competitive supply chains, something profound is happening. Warehouses are no longer rows of forklifts and operators walking kilometres a day. They are becoming living, breathing digital factories, driven by autonomous shuttle vehicles, intelligent software and goods-toperson robotics.

At the centre of this transformation sits ASRS shuttle technology – a system designed not merely to store goods, but to orchestrate the entire flow of inventory with speed, precision and reliability.

Instead of people travelling to the

product, the product travels to the people. And that one shift changes everything.

This is not theory. It is happening at scale.

In Liuzhou, China, Bosch’s United Automotive Electronics operation runs a multi-level shuttle ASRS across 40,000 square metres with 13,000 storage locations, 14 shuttle vehicles and inter-level lifts, supporting engine management and electric drive systems for the automotive industry. In Jiangsu Province, Phoenix Publishing distributes books and cultural

products through a 90,000 m² omni-channel logistics centre running 168 shuttles and 40 goods-to-person picking stations. In Wuhan, Zhongbai Group supplies thousands of supermarkets through automated replenishment systems that move 5,200 items per hour with one-third less labour.

Different industries.

Same technology backbone. What unites these operations is the use of compact, multi-level shuttle systems that bring unprecedented control, density and responsiveness into warehouse operations.

United (UAES) venture Electronics GmbH engaged and systems, electronics, trol achieved and ees. Customer

Traditional automation moved pallets and cartons in bulk. Shuttle ASRS systems think in terms of flow.

Each shuttle is a self-contained robotic vehicle that runs on rails inside dense racking. It retrieves totes, cartons or pallets and delivers them to lifts, conveyors or directly to goods-to-person stations. Multiply that by dozens or hundreds of shuttles, and the warehouse becomes a parallel-processing engine rather than a linear one.

In the Bosch UAES project, 14 shuttle

United Automotive Electronics Co., Ltd. (UAES) was established in 1995 as a joint venture between Zhonglian Automotive Electronics Co., Ltd. and Robert Bosch GmbH in China. The company is mainly engaged in the development, production sales of gasoline engine management systems, gearbox control systems, car body electronics, hybrid and electric drive consystems. In 2019, the company achieved sales revenue of USD 3.0 billion, the company has about 8,740 employees.

vehicles operate across two aisles with interlevel lifts, feeding production lines with a continuous, low-noise, highly stable flow of automotive components. Since going live in 2019, Bosch reports productivity increases of five to ten times, along with significant floor-space and labour savings

This is not just about speed. It is about resilience. If one shuttle is taken out for maintenance, the others continue working. The system does not collapse – it degrades gracefully, which is what industrial engineers care about most.

At Phoenix Publishing, the same principle is applied at massive scale. The system combines pallet shuttles, tote shuttles, 168 autonomous vehicles, European sorters and spiral conveyors to create a fully integrated omni-channel fulfilment engine capable of serving B2B bookstores and B2C e-commerce from the same building.

This is what modern shuttle ASRS enables: different order profiles, different product types, one unified automation backbone.

Goods-to-Person: where technology meets human productivity

The real magic of shuttle systems happens at the picking face.

In Phoenix’s legacy operation, books were placed on the floor and picked manually from printed lists. Turnaround time was two days, space was wasted, and errors were unavoidable. Today, shuttles and AGVs deliver totes directly to ergonomic picking stations. LED lights tell operators what to pick. Automatic case weighing verifies

whether the right books are in the tote. If the weight is wrong, the system flags it instantly

The result is not just faster picking –it is verifiable accuracy at scale.

Zhongbai Group applies the same philosophy to supermarket replenishment. Its automated replenishment system stores

The United Electronics Liuzhou production line logistics project undertaken by HwaChang Intelligent covers an area of more than 40,000 square meters, including 2 aisles of ASRS, 13,000 storage locations, shuttle vehicles, 2 inter-level lifts. The core equipment of the project is multi-level shuttle vehicle AS/RS warehouse, auxiliary goods receiving system, mixed goods to person decanting and picking system and etc.

25,000 items across 6,300 SKUs and feeds stores in real time, eliminating the stopstart chaos of manual picking Operators no longer walk long distances or wait for stock to be replenished. The system knows what is needed and delivers it.

That shift – from people hunting for stock to stock being delivered to people – is where labour productivity jumps by more than 50% and error rates collapse.

One of the most misunderstood aspects of shuttle ASRS is its economics.

In Phoenix’s Xingang Logistics Centre, the use of compact shuttle storage doubled the storage capacity while halving the required floor area compared with a traditional highbay warehouse. That is not an engineering curiosity – it is a real-estate revolution.

In Zhongbai’s case, eight automated replenishment systems each handle up to 380 boxes per hour, supporting both totes and cartons, while reducing overall labour costs by one-third and increasing per-capita productivity by 52%.

Bosch saw similar effects, with massive productivity gains and long-term operational stability.

What makes shuttle ASRS so commercially powerful is its modularity. You do not build it once and freeze it in time. You add aisles, add shuttles, add lifts and add picking stations as volumes grow. Capital investment follows revenue growth, not the other way round.

For CFOs, that matters.

What these three projects demonstrate is not incremental improvement – it is a new operating model for logistics.

Shuttle ASRS turns warehouses into automated factories for inventory. Goods flow continuously. Data flows in real time. Operators are supported by machines rather than exhausted by them. Space is used efficiently. Errors are detected instantly.

Phoenix now saves over USD 1.4 million per year in logistics costs while supporting B2B and B2C channels from one intelligent platform. Zhongbai is future-proofed for its 2030 convenience store expansion. Bosch runs a benchmark goods-to-person system for the global automotive industry.

Different markets.

Same conclusion.

ASRS shuttle technology is no longer the future of warehousing – it is the present. Those who invest in it gain speed, accuracy, resilience and cost control. Those who do not will simply struggle to keep up. And in today’s logistics world, keeping up is no longer enough.

Phoenix Publishing & Media Inc. is mainly engaged in books, periodicals, trade services, warehousing and transportation, and import and export trade. As the largest cultural enterprise listed on the Main Board of Shanghai Stock Exchange, it is among the top ten in the global publishing industry, with an annual turnover exceeding USD 2.8 billion.

J&T Global Express, a global leading integrated logistics service operator, and S.F. Holding Co., Ltd. jointly recently announced that they have entered into a strategic cross-shareholding agreement involving the mutual issuance of new shares, with an investment and transaction amount of HKD8.3 billion.

