FOOD AND DRINK NETWORK

Food, Drink & Hospitality Week returns with a joined-up view of the food & drink sector

Turn to page 08...

Eplore how Boughey Logistics is built to support your growth scan the QR code or turn to page 27

Food, Drink & Hospitality Week returns with a joined-up view of the food & drink sector

Turn to page 08...

Eplore how Boughey Logistics is built to support your growth scan the QR code or turn to page 27

The new ZQ901 pull-wire emergency stop switch by Schmersal is characterised by its robust stainless steel enclosure. It offers optimal mechanical and chemical protection in harsh environments and provides the ideal solution for a wide range of applications.

Thanks to the new housing material, the ZQ901 can be used on transport and material handling systems as well as on large system used in the food processing and chemicals industries. The tried-and-tested technology, used in industrial settings, meets the highest availability standards. The ZQ901 offers an emergency-stop function and manual rest, wire break detection and lengths of wire up to 75 metres.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

EDITORIAL:

Duo Consulting

Enertherm Engineering

Hale Events

Harford control

Montgomery Group

RSK Group

Smart Food Safe Think B2B

William Reed Exhibitions

ADVERTISEMENT

KIMBERLEY READ (Advertisement Sales Manager) JOANNE MURPHY

AMANDA WALMSLEY EVELYN WOOLSTON

RACHEL RILEY - Manager

WALTONS PUBLICATIONS LTD

46 HENEAGE ROAD, GRIMSBY N.E. LINCOLNSHIRE DN32 9ES

Kimberley Read at: kimberley@foodanddrinknetwork-uk.co.uk or Joanne Murphy at: joanne@foodanddrinknetwork-uk.co.uk foodanddrinknetwork.co.uk

Group

Next generation Illig thermoformer set to elevate operations and significantly increase production capacity for further global expansion

In a key strategic move designed to accommodate increased volume and support future global growth plans, Macpac (https://www.macpac.co.uk/)one of the UK’s leading thermoformed packaging manufacturers – has further elevated its operations with the installation of another Illig RDKP 72 automatic pressure thermoforming system at its state-of-the-art plant in Stockport. Representing a £700,000 investment, the new Illig six-bar machine is Macp ac’s twelfth thermoformer. Designed to strengthen its position in the worldwide plastic packaging, it is set to increase capacity and offer more scope in terms of run speed while delivering superior packaging quality, fast error free changeovers and ease of operation.

Graham Kershaw, Macpac’s Managing Director comments: “The installation of the new thermoforming machine underlines our

Odysea, the leading importer and distributor of authentic Greek speciality foods in the UK has launched its new Odysea Traditional Greek Cow’s Milk Yoghurt into Marks & Spencer, available nationwide from January.

The new listing introduces British shoppers to a style of yoghurt rarely seen outside of Greece.

Called “paradosiako” in Greek, this is a traditional Greek yoghurt made with nonhomogenised milk, resulting in a natural layer of set cream rising to the top of each pot during fermentation.

Paradosiako is recognisable by its ivory-coloured creamy skin, which is prized for its richness and depth of flavour. Unlike modern Greek yoghurt, where milk fat is broken down and evenly dispersed, paradosiako is made without homogenisation, resulting in a yoghurt that separates naturally into two distinct layers.

The top layer delivers creamy, buttery richness, while the yoghurt beneath is bright, tangy and slightly loose in texture, reflecting a slower, less industrial production method rooted in village dairy traditions.

In Greece, the two yoghurts sit side by side and while both traditional and modern Greek yoghurts are protein rich, calcium dense and probiotic thanks to fermentation, paradosiako appeals to shoppers seeking minimally processed foods, with its fat left intact and allowed to settle naturally.

Odysea’s Traditional Greek Cow’s Milk Yoghurt will be available exclusively at Marks & Spencer from January at £2.30

commitment to developing and offering customers a wide range of innovative 100% recyclable packaging solutions. It enables us to continuing providing the flexibility to meet orders of all sizes that fit budget constraints yet meet environment goals.

“Crucially, it will allow us to build on our growing worldwide customer base - especially in the food and pharmaceutical markets. On-going investment in best of breed equipment helps ensure we stay ahead of the competition and is a fundamental part of our ambitious business strategy,” he concludes.

The exclusive partnership kicks off a bold new era in Formula 1® racing for CELSIUS, bringing innovative experiences to fans around the globe

Aston Martin Aramco drivers, crew and fans will be inspired to LIVE. FIT. GO.™ on and off the track by CELSIUS

Multi-year partnership to activate on and off the track, garage, hospitality area, branded fitness activations, and at retail

The premium, functional energy drink brand CELSIUS®, has entered an exclusive, multi-year, global partnership with Aston Martin Aramco, naming CELSIUS an Aston Martin Aramco Formula One™ Team Partner and official Global Energy Drink Partner of the team.

The newly announced partnership represents a thrilling new chapter for CELSIUS, driving momentum and redefining the brands presence in Formula 1®. In aligning CELSIUS with one of the most dynamic, ambitious teams in the sport, the collaboration with Aston Martin Aramco further illustrates the brand’s commitment to fueling growth, energizing fans and setting the standard for excellence on a global scale.

