By Chuck MacDonald CEG CORRESPONDENT

U.S. 40 (National Pike) crosses over the Conococheague Creek in Maryland’s Washington County via a two-lane bridge

perched on two concrete piers. The bridge is a triple–span, reinforced concrete, open-arched design. It is in an idyllic location for fishermen and kayakers to access a favorite recreation spot.

The concrete arch bridge has been in use since 1936 and predates America’s Interstate Highway

System by decades. Today, U.S. 40 parallels and intertwines with I-70, especially in the Hagerstown area, and serves as a gateway to the Pennsylvania Turnpike in the north, the college town of Morgantown, W.Va., in the west and

see BRIDGE page 74

By Lucy Perry CEG CORRESPONDENT

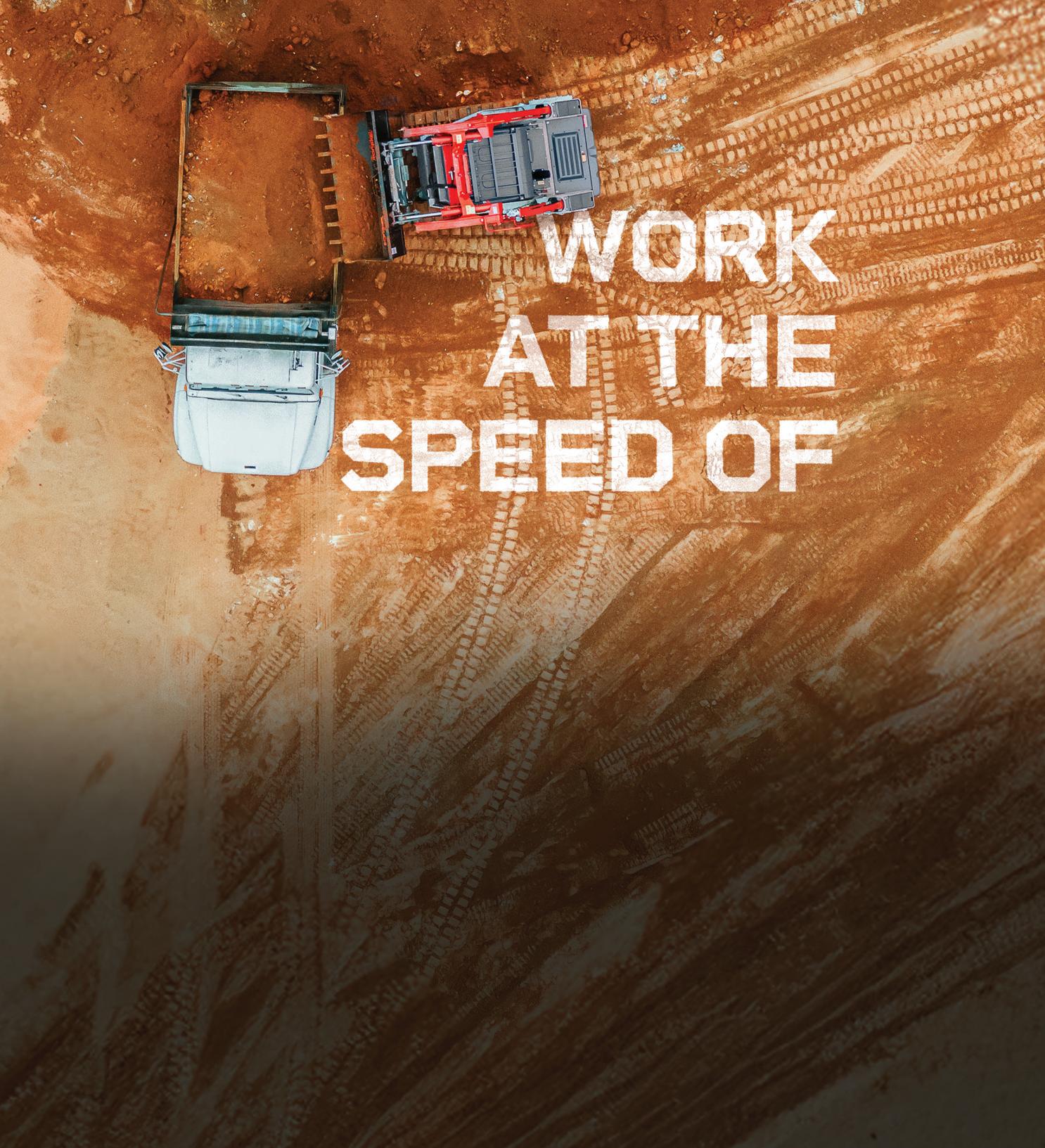

Even if you’re doing everything right, it may be time to schedule a jobsite consultation. An expert evaluation of your construction site, from fleet staging to safety practices, can offer a new perspective on operations, a better way to perform rudimentary tasks, plans to save costs in fuel, labor and equipment maintenance. The process can be as cursory or as detailed as you need.

Here is

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a problem.

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

As Caterpillar celebrates its 100th anniversary, three family-run companies marked the milestone in ways that reflected their own legacies of hard work, integrity and partnership with Milton CAT.

Three phases of a $40 million revitalization project at George Washington’s historic mansion in Virginia have been completed, according to the Mount Vernon Ladies Association.

In 1973, Robert Schaeffer found himself in training camp with the Baltimore Colts, a punter who could also play tight end, chasing a professional sports dream. But reality arrived with the first contract.

A project that improved a 7-mi. stretch of the original Pennsylvania Turnpike in Somerset County has been recognized with an engineering award. The $135 million project opened three travel lanes in each direction in 2024.

Maryland Gov. Wes Moore met with U.S. Transportation Secretary Sean Duffy to discuss “solutions to accelerate the reconstruction of the Francis Scott Key Bridge,” according to a U.S. Department of Transportation release.

20

For more than 60 years, the flexibility and versatility of HUDDIG machines have transformed and improved the way customers work, according to the company.

DDC managed the project for NYC DOT and Parks, which was completed on schedule and nearly 20 percent under the allocated $14.8 million budget, saving taxpayers approximately $2.8 million.

Fay, S&B USA Construction has been awarded a $39 million contract by PennDOT to replace the Layton Bridge and perform additional bridge, roadway and safety improvements

Humdinger Equipment, the TANA North America distributor, announced James River Equipment as its newest authorized TANA dealer in Maryland and Delaware, expanding the TANA dealership network in the New England region.

If you want to get around Alaska, your best bet is by air. The vast majority of the state isn’t reachable by road, making flying a necessity. There are more than 9,100 licensed pilots in Alaska.

70

IN WORKFORCE BUILDING IT

Caterpillar Inc. unveiled a set of AI-powered and autonomous innovations that mark a major step forward for heavy industry, transforming machines into intelligent, connected systems.

78 LIEBHERR CRANES VITAL TO ALASKA BRIDGE WORK

The construction of the Juneau Creek Bridge with a span of 951 ft. is the centerpiece of one of the largest infrastructure projects in Alaska. The bridge will significantly increase the traffic capacity on the Sterling Highway.

82 JLG ADVANCES FUTURE JOB SITE VISION WITH

JLG Industries Inc. announced the acquisition of the core technology developed by Canvas, a San Francisco-based construction robotics technology company known for pioneering robotic solutions for interior construction applications.

ysnop 150D

a ymentnoint y p t a terest . arts & on all p s no 150 D vice purc ser yment no int hases for 3.9% • 12 3.25% all-i

for 4.9%

in in 24 yon y on apply nline

%0 6 for $53OO 60 M O O.

CT, MA, ME, NH, NY, and 40+

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE............................................................................$99,995

CHIPPERS:

2020 BANDIT 15XP CHIPPER, 1322 HOURS, 15" CAPACITY, 4.3 PSI GAS ENGINE, AUTO FEED, HYD FEED WHEEL LIFT. NO WINCH................................................................................$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

2012 BANDIT 990XP CHIPPER, 949 HOURS, 12" CAPACITY, 99HP KUBOTA DIESEL ENGINE, WINCH, AUTO FEED, HYD FEED WHEEL LIFT....................................................................................$29,995

SKID STEER LOADERS:

2013 NEW HOLLAND L230, 2303 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..................................$26,500

2018 BOBCAT T770 TRACK SKID STEER, CAB HVAC, 2011 HRS, HIGH FLOW, 2 SPEED, KEYLESS $41,500

2019 NEW HOLLAND L220, 570 HRS, CAB HVAC, 2 SPEED, STD FLOW, BLOCK HEATER, HYD BKT COUPLER, RADIO

$29,995

FOR

2021 NEW HOLLAND L320, 362 HRS, CAB HVAC, 2 SPEED, STD FLOW, BLOCK HEATER, HYD BKT COUPLER SOLD $31,995

2009 NEW HOLLAND T5040, CAB AND ALAMO 62" SIDE FLAIL, 2WD. 6605 HOURS............................................................

