CIMC TIANDA

Drive the road of change.

Full offering

- Full range vehicles with the most advanced technologies

- Highly customized product driven by market needs and optimized Total Cost of Ownership

High capillarity of aftersales

- Repair and Maintenance contracts and competitive warranty conditions

- Origin 100% IVECO Parts and a widespread network coverage

European technology

- High quality complete line-up in terms of tonnage, power, torque, safety, ergonomics

- High performance and robust trucks for extreme Off-road conditions

Customer centricity

- Comfort, ergonomics and the latest safety technology to make on board easier

- Driver Style Evaluation tool on Heavy ON-road range and optimized vehicle design to improve customer profitability

SIGNATURE MEDIA FZ LLE

P. O. Box 49784, Dubai, UAE

Tel: 04 3795678

Email: info@signaturemediame.com

Exclusive Sales Agent Signature Media LLC

P.O. Box 49784, Dubai, UAE

Publisher: Jason Verhoven jason@signaturemediame.com

Editor: Abigail Mathias abigail@signaturemediame.com

Art Director: Johnson Machado johnson@signaturemediame.com

It has been an eventful summer for the team at Global Supply Chain. We have met some outstanding individuals from the field and are delighted to bring you the cutting-edge innovations of our time.

For starters, CIMC Tianda offers a fascinating insight into automated warehousing. We take you on a intriguing journey to DHL’s innovative warehouses in the United Kingdom where robotics are bearing the load of heavy and voluminous deliveries. The company’s developments in pharma storage offer a window into healthcare management for the years to come.

Printed and Distributed by Masar Printing and Publishing L.L.C., Part of Dubai Media Incorporated Dubai, UAE

Contributor’s opinions do not necessarily reflect those of the publisher or editor and while every precaution has been taken to ensure that the information contained in this magazine is accurate and timely, no liability is accepted by them for errors or omissions, however caused. Articles and information contained in this publication are the copyright of Signature Media FZ LLE & SIGNATURE MEDIA LLC and cannot be reproduced in any form without written permission.

AEDLER Logistik Solutions, partnership with Kardex enhances intralogistics efficiency, while Positive Zero encourages the use of electric transportation. A more sustainable option, offering a less polluted environment for all of us.

IVECO announces its merger with Tata Motors and Swedish based Scania increases orders by 6 per cent. Both international trucking companies are paving the way for others in the industry to follow their success journeys.

We look at how an essential everyday commodity like rice goes through the vital supply chain to reach consumers on time. Reinstating the value that this industry brings to every table.

One of the leading shipbuilders in the Middle East, Grandweld Shipyards have been closely monitoring the environmental footprint of maritime activities. Their focus to generate renewable energy on a large scale is commendable. They share the ripple effect of sustainability both on sea and land.

All this and a plethora of news, views and engaging commentaries, make this issue a September to remember.

Welcome to another exciting edition.

Abigail Mathias Editor

abigail@signaturemediame.com www.globalsupplychainme.com

1500+

150+

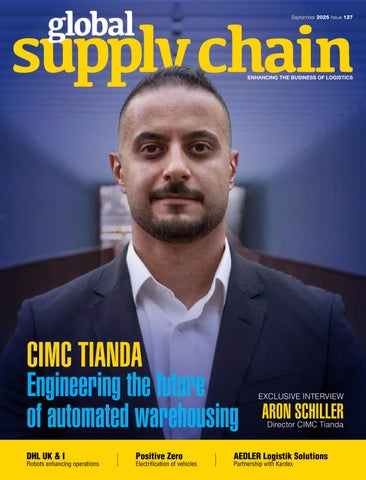

CIMC Tianda: Engineering the future of automated warehousing

CIMC Tianda Intralogistics is a powerhouse in intelligent logistics automation, offering cutting-edge solutions for warehouse and supply chain operations across the globe. It forms a part of the larger CIMC Group, a major Chinese conglomerate with deep roots in industrial manufacturing and logistics. The company recently expanded in the Middle East with a strategic focus on automation in warehousing and logistics. With more than 45 years of experience and over 1,800 global projects, its strong international footprint is noteworthy. In an exclusive interview with Aron Schiller, Director CIMC Tianda Intralogistics, Global Supply Chain uncovers how seamless integration can be tailor made for almost every business model.

Gulf Supply Chain: In your opinion how do smarter logistics make the market more efficient?

Aron Schilller: Smarter logistics transform the market by enhancing visibility, transparency, and responsiveness across the entire supply chain. By integrating real-time tracking, predictive analytics, and automation, inefficiencies are minimised and decision-making is accelerated. This

not only reduces costs and lead times but also enables businesses to adapt quickly to market fluctuations, ensuring products reach customers faster and more reliably.

GSC: CIMC Tianda Intralogistics is leveraging AI-driven logistics solutions to streamline storage, ensuring efficient international trade. Can you tell us more about this?

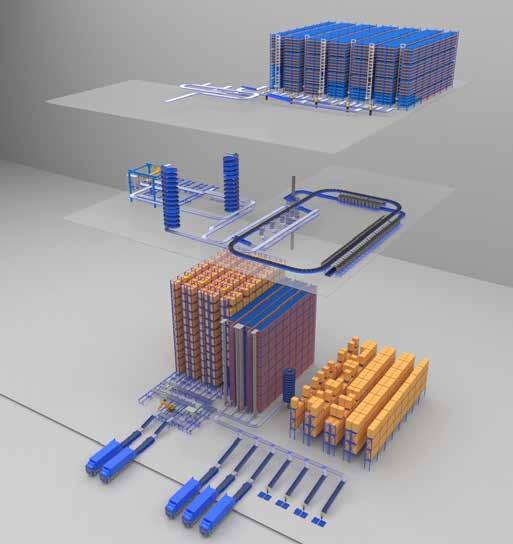

AS: Absolutely. At CIMC Tianda Intralogistics, we deploy advanced AI algorithms to analyse inventory patterns, forecast demand, and optimise storage allocation. Our “AI+WMS” system enables end-to-end warehouse automation through an “AIoT real-time perception + intelligent decisionmaking” framework. This includes dynamic path optimisation, intelligent task allocation, and real-time inventory alerts.

“Smarter logistics transform the market by enhancing visibility, transparency, and responsiveness across the entire supply chain.”

Aron Schiller Director CIMC Tianda

GSC: Can you share some of CIMC Tianda Intralogistics’s future industry trends?

AS: We foresee continued growth in automation, with robotics and AI becoming even more integrated into daily operations. Digital twins, virtual simulations, and advanced IoT sensors will provide unprecedented real-time insight into logistics networks. Sustainability initiatives—such as green warehousing and energy-efficient transport—will also become central, as the industry prioritises environmental responsibility alongside operational excellence.

GSC: What are some of the benefits of automated warehousing and intelligent tracking?

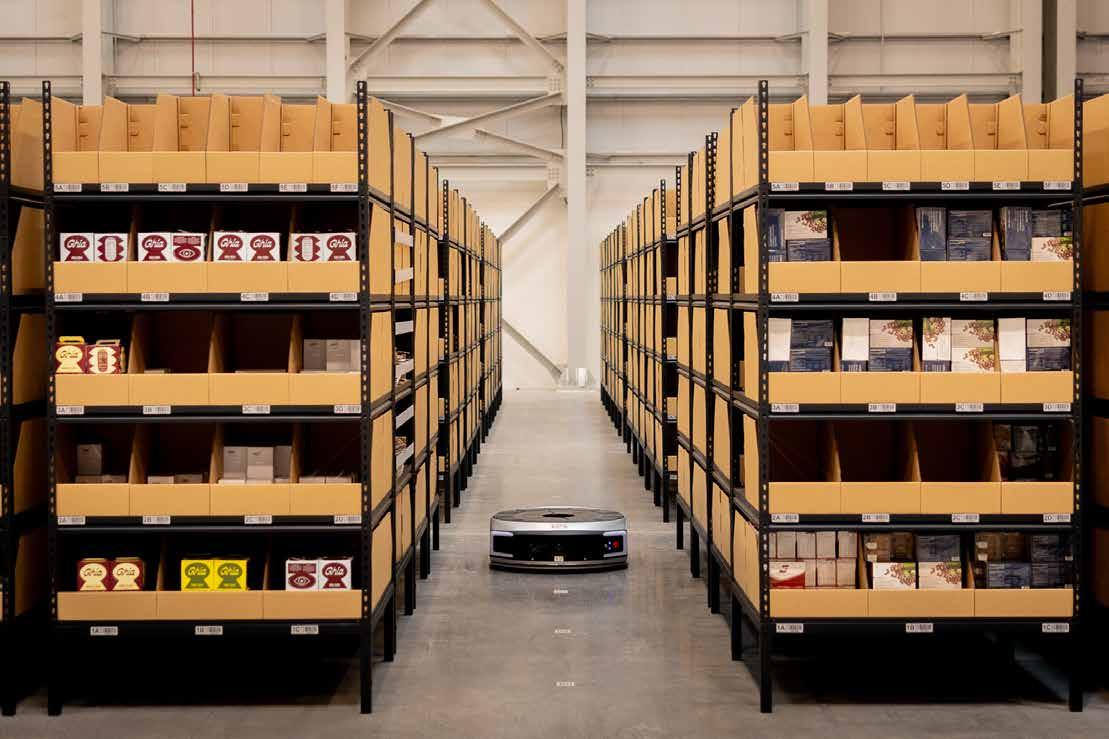

AS: Automated warehousing increases accuracy, reduces labour costs, and enhances safety by minimising manual handling. Intelligent tracking, powered by IoT and AI, offers end-to-end visibility, enabling proactive issue resolution, inventory optimisation, and improved customer satisfaction. Together, these technologies lead to faster turnaround times and a more resilient supply chain.