Jefferson Slack, Managing Director Commercial, Aston Martin Aramco Formula One™ Team:

“At Aston Martin Aramco, we pride ourselves on how we interact with and engage our fans, with the aim of creating unique experiences that can’t be found anywhere else in the paddock. Our new partnership with CELSIUS provides an exciting opportunity to bring fresh energy to our I/AM programme, further connecting ambition, culture and community.

“Kicking off with our first co-hosted Run Club in Melbourne, throughout the season we will create several creative activations to bring the partnership to life and celebrate a movement of positive energy together.”

“Aston Martin Aramco’s passionate fan base makes for a synergistic partnership, kickstarting an exciting new era for CELSIUS in Formula 1®,” commented Kyle Watson, Chief Brand Officer of Celsius Holdings, Inc.

As part of the partnership, CELSIUS and Aston Martin Aramco will collaborate on a series of events, engaging the fitness and Formula 1® community alike during key races, and bringing the LIVE. FIT. GO.™ mindset to life.

Just as Aston Martin Aramco pushes for excellence on the track, CELSIUS brings energy to moments off the track that celebrate active lives.

Trusted by professionals worldwide, Teknomek manufactures hygienic furniture and equipment tailored to the highest industry standards.

• Uncompromising quality & service

• Innovative, easy-to-clean designs

• Competitive pricing

• Bespoke and customised solutions

Reiser UK, a leading supplier of innovative processing and packaging solutions across the sausage, meat, poultry, seafood, alternative proteins, bakery and dairy sectors, has appointed James Couldwell as its new managing director.

James joins Reiser UK with extensive leadership experience in the packaging machinery sector. Before this role, he served as managing director of ULMA Packaging UK, where he led strategic growth initiatives, strengthened market presence, and championed customer-focused service excellence. His appointment at Reiser UK marks the next chapter in his leadership journey in the processing and packaging equipment market.

“Reiser UK’s commitment to delivering smarter, more efficient and reliable solutions aligns perfectly with my career focus on supporting customers through innovation and practical application,” said Couldwell. “I’m excited to work with the talented Reiser team to build on the company’s strong legacy and drive sustainable growth for our customers and partners, while staying closely connected to customers and their day-to-day challenges.”

Today Britain’s largest bakery brand, Warburtons, announces the launch of its new Fibre Fix range, including a Fibre Fix Loaf and Fibre Fix Rolls. The latest launch offers convenient, delicious solutions for consumers seeking to boost their daily fibre intake.

Fibre plays a crucial role in digestive health, yet recent data from Warburtons* highlights a concerning ‘fibre gap’ with almost half the nation (44%) unaware of how much fibre they should be consuming daily, and 43% not confident that they’re eating enough.

With one in four Brits unsure which foods are high in fibre, the new Warburtons Fibre Fix range offers a clear and delicious solution, making it easier for shoppers to make informed, healthier choices and incorporate more fibre into their daily diets.

The New Warburtons Fibre Fix Range consists of:

Warburtons 500g Fibre Fix Loaf: The sliced wholemeal loaf is expertly crafted to be rich in fibre featuring a diverse seed and grain blend alongside wheat bran. Each slice includes brown linseed, red lentil, chia seed, sunflower seed, pumpkin seed, malted barley flour, sesame seed, hemp seed, and millet seed. Each 100g of product delivers 8.0g of fibre, while an average 50g slice provides 4.0g of fibre. The loaf is suitable for vegetarians and vegans, pre-sliced into 10 pieces including end crusts.

Warburtons 4 Fibre Fix Rolls: Complementing the loaf, these 4 Sliced Wholemeal Rolls with a Seed and Grain Blend and Wheat Bran offer another versatile high-fibre option. Each roll contains brown linseed, red lentil, chia seed, sunflower seed, pumpkin seed, malted barley flour, hemp seed), and wheat bran. With an impressive 8.1g of fibre per 100g and 6.0g of fibre per average 74g roll, they provide a simple way to boost daily fibre. Suitable for vegetarians and vegans, the rolls are conveniently pre-sliced horizontally.

The Fibre Fix range also includes added calcium which helps contribute to the normal function of digestive enzymes.

Jonathan Warburton, Chairman of Warburtons, commented “At Warburtons, we are committed to making healthy eating easy and delicious for families across the UK. Our new Fibre Fix range offers consumers a great way to access high-fibre options. With almost half of Brits unsure about their daily fibre intake needs, we believe these new products will not only empower consumers to boost their fibre consumption but also provide a versatile and tasty addition to their diet.”

The Warburtons Fibre Fix 500g Loaf (RRP £1.85) and Fibre Fix Rolls (pack of 4, RRP £1.75) are now available in major retailers nationwide. For more information, please visit https://www.warburtons.co.uk/our-campaigns/nations-fibre-provider/

“We are delighted to welcome James as managing director,” said Steve Todd, Reiser’s President. “His proven leadership, industry insight and strategic mindset will strengthen our position in the market and advance our mission to deliver exceptional value to our customers.”

For more information about Reiser UK and its full range of processing and packaging solutions, please visit the Reiser UK website https://reiseruk.co.uk/

Cribbs is delighted to announce that Wingstop UKI will become the latest edition to its expanding F&B line-up later this year, after signing a 15-year lease for a 4,500 sq ft unit at Cribbs Venue.

The upcoming arrival of Wingstop UKI helps to cement Cribbs’ position as the South West’s leading retail and leisure destination which offers visitors a full-day out experience.