2016 NEW HOLLAND L234, 1025 HRS, CAB HVAC, 2 SPEED, HIGH, FLOW, BLOCK HEATER, HYD BKT COUPLER

DOZER:

$33,995

2022 CASE 850M, 850 HRS, WIDE TRACK, CAB, HVAC, COLD WEATHER START KIT, DRAW BAR, 24” TRACKS, 112”DOZER BLADE, HYD PUMP W/PTO..............................................

$159,995

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER........................................$98,500

$149,995

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER..........................................................................

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

$169,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................$295,000

TRACTOR:

1988 KUBOTA L2550GST, NEW KUBOTA ENGINE(400 HRS), 1880 HOUR ON TRACTOR, NEW BUCKET AND QUICK COUPLER, LOADER, 3 PT HITCH, 4WD, AG TIRES, GLIDE SHIFT TRANSMISSION..................................................................................V $9,995

As Caterpillar celebrates its 100th anniversary, three family-run companies, Onyx Corporation of Acton, Mass., Austin Excavating & Paving of Waverly, N.Y., and D&H Paving of Buffalo, N.Y., marked the milestone in ways that reflected their own legacies of hard work, integrity and partnership with Milton CAT. Each took delivery of a limited-edition Cat Centennial machine, turning a standard equipment delivery into a celebration of family values and decadeslong relationships built on trust.

For the Durkin family, the new Centennial D6 was more than another addition to the fleet; it was a heartfelt tribute. The dozer arrived as a complete surprise for founders John Sr. and Stacey Durkin, a gift from their sons John Jr. and Cale to commemorate 45 years in business.

“It’s not just a machine,” said John Durkin

Jr., vice president of Onyx Corporation. “It’s a tribute to everything our parents built— their values, their work ethic and the familyfirst approach that runs through everything we do.”

Finished in distinctive grey, the Cat D6 is one of only 50 Centennial editions of that model produced worldwide. The inscription

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

3rd,

Rogers SP55GR, 55 ton Gentle Riser No-Foot neck, 25' deck. bkt pocket, adjustable width bi-fold front ramps, 275's, aluminum outers, air lift 3rd, night lights, work lights, strobes. Rogers Black & Viper Red....IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

New Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint....................................................................IN STOCK

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Three phases of a $40 million revitalization project at George Washington’s historic mansion in Virginia have been completed, according to the Mount Vernon Ladies Association (MVLA), a nonprofit that manages the estate of America’s first president.

In late November, the MVLA reopened all first and secondfloor rooms in the historic mansion for the first time since January 2024. Its officials held a ribbon-cutting ceremony on Dec. 10, 2025, to mark the milestone, according to Northern Virginia Magazine.

The extensive restoration project focused on the long-term health and structural stability of the building, located on the banks of the Potomac River south of Washington, D.C.

Notably, the third and latest phase of the revitalization included the reopening of the Washingtons’ bedchambers, which was “returned as closely as possible to its documented 1799 appearance,” according to an MVLA news release. Enhancements also were made to the home’s Central Passage, Little Parlor and Old Chamber.

The privately funded four-phase project began in 2023 and is expected to be completed by September 2026.

Restoration crews worked on several other projects at the iconic home such as refinishing the siding, the roof and floorboards.

The revitalization’s goals include the installation of a new HVAC system, improving the drainage system and repairing the framing from moisture and termite issues. The last phase of the project will include the restoration of Washington’s basement cellar to better maintain the structure’s foundation.

The brick and stone foundation walls and chimney bases in the cellar provide the strong underpinning upon which the home stands, MVLA noted on its project website page. As with the framing, some necessary interventions, completed with modern materials, have proven to be unsympathetic to the original fabric of the house, slowly causing unintended damage.

Masonry repairs will include replacing modern Portland cement with a soft, lime mortar like that used in the mansion’s original 18th century construction. The brick and stone used during that time were soft and they required a soft mortar due to the fact that when moisture infiltrates a masonry wall, it eats away at the softest part, ideally the mortar, which can be replaced much more easily than brick or stone.

However, when repairs were made in the

home’s cellar over the next two centuries, instead of using soft mortar, hard mortar containing water-resistant Portland cement was applied — a standard practice. Unfortunately, it proved to be far too hard for the soft brick and stone of 18th-century buildings. Its water-resistant properties forced moisture into the brick and stone, exacerbating degradation of these materials.

Another major problem cropped up at Mount Vernon that also needed modern repair methods.

As the mansion’s first floor framing aged, it began to sag, a situation worsened by multiple generations of repairs. To shore up the sagging timbers, more than 30 brick piers were added in the cellar in the 19th and 20th centuries, significantly altering the appearance of the spaces.

Once the modern framing and masonry repairs have been completed, most of these piers will be removed. Those that are still needed will be replaced by less conspicuous supports, bringing the cellar closer to its 1799 appearance.

The Mount Vernon restoration project also revealed several archaeological surprises as well.

In 2022, crews began to prepare for the expansion of an underground utility bunker in the North Grove part of the property. While excavating the area, the archaeologists discovered artifacts like pre-Colombian arrowhead and spear points, two coins from 1798 and 1817 and a variety of American and European 18th-century ceramics.

During the restoration of the home’s living quarters, the preservation team also discovered an 18th-century fork behind a wall.

Similarly, archaeologists uncovered 35 glass bottles in Washington’s cellar. Twentynine of them were intact and sealed. The sealed bottles contained preserved cherries, gooseberries and currants.

Restoration crews worked on several other projects at the iconic home such as refinishing the siding, the roof and floorboards. The central passage, little parlor and old chamber appearances were enhanced to appear closer to the mansion’s 18th-century roots.

By Craig Mongeau CEG EDITOR IN CHIEF

Robert “Bob” Schaeffer is retiring after a long, successful career in the construction equipment industry and with Elliott & Frantz.

In 1973, Robert Schaeffer found himself in training camp with the Baltimore Colts, a punter who could also play tight end, chasing a professional sports dream. But reality arrived with the first contract. For what the NFL paid back then, he realized, that he could make as much money, if not more, in sales than in football — especially important with young children on the way. So, he stepped off the field and started a new career that would demand just as much discipline, endurance and commitment.

Late that same year, Schaeffer entered the equipment industry, going to work for an equipment dealer called Basic Equipment. His introduction was simple and blunt: a map, a box of literature and a territory. “Here’s what we sell,” he was told. “Go to work.” And he did.

The job meant long weeks on the road, five days at a time. As his family grew, that lifestyle became harder to sustain. During those years, Schaeffer had been appointed Elliott & Frantz as one of his dealers in the Philadelphia area, serving as their factory representative for two years. It turned out to be a relationship that would shape the rest of his career. In November 1982, Jim Elliott offered him a new opportunity: come to Maryland and help build something from the ground up.

Schaeffer accepted, becoming branch manager and moving into a small office in Baltimore City.

“Growth came quickly,” he said. “It soon became clear that the company needed room to expand, so land was purchased in Jessup, Md.”

Schaeffer helped build the facility that still stands today. He would remain branch manager until 1999, when he became president of Elliott & Frantz, a role he officially stepped into around the turn of the millennium.

Over the decades, Schaeffer learned that the toughest challenges in management had little to do with machines and everything to do with people.

“Recruiting the right employees, training them well and convincing them to stay was never easy,” he said. “The landscape changed dramatically from the 1980s to today. Salespeople became free agents, moving from company to company for better deals, much like professional athletes.”

Schaeffer himself received plenty of offers, but he stayed. Loyalty mattered to him — both personally and professionally.

That loyalty became a defining trait of Elliott & Frantz.

“While many competitors sold out, rebranded or reshuffled leadership, Elliott & Frantz remained independent, with the same management team it had from the beginning,” he said.

To Schaeffer, that stability wasn’t just good business — it was a promise to customers.

His philosophy was simple: build strong product lines, develop real relationships with manufacturers and always be there when help was needed. Those relationships paid off.

