By Irwin Rapoport CEG CORRESPONDENT

SER Construction Partners LLC is a year into the Texas Department of Transportation’s (TxDOT) $64 million State Highway 105 widening and reconstruction project in Montgomery County — an initiative converting 5-7 mi. of an east-west, two-lane asphalt driving surface into a four-lane concrete highway.

The project is among four ongoing segments totaling 20 mi. that will widen SH 105 between the cities of Conroe and Cleveland. SER’s section passes through an area with forested areas on both sides, along with homes and businesses and intersections for local roads.

“The project is intended to prepare the corridor for continued growth in the area, which has led to higher traffic volumes and increasing congestion on the existing roadway,” said Leo Flores, a TxDOT Houston District spokesman. “By widening the roadway to four lanes and adding a continuous two-way center turn lane, the project will improve traffic flow and give drivers a safer place to make turns, helping to reduce congestion and improve overall safety along the corridor.”

The estimated cost of the overall project, financed by state and federal funds, is approximately $175 million.

When completed, it will have four lanes with a continuous center turn lane, sidewalks and accommodations for bicycles within the project limits, and will convert approximately 75 percent of the project from an open ditch to curb and gutter drainage system.

Early project planning started in 2003, and public hearings were held in 2019, bolstered by various studies and environmental assessments. Construction began in 2021.

SER Construction was awarded a contract for its portion of the project on Oct. 31, 2024.

Before construction, SH 105 within the project limits generally consisted of a two-lane undivided roadway (one 12-ft. lane in each direction) with 11-ft. outside shoulders. A small section of the existing roadway near Conroe consisted of four 11-ft. travel lanes (two in each direction), no shoulders and a continuous two-way turn lane.

The project’s final section will be a 10-in. continuously

reinforced concrete pavement up to 95 ft. wide to provide for two lanes in each direction with full-width shoulders on each side with a continuous center turning lane.

BGE Inc. designed the project. Public input helped shape the final design.

“The original project was environmentally approved on February 20, 2020,” according to a TxDOT web page. “Since environmental approval, continued project development efforts have identified the need for several design changes. The proposed design changes include the elimination of a section of sidewalks on the south side of SH 105 from 10th Street to FM 3083/Beach Airport Road, the addition of turn lanes on FM 1314 and FM 3083 and the addition of U-turns at the Burlington Northern Santa Fe Railway crossing located east of Walker Rd. Two additional detention ponds would also be added; one located west of Jefferson Chemical Road, and one near Caney Creek.”

The traffic management plan is based on closing large full sections of SH 105 to permit crews to excavate the existing asphalt lanes and construct the concrete lanes. TxDOT has set up detours to help motorists.

“The project is phased such that existing traffic has been shifted to permit one-half of the 95-foot roadway section to be constructed at a time,” said Scott Ashmore, an SER senior project manager. “SER is nearing completion of the 5.2 miles of the westbound travel lanes, the outside shoulder and half of the continuous center turning lane.”

SER Construction has made steady progress throughout, Ashmore said.

“Thus far, the project has been working five and sometimes six days per week, with all earthwork, drainage, bridge and subbase crews working typical daytime work shifts,” he said, “but concrete paving activities typically start during the early morning hours with the anticipation of being completed with each shift prior to the afternoon/after school traffic congestion that develops.

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps. The NFL3000 Off Road, Fuel and Lube Bed offers 3,000

of diesel fuel. The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

Agricultural

2023 JOHN DEERE 6R165....................$242,000

2022 JOHN DEERE 6R 155....................$189,500

2015 JOHN DEERE 6215R....................$120,000

(3) 2020-2023 JOHN DEERE 6130M..From $115,000 (5) 2018-2024 JOHN DEERE 6120M....From $69,500

2022 JOHN DEERE 5125M ....................$125,000

2023 JOHN DEERE 5115M......................$98,500 (3) 2021-2023 JOHN DEERE 5100M....From $81,000

Artic Trucks

2025 CAT 745......................................$CALL

(2) 2019 CATERPILLAR 740GC........From $299,500 (4) 2022-2025 CATERPILLAR 725....From $339,500 (9) 2023-2024 ROKBAK RA30....................$CALL (5) 2023 ROKBAK RA40............................$CALL

Attachments

(3) CATERPILLAR 293-5556 LIFTS........$2,000 Ea.

