Science and Technology of Liquid Metal Coolants in Nuclear Engineering 1st Edition - eBook PDF download

https://ebookluna.com/download/science-and-technology-of-liquidmetal-coolants-in-nuclear-engineering-ebook-pdf/

Environmental Science and Engineering 1st EditioneBook PDF

https://ebookluna.com/download/environmental-science-andengineering-ebook-pdf/

Ethanol : science and engineering 1st Edition- eBook PDF

https://ebookluna.com/download/ethanol-science-and-engineeringebook-pdf/

Chain Mobility and Progress in Medicine, Pharmaceuticals, and Polymer Science and Technology 1st edition - eBook PDF

https://ebookluna.com/download/chain-mobility-and-progress-inmedicine-pharmaceuticals-and-polymer-science-and-technologyebook-pdf/

Simultaneous Mass Transfer and Chemical Reactions in Engineering Science: Solution Methods and Chemical Engineering Applications 1st Edition- eBook PDF

https://ebookluna.com/download/simultaneous-mass-transfer-andchemical-reactions-in-engineering-science-solution-methods-andchemical-engineering-applications-ebook-pdf/

Structure in the Sea: The Science, Technology and Effects of Purpose-Built Reefs and Related Surfaces 1st edition - eBook PDF

https://ebookluna.com/download/structure-in-the-sea-the-sciencetechnology-and-effects-of-purpose-built-reefs-and-relatedsurfaces-ebook-pdf/

ScienceandTechnology ofLiquidMetalCoolants inNuclearEngineering FormerlyAssociateDirector,ChemistryGroup, IndiraGandhiCentreforAtomicResearch, Kalpakkam,TamilNadu,India

T.Gnanasekaran

WoodheadPublishingisanimprintofElsevier 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,OX51GB,UnitedKingdom

Copyright © 2022ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorage andretrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowto seekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandthe CopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightby thePublisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribed herein.Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafety andthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatter ofproductsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-95145-6

ForinformationonallWoodheadPublishingpublicationsvisit ourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CharlotteCockle

EditorialProjectManager: RupinderK.Heron

ProductionProjectManager: PremKumarKaliamoorthi

CoverDesigner: VickyPearsonEsser

TypesetbyTNQTechnologies

Dedicatedtomybelovedparents.

3.5Chemicalcharacterizationofliquidmetalcoolants

3.9Regenerationofcoldtrapsofsodiumsystems

4Pumpsandinstrumentsforliquidmetalcoolantcircuits239

4.1Introduction

5Corrosionandmasstransferinliquidmetalsystems385

5.1Introduction

5.2Generalfactorsthatdeterminecorrosionandmasstransferof structuralmaterialsinliquidmetalsystems

5.3Corrosionandmasstransferinliquidsodiumsystems

5.4Corrosionandmasstransferinliquidlithiumsystems

5.5Corrosioninliquidleadandlead-bismutheutecticsystems

5.6Corrosioninliquidlead-lithiumeutecticsystems

5.7Wettingofstructuralmaterialsbyliquidmetals

Epilogue437

Annexure1Radialdensityfunction441

Annexure2Ferromagneticmaterials447

Annexure3Basicsofheattransferbyliquidmetals455

Annexure4Thermochemicalaspectsofdissolutionofsolutesinliquid metals465

Annexure5Kineticsofprecipitationofsolutesfromsolutions473

Annexure6Magneticeffectsofcurrent,inductance,andeddycurrents481

Annexure7Propagationofsoundwavesthroughmatter491

Annexure8Piezoelectricityandpiezoelectricmaterials499

Annexure9Solidelectrolytes507 Index523

ForewordbyAnilKakodkar

Nuclearenergywouldplayasignifi cantroleinmeetingtheenergyneedsandclimate challengesbecauseofitsimmenseenergypotentialandlowcarbonfootprint.Inadditiontorapiddeploymentofcurrentnuclearreactorsystemstomeetthenetzerodeadlines,newandinnovativenuclearreactorsandtransmutationsystemsneedtobe developedtomeetthisrequirementonasustainablebasis.Inadditiontoadvanced thermalreactors,hightemperaturegas-cooledreactorsandmolten-salt-basedbreeder reactors,liquidmetal cooledfastbreederreactors(FBRs),andaccelerator-drivensystems(ADS)occupyimportantpositionsinthisdevelopmentstrategy.WhileliquidsodiumischosenasacoolantforpresentgenerationFBRs,liquidleadisacandidatefor futurereactors.Liquidleadorlead-bismutheutecticalloyalsoservesascoolantcum spallationtargetinADS.Fusionreactors,whichareexpectedtocontributesignificantlytothelongertermenergysecurity,couldalsouseeitherliquidlithiumor lead-lithiumalloyascoolantandforgenerationoftritium.Thus,liquidmetalswould playanimportantroleinthesefuturenuclearenergysystems.