Wingstop UKI will join favourites Wagamama, Nando’s, Chopstix, Itsu, Patisserie Valerie, and Slim Chickens as part of Cribbs’ F&B line-up –as well as recent arrivals Pizza Express and Honest Burger who have both opened new restaurants at Cribbs over the past couple of months.

Founded in 1994 in Texas, Wingstop quickly became one of the fastestgrowing restaurant chains in the US. The brand launched in the UK in 2018, and into Ireland last year, and now operates over 85 locations.

Known for its signature wings, tenders and burgers all cooked to order and hand-sauced-and-tossed in a choice of ten bold flavours, Cribbs shoppers will soon be able to try the full Wingstop UKI menu, including milkshakes, dips, and recently launched side option of corn.

Wingstop UKI will look to tap into Cribbs’ growing GenZ audience which increased by 13% over 2025 with 36% of visitors being younger shoppers –above the 30% national average.

Iain Minto, Senior Director, Asset Management at Sovereign Centros by CBRE, said: “As we continue to evolve the F&B lineup at Cribbs to cater for a growing GenZ audience it is important to welcome popular brands such as Wingstop UKI. With a great offering, Wingstop UKI has grown into one of the UK and Ireland’s most popular restaurant chains, especially amongst younger demographics.

“With further development and investment taking place across Cribbs Causeway, we are working hard to ensure Cribbs remains a full-day out destination and a strong F&B offering is key to this. With a wide selection of eateries across Cribbs Mall and Cribbs Venue there is something for everyone at Cribbs which is allowing us to attract visitors from across the region and beyond.”

Sovereign Centros from CBRE provide full asset management services across Cribbs on behalf of M&G Real Estate, while Time Retail Partners and Cushman & Wakefield are retained letting agents for the centre, with Green & Partners retained in the leasing advisory role.

Turn the factory floor into a single source of truth.

Harford Control connects physical production to digital accountability — in real time.

One platform. One version of the truth. Zero guesswork.

Paperless Quality

No more paperwork!

Scheduled quality assurance checks with instant verification and corrective action advice to improve quality consistency.

Weight & Volume Control

Reduce giveaway. Cut ingredient loss. Lower the total packaging weight you place on the market — legally and safely & reduce the risk of product recalls

Autocoding & Label Verification

Remove human error from coding and labelling. Avoid recalls, rework, and increased EPR penalties.

OEE & Energy Tracking

Expose hidden downtime and energy drains. Reduce cost per unit while energy prices remain excessive.

The first quarter of 2026 has arrived not with a whimper, but with a roar of regulatory change. For the UK food and drink sector, we are currently navigating a “perfect storm.” Between the full implementation of Extended Producer Responsibility (EPR), restrictive new HFSS (High Fat, Salt, Sugar) advertising bans, and a consumer base that is increasingly sceptical of “ultra-processed” labels in favour of “Real Food” transparency, the margin for error on the factory floor has effectively vanished.

In this new landscape, packaging is no longer just a line item; it is a headline financial risk. With Eco-Modulation now dictating fees—where “Red” rated materials face 20% surcharges—manufacturers can no longer afford to treat the factory floor as a black box. To survive 2026, we must bridge the gap between physical production and digital accountability. At Harford Control, we believe that in this regulatory climate, guessing is no longer a viable strategy.

The challenge for most manufacturers isn’t just the tax itself; it’s the data vacuum on the shop floor. Despite the talk of Industry 4.0, many factories still rely on “estimated”

waste percentages or retrospective paper logs. Under EPR, these estimates are dangerous. If you cannot prove your waste reduction with granular, real-time data, you are almost certainly overpaying your fees.

Without a digital “backbone,” manufacturers are currently struggling with three critical leaks:

Inaccurate Reporting: If your system doesn’t capture the exact amount of packaging scrapped during a botched changeover or a trial run, you are likely paying fees on materials that never even reached a consumer.

The “Giveaway” Penalty: This is a silent profit killer. Overfilling a product doesn’t just waste ingredients; it means you are placing more packaging weight into the market than necessary. In 2026, this compounds your EPR liability, essentially forcing you to pay a tax on your own inefficiency.

Audit Anxiety: PackUK, the scheme administrator, requires more than just good intentions. The inability to provide a transparent, searchable, and tamperproof audit trail when they come knocking can lead to heavy financial penalties.

The first step in closing the data gap is eliminating “Clipboard Culture.” As consumers demand cleaner labels and minimally processed ingredients, the pressure on Quality Assurance (QA) has intensified. Retailers now demand real-time transparency that manual paper logs simply cannot provide.

Harford’s Paperless Quality solutions replace fragmented paper checks with a unified digital stream. By automating data collection, you ensure “Right First Time” production. The system alerts operators the moment a process drifts out of tolerance, preventing hours of noncompliant production.

If Paperless Quality provides the data, Weight and Volume Control provides the immediate ROI. In an EPRregulated world, overfilling is a doubleedged sword: you lose expensive raw materials and increase your packaging tonnage.

Harford’s Weight Control solutions can even integrate directly with your fillers to provide real-time feedback loops. By narrowing the distribution curve and sticking closer to the “Target Weight” without violating Legal Metrology (Average Weight) rules, manufacturers can see massive savings. Reducing “giveaway” by just 1% on a high-speed line doesn’t just save tons of product; it significantly lowers the total weight of packaging reported under EPR. Precision, in this case, acts as a direct tax shield. Overpacking product can also lead to distorted outer case and pallet stacking, leading to more scrap.