CATERPILLAR D6 ANGLE BLADE................$5,000

CATERPILLAR D8T ANGLE BLADE..............$7,500

CATERPILLAR D10T SS RIPPER..................$CALL

CATERPILLAR ANGLE BLADE....................$7,500

CATERPILLAR WINCH..............................$CALL

2018 NPK GH15 HAMMER........................$CALL

(6) 2022-2025 CATERPILLAR

(5) 2025 JLG AG925......................$169,500 Ea.

Crawler Loaders

(5) 2021-2024 CATERPILLAR 963....From $279,500 (2) 2024 CAT 953 LGP............................$CALL

Crawler Carriers

(2) 2019-2020 MOROOKA MST4000VDFrom $219,500 2018 MOROOKA MST3000VD................$159,500 (3) 2018-2019 MOROOKA MST2200VDFrom $119,500

Dozers - Crawler

(3) 2023-2024 CATERPILLAR D10....From $1,695,000

2023 CATERPILLAR D9......................$1,375,000

(4) 2019-2023 CATERPILLAR D8T......From $675,000

2023 CATERPILLAR D7..............................$CALL

(2) 2020-2025 CATERPILLAR D6......From $269,500

(10) 2020-2025 CATERPILLAR D6 LGP From $389,500

2020 CATERPILLAR D6 XL....................$255,000

(3) 2023-2025 CATERPILLAR D5......From $399,500

2023 CATERPILLAR D4........................$249,500

(2) 2022-2023 CATERPILLAR D3......From $159,500

2022 CATERPILLAR D2........................$169,500

2017 KOMATSU D61EXi-24....................$149,500

(4) 2023 KOMATSU D71PXi-24........From $359,500

Dozers - Wheel 2015 CATERPILLAR 834K......................$285,000

Motor Graders

(2) 2022 CATERPILLAR 16............From $945,000

14........................$765,000 (4) 2023-2025 CATERPILLAR 150....From $439,500

(2) 2022 CATERPILLAR 395-07........From $945,000

(3) 2019-2022 CATERPILLAR 374FL..From $525,000 (6) 2021-2025 CATERPILLAR 352....From $427,500

2019 CATERPILLAR 349FL....................$379,000

2022 CATERPILLAR 349......................$409,500

2022 CATERPILLAR 340......................$379,500

(4) 2019-2025 CATERPILLAR 336....From $139,500

2018 CATERPILLAR 336FL....................$139,500 (2) 2023 CATERPILLAR 330-07..........$309,500 Ea.

2020 CATERPILLAR 326-07..................$269,500

2020 CATERPILLAR 320......................$189,500

2017 CATERPILLAR 316FL....................$139,500 (2) 2023 CATERPILLAR 306CR..........From $82,500

2021 CATERPILLAR 305E2......................$71,500

2023 HITACHI ZX690LC-7......................$659,500

Rigid

(2) 2017 CATERPILLAR 772G............$295,000 Ea.

(3) 2021-2024 CATERPILLAR 299D3 XEFrom $62,500

2022 CATERPILLAR 299D3 XPS................$92,500

2022 CATERPILLAR 299D3......................$89,500

2025 CATERPILLAR 285..........................$CALL

(4) 2025 CATERPILLAR 275 XPS................$CALL (2) 2025 CATERPILLAR 275XE....................$CALL

Water Equipment - Tower/Tanks (3) 2024-2025 KLEIN KPT-120 WATER TOWERS..........

Water Equipment - Trucks (5) 2022-2025 CATERPILLAR 740GC....From $650,000 2022 CATERPILLAR 730-04........................$589,500 (6) 2021-2024 CATERPILLAR 725-04....From $349,500 2024 KENWORTH T480 ................................$CALL (16) 2018-2022 KENWORTH

Wheel Loaders

Miscelleneous Equipment

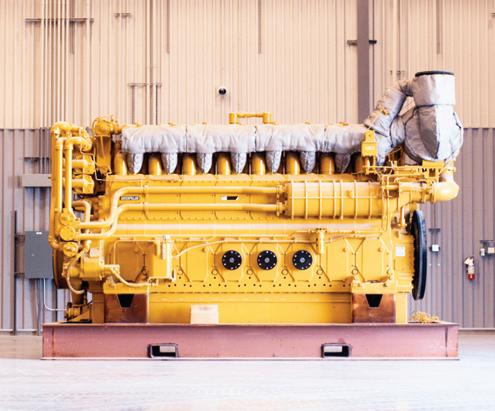

Warren CAT celebrated the grand opening of its new Engine Rebuild Center on Nov. 12, 2026, marking a major investment in West Texas and a significant expansion of the company’s service capabilities for the oil and gas and electric power industries.