Understandingofpropertiesandperformanceofliquidmetalsiscrucialtodevelopmentandengineeringofsystemsthatarebasedonthem.Althoughtherehavebeen earlierpublicationscoveringthisdomain,therewasafeltneedforabookthatis moreuptodateandcomprehensive,coversallaspectsofbehaviorandpropertiesof liquidmetalsincludingtheirmicroscopicorigins,anddealswithinterfacebetween liquidmetalsandequipment/environmentinwhichtheywork.Thisbookwould addressthatneed.Entry-levelscientistsorengineersstartingtheirworkinvolving liquidmetalswould fi ndthisbookparticularlyhelpfulingettingstartedwiththeir work.

Thisbookprovidesauniquecoverageonallpropertiesandtechnologicalaspectsof liquidmetalcoolants:thermophysical,nuclearandchemicalproperties,handling,puri fication, firehazards,andmethodsfortheirsafedisposal,instrumentationrequiredin heattransfercircuits,andcorrosionandmasstransferaspects.Startingfromtheir manufacture,methodstohandlethemsafelyinthelaboratory,andtheheattransfercircuitsthatleveragethemareoutlined.Pumpsandvariousinstrumentsneededinthe heattransfercircuitaredealtindetail.Theiroperatingprincipleswithdescriptionof theirbasicdesign,capabilities,andlimitsarediscussed.Corrosionandmasstransfer processesobservedintheliquidmetalcircuitsandthemechanismsinvolvedare discussed.

IcongratulateDr.T.Gnanasekaranonthisimportantinitiativethatwillprovidea uniquesourceofinformationforallresearchersandtechnologistswhowouldbe

ForewordbyChristianLatgé Advancednuclearsystemssuchasfastbreederreactorsandfusionreactorsarepowerintensivesystemsandnecessitateliquidcoolantswithhighheattransferproperties. Liquidmetalcoolantsareideallysuitedforthispurpose.Athoroughunderstanding ofthepropertiesofliquidmetals,improvementofexistingtechnologiesandequipment,anddevelopmentofnewonesisessentialforoperatingsafelywithhighefficiencythecoolantcircuitswiththeliquidmetals.Liquidsodiumhasbeenthe coolantofchoiceforthefastbreederreactorsrightfromtheearlyyearsandhence lotofexperiencehasbeengeneratedwithliquidsodium.Liquidlithiumandleadlithiumeutecticalloyarechosenfortritiumbreedingandascoolantforfusionreactors. Liquidleadandlead-bismutheutecticalloyarethecandidatecoolantscumneutron multipliersforaccelerator-drivensystemsandarealsoconsideredascoolantsfor somefuturefastbreederreactors.

O.J.Foustpublisheda five-volumehandbookonalkalimetalsinthe1970s.Inthe 1980s,twobookswerepublishedbothdealingwiththechemistryofliquidalkali metals.OnewasbyC.C.AddisonandtheotherwasbyH.U.BorgstedtandC.K.Mathews.Afterthesepublications,enormousamountofresearchworkhasbeencarriedout aspartofliquidmetalfastreactorsandfusionreactorstechnologiesdevelopment. Morerecently,acollaborativeworkisgoingtobepublishedbyIAEA(Tecdocs) focusedonphysicalandchemicalproperties,heattransfer,andpressuredropcorrelations,onlyforsodium.However,theinformationgeneratedbytheresearchliesscatteredasjournalpapers,reports,patents,andotherpublications,andnowherethesedata areconsolidated.Inthepast25years,severalstudieshavebeencarriedoutonliquid leadandlead-bismutheutecticalloyalso.Ahandbookprovidingthedataonleadand lead-bismutheutecticalloy(HandbookonLead-bismuthEutecticAlloyandLead Properties,MaterialsCompatibility,ThermalhydraulicsandTechnologies)hasbeen publishedin2015.However,thishandbookdoesnotdiscussthedetailsofvariousinstrumentsusedintheheavyliquidmetalsandtheirprinciples.

Thereisdefi nitelyaneedforacomprehensivebookdiscussingallthepropertiesof liquidmetalsincludingtheirmicroscopicoriginsandalsodiscussingthebasic principlesandoperationalexperienceofspecialinstrumentsandequipmentneeded foroperatingliquidmetalsystems.ThisbookbyT.Gnanasekaranamplyful fillsthe requirement.