“One of the most notable successes came with milling machines,” he said. “In a single standout year, we sold 45 units. Over 23 years, Elliott & Frantz has sold nearly 600

A project that improved a 7-mi. stretch of the original Pennsylvania Turnpike (PA Turnpike) in Somerset County has been recognized with an engineering award.

The PA Turnpike, along with the project’s construction manager and inspection team SAI Consulting Engineers Inc., construction contractor New Enterprise Stone & Lime and designer AECOM, was awarded the American Society of Highway Engineers (ASHE) Pittsburgh Section, 2025 Outstanding Highway Engineering Award for Projects more than $30 million, for their work on the Milepost 102-109 reconstruction and widening project.

The $135 million project, paid for with toll dollars as part of the PA Turnpike’s capital plan, opened three travel lanes in each direction in 2024. The work included moving 2.7 million cu. yds. of dirt in the mountainous terrain, installing several stormwater controls, including basins and rain gardens, plus building three retaining walls.

machines, helping define the market and set a standard in the industry.”

Yet numbers were never what mattered most to Schaeffer. Contractors, he believes, are “the greatest people in the world. They’re loyal, hardworking and straightforward. Over time, customers became friends. Respect came first; business followed.”

His advice to younger people entering the industry reflects that belief: don’t chase instant gratification. Earn trust. Once you have it, protect it.

As retirement approached — January 9 marked the official date — Schaeffer joked about what he wouldn’t miss: the 50-hour workweeks.

“But I will miss the people … the customers and the manufacturers I worked with for four decades,” he said. “Without people, you have no reason to turn the lights on.”

Catherine Elliott, principal owner of Elliott & Frantz, reflected on Schaeffer’s long and loyal service to the company.

“Elliott & Frantz wouldn’t be what is today without Bob’s leadership,” she said. “He led with integrity, respect and warmth. He also taught all of us the importance of creating relationships with colleagues and customers that turn in lifelong friendships. I’ve known Bob my whole life. He was not only the president of our company who worked closely with my father [Jim Elliott], but they were very close friends. Their relationship shaped my opinion and of the industry and working under him for 15 years, his mentorship also was invaluable to me.”

As he begins his retirement, Schaeffer said is what he’s most looking forward to is freedom.

“No more 4 a.m. alarms,” he said. “No more being the first one in the building and the last to leave, night after night.”

He is looking ahead to the next phase of life that includes more time for his church, for community and for the things that had waited patiently while work came first. CEG

“We are honored to be recognized for the great work done on this project to bring a safer and more efficient highway to our customers,” said Brad Heigel, chief engineer of the PA Turnpike. “We are proud to continue modernizing America’s first superhighway to meet the needs of everyone who travels our roadway every day.”

The ASHE Awards recognize the outstanding work completed by its members each year and scores submissions based on such things as the complexity of the project, safety, innovation, aesthetics and sustainable features.

“It feels good to know this project has been recognized for the outstanding work the PA Turnpike team and our contractors have done,” said John Dzurko, senior engineer project manager. “We had a good team working together with a mission to make this stretch of highway wider, straighter and safer, and I’m proud of the team that brought this project to life.”

The project was part of the ongoing statewide total reconstruction of the PA Turnpike, which has rebuilt 174 mi. of the highway so far to modern standards, including widening of the roadway from four-lanes to six-lanes. The effort contributes to the safety and mobility of the roadway and improves the travel experience for customers.

For more information, visit paturnpike.com.

1 - 2016 Phoenix Glider Cummins ISM (Engine Replaced w Cummins Certified) . $65,000

2 - 2016 Phoenix Glider, Cummins ISM. $30,000

1 -2019 Phoenix Gliders, Cummins ISM. $40,000

2 - 2020 Phoenix Gliders, Cummins ISM. $45,000 - $55,000 each

1 - 2015 Terex Mixer, Glider Mack E-7. $50,000

3 - 2016 Terex Mixers, Cummins ISX12. $115,000 each

6 - 2017 Terex Mixers, Cummins ISX12. $125,000 each

2024 YANMAR VIO17-1E MINI EXCAVATOR: 39” WIDE IN NARROW POSITION, HYDRAULICALLY EXPANDING UNDERCARRIAGE, AUXILIARY HYDRAULICS, OPEN ROPS, 55 HOURS!..........................................................................................................CALL FOR PRICE

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 6 UNITS IN STOCK........................................................CALL FOR PRICE

2021 ANACONDA FTR200 TRACKED FEEDER CONVEYOR: 2 DECK VIBRATING GRID WITH 42" X 65' CONVEYOR, UNIT# AG1335..........................................................................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 300 HRS, UNIT# 4310............................................................

2025 KOBELCO SK85CS-7: NEW 70HP YANMAR POWER, 19,270LBS, 17.7" RUBBER TRACKS, HEATED AIR RIDE SEAT, 7' ARM, DOZER BLADE WITH FLOAT, TWO WAY AUXILIARY HYDRAULICS & LOW FLOW ROTATION CIRCUIT, SWING BOOM........................CALL FOR PRICE

2024 KOBELCO SK17SR-6E: 14.5 YANMAR POWER, 3671 LBS, EXPANDABLE UNDERCARRIAGE 3'1" TO 4'2", 12" & 36" SMOOTH LIP BUCKET, TWO WAY AUXULIARY HYDRAULICS, PATTERN CHANGER, UNIT# N4997 ....................................................................................CALL FOR PRICE

KOBELCO SK350LC-10, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION, UNIT# N3651................................................................$183,000 AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION........................CALL FOR PRICE

30”X50’ ELECTRIC RADIAL STACKERS: 5 IN STOCK..........................................CALL FOR PRICE

2020 KOBELCO SK210LC-10: 2 WAY AUX HYDRAULICS, 31.5” SHOES, PATTERN CHANGER, 850 HOURS, 1 OPERATOR. UNIT# U5865............................................................CALL FOR PRICE

VERY CLEAN 2015 CASE CX80C: BOLT ON RUBBER TRACK PADS, AUX. HYDS, HYD BUCKET COUPLER, DOZER BLADE. EXCELLENT CONDITION 2100 HRS! MANY BUCKETS AVAILABLE..........$CALL FOR PRICE

2024 KOBELCO SK35SR-7: 100 HRS, ENCLOSED CAB W/ HEAT, AC, RADIO W/ BLUETOOTH, SUSP. SEAT, LOW FLOW ROTATION CIRCUIT & 2-WAY AUX. HYDS, 23.1HP YANMAR POWER, DOZER BLADE W/ FLOAT, COLOR MONITOR, 9255 LBS, 5'7" WIDE, 8'3" TALL, ORIEL HYD COUPLER & THUMB. MANY BUCKETS AVAILABLE, UNIT# N4999..................$CALL FOR PRICE

2023 ANACONDA TR100 TRACK CONVEYOR: 42”X100’ TRACK MOUNTED CONVEYOR, LESS THAN 500 HOURS, INCLUDES A WEIGHT SHARK BELT SCALE................................$CALL FOR PRICE

2023 KOBELCO SK25SR-6E: ENCLOSED CAB W/ HEAT, 19.7HP YANMAR POWER, 5930 LBS, 4'11" WIDE, 8'4" TALL, DOZER BLADE, AUX. HYDS, PATTERN CHANGER, GRYB COUPLER, GRYB HYD THUMB. 12", 18", 24" & 30" BUCKETS AVAILABLE. UNIT # N4747..............................$CALL FOR PRICE

Maryland Gov. Wes Moore met with U.S. Transportation Secretary Sean Duffy to discuss “solutions to accelerate the reconstruction of the Francis Scott Key Bridge,” according to a U.S. Department of Transportation release.

They also discussed the reconstruction of the American Legion Bridge between Montgomery County, Md., and Fairfax County, Va., according to Fox 5 Baltimore. In a joint statement, Moore and Duffy said they “agreed to accelerate the reconstruction of both the Francis Scott Key Bridge and the American Legion Bridge,” as well as making “significant progress on cost sharing for the Francis Scott Key Bridge to ensure fairness.”

According to the U.S. Department of Transportation, Duffy previously sent a letter to Moore in September 2025 outlining his concerns over rising project costs and a lengthening rebuild timeline.

According to a report from Fox 5 Baltimore, The Key Bridge is set to reopen in late 2030 at a cost between $4.3-5.2 billion.