In the 2026 landscape, a labelling error is a sustainability disaster. A product recall due to an incorrect label results

in a “double tax” hit: you pay the EPR fees for the wasted packaging of the recalled goods, and you pay again for the replacement run.

Harford Autocoding Solutions minimise the risk of “human error” from the packaging line. By automating the setup of scanners and date coders, we eliminate the primary causes of product recalls. In an era of highspeed production and environmental accountability, Autocoding is a vital pillar of waste reduction and brand protection.

Finally, to combat the volatile energy costs of 2026, manufacturers must find “invisible” capacity. This requires a move beyond simple uptime toward Short Interval Control (SIC) and machine-level Energy Tracking.

Standard Overall Equipment Effectiveness (OEE) systems often miss “micro-stoppages”—those 30-second pauses that can bleed 15% of your capacity over a shift. Harford’s RealTime OEE monitoring identifies these patterns instantly, categorising root causes so your engineering team can act on data, not hunches. By correlating this with energy usage for electricity, gas, and water, you can identify exactly which SKUs are the most energy-intensive. Improving your OEE by even 5% reduces the energy and labour cost per unit, directly offsetting the rising operational costs of the 2026 economy.

The “Perfect Storm” of 2026 is a catalyst for the digital transformation that the industry has long discussed but often delayed. The manufacturers who will thrive in this decade are those who treat shop-floor data with the same respect as their raw ingredients.

By integrating Paperless Quality, Weight Control, Autocoding, and OEE into a single “Source of Truth,” Harford Control enables you to reclaim your margins. We help you stop paying for waste—whether that waste is measured in packaging waste, lost kilowatts, or unnecessary EPR tax payments.

The data vacuum is a choice; precision is a strategy. As we look toward the remainder of the year, the question for leadership is simple: Can you afford to remain analogue in an EPR-regulated world?

If your organisation is preparing for the next phase of its digital transformation, we are here to help. Email us at sales@harfordcontrol.com or call us on +44 (0)1225 764461.

Food, Drink & Hospitality Week will return to Excel London from 30 March to 01 April 2026, bringing together six major trade events under one roof and offering a joined-up view of the food, drink and hospitality supply chain.

For buyers, manufacturers and operators navigating a period of rapid change, the week provides a concentrated opportunity to source new products, assess emerging trends and connect with partners across retail, foodservice and hospitality.

At the heart of the week sit IFE and IFE Manufacturing, which together form one of the UK’s most comprehensive platforms for food and drink product discovery and development. From finished products and early-stage brands to ingredients, processing and packaging solutions, the two shows create a full end-to-end view of how products move from concept to market.

IFE: Product discovery across retail, wholesale and foodservice

IFE remains the UK’s largest product sourcing platform for food and drink, bringing together buyers from retail, wholesale, import and export, and hospitality. The show floor is organised into 13 dedicated sections by product category, making it easier for buyers to navigate the breadth of the offer and focus on relevant ranges, formats and price points.

A strong international presence continues to be a defining feature of IFE, with pavilions and exhibitors representing producers from across Europe, Asia, the Americas and beyond. For buyers looking

to expand or refresh ranges, the show offers direct access to brands exploring new flavours, formats and positioning, alongside established suppliers seeking distribution, private-label partnerships or export opportunities.

The Startup Market once again provides a platform for early-stage brands entering the UK market, while the Speciality Food section highlights producers focused on provenance, craftsmanship and smallerbatch production. Together, these areas reflect the ongoing demand for differentiation and storytelling alongside commercial viability.

The New Products Discovery Theatre, sponsored by TT ICE TEA, offers a fast-paced programme focused on new launches and emerging brands, with short, 10-minute pitches from producers exhibiting in the Startup Market in addition to hour-long takeovers from organisations including FICT (French Charcuterie & Deli Companies), Vatsak and Qualiko.

Alongside this, the Future Food Stage, sponsored by Brambles Digital, explores the wider forces shaping food and drink. Sessions examine evolving consumer expectations, category development and the ideas influencing future ranges, offering strategic context for buyers and brand owners planning ahead.

IFE Manufacturing: From ingredients to operations

Running alongside IFE, IFE Manufacturing focuses on the technical and operational side of food and drink production. The show brings together ingredient suppliers, processing and packaging specialists, manufacturing service providers and technology companies, creating a space for manufacturers and brand owners to address challenges around efficiency, reformulation, sustainability and scale.

A key feature of IFE Manufacturing is the Trends & Innovation Platform, which draws on insight from organisations including Mintel, FMCG Gurus and the Soil Association. Sessions explore how shifting consumer expectations, regulatory pressures and supply-chain realities are shaping product development, with a particular focus on reformulation, functional ingredients and responsible sourcing.

For manufacturers working across multiple categories or channels, the proximity of IFE Manufacturing to IFE allows for valuable crossover between product inspiration and practical delivery, supporting more integrated conversations between commercial, technical and operational teams.

Beyond retail and manufacturing, Food, Drink & Hospitality Week also provides targeted insight for foodservice and hospitality professionals. HRC brings together suppliers across food, drink, equipment, furniture and interiors, serving operators from restaurants, cafés, hotels and contract catering. The show focuses on products and solutions designed for consistency, efficiency and scale, alongside inspiration for menu development and front-of-house experience.

