Full offering

- Full range vehicles with the most advanced technologies

- Highly customized product driven by market needs and optimized Total Cost of Ownership

High capillarity of aftersales

- Repair and Maintenance contracts and competitive warranty conditions

- Origin 100% IVECO Parts and a widespread network coverage

European technology

- High quality complete line-up in terms of tonnage, power, torque, safety, ergonomics

- High performance and robust trucks for extreme Off-road conditions

Customer centricity

- Comfort, ergonomics and the latest safety technology to make on board easier

- Driver Style Evaluation tool on Heavy ON-road range and optimized vehicle design to improve customer profitability

SIGNATURE MEDIA FZ LLE

P. O. Box 49784, Dubai, UAE

Tel: 04 3795678

Email: info@signaturemediame.com

Exclusive Sales Agent Signature Media LLC

P.O. Box 49784, Dubai, UAE

Publisher: Jason Verhoven jason@signaturemediame.com

Editor: Abigail Mathias abigail@signaturemediame.com

Art Director: Johnson Machado johnson@signaturemediame.com

Printed and Distributed by Masar Printing and Publishing L.L.C., Part of Dubai Media Incorporated Dubai, UAE

Contributor’s opinions do not necessarily reflect those of the publisher or editor and while every precaution has been taken to ensure that the information contained in this magazine is accurate and timely, no liability is accepted by them for errors or omissions, however caused. Articles and information contained in this publication are the copyright of Signature Media FZ LLE & SIGNATURE MEDIA LLC and cannot be reproduced in any form without written permission.

For most of the superheroes of this industry, there seems to be no stopping. We present some of the outstanding partnerships in the region. Starting with BinDawood and Slimstock, who are transforming supply chain in the Kingdom of Saudi Arabia.

TCE and AERION’s senior leaders discuss how to deliver a sustainable performance, while maintaining future-readiness. We bring you the latest detailed report, ‘Logistics 2025,’ from Brand Finance. Read all about warehouse automation from Swisslog ME. Strategic supplier collaboration is discussed in a guest column. Meet Anchanto, a Singaporebased SaaS company that’s keen on learning and facilitating what its GCC client’s need.

All roads lead to the upcoming Air Cargo Forum, in Abu Dhabi, we bring you the details in this issue.

This month also has a special marine focus which we hope you will enjoy. Our special features on heavy trucks, forklifts and EV batteries besides a healthy dose of important news and events, make this an extremely power packed issue.

We’d love to hear from you. Reach out and tell us why you believe you belong in the next edition. Your story is merely waiting to be told.

Happy reading.

Abigail Mathias Editor

abigail@signaturemediame.com www.globalsupplychainme.com

1500+

150+

The retail industry in Saudi Arabia is standing at a turning point. The two Saudi cities Jeddah and Riyadh present distinct realities to visitors who explore them on foot. Traditional markets that have operated for generations alongside gleaming shopping centers and fast-growing e-commerce platforms. The Kingdom through Vision 2030 requires businesses to evolve into contemporary leaders who will deliver elevated performance results.

At the centre of this shift is the supply chain. Once in the background, it now defines the customer experience as much as store design or digital apps. Customers have zero tolerance for empty shelves or late deliveries. They expect reliable service, fast fulfillment, and a wide range of choices.

In this feature, Waleed Bindawood, CCO of BinDawood Holding, and Rachid Labrik, CEO of Slimstock MEA, share their views on Saudi retail transformation, the challenges ahead, and how supply chains will shape the future of the region.

Rachid Labrik: Salam Alaycom Waleed, before we get into our work together, let me ask a broader question. When you look at Saudi retail today, what strikes you most?

Waleed Bindawood: The speed. Everything is moving faster. Customers are younger, they live online, they compare everything instantly. They want convenience with no compromise. On top of that, Vision 2030 creates pressure for businesses to modernise. It is not about survival, it is about proving we can lead.

Rachid: I feel the same. Ten years ago, supply chain was considered a technical support function. Now it is in the boardroom discussions. If it fails, everything fails.

Waleed: That is the point. Customers do not care if the delay comes from a supplier or a forecasting mistake. They just see an empty shelf. They just see that their order did not arrive on time. For them, complexity does not matter. For us, it matters every day. We run hypermarkets, supermarkets, and e-commerce platforms. It must look simple from the outside, even though it is complex on the inside.

Rachid: The omnichannel experience must feel seamless to customers, no matter how complex the supply chain is behind it. And when it comes to delivering on that promise, few names carry as much weight in the Kingdom as BinDawood. How do you see your role evolving?

Waleed: Being established gives us trust, but it also raises expectations. Families rely on us. That means consistency and reliability. We cannot rely on tradition alone. We need a supply chain that can anticipate, respond, and adapt quickly.

Rachid: And that was clear to us from the beginning. Slimstock did not come in to sell a piece of software. We came in to build a long-term partnership.

Waleed: What impressed me most was the way you approached it. You did not start by describing the features of your platform (Slim4). You came to listen to our pain points and challenges. You have quickly understood where the company is going and our vision. You built a solid roadmap to take our supply chain and business to the next level.

“Ten years ago, supply chain was considered a technical support function. Now, if it fails, everything fails.” – Rachid Labrik

Rachid: People gain clarity from technology, but the actual transformation occurs when they understand they are gaining control instead of losing it. That is why change management is central to our approach. You cannot force it from the outside. Real change must grow within the organisation if you want it to last.

Waleed: Yes. The duties of people are transformed because of social development. Our planners no longer see themselves as order processors. They view themselves as decision managers. That is a real transformation.

Rachid: Let’s talk about the future. What excites you most about where supply chains are heading?

Waleed: For me, it all comes down to anticipation. AI is no longer just theory, we have proven use cases today. From building predictive models for seasonal peaks to adapting to regulatory changes, AI gives us the foresight to prepare rather than react. One of the most powerful capabilities is predicting shifts in shopping and buying patterns. Instead of waiting for disruptions, we can proactively align inventory, pricing, and supply strategies. That is what excites me most, turning uncertainty into clarity.

“Customers want convenience with no compromise.” – Waleed Bindawood

Rachid: I couldn’t agree more. AI transformation in supply chain is no longer a ‘nice-to-have’, it’s a must. Foresight is everything. The ability for BinDawood to simulate and test multiple future scenarios, whether it’s demand surges, new compliance rules, or market shocks is a game-changer for readiness and resilience. And when we look at the Vision 2030 ambition, it’s clear: Saudi has the opportunity not just to catch up with global leaders, but to set the standard. With AI-powered supply chains, we can truly lead the way. Our platform will definitely contribute to this.

Waleed: Exactly. The Kingdom’s goal is to become the regional benchmark. That will happen when Saudi supply chains are digital, resilient, and built to deliver customer satisfaction. That is the target we are working toward.Rachid: And that is why this partnership matters. The work reaches further than addressing present-day problems. The goal is to create a model which will serve as a foundation for future development.

Rachid: I recall the first conversations we had. We were very happy to hear and understand what is already working as an established business for many years. We always link the capabilities of our software with the value-add and the impact on your topline. What was the most challenging aspect of the project from your perspective?

Waleed: Mindset was the toughest barrier. Retail teams are used to reacting in the moment. A promotion starts, a supplier is late, demand spikes, and they rush to fix it. Shifting that habit toward planning was difficult. At first there was resistance. But once people saw the system helping them anticipate issues and stay in control, doubts turned into trust.

That is why change management was critical. Adoption did not come from technology alone, it came from involving planners and managers from the start. When they felt ownership of the process, they embraced the software and made the change last.

“Our planners no longer see themselves as order processors. They view themselves as decision managers.” – Waleed Bindawood

Throughout the conversation, both entrepreneurs discussed the role of people. The process of transformation reaches further than digital platforms and operational systems for them. It is about people and culture.

Waleed: At the end of the day, technology only works if people trust it. That is why we brought our planners and managers in from the very start. They needed to feel ownership, and once they did, adoption followed naturally.

The leaders finished their discussion by evaluating the effects of this experience on their organisations together with the Saudi retail industry.