GSC: How does CIMC Tianda Intralogistics perceive optimising warehouses with the best automation?

AS: We view warehouse automation and air cargo handling systems as a strategic imperative. By incorporating advanced robotics, automated storage and retrieval systems (AS/RS), and AI-powered management platforms, we create highly flexible and scalable environments. Our approach is tailored to each client’s unique requirements, ensuring optimal throughput, space utilisation, and cost efficiency.

“With advanced robotics, AI-powered platforms, and intelligent storage, we engineer automation that adapts to every industry and every square metre.”

“We believe in a collaborative approach, where AI augments human capabilities rather than replacing them.”

GSC: How can CIMC Tianda Intralogistics help overcome the shortage of space for warehouses especially in the UAE?

AS: The UAE’s logistics sector faces spatial constraints due to rapid growth and regional growth of surrounding competitors in the logistics sector. We aim to address this by working hand-inhand with our customers, designing high capacity and high performing automated solutions that maximise the logistic challenges faced in the country. Modular storage solutions and dynamic slotting algorithms ensure every square metre is used efficiently. Additionally, our systems enable faster goods turnover, reducing the need for excess inventory storage.

GSC: How does CIMC Tianda Intralogistics ensure seamless integration between AI and human workers in automated warehouses?

AS: We believe in a collaborative approach, where AI augments human capabilities rather than replacing them. Our systems are designed for intuitive human-machine interaction, offering user-friendly interfaces and real-time decision support. Comprehensive training and change management programs

ensure our teams are empowered to leverage automation effectively, fostering a culture of continuous improvement.

GSC: What role does predictive analytics play in optimising warehouse operations?

AS: Predictive analytics is at the core of our operational strategy. By analysing historical and real-time data, we can anticipate demand fluctuations, identify maintenance needs, and prevent stockouts or overstocking. This proactive approach minimises downtime, reduces operational costs, and ensures that resources are allocated where they’re needed most.

GSC: How is CIMC Tianda Intralogistics adapting warehouse automation for different industries (e.g., retail, pharmaceuticals, or heavy manufacturing)?

AS: Each industry has unique requirements. For retail, we focus on high-speed order fulfillment and returns management. In pharmaceuticals, our solutions prioritise traceability, regulatory compliance, and climate-controlled storage. For heavy manufacturing, we offer robust systems capable of handling large, heavy components. Our modular platforms allow

for industry-specific customisation, ensuring optimal performance regardless of sector.

GSC: What strategies does CIMC Tianda Intralogistics use to manage data security in IoT-enabled warehouses?

AS: Data security is critical in warehouse management, especially in IoT-enabled environments. ClMC Tianda Intralogistics has developed a comprehensive security framework that protects warehouse data throughout its entire lifecycle, covering data access, transmission, storage, and device security. At the data access layer, role-based access control (RBAC) is fully implemented to restrict unauthorised operations. At the data transmission layer, communication channels are encrypted using protocols such as TLS/SSL and MQTT over TLS to prevent data interception. For data storage, AES encryption ensures data integrity and protection against tampering, while data minimisation principles and anonymisation/desensitisation techniques are applied to protect sensitive information. Additionally, at the device security level, a secure OTA firmware update mechanism is in place to automatically patch vulnerabilities and verify firmware integrity. Security modules are also embedded at the hardware level to defend against physical attacks.

The 7 best material-handling companies for modern supply chains

Even if your throughput return on investment and lead times are great, there is always room for improvement. Material-handling systems suppliers can help companies optimise, regardless of whether they need spare parts or a system rebuild.

If you want the best results, not just any business will do. The best materialhandling companies will use their extensive expertise, cutting-edge technologies and in-depth knowledge to meet a company’s facility-specific needs.

1. Solutions in Action LLC

Solutions in Action is among the best material-handling companies. It specialises in tailored material handling and automation solutions for manufacturing and distribution facilities. A company’s project manager oversees everything from conceptualisation to installation. They even visit sites to tailor products more effectively and ensure a seamless transition.

Its optional multi-phased approach can make the implementation investment more digestible and reduce disruption to daily operations.

Whether you need spare parts, preventive maintenance or a multimillion-dollar machine, SIA can help. It can integrate new equipment into existing systems or refurbish old machines, even if other vendors made them. Even though every solution is custom-built, it combines indepth industry knowledge and experienced technicians to minimise downtime.

2. Material Handling & Storage Inc.

The family-owned and operated firm Material Handling & Storage primarily serves the West and Southwest United States, with branches in California and Arizona. Its core services include facility design, consulting and equipment installation for warehouses, manufacturers and distributors.

It can provide high-density shelving, structural mezzanines, in-plant modular offices and automated storage solutions. Its turnkey process involves permit submission and structural engineering, freeing up

your time. The team analyses a company’s operations before implementation to address business-specific material-handling inefficiencies.

3. Daifuku Co.

Japan-based Daifuku is a global materialhandling equipment supplier with over 11,000 employees. Its core services include consulting, engineering, design, production, installation and post-sales support for automated storage, transport, sorting, picking and control systems. It primarily serves automakers, warehouses, electronics manufacturers and distributors.

Like its competitors, it offers custom solutions. For instance, it can tailor its sorting and picking systems for your load profile and shipping frequency. In addition to hardware, it can create, integrate, and service information and communications technology and warehouse management software.

4. Dematic

Dematic can replace, rebuild or modernise existing machinery to increase uptime. It specialises in transport, storage, picking and shipping hardware. Its services can extend

to training and troubleshooting technical issues if additional help is required — its life cycle support framework provides longterm assistance.

Since it has over 100,000 replacement parts from original equipment manufacturers, one does not have to worry about products being on back order.

There are three service tiers. The first includes 24/7 remote support, basic training and discounted field assistance at a fixed price. Tier 2 offers a guaranteed 98% uptime, on-site maintenance, and continuous diagnostics and mitigation. The third and final one has all of those features, plus parts discounts and an extended warranty at a fixed cost based on throughput.

5. U.S. Materials Handling Corp.

In around seven decades, U.S. Materials Handling grew from a two-person office into a multimillion-dollar corporation. Its large selection of new and used equipment includes scissor lifts, cranes, floor scrubbers, people movers and forklift trucks for purchase and rent. Since it is an authorized HELI dealer, it carries models in all classes. Its spare parts inventory covers materialhandling equipment of all makes and models, ranging from attachments to filters. The team will help customers locate specific components quickly, minimising downtime. If a more hands-on approach is preferred, the service department provides on-site repairs, planned maintenance and technical assistance.

6. Swisslog

Established in 1900, Swisslog has amassed over 3,000 employees who have completed 2,500 projects worldwide. It provides comprehensive project support from conceptualisation to realisation, developing a strategy based on a client’s needs. Its material handling services cover consulting, implementation and ongoing technical support.

Its retail industry expertise covers apparel, general merchandise, e-commerce, grocery, and food and beverage.

In addition to an inventory of 120,000 replacement parts, it offers custom design services for transport, storage and picking. This includes pallets, palletizers, shuttles, robots and software. Whether you need to modernize a machine or enhance equipment efficiency, you can rely on its range of managed services.

7. Bastian solutions

Bastian Solutions has grown from a small Midwest business into a global corporation with 20 offices in the U.S. and multiple abroad. Its specialty is material-handling equipment — both simple and highly automated systems. However, it also offers warehouse design, hands-on training and dedicated support services.

The material handling and software customer support teams are available around the clock. Prompt feedback helps decrease unplanned downtime.