Mr. Charles Junyi Hou (“Mr. Hou”), Vice President of J&T Express, addressing the operations and commitment to the UAE and the Middle East region, says, “As we continue to expand our global smart logistics network across 13 countries, J&T Express remains dedicated to our mission of ‘connecting the world with greater efficiency.’ The Middle East represents a strategic anchor in this global footprint, where we are applying the scalable, efficiency-based operating model that has cemented our market leadership in China and Southeast Asia. By leveraging our strategic partnership with SF Holding to harmonise their global line-haul strength with our deeply rooted local lastmile network—effectively bringing cargo to the country and delivering it to the door—we are empowering the region’s e-commerce growth with the full weight of our global resources.”

Pursuant to the agreement, J&T Express will issue 822 million Class B Shares to SF Holding at an Issue Price of HKD10.10 per share; simultaneously, SF Holding will issue 226 million H Shares to J&T Express at a Subscription Price of HKD36.74 per share. Upon completion, SF Holding will hold 10% of the issued shares of J&T Express as enlarged by the issuance, and J&T Express will hold approximately 4.29% of the issued shares of SF Holding as enlarged by the issuance.

This collaboration is designed to deeply integrate the resources of both industry leaders. The goal is to jointly construct a

more extensive, efficient, and resilient global integrated logistics network, better positioning both companies to serve Chinese companies expanding overseas and adapt to the evolving landscape of the global e-commerce logistics market.

J&T Express is a global logistics service provider with leading express delivery businesses in Southeast Asia and China, the largest and fastest-growing market in the world. Founded in 2015, J&T Express’ network spans 13 countries, including the UAE, Indonesia, Vietnam, Malaysia, the Philippines, Thailand, Cambodia, Singapore, China, Saudi Arabia, Mexico, Brazil and Egypt.

The cross-shareholding structure aims to unlock highly complementary strategic synergies. J&T brings its extensive last-mile network and localized operational experience across 13 countries, pairing effectively with SF Holding’core resources and mature operating systems in cross-border first-mile and line-haul. Together, the parties will enhance the network coverage and competitiveness of their end-to-end cross-border logistics solutions. In the China market, large complementarities in network resources, customer bases, product structures, and differentiated positioning will create broad opportunities to expand service boundaries.

In a joint statement, Mr. Jet Lee, founder of J&T Express, and Mr. Wang Wei, founder of SF Holding, noted that the two companies are long-standing strategic partners and that this cross-shareholding marks a major milestone, elevating their relationship from operational collaboration to a closer, mutually beneficial strategic partnership. They will work together to build a more efficient global smart logistics network, seize the historic opportunities created by Chinese enterprises going global and the rise of cross-border e-commerce, and deliver greater value to customers across global supply chains.

Turkish Airlines has launched a comprehensive investment initiative that will strengthen Türkiye’s aviation infrastructure and further advance its competitive edge. As part of this strategic move, shaped in line with the national flag carrier’s 2033 vision, groundbreaking ceremonies were held for eight new facilities with a total investment value exceeding TRY 100 billion at several locations, primarily Istanbul Airport, homebase of the flag carrier.

The ceremony held at Istanbul Airport was attended by the Minister of Transport and Infrastructure of the Republic of Türkiye Abdulkadir Uraloğlu, Turkish Airlines Chairman of the Board and the Executive Committee Prof. Ahmet Bolat, senior executives of Turkish Airlines and its subsidiaries, and leading figures in Turkish aviation.

Stating that Türkiye will surpass a new threshold in aviation with these investments, Minister of Transport and Infrastructure of the Republic of Türkiye

Abdulkadir Uraloğlu stated: “With a breakthrough that will leave its mark on the skies, opening a new page at the pinnacle of aviation, and further strengthening the wings of our national flag carrier, we will make a determined and ambitious start to 2026. These eight projects’ foundations we are laying today are strong steps taken towards Turkish Airlines’ magnificent rise and its goal of becoming the world’s number one airline. With the second phase of the air cargo terminal SmartIST underway, the facility’s usage area will increase. The cargo handling capacity, currently at 2.2 million tons, will rise to 4.5 million tons, propelling Turkish Cargo to global leadership. These projects will further strengthen not only Turkish Airlines’ wings but also those of Türkiye’s economy. Within the scope of these major investments totaling TRY 100 billion, 26,000 new job opportunities will be generated in 2026, and our aviation ecosystem will continue to grow.”

Commenting on the new investments, Turkish Airlines Chairman of the Board and the Executive Committee Prof. Ahmet Bolat said: “In line with our 2033 targets, we are developing not only our fleet but also the robust infrastructure that will allow us to fully utilize this fleet. This investment initiative, exceeding TRY 100 billion and spanning from our cargo operations to our technical maintenance capacity, from our catering centres to integrated operational solutions, strengthens our global competitiveness and is a concrete evidence of our vision to make Türkiye one of the world’s foremost aviation hubs. These investments, which will provide 26,000 new jobs in 2026, will increase to 36,000 when all phases are completed. With these steps, we are building not only facilities but also an ecosystem for the future of our country’s economy and aviation sector. Today, our company’s contribution to our country’s economy is USD 65 billion, and when we reach our 2033 goals, this figure will reach USD 144 billion.”

As part of its new investments, Turkish Airlines is implementing the following projects to maintain global leadership in Cargo, Technical Maintenance, and Catering: • Turkish Cargo SmartIST Phase 2 project, which will be one of the world’s

largest air cargo centres with an annual capacity of 4.5 million tons and is planned to be completed gradually during the 2027-2028 period.

• Turkish Airlines Main Catering Facility, positioned as one of the world’s largest inflight catering centres with the capacity to serve more than 500,000 passengers per day and expected to become operational during the 20272028 period.

• Turkish Technic Engine Maintenance Centre, set to be completed in 2027, as one of Europe’s largest new-generation aircraft engine maintenance centres possessing the capability of servicing Trent XWB-84, Trent XWB-97 and Trent 7000 Rolls Royce engines.

• Moreover, Additional Aircraft Maintenance Hangars to be built under Turkish Technic and planned for completion within 2026 will create a simultaneous maintenance capacity for 12 aircraft, increasing the company’s current maintenance capability by an average of 20%.

• E-Commerce Complex, a key element in the logistics and digital transformation vision and planned to enter service within 2026, further strengthens Turkish Airlines’ role in global trade through Widect, its new-generation operational model offering “door-to-door integrated cargo

solutions.”

• Istanbul Data Centre, which will form the digital backbone of operational continuity and is planned to become operational during the 2027-2028 period, will elevate the company’s technology capacity to a new level with its highsecurity infrastructure and advanced data management capabilities, while Flight Training Centre (Phase 1), scheduled for the 2026-2027 period, is positioned at the centre of human resource investments, supporting Turkish Airlines’ long-term growth strategy.