Waleed: We are not just modernising. Our company has established new customer service standards for the modern business environment. The situation presents both a duty and a chance for action.

Rachid: The future is being written here. The system needs to operate through intelligence and trust and ambition.

The interview showed that Saudi Arabia’s retail supply chain is carving its own path, rather than following global trends. The sector is transforming, and the partnership is focused on delivering sustainable results by building trust and creating lasting impact across the region.

This conversation goes beyond partnership. It is about the mindset shaping modern Saudi retail, moving from reaction to anticipation, from silos to integration, from support function to boardroom strategy. It captures a sector in transition, a partnership built on trust, and a vision set to influence the region for years ahead.

TCE (Total Cargo Expertise) uses AIbased systems to detect anomalies during cargo operations, helping prevent issues before they escalate. These tools also support trend analysis, allowing teams to anticipate disruptions and optimise planning.

At its core, AERION offers airlines a highlevel task force, ready to activate commercial, digital, regulatory, or organisational levers without the need for internal expansion. In an exclusive interview Sarah Scheibe, Managing Director TCE and Adrien Thominet – Chairman AERION discuss how to deliver a sustainable performance, while maintaining future-readiness.

Global Supply Chain: What emerging technologies are you currently exploring and piloting?

Adrien Thominet – Chairman AERION: Beyond the day to day operational improvements, the most relevant emerging technologies for the cargo sector are those that connect operational, commercial, and regulatory data streams in real time. The real competitive advantage lies not in the individual tool, but in integrating predictive analytics, real time monitoring, and automation across the full value chain to enhance safety, efficiency, and commercial outcomes simultaneously.

Sarah Scheibe, Managing Director TCE: We’re currently looking into digital tools that help us monitor cargo movements in real time and streamline reporting. Things like automated checklists and AI-based systems who are detecting anomalies during cargo operations are very promising for improving both efficiency and safety.

GSC: How do you stay ahead of industry trends in aerospace/manufacturing/ engineering?

lot of

comes

to staying connected with carriers, industry partners, and regulatory bodies. We also keep a close eye on developments through conferences, workshops, and feedback from our teams on the ground.

GSC: What role does sustainability play in your innovation strategy?

Sarah Scheibe: Sustainability is becoming more and more important. We’re working on reducing paper usage through digital processes across our network and helping our suppliers and partners to implement more eco friendly procedures. Even small changes in ground operations can make a big difference.

How do you evaluate the ROI of new innovations before scaling them?

Adrien Thominet: Evaluating ROI goes far beyond immediate productivity gains. We look at resilience, compliance, and the ability to scale across different customer environments. The key is to test innovations in multiple operational contexts, gather measurable performance data, and only scale when a solution proves it can deliver consistent value across the network.

Sarah Scheibe: We usually run pilot programs and measure things like time savings, error reduction, and overall impact on service quality. If it improves safety, efficiency, or customer satisfaction, it’s worth scaling.

GSC: What processes have you automated recently, and what benefits have you seen?

Sarah Scheibe: We’ve automated parts of our documentation and incident reporting. It’s made things faster and more accurate, and it gives our teams more time to focus on supervision and quality control.

GSC: Are you using AI or machine learning in any part of your operations?

Sarah Scheibe: Yes, we’re using AI to analyze some data, especially for spotting trends or potential issues before they become problems. It’s a great tool for improving safety and planning.

GSC: How do you balance automation with workforce development and job retention?

Adrien Thominet: Automation should be a catalyst for upskilling, not a threat to jobs. The right approach is to involve operational teams in the process design phase, ensure they understand and shape the technology, and reinvest time savings into higher value tasks. This way, technology works in service of people, not in their place.

Sarah Scheibe: We see automation as a way to support our teams, not replace them. We motivate the team to work alongside new tech. It’s about growing together.

GSC: What challenges have you faced in implementing automation technologies?

Sarah Scheibe: One of the biggest challenges is integrating new tools with existing systems, especially when working with different carriers and partners. Change management is also key and to get everyone on board takes time and clear communication.

GSC: Are your automation systems integrated with real-time data analytics?

Sarah Scheibe: Yes, we’ve made sure our systems feed into real-time dashboards. That way, we can make quick decisions and keep a close eye on safety, quality, and performance metrics.

GSC: What kind of storage systems do you use for raw materials and finished goods?

Sarah Scheibe: Since we focus on cargo operations, we work with the storage systems provided by our ground handling partners. Our role is to ensure those systems meet safety and quality standards.

GSC: How do you ensure traceability and inventory accuracy?

Sarah Scheibe: We use barcode scanning, digital logs, and integrated reporting tools as well as AI supported cameras in the warehouse facilities of our partners. Everything is tracked from arrival to departure, which helps us maintain accuracy and accountability.

Sarah Scheibe, Managing Director TCE

GSC: How often do you update your safety protocols, and what drives those updates?

Sarah Scheibe: We review safety protocols regularly, usually every quarter or after any incident. Updates are driven by regulatory changes, carrier requirements, and feedback from our teams.

GSC: What kind of training do employees receive on safety and emergency response?

Sarah Scheibe: Safety training is a big part of our onboarding, and we run regular refreshers and emergency drills. We also tailor training to specific roles, especially for those working in high risk areas.

New data from Brand Finance, (the world’s leading brand valuation consultancy) shows global logistics brand value are at USD168 billion in 2025 as digital transformation and e-commerce continue to reshape the sector.

• UPS holds the top position as the most valuable logistics brand for the 11th consecutive year

• 81% growth: Hyundai Glovis is the fastest-growing logistics brand in 2025

• JINGDONG Logistics crowned as the strongest logistics brand ranked

• Brand to watch: DP World emerges as the Middle East’s most valuable logistics brand

• JINGDONG Logistics leads in sustainability perceptions among logistics brands

Every year, leading brand valuation consultancy Brand Finance puts 6,000 of the world’s biggest brands to the test, and publishes over 100 reports, ranking brands across all sectors and countries. The world’s most valuable and strongest logistics brands are included in the Brand Finance Logistics 2025 report.

US brands continue to dominate the global logistics landscape, accounting for half of the top 10 ranked in the Logistics 25 2025 report from Brand Finance, the world’s leading brand valuation consultancy.

The total value of the world’s top 25 logistics brands ranked stand at USD168 billion in 2025, marking a 4% year-on-year decline riding on several factors, including lower revenues among major courier brands as competition intensifies from local and domestic players. Additionally, freight revenues across all modes of transport have declined, reflecting the cooling of commodity prices from their 2022 highs, which were largely fuelled by geopolitical tensions such as the Russia-Ukraine conflict.

Of the top 25 brands in the rankings, 68% or 17 brands recorded growth in their respective brand value, reflecting strong demand driven by e-commerce, digital innovation, and supply chain resilience.

UPS (brand value down 6% to USD32.6 billion) remains the most valuable logistics brand ranked for the 11th consecutive year. Despite a slight decline in value, UPS

maintains its market leadership through a robust presence in the US and expanding capabilities in healthcare logistics.

FedEx (brand value down 20% to USD22.9 billion) holds its second-place position for the third year in a row. The company’s strategic spin-off of its freight division highlights a renewed focus on core parcel operations amid heightened global competition.

Japanese logistics brand JR (brand value up 11% to USD13.3 billion) climbs to third, overtaking Germany’s DHL (brand value down 8% to USD11.2 billion). JR’s growth

is fuelled by Japan’s tourism recovery and consumer confidence, along with tech innovations such as its blockchain-based JRE Wallet. The brand also ranks as the thirdstrongest logistics brand globally, bolstered by high familiarity and trust among Japanese consumers.

JINGDONG Logistics (brand value up 15% to USD4.1 billion) emerges as the strongest logistics brand ranked in 2025 with a Brand Strength Index (BSI) score of 90.5/100 and an AAA+ brand strength rating. Its ascent is driven by global expansions, premium positioning, and industry leadership in ESG and sustainable delivery practices.