Inthisbook,thethermophysicalpropertiesofliquidmetalsincludingtheircorrelationwiththestrengthoftheirmetallicbond,therelevantnuclearpropertiesofthe candidatecoolants,andtheirchemicalpropertiesarediscussedindetail.Besidesthe

above,themethodsofthemanufactureofthecoolants,theirpurificationandsafe handlinginlaboratoryaswellasinheattransfercircuits,andthe firesafetyaspects andsafedisposalofthesematerialshavealsobeenextensivelycoveredinthis book.Detaileddiscussiononthepumpsandvariousinstrumentsneededintheheat transfercircuitincludestheiroperatingprinciples,theirbasicdesign,capabilities, andlimits.Corrosionandmasstransferphenomenaandwettingofstructuralmaterials byliquidmetalsaretheothertopicsdiscussedinthisbookwhichareofimportance fromthetechnologydevelopmentpointofview.

Itisindeedveryrareto findabookthatcoverssuchawiderangeoftopicsright fromthebasicpropertiesofliquidmetalsuptothecorrosionaspects,andhence,I amcertainthisbookwillbecomeasourcebookonliquidmetalcoolantstothescientistsorengineersattheentrylevelstartingtheirworkinvolvingliquidmetalsandalso forpracticingtechnologists.

Dr.ChristianLatgé CEACadarache(France)

Preface Advancednuclearsystemssuchasfastbreederreactors,fusionreactorfacilitiesand accelerator-drivensystemsgeneratehighpowerandrequirecoolantswithveryefficientheattransportproperties.Liquidmetalspossessexcellentheattransfercharacteristicsandarechosenforuseinthesesystems.Whileliquidsodiumisthecoolantof choiceforthecurrentgenerationfastbreederreactors,liquidlithiumandleadlithiumeutecticalloysarecandidatecoolant-cum-tritiumbreedersinfusionreactor systems.Liquidleadandlead-bismutheutecticalloysarebeinginvestigatedforuse ascoolant-cum-neutronmultipliersinaccelerator-drivensystemsandalsoasacoolant forfuturefastbreederreactors.Thetechnologyofliquidalkalimetalshasbeenunder intensivedevelopmentsincethe1950s.Similarinvestigationsonheavyliquidmetal coolantsarebeingcarriedoutoverthepast20 30years.Severalsystemsandcomponentsneededforreliableoperationoftheseliquidmetalcircuitsareundervarious stagesofdevelopment:pumps(mechanicalandelectromagnetictypes),instruments tomeasurethe flowandlevelsoftheliquidmetals,andforviewingcomponents immersedintheliquidmetals,whichareopaque;chemicalandphysicalsensorsfor on-linesurveillanceoftheconcentrationofthedissolvednon-metallicimpuritiesin theliquidmetalsetc.

Manyoftheinstrumentsdevelopedforuseinliquidmetalcircuitsexploitthethermophysicalandchemicalpropertiesofliquidmetals.Methodologiesforsafehandling ofliquidmetals,particularlytheveryreactiveliquidalkalimetals,havenowbecomea routine.Techniquesforonlinepuri ficationoftheliquidmetalsintheheattransfercircuitsandmaintainingthematdesiredpuritylevelsareatdifferentstagesofmaturity. Structuralmaterials,whichpossessrequiredmechanicalpropertiesatthehighoperatingtemperaturesandradiationenvironments,andwhicharechemicallycompatible withthecandidateliquidmetalcoolant,arealsobeingdeveloped.The finalchoice amongthecandidatestructuralmaterialsisbasedontheoutcomeofthelongterm corrosionandmasstransferstudiesundertheintendedoperatingconditionsinthe liquidmetalcircuit.Detailsofmostofthesetechnologicaladvancesareavailableas publicationsinjournals,reports,conferenceproceedingsandcertainbookchapters inascatteredform.Foranefficientdesignandfortheoperationandutilizationofa liquidmetalsystem,anunderstandingofallthesetechnologiesstartingfromthe manufactureofliquidmetalsisrequired.Also,basicknowledgeofthethermophysical andchemicalpropertiesofliquidmetalsandthecorrelationsamongthemisalso needed.

Thefourthchapterdealswiththecomponentsandinstrumentsrequiredforthesafe andreliableoperationoftheheattransfercircuitswithliquidmetals.Centrifugaland electromagneticpumpsusedforcirculatingliquidmetalinthesecircuitsaredescribed indetail.Instrumentsfordetectingthelevelsand fl owofliquidmetals,aswellasultrasonictransducersforviewingcomponentsimmersedinliquidmetalsaredescribed indepth.Methodstodetectliquidalkalimetalleaksandforonlinemonitoringofimpuritiesinliquidmetal,circuitsarealsodiscussedindetail.Theoreticalprinciplesof operationofthesepumpsandinstrumentsareexplained.