• Turkish Airlines Additional Crew Terminal Building, planned in line with the expanding operational volume and scheduled for completion within 2026, is included among the investments as a complementary infrastructure element that provides seamless logistics flow between ground services, maintenance, and flight operations. These investments form the foundation of an integrated growth model that advances operational capacity, technical infrastructure, and digital capabilities in line with Turkish Airlines’ 2033 objectives to become one of the world’s five largest fleets as the carrier celebrates its centennial. They also serve as the backbone of a strategic aviation ecosystem supporting global operations.

• Sheikh Mohammed Bin Hamad: Committed to cementing our regional leadership

Gulf Warehousing Company Q.P.S.C (GWC), one of the leading logistics providers in the region, has announced its financial results for the year ended 31 December 2025. The company reported total annual revenues of QR 1.38 billion, operating profits of QR 232 million, and a net profit of QR 120 million, while earnings per share stood at QR 0.205 for the year ended on 31 December 2025. The company’s Board of Directors recommended a 10% cash dividend, at QR 0.10 per share.

Sheikh Mohammad Bin Hamad Bin Jassim Bin Jaber Al Thani, GWC chairman, said: “Our focus is on strengthening GWC’s leadership by integrating our portfolio of logistics assets and capabilities into a unified offering that serves regional and global markets, while maintaining a disciplined approach to risk and capital allocation and pursuing measured expansion into new operational sectors that enhances our competitive capabilities.”

He added: “We will continue to strengthen our leading position in the logistics sector. By aligning growth with the objectives of the Third National Development Strategy and Qatar National Vision 2030, GWC continues to support national economic diversification while optimizing value creation and expanding market share in a disciplined manner.”

Sheikh Abdulla Bin Fahad Bin Jassim bin Jaber Al-Thani, GWC Managing Director, said: “The Company is implementing a strategy focused on diversifying its investment portfolio, creating added value

• Sheikh Abdulla Bin Fahad: Advancing portfolio diversification through integration and expansion

for shareholders, facilitating trade across regional and international markets, and delivering innovative logistics solutions that support sustainable profitability. Through this approach, we serve the needs of large enterprise customers while empowering small and mediumsized enterprises to scale efficiently.”

A leadership culture that is highly adaptive to market changes and supported by a solid foundation of integrated assets. Sustainability and responsible business conduct are embedded within our business model, alongside continued investment in technology and innovation to support long-term value creation.”

He further added: “We are scaling our e-commerce offering through end-to-end logistics solutions that span the full value chain, from warehousing and inventory management to fulfilment and last-mile delivery. Supported by intelligent systems and an extensive logistics network, this capability allows us to serve online retailers at scale across the GCC, Europe, and the United States with speed and reliability.”

In October 2025, GWC acquired a strategic, non-controlling stake in European technology and logistics scale-up Quivo. The investment expands GWC’s footprint across three continents and more than 15 cities, enabling homegrown Qatari and GCC brands to gain fast access into major European and US marketplaces and major e-commerce platforms through integrated logistics capabilities

• Matthew Kearns: Scaling an integrated and efficient logistics platform

that seamlessly connect regional infrastructure with global markets.

Matthew Kearns, GWC’s Acting Group CEO, said: “Our priority is to scale the business by transforming our assets into an integrated logistics platform that connects physical infrastructure with digital capability, allowing us to manage growth more effectively and optimize operations as we scale.”

He added: “Through interoperability across systems and services, we are improving scalability and consistency across the Group, allowing our integrated platform to support expansion into specialized, high value sectors, with fine art logistics serving as a clear example through our partnership with QC+.”

“This development represents a significant milestone for GWC and reflects Qatar’s growing role as a regional center for cultural and creative activity, supported by specialized infrastructure that meets the highstandards,” he stated.

GWC has announced, in partnership with QC+, the development of the largest fine art logistics facility in the region, scheduled to be established in the Ras Bufontas Free Zone. The facility will provide museum grade preservation, secure storage, and professional care for artworks and cultural assets, supported by a conservation laboratory, private and shared storage spaces, viewing rooms, and custom bonded areas for art logistics and handling. It will also include learning and collaboration zones designed to advance local expertise in art preservation and management.

• Total demand, measured in cargo tonne-kilometers (CTK), rose by 5.5% compared to November 2024 levels (+6.9% for international operations).

• Capacity, measured in available cargo tonne-kilometers (ACTK), increased by 4.7% compared to November 2024 (+6.5% for international operations).

The International Air Transport Association (IATA) released data for November 2025 global air cargo markets.

“Air cargo demand grew 5.5% year-on-year in November 2025, boosted by shippers prioritizing timely delivery in the lead-up to the year-end holiday season. Strong emerging market demand and selective Middle Eastern growth more than made-up for softness in the Americas amid ongoing adjustment to the new US tariff regime. Globally, the fourth quarter for air cargo was resilient as strategic re-routing of trade shaped performance across key markets. The strong end for 2025 bodes well for the air cargo industry as it enters the new year,” said Willie Walsh, IATA’s Director General.

Several factors in the operating environment should be noted:

The global goods trade grew by 3.2% year-on-year in October.

Jet fuel prices rose 5.9% in November despite falling crude prices, driven by refinery disruptions, EU restrictions on Russian-derived products, and limited spare refining capacity, pushing crack spreads close to double last year’s levels.

Global manufacturing sentiment strengthened in November, with the PMI rising for the fourth consecutive month to reach 51.17. New export orders improved slightly to 49.87, but remained below the 50-point expansion threshold, reflecting ongoing caution amid tariff uncertainty.

Asia-Pacific airlines saw a 10.3% year-on-year growth in air cargo demand in November. Capacity increased by 8.4% year-on-year.

North American carriers saw a 1.6% yearon-year decrease in growth for air cargo in November. Capacity decreased by 2.3% year-on-year.

European carriers saw a 5.8% year-on-year

increase in demand for air cargo in November. Capacity increased 4.1% year-on-year.

Middle Eastern carriers saw a 7.4% year-on-year increase in demand for air cargo in November. Capacity increased by 11.0% year-on-year.

Latin American and Caribbean carriers saw a 4.8% year-on-year decrease in demand for air cargo in November, the weakest performance of all regions. Capacity decreased by 3.0% year-on-year.

African airlines saw a 15.6% year-on-year increase in demand for air cargo in November, the strongest rise of all regions. Capacity increased by 18.1% year-on-year.

YOUR

FOR AIR CARGO HANDLING AUTOMATION

Leadership isn’t broken, it’s doing what the system rewards

For too long, leadership debates have focused on what leaders lack: courage, vision, decision-making flair, or decisiveness. But that framing is incomplete. In truth, leaders rarely fail because they lack ability. Most fail because they are rationally responding to the incentives embedded in today’s organisations, incentives that reward short-term safety over long-term progress. This is a profound shift: the problem is not people. It is systems.