Independent consultants and engineers will guide customers through the consultation, design and implementation processes to make sure their voice is heard. They travel to one’s facility to ensure their plan aligns with their operations, optimising where they can. Material-handling support includes spare parts, warranty replacements and preventive maintenance.

Why are these material-handling companies the best?

Modern supply chains must move fast to outpace demand fluctuations and delays. These seven companies were selected because they can match your pace. They have extensive parts inventories and vast manufacturing facilities, providing unparalleled lead times. Several on this list have a global reach, enabling them to maintain sourcing flexibility in unprecedented times.

Any business in this industry can provide spare parts and sell storage automation solutions, but only a handful have impressive portfolios and are equipped to meet one’s every need.

Those who conduct on-site visits to tailor their products to your floor plan and budget constraints are forward thinkers. The more their material-handling machines align with your facility-specific needs, the faster one’s supply chain moves. They reduce downtime further by troubleshooting technical issues, conducting preventive maintenance and supplying replacement parts.

Choosing between material-handling systems suppliers

Selecting the best material-handling companies comes down to service offerings. Pick the firm that aligns best with your needs — those providing tailored solutions are ideal. One should also consider pricing and location, which can impact budgets and lead times.

Saudia Cargo and ASL Aviation Holdings bolster global logistics with two A330-300 freighters

Saudia Cargo, a leading global cargo carrier, announced the addition of an Airbus A330-300P2F cargo aircraft, MSN 1272, to their fleet under a wet lease agreement with ASL Aviation Holdings, a global aviation services company. This strategic expansion underscores both companies’ commitment to strengthening global air cargo capabilities and connectivity.

The aircraft arrived at Shannon Airport (SNN) in mid-June following P2F conversion, where it was painted in the Saudia cargo livery. Formerly registered as N810CM the aircraft will operate for ASL Airlines Ireland as EI-LKD.

This is the first of two aircraft under this wet lease agreement. The initial A330300P2F is expected to begin service with ASL Airlines Ireland in September 2025 before being delivered to Saudia Cargo in the fourth quarter. The second aircraft is also scheduled to arrive in Q4. This ACMI (Aircraft, Crew, Maintenance, and Insurance) lease agreement includes comprehensive operational support, such as dedicated crews, a robust maintenance program, and insurance.

The introduction of this aircraft marks the return of the A330F type to ASL Airlines Ireland’s operated fleet. The aircraft will join the airline’s global fleet, providing air cargo services on an extensive network of more than 50 regular destinations across Europe, North America, and Asia, supported by a fleet of 40 aircraft.

The A330-300P2F will complement ASL Airlines Ireland’s existing fleet of B737 and ATR72 freighters, offering cost-efficient new opportunities to air cargo customers in

global markets. With its capability to move both express parcels and larger cargo, the aircraft can cover distances of up to 6,850 kilometers (3,700 nautical miles) and carry up to 62 tonnes (115,808 pounds) of revenue payload, with 26 pallets available on the main deck and a further 11 pallets (32 LD3) available in the lower hold.

Eng.Loay Mashabi, CEO and Managing Director of Saudia Cargo, said: “Expanding our capacity and global reach is a strategic imperative for Saudia Cargo, ensuring uninterrupted supply chains for our customers. The integration of this A330300P2F, in partnership with ASL Aviation Holdings, will significantly support our network capabilities, enabling us to connect markets with greater agility and efficiency. This pivotal addition directly supports our vision to solidify our position as a leading global air cargo carrier and solidifies the Kingdom’s role as a global logistics hub.”

Dave Andrew, Chief Executive of ASL Aviation Holdings, added, “We are delighted to partner with Saudia Cargo to welcome an A330-300P2F to the ASL fleet. This partnership is a positive statement for ASL as we continue to strengthen and grow. The new A330300P2F aircraft is ideal for Saudia Cargo’s express shipping and e-commerce services, providing a flexible solution to meet the diverse shipping needs of its customers and deliver reliable, high-quality cargo services.”

Saudia Cargo stands as a leading national cargo carrier, headquartered in the Kingdom of Saudi Arabia. Leveraging the strategic advantage of the country’s location, it serves as a highly efficient aerial bridge connecting the East and the West, seamlessly bridging

continents. Its extensive reach encompasses approximately 100 airport destinations and 250 customer destinations across four continents, establishing us as a pivotal player in the global air cargo industry.

With a legacy spanning over seven decades and a commitment to a ‘humanfirst’ approach, Saudia Cargo has consistently upheld its esteemed reputation as one of the world’s most dynamic cargo carriers.

ASL Aviation Holdings, a global aviation services company with five airlines is based in Europe and Australia and three associate and joint-venture airlines in South Africa and Asia. ASL is a world leader in ACMI airline operations, and both scheduled and charter cargo and passenger services.

Headquartered in Dublin, Ireland, ASL’s airlines include ASL Airlines Ireland, ASL Airlines Belgium, ASL Airlines France and ASL Airlines United Kingdom in Europe and ASL Airlines Australia, formerly known as Pionair.

ASL also has an associate low-cost passenger airline, FlySafair, in South Africa and joint venture cargo airlines K-Mile Asia in Thailand and Quikjet Airlines in India.

ASL Aviation Holdings airlines operate cargo services for the world’s leading express parcel integrators and eCommerce retailers. Group airlines also operate scheduled and charter cargo and services under its own airline brands on domestic, international, and intercontinental routes in Europe, Asia, the Middle East, North America and Africa.

ASL has a global team of 3,000 people of 51 nationalities. The Group has a fleet of 150 aircraft that includes seven aircraft types ranging from the turbo-prop ATR 72 to the Boeing 747.

Emirates SkyCargo becomes first regional airline to partner with PayCargo, bringing digital payment solutions to the UAE

PayCargo, a trusted logistics payment platform, has officially launched in the United Arab Emirates, with Emirates SkyCargo, the first carrier in the region to adopt PayCargo’s solution. This new collaboration simplifies the cargo payment process, providing customers with a seamless, efficient, and digital payment solution.

PayCargo offers an online payment solution that connects carriers with freight forwarders and vendors on a single platform. The launch in the UAE marks a shift in the cargo industry, which still relies on traditional and often inefficient payment systems, including cash transactions. Through the integration with PayCargo, Emirates SkyCargo customers in the UAE can now make instant payments via credit card or direct debit, ensuring same-day or nextbusiness-day cargo release, underscoring the airline’s commitment to implementing digital solutions that improve operational efficiency and enhance customer service.

Badr Abbas, Divisional Senior Vice President, Emirates SkyCargo, said, “The next era of logistics, and of Emirates SkyCargo,

will be defined by smart technology and digital solutions. This partnership with PayCargo ensures we are at the forefront of that evolution, providing faster and more secure transactions for our customers, streamlining processes for our internal teams, and solving industry-wide challenges of accessing air freight capacity.”

Eduardo Del Riego, President and CEO of PayCargo, said, “We’re thrilled to launch in the UAE with Emirates SkyCargo as our first regional partner. This solution will help streamline the cargo payment process and save customers valuable time. By eliminating manual payment systems, we can provide a more efficient and reliable solution. We look forward to our continued collaboration with Emirates SkyCargo as they lead the way in digital solutions for the logistics industry.”

The collaboration follows a strategic alliance formed in 2022 between PayCargo and Seed Group, a company of the Private Office of Sheikh Saeed bin Ahmed Al Maktoum. Seed Group played a key role in introducing PayCargo to the UAE market and supporting its expansion in the Middle East and North Africa. Already a central hub of trade, the UAE has strategically invested in multi-modal infrastructure, digital and technology acceleration, and forwardlooking policies to cement its role as a leading global logistics hub. The launch of PayCargo in the UAE, with the world’s largest international airline as a partner, will lay the foundation for increased resilience in logistics, underpinned by world-class digital infrastructure.

In partnership with EKSC, PayCargo expands to the UAE.

ASMO launches procurement services and begins operations at second warehouse in Saudi Arabia

● Strengthening national supply chain capability through integrated procurement and logistics operations

● Advancing a scalable supply chain model aligned with Aramco’s priorities and Vision 2030

ASMO, a joint venture between Saudi Aramco Development Company and DHL, has commenced its procurement services for general supply materials, issuing its first purchase orders for Aramco in July, 2025, and launching warehousing operations at its second site in Saudi Arabia: the Jazan warehouse. These milestones are part of ASMO’s phased national rollout under its 15-year strategic agreement with its anchor customer, Aramco, and support Saudi Arabia’s Vision 2030 agenda by localising supply chains and strengthening the Kingdom’s logistics infrastructure.