Savio D’Souza, Managing Director, Middle East & Africa at Brand Finance, commented: “The GCC’s logistics sector is undergoing a remarkable evolution, driven by sustained investments in infrastructure and digital transformation. Logistics brands in the region are rapidly scaling their global presence, positioning the GCC as a critical hub for trade, supply chain integration, and economic diversification. DP World’s impressive rise, with its brand value up 39% to USD3.4 billion, exemplifies this transformation and underscores the region’s growing global influence in logistics.”

SF Express (brand value up 8% to USD6.4 billion) follows closely, ranking second in brand strength (BSI score 90.4/100).

Recognised as China’s equivalent to FedEx, SF Express continues to gain global momentum through partnerships such as its recent collaboration with GLS to enhance international express services.

Hyundai Glovis (brand value up 81% to USD3 billion) is the fastest-growing logistics brand of 2025. Its sharp rise is driven by investments in green logistics and advanced shipping, including LNG and hydrogen-powered vessels, reinforcing its leadership in sustainable transport solutions.

Alex Haigh, Managing Director Asia Pacific, Brand Finance, commented: “Logistics brands are rapidly evolving to meet new demands across global supply chains. While US brands continue to dominate in scale and recognition, challengers from Asia and the Middle East such as JINGDONG Logistics, SF Express, Hyundai Glovis, and DP World are rising fast through innovation, sustainability, and digital leadership. These shifts mark a new chapter of transformation in the logistics sector.”

DP World (brand value up 39% to USD3.4 billion) makes its debut in the rankings as the Middle East’s top logistics brand. This rapid rise reflects a bold transformation shift from a traditional ports and terminals operator to a global leader in fully integrated, bespoke supply chain solutions.

Brand Finance also assesses the brands consumers consider most committed to sustainability. JINGDONG Logistics ranks as the top brand in the logistics ranking for its perceptions across all three pillars - environmental, social and governance sustainability.

The top five Brand Guardians among logistics brands are Sultan Ahmed bin Sulayem (DP World), Aili Liu (SF Express), Tobias Meyer (Deutsche Post DHL Group), Raj Subramaniam (FedEx), and Mohamed Juma Al Shamisi (Abu Dhabi Ports).

Atlas Air, Inc., a subsidiary of Atlas Air Worldwide, the leading global provider of outsourced aviation logistics, recently announced a new long-term partnership with Etihad Cargo, the cargo and logistics arm of Etihad Airways, the national airline of the United Arab Emirates.

Under the agreement, Atlas Air will provide Etihad Cargo with dedicated freighter capacity through the operation of a newly delivered Boeing 777 freighter. Beginning in August, the aircraft will initially serve routes connecting Hong Kong, Abu Dhabi and Madrid.

The partnership comes at a time of growing demand for general air cargo, e-commerce, automotive, pharmaceuticals and perishable products across Asia, the Middle East and Europe.

The 777F offers state-of-the-art, efficient capacity to support Etihad Cargo’s growth and customer product offering. The agreement reflects the strength of the

longstanding relationship between Atlas Air and Etihad Cargo, dating back to 2012 when Atlas Air first began providing flight services over a multi-year period.

“We are pleased to again partner with Etihad Cargo, one of the industry’s most respected carriers,” said Michael Steen, Chief Executive Officer, Atlas Air Worldwide.

“This partnership reflects our strong value proposition and the trust we’ve built with customers over time. We are pleased to tailor this long-term dedicated capacity solution to help Etihad capture growth opportunities. With our global scale and flexible, agile network, Atlas Air is enabling Etihad to expand their operations and serve their customers with confidence. With our industry-leading fleet of widebody freighters and deep operating expertise, Atlas Air is proud to be a trusted partner of choice, and we look forward to supporting Etihad’s continued success.”

“Etihad Cargo’s expanded collaboration with Atlas Air represents a strategic step

in scaling capacity and extending our global reach,” said Stanislas Brun, Chief Cargo Officer, Etihad Airways. “With Etihad Airways’ passenger fleet continuing to grow, it is essential that our freighter fleet expands in parallel to sustain this momentum and deliver end-to-end network connectivity. By aligning growth across both passenger and freighter operations, Etihad Cargo reinforces its ability to meet evolving customer demand, strengthen high-volume trade lanes and introduce greater flexibility across key markets. This additional capacity further enhances the reliability and agility of our services, ensuring the delivery of seamless and efficient cargo solutions worldwide.”

The 777 freighter is the world’s largest, longest-range twin-engine freighter, with a payload of more than 100 tons. With its fuel efficiency and reliability, this aircraft supports Etihad Cargo’s commitment to delivering sustainable, high-quality cargo solutions across its global network.

Speed

Future-proof

Scale

Gulf Warehousing Company Q.P.S.C (GWC)

– Qatar’s leading logistics services provider – has been named the National Winner for Qatar in the wastewater treatment sector for its sewage water treatment plant in the GWC Bu Sulba Warehousing Park.

The award was announced as part of the 15th edition of the annual MEED Projects Awards, held in collaboration with Mashreq Bank. This recognition qualifies the company for the regional stage, where the MENA winners will be announced on 19 November 2025.

His Excellency Sheikh Abdulla Bin Fahad Bin Jassim Bin Jaber Al Thani, GWC Group Managing Director, said: “We are honoured to receive the MEED Projects Award at the national level, standing alongside a distinguished lineup of leading infrastructure projects across the Middle East and North Africa. This prestigious recognition underscores the quality of our project and the dedicated efforts invested in developing sustainable infrastructure that supports Qatar’s development journey in line with the Third National Development Strategy and Qatar National Vision 2030.”

He added: “This award not only celebrates our contribution to national development but also highlights the strategic importance of the Sewage Treatment Plant in the GWC Bu Sulba Warehousing Park. It marks a milestone in our ongoing commitment to upholding the highest sustainability standards, safeguarding the environment, and advancing sustainable development and support to the Small & Medium Entreprises (SMEs).”

The Sewage Treatment Plant at GWC Bu Sulba Warehousing Park adheres to world-class standards for water treatment and sustainability best practices, effectively generating TSE Water (Treated Sewage Effluent) to irrigate plants and trees. Using TSE water for irrigation can improve soil fertility, reduce the need for chemical fertilizers, and conserve water resources, which promotes sustainable agricultural practices and aligns with Qatar’s sustainable development goals.

• SHEIKH ABDULLA BIN FAHAD: Committed to upholding the highest sustainability standards

• MATTHEW KEARNS: Driving the development of sustainable infrastructure and growth-orientedprojects

The plant treats 456 cubic meters of water daily, ensuring a reliable and sustainable supply for irrigation systems. The recycled water is used to irrigate a total of 20,000 square meters of landscaped areas, including trees, shrubs, and grass.

The GWC Bu Sulba Warehousing Park spans 520,000 square meters in total, comprising 200,000 square meters of warehouses and distribution centres, 21,000 square meters of residential facilities, and 21,000 square meters allocated to container yards and open storage spaces.

Matthew Kearns, GWC’s Acting Group CEO, stated: “This is the second award in just a few months for the Sewage Treatment Plant at the GWC Bu Sulba Warehousing Park, following its recognition in November 2024 as the ‘Best Water Recycling Initiative’ at the Tarsheed Energy Efficiency Forum, organized by Qatar General Electricity &

Water Corporation (Kahramaa) as part of its National Program for Conservation and Energy Efficiency (Tarsheed). This achievement clearly highlights the project’s significance and serves as a strong motivation for GWC to continue advancing sustainable infrastructure, driving growth-oriented projects, and leading the development of the logistics services sector.”

The annual MEED Projects Awards, in association with Mashreq, represent the pinnacle of recognition for the most outstanding projects across the Middle East and North Africa. This year, 87 projects across 17 categories were shortlisted following a thorough and impartial judging process that focused on engineering brilliance, technological innovation, sustainable practices, and the significant benefits these projects bring to society.