The fifthchapterdwellsoncorrosionandmasstransferprocessesthatoccurinthe liquidmetalcoolantcircuits.It firstdealswiththedrivingforcesforthiscorrosionand masstransferphenomenon.Sincethestructuralmaterialsusedaredependentonthe coolantemployed,thecorrosionandmasstransferphenomenaareuniqueforeachsystem.Hence,theobservedcorrosionphenomenonineachliquidmetal structuralmaterialsystemandtheunderlyingmechanismsaredescribed.Thischapteralsodeals withtheexperimentallyobservedcharacteristicsofwettingofsurfacesofthestructural materialsbyliquidmetals,whichistheprerequisiteforcorrosionandmasstransfer processesinthesystemtosetin.

Thebookhasnineannexures.Beingabookdealingwithmulti-disciplinarysubjects andprimarilyintendedforthoseembarkingonliquidmetaltechnologyatentry-level, theannexuresdiscussthebasicsciencebehindrelevantphenomena/processesdealt withinthemaintext.Thiswouldfacilitateeasyreadingofthemaintext.Annexures providedareon(1)radialdistributionfunctionforabetterunderstandingofthestructureofliquidmetalsbasedontheiratomicarrangements,(2)ferromagneticmaterials, whichareusedinsometypesof flowmetersandelectromagneticpumps,(3)basicsof heattransfer,todescribetheheattransfercoeffi cientandthecorrelationsusedfor liquidmetals,(4)thermochemicalaspectsofdissolutionofsolutesinliquidmetals, (5)kineticsofprecipitationofsolutesfromaliquidmetal,(6)magneticeffectsofcurrent,whichareneededtounderstandtheoperationofleveldetectorsand flowmetersin liquidmetalcircuits,(7)propagationofsoundwavesthroughmattertounderstandthe operatingprinciplesandlimitationsoftheultrasonictransducersusedforviewing componentsimmersedinliquidmetals,(8)piezoelectricityandpiezoelectricmaterials tounderstandtheprinciplesofgenerationofultrasonicwavesandoperationofultrasonictransducersand(9)basicsofsolidelectrolytematerials,whichareusedinchemicalsensorsemployedforon-linemonitoringofdissolvedimpuritiesinliquidmetals.

TheEpiloguelistssomeoftheunsolvedproblemsandthedevelopmentsrequiredin the fieldofliquidmetalcoolants.

Thispageintentionallyleftblank

Acknowledgments IamindebtedtomymentorsDr.C.K.Mathews(Ex-Director,ChemistryGroup,Indira GandhiCentreforAtomicResearch,Kalpakkam,India)andDr.H.U.Borgstedt (formerlywithNuclearResearchCentre,Karlsruhe,Germany)forintroducingmeto theexciting fieldofliquidmetalcoolants.Theirbook “AppliedChemistryofAlkali Metals” wastheinspirationformetoventureintothepresentbook.Iamalsograteful tomyseniorcolleagueDr.G.Periaswami,whoencouragedmeinallofmyendeavors intheareaofliquidmetalsresearch.IthankmyfriendsfromAustria,Prof.Herbert IpserandProf.AdolfMikula,whohadencouragedmetowritethisbookandprovided mewithmanyvaluablereferences.IamgratefultotheDepartmentofAtomicEnergy, GovernmentofIndia,forprovidingmethe “RajaRamannaFellowship” aftermysuperannuationduringwhichIcouldpreparethemajorcontentsofthebook.Iamalso thankfultotheDepartmentforgrantingpermissiontopublishthebookinitspresent form.MyspecialthanksgoestoDr.P.R.VasudevaRao,FormerDirectorofIGCAR, Kalpakkam,andcurrentlyViceChancelloroftheHomiBhabhaNationalInstitute,India,forhisvaluableguidanceandveryhelpfulsuggestionsduringvariousstagesof writingandpublishingthebook.

Ithanktheanonymousreferees,whomadeusefulcommentsbasedonadetailed outlineforthebook.IamalsothankfultomanyoftheexpertsandcolleaguesatIGCAR fortheirusefuldiscussionsandforofferingsuggestions/commentsonthecontentsofthe book.MyspecialthanksgoestoDr.G.Vaidyanathan,Dr.K.K.Rajan,Dr.Christian Latge(CEA,France),Mr.M.Rajan,Dr.K.Swaminathan,Dr.B.K.Nashine,Mr.PrasantSharma,Mr.Hemanath,Mr.K.C.Srinivas,Dr.K.Nagarajan,Dr.K.V.Govindan Kutty,Dr.K.S.Viswanathan,Dr.V.Jayaraman,Dr.RajeshGanesan,Dr.K.I.Gnanasekar,Dr.S.Anthonysamy,andDr.T.S.LakshmiNarasimhanforstudyingdifferent partsofthebookandprovidingvaluablesuggestionsandcommentstoenrichitscontents.IextendmythankstoDr.R.KumarandDr.G.V.S.AshokKumarfortheir helpincollatingthedataonradioactivenuclideslistedin Tables1.15 and 3.1.Iam verythankfultoMr.V.SureshKumar,Mr.B.ArulKumarandM.Janarthanamfortheir helpinpreparingmanyofthe figuresincludedinthebook.Iamthankfultothemembers oftheElsevierteam,whowereextremelyhelpfulduringpublicationofthebook. Lastbutnottheleast,IamthankfultomywifeMalliga,daughterArunaandher family,andsonBharani,forbeingsounderstandingandprovidingmeconstantsupportandencouragementduringtheyearsofpreparationofthebook.