“With the start of procurement services for general supply materials and the transition of Jazan warehousing operations to ASMO, we’re laying the foundation for a new era to transform and revolutionise supply chains, not only for Aramco but also for the Kingdom and broader region,” said Sulaiman M. Al Rubaian, SVP of Procurement & Supply Chain Management at Aramco. “It’s early days, but the momentum reflects the dedication of our joint teams and the strength of our shared vision with ASMO. ASMO aims to bring greater control, visibility, and responsiveness to our supply chain, and strengthen our ability to plan, source, and operate more efficiently. As ASMO continues to scale, it intends to play a key role in

supporting our operational priorities and national supply chain goals.”

Phased approach

ASMO is adopting a phased approach to its procurement rollout, extending through 2027 and aligned with customer operations. It begins with General Supply, followed by MRO, Drilling & Chemicals, and Projects materials. This structured approach ensures scalability and supports evolving operational priorities across the supply chain.

In parallel, ASMO has begun operating the Jazan warehouse, an Aramco owned facility, located within the Jazan Refinery Complex. Now under ASMO management, the facility supports Aramco downstream, fire protection, distribution, and terminal operations. The transition is aimed to strengthen supply chain resilience, enhance operational efficiency, and improve responsiveness to customer demand of critical MRO inventory items.

“Delivering on procurement and logistics for Aramco is a responsibility we approach with focus and intent,” said Craig Roberts, CEO of ASMO. “These are foundational steps, building trust, generating measurable value, and setting the stage to scale an integrated supply chain model across the Kingdom. This progress reflects the dedication of our growing team and the strong coordination

with Aramco through the ASMO Transition & Oversight team, whose structured approach has been key to a successful rollout.”

ASMO’s model is designed to integrate procurement, warehousing, inventory management, and logistics into a unified digital platform. While currently being rolled out in phases, this system will ultimately improve visibility, simplify decision-making, and unlock economies of scale. Built to serve Aramco and a broader base of industrial customers, including in energy, chemicals, healthcare, and aviation, it also supports localization, supplier development and broader national goals.

Since the announcement of its establishment in 2024, ASMO has signed 26 MoUs with strategic partners, launched operations in Riyadh and Jazan, and commenced procurement services for general supply materials. Early development efforts are also underway for future facilities in SPARK, Jubail, and Yanbu, alongside plans to scale its digital procurement platform into a full B2B e-marketplace.

Looking ahead, ASMO aims to operate more than 8 million square meters of warehousing, manage over 500,000 inventory items, and oversee procurement activity valued at over USD 8 billion by 2030, positioning both ASMO and Saudi Arabia at the centre of a modern, resilient, and globally competitive supply chain network.

Picking small parts manually is a time consuming process — but a smart picking robot changes that.

Make that perfect pick every time with SSI Piece Picking. A solution that delivers accuracy and consistency, even with delicate pharmaceutical products and luxury cosmetics and fragrances.

Automate your picking process today.

LEARN MORE

Enhance Your Picking Efficiency

> 99% picking accuracy

Increased throughput and efficiency

Seamless WMS integration

Scalable for peak demands

Optimize labor costs and resourcing

GWC and Qatar Airways extend partnership with a landmark logistics agreement

In a major milestone for Qatar’s aviation and logistics sectors, GWC and Qatar Airways has officially renewed their long-standing partnership through the signing of a five-year service agreement. The highprofile signing ceremony, held in Doha, underscores both organisations’ shared commitment to operational excellence, innovation, and delivering world-class standards on a global scale.

As one of the world’s most awarded and respected airlines, Qatar Airways consistently sets the benchmark for aviation excellence. Known for its unwavering commitment to service, safety, and innovation, the airline has earned multiple “Airline of the Year” accolades and continues to expand its global footprint from its hub at the world-class Hamad International Airport.

For over a decade, GWC has proudly served as the logistics service provider for this prestigious airline and its key affiliates – including MATAR, and Qatar Duty Free. The airline’s success on the global stage is powered not only by its premium passenger experience, but also by the seamless, behind-the-scenes logistics operations that enable it to thrive.

GWC Group Managing Director, H.E. Sheikh Abdulla Bin Fahad Bin Jassim Bin Jabor Al Thani, said: “This renewed agreement with Qatar Airways reflects the strength of Qatar national institutions working together to achieve excellence on a global stage. At GWC, we are proud to support the operations of the World’s Best

Airline with world-class logistics solutions rooted in innovation, efficiency, and reliability. Our long-standing partnership with Qatar Airways is a testament to our shared values and our unwavering commitment to Qatar’s continued progress and global connectivity.”

Qatar Airways Group Chief Executive Officer, Engr. Badr Mohammed Al-Meer, said: “We are pleased to renew our long-standing partnership with GWC. This agreement strengthens our operational capabilities and supports our continued global growth. By working together, we remain committed to delivering world-class services across a broad range of functions, guided by our shared pursuit of excellence.”

A logistics landmark

GWC stands at the forefront of Qatar’s logistics industry, delivering integrated, end-to-end supply chain solutions across diverse sectors including aviation, oil and gas, healthcare, retail, and e-commerce. As the Official Logistics Provider for the FIFA World Cup Qatar 2022™, GWC has consistently demonstrated world-class

execution, innovation, and scale. With a robust infrastructure network, a reputation for operational excellence, and a deep commitment to supporting Qatar’s National Vision, GWC continues to be the logistics partner of choice for many of the world’s most respected institutions.

GWC Chief Commercial Officer, Syed Maaz, said: “This partnership reflects the very best of Qatari ambition and capability. To serve a world-renowned airline like Qatar Airways is a responsibility we take immense pride in. This renewed agreement is not only an extension of services – it’s a renewed promise to uphold the gold standard of logistics that supports a globally admired aviation brand, every day.”

Under the newly signed agreement, GWC will continue delivering a full spectrum of integrated logistics services including import/export handling, customs clearance, warehousing and distribution, inventory management, document storage, and other value-added solutions. These services will ensure seamless, end-to-end support for Qatar Airways’ operations on the ground, mirroring its excellence in the skies.

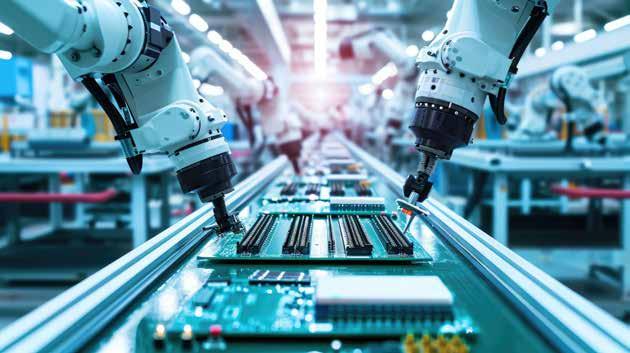

DHL deploys 1,000+ additional robots across UK operations to support e-commerce growth and life sciences health care sector

● Investment aligns with DHL Group’s Strategy 2030, reinforcing the UK’s pivotal role in resilient global trade and cross-border logistics

● Announcement comes as UK launches new Trade Strategy to boost competitiveness and global market access for British businesses

● Company leads innovation with first deployment of Boston Dynamics’ Stretch Robots in the UK

By Abigail Mathias

DHL Supply Chain recently announced the investment of £550m (Dhs 2,724m) to expand its infrastructure and accelerate the rollout of automation across its customer operations in UK and Ireland (UK and I), to support growing demand in the e-commerce and life sciences health care sectors.

The new investment builds on the €1bn already spent on automation by DHL Supply Chain over the last three years, with more than 3,200 digitalisation projects deployed across the UK & Ireland and EMEA. Until 2030, DHL’s contract logistics business plans

to significantly increase its scale in UK&I as well as globally, with automation, robotics and digitalisation being a key enabler of this growth.

Saul Resnick, CEO DHL Supply Chain UK & Ireland says, “Our investment reflects the growing opportunities across the UK market. Customers are increasingly recognising the benefits of digitalisation and, to date this year, we’ve already surpassed the number of deployments achieved last year. What’s more, the integration of robotics and automation in customer operations is becoming more

sophisticated, so customers are seeing greater benefits and faster ROI.

“This momentum is only possible with the right infrastructure and expertise in place, tailored to support high-growth industries like e-commerce and healthcare. That’s why we’re investing for long-term impact, ensuring we are the go-to supply chain provider. The UK’s new Trade Strategy reinforces this direction by supporting fast-growing sectors and enhancing access to global markets –priorities that closely align with our investment focus and customer needs.”

Through strategic partnerships with technology companies, DHL is intensifying its commitment to go beyond classical vendor relationships to emphasise codeveloping, testing, and scaling robotics solutions with leading innovators. This strategy has already resulted in more than 2,000 robots working collaboratively alongside its associates in the UK, Ireland and EMEA region. More than 750 Assisted Picking Robots from its strategic partners Locus Robotics and 6 River Systems are live across 18 sites in the region and DHL recently deployed the first Boston Dynamics Stretch Robot for container unloading in the UK.