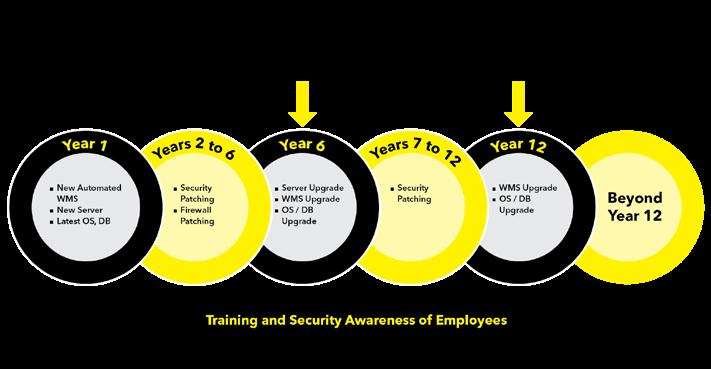

In today’s digital economy, warehouses are no longer just physical storage space, they are high-stakes ecosystems driven by software, where virtual activities can either bring operations to a halt or redefine the business margins. As Middle Eastern companies modernise their supply chains, in line with the national transformation agendas such as Saudi Arabia’s Vision 2030 and the UAE’s Operation 300 Billion, one fact that is unavoidable is that cyber-resilience isn’t an option but a key to achieving these goals.

Airyn Ong, Head of Software for APAC and MEA, SSI SCHAEFER said, “Today, cyber-resilience is more critical than ever to drive the success of warehouse software systems. Our Chief Information Security Officer constantly reminds us that cyberattack isn’t a question of if, but of when”. Warehouse systems are no longer one-off install-and-forget solutions, but rather it is an ongoing exercise to ensure the whole eco-system is secure. Some of these activities include life-cycle planning, patching, network segmentation, but most importantly, having the right supplier who can secure solutions throughout the life of the system and enable the business to mitigate the risk of cyberattack.

Across the Middle East, automation, artificial intelligence (AI), and digital control systems are gaming the system, redesigning business processes, and transforming the way businesses operate. Yet, beneath the electronic highway, a glowing threat resides – Legacy systems still dominate many companies’ software backbone. According to CyberDB, globally, 70 to 80% of the IT budgets are consumed by maintaining outdated systems.

In the Middle East, sectors such as oil and gas and finance allocate 60% to 70% of their

IT budgets to maintaining legacy systems, which is consuming a significant portion of the budget. This pattern of keeping inherited systems running is echoed in the logistics realm – all to avoid a higher capex or unexpected disruption.

For years, many companies could get by with “if it isn’t broken, don’t fix it.” But today, cyber resilience is no longer a back-office concern. Data protection laws like GDPR, new mandates like EU NIS2 and the Cyber Resilience Act, and increasing ransomware attacks are reshaping the playing field. Legacy systems — once reliable — are now liabilities.

Transitioning from legacy to modern systems is no small feat. For large enterprises, the shift from store ordering systems to ERP, to Warehouse Management Systems (WMS), and then to automation controllers like WES/ WCS can take years.

Take SSI SCHAEFER’s project in one of the countries in APAC MEA. When launching automation, the client simultaneously upgraded its software stack:

Year 1–2: Laying it Core ERP backbone

Year 3: Implemented SSI SCHAEFER WES Year 4–5: Surrounding the system with upgrades and process alignment

“We often recommend a phased approach because it allows the business to keep running while preparing the foundation for automation and resilience,” said Airyn Ong.

“There’s no one-size-fits-all. A big overhaul offers speed but carries high risk—cost, downtime, staff disruption. A phased transformation, though slower, allows for Sandbox testing and rollback options, Integration with existing infrastructure, and then Gradual adoption and employee training.”

The most successful transitions, Airyn Ong notes, are guided by a clear patching plan, modular design, testing protocols and most importantly, robust change management plan. A system’s upgrade or migration is not just about the technology, but also about the people. With insufficient or lack of proper change management plan, the transformation will fail.

Digital shift isn’t unique to the Middle East, it is a global challenge even for regional operators

“25 Case Studies of Companies That Mastered Supply Chain Management” by AllMeld cited multinational conglomerate General Electric (GE), which recently overhauled its global supply chain. GE significantly enhanced its supply chain operations by integrating digital twin technology – a virtual replica of physical assets and processes that enables real-time monitoring, simulation, and analysis. This innovation enables GE to simulate disruptions, optimise resource allocation, and make datadriven decisions proactively, thereby futureproofing complex logistics systems.

Such a challenge isn’t unique to the Middle East. GE’s transformation reinforces a pivotal lesson: resilience starts with visibility, modularity, and software alignment—the values SSI SCHAEFER builds into every deployment. At SSI SCHAEFER, similar principles are applied in smart warehouse design, automation integration, and system transparency to help customers build an agile, data-driven supply chain.

For Middle Eastern enterprises ready to evolve, SSI SCHAEFER offers more than just software—it provides a resilience roadmap: Cybersecurity by design

• Up-to-date software developer training

• Segregation of standard vs. custom modules

• Detailed Bill of Materials for transparency Operational

• Firewall patching co-planned with business teams

• Vanilla (clean, standard) WMS/WES/WCS deployments

• Security patching schedules, tested rigorously before release Network integrity

• Network segmentation across VLANs

• Restricted port communication

• Trusted authentication protocols

• Secure remote access

• Traceable audit logs for compliance Built-in testing efficiency

• Automated test environments for deployment

• Simulations that save time, reduce errors, and boost confidence

“We are not just delivering intralogistics software. We’re delivering software you can trust when it matters most,” Airyn Ong concluded.

The only certainty in today’s warehouse landscape is change. New automation. Evolving customer expectations. Emerging cyber threats. Regulatory shifts. The businesses that will thrive are those with the right digital scaffolding — modular, secure, and future-ready. Legacy may still run in some systems, but it can no longer run the strategy.

With SSI SCHAEFER, the Middle East is ready to move from reactive patching to proactive resilience — one line of secure code at a time.

Swisslog is a global leader in warehouse automation and logistics solutions. Known for their cutting-edge systems, including robotic picking, automated storage and healthcare transport technologies. To uncover the latest from this dynamic entity we speak to Rami Younes, General Manager, Swisslog Middle East.

Global Supply Chain: What are the biggest fulfilment challenges retailers face today?

Rami Younes: Retailers today are under immense pressure to balance speed, accuracy, and scalability in fulfilment. Consumer expectations have shifted dramatically: same-day or next-day delivery is increasingly standard, leaving little margin for error. Manual processes struggle to keep up, as they are labour-intensive, prone to errors, and lack flexibility to handle demand spikes. Another layer of complexity is labour shortages with extremely high warehouse turnover rates. This makes scaling operations during seasonal peaks extremely difficult. Additionally, inefficient warehouse layouts and low storage density often force companies to expand prematurely, driving up operational costs. For retailers competing in high-growth areas like e-commerce and omnichannel fulfilment, these inefficiencies directly impact sales and customer satisfaction. High-performing supply chains already yield above-average revenue growth, underlining how critical fulfilment excellence has become.

The challenge is no longer only about cost reduction; it’s about resilience and agility. Scalable automation not only addresses operational constraints but also reduces repetitive manual tasks, freeing staff to focus on strategic, higher-value activities. Retailers who fail to invest in flexible automation risk falling behind more agile competitors and losing market share.

GSC: How is warehouse space utilisation evolving in the industry, and why is storage density becoming more important?

RY: In modern supply chains, the most valuable asset is warehouse space. With e-commerce volumes rising and SKU proliferation increasing, many companies are running out of space long before their

leases end. Expanding or relocating to larger facilities can often be costly, particularly in high-demand markets like the Middle East.

This is well addressed by automation, which dramatically improves storage density. Automation technologies, including AutoStore, shuttles, and smart storage solutions, allow warehouses to store up to four times more products within the same footprint compared to traditional shelving. This can increase storage density by up to 150%, enabling businesses to handle more SKUs efficiently without compromising speed.

In addition to space savings, highdensity systems also reduce travel time for workers and robots, boosting overall throughput. With storage and picking taking place in a compact, optimised grid, retrieval becomes faster and more accurate. This allows warehouses to stay away from costly expansions and instead maximise their current infrastructure.

As demand surges, the ability to maximise existing infrastructure has become a strategic differentiator. Those who optimise for density not only save costs but also position themselves for sustainable growth.