Igratefullyacknowledgethepermissionsforreuseofthefollowing figuresfrom previouspublications:

FigureNo.ReferencesourceUsedwithpermissionfrom Chapter4

Fig.4.2Fig.7ofRef.6IOPPublishingLtd.(CCBY3.0)

Fig.4.5Fig.6inRef.11Elsevier

Fig.4.7Fig.2.4inRef.8Elsevier

Fig.4.13Fig.3inRef.20Elsevier

Fig.4.18Fig.12inRef.39Elsevier

Fig.4.19Fig.11inRef.39Elsevier

Fig.4.21Fig.2inRef.48Elsevier

Fig.4.22Fig.5inRef.48Elsevier

Fig.4.23Fig.3inRef.56Elsevier

Fig.4.27Fig.3inRef.69Elsevier

Fig.4.28Fig.8inRef.45Elsevier

Fig.4.30Fig.1inRef.75SpringerNature

Fig.4.37Fig.1inRef.105Elsevier

Fig.4.39Fig.7inRef.113TaylorandFrancisLtd., © AmericanNuclearSociety

Fig.4.40Fig.15inRef.106Elsevier

Fig.4.46Fig.2inRef.141Elsevier

Fig.4.49Fig.1inRef.162TaylorandFrancisLtd.,

Fig.4.50AFig.8inRef.161Elsevier

Fig.4.50BFig.2inRef.162TaylorandFrancisLtd.,

Fig.4.51Fig.1inRef.163ArgonneNationalLaboratory, USA

Fig.4.56Fig.2inRef.183Elsevier

Fig.4.62Fig.2inRef.209Elsevier

Fig.4.63Fig.8inRef.208Elsevier Chapter5

Fig.5.14Fig.5inRef.135Elsevier

Annexure-1

Fig.A1.1Fig.4.8inRef.1JohnWileyandSons

Fig.A1.2Fig.4.8inRef.1JohnWileyandSons

Fig.A1.3Fig.4.8inRef.1JohnWileyandSons

Fig.A1.4Fig.4.8inRef.1JohnWileyandSons

Annexure-7

Fig.A7.4Fig.2inRef.1OfficeoftheScientificand TechnicalInformation(OSTI), DepartmentofEnergy(DOE), USA

Annexure-9

Fig.A9.3Fig.8.22inRef.1JohnWileyandSons

Fig.A9.8Fig.7inRef.4,andFig.2in Ref.5 IOPPublishingLtd.,

Author

Thispageintentionallyleftblank

Thermophysicalandnuclear propertiesofliquidmetal coolants 1 Chapteroutline 1.1Introduction2

1.2Metallicbondingandthestateofliquidmetals3

1.3Cohesiveenergyofliquidmetals7

1.4Structureofliquidmetals13

1.5Surfaceenergyofliquidsandthephenomenonofwetting17

1.5.1Surfaceenergiesofliquidmetalsandalloys19

1.5.2Surfaceenergyofmetallicsolids25

1.5.3Wettingphenomenoninliquidmetalsystems27

1.5.3.1Inertwetting29

1.5.3.2Reactivewetting31

1.6Viscosityofliquidmetals32

1.7Electricalconductivityofmetallicmaterials37

1.7.1Electricalconductivityofcrystallinemetals38

1.7.2Electricalconductivityofamorphoussolidandliquidmetals48

1.8Thermalconductivityofmaterials53

1.8.1Thermalconductivityofsolid-statematerials53

1.8.2Thermalconductivityofliquidmetals59

1.9Molarheatcapacityofliquidmetals62

1.10Vaporpressureofliquidmetals67

1.11Magneticpropertiesofmetals70

1.11.1Magneticpropertiesofsolid-statematerials70

1.11.1.1Diamagnetism73

1.11.1.2Paramagnetism74

1.11.1.3Ferromagnetism77

1.11.2Magneticpropertiesofmoltenmetals78

1.12Nuclearpropertiesoftheliquidmetalcoolants80

1.13Choiceofcoolantforadvancednuclearsystems80

1.13.1Fastbreederreactors80

1.13.2Tokamakfusionreactor choiceoflithiumandPb-Lieutecticalloyascoolant andtritiumbreeder91

1.13.3AcceleratordrivensystemandchoiceofleadandLBEasspallationtargetand coolant94