New for 2026, Hospitality Tech360 launches as a dedicated home for hospitality technology. The event brings together platforms and solutions supporting digital operations, from ordering and payments to data, workforce management and guest engagement. Its content programme explores how technology can support growth, resilience and better decision-making across hospitality businesses, with a clear focus on practical application.

The Pub Show and International Salon Culinaire

Also taking place during the week, The Pub Show provides a dedicated platform for the UK pub and bar sector. Suppliers across food, drink, equipment and services meet with operators responding to changing consumer behaviour, cost pressures and evolving drinks trends. Content on the Future of Drinks Stage offers insight into range development, pricing and consumer expectations.

Completing the portfolio, International Salon Culinaire returns as the UK’s largest programme of live culinary competitions. Taking place across all three days, the competition programme provides a platform for chefs at every stage of their careers, while reinforcing the skills, standards and professionalism that underpin the hospitality sector.

With a single badge providing access to all six events across both halls of Excel London, Food, Drink & Hospitality Week offers a rare opportunity to view the industry as an interconnected whole. The strength of the week lies in its ability to bring product discovery, manufacturing insight, retail trends and foodservice application together in one place.

Whether sourcing new products at IFE, addressing production challenges at IFE Manufacturing, or understanding how those products perform in hospitality and retail environments, the week provides a practical, commercially focused snapshot of where the industry is heading in 2026.

Find out more about everything happening at IFE 2026, and register for your free trade ticket, at ife.co.uk.

Cornwall’s hospitality season might peak in the sunshine months, but the smart money gets ready long before the summer crowds arrive. This March, the region’s most influential operators will once again gather in Wadebridge for Expowest Cornwall 2026 - a two-day showcase of the ideas, flavours, and innovations set to define the year ahead.

Taking place on Tuesday 3rd and Wednesday 4th March at the Royal Cornwall Events Centre, the show remains the essential annual meeting point for anyone working in food, drink, leisure, and hospitality across the South West. Whether you’re refining menus, upgrading rooms, rethinking your drinks range, or simply looking for a new spark of inspiration, Expowest provides a unique opportunity to explore what’s next - in person.

A showcase built for doers, tastemakers, and decision-makers.

Over 150 exhibitors will fill the halls this year, bringing everything from fresh produce and artisan foods to tech solutions, equipment, beverages, and operational must haves. It’s a genuine “try before you buy” environment—ideal for chefs, buyers, F&B managers, and business owners who rely on firsthand experience before making decisions that shape their season.

And the visitors aren’t just browsing. They’re buying. Many exhibitors bring exclusive show only deals - discounts, delivery offers, added-value packages, and on stand promotions - making Expowest Cornwall one of the most cost effective dates in the calendar for stocking up or switching suppliers.

A taste of 2026—before anyone else. If your business depends on staying ahead of consumer trends, this is where you’ll find them. From emerging drinks categories and plant-forward eating to sustainable packaging, local sourcing, and tech that improves service and efficiency, the show is a concentrated look at what will influence the region’s hospitality landscape in the year ahead.

Long-standing show partner LWC Drinks, the UK’s largest independent drinks wholesaler, will once again bring an impressive portfolio of wines, spirits, beers, mixers, and NPDled launches - helping operators refresh their drinks menus with confidence.

A meeting point for Cornwall’s hospitality community. Beyond the products, Expowest Cornwall is a social occasion - an annual chance to reconnect with colleagues, meet new suppliers, and share ideas with other operators facing the same challenges and opportunities. The atmosphere is informal, energetic, and geared entirely towards helping businesses thrive.

With free parking, easy access, and clear signage from all main routes, attending couldn’t be simpler. Whether you run a pub, hotel, restaurant, café, deli, farm shop, holiday park, tourist attraction, catering business or retail operation, the show offers something tailored to your world.

For full show details and to register for free entry, visit expowestcornwall.co.uk or call the Ticket Hotline on 01934 733456. Follow the latest updates on Facebook and Instagram (both @expowestcornwall).

Get ready for 2026 the right way - with the contacts, products, and insights that matter.

Food and drink industry event

Foodex Manufacturing Solutions has appointed Joe Brammall as commercial director.

Foodex is the UK’s leading trade show for the food and drink processing, packaging and logistics industries. Held every two years, the event attracts manufacturers of all sizes - from challenger brands and SMEs to established industry leaders - and showcases food manufacturing innovation from across the globe.

Brammall is stepping up to the commercial director role after almost 12 years at the exhibitions division of Foodex organiser William Reed. He joined the business in 2014 as a sales executive and worked his way up through a variety of positions, most recently commercial manager for the National Convenience Show and Forecourt Show.

Brammall said he was excited to be joining Foodex and working with the event’s exhibitors, associations, and partners.

“I look forward to creating an event that reflects the sector’s ambition and addresses its most pressing challenges—from sustainability and automation to workforce development and navigating complex legislation,” he added.

Foodex Manufacturing Solutions will next be held at the NEC Birmingham from 12 to 14 April 2027 as part of the UK Food & Drink Shows umbrella event. Offering direct access to decision makers, exhibitors and visitors can look forward to strategic networking, high-quality leads and commercial opportunities.

The UK Food & Drink Shows 2026 are taking place this year at the NEC Birmingham from Monday 13 to Wednesday 15 April at NEC Birmingham and will comprise four events.