Decades of leadership research reinforce that leadership isn’t just about personality traits or leadership styles, it’s about context, incentives, and organisational architecture. Strategic leadership research shows that sustainable competitive advantage comes from how leaders make and act on decisions that align human capital with long-term goals.

Research in leadership decision science highlights that many leaders excel early in their careers only to become bottlenecks later, as instinctive approaches fail to scale

with systems-level complexity. Experimental studies on leadership and incentives consistently find that leadership behaviour interacts directly with incentive structures to influence innovation and performance.

In other words, leadership behaviour cannot be separated from what the organisation rewards.

The incentive frame no one discusses Leadership incentives are rarely explicit. They are implicit, shaped by what gets rewarded and what gets punished quietly.

Scholars of organisational culture have long observed that leaders transmit and embed culture not through what they say, but through what they measure, tolerate, and reward.

If an organisation’s incentive system punishes visible failure more harshly than silent stagnation, leaders will naturally gravitate toward safe decisions, not because they fear risk, but because their survival depends on it.

In capital-intensive, operationally complex sectors such as global supply chain, logistics, and industrial technology, the cost of visible failure is amplified, which makes incentive-driven caution not just common, but rational.

This is not a character judgment. It is a functional description of rational behaviour inside a system where failure is punished more visibly than stagnation is recognised.

One of the most trusted phrases in executive hiring is “proven experience.” On the surface, it signals prudence. In practice, it often codifies sameness, the selection of leaders who have succeeded in familiar contexts, solving familiar problems.

But leadership effectiveness is not proportional to how many times someone has done something before. In complex environments, novel problems require novel thinking, not old templates.

Research on executive staffing and decision-making, including Donald Hambrick’s work on upper-echelons theory, shows that leadership choices are heavily shaped by prior experiences and cognitive biases, often reinforcing the status quo.

In this sense, “proven experience” becomes a form of incentive camouflage. It appears rational and defensible but quietly institutionalizes repetition over relevance.

A related but under-discussed behaviour is decision delay. In many organisations, hesitation is reframed as careful consideration. Yet research consistently shows that indecision carries real costs: momentum stalls, high performers disengage, and ambiguity becomes culture.

Leaders who could act decisively often withhold decisions not because they lack wisdom, but because the system’s implicit incentives deem delay less risky than decisive missteps.

High performers rarely leave because of bad leadership. They leave because nothing moves.

The most effective leaders I have observed across technology, industrial, and operationally complex organisations share one counterintuitive trait:

They are willing to disappoint early.

Not because they enjoy conflict, but because they understand that ambiguity compounds into dysfunction faster than clarity does.

By Marium Dahar, Founder & CEO, Bricks Executive Search

Early disappointment signals clarity before convenience and clarity accelerates alignment.

This aligns with research on participative and empowering leadership, which shows that environments valuing shared accountability consistently outperform those governed by hierarchical avoidance and delayed decision-making.

Here is the unsettling reframe:

Leadership is not the expression of intent. It is the design of consequences.

Great leaders do not simply articulate vision. They shape the incentive architecture of their organisations. What gets rewarded, what gets ignored, and what behaviours become normal.

If leaders reward caution, they get caution. If leaders unintentionally reward stagnation, stagnation becomes culture. If leaders align incentives with progress, even when it causes short-term discomfort, they get movement.

Leadership today is not failing. It is doing exactly what the system rewards.

I. Angelov, I. (2024). Key Leadership Functions for Achieving Long-Term Competitive Advantage in Business. Sciendo. https://www.sciendo.com

II. Harvard Business Review. Strategic Decision-Making and Leadership in Complex Organizations. https://hbr.org

III. Ilyana, S., et al. The Effect of Incentives and Leadership Styles on Creative Performance. Journal of Indonesian Economy and Business. https://journal. ugm.ac.id/jieb

IV. World Bank Independent Evaluation Group. Incentives, Leadership, and Organizational Culture. https://ieg. worldbankgroup.org

V. Harvard Program on Negotiation (PON). Participative Leadership and Organizational Performance. https:// www.pon.harvard.edu

VI. Hambrick, D. C. Upper Echelons Theory: An Update. Academy of Management Review. https://journals. aom.org

Ibelieve the role of a CEO has fundamentally changed. In an era defined by rapid technological acceleration and Artificial Intelligence, leadership can no longer be reduced to managing numbers, processes, or efficiency. Those things matter—but they are no longer enough. Today, a CEO’s real responsibility is to act as a moral and strategic anchor, ensuring that innovation moves society forward, not just markets.

As AI automates more cognitive and operational tasks, what remains distinctly human becomes increasingly valuable. Judgment. Curiosity. Empathy. Purpose. For me, passion for creating long-lasting, useful impact is not a “soft” leadership trait—it is a core business requirement. Technology itself is neutral. It amplifies intent. And it is the responsibility of leadership to decide whether that amplification serves shortterm optimization or long-term progress.

My priority as a CEO is simple: to be useful. When a leader is genuinely driven by usefulness rather than ego or optics, the direction of the company becomes clearer. Decisions are not made solely to win the next quarter, but to build something that matters over time. In that sense, passion becomes a safeguard—it ensures that as technology scales, responsibility scales with it. Innovation, to me, must always be synonymous with improvement in the human condition.

I don’t believe in visions that exist only in slide decks. A meaningful vision must extend beyond trends, beyond hype cycles, beyond the next funding milestone. Especially in the age of AI, a CEO must articulate a future where technology acts as a bridge—between people, industries, and

opportunities—not as a barrier.

This means committing to ethical innovation: systems that are transparent, fair, and designed to augment human potential rather than replace it. A vision rooted in long-term utility gives an organization strategic stamina. Markets shift. Technologies evolve. But the need for meaningful solutions—to real, systemic problems—remains constant.

This is also what attracts the right ecosystem. Investors, partners, and customers today are increasingly valuesdriven. They don’t just ask what you’re building, but why. A vision grounded in usefulness creates resilience, trust, and alignment across every layer of the organization.

Team development: Building a human-first culture

If vision is the compass, people are the engine.

One of the most complex challenges of the AI era is the fear it creates—fear of replacement, irrelevance, or loss of meaning. A mission-driven CEO has a responsibility to address this directly, not by resisting technology, but by reframing its role.

I believe in using AI to remove friction, not purpose. When machines handle the repetitive and mundane, humans are given something incredibly valuable: time. Time to think, to create, to empathize, and to solve higher-order problems. Team development, for me, is about shifting from a culture of “labour” to one of “leverage.”