References97

1.2Metallicbondingandthestateofliquidmetals1 Majorityofthemetals( >90%)intheirsolidstateexisteitherasbodycenteredcubic(BCC)orasclosepackedcrystallinestr uctures(facecenteredcubicorhexagonal),althoughsomemetalstakeotherstructuresalso. Table1.1 liststhecrystal structureofsomeofthemetallicelements.Coordinationnumbersofatomsinthe BCCandcubic/hexagonalclosepackedstructuresare8and12,respectively.The crystalstructureadoptedbyametalisinfl uencedbyvariousfactorssuchas (a)theatomicradiioftheconstituentmetal atoms,(b)cohesivee nergiesresulting frommetallicbonding,and fi nally(c)theinevitablethermodynamicdrivetoattain thelowestenergystate.

Accordingtothefreeelectrontheoryofbondinginmetals,electronsfromthe valenceshelloftheatomsarefreeanddelocalized.Theioniccoresformaperiodic structure(lattice)andthedelocalizedelectronspropagatefreelyinthisperiodiclattice. Thephysicalpropertiesofthemetalsaredictatedbytheioniccoresinthelatticeand thedelocalizedelectrons.Thedelocalizedelectronsactaschargecarriersfortheconductionofelectricity.Theyalsoactasenergycarriersfortheconductionofheatand hencemetalsexhibitveryhighelectricalandthermalconductivities.Itisthisdelocalizationoftheelectronsovertheentirelatticethatrendersthemetallicbondingtobe nondirectional.Whenastressisapplied,ioniccorescanrollovereachotherwhile themobileelectronscontinuetoholdthestructuretogether.Thismakesthemetals malleableandductile.Thestrengthofthemetallicbonddependsonthenatureof themetal,thetypeofcrystalstructureadoptedbyit,thechargeandsizeofthemetal ionsinthecore,andthenumberofelectronscontributedbyeachatomtothedelocalized “sea” ofelectrons. Table1.2 showsthecomparisonofmechanicalstrengthsof somepuremetalsandascanbeseen,thesepropertiesdifferwidelydependingon thedegreeofmetallicbondinginthem.

Atagivenpressure,solidandliquidphasesofasubstancecancoexistwitheach otheronlyatitsmeltingpoint.Column3of Table1.1 showsthemeltingpointsof someofthemetalsanditisseenthatthevaluesvaryoveraverywiderange.Melting occursatthetemperaturewherethethermalenergyoftheatomsofthecrystalline metalisenoughtoovercometheforcesholdingtheminlatticepositions.Forexample, alkalimetalshavelowermeltingpointsthanthealkalineearthmetals.Thisisbecause (i)atomsofalkalimetalscontributeonlyoneelectroneachtothedelocalizedseaof electronscomparedtoalkalineearthmetalatomswhichcontributetwoelectrons each,(ii)alkalineearthmetalscrystallizeinclosepackedstructure(packing efficiency ¼ 74%)whilealkalimetalscrystallizeinbodycanteredcubicstructure (packingeffi ciency ¼ 68%)and(iii)atomicradiiofalkalimetalsarehigherresulting inthedelocalizedelectronstobefarawayfromthenucleiithaninthecaseofalkaline earthmetals.Onthesamecount,transitionmetals(whicharethealloyingcomponents

1 Theterm “liquidmetal” wouldbeusedtorefertoallmetalsintheirliquidstateinthisbook,althoughit shouldstrictlyrefertothosewithmeltingpointbelow660.2 C.

Table1.1 Structuralpropertiesofsometypicalmetalsinsolidandliquidstatesa.