Global Supply Chain was invited to witness operations. The Stretch robots have the ability to unload up to 700 boxes per hour, significantly reducing physical strain on warehouse colleagues and enhancing productivity in fast turnaround environments such as e-commerce. With a 16-hour battery life, the robots need only an hour to charge, there by increasing efficiency.

Health Logistics facility

Further supporting DHL Group’s Strategy 2030, DHL will open a new DHL Health Logistics facility in Derby. The facility has been designed to support growth in the life sciences and healthcare sector, which is projected to experience double digit growth in the UK over the next five years, driving demand for specialist logistics capabilities. Each site will feature cold chain and cleanroom facilities and will play a pivotal role in the wider DHL Health Logistics network, globally.

The investment plan reinforces the role of the UK as one of DHL Supply Chain’s largest and most strategically significant regions. With long-standing trade and supply chain expertise, the UK has proven to be a resilient and adaptable logistics hub and plays a key role in global commerce as trade patterns continue to shift.

The announcement comes as the UK Government sets out its first Trade Strategy since leaving the EU – a timely backdrop that reflects a shared emphasis on strengthening global trade networks and supporting high-growth sectors,

while aiming to unlock £5billion in new opportunities for British businesses. As the UK looks to strengthen its position as a global trade leader, DHL’s continued investment in automation and infrastructure in the UK and Ireland aligns with the strategy’s focus on high-growth sectors and resilient, future-ready supply chains.

Tim Tetzlaff, Global Head of Digital Transformation, DHL Supply Chain, says, “At DHL, we’re driving the next wave of automation, not as a one-size-fits-all approach but as a set of intelligent, adaptive technologies tailored to the specific needs of individual sectors. For e-commerce, for example, where the market is evolving and demand is growing, we’re expanding our fulfilment capabilities to support that shift with automated solutions that significantly simplify high-volume operations. Meanwhile, in the growing life sciences sector, we’re leveraging automation to respond faster to demand and manage complexity at scale with end-to-end visibility, amid a larger focus on patientcentric approaches and differentiated routes to market.”

DHL spotlights top AI and social media trends in the UAE

The

DHL

E-Commerce Trends Report 2025

The E-Commerce Trends Report 2025 surveyed 24,000 consumers from Europe, the Americas, AsiaPacific, Africa, and the Middle East. Its findings offer actionable insights for e-commerce brands seeking to meet changing expectations, personalize experiences, and create growth through smarter logistics and innovation.

● 96% of UAE consumers expect to shop primarily through social media by 2030, bypassing traditional websites entirely

● 89% want AI-driven shopping tools — from virtual try-ons to voice search — to guide their decisions

Social commerce is rapidly becoming the new e-commerce as a vast majority of UAE consumers (86%) say they have already made a purchase via social media, and 96% expect these platforms to become their primary shopping destination by 2030. This is according to the findings of DHL’s E-Commerce Trends Report 2025, which draws on insights from 24,000 online shoppers across 24 key global markets, including the UAE.

The report underscores how the traditional e-commerce website is increasingly being replaced — or bypassed — by social platforms as consumers are turning to apps like TikTok, Instagram, and Facebook not just for discovery, but for purchase. The power of influence also plays a critical role, as 93% of shoppers in the UAE say viral trends and social buzz influence their buying decisions. Facebook and Instagram, in particular, are driving change in the UAE, where 69% and 68% of online shoppers report buying through the app. This shift signals a major transformation in how and where brands need to engage with their audiences, and calls for seamless, mobile-native experiences built for in-app conversion.

“Our E-Commerce Trends Report underscores how UAE shoppers are becoming far more discerning as they increasingly rely on devices to make purchases. To succeed in today’s competitive e-commerce market, online retailers need to understand how they can attract a diverse mix of shoppers and turn these browsers into repeat buyers. The rise of the environmentally-conscious shopper also marks a transformational shift in buying behavior – one that retailers should not take lightly,” states Samer Kaissi, CEO of Gulf Cluster and UAE Country Manager at DHL Global Forwarding Middle East and Africa. Delivery remains the No. 1 conversion

killer and the biggest drivers of cart abandonment, with 84% of consumers in the UAE saying they would abandon their purchase if their preferred delivery option is not available. Just as critically, 85% will leave if the return process doesn’t match their expectations. Trust also plays a major role, with 67% of shoppers in the UAE reporting that they will not buy from a retailer if they don’t trust the delivery and returns provider. A vast majority (82%) also now consider sustainability when making online purchases and 42% have actively abandoned their carts due to sustainability concerns. These expectations emphasize the importance of transparent, customercentric logistics strategies — not just as an operational concern, but as a core part of the conversion funnel.

Virtual try-ons

One of the most highly anticipated and demanded innovations among consumers is virtual try-ons, AI-powered shopping assistants, and voice-enabled product search. Shopping via voice commands is already on the rise, with 59% shoppers in the UAE making purchases handsfree. Additionally, 68% of shoppers in the UAE express willingness to participate in recycling or buy-back programs offered by retailers. These behaviors point to a growing expectation that brands will not only reduce their footprint, but actively empower consumers to shop more sustainably. DHL’s insights provide a clear roadmap for retailers aiming to capture the attention of today’s diverse shopper demographics. By embracing technology, prioritizing sustainability, and understanding the evolving preferences of consumers, businesses can transform challenges into opportunities.

Samer Kaissi, CEO of Gulf Cluster and UAE Country Manager at DHL Global Forwarding Middle East and Africa.

JD.com opens new warehouse in the UAE

JAFZA project brings total number of warehouses in the country to six

JD.com, also known as JINGDONG, a technology and service enterprise with supply chain at its core, announced the opening of its new warehouse in Dubai. The official opening took place on August 8 this year. The facility represents JD.com’s first asset investment in the country, made through its infrastructure investment and management platform, JINGDONG Property, and is operated by JINGDONG Logistics.

Text: Located in Dubai’s Jebel Ali Free Zone (JAFZA), the warehouse has a floor area of over 10,000 square meters and brings JINGDONG Logistics’ total number of warehouses in the UAE to six. It adopts a digital operations model, powered by real-time inventory management, optimising performance and traceability. The warehouse, which is already providing storage for nearly 1 million items for a major electronics manufacturer, consistently achieves an outbound ‘in-time’ rate exceeding 99.9%.

JINGDONG Logistics’ supply chain service, JoyLogistics’ solution supports a tailored approach that improves space utility and inventory control, while helping customers manage seasonal fluctuations and categoryspecific complexities more effectively.

JD.com has evolved from a pioneering e-commerce platform into a leading technology and service provider with supply chain at its core. JD.com, Inc.’s business has expanded across retail, technology, logistics, health, property development, industrials, private label, insurance and international business. Ranking 44 on the Fortune Global 500, JD.com, Inc. is China’s largest retailer by revenue.

This new warehouse is the next step of JD.com’s strategy to build its logistics business across the UAE, Saudi Arabia, and Turkey, enhancing inter-market movement and operational synergies. JINGDONG Property is actively scaling its presence in the region, including plans for a 70,000 sqm smart logistics hub in Abu Dhabi in partnership with Abu Dhabi Airports Free Zone (ADAFZ). JoyLogistics offers end-to-end logistics services, integrating

international freight (sea, air, express) with last-mile delivery and bonded warehousing, supporting seamless B2B and B2C operations in the Middle East.

Feng Guo, General Manager of Middle East, JD.com, said: “The investment marks a strategic milestone in our long-term investment and growth in the Middle East, enhancing the existing operational footprint to support greater regional scalability and trade. We are investing not just in physical infrastructure, but in the long-term digital transformation of the region’s logistics landscape, empowering cross-border trade and supply chain transformation.”

Charlie Peng, Head of Middle East at JINGDONG Logistics, said: “JD.com brings nearly two decades of global supply chain experience. We are renowned for speedy, trustworthy and tech-driven solutions, with a strong track record in building smart logistics ecosystems across e-commerce, electronics, FMCG, apparel, and automotive sectors. Dubai’s location at the crossroads of Asia, Africa, and Europe, combined with JAFZA’s status as a tax-free zone, makes our warehouses an ideal choice to

serve multinational corporations seeking to expand or optimise their presence in the Middle East and beyond.”

JD Logistics, is a leading technologydriven supply chain solutions and logistics services provider. JINGDONG Logistics has established six highly synergized logistics networks including warehousing, linehaul transportation, last-mile delivery network, bulky items, cold chain logistics, and cross-border logistics networks. As of December 31, 2024, including cloud warehouses operated by third parties, JINGDONG Logistics manages over 3,600 warehouses, with a total area exceeding 32 million square meters. JINGDONG Logistics has strategically built a Global Smart Supply Chain Network, featuring highly automated warehousing systems and reliable international transportation solutions.