When people feel connected to a mission that matters, work stops being transactional. It becomes collective. It becomes a legacy. That shared sense of purpose is the strongest tool for engagement, creativity,

By Jessica Panigari, CEO, Founder & Strategic Leader, Goods2Load

and long-term retention in a global, competitive market.

In a world where machine intelligence is becoming ubiquitous, the most valuable differentiator is human intention— expressed through ethics, passion, and responsibility. My goal is to build not just a company, but a welcoming ecosystem for curious, driven, and values-aligned humans who want to contribute to something bigger than themselves. I see the CEO as a

Leadership today is not about predicting the future—it’s about shaping it with care.

By aligning technological progress with social advancement, I aim to ensure that what we build doesn’t just exist in the future, but actively helps make that future better. To me, that is what real leadership looks like in the 21st century—and it is exactly what I aim to achieve through Goods2Load and my position.

By Robin V., Founder of RV Consultancy

For years, CEOs have been told that digital transformation is the key to staying competitive. Yet the reality inside boardrooms is far more complex. Technology is advancing at a pace that outstrips most organisations’ ability to absorb it, and leaders are expected to make high-stakes decisions in an environment where the rules are constantly being rewritten.

As someone who works closely with executives across industries, I see a consistent truth: adopting new technology is not the hardest part. Leading people through the change is.

Why technology adoption still feels daunting

Despite the clear benefits of digital tools, automation, and AI, many CEOs hesitate. A recent McKinsey study found that 70% of digital transformation initiatives fail to meet their objectives, often due to resistance within the organisation rather than the technology itself. That statistic alone captures the real challenge: transformation is fundamentally a human journey. Three barriers appear repeatedly:

1. Organisational disruption

Introducing new systems can feel like rewiring an aircraft mid-flight. CEOs worry—rightly—that one wrong move could slow operations or unsettle customers.

2. Capability gaps

Technology is only as strong as the people who use it. Many leaders fear their

teams aren’t ready, or that the learning curve will be too steep.

3. Uncertain returns

Boards want clarity. CFOs want numbers.

Yet the ROI of emerging technologies often unfolds over years, not quarters.

As one CEO told me recently, “It’s not the technology that keeps me up at night—it’s whether my people will come with me.”

Leadership skills the modern CEO must master

The role of the CEO has evolved. Today’s leaders must be both digitally fluent and deeply human. The most successful CEOs I work with share five core capabilities:

1. Curiosity over certainty

You don’t need to be a technologist, but you must be willing to explore. Leaders who ask better questions make better decisions.

2. Agility as a strategic asset

The pace of change demands leaders who can pivot without losing direction. Agility is no longer optional; it is a competitive advantage.

3. Empathy as a performance driver

Employees don’t resist technology—they resist uncertainty. CEOs who communicate openly, acknowledge concerns, and involve teams early create cultures that embrace change rather than fear it.

4. Long-term vision

Technology is not a quick fix. It is a long-term investment in capability, resilience, and relevance. Leaders must look beyond immediate metrics and focus on sustainable value.

5. Courage to Experiment

Innovation requires a tolerance for failure. CEOs who create safe spaces for experimentation unlock creativity and accelerate progress.

Where leadership and technology converge

The CEOs who thrive in this era understands that digital transformation is not an IT project—it is a cultural shift. They:

• Lead by example

• Invest in continuous learning

• Break down silos between technology and operations

• Celebrate incremental wins

• Build organisations that learn faster than the competition

When leadership and technology align, companies don’t just adapt—they advance.

A CEO’s responsibility in a transforming

The CEO of today must be a bridge: connecting people to possibility, strategy to innovation, and technology to purpose. The future will reward leaders who embrace technology with confidence while leading with humanity.

In my work at RV Consultancy, I see this every day. The organisations that succeed are not the ones with the most advanced tools—they are the ones with leaders who inspire their people to grow alongside the technology.

The message is clear: technology will continue to evolve. The question is whether leadership will evolve with it.

New data centres in Dubai and Abu Dhabi to host 100+ cloud-based solutions of both Zoho and ManageEngine, the company’s two key brands

Zoho Corporation, a global technology company, recently announced the launch of its data centres in UAE in Dubai and Abu Dhabi. The data centres form a part of AED 100 million investment in the UAE that the company had announced in 2023. The data centre will host solutions from Zoho Corporation’s two key brands: ManageEngine (enterprise IT management) and Zoho (cloud business solutions). We caught up with its CEO and Co Founder Shailesh Davey.

“The opening of our data centres is part of our ongoing investment in the UAE, which remains one of the largest markets in the region for both ManageEngine and Zoho brands,” said Shailesh Davey, Co-founder and CEO, Zoho Corporation. “With this move, Zoho Corporation will be enabling businesses store their data locally, strengthening data sovereignty, and supporting National Cybersecurity Agenda. Furthermore, 100+ solutions across Zoho and ManageEngine, will enable businesses of all sizes, and government and semigovernment organisations adopt cloud technology for digital transformation in nearly every area of operation, and help Dubai become a digital economy line with Dubai Vision 2030.”

The data centres have also received certification from CSP Security Standard Certificate by DESC (Dubai Electronic Security Center). This qualifies Zoho Corporation to serve government and semi-government entities in addition to local businesses. As part of this, the data centres are also compliant with: ISO 27001, ISO 22301, ISO 27017 and CSA STAR Level 2 Certificate for data centres. In addition, the company’s Dubai office has received ISO 27001 certificate.

Zoho has grown by 38.7% in 2025 in UAE, and expanded its partner network by 29% in the same period. It has further increased its employee count by 35% last year to serve the needs of its increasing customer

“(From L-R) Rajesh Ganesan, CEO, ManageEngine, Shailesh Kumar Davey, Co-founder and CEO, Zoho Corporation & Hyther Nizam, President, Zoho – Middle East and Africa

base, and expanded into a larger office. The key solutions driving Zoho’s growth are: Customer Experience platform (Zoho CRM, Desk and Zoho CRM Plus), Zoho Books (VATcompliant and FTA-approved accounting software), Creator (low-code app development platform), Zoho Workplace (communication and collaboration platform), and Zoho One (all-in-one suite of 55+ products).

In the past five years, Zoho has invested AED 80 million on enabling over 7,000 businesses in their digital transformation journey through various partnerships such as those with DET and Dubai Culture. In the past few years, Zoho has seen a steady upmarket growth in the country, 48% in 2025, led by its strong platform capabilities that allow enterprises achieve faster time to value and lowers their total cost of ownership.