Li6.941180.54.6BCC(He)2s1

Na22.989897.82.64BCC(Ne)3s1

K39.098363.62.4BCC(Ar)4s1

Mg24.30506508.8HCP(Ne)2s2

Ca40.0788428.4FCC(Ar)4s2 0.06311.1

Sr87.6277710.0FCC(Kr)5s2 0.06011.1

Cu63.5461084.6213.0FCC(Ar)3d104s1 0.05711.3

Ag107.8682961.7811.09FCC(Kr)4d10 5s1 0.05611.3

Au196.96651064.1812.76FCC(Xe)4f14 5d10 6s1 0.05910.9

Cr51.9961190720.9BCC(Ar)3d5 4s1 0.04311.2

Fe55.847153813.77BCC(Ar)3d6 4s2 0.05110.6

Co58.9332149515.48HCP(Ar)3d7 4s2 0.05311.4

Ni58.6934145517.15FCC(Ar)3d8 4s2 0.05211.6

Ti47.88166814.6HCP(Ar)3d2 4s2 0.05610.9

Mo95.94262335.6BCC(Kr)4d5 5s1 0.078

Ta180.9479301724.7BCC(Xe)4f14 5d3 6s2 0.065

Al26.9815660.3210.46FCC(Ne)3s2 3p1 11.5

Zn65.39419.537.28HCP(Ar)3d10 4s2 0.03910.5

Cd112.411321.076.4HCP(Kr)4d10 5s2 0.03810.3

In114.818156.63.26Tetragonal(Kr)4d10 5s2 5p1 0.04511.6

Sn118.710231.937.07Tetragonal(Kr)4d10 5s2 5p2 0.03310.9

Pb207.2327.45.12FCC(Xe)4f14 5d10 6s2 6p2 0.05010.9

Bi208.9804271.410.48Rhombohedral(Xe)4f14 5d10 6s2 6p3 0.0408.8

aDataonM.P.andmolarenthalpyoffusionforLi,Na,K,Pb,BiaretakenfromRef.[7]andthecorrespondingdataforallothersarefromRef.[8].

Thermophysicalandnuclearpropertiesofliquidmetalcoolants5

Table1.2 Mechanicalpropertiesofsomepuremetalsunderannealedconditionatroom temperature[12].

Metal

Ultimatetensile strength(MPa)

Modulusof elasticity(GPa)

Brinellhardness (MPa)

Al5069 72150

Cu215110 130

Ag140 18072 83.5500

Au15078 83220

Fe290195 205800

Cr300280 3151000

Ni400200 220800

Mo670300 3301800

Ta5001901250 1400

Ti250110600

Pb14 1814 18

Bi5 203290

Zn125110 130

Cd7550 5375

instructuralmaterialsforliquidmetalcoolantsystems)haveveryhighmeltingpoints because(i)electronsfromtheird-orbitalsalsoparticipateinthedelocalizationinadditiontothosefrom s- and p-orbitalsand(ii)theiratomicradiiaresmall. Lindemannproposedamodeltopredictthemeltingpointsofcrystallinesolids basedonthecharacteristicsofvibrationsofatomsinthelattice[9].Hesuggested thatacrystallinematerialwouldmeltwhentheamplitudeofthethermalvibration oftheatomexceedsacriticalfractionoftheaverageinteratomicdistanceinthelattice. Ifweconsidertheatomsinametallicsolidtobehaveasharmonicoscillators,each atominthesolidwouldvibrateindependentoftheneighborsatafrequencyvwhere v ¼ 1 2p k mr ,misthemassoftheatom,andkistheforceconstantoftheoscillator.2 If [x istheamplitudeofthevibrationoftheatominthex-directionfromitsequilibrium positioninthelattice,thesumofpotentialandkineticenergiesassociatedwiththis vibrationisgivenby3:

2 Insteadofreducedmassofthesysteminvolvingitsneighbors,onlymassoftheatomisusedforsimplicity.

3 Notethat [x isthepointofmaximumamplitudewhere all theenergyispotentialandhencethepotential energy 1 2 kð[x Þ2 becomesthetotalenergy.

Thermophysicalandnuclearpropertiesofliquidmetalcoolants7

Bydeducingtheforceconstantkfromexpression Eq.(1.4) andsubstitutingitin Eq.(1.3),wegetthefollowingexpressionforthecriticalfractionfcri (alsocalledas Lindemannfraction)as:

Theinteratomicspacinginametalcanbeestimatedfromitsdensity d andgram atomicmassM:

whereNA istheAvogadro’snumber.Usingthedataontypicalmetals[10,11],the Lindemannfractionsarecalculatedandlistedin Table1.1.ItisseenthattheLindemannfractionsofthetypicalmetalsareintherangeof0.04 0.08inspiteoftheir variedstructuresandlargedifferencesintheirelectronicconfiguration.

Meltingpointofthemetalsandthemolarenthalpyoffusionaresystematically relatedandthisisexpressedbyRichard’srule[13]:

where DSmfusion and DHmfusion arethemolarentropyandmolarenthalpyoffusion, respectively.Entropyoffusionispositiveandisassociatedwithincreasein randomnessonmelting.Meltingpointandmolarenthalpyoffusionofsometypical metalsaregivenin Table1.1

Whenacrystallinemetalmelts,almostallofitsphysicalpropertieschangesharply by fi niteamounts.Amongthem,thechangeinresistancetoshearstressisverylarge andsubstantial.Whentherigidcrystaltransformsintoaliquid,viscositychangesbya factorofabout1020.