GSC: How does the “all-to-all” design in modern automation systems improve throughput and order fulfilment efficiency compared to traditional methods?

RY: Traditional warehouse designs typically follow linear or fixed-path workflows, where goods move in a sequential order from storage to picking to packing. This creates bottlenecks, particularly during peak periods, as multiple orders compete for the same resources.

Modern “all-to-all” designs, like those enabled by Swisslog’s AutoStore, change this dynamic completely. Every bin in the grid is accessible to every robot and every workstation, eliminating the dependency on a single path or process flow. This flexibility also ensures that high-demand items can be dynamically prioritised and retrieved without any delays.

The impact on throughput is significant. AutoStore systems can scale to 20,000 picks per hour, with modular expansion possible by simply adding more robots or ports. In one Swisslog deployment with

“In one Swisslog deployment with Almarai, throughput increased by 25% and order fulfilment time dropped by 30%. The “all-to-all” model ensures that productivity grows in proportion to demand instead of being constrained by bottlenecks.”

Almarai, throughput increased by 25% and order fulfilment time dropped by 30%. The “all-to-all” model ensures that productivity grows in proportion to demand instead of being constrained by bottlenecks.

This design also increases system resilience. If one robot or workstation goes offline, others can take over without disrupting operations. This results in faster and more accurate fulfilment.

GSC: How is the growth of e-commerce in the Middle East shaping warehouse automation strategies?

RY: Studies show that the Middle East’s e-commerce market is projected to surpass $50 billion by 2025, making it one of the fastest-growing regions in the world. This rapid growth is also changing how warehouses in the region operate. Traditional, manual processes cannot scale to meet the increasing demand for speed, accuracy, and omnichannel flexibility.

As a result, businesses are accelerating automation investments. Governments are also realising this and fuelling this shift, with initiatives like Saudi Arabia’s Vision 2030 and the UAE Centennial 2071 prioritising smart logistics hubs and advanced technologies.

E-commerce’s demand further emphasises the need for flexible, modular systems. Retailers require automation solutions that can quickly scale up during peak seasons without requiring full-scale overhauls. Technologies like Autonomous Mobile Robots (AMRs) and AutoStore grids are increasingly popular because they can be deployed incrementally, aligning capital investment with demand growth.

Ultimately, e-commerce in the Middle East is pushing companies to view fulfilment not just as an operational cost but as a customer experience driver. Automation is no longer optional; it is now the foundation for competitiveness and long-term growth in the digital retail economy.

H.E. Eng. Saleh bin Nasser Al-Jasser, Minister of Transport and Logistics Services and Chairman of the Transport General Authority; H.E. Dr. Rumaih bin Mohammed Al-Rumaih, Vice Minister of Transport and Logistics Services and Acting President of the Transport General Authority; and FedEx executives Raj Subramaniam, President and CEO of FedEx Corporation; Richard Smith, COO, International and CEO, Airline; and Kami Viswanathan, President of FedEx Middle East, Indian Subcontinent and Africa, along with other FedEx leadership, marking the latest developments in Saudi Arabia.

FedEx completes direct-serve transition, launches West-to-Kingdom (Kingdom of Saudi Arabia or KSA) nonstop express flight, plans for future hub, and introduces FedEx Logistics freight forwarding services, contributing to the Saudi Vision 2030 goals for logistics, connectivity, trade, and economic diversification.

Federal Express Corporation (FedEx), the world’s largest express transportation company, recently announced the completion of its transition to a directserve presence in Saudi Arabia. This milestone comes amid robust economic growth in the Kingdom and includes the launch of the first dedicated FedEx flight into Saudi Arabia, development of a regional hub at the King Salman International Airport, and the expansion of FedEx Logistics freight forwarding services into the country. These initiatives boost operational capacity, generate employment opportunities, and align with Vision 2030 priorities for economic diversification and global trade integration. The milestone was marked by H.E.

Eng. Saleh bin Nasser Al-Jasser, Minister of Transport and Logistics Services and Chairman of the Transport General Authority; H.E. Dr. Rumaih bin Mohammed Al-Rumaih, Vice Minister of Transport and Logistics Services and Acting President of the Transport General Authority; and FedEx executives Raj Subramaniam, president and chief executive officer of FedEx Corporation; Richard Smith, chief operating officer, International and chief executive officer, Airline, FedEx; Kami Viswanathan, president of FedEx Middle East, Indian Subcontinent and Africa; along with other members of the FedEx leadership team, during a ceremony held in Diriyah - a historic centre of Saudi heritage and culture in Riyadh.

His Excellency Eng. Saleh bin Nasser Al-Jasser, Minister of Transport and Logistics Services and Chairman of the Transport General Authority, said, “FedEx strengthened presence reflects the Kingdom’s growing appeal as a premier destination for logistics and global investment. Saudi Arabia’s rising influence as a key global logistics hub and a strategic gateway for trade and transport services is clear. The increasing

number of leading global logistics and courier companies establishing direct operations in the Kingdom demonstrates the strength of Saudi Arabia’s logistics sector and its pro-investment environment, as well as the global confidence in the Kingdom’s transformation journey.”

“Our recent investments underscore Saudi Arabia’s role as a vital link in our global network, connecting major economies across Asia, Europe, and the Americas,” said Richard Smith, Chief Operating Officer, International, and Chief Executive Officer, Airline, FedEx. “By expanding in the Kingdom, we are broadening our network’s reach and creating faster, more dependable trade routes. As global commerce evolves, Saudi Arabia’s strategic position ensures we can move goods with both speed and scale to connect more people and possibilities.”

FedEx direct-serve operations in the Kingdom provides customers with an end-to-end shipping experience. The company now directly manages pickup, delivery, and customs clearance, supported by its local infrastructure that includes four gateways and four stations.

Founded in 1979 and joining ClMC Group in 2014, we are a proud member of ClMC TlANDA and a global leader in intralogistics and material handling solutions. With 40+years of expertise and 1000+ large-scale projects, we provide customized automation system solutions for industries including 3PL, retail, express, pharmaceuticals, FMCG, petrochemicals, new energy, F&B, cold storage, and CHS.

Seamless Integration: Enhance your warehouse with our automated storage systems and robotic picking solutions.

Advanced Control: Real-time monitoring and predictive analytics to optimize performance.

Scalable Solutions: Adapt to growing demands with flexible, customizable systems.

Aron.Schiller@stas.cimc.com

Linkedin: https://www.linkedin.com/in/aron-schiller/

Allison Transmission, a global leader in fully automatic transmissions for commercial vehicles, marked a key milestone during the 2025 Hajj season with the introduction of 12-metre Kinglong city buses equipped with its technology for the first time.

This achievement comes amid rising demand for Allison’s high-performance drivetrain solutions across the UAE, Saudi Arabia, Qatar, and Oman, driven by continued investment in tourism, public mobility, and intercity transport, particularly in premium segments.

The company’s Torqmatic Series, which is designed specifically for high-end coach and bus applications, is becoming the transmission of choice for operators prioritising refinement, reliability, and passenger comfort.

In the Middle East, the Torqmatic Series is already widely deployed in both premium

and high-capacity applications. During previous Hajj seasons, the series played a crucial role in efficiently transporting millions of pilgrims across long distances and extreme terrain in Saudi Arabia through coach buses. The series already powers over 500 airport shuttle buses, all operating at major airports across the UAE, Qatar, Saudi Arabia, and Oman. Together, these deployments reflect a regional shift toward smooth, fuel-efficient and low-maintenance automatic transmissions that elevate both operational uptime and passenger

The series includes a range of models engineered for various fleet needs. Among those used across key GCC countries are the T2100xFE, T270R, T350R, T375R, and T390R, which support different horsepower and torque levels and are fitted into 8-metre, 10-metre, and 12-metre vehicles in city and intercity operations across the region.

The T525R transmission, part of the same family, is engineered for long-haul, city-tour, and VIP shuttle vehicles requiring smooth and high-performance drivetrains. It features six forward gears, one reverse

enhanced diagnostics and fuel efficiency, and an integral retarder to support smooth deceleration and reduced brake wear, which are key attributes for luxury and highmileage fleets.