Food & Drink Expo is the destination for discovering fresh ideas, forging connections and gaining insights into the future of food. It attracts key foodservice buyers as well as decision makers from retail and wholesale grocery operations.

Farm Shop & Deli Show offers the best-quality local and regional produce alongside new product development and the latest in equipment, labelling and packaging solutions.

National Convenience Show is the biggest event for the convenience retailing sector and is a one-stop destination for

c-store specific products, services and innovations to help boost footfall, increase basket spend and gain a competitive edge.

Forecourt Show is the must-attend event for sourcing products, fresh ideas and smart solutions to future-proof your business, whether you are part of a symbol group, an independent forecourt, fuel company or dealer.

Around 1,200 businesses will be exhibiting across the four shows, and more than 25,000 visitors are expected to attend to sample the latest in food and drink innovations and explore services and equipment that will help their businesses flourish.

The UK Food & Drink Shows is organised by market-leading business information provider William Reed. Covering industries ranging from food and drink to pharmaceuticals and cosmetics, William Reed publishes digital and print media, including The Grocer, and organises prestigious awards, business events and conferences.

The UK Food & Drink Shows

Comprising:

Food & Drink Expo, Farm Shop & Deli Show, National Convenience Show, Forecourt Show Monday 13 to Wednesday 15 April 2026

NEC Birmingham www.ukfoodanddrinkshows.co.uk

Ingredient distributor and supply chain expert ACI Group has raised serious concerns over proposed changes to the government’s nutrient profiling model, warning that the revised health scoring system risks unfairly penalising whole-food products while allowing ultra-processed alternatives to slip through the net.

The updated model, which underpins HFSS advertising and promotion restrictions, could see fruit-based products such as smoothies and juices treated in the same category as crisps and confectionery despite being nutritionally and behaviourally distinct.

“Under the proposed scoring model, a smoothie packed with fruit, fibre, vitamins and polyphenols is judged using the same blunt logic as crisps,” said Jack Helm, Account Manager - Beverage, Bakery & Functional Foods at ACI Group. “The system is unable to distinguish between naturally occurring sugars in fruit and added sugars in junk food, which fundamentally misrepresents how these products contribute to a balanced diet.”

ACI Group argues that the current approach fails to reflect how foods are actually consumed. Drinking a smoothie as part of a meal or daily nutrition routine is treated identically to eating crisps as an indulgent snack - ignoring context, intent and dietary role.

“The legislation refuses to acknowledge why or when foods are consumed,” added Helm. “This lack of nuance undermines public understanding of healthy eating rather than supporting it.”

Helm also warned that the revised scoring model risks disincentivising whole-food products, while unintentionally rewarding ultra-processed formulations.

“Whole-food products are penalised for naturally occurring sugars, while ultra-processed foods can game

the system through sweeteners or salt manipulation to sneak under thresholds,” said Helm.

“That creates a perverse incentive structure that runs counter to long-term public health goals.”

ACI Group highlighted what it sees as a growing contradiction at the heart of policy messaging.

“The government rightly encourages people to eat more fruit and fibre,” said Helm. “Yet at the same time, it is proposing to restrict the visibility of fruit-based products because they score poorly against its own algorithm. That inconsistency risks confusing consumers and eroding trust – not to mention penalising businesses who have already spent millions on reformulating their product lines, only to find their visibility will be restricted anyway because the government has moved the goalposts.”

ACI Group is calling for a more evidence-based, differentiated approach to nutrient profiling - one that recognises whole foods, dietary context and genuine reformulation efforts, rather than relying on a one-size-fits-all scoring system.

“Public health policy should support informed choices, and flattening complex nutritional data into a single score undermines that,” Helm concluded. “If the goal is better diets and better outcomes, the tools used must be fit for purpose.”

ACI Group is available to support food and drink brands navigating the evolving HFSS landscape, offering expert guidance on formulation, ingredient strategy and regulatory compliance.

Ingredient distributor and supply chain expert ACI Group has urged the food industry to focus on reformulation and authenticity as brands adapt to the UK’s new junk food advertising ban.

While advertisers have been adhering to the regulations on a voluntary basis since October, the New Year marked the official implementation of the ban, which imposes major restrictions on TV and online adverts promoting 13 in-scope product categories, including snacks, baked goods, cereals, and protein bars. To be permitted to feature in any online advertisement or pre-watershed TV spot, products must pass a scoring assessment that balances their fat, sugar, and salt content against their nutritional value. Products fortified with nutrients like fibre and protein are more likely to meet these new requirements.

Karsten Smet, CEO of ACI Group, says that a focus on nutrition and value-adding ingredients is the best way to navigate the complex new restrictions.

“Functional ingredients are no longer supporting players, they’re now headline acts for brands looking to improve the nutritional score of their products,” he explains. “There is a huge variety of ingredients and additives that can boost the nutritional value of food and beverages, and a little added fibre or protein into a recipe could be the difference between maintaining that share of voice, or ceding it to a competitor.

“Rather than investing in advertising sleight-of-hand and looking for ways to game the system, the best approach is transparency. Any brand looking to maintain its presence online or on daytime TV should carefully examine its supply

chains to see what it can add or remove without compromising on quality or cost.”

The new nutrient profiling system works by scoring products based on their energy, salt, fat, and sugar, then subtracting points based on fibre and protein content. Any food product that scores more than four points, or any beverage that scores above one point, will be classed as “less healthy” and be subject to the ban.