The facility at 3809 S. FM 1788 in Midland is designed to deliver efficient, precise and Caterpillar-backed engine and powertrain rebuild services while providing a modern, safe and climate-controlled work environment for technicians.

A ribbon-cutting ceremony was held, followed by guided tours of the facility and lunch for guests and members of the media.

The approximately 220,000-sq.-ft. complex includes a newly constructed 156,000-sq.-ft. Engine Rebuild Center featuring 26 rebuild bays and 10 teardown bays. The facility is equipped with four engine dynamometers, one transmission dynamometer and four 40-ton overhead cranes to support large-scale rebuild operations.

A key feature of the center is its Parts AutoStore system, an advanced robot-powered automation solution that

streamlines the will-call process and improves parts order accuracy and speed.

Warren CAT is the first company outside of Caterpillar corporate to operate a facility with this level of automation.

Designed with climate-controlled bays, advanced tooling and leading-edge technology, the Engine Rebuild Center elevates the technician experience, according to the company.

These investments create a safer, more efficient workplace while supporting training, retention and career development.

The result is a facility that attracts top talent and delivers higher-quality outcomes for customers.

Warren CAT supplies and services Caterpillar equipment and power systems across West Texas, Oklahoma and the Texas Panhandle. The new Midland facility reinforces the company’s role as a key service provider for regional energy and infrastructure customers while supporting local jobs and career development.

For details, visit warrencat.com/grandopening.

(All photos courtesy of Warren CAT.)

Richard S. Burns Co. (Burns), a sustainable construction waste solutions provider, is expanding its TOMMYcart system into San Antonio, Houston, Austin and Chicago.

This highly maneuverable job-site debris collection solution is designed to replace traditional dumpsters.

In the past year, TOMMYcart has experienced significant growth, driven by demand from contractors navigating increasingly dense job sites and tightening environmental expectations, Burns said.

Burns reports 25 percent growth, with more than 5,000 carts in service and TOMMYcart 2026 revenue is projected to reach $4 million as the system expands into additional metropolitan markets.

Company-wide revenues are projected to exceed $25 million in 2026.

“Based on our own experience here in Philadelphia, we noticed in the marketplace that contractors here and in major cities face

real challenges: limited space, strict safety requirements and pressure to operate cleaner and more efficiently,” said Allen Burns, president of Richard S. Burns Co. “TOMMYcart is built for exactly these environments. We experienced these challenges ourselves, so I understand their needs. I designed and created this system from the ground up. Expanding into Chicago, San Antonio, Houston and Austin allows us to bring a smarter, more sustainable waste-handling solution to some of the fastest-growing construction markets in the country.”

Engineered specifically for metro environments, Burns said TOMMYcart replaces the logistical burden of traditional roll-off dumpsters with a compact, highly maneuverable cart system that improves workflow and delivers measurable sustainability benefits.

Burns’ early data shows a 20-30 percent increase in recovery rates versus traditional MRFs (Material Recovery Facilities), a 30

percent reduction in contamination rate, and 15-18 percent reduced hauling emissions using box trucks versus traditional roll-off trucks across projects using TOMMYcarts.

Burns said contractors will see immediate value in the ways TOMMYcart enhances job-site operations. The system improves overall site safety by reducing floor clutter, tripping hazards and dust. Efficiency is increased as crews can wheel debris directly from the work area to collection points, eliminating double-handling and cutting down on transport time, according to the company.

TOMMYcarts also support better recycling outcomes, allowing for cleaner material separation that aligns with LEED reporting and waste-diversion goals, the company said.

And because of their compact footprint, TOMMYcarts can be used in tight urban spaces where traditional dumpsters cannot fit, making them ideal for interior fit-outs, adaptive reuse projects, multifamily con-

struction and high-density renovations.