The company currently operates over 100 bonded, direct mail and overseas warehouses, with a total GFA exceeding 1 million square meters, spanning 19 countries and regions worldwide.

“JoyLogistics” and “JoyExpress” are JINGDONG Logistics’ international business brands.

AJEX Logistics Services expands B2C delivery services across Qatar, Oman and Kuwait

AJEX Logistics Services, the Middle East specialist in e-commerce distribution and logistics solutions, has announced the expansion of its B2C Full Mile and Last Mile delivery services to Qatar, Oman, and Kuwait. The company’s ongoing expansion marks the latest milestone in its mission to provide seamless, end-to-end e-commerce logistics across the region.

In response to rising demand, AJEX is now offering a single one-stop-shop for all B2C deliveries across the GCC, providing businesses with convenient, tech-enabled delivery solutions. Customers across the newly added AJEX network in Qatar, Oman, and Kuwait will now benefit from services including cross-border fulfilment, customs clearance, cash-on-delivery (COD), returns, and insurance, tailored to local

The Saudi headquartered logistics company now offers its Full Mile and Last Mile B2C Services across all GCC markets

market needs. Designed to ensure service excellence, all AJEX parcel deliveries are supported by real-time tracking for full visibility and control.

E-commerce adoption continues to accelerate across the Middle East, driven by rising digital connectivity, shifting consumer expectations, and strong investment in both digital and logistics infrastructure. According to recent market research, e-commerce sales are projected to grow approximately 11% annually from 2023 to 2027 across the Gulf region, reaching $49.78 billion by 2027, with emerging markets like Kuwait, Oman, and Qatar, and key sectors such as fashion, groceries, and healthcare, anticipated to be major contributors.

With its latest expansion, AJEX is fast becoming the preferred logistics provider in the Middle East, trusted by businesses for

speed, reliability, and innovation.

“With the expansion of our B2C delivery services into Qatar, Oman, and Kuwait, AJEX is now uniquely positioned to support the entire GCC region with fast, reliable, and customer-centric e-commerce logistics,” said Mohammed Albayati, Group CEO of AJEX Logistics Services. “As online retail continues to reshape consumer habits, we remain committed to building agile and scalable logistics solutions that meet the needs of retailers and customers alike, while supporting national visions for diversification, digital growth, and regional integration.”

This latest expansion underscores strategic role of AJEX in advancing e-commerce enablement across the region—helping businesses grow, consumers connect, and economies thrive through smarter logistics.

Smarter Logistics, Stronger Future

Founded in 1979 and joining ClMC Group in 2014, we are a proud member of ClMC TlANDA and a global leader in intralogistics and material handling solutions. With 40+years of expertise and 1000+ large-scale projects, we provide customized automation system solutions for industries including 3PL, retail, express, pharmaceuticals, FMCG, petrochemicals, new energy, F&B, cold storage, and CHS.

3 Reasons to Choose CIMC TIANDA Automation Solutions

Seamless Integration: Enhance your warehouse with our automated storage systems and robotic picking solutions.

Advanced Control: Real-time monitoring and predictive analytics to optimize performance.

Scalable Solutions: Adapt to growing demands with flexible, customizable systems.

Aron.Schiller@stas.cimc.com

Linkedin: https://www.linkedin.com/in/aron-schiller/

Dubai Airshow 2025 launches future-facing conference programme to drive global aerospace innovation

Event to showcase over 350 speakers.

The UAE is gearing up for a reimagined Dubai Airshow. From 17 to 21 November 2025, the world’s most influential aerospace event returns to Dubai Airshow Site (DWC) with a dynamic new conference line-up built to spark ideas, tackle industry shifts, and accelerate progress in aviation, space, and defence.

This year’s programme brings together more than 350 expert voices, delivering over 90 hours of live content across 12 focused tracks. Spread over four interactive stages, the agenda reflects the industry’s changing priorities—looking ahead without losing sight of what matters now.

To meet the pace of transformation, the 2025 edition adds six new tracks covering smarter maintenance and turnaround strategies, digital breakthroughs in airline and airport operations, emerging challenges in cybersecurity, the latest in airport technologies, inclusive workforce development, and a dedicated “Future Flight: Powered by Women” programme, created in collaboration with the International

Aviation Women’s Association (IAWA). Dubai Airshow 2025 isn’t just built for content—it’s built for connection.

This years’ experience goes beyond the stage, with immersive technology demonstrations, high-energy startup pitches, and personal boardroomstyle discussions. The newly launched Academy Stage brings timely, relevant conversations to the heart of the show, while Vista returns to amplify the voices of emerging innovators and disruptors.

Paul Griffiths, CEO of Dubai Airports, said: “Dubai Airshow 2025 will bring together global aviation leaders at a time when our industry is redefining the way people and economies connect. As hosts of the Airport and Airline Keynotes, Dubai Airports is proud to contribute to developing a vision for a future that is built on innovation, sustainability, and new models of global connectivity. This gathering in Dubai provides a platform to chart bold ambitions and forge the partnerships that will help write the next chapter of air travel worldwide.”

For the first time, Dubai Airports will host the Airport & Airline Keynote Track, spotlighting some of the most influential leaders in global aviation. Attendees can hear from Paul Griffiths, CEO of Dubai Airports; Sir Tim Clark, President of Emirates Airline; Tony Douglas, CEO of Riyadh Air; and others as they share insight on air traffic growth, digital transformation, airport strategies, and new approaches to aviation safety.

Ivan Bassato, Chief Aviation Officer at Aeroporti di Roma, said: “The Dubai Airshow is a premier global stage for aerospace innovation, and we are proud to showcase Aeroporti di Roma’s vision in such an exceptional setting. Recognised internationally for innovation, sustainability, and operational excellence, ADR continues to lead the transformation of the aviation sector. At the heart of our presence will be Advanced Air Mobility (AAM), where our subsidiary UrbanV stands as a global leader in vertiport development. Dubai, a symbol of excellence in both airport infrastructure and airline operations, is

also emerging as a global pioneer in AAM. We are ready to contribute to this revolution, bringing our expertise in safely and efficiently integrating new forms of mobility into the urban airspace.”

The UAE Space Agency returns with a two-day Space conference, this time with a sharper focus on sustainability, security and innovation in orbit. Expect bold conversations on space advancements that’s changing how we live, work and connect - plus fresh opportunities in the growing downstream sector.

Brian Cobb, Chief Innovation Officer at Cincinnati/Northern Kentucky International Airport (CVG), said: “From the heartland of America to the flight paths around the world, Dubai Airshow is a launchpad for partnerships that fuel economic growth and transform global connectivity. We’re honoured to showcase and share CVG’s prowess in evolving passenger experience, advancing airport technologies, leveraging sustainability, and accelerating Advanced Air Mobility. CVG is leaning into the future for lasting economic goodness at global scale.”

Alongside it, a two-day sustainability

track dives into the future of greener skies- from cutting-edge aircraft and cleaner fuels to the policies that support building a net zero future for aviation.

“The Dubai Airshow 2025 conference is a vital platform for ideas and innovations that will define the next decade and beyond of aviation, space and defence,” said Timothy Hawes, Managing Director of Informa Markets. “We are proud to bring together the world’s most influential industry voices to explore the opportunities ahead, and to solidify the UAE’s leading position as a global hub for the aerospace and defence industry.”

The inaugural MRO track goes deep into fresh technology, evolving business models, and growth opportunities— giving attendees practical strategies they can apply right away.

At the Academy Stage, the spotlight turns to vital themes like cyber risk, tech innovation, and workforce inclusivity. The “NextGen Leaders” series opens the floor to students and young professionals ready to shape the next chapter of aerospace.

Advanced Air Mobility (AAM) will

take centre stage, offering a close-up look at the technologies, policies, and partnerships changing how we think about flight. Meanwhile, sessions on Passenger Experience dive into how aviation can better serve travellers— offering smoother journeys, smarter services, and stronger connections.

“The Dubai Airshow is one of the most important global stages for aviation, and Archer is thrilled to take centre stage at such a pivotal moment for our industry,” said Adam Goldstein, Founder and CEO of Archer Aviation. “Building off the flight test program we now have underway in Abu Dhabi, we look forward to flying Midnight at the event and sharing Archer’s latest updates as we continue to showcase our global leadership in shaping the future of mobility with our partners in the UAE.”

Vista, the show’s flagship innovation platform, brings together startup founders, investors, and decision-makers over four energetic days. Expect breakthrough ideas, high-impact pitches, and realtime deal-making—all designed to turn bold thinking into business results.