The Middle East’s growing preference mirrors global trends. In the UK, Sharpes of Nottingham, a major premium executive coach operator, has recently committed to standardising future fleet orders with the Allison T525R after achieving excellent results in its Van Hool TX21 Altano. Sharpes serves clients across corporate hospitality, football teams, and luxury tours, and is next equipping its Van Hool T17 Astron with Allison.

Muhammad Ibrahim Khan, Area Manager for Middle East and Pakistan at Allison Transmission, said: “Luxury and mass transport operators in the Middle East are looking for more than just performance as they’re seeking refinement, reliability,

and an exceptional passenger experience.

Demand globally echoes what we’re seeing in this region, where demand is rising for drivetrain solutions that elevate comfort without compromising on durability. From high-end tourism to VIP mobility and hospitality fleets, Allison’s transmissions deliver the smooth, seamless drive expected in premium transport.”

Allison Transmission has a long-standing presence across the GCC, supporting major fleets in markets such as the UAE, Saudi Arabia and Qatar. Its technology powers a wide variety of applications, including high-capacity intercity buses, airport shuttles, school buses, VIP tour coaches, and government mobility fleets. The company also offers region-specific service and support infrastructure, including training, diagnostics, and parts availability, reinforcing Allison’s commitment to uptime and operational excellence.

Allison products are used in a wide variety of applications, including onhighway trucks (distribution, refuse, construction, fire and emergency), buses (school, transit and coach), motorhomes, off-highway vehicles and equipment (energy, mining and construction applications) and defense vehicles (tactical wheeled and tracked). Founded in 1915, the company is headquartered in Indianapolis, Indiana, USA. With a presence in more than 150 countries, Allison has regional headquarters in the Netherlands, China and Brazil, manufacturing facilities in the USA, Hungary and India, as well as global engineering resources, including electrification engineering centers in Indianapolis, Indiana, Auburn Hills, Michigan and London in the United Kingdom. Allison also has approximately 1,600 independent distributors and dealer locations worldwide.

Sforklifts are equipped with IP67rated core systems with liquid cooling, making them suitable for operations across ports, factories, chemical plants, and cold-chain logistics.

Based on the “Three Transformations” strategy of Globalisation, Digitalisation, and Decarbonisation, Sany is actively expanding into the emerging blue ocean of smart and low-carbon logistics and warehousing.

The forklifts integrate autonomous driving and AI technology which the company says creates “a low-carbon, intelligent logistics ecosystem”.

The company says its forklifts are now in use in more than 50 countries, while Sany Heavy Industries is this investing 5% (USD300 million) of its revenue on research and development.

Diesel forklifts have been associated with high emissions, energy consumption,

In a boost to green logistics, Beijingheadquartered Sany Robotics has delivered 40 electric forklifts to the Abu Samra Border logistics project in Qatar. This is its single largest forklift order for the Middle East to date. We bring you the details.

and noise, while traditional electric forklifts often struggle with inefficient power, poor adaptability, and range anxiety under extreme conditions such as high temperatures, humidity, dust, and heavy loads, making them difficult to fully replace diesel models. Thus, market demand and customer pain points have become a source of Sany’s technological innovation.

Sany utilised the cutting-edge newenergy vehicle technologies for forklifts, and became the pioneer in China to launch a 300V high-voltage lithium platform. Fully integrating automotive-grade batteries, motors, and electronic controls with the vehicle control unit (VCU), Sany’s electric forklift owns diesel-level—or even superior—power performance. In this way, the forklift features a full-load gradeability of 25%, and a “1-hour charge for 8-hour operation” cycle, removing any concerns about battery life.

Simultaneously, the machine has

experienced strict technical tests, proven its stability in extreme conditions. Equipped with IP67-rated core systems with liquid cooling, the machine ensures reliable operation across ports, factories, chemical plants, and cold-chain logistics. Beyond high-performance, these forklifts integrate autonomous driving and AI to create a low-carbon, intelligent logistics ecosystem covering warehousing, handling, sorting, and loading. This strategic vision underscores the company’s commitment to driving global green logistics transformation. Today, Sany electric forklifts are running in over 50 countries and more than 40 challenging job sites worldwide. According to the first half of 2025 results, Sany Heavy Industry invested $0.3 billion in R&D, accounting for over 5% of its total revenue. In the future, it says it will continue to advance product upgrades and sustainable solutions while creating greater value for customers and partners worldwide.

Survey of supply chain decision-makers shows organisations scaling AI workflows, hiring for AI-specific roles, and prioritising data-centric investments to better navigate disruption.

AI is no longer experimental, but rather reshaping how supply chain businesses are prioritising operational, staffing, and data-centric investments, according to the newly released 2025 Agility Index research study from Epicor and Nucleus Research.

“AI is becoming an essential tool in helping supply chain businesses anticipate and respond to inevitable change,” said Kerrie Jordan, Chief Marketing Officer and Senior Vice President of Product at Epicor. “We’re seeing organisations unlock the agility needed to lead through disruption by not just deploying AI but by building a digital foundation and workforce behind it.”

From the study, more than 56 percent of supply chain businesses surveyed reported high AI readiness, with many scaling AI across operations and modernising their data systems to improve agility and reliability. Within this group, more than 90 percent are actively creating or investing in AI-specific roles, suggesting that organisations already leveraging AI tools

are also the most likely to invest in building dedicated AI talent pipelines.

Further, AI is enabling more thoughtful decision-making but not displacing human judgment. The most common roles for which companies are hiring, include AI Logistics & Route Optimisation Specialists (38.0 percent), Supply Chain AI Data Scientists (37.2 percent), and AI Automation Engineers (35.4 percent). Organisations running geopolitical what-if scenarios report higher levels of AI-related hiring. Moreover, these roles aren’t confined to labs or pilot teams – they’re embedded directly in planning, fulfillment, and logistics functions.

“What’s changing is how companies see AI, not as a replacement for people, but as a way to empower them,” Jordan added. “They’re hiring for expertise that brings context and adaptability to the data, which is where real agility lives.”

More companies are investing in platforms that connect and analyze operational data. These systems, adopted

by just over half (50.6 percent) of all respondents, are now the most widely used data intelligence tools among digitally mature organisations. Companies using them were 1.4 times more likely to have adopted AI applications. The results suggest that companies are reevaluating their planning, response, and day-to-day operations. Agility, once a stopgap measure, has evolved into a strategic capability.

Across all regions, companies are strengthening scenario planning and supply chain resilience in response to rising uncertainty. In Southeast Asia, for example, 61 percent of respondents cited trade restrictions as their biggest risk, and 73 percent said they’re actively reworking sourcing strategies. Similar trends are unfolding globally, as companies utilize forecasting tools and talent to anticipate and prepare for disruption.

Expectations around ROI are also maturing, reflecting lessons learned from past technological deployments. A majority of respondents now expect to see returns

on their technology investments within six to 18 months. But, looking ahead, organisations cannot approach AI as a standalone technology project. Success will depend on organisational readiness, leadership engagement, and the ability to act on predictive insights.

“Investing in AI and data-centric platforms is changing how quickly companies can respond to disruption and optimize decisions,” Jordan continued. “As AI matures and time to value approaches zero, these companies will outpace competitors. They will be able to make decisions in minutes, not months, with systems that adapt as fast as the market shifts.”

Nucleus Research surveyed more than 1,000 supply chain professionals across regions including the U.S., Canada, the UK/Ireland, Southeast Asia, Australia/New Zealand, and the UAE.

Epicor equips hard-working businesses with enterprise solutions that keep the world turning. For 50 years, Epicor customers in the automotive, building

supply, distribution, manufacturing, and retail industries have trusted Epicor to help them do business better. Innovative Epicor solution sets are carefully curated to fit customer needs and built to respond flexibly to their fast-changing reality.