1.3Cohesiveenergyofliquidmetals Classicaldefinitionofcohesiveenergy(orcohesiveenthalpy)ofacrystallinesolidis theenergythatmustbeaddedtothecrystaltoseparateitscomponentsintoneutral,free atomsatrest,atinfiniteseparationwiththesameelectronicconfiguration[11].Forone g-atomofametalat0Kand1barpressure,thiscanberepresentedas:

Sincemolarheatcapacityofanidealgascontainingmonomericspecies,Cg;ideal P ¼ (5/ 2)R, Eq.(1.11) canbewrittenas:

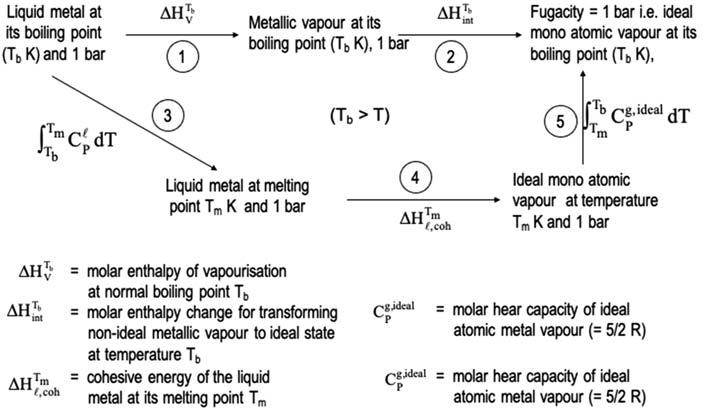

Cohesiveenergyofametalismainlyduetotheelectrostaticattractiveforcesbetweentheioniccoresandthedelocalizedvalenceelectronsthatcontributetothe metallicbond.Cohesionofatomsinaliquidmetalbecomesweakerwithincrease intemperaturesincethethermaloscillations/vibrationsanddiffusionofthemetal atoms(ioniccores)intheliquidphaseincreasewithincreaseintemperatureresulting inanincreaseinthemolarenthalpyoftheliquidphaseHT [ (see Eq.(1.9)).Considering theBorn-Habercyclein Fig.1.1,thecohesiveenergyoftheliquidatanytemperature T(T > Tm)canberepresentedintermsofmolarheatcapacityandcohesiveenergyof theliquidatitsmeltingpoint.Sincethesumoftheenthalpychangesinsteps5and6is equaltothesumoftheenthalpychangesinsteps7and8,

Asmentionedabove,themolarheatcapacityofanidealgascontainingmonomeric species,Cg;ideal P ¼ (5/2)R.Hence, Eq.(1.14) canbewrittenas:

;coh

Correlationofenthalpyofvaporizationofaliquidmetalatitsnormalboilingpoint tothecohesiveenergyofcrystallinemetallicsolidisshowninRef.[8]andtherelation betweentwoisgivenbythefollowingexpression:

Enthalpyofvaporizationatthenormalboilingpointistakenasameasureofits cohesiveenergyatthemeltingpointalso[15].Theenergeticsandapproximations involvedinthiscanbeexaminedbyconsideringtheBorn-Habercyclegivenin Fig.1.2.EnthalpyofvaporizationattheboilingpointTb,i.e., DHTb V corresponding Thermophysicalandnuclearpropertiesofliquidmetalcoolants9

D

10ScienceandTechnologyofLiquidMetalCoolantsinNuclearEngineering

Figure1.2 Born-Habercycleforcalculationofcohesiveenergyofaliquidmetalfromits enthalpyofvaporization.

tostep1istheenthalpychangeintransforming1g-atomofaliquidmetalatTb tothe gaseousphaseat1barandatthesametemperature.Sincethevaporphaseiscondensableandisinequilibriumwiththepureliquidphase,thespeciesinvaporphasewould exhibitinteractionsamongthemanditsfugacitywouldbe < 1.Theenthalpychangein step2 ¼ DHTbint istheenthalpychangeinbringingthisnonidealmetalvaportothe statewithfugacity ¼ 1(idealstate)andthiswouldbeanendothermicprocess.While thisisthecasewhenthevaporphasecontainsonlymonomeric(atomic)species,additionalenthalpytermsneedtobeincorporatedwhenthevaporphasecontainspolymeric species.Vaporphaseofmetals,particularlythoseofalkalimetals,containspolymeric speciessuchasdimer,trimer,tetramer,etc.(e.g.,Na2,Na3,Na4)inadditiontothemajormonomericspecies[16].Dissociationofthesepolymericspeciestotheatomicspeciesalsowouldbeinvolvedinstep2.Thisisalsoanendothermicprocessandwould needtobeincorporatedin DHTbint 6 Thesumoftheenthalpiesinvolvedinsteps3,4,and 5isequaltothesumofthoseinvolvedinsteps1and2.Wecanrepresentthesameas:

6 Althoughitispossibletogettheenthalpychangeforthedissociationofpolymericspeciestoatomic speciesbyknowingthevaporphasecompositionandthebondenthalpies,theenthalpychangeinvolvedin changingfromnonidealtoidealstate(DHTb int )isdifficulttoestimate.