Initial projections from Maryland Department of Transportation officials call for rebuilding the bridge by late 2028 for $1.7-1.9 billion.

rear manual coupler, stk#BH38................................................................$79,500

HUDDIG UTILITY is optimized for handling many different tasks within a single workday.

For more than 60 years, the flexibility and versatility of HUDDIG machines have transformed and improved the way customers work, according to the company, adding, “The ability to use a single machine for a wide variety of tasks is one of HUDDIG’s greatest strengths. So, what can a HUDDIG actually do?”

According to HUDDIG, the answer is the machine itself. The latest model, HUDDIG 1370, is available with two different power options: a traditional Cummins diesel engine or a hybrid solution. With the hybrid system, the machine can operate fully on electric power for up to two hours, significantly reducing fuel consumption and environmental impact.

There are more than 43 million ways to configure a HUDDIG – but to make things easier, the factory has developed three specialized models tailored for specific applications, the company said.

HUDDIG UTILITY is optimized for handling many different tasks within a single workday.

“The machine can be equipped with a wide range of attachments, delivering unbeatable flexibility and efficiency in everyday operations,” said HUDDIG.

HUDDIG RAIL is the obvious choice for railway professionals, according to HUDDIG.

“It streamlines both maintenance and construction of rail networks around the world,

offering exceptional performance on and off the tracks,” said the company.

HUDDIG CABLE is designed for the toughest conditions in service, maintenance, and the construction of power lines and cable plowing. It excels in hard-to-reach, demanding environment, according to HUDDIG.

“Once you’ve chosen your specialized HUDDIG model, that’s when the fun really begins,” the company said. “This is where you can tailor the machine to your specific business and operational needs. A HUDDIG can operate almost any hydraulic attachment that can be lifted — including snow blowers, plows, brush cutters, drills, cable plows and sweepers — making it one of the most flexible machines on the market.”

Its versatility can be further enhanced with the optional integrated manlift, which is mounted on the side of the machine. The manlift offers a working height of up to 73 ft. and electrical insulation up to 46 kV.

Another available option is the HUDDIG LCC (Loader Coupled Crane), which is primarily used to lift poles and wires for utility

A HUDDIG can operate almost any hydraulic attachment. With a quick swap at the maintenance garage, it can be a snow blower, a plow, a brush cutter, a drill, a cable plow or a sweeper. That variety makes it one of the most flexible working machines on the global market, according to the company. see HUDDIG page 28

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

The NYC Department of Transportation, NYC Parks and the NYC Department of Design and Construction announced the completion of a $12 million project that transformed the Monsignor Raul Del Valle Square in Hunts Point, Bronx, into a versatile public space surrounded by calmer traffic and improved pedestrian safety features.

DDC managed the project for NYC DOT and Parks, which was completed on schedule and nearly 20 percent under the allocated $14.8 million budget, saving taxpayers approximately $2.8 million.

“Our streets and plazas must put people first, creating places that are safe, welcoming and easy to navigate,” said Mike Flynn, NYC DOT commissioner. “This project improves safety and delivers a world-class public space in Hunts Point that truly belongs to the community — and I thank DDC and Parks for their dedicated partnership.”

“Thriving open space is essential in our city, and the redesign of Monsignor Raul Del Valle Square has beautified a vital community hub while increasing its safety and accessibility,” said Iris Rodriguez-Rosa, NYC Parks commissioner. “We’re grateful to DDC and DOT for their partnership in completing this important project, which makes the plaza a more dynamic public space while reducing traffic flow and enhancing safety for pedestrians and drivers alike.”

“Del Valle Square and the surrounding area has been completely transformed, making it a more beautiful and safer place and also helping people access nearby public transportation,” said Eduardo del Valle, NYC Department of Design and Construction acting commissioner. “We are very proud to have completed this project on time and $2.8 million under budget, saving taxpayers’ dollars. I thank the DDC project team that did a great job and our partners at DOT and Parks for working with us on this important project.”

Del Valle Square is bounded by Bruckner Boulevard, East 163rd Street and Hunts Point Avenue. A previous study revealed that two of the three intersections at the site had high rates of pedestrian-vehicular conflict, including long crossing distances, high incidents of illegal left and U-turns, as well as inadequate signage. The reconstruction project addressed these issues by realigning the roadway to reduce traffic flow on East 163rd Street, and by adding a new traffic lane on Hunts Point Avenue.

New roadway upgrades and a bus shelter were added to ease bus traffic in the area for smoother transfers, rider pickups and loading. The project also facilitates access to the Hunts Point Avenue subway station. Street and traffic lighting were upgraded and new DOT wayfinding signage were added. Nearly 30 ADA-compliant pedestrian ramps, 35,000 sq. ft. of sidewalk, 3,500 ft. of curb and 1.2 acres of asphalt were installed as part of the project. The area now has connections to the bike lane network, making it safer for cyclists.

spaces and community-cultivated art, allowing residents to gather safely and take pride in their neighborhoods. I look forward to supporting more spaces like these in our borough to promote a healthier, inclusive and safe environment for Bronx residents of all backgrounds.”

Inside the plaza itself, new light poles, seating and 10 trees were added. A bottle filler, drinking water fountain, bike racks and movable planters were installed. The project also upgraded local water mains and added eight fire hydrants plus 10 catch basins to improve drainage.

In 2024, the city worked with students to install art along the project’s 176-ft.-long construction fence. The 14 artworks, done by students ranging from 8- to 16-years-old

from Casita Maria Center for Arts & Education and The Point Community Development Corporation, featured the elements the students felt best represented their community.

“Today is a testament to how investing in our infrastructure can transform a community for the better,” said Vanessa L. Gibson, Bronx Borough president. “The Del Valle Square project improves safety for pedestrians, cyclists and drivers while creating a public space that reflects the Hunts Point community’s character, culture and creativity. The reconstruction of Del Valle Square introduces new seating, green

“This project reimagines Monsignor Raul Del Valle Square as a true community hub — one that is safer, greener and easier to navigate for everyone who lives, works and travels through Hunts Point,” said Emerita Torres, 85th district assembly member. “By redesigning traffic patterns, shortening pedestrian crossings, improving transit access and adding ADAcompliant infrastructure, we’ve created a more welcoming public space that better serves the neighborhood. Completing this work on schedule and under budget is a testament to strong interagency collaboration and our shared commitment to delivering high-quality projects for New Yorkers.”

“The redesign of Del Valle Square took serious communication and collaboration between multiple city agencies, partners, and the community,” said Justin Sanchez, 17th district council member. “The results of their effort speaks for itself. As we enter this new year, with a new council and a new administration, we need to look at Del

Square as an example to follow for all future projects and projects which are currently in motion.”

HUDDIG from page 20

work. This version also is useful on construction sites as a complement to crane trucks. HUDDIG holds certifications for a lifting capacity of up to 6 tons and a reach of up to 82 ft.

“The HUDDIG excavator loader has long been recognized as a market-leading solution for its ability improve operational efficiency,” said the company. “Why? Because this one machine can often replace several traditional machines, significantly reducing investment costs, operating expenses and labor requirements. With its oscillating pivot, powerful driveline and impressive strength, the HUDDIG 1370 delivers outstanding performance in almost any terrain.”

Combined with extreme on- and off-road capability, a HUDDIG delivers true multifunctionality in a single machine, added the company.

“This is why it’s often referred to as a ‘toolbelt machine’ – capable of handling almost any task while out in the field. Like a toolbelt, everything you need is right there.”

(All photos courtesy of HUDDIG.)

HUDDIG CABLE

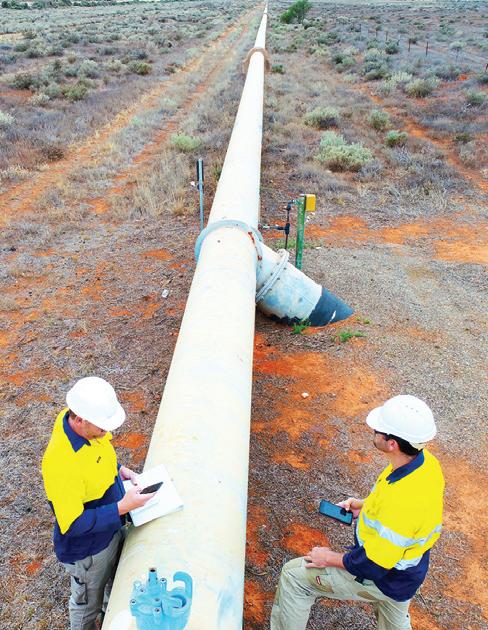

Fay, S&B USA Construction (Fay), a Pittsburgh-based firm specializing in heavy civil infrastructure projects in the MidAtlantic region, has been awarded a $39 million contract by the Pennsylvania Department of Transportation (PennDOT) to replace the Layton Bridge and perform additional bridge, roadway and safety improvements in Perry Township and Perryopolis Borough, Fayette County.