TOMMYcart units feature all-steel construction, polyurethane wheels for smooth rolling over cords and uneven surfaces, integrated floor locks for safety, forklift pockets for secure transport and a tapered design that protects walls and door frames. Burns maintains continuous workflow on job sites by delivering clean, empty carts as full ones are removed, ensuring uninterrupted operations.

“In every new market we enter, the feedback is the same. Contractors are tired of the limitations of traditional dumpsters,” Burns said. “TOMMYcart gives them a faster, cleaner, more responsible option, and our expansion positions us to support thousands of new projects in 2026 and beyond.”

This new multi-city rollout lays the foundation for broader national expansion as the company evaluates additional markets for 2026-2027.

For details, visit tommycarts.com.

Bobcat of Marble Falls 830-220-6070 Bobcat of Marion 830-420-9020 Bobcat of Midland–Odessa 432-685-9298

Bobcat of Lubbock 806-745-1322

Bobcat of Pleasanton 830-580-4020

Bobcat of the Rio Grande Valley 956-425-4300 Bobcat of San Antonio 210-337-6136

Bobcat of Temple 254-523-4900

Bobcat of Victoria 361-579-0922

Bobcat of Waco 254-488-7004

830-315-2330

PIRTEK Denton

2126 Hamilton Rd Ste 350-360 Argyle, TX 76226 (940) 241-0082

PIRTEK Riverside

15301 N Interstate Hwy 35 Unit G Pflugerville, TX 78660 (512) 448-0800

PIRTEK Waco

125 Topeka Dr, Suite D Woodway, TX 76712 (254) 294-8508

PIRTEK Brownsville

Mobile Service Only Brownsville, TX 78521 (956) 346-2582

PIRTEK Brushy Creek Mobile Service Only Brushy Creek, TX 78681 (512) 363-5973

PIRTEK College Station Mobile Service Only (979) 789-4673

PIRTEK Tomball

26010 State Hwy 249 Suite B Tomball, TX 77375 (281) 741-8090

PIRTEK Baytown

4308 Garth Rd. Suite A Baytown, TX 77521 (281) 837-7203

PIRTEK Beltway North 1920 Rankin Rd. Suite 170 Houston, TX 77073 (713) 649-3801

PIRTEK Conroe 1775 N Loop 336 E, STE13 Conroe, TX 77301 (346) 406-4122

PIRTEK Gulfgate 6205 Brookhill Dr. Suite 1 Houston, TX (713) 649-3800

PIRTEK Katy

1920 Primewest Pkwy. Suite 500 Katy, TX 77449 (832) 737-4673

PIRTEK Northwest Crossing 13230 Hempstead Rd. Suite 306 Houston, TX 77040 (281) 741-2979

PIRTEK Pearland

2201 Hwy. 35 Bypass N Suite D Alvin, TX 77511 (713) 572-5439

PIRTEK Rosenberg

Mobile Service Only Rosenberg, TX 77471 (346) 576-4673

PIRTEK Stafford

Mobile Service Only Stafford, TX 77477 (281) 982-5246

PIRTEK Plano South 811 E Plano Parkway, Suite 121, Plano, TX 75074 (972) 423-1111

PIRTEK Sherman Mobile Service Only Sherman, TX 75090 (903) 487-4750

PIRTEK Temple Mobile Service Only Temple, TX 76501 (254) 299-5751

A new asphalt testing method will help improve pavement quality and make roads more durable over time, not just in Texas but across the country.

The method, developed by the Texas Department of Transportation (TxDOT) and the University of Texas at Austin Center for Transportation Research, fills missing gaps in testing for asphalt binder.

The test, called the “poker chip method,” models the stress that asphalt endures on a roadway to check for cracking in the material. A sample of asphalt binder in the shape and size of a poker chip is sandwiched between two plates and then pulled until the sample cracks or fails.

The method has been in development and refinement since 2016. Zahra SotoodehNia, an engineer in TxDOT’s Materials and Tests Division, was a researcher at CTR during the implementation stages of the project.

“The previous testing methods were developed over 30 years ago, and they simply don’t account for the wide range of modifiers used in today’s asphalt binders,” SotoodehNia said. “The poker chip test is highly sensitive to both the type and quality of these modifiers. That means it can better predict how long a pavement will last and how well it will resist cracking over time. Ultimately, it helps us build roads that are more durable and require less maintenance.”