“Reformulation is always a challenge – even the smallest tweaks to a recipe can have a major ripple effect throughout supply chains,” adds Smet. “But by tapping into new supply chains and niche ingredients, businesses can turn that challenge into an opportunity to stay ahead of increasing consumer demands for health-boosting meals and snacks. Health claims will become an even more important point-ofdifference for disruptive brands looking to protect or increase their share of voice in the UK.

“We’re here to support businesses in this new era for the industry, connecting them with the most innovative, highperformance functional ingredients that will help their products stand out from the crowd,” added Smet.

To learn more about ACI’s portfolio of products for the food industry, visit www.acigroup.biz

New research has revealed key trends for the UK food industry over the next 12 months. Consumers consider sustainability an essential for brands, along with ingredient simplicity driven by the recent increase in awareness of UPF. Value and health also rank highly.

Sustainability will be a baseline expectation as environmental impact moves firmly into the mainstream. Nine in ten shoppers now consider the environmental consequences of their packaging choices, making recyclable or natural formats a core part of product quality rather than a bonus.

According to the latest Consumer Horizon Report from product intelligence business, Vypr, the confidence gap is widening as consumers gravitate towards products that feel simple, transparent and low-risk. Nearly four in five (79%) trust snacks with fewer, more natural ingredients, and almost two in five (39%) feel ‘definitely’ more assured by this. Meanwhile, ingredient complexity is actively deterring purchase: less than one in seven (13%) will buy a snack containing too many unfamiliar ingredients, dropping to just 7% among women over 45.

This shift links directly to formulation too, with 22% of consumers putting high-protein snacks back on the shelf because the ingredients feel artificial, showing how sustainability, simplicity and authenticity are becoming intertwined purchase cues. Traditional and more familiar treats such as standard chocolate bars are preferred over a protein bar by 55% of consumers, rising to 65% among over-55s.

Value is redefined for 2026 through own-label growth and affordable indulgence, as the cost-of-living landscape drives shoppers to seek reassurance and small pleasures simultaneously.

One in three (33%) of shoppers now have a more positive view of own-label than three years ago, rising to 47% among women aged 18–24, who see supermarket brands as credible, not a compromise.

Health is being reframed around low sugar and natural cues. When seeking healthier choices, 41% gravitate towards low-sugar products, 38% towards natural ingredients, and 34% towards low-calorie positioning, while only 26% see protein as the most persuasive claim.

Ben Davies, founder of Vypr, said: “Consumers are rewarding brands that are transparent, open and brilliantly focused on their niche. With 79% of shoppers trusting snacks with fewer, more natural ingredients, the market is telling us that clarity beats complexity. Brands that reduce cognitive load, offering fewer additional benefit claims, fewer additives and clearer labels are the ones that convert.

“It is an exciting time for food brands, especially new to market and challenger brands as the industry landscape is more diverse than ever before. From own-label innovation to new wellness-led formats, there has never been a stronger market for emerging brands to gain traction, provided they communicate simply, honestly and with purpose.”