The infrastructure investment will improve safety, reliability and mobility for residents, school transportation, first responders and pedestrians in these southwestern Pennsylvania communities.

The project will replace the Layton Bridge, a 17-span, steel Pratt Truss bridge over the Youghiogheny River with a modern two-lane, three-span composite steel I-girder bridge. The current one-lane structure has reached the end of its service life due to age and corrosion. Fay also will:

• replace a single-lane bridge over Washington Run near Falbo Road with a new two-lane structure;

• rehabilitate another bridge over Washington Run near Strawn Road, including new pavement, concrete repairs and updated guide rail;

• close and seal the Layton Tunnel, which is restricted to one traffic lane;

• demolish and remove the current Layton Bridge and Washington Run bridge after these two new structures open to traffic; and,

• realign Layton Road and make improvements, including full-depth reconstruction and widening, to connect the new bridges.

will build from a temporary trestle, which is a work platform that will span the Youghiogheny River and is capable of supporting multiple cranes. This approach will allow PennDOT to keep the current bridge and tunnel open during most of the construction and avoid a 17.5-mi. detour.

Upon completion of the bridge and road realignment, Fay will close and seal the Layton Tunnel, which will no longer align with the new Layton Road alignment.

Built in 1899, the Layton bridge was originally designed as a railroad crossing and carries only one lane of traffic. Fay will construct the new bridge approximately 200 ft. southeast of the current structure. Fay crews

safety and mobility of Fayette County,” said Bryan Frye, project executive of Fay. “Our team is proud to partner with PennDOT to replace this aging structure with modern infrastructure that will serve the community for generations. Fay brings deep bridgebuilding expertise, disciplined execution and strong safety performance to deliver this work efficiently while minimizing impacts to the traveling public.”

For more information, visit shikunusa.com. Fay, S&B USA Construction photo Fay, S&B USA Construction has been awarded a $39 million contract by PennDOT to replace the Layton Bridge.

“This project is a critical investment in the

Humdinger Equipment, the TANA North America distributor, announced James River Equipment as its newest authorized TANA dealer in Maryland and Delaware. This collaboration expands the strong TANA dealership network in the New England region.

James River Equipment will provide sales, serv-

ice and technical support for the full line of TANA landfill compactors and waste shredders. Built for durability and efficiency, TANA machines help waste and recycling operations increase uptime and profitability, according to the company.

This partnership strengthens TANA North America’s commitment to excellent customer

service and ensures businesses across the country have access to reliable waste processing equipment supported by knowledgeable experts.

For more information about TANA North America, visit tananorthamerica.com. For more information about James River Equipment, visit www.jamesriverequipment.com.

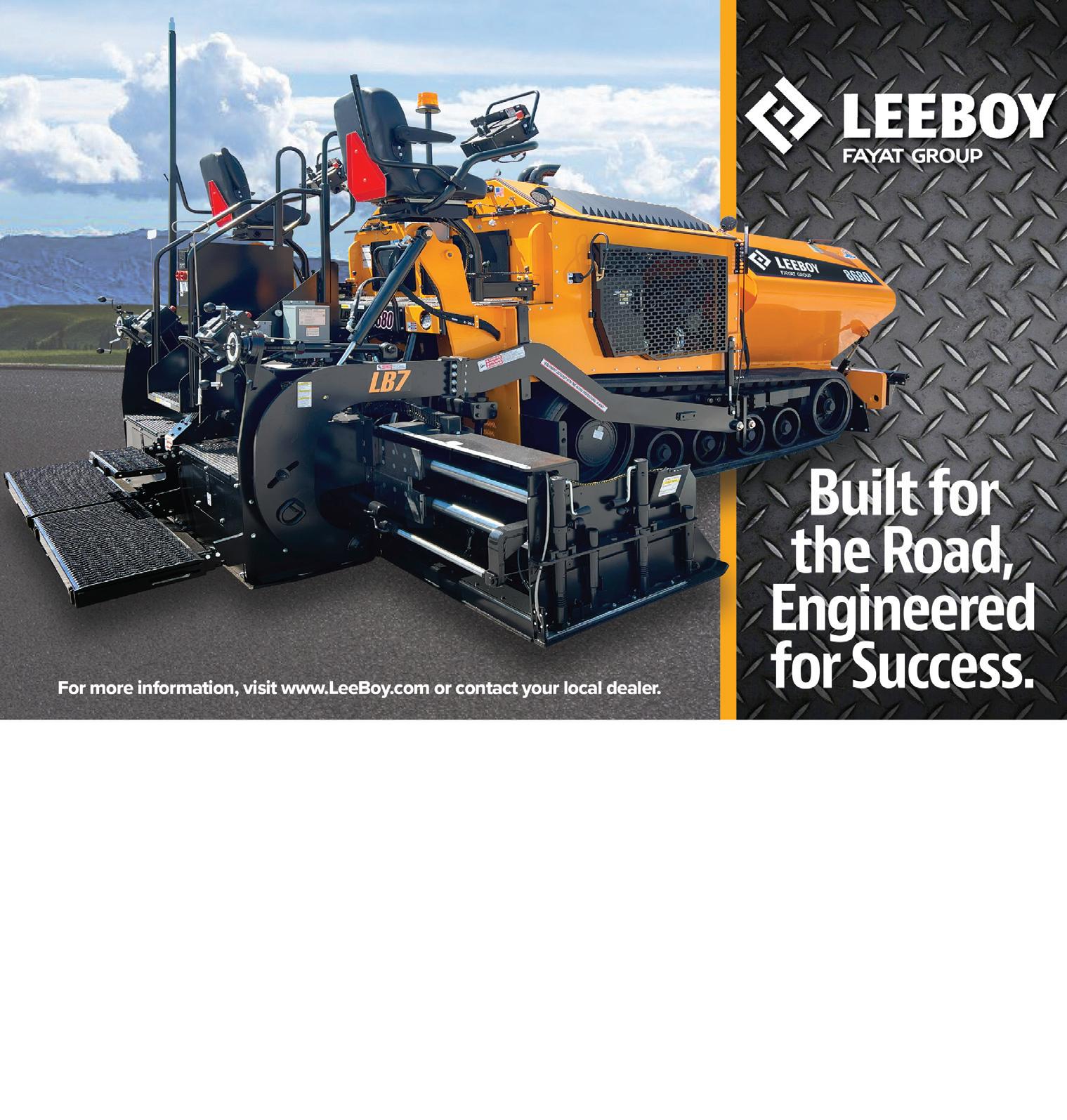

Vögele has announced the Super 800-5 P-Tier mini-paver. With its new material hopper, new paver operator’s platform and new lighting concept, the Super 800-5 P offers a high level of operating comfort and optimum visibility, according to Vögele.

As with all pavers of the Dash 5 generation, Vögele also focuses on high operating convenience and short setup times with the new Super 800-5 P. In combination with the AB 200 V and TV and AB 220 V and TV extending screeds, it offers pave widths from 1.6 ft. to 11.5 ft. — making it ideal for narrow construction projects, according to Vögele.

The successor to the Super 700 and Super 800 has an engine output of 74.3 hp, a laydown rate of up to 300 tons per hour and is compact with a width of 4.6 ft. and a length of 14.4 ft. Compared to its predecessors, the Dash 5 model also integrates numerous practical innovations.

An advantage of the mini-paver is the newly developed material hopper: as before, both hopper walls can be hydraulically adjusted separately or together. In addition, the asymmetrical setting, for example for paving along a wall,

now be completed on both sides.