Asphalt binder is one of the components used to produce hot asphalt mix and seal coats — which is used in large amounts to pave and maintain the more than 200,000 mi. of TxDOT roads across the state. By improving the quality of the binder, the pavement will last longer and be less expensive to maintain over time.

“When you drive on asphalt roads, asphalt binder is quite literally the glue that’s holding these roads together,” said Amit Bhasin, CTR director and lead researcher on the project. “That inherent ability of the binder to resist cracking is what dictates the serviceable life of an asphalt pavement.”

The method has been adopted by the American Association of State Highway and Transportation Officials (AASHTO) as the provisional standard test method to be used nationwide. TxDOT plans to specify this test in the upcoming year and will use it to check the quality of asphalt binders both before and after they are shipped to projects.

“That's a major milestone for us and it shows that Texas is leading the way in innovation and that the other 49 states see the value in this approach,” SotoodehNia said. “We hope that with AASHTO's endorsement, we see more states adopting this method, which could elevate pavement performance nationwide.”

(This article is reprinted courtesy of the Texas Department of Transportation.)

(All photos courtesy of the Texas Department of Transportation.)

Construction and development firm Skanska announced the promotion of Ben Johnson to vice president — account manager for Skanska USA Building in North Texas.

As a leader in Texas’s construction sector, Johnson will play a pivotal role in delivering innovative, community-shaping projects that support the region’s rapid growth across key market sectors, Skanska said in a news release.

Johnson joins the North Texas market after nearly 13 years with Skanska in Houston, where he established himself as a trusted

leader with broad expertise spanning commercial office, light industrial, health care and higher education.

Building on his most recent role as project executive, he will focus on expanding Skanska’s project pipeline, deepening client relationships, and ensuring the successful delivery of major projects across the region.

“Ben is a leader who garners respect from clients and his teams,” said Dennis Yung, executive vice president and general manager for Skanska USA Building in Texas. “Clients appre-

ciate the environment he creates — one where teams can truly thrive — and what stands out most is the humility with which he leads. He is a true servant leader who will not ask anyone to do anything he hasn’t done or isn’t willing to do himself. Ben is a strong steward of Skanska’s values, and he has always been willing to go where the opportunity is.”

Johnson’s career accomplishments include leadership roles on notable Houston projects such as the Norton Rose Fulbright Tower and the Bank of America Tower downtown. He also oversaw proj-

ect delivery for Texas A&M University’s Mays Business School Wayne Roberts ’85 Building and Harris County’s Central Pharmacy, scheduled for completion toward the end of 2026.

He began his career with Skanska as a project engineer, progressing through roles including assistant project manager, project manager, senior project manager and project executive. Johnson holds a bachelor’s degree in construction management from the University of Louisiana Monroe. For details, visit skanska.com.

U E F EF H T E O EO R U T

From long-awaited intersection reopenings and new flyovers to pedestrian upgrades, mobility improvements surged statewide in November, according to the Texas Department of Transportation.

And from transformative urban highway projects in Austin and San Antonio to flood recovery and safety improvements, TxDOT saw progress on major projects in December, benefiting communities throughout the state.

TxDOT closed out November with major progress on transportation projects across the state, delivering new mobility options for drivers and pedestrians while advancing key long-term improvements for growing communities.

Drivers in the Lake Houston area saw noticeable relief as three reconstructed intersections along Farm-to-Market 1960 reopened after nearly four years of phased construction. The intersections at Atascocita Road, West Lake Houston Parkway and Farmingham Road now feature updated signals and improved traffic flow as part of TxDOT’s two-segment widening project.

The $128 million effort will expand FM 1960 from a four-lane roadway to a six-lane divided corridor with new sidewalks, raised medians, turn lanes and drainage upgrades.

Segment B wrapped up around Christmas, with Segment A following in February.

TxDOT announced two new pedestrian infrastructure projects aimed at improving safety and accessibility for people walking, rolling and biking in Central Texas communities:

• Mart: Beginning Dec. 1, TxDOT launched a $1 million project along South Carpenter Street to build sidewalks, ramps and marked crosswalks from State Highway 164 to Lumpkin Street. Work is expected to finish in early 2026.