Noblelift names exclusive dealer for Saudi Arabia

Bakheet Machinery, a material handling equipment distributor, has recently been named as Noblelift Intelligent Equipment’s exclusive dealer for the Kingdom of Saudi Arabia.

Noblelift is a leading global manufacturer and service provider specializing in material handling equipment and logistics solutions.

The company says the dealership agreement is an important step in strengthening the company’s presence in the Saudi market will include internal combustion engine (ICE) forklifts, lithiumpowered solutions and smart technologies for warehouse management. “The collaboration aligns with the objectives of Saudi Vision 2030, supporting industrial development, enhancing supply chain efficiency, and promoting environmental sustainability,” states a Noblelift source.

Saudi Vision 2030 is a government plan to diversify the country’s economy and reduce its dependence on oil, by developing public sectors and infrastructure.

Bakheet Machinery was founded more than 50 years ago in Saudi Arabia and now also has operations in Riyadh, Abha, Jeddah, and Dammam.

Noblelift offers a wide range of forklifts designed to meet diverse industrial needs, from warehouse operations to outdoor logistics.

Forklifts play a vital role in various industries by improving the efficiency of material handling and transportation. Their ability to lift and move heavy loads safely makes them indispensable in warehouses, construction sites, manufacturing plants, and more. Understanding the different types of forklifts and their specific applications can help businesses choose the right equipment for their needs.

Safety matters

Working with forklifts requires a strong focus on safety, training, and operational awareness. Whether you’re an operator, supervisor, or safety manager. We bring you the details.

Certification: Operators must be trained and certified.

Daily inspections: Check brakes, tires, forks, and hydraulics before use.

Load limits: Never exceed the forklift’s rated capacity.

Visibility: Maintain 360° awareness and use mirrors or spotters.

Speed control: Drive slowly, especially around corners and pedestrians.

No passengers: Forklifts are not designed to carry extra riders.

Safe parking: Lower forks, set brake, and turn off engine when parked.

Common hazards

Operator error: Often due to poor training or fatigue.

Poor visibility: Can lead to collisions or pedestrian injuries.

Unstable loads: Improper stacking or overloading can cause tipping.

Environmental risks: Wet floors, uneven surfaces, or poor lighting.

Best practices

Pre-operational checks: Inspect equipment before each shift.

Pedestrian safety: Use warning signals and maintain safe distances.

Clear pathways: Keep aisles free of clutter and clearly marked.

Emergency preparedness: Know evacuation routes and first aid procedures.

Training and compliance

OSHA standards: In many regions, forklift operation is regulated by workplace safety laws.

Refresher courses: Regular training updates help maintain safety awareness. Record keeping: Document inspections, incidents, and certifications.

Our SynQ software delivers data-driven intelligence that empowers your business by synchronizing the performance of your people, processes and machines. The result is a level of efficiency and performance you never thought possible.

swisslog.com

AEDLER Logistik Solutions partners with Kardex to deliver seamless intralogistics in the UAE

As the logistics and supply chain sector in the United Arab Emirates continues to evolve at an unprecedented pace, the need for smarter, more integrated warehousing solutions has never been greater. In a strategic move to meet this demand, AEDLER Logistik Solutions has joined forces with Kardex, a global leader in automated storage and retrieval systems to enhance intralogistics efficiency across the UAE.

This collaboration is set to revolutionise intralogistics across the UAE by delivering cutting-edge, intelligent storage solutions tailored to the region’s growing logistics demands.

Smart storage for smart operations

At the core of this partnership is the introduction of cutting-edge Vertical Lift Modules (VLMs) and Vertical Carousel Modules (VCMs) - high-density, automated storage and retrieval systems designed to help operations reclaim up to 85% of floor space while significantly improving picking speed, accuracy, and productivity. Using a “goods-to-person” approach, VLMs bring the right part directly to the operator—eliminating wasted travel time and manual searching. Whether you’re managing a wide variety of part sizes or looking to streamline order picking, VLMs offer unmatched flexibility. They can be outfitted with trays that handle up to 1,000 kg each. For applications with heavier loads, lift assisting equipment can be added to a VLM as well. These systems

can be seamlessly integrated with barcode scanners, conveyors, and robotics—creating a fully automated, high-efficiency workflow.

VLMs can be used for automated product handling by integrating robots. With this automated integration, a robotic arm picks items out of the tray and distributes them accordingly. This versatility ensures that our storage solution evolves with your operation - whether you are scaling up, relocating or optimising across departments. VLMs deliver measurable results—more floor space, faster picks, and fewer errors. Whether used for production parts, or fulfillment, they provide a scalable, high-performance solution for modern material handling.

Seamless integration, local support

One of the remarkable features of this partnership is AEDLER’s ability to offer turnkey integration — from solution design and engineering to implementation, training, and after-sales service, ensuring that Kardex’s advanced technology is deployed with precision and adapted to the unique needs of companies

operating in the UAE. AEDLER’s customercentric approach ensures that every Kardex system is implemented with maximum efficiency, minimum disruption, and long-term operational value.

As the UAE doubles down on logistics as a strategic sector for its economic diversification plans, investments in automation and smart warehousing are no longer optional — they are essential. The AEDLER–Kardex partnership brings automation within reach for businesses of all sizes and sectors, offering an efficient solution to smarter, more responsive supply chains.

For companies ready to elevate their operations, improve margins, and meet rising customer expectations, VLMs and VCMs are no longer technologies of the future — they are crucial for today’s Industry.

The AEDLER–Kardex alliance is poised to make a significant impact across several key sectors in the UAE, especially those where space optimisation, inventory accuracy, and operational efficiency are critical.

Focusing on Q-Commerce

Q-Commerce, or Quick Commerce, is revolutionising the way supply chain companies operate by enhancing speed, convenience, and offering hyper-local fulfillment. HWArobotics is putting Q-Commerce to the test and showcases how it can reduce delivery costs and improves customer satisfaction.

HWArobotics is a global leader in warehouse automation solutions, specialising in advanced ASRS (Automated Storage and Retrieval Systems) shuttle technologies. With a DNA rooted in innovation, reliability, and scalability. We design systems that enable businesses to optimise intralogistics, enhance throughput, and achieve operational excellence,” explains Umer Saleem, Vice President Sales and Business Development.

“Our mission is to empower retailers, e-commerce players, and logistics providers with intelligent and futureready automation systems that integrate seamlessly with the demands of fastmoving consumer industries such as q-commerce, grocery, fashion, and general merchandise,” he adds.

The DNA of HWArobotics rests on three pillars:

• Innovation at scale – cuttingedge R&D and robotics design.

• Customer-centric solutions – tailored automation systems for diverse industries.

Case Study A –

Leading Chinese retail innovator

Background: One of China’s largest data and technology-driven retail platforms, fully integrating online, offline, and modern logistics. Known for its pioneering role in grocery-focused new retail, the company combines big data, IoT (Internet of Things), and automation to optimise the match between people, goods, and demand.

Configuration:

• Multi-level Shuttle Robot ASRS: 7 aisles (5 at 17 layers, 2 at 15 layers), height 7.5 meters, total 25,509 standard totes

• Shuttle Robots: 115

• Goods Lifts: 28

• Efficiency: Shuttle robots 110 boxes/ hour/set; Lifts 560 boxes/hour/set

• Global expertise, local commitment – proven deployments across Asia, Europe, and the Middle East.

Expansion: HWArobotics is expanding rapidly into the Middle East & North Africa (MENA), bringing world-class automation technologies to one of the fastest-growing logistics and e-commerce markets globally. Saleem is spearheading this expansion from the company’s Dubai hub. With nearly 17 years of experience advising businesses across multiple sectors, he is focused on building strategic partnerships with retailers, 3PLs, and last-mile logistics providers to meet the region’s surging demand for intralogistics automation.

Q-Commerce: A global movement

Quick commerce (q-commerce) represents the next stage of retail, where customer expectations demand groceries, essentials, and consumer products delivered in less than 30 minutes. Globally, q-commerce is witnessing double-digit annual growth, with billions invested in fulfillment infrastructure.

Case Study B –

Global fast fashion powerhouse

Background: Founded in 2008, this leading B2C Internet enterprise focuses on fast fashion, offering cost-effective products to consumers worldwide. With headquarters in China and branches in the US, Belgium, Dubai, and beyond, the company has penetrated North America, Europe, Russia, MENA, and India.

Configuration:

• Multi-level Shuttle Robot ASRS: 6 aisles, 15 layers, height 9 metres, total 28,800 standard totes

• Shuttle Robots: 90 (+1 spare)

• Goods Lifts: 24 (without layer changing)

• Throughput Peak: 12,000 boxes/hour (6,000 inbound + 6,000 outbound).