39 Jersey Street West Babylon, NY 11704

631/643-2605

www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020

www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542 845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Now Open!!! Lancaster, PA 20 Stauffer Lane Ephrata, PA 800/200-2611 www.stephensonequipment.com

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455 Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

www.traceyroad.com 6803 Manlius Center Road East Syracuse, NY 13057 315-437-1471 • 800-872-2390

Albany, NY 518-438-1100 866-740-8853 Kirkwood, NY 607-775-5010 800-370-9488

Queensbury, NY 518-793-9688 833-817-2917

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390

Adams Center, NY 315-788-0200 888-335-0200

Wilkes-Barre Township, PA 570-410-2123 • 800-872-2390

AdClosingDate February12,2026

PublishingDate February25,2026

AdClosingDate March12,2026

PublishingDate March25,2026

AdClosingDate April9,2026

PublishingDate April22,2026

AdClosingDate May7,2026

PublishingDate May20,2026

AdClosingDate June4,2026

PublishingDate June17,2026

2019 Rosco Max 2B distributor, 1950 gallons, Max 2B computer, 12 ft spray bar, diesel burners, Freightliner M2, Cummins 6.7L dse eng, auto trans, front tires new $149,000

2012 Etnyre Centennial II distributor, 2000 gallons, BT-1 computer, 12 ft spray bar, spray wand & hose, diesel burners, PTO pump, Ford F750XL, Cummins 6.7L dsl eng, push button auto trans, 2 spd axle, 122,832 miles $100,000

2019 Volvo DD30B double drum 49” vibratory roller, Kubota dsl eng, double drum drive, water system, 3 tons $26,000

www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454

19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

80 John Deere Lane Norton, WV 26285

New Marathon TPS250PT tack distributor, Briggs gas eng, 18GPM pump, 250 gal, spray wand & hose, hose reel, 6 ft spray bar, operator’s platform, propane burners, flushing system $22,500

2022 Volvo PT125C pneumatic roller, 9 wheels, Volvo dsl eng, water system, tires 90%, 365 hrs

$62,000

2015 Etnyre Centennial II distributor, 2000 gal, BT-1 computer, 12 ft spray bar, propane burners,PTO pump, Ford F750XL, Cummins 6.7L dsl eng, auto trans, 2 spd axle $120,000

www.jfwequipment.com

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741 6 Equipment Drive Binghamton, NY 13904 607/754-6570

www.grofftractor.com 800-33-GROFF 800-33-(47633)

unitedequip.com

80 Southbridge Rd. • Route 20 No. Oxford, MA 01537 508/987-8786

2397 GAR Highway • Rte 6 & 136 No. Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road Billerica, MA 01862 978/667-4345

603 Coldbrook Rd. Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730 207/532-6517

1505 Caribou Road Fort Kent, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

375 Engineers Drive Williston, VT 802/658-2121

Engineered and built to exceed the demands of commercial paving, the Weiler pavers incorporate proven designs with new innovations to provide performance, reliability and outstanding mat quality in a wide range of

Murrysville, PA

724-327-1300

Erie, PA

814-898-3388

Somerset, PA 814-445-7915

Clearfield, PA 814-765-1611

Mansfield, PA 570-662-7171

Kane, PA 814-778-5250

Mt. Pleasant, PA

724-696-4080

Watsontown, PA 570-538-2551

Ephrata, PA 717-859-4905

State College, PA 814-237-8338 Harrisburg, PA 717-564-2121

Pittston, PA 800-922-8630

Bridgeport, WV 304-842-2222

Shinnston, WV 304-592-5855

Bellefonte, PA 814-353-2800

Blawnox, PA 412-828-7810

Camp Hill, PA 717-730-7435 Cranberry Twp, PA 724-776-7660

Ebensburg, PA 814-471-1710 Indiana, PA 724-463-8743

Barnesville, PA 570-773-1720

Howard, PA 814-355-3500

Hunker, PA 724-861-6080

Eighty Four, PA 724-325-9297

Piscataway, NJ 732-885-5555

Hammonton, NJ 609-561-0308

Bensalem, PA 215-639-4300

Poughkeepsie, NY 845-452-1200 Bronx, NY 718-863-3800 Bloomingburg, NY 845-733-6400

Richmond, VT 802-434-7800

Londonderry, NH 603-665-4500

Brewer, ME 207-991-3100

Binghamton, NY

607-772-6500

Clifton Park, NY 518-877-68000

Tonawanda, NY 716-799-1320 N. Syracuse, NY 315-703-7000 foleyinc.com

Holtsville, NY 631-758-7500

Newington, CT 860-666-8401

Breinigsville, PA 610-261-4887 Bear, DE 302-328-4131 hopenn.com

Cranston, RI 401-946-6350

Scarborough, ME 207-885-8000

Batavia, NY 585-815-6200

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605 allislandequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W

Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787

ambroseequipment.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741 www.monroetractor.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810 203/775-1203 80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA

600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111

703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Now Open!!!

Lancaster, PA 20 Stauffer Lane Ephrata, PA

800/200-2611

Blue Diamond Attachments announces its new line of self-leveling extreme-duty Series 2 cold planers, designed for road surface milling, concrete scarification and asphalt removal applications. The comprehensive line includes eight models ranging from 14 in. to 48 in. in milling width, compatible with skid steer and compact track loaders and the attachments are available in both low and high flow.

The new cold planer line features several design elements that enhance performance and precision:

• a patented self-leveling system ensures constant milling depth regardless of ground contour or machine position;

• independent right and left depth adjustment capability, available in both mechanical and hydraulic configurations, enables precise surface matching and perfect side-by-side passes;

• standard hydraulic side shift functionality allows flush milling against walls and other obstacles; and

• multiple drum options with different widths and teeth layouts accommodate various applications from asphalt to concrete milling.

“Our extreme-duty Series 2 cold planer line represents a significant advancement in road maintenance and construction capabilities for contractors and municipalities,” said Drew Truan, chief operating officer of Blue Diamond Attachments. “By combining precise depth control with exceptional stability and versatility, we’re enabling operators to achieve superior results across a wide range of applications, from pothole repair to complete surface removal.”

The cold planers feature milling depths from 4.3 in. to 6.7 in., depending on model and working speeds of up to 16.4 ft. per minute. All models have an optional dust suppression spray system and clear depth indicators for precise control. The line’s robust construction and direct-drive hydraulic motors ensure reliable performance while minimizing maintenance requirements, according to the manufacturer. CEG

The successor to the Super 700 and Super 800 has an engine output of 74.3 hp, a laydown rate of up to 300 tons per hour and is compact with a width of 4.6 ft. and a length of 14.4 ft.

In addition, the hopper walls of the new Super 800-5 P can be folded twice. Together with the flat engine hood, the low hopper height and the raised operator’s platform, this gives the operator an unrestricted view to the front. This makes maneuvering and loading the new Dash 5 paver much easier, according to Vögele.

Vögele also has improved the operating system: As before, the new operator’s control console can be moved horizontally. In addition, its angle can now be adjusted in four stages and ergonomically adapted to the height of the operator.

The new ErgoBasic 5 operating concept follows the operating logic of the larger machines but has been specially adapted to the mini paver. For the first time, the paver operator’s console incorporates a display that allows the operator to view the machine’s operating data. In addition, Vögele has fully integrated the operation of

the auto grade basic system for automated grade and slope control into the screed control system.

This enables screed operators to control the Super 800-5 P with just one compact console — just like on large Vögele pavers. A new storage system with a tool and drink holder, coat hooks and 24-volt socket for mobile devices also ensures organization and more convenience.

With light package or light package plus of the Dash 5 generation, users can pave safely, relaxed and precisely even in the dark or in poor visibility conditions. The light package for the Super 800-5 P includes LED lighting for the paver operator’s console, the tow point cylinder and the auger tunnel. This ensures that all points relevant to the paving are specifically illuminated without casting shadows. The optional light package plus also offers two LED floodlights that optimally illuminate the entire working area. For more information, visit wirtgen-group.com.

Brockway, PA 814-371-3600

585-334-5120

Queensbury, NY 518-793-9688 Utica, NY 315-765-8746

McKean, PA 800-872-2390 Wilkes-Barre, PA 800-872-2390

Zelienople, PA 724-452-7800

AltaEquipNY.com

5985 Court Street Road

Syracuse, NY 13206

315-437-2611

17 Northway Lane

Latham, NY 12110

518-220-9500

4554 West Saile Drive

Batavia, NY 14020

585-344-1931

www.chadwick-baross.com

Westbrook, ME

207.854.8411

Bangor, ME

207.942.4838

Caribou, ME

207.498.2547

Lancaster, NH

603.788.8200 Concord, NH

603.224.4063 West Warwick, RI

844.238.7673

Chelmsford, MA

978.513.1090 Whitman, MA 339.469.2558

www.hwyequip.com

Harrisburg, PA

www.hoffmanequip.com

www.ruddequipment.com Pittsburgh, PA 412.741.1731 Clearfield, PA 814.765.8500 Louisville, KY 502.456.4050 Charleston, WV 304.755.7788

www.tylerequipment.com East Longmeadow, MA 413.525.6351 Berlin, CT 860.356.0840

woodscrw.com

795 Marshall Avenue Williston, VT 05495

802-658-1700

As land clearing, forestry and recycling operations continue to overlap on today’s job sites, contractors are looking for attachments that deliver flexibility beyond a single task. NPK Construction Equipment’s Demo Grabs are designed to support that need by providing a rugged, multipurpose solution for handling, sorting and processing materials generated during wood and brush clearing operations.