• Waco: A $2.7 million project on Valley Mills Drive will add new sidewalks, upgrad-

Texas Department of Transportation photo A crew in Texas demolishes a bridge.

ed curb ramps and improved pedestrian signals stretching from Bagby Avenue to U.S. 84. Construction will run through summer 2026, with intermittent sidewalk and shoulder closures expected.

Both projects advance TxDOT’s continued efforts to support pedestrian mobility in communities experiencing population and traffic growth.

In San Antonio, two additional flyover ramps opened at the Loop 1604 North Expansion project, connecting eastbound Interstate 10 to both directions of Loop 1604. The openings bring the total to seven flyovers completed in 11 months, with all eight scheduled to be operational by the end of 2026.

When finished, the five-level interchange will feature:

• eight high-speed flyover ramps;

• new roundabouts at ground level;

• added turnarounds and sidewalks;

• expanded main lanes on both I-10 and Loop 1604, including a future HOV lane; and

• collector-distributor roads to help reduce weaving and congestion.

The upgrades aim to improve traffic flow and safety in one of the region’s fastestgrowing corridors.

On Nov. 20, the Federal Transit Administration announced that TxDOT will receive $36 million in grants for transit.

The funding will be used to buy replacement buses for 26 rural transit agencies and to build a new facility in El Paso. This funding focuses on 26 rural transit districts that collectively serve 193 Texas counties and cover more than 73 percent of the state’s land area, encompassing about 197,000 sq. mi.

Meantime, in December, TxDOT reported the following progress.

TxDOT’s work on the I-35 Capital Express Central project — the first major redesign of the corridor since 1974 — is well under way. Crews are reconstructing the MLK bridge, advancing work on the Lady Bird Lake segment and building the critical drainage infrastructure needed to support the lowering of the main lanes between Holly Street and Airport Boulevard.

The project includes 6.5 mi. of massive, 22-ft.-diameter drainage tunnels, access shafts and a pump station to manage stormwater before excavation begins. Two tunnel boring machines are scheduled to arrive from Germany in 2026. Once complete in 2033, the project is expected to significantly improve mobility, safety and flood resilience in Austin.

TxDOT’s Amarillo District reported steady progress on five major safety and capacity projects, including:

• widening Interstate 27 between Amarillo and Canyon to six lanes;

• improving intersections and turn lanes on State Loop 335;

• upgrading lighting and drainage at Farm-to-Market 1061 and Farm-to-Market 2590; and

• enhancing safety on Business Interstate 40, including shared-use paths and median

barriers.

Collectively valued at hundreds of millions of dollars, the projects are aimed at improving safety, supporting growth and reducing crashes across the region.

In San Angelo, drivers received welcome news as repairs on U.S. 67/Houston Harte Expressway neared completion following flood damage caused by historic July rainfall. TxDOT replaced metal pipe culverts — installed in the 1980s — with modern concrete box culverts.

The Loop, closed since late September between Bell Street and North Oakes, is now fully reopen.

December marked a major milestone in San Antonio as TxDOT began construction on the $473 million U.S. 90 Expansion Project in west Bexar County. The project will widen the highway from four to six lanes, add continuous frontage roads, construct a new flyover ramp to Loop 1604 and build multiple turnaround bridges and upgraded intersections.

Phase I, from Loop 410 to Loop 1604, is under way and expected to finish by 2030. Phase II, extending to State Highway 211, is expected to begin in 2027.

Another major San Antonio-area project — the Farm-to-Market 1518 expansion — continued to move forward in December. Crews completed portions of new lanes, shared-use paths and utility upgrades in Schertz, with bridge widening at Woman Hollering Creek scheduled to finish by year’s end.

The $72.78 million project will ultimately reconstruct 5.6 mi. of FM 1518 with wider lanes, a raised median, sidewalks and shared-use paths, improving safety and connectivity through 2028.

(This article is reprinted courtesy of the Texas Department of Transportation.)

The Texas Department of Transportation (TxDOT) announced that it awarded El Pasobased Jordan Foster Construction a $146 million contract to build the first phase of a project to reconstruct U.S. 90 between Interstate 410 and State Highway 21 in western Bexar County.

The main east-west corridor in western San Antonio handled approximately 60,000 to 70,000 vehicles each day in 2019, and city offi-

cials anticipate a doubling in traffic volumes by 2045. If no improvements are constructed, the added congestion will cause travel times to increase to 70 minutes by 2045. With the expanded U.S. 90, travel times will be just 6-8 minutes, according to TxDOT.