ManageEngine has grown by 20% in 2025 in the UAE, led by its continued focus on the enterprise sector. The brand has

strengthened its local presence, including through the partner network, to support the increasing adoption of its solutions across both private and government organizations. The key solutions driving the growth are: Endpoint Central (unified endpoint management), ServiceDesk Plus (unified service management) and Site24x7 (cloud-based observability platform).

In the recent years, growth in the UAE for ManageEngine has been particularly strong in BFSI, government and public sector, and manufacturing, fuelled by cloud adoption, which is growing at nearly 35% in the region for the brand’s cloud solutions. This trend reflects a broader shift toward cloudfirst strategies, as organizations prioritise scalability, agility, and faster innovation.

Zoho Corporation is a privately-held, profitable technology company, founded in 1996. Zoho Corporation has more than 18,000 employees globally. It is the parent company of prominent technology brands including ManageEngine, Zoho, TrainerCentral, and Qntrl.

The air cargo sector is entering a new phase of strategic maturity, where competitive advantage is defined not by scale alone but by the ability to integrate data, technology, and commercial execution into a unified performance framework.

At the forefront of this shift is Adrien Thominat, Chairman of AERION, who is reshaping how airlines, GSAs, and digital ecosystems collaborate to deliver measurable, outcome‑driven results.

Discussing this with our Editor, Abigail Mathias, Thominat outlines the industry’s transition from transactional representation to orchestrated value creation, the leadership principles required to align global and regional priorities, and the organisational capabilities needed to navigate an increasingly complex operating environment.

Abigail Mathias: What strategic priorities are shaping the air cargo industry today?

Adrien Thominat: The industry is undergoing a fundamental shift from transactional GSA models toward integrated performance orchestration. The real competitive advantage no longer comes from information access, data is now widely available, but from the ability to interpret and act on it with commercial discipline. Three dynamics are driving this: airlines increasingly demand outcome based partnerships with clear KPIs linked to their bottom line; the convergence of commercial logic and technology means digital tools must be guided by strategic intent; and profitability is now steered continuously through shared metrics and transparent data flows. AERION reflects these priorities by orchestrating commercial

strategy, technology deployment, and operational execution as one system.

AM: What leadership principles guide your decision-making when balancing global strategy with regional markets such as the Middle East?

AT: My principle is: centralise strategic intent and performance metrics, decentralise execution and adaptation. The Middle East operates within the same profitability framework as every other region, but local teams have full autonomy to shape commercial approaches and partnerships that fit market reality.

What matters is coherence across commercial, operational, and technology layers. When all teams work toward the same KPIs and share the same data, regional markets move fast because there are no misalignments to resolve. Leadership in this context is orchestration, not command.

AM: As someone overseeing several departments with specific goals, how do you ensure alignment across teams while empowering local leaders to innovate and adapt?

AT: Alignment doesn’t come from hierarchy. It comes from transparency and a shared performance language. Each

entity operates independently within a unified commercial framework, with full authority over execution.

Local innovation is encouraged because it improves overall performance. What drives alignment is accountability. When every team sees the same data on profitability and customer contribution, and their success is measured against shared metrics, alignment happens naturally.

AM: How has your leadership approach evolved in response to global disruptions — economic, geopolitical, or technological — over the past few years?

AT: Our leadership approach has evolved with each major disruption, and AERION itself is the result of that evolution. It started with the creation of ECS Group, built to give airlines a powerful, agile commercial and operational network at a time when the market needed reach and execution more than anything else. Then came the integration of Global GSA Group, which reinforced this footprint and gave us a unique vantage point on how different markets, products and cycles really behave.

Over time, successive shocks, economic, geopolitical, technological, showed the limits of a purely transactional GSA model. When supply chains break or demand patterns flip overnight, simply “selling capacity” is not enough. That is why the Group deliberately moved beyond representation: by creating CargoTech, we brought together best in class digital capabilities to steer planning, optimisation and distribution, and by building specialised Abilities such as TCE, Healthc’Air, Mail&More and Squair, we industrialised deep expertise in TCM, pharma, parcels, safety, security and back office excellence.

AERION is the hybrid answer born from this journey. It operates as a purpose built GSA, combining the reach and field know how of a classic GSA with the analytical discipline of a data native organisation and the focus of a strategic advisory firm. Instead of reacting market by market, AERION centralises strategic intelligence, commercial data, operational performance, market signals and uses it to coordinate the entire ecosystem around clear, shared profit trajectories.

In this sense, leadership has shifted from managing separate entities to orchestrating a bionic like model, where human expertise and digital capabilities reinforce each other. Healthc’Air and Mail&More, for example, are not side businesses; they are precision instruments for managing pharma and e commerce flows under pressure, plugged into the same data and performance framework as ECS or CargoTech. The role today is less about “fixing problems” after the fact, and more about designing an organisation that anticipates, absorbs and leverages disruption as a source of competitive advantage.

“When all teams work toward the same KPIs and share the same data, regional markets move fast because there are no misalignments to resolve. Leadership in this context is orchestration, not command.”

AM: What qualities do you believe CEOs must cultivate to remain effective in an increasingly interconnected and unpredictable business environment?

AT: Four qualities matter: the ability to connect strategy, technology, and execution into one coherent framework; comfort in leading expert ecosystems rather than controlling everything directly; strong prioritisation discipline in environments exposed to regulatory and geopolitical uncertainty; and relentless execution discipline backed by data and expert insight. A CEO must insist that every decision be grounded in data, every outcome be measurable, and every team be accountable.

AM: How do you foster a unified company culture across your entities while respecting regional differences and market dynamics?

AT: AERION’s culture is built on shared objectives and transparent accountability, not uniformity. Every entity operates with autonomy in execution but aligns around

the same profitability metrics and data transparency standards.

Teams compete on execution excellence and innovation, not on protecting turf. When a Mail&More innovation improves parcel economics in one region, it spreads. Regional differences are not obstacles; they are learning opportunities. We anchor culture in performance metrics and data transparency and let local teams adapt execution to their market reality.

AM: What role does the Middle East play in your global strategy, and how do you adapt your leadership style to the business environment in this region?

AT: The Middle East is not a special case. It is a validation and stress test of AERION’s integrated model. The region concentrates hub dependency, geopolitical exposure, rapid e commerce growth, and pharma flows with strict compliance demands. The need for coordination between commercial, digital, and operational teams is acute.

My leadership approach prioritises speed, reliability, and trust backed by data transparency. Hub dependency means you cannot afford miscalibration. Geopolitical exposure demands real time market intelligence and rapid coordination. The Middle East doesn’t redefine our strategy. It validates it.

AM: Looking ahead, what leadership capabilities will define the next generation of successful CEOs?