Demo Grabs play a key role after initial clearing, allowing operators to efficiently handle brush, logs, demolition debris and mixed materials. Their 360-degree continuous rotation gives operators precise control for positioning loads, improving productivity when sorting reusable material, feeding grinders or loading trucks.

Built for demanding environments, NPK Demo Grabs feature heavy-duty construction and powerful hydraulic clamping force, enabling secure handling of bulky and irregular materials, according to the company. The jaw design supports a wide range of applications, from vegetation management and land development to demolition and recycling operations.

By reducing the need to switch attachments, Demo Grabs help streamline workflows and keep machines productive throughout multiple phases of a project. Their ability to bridge clearing, processing and material recovery makes them a natural fit for contractors working across forestry, brush clearing and recycling markets.

NPK Demo Grabs are available in multiple sizes to match a wide range of excavators, offering contractors a durable attachment option that enhances efficiency and versatility on today’s multiuse job sites.

For more information, visit npkce.com. CEG

The jaw design supports a wide range of applications, from vegetation management and land development to demolition and recycling operations.

NPK Construction Equipment’s Demo Grabs provide a rugged, multipurpose solution for handling, sorting and processing materials generated during wood-andbrush-clearing operations.

Caterpillar has introduced the FM528 GF/LL (general forestry/log loader), a forestry excavator designed for adaptability and efficiency, according to the company.

This machine is crafted to meet the diverse demands of forestry professionals, providing them with versatility, enhanced operator comfort and cost-effective performance, according to Cat.

Whether it’s land clearing, fire clean-up, chipping, grinder loading, mulching or processing, the Cat FM528 is equipped to tackle a variety of tasks with ease. The machine is compatible with a wide range of Cat forestry grapples, available in sizes from 52 in. to 60 in.

Caterpillar has debuted the FM528 GF/LL (general forestry/log loader), a forestry excavator designed for adaptability and efficiency, according to the company.

The machine is equipped with Triple Grouser track shoes that help provide high maneuverability while minimizing disturbance in soft, wet underfoot conditions, according to Cat. To help keep operators safe, the machine is equipped with a certified side-entry forestry ROPS cab, which includes a spacious door and an easy-to-use tilt-up armrest, according to Cat. Refined visibility is integrated into the design with a large 1.25-in thick polycarbonate windshield, narrow cab pillars, large panoramic windows and a flat engine hood, helping operators maximize engagement with their work environment.

The Cat FM528 offers a unique fixed or live heel and blade configuration, allowing operators to easily adapt to various applications like navigating steep terrain, managing heavy logs or performing detailed sorting tasks.

With options for processor, roadbuilder, log loader and knuckleboom loader controls, this multi-configurable machine helps crews easily transition

between forestry and millyard work, increasing productivity and profitability, according to the company.

Powered by the Cat C4.4 173 hp (129 kW) engine and an advanced electrohydraulic system, the FM528 is designed to help lower fuel consumption while delivering superior performance, according to Cat. The high-torque engine operates effectively at low RPMs, minimizing maintenance costs from wear and tear while maintaining precision in various job tasks. Further, the hydraulic system features cooling E-Fans with reversing capabilities to optimize engine efficiency and temperature control.

To help keep operators safe, the machine is equipped with a certified side-entry forestry ROPS cab, which includes a spacious door and an easy-to-use tilt-up armrest, according to Caterpillar.

Sharing common parts and service with the Cat Next Generation excavator line, the FM528 ensures readily available components, significantly reducing downtime, according to Cat. Using Cat long-life fuel and hydraulic oil filters with extended and synchronized service intervals also helps lower maintenance expenses.

For more information, visit cat.com.

(All photos courtesy of Caterpillar.)

When it comes to land clearing, mowing and mulching, safety should never take a back seat.

From flying debris and dust to unpredictable weather and rough terrain, operators face constant exposure to hazards that can quickly turn a routine job into a risky one. Because modern attachments move material at higher speeds than ever before, proper protection is not just recommended, but essential.

“Polycarbonate cab reinforcement offers a proven line of defense between operators and the harsh realities of the job site,” said Nate Cleveringa, vice president of engineering and product management of Diamond Mowers. “Built to withstand heavy impact and designed for easy installation, these durable panels keep your team safe and your equipment in top shape, all while reducing interruptions that can cost time and productivity. The result is greater uptime, longer equipment life and peace of mind knowing crews are backed by industry-grade safety materials.”

Every job and machine is different, so the right fit and design matter. While a variety of solutions exist across the industry, the experts at Diamond Mowers outline several key factors operators should consider when evaluating or upgrading their cab protection. These

solutions make it simple to outfit skid steers, excavators or tractors with a perfectly matched kit that enhances visibility and job site confidence without slowing down operations.

Operator safety is a top priority, so it is widely recommended to use a minimum ½in. polycarbonate shield when running heavy-duty attachments. This high-impact protective barrier offers strength and shatter resistance, making it one of the most effective ways to help prevent injuries caused by flying material, wood chips and other projectiles.

Polycarbonate solutions are engineered to outperform standard cab glass and are designed to help operators stay protected without sacrificing visibility. The heavy-duty layer not only absorbs impact but also reduces glare, blocks dust and deflects branches.

“Whether managing overgrown brush, tackling roadside maintenance or operating in unpredictable environments, it helps crews stay safe and focused no matter the challenge,” Cleveringa said.

Diamond Mowers’ polycarbonate solutions are engineered to handle the toughest

outdoor environments, according to Diamond Mowers. Each kit is engineered to match the dimensions and contours of a machine’s cab, ensuring a secure fit that stands up to long hours, heavy workloads and the demanding nature of vegetation management, according to Diamond Mowers.

Treated with UV and abrasion-resistant coatings, these panels maintain clarity and strength season after season, meaning less wear, fewer replacements and lasting visibility operators can rely on.

“This level of resilience gives operators confidence that their cab protection will hold up season after season, no matter how demanding the job or environment,” said Cleveringa. “It’s the kind of long-term dependability that keeps equipment performing at its best, and crews focused on the work ahead instead of the wear and tear on their machines.”

Minimizing downtime is crucial, so a welldesigned polycarbonate panel should install quickly and securely. Through close collaboration with equipment manufacturers, Diamond offers exact-fit solutions for brands such as John Deere, Bobcat and Kubota that help eliminate guesswork during installation and maintain the integrity of the

machine’s original enclosure.

Each self-installed kit arrives ready to go, drop-shipped directly to a shop or job site, so operators can get back to work without delay. Fleet managers also appreciate the consistency across equipment lines, making it simple to outfit an entire team with coverage. Whether running a single skid steer or a mixed fleet of excavators and tractors, Diamond’s customfit approach ensures every operator benefits from the same dependable coverage.

Even the toughest materials eventually show signs of wear.

“Operators should inspect polycarbonate panels regularly and replace them if they show visible scratches, hazing or impact marks that could impair visibility or reduce structural strength,” Cleveringa said. “Staying proactive not only keeps crews safe but also extends the life of equipment and upholds the highest standards of job site safety.”

Polycarbonate cab protection is a smart, cost-effective way to enhance safety while ensuring every machine meets recommended protection standards.

For more information, visit diamondmowers.com.

Delivering an enhanced operator experience through new assistance and comfort features, John Deere rolls out its L-III Skidder machines for the forestry industry.

Boasting all-new cab design options, serviceability enhancements and visibility improvements, the L-III Skidders are designed to help operators maximize uptime in the woods and transform the way they work. In addition, the L-III models feature a variety of technology tools and precision solutions and options, supporting operator and job site productivity, according to John Deere.