The first phase includes construction with a 3.3-mi. stretch on U.S. 90 between I-410 and Loop 1604, a stretch of approximately 3.3-mi.

The first phase is expected to be completed by early 2030.

When work is complete, U.S. 90 will be a six-lane highway with three main lanes and continuous frontage roads in each direction. U.S. 90 is only four lanes in each direction now.

Plans also include a roundabout constructed on the south side of U.S. 90 at Ray Ellison Boulevard; sidewalk and intersection improvements; and upgraded shoulders and auxiliary lanes.

A second phase incorporates work from Loop 1604 to State Highway 211, about 4.3 mi. That cost for that phase hasn’t been determined, although TxDOT anticipates work possibly beginning in 2028 and lasting for four years. This phase of the project hasn’t been funded, nor has a contractor been announced.

touch of a button. The DewEze wireless remote gives you untethered control within a twenty foot radius of your bed.

behind our equipme

For over 120 years, w ent and supporting customers long e’ve earned a reputation for standing inventory to keep yo experienced, respon after the sale. And a ur machines up and running. sive technicians and deep parts s an authorized DEVELON dealer,

“Aside from a large diameter gas pipeline that traverses the project in one area causing some impacts to the planned construction, there have not been any significant issues,” he added. “SER has a strong working relationship with TxDOT and TxDOT’s construction engineering and inspection partners.”

The construction of the new lanes is on schedule.

“The project includes the construction of two bridge structures — one over Jayhawker Creek and the other over Bee Branch,” Ashmore said. “Both bridges are relatively short in length and in height. The bridges are supported by 36-in. diameter and 42-in. diameter drill shafts. The bridges include the offsite fabrication and delivery to the site for placement of approximately 5,400 linear feet of TX34 pre-stressed concrete girders.”

Cranes were instrumental in placing the beams.

The work for this section required its closure. The sidewalk section of the existing bridge was retained, while the section with the lanes were demolished.

For one portion of the widened highway,

a shoulder, which served as a driving lane, was separated from a work area. The section had been excavated and prepped for the pouring of the concrete lanes.

With the asphalt lanes excavated and the space for the two new lanes prepared, crews placed rebar the length of two lanes for the concrete pours.

On another section of SH 105, which is bordered on both sides by forests, a similar process was followed.

The inner section was used to permit ready-mix vehicles to deliver concrete for the pours and for other vehicles and pieces of equipment to move about and be deployed.

Excavation crews also prepared the site of the new shoulder, which gave crews an additional area to place equipment and materials.

“Once the outer lanes are poured, crews will focus on the inner lanes,” Ashmore said.

“The concrete pavement being constructed consists of approximately 260,000 square yards of 10-inch-thick continuously reinforced concrete pavement. Beneath the concrete pavement is a 1-inch thick hot mix asphalt bond breaker section that is constructed atop a 6-inch-thick plant-mixed cement-treated aggregate base layer roller

compacted in place.

“The first phase of the project included multiple steps that installed large-dimensioned drainage features across the roadway. This ensured that stormwater runoff would not be compromised, nor interfere with the new roadway’s construction.”

SER is slipform paving most of the project.

The general contractor is using GOMACO equipment to construct the concrete pavement: GP-2600 slipform paver, a PS2600 placer/spreader and a TC-600 texture/cure machine. A GOMACO C-450

bridge deck finisher is used to construct the concrete deck pours on the bridges.

SER’s management team includes a project manager; a project engineer; a project superintendent; a concrete batch plant and pugmill manager; and numerous craft/tradespecific superintendents and foremen.

“The team of SER’s personnel and specialty subcontractors is very familiar in working with one another,” Ashmore said. “The crews are very experienced in working in the region and are very accustomed to the requirements of the TxDOT standard specifications.”

Typical days have many SER and subcontractor personnel on site.

SER is producing the project’s 270,000 sq. yds. of cement-treated aggregate subbase at an onsite screening and pugmill yard.

“One hundred percent of the material used to produce this base material is comprised of old materials removed from the SH 105 corridor and is recycled,” Ashmore said. “The new concrete roadway requires approximately 75,000 yards of concrete, which SER is producing at its portable concrete batch plant that is erected on the SH 105 corridor.” CEG

(All photos courtesy of SER Construction Partners.)