Key findings include

• More than 56% of supply chain businesses reported high AI readiness

• The most common roles for which companies are hiring include AI Logistics & Route Optimisation Specialists (38%), Supply Chain AI Data Scientists (37%), and AI Automation Engineers (35%)

• Companies that are investing in platforms that connect and analyse operational data are 1.4 times more likely to have adopted AI applications

• A majority of respondents now expect to see returns on their technology investments within six to 18 months

Kerrie Jordan, Chief Marketing Officer and Senior Vice President of Product at Epicor.

Just when it seemed the global supply chains had finally cleared the shadow of the pandemic, they have once again found themselves disrupted, this time by recent tariffs. Businesses worldwide are having to deal with the ripple effects — rising costs, disrupted supply lines, and a fresh layer of uncertainty in an already fragile global economy.

The sheer complexity of modern supply chains means that protectionist policies rarely impact just one country or sector; instead, they send shockwaves through a tightly interconnected web of suppliers, manufacturers, and logistics networks. Even businesses that have no direct dealings with the US can find themselves caught in the crossfire as trade tensions force companies to rethink sourcing strategies, reroute shipments, and scramble to maintain stability.

Against this backdrop, the UAE stands in stark contrast, championing an open, rules-based trade agenda built on strategic supplier collaboration. Rather than retreating behind trade barriers, the UAE government is actively forging stronger partnerships across its borders, investing

in resilient supply chains, and ensuring smoother market access for businesses at home and abroad. At the most recent G20 Trade and Investment Working Group, the UAE reaffirmed its commitment to free and fair trade, underscoring its role as a global logistics powerhouse and a key facilitator of economic growth. By prioritising supplier partnerships and regional value chain development, the UAE is not only futureproofing its economy, but also setting a model for trade policies that foster innovation, sustainability, and long-term prosperity.

This strategy is not just about opening new markets; it reflects a strategic shift in how global trade relationships are managed.

A key element of this transformation is the move towards deeper supplier collaboration. Traditional cost-cutting measures that prioritize short-term gains over long-term resilience are increasingly being replaced by partnerships that drive efficiency, innovation, and sustainability across supply chains. This approach is critical for the UAE’s economic agenda, as it seeks to position itself as a hub for trade and investment that benefits all parties involved. Supplier collaboration is emerging as a cornerstone of modern trade relationships. Research shows that businesses focusing on supplier partnerships see increased efficiency, resilience, and innovation. In contrast, those who treat suppliers purely as cost centers often struggle with quality issues, supply chain disruptions, and reputational risks. By embedding

collaborative principles into procurement and supply chain management, businesses operating in the UAE can align with the country’s broader economic vision while gaining competitive advantages.

One of the fundamental benefits of deeper supplier collaboration is risk mitigation. In an era of geopolitical uncertainties, fluctuating tariffs, and supply chain disruptions, businesses need stable and reliable partners. By working closely with suppliers, companies can diversify sourcing strategies, ensure consistent quality, and develop contingency plans that prevent costly bottlenecks. The UAE’s investments in Africa’s logistics infrastructure demonstrate this principle in action — by facilitating the movement of goods more efficiently, businesses benefit from improved supply chain continuity.

Transparency is another critical advantage of a collaborative approach. When businesses share demand forecasts, inventory data, and production schedules with suppliers, it allows for better resource planning and waste reduction. The UAE’s emphasis on rules-based trade aligns with this philosophy, as transparency fosters trust and ensures that all stakeholders operate under fair and predictable conditions. Supplier scorecards, for instance, offer a structured way to evaluate performance, identify areas for improvement, and build stronger, more accountable relationships.

Moreover, collaboration with suppliers opens doors for shared investment in innovation. Rather than negotiating for the lowest possible price — often at the expense of quality and reliability — companies can co-develop solutions that enhance productivity, sustainability, and market competitiveness. The UAE’s Africa Economic Corridor Strategy illustrates this approach by encouraging investment in new trade routes and logistics capabilities that benefit both Emirati businesses and their African counterparts. Similarly, businesses that partner with suppliers on innovation projects, such as sustainable packaging or digital supply chain solutions, can drive efficiencies

while reinforcing their commitment to responsible business practices.

Sustainability is another area where supplier collaboration is essential. The UAE’s vision for economic development includes strong environmental and social governance principles, making it imperative for businesses to work with suppliers who align with these values. Collaborative supplier relationships enable companies to evaluate alternative sourcing options, explore lower-carbon transport solutions, and establish fair labor practices across the supply chain. By fostering a culture of shared responsibility, businesses can contribute to the UAE’s long-term sustainability goals while improving their own reputations and resilience.

All these benefits can be realised only through the application of the right technology, which today plays a vital role in enabling supplier collaboration. Advanced procurement platforms in particular provide real-time insights into supply chain performance, allowing businesses to identify inefficiencies, optimise procurement strategies, and enhance decision-making. These platforms act as a bridge between

buyers and suppliers, enabling seamless communication, automating processes, and ensuring compliance with trade regulations. By leveraging AI-powered analytics and automation, businesses can move beyond transactional supplier relationships to more strategic, value-driven partnerships.

The UAE’s emphasis on digital transformation extends to its trade agenda, with smart trade platforms and blockchainbased solutions enhancing transparency, reducing paperwork, and facilitating faster transactions. Procurement technology is not just a tool — it is a catalyst for the future of open, collaborative trade.

Ultimately, the country’s push for an open, rules-based foreign trade agenda is not just about signing agreements or reducing trade barriers; it is about fostering a more cooperative and interconnected global economy. Supplier collaboration is at the heart of this vision, offering businesses a pathway to greater efficiency, resilience, and innovation. As trade relationships become more interdependent, those who invest the technologies that enable strong, transparent, and mutually beneficial supplier partnerships will be the ones who thrive in the new global trade landscape.

By: Hany Mosbeh (Don), Senior Vice President – MEAPAC, JAGGAER

Anchanto is a leading SaaS company specialising in eCommerce and logistics technology solutions. Its mission is to empower businesses to streamline operations, improve fulfilment efficiency, and scale seamlessly across multiple sales channels and markets. The company’s senior leadership team recently visited Dubai to gauge how to optimise operations and launch its latest venture. In an exclusive interview with Founder and CEO, Vaibhav Dabhade, we discuss order management, warehousing automation and how all commerce is e-commerce.

Anchanto Orbit is a complete suite of SaaS solutions developed by Anchanto—a Singapore-based tech company that empowers e-commerce and logistics businesses to manage their operations seamlessly across multiple channels and markets.

While “Orbit” isn’t a single product, it symbolises Anchanto’s integrated ecosystem of tools that cover the entire e-commerce and supply chain lifecycle. This includes:

For brands and retailers

Order lifecycle management: Automates order processing across marketplaces. Inventory management: Real-time stock visibility and optimisation. Catalogue and listing management: Centralised control of product listings.

Pricing and promotions management: Dynamic pricing strategies and campaign control.

Digital shelf analytics: Tracks product visibility and competitor performance.

Omnichannel retailing: Syncs online and offline sales for a unified experience.

For logistics providers

Warehouse management efficiency: Streamlines fulfilment operations.

Control tower: Coordinates logistics across multiple carriers.

Parcel tracking: Real-time shipment updates for customers.

Fulfilment cost reduction: Optimises delivery routes and resources.

Designed to help businesses: Expand into new markets with plug-andplay integrations.

Reduce operational costs and manual errors. Deliver better customer experiences through automation and visibility.

Anchanto is trusted by major platforms like Shopee, Lazada, Amazon, and Tokopedia, and has been a key player in Southeast Asia’s digital commerce transformation. Speaking at the close of a roundtable discussion, Founder and CEO, Vaibhav Dabhade explains, “This event was created to involve inputs from our leading clients and align a road map for the company. This is the first time we created a meeting ground with them in mind. We are super proud of the result.

“Anchanto is not just a company that sells software products. We help our customers fulfil their vision faster and more efficiently,” – Founder and CEO, Vaibhav Dabhade.

A meeting like this gives us direction. For example, iSTYLE Apple’s premium partner operates one of the biggest chains of Apple stores in CEMEA (Central Europe, Middle East & Africa), running more than 100 dedicated Apple points of sale in 14 different countries. They use our software. We want our customers to feel free to speak about the challenges, the wins, how they see the market. And then we’re taking these inputs to incorporate them.”