“Our new L-III Skidder line-up was designed to enhance the overall comfort and efficiency of our operators,” said Matt Flood, product marketing manager, John Deere. “We know that working long days in the woods can be taxing on operators, and the L-III models answer the need for more comfortable equipment that delivers the same powerful performance our customers demand.”

Prioritizing the operator’s experience, the L-III models are designed with new, comfort-focused features and are available in

two package options: base and premium. Both package options are equipped with new operator seats, amplifying job site comfort for day-long success. In addition, both models’ seats include the ability to tilt and extend the cushion for a customized fit and offer three operating positions: forward facing, rear facing and the newly released rightside door facing.

On the premium package, the seat is made from vented leather and features builtin cooling and heating functions, for comfort in all weather conditions. The premium seat option also offers seven-way adjustability and includes air-operated bolsters that can be modified to the operator’s preferences.

With countless hours spent in the seat of the cab, these premium options are designed to help operators tackle long days and remain productive, according to John Deere.

With crews working during all hours of the day and through seasons with shorter windows of daylight, the L-III models were strategically designed to improve the operator’s visibility and reduce shadows in challenging settings, according to John Deere.

With new, advanced lighting systems, the L-III Skidders come standard with LED

lights on the front, rear and boom. Also, the newly improved in-cab dome lights provide visibility during all hours of the day.

For customers needing enhanced visibility, especially those working in darker settings, the premium lighting package option offers added high beam, grill and service lighting, which has a 200 percent increase in light output than previous models.

With added visibility under the cab and in the engine bays, operators can easily view essential service areas, even in the dark.

Upgrades to the camera systems provide operators with added confidence. Available on the premium L-III machines, blade-view and tong-view camera options provide views for operators. The blade view camera delivers a precise look at blade position and movement, while the tong view camera supports tasks requiring accurate control and placement.

Camera views can be configured to display on either the primary or secondary screen, giving operators flexible access to the visuals they need for operations that require precise control and positioning.

Advanced machine diagnostics are a crit-

ical tool in helping customers and their dealers maintain uptime. The new intuitive and diagnostics capabilities allow for quick access to the machine’s diagnostic trouble codes, which are easy-to-use and crucial for maintaining equipment health and efficiency, according ot John Deere.

Remote Display Access (RDA) enables dealers, owners and support personnel to view and interact with a machine’s display from any location with an internet connection. Whether it’s adjusting settings, pulling data or troubleshooting issues, RDA allows users to operate the display as if they were sitting in the cab.

All L-III Skidder models boast a variety of precision solutions aimed at delivering optimal machine efficiency. These solutions, including TimberMatic maps, are integrated into the machine for a seamless user experience. The TimberMatic maps technology provides onboard job site visualization and awareness, helping operators to see near real-time data on the job site, according to John Deere.

For more information, visit johndeere.com.

Waratah Forestry Equipment has launched two new harvester heads — the H427 and the H427X — to deliver powerful, durable and reliable solutions for today’s toughest forestry applications.

Built to handle large timber, the H427 offers high productivity and precision, while the H427X extends that performance with heavy-duty features, purpose-built for tracked machine applications.

“As the largest heads in our 400 Series lineup, the H427 and H427X are built to give loggers the confidence they need in the forest,” said Brent Fisher, product marketing manager of Waratah. “Whether it’s the versatility of the H427 or the heavy-duty capabilities of the H427X, both models are designed to enhance performance, durability, productivity and reliability in demanding environments.”

The H427 is built for big timber and demanding applications from late thinning to the final cut. Featuring a strong frame, high-performance saws including an optional top saw and HD tilt frame, it delivers durability, feed force and cut capacity needed for reliable productivity. Its saws are a

standout feature, providing fast, precise cutting even in the toughest conditions, according to Waratah.

With an operating weight of 3,649 lbs., the H427 balances strength and stability in rugged forestry conditions. The latest measuring system design improves length and diameter accuracy, while an efficient control valve and optimized four-roller feed arm geometry ensure consistent performance on wheeled and tracked carriers. A four-knife delimbing system and streamlined service access further enhance uptime, making the H427 a high-output solution for loggers, according to Waratah.

Weighing in at 4,085 lbs., the H427X delivers the same performance benefits as the H427 but is purpose-built for heavy-duty tracked machine applications. The H427X features a standard, heavy-duty tilt frame and heavy-duty feed motor covers for added durability and protection. This helps provide operators with the toughness and responsiveness required with tracked applications, hardwood and large timber, according to Waratah.

Backed by easily accessible dealer support, genuine Waratah parts and warranty, the H427 and H427X heads are available to customers across the United States, Canada, Europe, Australia, New Zealand, Africa, Brazil and Latin America.

For more information, visit Waratah.com.

Metro Bobcat, Inc.

Eldersburg 410-795-1500 Forestville 301-568-1104 Gaithersburg 301-840-9300 White Marsh 410-483-0600 www.metrobobcat.com

Bobcat of the Finger Lakes Fairport 585-223-4056 www.djmequipment.com

Robert H. Finke & Sons Inc. Selkirk

888-266-9821 • 518-767-9331 www.finkeequipment.com

Bobcat of Saratoga Gansevoort 877-461-5065 www.bobcatofsaratoga.com

Summit Handling Systems, Inc. Poughkeepsie 845-324-7765 Walden 845-569-8195 www.summitbobcat.com

Bobcat of Connecticut East Hartford

860-282-2648 www.bobcatct.com

Bobcat of Stratford Stratford 203-380-2300 www.bobcatct.com

Bobcat of Greater Springfield West Springfield 413-746-4647 www.bobcatct.com

Bobcat of Worcester Worcester 508-752-8844

RHODE ISLAND

Bobcat of Rhode Island Warwick 401-921-4300 www.bobcatct.com

C I P G E

from page 8

on its back, “First Generation Values. Next Generation Vision.,” captures how the company has grown from a single truck in 1980 to a full-service heavy civil construction, landscape construction and materials producer with sand and gravel/quarrying operations serving communities across eastern Massachusetts and southern New Hampshire.

Durkin Jr. said the family has relied on Milton CAT for dependable equipment and service since the early days of the business. That partnership, he explained, has supported Onyx’s expansion and helped the company maintain the efficiency and reliability its customers expect. While machines and technology continue to evolve, he added, the trust and relationships built over the years remain the true foundation of success.

At Austin Excavating & Paving, the arrival of the Centennial Cat D5 dozer brought together family members, employees and Milton CAT representatives to celebrate generations of workmanship and community.

“We’ve been running Cat machines since the beginning,” said Mike Austin, president of Austin Excavating & Paving. “Our crew takes pride in our work, and we count on Milton CAT to help us deliver the quality our name stands for. It’s a relationship built on respect — they’ve always treated us like partners, not just customers.”

From earthmoving to paving projects across the southern tier of New York, the Austin family has relied on Caterpillar equipment for performance and durability, and on Milton CAT for responsive service and local expertise. Its collaboration extends beyond machines, encompassing training, technology and long-term support that keeps crews productive and projects on schedule.

In Buffalo, N.Y., D&H Paving also marked Caterpillar’s centennial with the delivery of a special-edition machine. With rain moving the event indoors, D&H Paving welcomed its Centennial wheel loader inside the service bay, turning a small gathering into a meaningful moment shared with Milton CAT representatives.

For Mike Vaccaro, the wheel loader holds a special place. He noted this Centennial edition won’t be rotated through the fleet or handed off to different crews — it’s the machine he plans to keep and care for himself.

“This one’s staying with me,” Vaccaro said with a smile. “It’s a special machine, and I want to be the one looking after it.”

The 920 wheel loader represents the latest step in a relationship built on dependable support, reliable parts availability and a service team the company knows it can count on. For D&H, the Centennial edition is both a nod to Caterpillar’s 100-year milestone and a reflection of the company’s ongoing commitment to reliable equipment and long-term partnerships that keep projects moving across western New York.

Erb & Henry Equip., Inc.

www.erbhenry.com

New Berlinville, PA 19545

610/367-2169

ADMAR Construction Equipment & Supplies

www.admarsupply.com

Vestal, NY 13850

607/798-0333

Tonawanda, NY 14217

716/873-8000

Canandaigua, NY 14424

585/396-0031

Rochester, NY 14623 585/272-9390

Cicero, NY 13039 315/433-5000

Eagle Power Kubota

www.eaglepowerkubota.com

West Chester, PA 19380 610/458-7054

Doylestown, PA 18901 215/348-9041