Gov. Greg Abbott announced on Dec. 9, 2025, that Loloi, Inc., a textile brand leader, is building a distribution facility of more than 1 million sq. ft. in Ennis, creating more than 380 new jobs and $20 million in capital investment as part of a multi-phase distribution headquarters development.

Raymond Construction Co. of Richardson was named project contractor.

A Texas Enterprise Fund (TEF) grant of $2,451,000 was extended to Loloi. In addition, the company has been offered a $45,000 Veteran Created Job Bonus.

“Texas is where the crossroads of hard work and opportunity lead to success,” Abbott said. “This $20 million investment by Loloi in Ennis just south of Dallas will create hundreds of good-paying jobs for hardworking Texans. With robust infrastructure and transportation networks providing easy access to key markets, Texas offers unmatched operating advantages for companies looking to expand. There truly is no better place than Texas to live, work, build a business and raise a family.”

Headquartered in Dallas since its founding in 2003, Loloi is a family-owned wholesale producer and distributor of designer rugs, pillows and throws and is expanding into other home furnishing categories.

The first phase of the $710 million revamp of the Fort Worth Convention Center was completed in December 2025, according to fortworthreport.org.

The $95 million first phase totaled 76,794 sq. ft. and includes a new southeast entrance and terrace, upgraded food and beverage facilities, as well as four new loading docks and a Commerce Street realignment that creates space for a future hotel and additional retail or restaurants.

AECOM Hunt, Byrne Construction Services and E.J. Smith Construction formed a joint venture to serve as the project’s construction manager at risk, according to fortworthreport.org.

In partnership with Elements of Architecture, Broaddus & Associates is serving as project manager, while Thompson, Ventulett, Stainback & Associates joined forces with Bennett Partners on design and construction administration services.

“Fort Worth provides the Texas experience that meeting planners want, and the Phase I convention center expansion and modernization exceeds those expectations,” Mayor Mattie Parker said at a December tour of the facility, according to fortworthreport.org. “This milestone, along with Phase II construction, will increase capacity to host conferences from across the nation, bolstering our already impressive convention and tourism industry.”

Tourism is a $3.5 billion industry for Fort Worth and one of its largest employers, with more than 30,000 jobs, according to Visit Fort Worth. In 2024, Fort Worth welcomed 11.5 million visitors, generating $251 million in state and local taxes. The convention center expansion is part of the city’s larger economic development strategy to attract meetings from across the state and nation.

A combination of $52 million in federal pandemic-era stimulus money and $43 million in debt funded the first phase. Voters in May 2024 approved a 2 percent increase in the city’s hotel tax in 2024 to repay that debt and fund the second phase, according to fortworthreport.org.

The first phase upgrades and emphasizes pedestrian access while improving the area’s walkability and connection to the surrounding area, including the Water Gardens, Trinity Metro Central Station, the new Texas A&M-Fort Worth campus and adjacent hotels.

The convention center remained open during the first phase and will remain operational during the second phase, fortworthreport.org reported. Renderings of the second phase are scheduled to be shared in the next few months.

The second phase of renovations is expected to begin in late 2026, with completion anticipated in early 2030. That includes the demolition of the original 1968 arena — often dubbed as the “flying saucer” — at the building’s northern end. The center opened as the Tarrant County Convention Center and hosted many top musicians during its tenure.

The second phase cost is expected to be $60 million for design and preconstruction, with the remaining $546 million for construction, according to fortworthreport.org.

o d w f har time o e y a lif ed b arv C

er day t Day af

er de t ade af Dec

e bu s ar ed hauler ticulat okbak ar rk, R

o t t er s f the de om the heat o . Fr ade e c

o ely on R an r ou c , y ctic f the ar o

or m aler f al de our loc t y ac ont C

ion. ormat e inf or kbak.

om okbak.c r old the c orm. o perf ilt t

Bane Machinery is a family owned and operated business that offers heavy machinery sales, rentals, parts, and service. We are proud to offer Liebherr equipment with full service including preventative maintenance and warranty up to OEM standards.

Liebherr machines are custom-engineered to perform efficiently. From material handling to waste management, these machines showcase a range of what’s possible.

Contact us today to find the right solution for your project application.