The company has been in the region for four years. “Coming to Dubai to launch this was worth it and we’ll do it again, for sure. One of the challenges that logistics company’s face, particularly in the region is a shortage of space. So that is something that we have openly discussed. And there’s no quick fixed solution for it, right? If you’re exploring tools for scaling e-commerce or logistics operations, Anchanto Orbit could be a powerful ally,” suggests the CEO.

‘The desire to explore new possibilities and innovate is deeply engrained in the company’s DNA and fuels what we build and how we do it,’ says its website. Derived from the word, ‘enchantment,’ Anchanto is committed to offering an ‘enchanting experience’ to its stakeholders.

One of the challenges addressed was geo-fencing. Many street names are not

known in some areas causing delays for last mile delivery. Geo-fencing is location-based marketing and advertising. A mobile app or software uses the Global Positioning System (GPS), radio frequency identification (RFID), Wi-Fi or cellular data to define a virtual geographical boundary and trigger a targeted marketing action when a device enters or exits that boundary. This boundary is known as a geofence.

One of the key advantages of geofencing is that it allows businesses to create omnichannel marketing campaigns to further boost sales and revenues.

Discussing the future, Dabhade says, “New models of e -commerce will soon enter the GCC market. For example, we see some warehouses in Southeast Asia purely built on processes around live commerce. Here we are referring to ‘Tik Tok selling’. This was not available three years ago. The studio set up for live streamers, getting in products just in time for inventory, all of that will happen, and after this platform fades in popularity, it’ll be something new. The models of e-commerce will keep evolving. Every time the channel or model of e-commerce for a customer changes, underlying logistics and the underlying supply chain has to change. This is where we believe that quick commerce, will exist.”

Electric vehicles (EVs) have transitioned from mere pilot projects or luxury items to a priority in national policy. Across the GCC, national EV strategies are driving rapid investment in clean mobility. In the UAE, the National Electric Vehicles Policy targets 50% EV penetration by 2050. Saudi Arabia’s Vision 2030 includes goals for local EV manufacturing and the deployment of tens of thousands of charging stations.

These targets are tied to broader economic diversification agendas and long-term sustainability goals. The impact of these national strategies is already visible, with tangible results emerging across the region: According to data from global consulting firm Bain & Company, the regional EV market could reach up to €54 billion in value by 2035. In the Global Electric Mobility Readiness Index (GEMRIX) by consultancy Arthur D. Little, the UAE already ranks among the world’s top 10 countries. What’s often overlooked in the electric

vehicle transition is the true source: the battery. It’s not just what powers the car; it is what makes the entire shift to electric mobility viable. Behind every battery lies a complex logistics chain that brings this transformative technology to life. As governments and automakers race toward electrification, battery logistics is being stretched by the realities of capacity, regulation, and scale.

At DHL Global Forwarding, we’ve seen firsthand how battery shipments have become more frequent, diversified, and scrutinized. We’re not just shipping

finished cars. We’re handling batteries that are heavier, more regulated, and more expensive than anything in the traditional automotive supply chain. It is expected that there will be over 400 gigafactories to be operational by 2030. The batteries they produce must move through international ports, bonded warehouses, and last-mile facilities compliant and certified for dangerous goods. Failing to meet regulatory thresholds isn’t just a bureaucratic risk; it’s a safety issue.

The industry is still catching up. For example, lithium-ion batteries are classified

“What’s often overlooked in the electric vehicle transition is the true source: the battery. It’s not just what powers the car; it is what makes the entire shift to electric mobility viable.”

as UN 3480 dangerous goods. There are various regulations that are mandatory and that vary depending on the size and power, alongside the mode of transport and other variables. Not all routes allow them, and not all aircraft can carry them. Air freight restrictions can mean relying on ocean shipping or custom-designed flat racks.

The complexity doesn’t end at transport. EV batteries have a life cycle that extends long after the first sale. Return logistics, battery disassembly, second-life repurposing, and end-of-life recycling are all part of the battery circular economy. This requires integrated warehousing, aftermarket repair networks, and new regulatory cooperation with local fire departments and insurance providers. In short, batteries don’t just move once; they move repeatedly, across borders and years.

At DHL Global Forwarding, we’ve seen logistics demand rise across the full EV ecosystem, from last-mile e-motorbikes to commercial trucks, off-highway vehicles, battery energy storage systems, and charging stations. In the Gulf, where industrial electrification is gaining traction, supply chains now need to adapt to varied battery types, special storage conditions, and new return protocols.

The national visions in the Gulf region are backed by serious capital. The Saudi Public Investment Fund has committed to building a local EV manufacturing base through ventures. The UAE is rolling out green mobility initiatives through Etihad Rail, DEWA, and the Ministry of Energy and Infrastructure, all pointing to a future of connected, electrified transport. Oman

Toby Groom, Global Head of EV Logistics Solutions, DHL

and Qatar are also rolling out national EV strategies. Qatar’s successful electrification of 25% of its public transit bus fleet sets an important precedent in the region. Bahrain’s Economic Vision 2030 also places sustainability and green transport at the center of its infrastructure ambitions.

But all EV players need one thing above all: supply chain resilience. Markets are volatile, regulatory frameworks are evolving, and technology is changing faster than most logistics networks were designed to accommodate. That means having modular, scalable, and multi-modal

transport options is no longer optional.

This region has a chance to build this infrastructure from the ground up. Middle East governments are investing in clean energy and EV ecosystems. But to unlock the full value of electrification, battery logistics must become a firsttier priority in policy, infrastructure, and procurement decisions.

The Gulf is leading on ambition. Logistics must now rise to match it.

By Toby Groom, Global Head of EV Logistics Solutions at DHL

World-leading transport provider, Scania is strengthening its electrification portfolio with the launch of Scania Industrial Batteries, headquartered in Sweden. The new organisation is dedicated to off-road and industrial applications such as mining, construction and material handling.

This launch follows Scania’s acquisition and carve-out of Northvolt Systems’ Industrial Division in April 2025, positioning Scania Industrial Batteries to deliver a fully integrated solution now available to customers.

Scania’s off-road portfolio includes a fully electrified solution, covering battery systems, electric motors, software, connectivity and dedicated support services – all engineered to meet the demanding conditions of challenging terrains.

With the two product platforms Core and Compact, Scania Industrial Battery packs simplify electrification across a wide range of industrial applications from 21 to 624 kWh, up to 1000 V. The solutions are available as part of a complete electric powertrain, or as stand-alone products, and are designed and manufactured in Europe.

The market for electric off-road equipment is expanding rapidly. Scania sees increasing adoption of electrified solutions in sectors such as construction and mining, where the benefits are particularly evident. Electrification delivers significant energy cost savings and enables substantial long-term emissions reductions, key factors for energy-intensive industries.

Transitioning from combustion engines to electric powertrains presents complex challenges, including the need for highcapacity batteries and precisely engineered e-machines to meet power, voltage, and thermal demands. Scania is addressing these challenges through a comprehensive portfolio of electric powertrain components, from battery systems to e-machines. These solutions are developed in close collaboration with OEMs and operators to enhance efficiency and reduce emissions in the world’s most demanding operations.

“With this new offering, we aim to lead the electrification of off-road applications and support our customers in making the transition to sustainable solutions,” says Gustaf Sundell, Executive Vice President and Head of Ventures and New Business at Scania. “By combining the agility and speed of our newly acquired company with Scania’s deep engineering expertise and extensive global network, we are well positioned to accelerate electrification in the toughest off-road environments.”

Scania reinforces its role as a leader in both on-road and off-road electrification with a battery portfolio that now includes solutions for buses, trucks and industrial

Elin Åkerström, CEO Scania Industrial Batteries.

Gustaf Sundell, Executive Vice President and Head of Ventures and New Business at Scania.

off-road applications. The new battery systems, compatible with Scania’s existing electric powertrain components, enable faster development, testing, and deployment, helping OEMs and end-users adopt cleaner, more efficient machinery.