• Global market growth: Q-commerce has become a multi-billion-dollar industry, driven by urbanisation, smartphone adoption, and shifting consumer habits.

• MENA focus: The MENA region is uniquely positioned for q-commerce growth due to young demographics, high mobile penetration, and evolving consumer preferences. Countries like Saudi Arabia, the UAE, and Egypt are witnessing rapid adoption of on-demand delivery, especially in fresh groceries and FMCG (Fast Moving Consumer Goods).

Alignment with ASRS & Warehousing intralogistics

Q-commerce thrives on speed, efficiency, and precision—values that directly align with ASRS and intralogistics systems. By deploying shuttlebased warehouse automation, companies can:

• Maximise storage density in urban fulfillment centers.

• Achieve high throughput to meet delivery time guarantees.

• Integrate seamlessly with last-mile networks.

• Ensure scalability as demand grows. In MENA, this synergy is particularly critical as governments invest heavily in smart logistics, digital economies, and supply chain modernisation.

Fresh groceries & Q-commerce: Hand in hand

“Fresh groceries are at the heart of q-commerce. Consumers expect not just speed, but also quality and freshness,” adds Saleem. ASRS solutions enable:

• Temperature-controlled automation for perishable goods.

• Seamless stock rotation (FIFO) to guarantee freshness.

• Real-time inventory visibility, reducing waste and out-of-stock incidents. For grocery players, automation is no longer optional—it is essential for maintaining a competitive advantage.

“We’re only just getting started”

– Jessica Panigari, CEO, Goods2Load

The International Air Cargo Association, (TIACA) recently hosted this year’s Executive Summit in Hong Kong. The event served as a platform for the 2025 TIACA Awards, including the Hall of Fame, Inspirational Leader, Rising Star, and Sustainability Awards, each recognising outstanding achievements and emerging talent shaping the future of air cargo.

“The energy at this year’s Executive Summit reflects the optimism and innovation driving our industry forward, with focus on agile adaptation to evolving market conditions,” said Glyn Hughes, TIACA Director General. “From digital breakthroughs to sustainability strategies, this was a gathering of momentum,” he added.

Newly established Goods2Load was recognised for its contribution. Speaking exclusively to Global Supply Chain, its Founder and CEO, Jessica Panigari said, “Receiving the second prize in the StartUp/Small Business category at TIACA’s 7th Air Cargo Sustainability Awards is an incredible milestone for us. It affirms that the work we’re doing—quietly, consistently, and often behind the scenes—is now being recognised on a global stage.”

Founded in 2023, Goods2load is transforming the global logistics landscape with a bold, digital-first approach. Its cutting-edge platform redefines freight forwarding, delivering optimised solutions that turbocharge both time and cost efficiency. Panigari explains, “At Goods2Load, we focus on a segment of the logistics world that is often overlooked: small and medium-sized freight forwarders who are still working offline—representing nearly 80% of the global market. These are companies with deep operational knowhow but limited access to digital tools. Our platform gives them simplified visibility, connects them with demand, and helps transition their operations from analog to smarter, more sustainable workflows.

But our innovation goes beyond digital access. We are building a system

that enables shippers to not only move cargo efficiently but also choose greener solutions—filtered by CO₂ emissions, certifications, and sustainable route options. In doing so, we’re not just digitalising freight—we’re helping shape demand for more responsible logistics.”

A sustainable approach

“What sets us apart is our focus on tracing user behaviour. We collect real-time data on the types of solutions businesses are seeking—what filters they use, what matters most to them, whether it’s eco-certifications, speed, or multimodal flexibility. These insights allow us to nudge the market in the right direction by showing providers

what their customers actually value.

Being recognised in Hong Kong and standing alongside pioneers like Fraunhofer IML was humbling. We’re deeply grateful to TIACA, CHAMP Cargosystems and the expert jury for acknowledging the importance of empowering this “unseen” segment of global logistics—the offline professionals who quietly keep trade moving every day.

“This award is more than recognition— it’s a reminder that in a complex industry like logistics, the road to sustainability begins with access. When you give the right tools to the right people, you create a ripple effect that drives impact far beyond technology alone. We’re proud to be part of that ripple. And we’re only just getting started,” she concludes.

Glyn Hughes, TIACA Director General with Jessica Panigari, CEO of Goods2Load

Why supplier development holds the key to the GCC’s economic resilience

Passive localisation is no longer enough. As the GCC strives for long-term economic resilience, countries must move beyond incentives and mandates to actively build capable, competitive local suppliers. Vinay Goyal, Principal, and Soundous Boualam, Manager at Kearney Middle East & Africa - Strategic Operations Practice, explain their perspective.

Vinay Goyal, Principal, Kearney Middle East & Africa

Countries reliant on finite natural resources have long faced heightened risks amidst volatile commodity markets and rising geopolitical uncertainty. In response, many are prioritising economic diversification and domestic capacitybuilding to reduce external reliance and strengthen resilience.

GCC countries are at the forefront of driving national transformation. Through bold national visions like Saudi Arabia’s Vision 2030, they’re pushing for local industry development and economic diversification to foster innovation, competitiveness, and long-term prosperity.

Programs like Saudi Arabia’s IKTIVA and Nusaned, the UAE’s In-Country Value (ICV) Program, and Oman’s Tanfeedh initiative reflect this growing focus on reinforcing domestic industrial ecosystems. Despite progress, localisation efforts continue to face structural hurdles, as many local suppliers lack the capacity and scale to compete globally, often relying on government support that limits long-term innovation and growth.

In order to overcome structural barriers, governments and businesses are adopting structured Supplier Development Programs (SDPs) to strengthen local suppliers, enhance industrial capabilities, and drive sustainable, competitive localisation.

What’s needed now is a shift from passive localisation to strategic supplier development, and that’s where structured Supplier Development Programs (SDPs) come in.

A holistic SDP enables governments and private entities to unlock substantial value:

● It can boost an organisation’s local content score by up to 10%, supporting economic growth and aligning with national localisation policies.

● It reduces international trade risks—such as supplier, logistics, and geopolitical disruptions—by up to 45%.

● It drives operational performance: cutting costs by 10–15%, improving OTIF (On Time, In Full) performance by 20–25 points, and increasing customer satisfaction by up to 30%.

Soundous Boualam, Manager, Kearney Middle East & Africa

The benefit for local suppliers is equally powerful. SDPs give local businesses access to cutting-edge technology and expertise, raise their quality standards through assessments and certifications, and strengthen their market credibility. More importantly, they build a robust local supply base, cutting import dependence and boosting local content in key sectors.

What a successful SDP looks like

At Kearney, we’ve developed a comprehensive framework that outlines six core elements to for successful SDP design and implementation.

1. Setting the SDP strategy

A successful SDP begins with a clear, strategy-aligned vision and targets, followed by prioritising categories, forecasting demand, and setting KPIs to guide implementation and measure impact.

2. Building the Operating Model

Effective SDP execution needs a tailored operating model and structure — procurement-led, dedicated, or sectorwide — based on ambition, readiness, and stakeholder alignment.

3. Prioritising Suppliers

To maximise impact, SDPs should target high-spend, high-criticality categories and select pilot suppliers by prioritising those with strong development potential, future spend relevance, and KPI improvement opportunities—while deprioritising agents, low-potential, misaligned, or long-engaged suppliers.

“A holistic SDP drives operational performance, cuts costs by 10–15%, improving on time in full performance by 20–25 points, and increasing customer satisfaction by up to 30%.”

4. Identifying Development Initiatives

Tailored initiatives should address supplierspecific gaps, supported by enablers like access to finance, matchmaking for demand visibility, structured long-term contracts, and supply-side upgrades such as R&D and training—complemented by governmentled programs.

5. Engaging Suppliers

Organisations must communicate tailored engagement plans with clear timelines and success metrics to ensure supplier alignment, foster collaboration, and track commitment effectively.

6. Tracking and Reporting on Supplier Performance

To ensure SDP effectiveness, organisations should implement a robust performance tracking framework with dashboards for leadership and scorecards for suppliers, enabling data-driven decisions, continuous improvement, and clear visibility into progress and outcomes.

As GCC nations pursue economic competitiveness and self-sufficiency, SDPs have become vital tools to boost local industry, innovation, and resilience. To be effective, these programs must be tailored to each organisation’s business priorities, maturity level, and local supply market conditions, ensuring alignment with strategic goals and supplier capabilities. Done right, SDPs can transform local suppliers from under-leveraged players into the backbone of national growth. For the GCC, the moment to act is now.

How the Middle East can effectively electrify commercial and logistics fleets