AT: Four capabilities will matter: the ability to orchestrate multiple expert entities toward a single performance objective; turning technology platforms into decision accelerators, not support tools; leading specialised capabilities (pharma, parcels, compliance, across volatile regions without losing profitability sight; and shifting from control based leadership to performance enablement.

The best leaders don’t control outcomes. They create conditions, transparent data, clear KPIs, expert teams, decentralised authority, that enable teams to drive outcomes. These capabilities require deliberate practice and intellectual rigor, but they define the leadership model AERION is built on.

Under the leadership of Eng. Mahmoud Sabra since 2020, DRVBOT has evolved from a startup into an SME, delivering complex engineering and material handling projects across the MENA region, with a strong focus on large-scale and government-led initiatives, particularly in Saudi Arabia.

Across the MENA region, logistics companies are operating under growing pressure to deliver faster, safer, and more cost-efficient services while managing increasing volumes, heavier payloads, and diverse cargo types. Traditional, standardised material handling systems are often unable to cope with these realities. As a result, custom-engineered material handling solutions are becoming a strategic necessity rather than a technical upgrade.

Modern logistics facilities face a wide range of operational challenges, including non-uniform pallet sizes, oversized or irregular loads, mixed inbound container profiles, labour shortages, and space constraints. These challenges are particularly common in ports, airports, industrial zones, and government-operated facilities, where operations rarely follow standard patterns. In such environments, off-the-shelf automation systems often fall short, forcing operators to rely on manual processes that increase cost and risk.

Custom material handling solutions address these issues by being engineered around

the specific requirements of each operation. Systems such as heavy-duty transfer carts, intelligent mobile robots, automated pallet movers, and container loading and unloading solutions can be designed to match exact payloads, travel paths, environmental conditions, and safety requirements. For logistics companies, this means smoother material flow, fewer bottlenecks, and more predictable operations.

One of the most significant benefits for logistics operators is improved operational efficiency. Tailored automation reduces cycle times and enables higher throughput without expanding physical infrastructure. For example, custom solutions for handling loose or non-standard containers can drastically reduce unloading times while maintaining consistent performance throughout long operating hours. This allows logistics providers to process more volume per day and improve turnaround times for customers.

Safety is another critical factor driving the adoption of engineered handling systems. Logistics operations often involve repetitive tasks, heavy loads, and shared spaces

By Eng. Mahmoud Sabra

between people and equipment. Customdesigned material handling systems reduce human exposure to high-risk activities by automating lifting, transport, and positioning tasks. This not only lowers accident rates but also supports compliance with increasingly strict safety regulations and insurance requirements across the region.

Scalability and adaptability are equally important. Logistics companies must respond quickly to seasonal demand fluctuations, new customer requirements, and changes in supply chain models.

Custom material handling solutions are often designed with modular architectures, allowing systems to be expanded, reconfigured, or integrated with additional equipment over time. This protects capital investment and provides long-term flexibility that standardised systems often lack.

In the MENA region, logistics operations frequently intersect with aviation, oil and gas, heavy industry, and government projects, where requirements are highly specialised. Facilities in these sectors may require equipment capable of handling extreme loads, operating in harsh environments, or integrating seamlessly with existing infrastructure. Engineeringled solution providers play a vital role in translating these operational needs into practical, reliable automation systems.

Our SynQ software delivers data-driven intelligence that empowers your business by synchronizing the performance of your people, processes and machines. The result is a level of efficiency and performance you never thought possible.

swisslog.com

How many times do you look at a plastic cup and wish it were recycled?

Polygreen, a leading provider of global circular economy solutions, launched “Again, Please”, a reusable foodware system aimed at replacing singleuse plastics, during the World Future Energy Summit (WFES) at ADNEC Centre Abu Dhabi, as the UAE accelerates its transition towards a circular economy.

As part of the launch, Again, Please hot and cold reusable cups were used across participating exhibitors at ADNEC Centre Abu Dhabi throughout WFES, demonstrating the practical application of reusable foodware at one of the region’s largest sustainability events.

Global Supply Chain offers insights from the people driving this initiative.

Up close and personal with Theodossios Kassapantoniou, General Manager, Again Please

Global Supply Chain: Consumer participation is essential for circular systems to work. What behavioural insights have shaped your business model, and how do you encourage long term engagement from users and clients?

Theodossios Kassapantoniou: Driving a high rate of return is subject to a robust reuse system design, from the reusable cup packaging to the collection, logistics and participation of the consumer, and not to the consumer behaviour alone. The design of the system should ensure that consumers are motivated in adopting a return habit.

GSC: How do you communicate the value proposition of circularity to businesses that may still view sustainability as a cost rather than a strategic advantage?

TK: We focus on operational and commercial outcomes rather than abstract sustainability benefits. Circular systems can offer predictable costs compared to fluctuating single-use procurement, improved operational efficiency, and reduced exposure to regulatory risk.

By providing measurable data on waste reduction and carbon savings, we help businesses understand circularity as a strategic investment that supports resilience, brand credibility, and long-term value creation.

GSC: If you could change one misconception that governments, businesses, or consumers have about waste and resource recovery, what would it be and why?

TK: The most persistent misconception is that recycling alone is sufficient to address the waste challenge. While recycling remains important, it is energy-intensive and still relies on continuous material production. True circularity starts with reducing consumption and prioritising reuse wherever possible. Shifting this mindset is essential for achieving meaningful environmental impact.

GSC: Describe the relevance of being at the World Future Energy Summit (WFES)? What has been the outcome of participating in this event?

TK: WFES provides a unique platform where policymakers, industry leaders, and sustainability innovators converge, making it highly relevant for demonstrating practical circular solutions.

Participating at this summit allows us to move beyond conceptual discussions and showcase a working system in a live, high-volume environment. The outcome has been increased visibility, meaningful stakeholder engagement, and the initiation of conversations around future partnerships and scale-up opportunities beyond the event itself.

GSC: Partnerships are often critical in sustainability ecosystems. What types of collaborations—public, private, or community based—have proven most effective for accelerating your impact?

TK: Public-private partnerships have been particularly effective, as they combine policy direction with operational capability. Collaborations with venue operators and large event organisers are also critical, as they enable scale and normalisation of reuse. Ecosystem-based partnerships, where multiple stakeholders work toward shared outcomes, have proven far more impactful than isolated pilots or one-off initiatives.

Caption with picture: Again, Please is a reverse logistics (closed loop) reusable foodware packaging solution designed for events, exhibitions, entertainment venues, and F&B operators. The system goes beyond cups, offering tailored reusable packaging formats supported by end-toend infrastructure, including collection points, logistics, industrial washing, and redeployment, ensuring hygiene, convenience, and operational efficiency.

Athanasios Polychronopoulos, Chairman and Group Chief Executive Officer at Polygreen, offers his perspective.

GSC: Circular economy solutions are gaining momentum globally. Where do you see the biggest gaps in current waste management systems, and how are Polygreen and Again Please positioning themselves to fill those gaps?

Athanasios Polychronopoulos: One of the biggest gaps in current waste management systems is the continued reliance on end-of-life solutions such as

recycling, rather than addressing waste generation at the source. There is also a lack of infrastructure to support reuse and reverse logistics at scale.

Polygreen and Again, Please focus on system-level solutions that prioritise reduction and reuse, supported by operational infrastructure and data-driven accountability, rather than isolated or symbolic interventions.

GSC: Many companies talk about sustainability, but few achieve measurable impact. What specific metrics or KPIs do you use to evaluate the success of your circular economy initiatives?

AP: We focus on measurable indicators such as reductions in single-use material consumption, return and reuse rates, carbon emissions avoided, and operational efficiency. We also assess system reliability, partner adoption, and longterm engagement to ensure solutions are delivering sustained impact rather than short-term gains.

GSC: What technological innovations— either developed in house or adopted externally—have been most transformative for your operations and customer engagement?

AP: Digital tracking of reusable assets and data analytics have been particularly transformative. These technologies allow us to monitor return cycles, optimise logistics, and provide transparent reporting to

partners. Integrating operational data with sustainability reporting has strengthened customer engagement and decisionmaking.

GSC: How do you balance the need for rapid innovation with the operational realities of scaling waste management and recycling infrastructure across different markets?

AP: We prioritise piloting solutions in real-world conditions before scaling them further. Innovation is approached pragmatically, ensuring systems are operationally robust and commercially viable. Infrastructure readiness is a prerequisite for expansion, rather than an afterthought.

GSC: Polygreen and Again Please operate in markets with very different regulatory environments. How do you navigate these variations, and what makes a market attractive for expansion?

AP: Navigating regulatory differences requires close collaboration with local stakeholders and alignment with national sustainability frameworks. Markets with clear policy direction, infrastructure readiness, and strong public-private collaboration are particularly attractive for expansion, as they enable faster deployment and long-term impact.

With recent global events, we’re seeing a lot of emerging concepts in supply chain management, designed to counteract a variety of issues. A unique concept one might have heard of is “friendshoring.”

It is something we have been developing recently, as a reaction to the fact that we can no longer overly depend on any particular supplier.

Friendshoring is when countries, or companies, choose to source goods and services from trusted (politically stable) allies rather than from the cheapest or most convenient suppliers, to reduce risk and improve resilience.

Geopolitical factors have been a big contributor to this shift in our supply chain management. For example, when the security and shipping disruptions in the Red Sea saw attacks on commercial vessels, we suffered a lot of disruption with our raw material supply coming in from Europe.

Many vessels which normally arrive here in the UAE in 30 to 40 days took over 60and sometimes even 90 - days to arrive at Jebel Ali Port. This, of course, played havoc

with our production planning, so we had to rapidly diversify our supplier base, despite it being more costly.

With rising tensions and policies on export being unclear, sometimes there is a lot of disparity between our production levels and the availability of raw material at a competitive price.

We have seen raw material (timber) costs increase, on average, because of the need to depend on friendshoring. A good example of this was when we had accepted a big order from a key customer, but an issue developed with delivery of the raw material.

Since our reputation was at stake, we decided to take a hit on margins, and procured a lot of the raw material from a merchant in a nearby country.

This move made us realise the need to break away from over-dependence on a particular supplier, or geographical region.

Many companies now see the need to incorporate friendshoring in their supply chain planning and execution.

This became especially visible after the pandemic, when countries began reshaping their trade relationships, a shift that was widely discussed and promoted at global forums such as the World Economic Forum.

A lot of the shift to friendshoring was from cheap supply to reliable supply. The pandemic, trade wars, geopolitical conflicts and climate change disruptions have all been a factor in creating this new trend.

Supply chain resilience is a key argument for the strategy shift. For example, overdependence on Taiwanese semiconductors saw a lot of delays in mobile phone markets in creating newer models. The automobile industry was also heavily impacted by a shortage of semiconductors for chips, resulting in many companies bringing in

the manufacturing to their borders. This also protected a lot of proprietary information.

In terms of resilience, friendshoring also reduces exposure to things like sudden export bans. We saw this with the US putting bans on Nvidia exporting some of its high-performance chips to China. The Chinese then started doing a lot of their own development in the high-tech semiconductor space.

And when sanctions were imposed on Russia, we saw a lot of disruption in importing Russian plywood. That was a big slice of our business that we had to give up. We had to scramble to discover other Asian sources for our plywood requirements and, in many cases, found it difficult to enter into agreements with new suppliers, as they had

order books full with everyone racing to find a replacement for their Russian suppliers.

In terms of advantages from a business point of view, we see low geopolitical risk, in addition to the benefits of higher supply continuity. In the long term, this translates to higher customer trust in our ability to deliver.

Most companies now look at low risk instead of just low cost for their supply chains as the frequency of geopolitical pressures are higher now than ever before.

In an era where disruptions are no longer exceptions but constants, friendshoring is redefining supply chains, transforming trust, alignment and resilience into strategic assets.

By Alex George, Managing Director, Al Ostad Pallet Factory

In today’s competitive business landscape, supply chains are not just about moving goods from point A to point B, they are the lifelines of innovation. Increasingly, companies are realising that the structure of their supply networks can shape not only their operational efficiency but also their ability to develop new products and services. This is especially true in knowledgeintensive industries such as electronics, semiconductors, and automotive, where firms increasingly rely on their knowledge assets and that of specialised suppliers in their supply network to produce innovative products.

In my opinion, two factors in particular stand out as facilitators of innovation within supply chains: the presence of shared suppliers and the centrality of those suppliers in the broader network.

Shared suppliers: double-edged sword of knowledge and risk

Working with suppliers that also serve your competitors can be both a blessing and a curse. On the one hand, shared suppliers give you access to broader industry knowledge and technical expertise. Think of them as hubs where ideas, best practices, and capabilities are aggregated across multiple firms. By tapping into this shared pool of expertise, your company gains insights that might otherwise be out of reach.

For example, in the technology sector, suppliers who serve multiple device manufacturers often become specialists in refining components that can serve several use cases. By sourcing from such suppliers, a company benefits from cutting-edge improvements without having to fund all the R&D itself. In industries like FMCG, where delivery times and customer experience are paramount, working with suppliers that cater to several competitors allows you to leverage efficiencies that come with scale.

But there is a flip side. Shared suppliers also mean that whatever you invest, whether