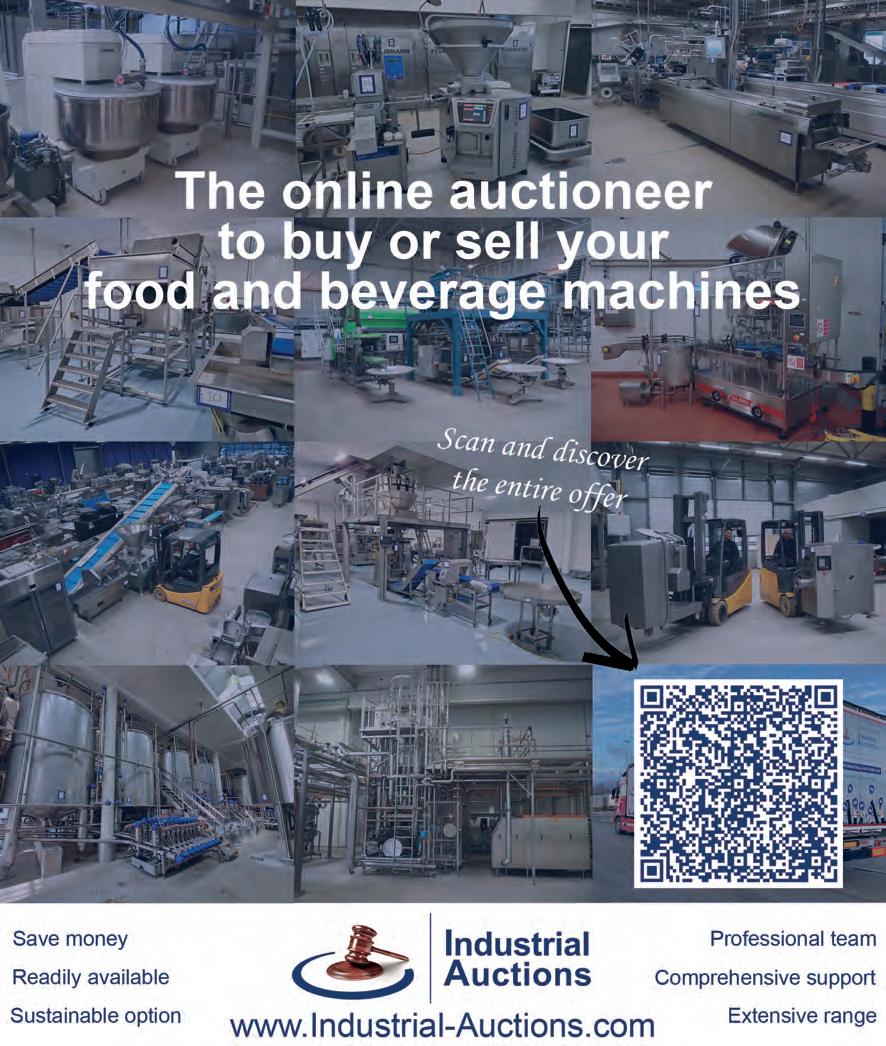

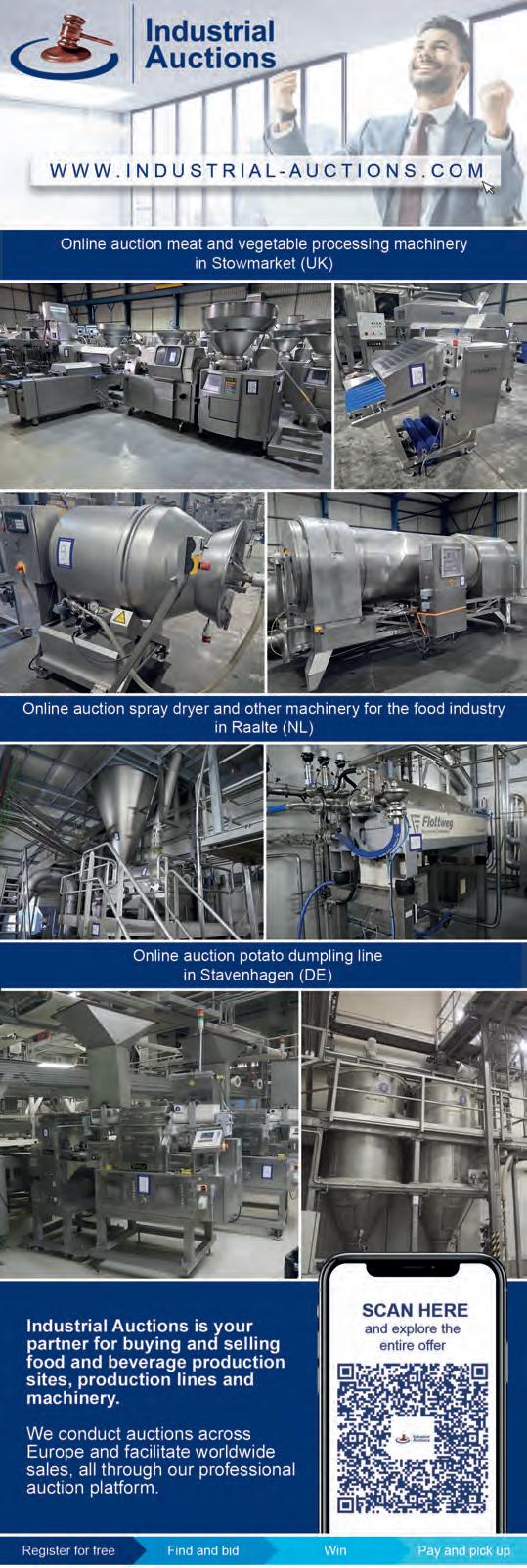

Give machinery a second life

Working to protect nature is an increasing priority for many businesses. In retail, there is a genuine desire to do the right thing, but many feel they do not know where to start.

RSK Group Retail, Food and Drink Director Christophe Lavialle explores how the sector can make positive progress on this important issue starting now.

Sustainability and nature concerns have increasingly become a priority for the retail sector. Its close links with supply chains and raw resources, as well as consumer perspectives and buying preferences, make this a crucial issue to act on. Recently, I spoke to representatives and stakeholders of a range of retail businesses at a British Retail Consortium event focused on nature, along with RSK colleagues from Nature Positive and ADAS. The main challenge presented here was how to make sense of what nature means to business and why it’s important to get it right and to act now.

Declining nature is anticipated to reduce global GDP by $2.7 trillion annually by 2030. This is well within current business cycles and therefore is a present, immediate risk to address.

For the retail sector, where and how it sources products is the most prominent interface with nature. The sector is diverse; it

encompasses everything from supermarkets to fashion, hardware to electricals. As a result, there are varied supply chains that have different nature dependencies, those nature dependencies being where there is reliance on natural resources for raw materials or to deliver a service.

Getting started with nature risk begins with forming an understanding of what commodities, natural resources and ecosystem functions are financially material for business operations and supply chains. Many businesses will have already conducted climate change risk assessments as part of their climate reporting obligations and public disclosures. Through this, they have likely identified and quantified climate-linked risks, such as floods, droughts, increased temperatures or extreme weather events, that may disrupt operations and service delivery. This means that, in reality, when it comes to assessing nature in the business context, most are not starting from scratch, as many of the key steps will have already been worked through, providing a well-informed foundation on which to build.

There are already several regulatory drivers encouraging businesses to look at nature in this way and to consider how they interact with it. The voluntary Taskforce on Nature-related Financial Disclosures (TNFD) in the UK, the Corporate Sustainability Reporting Directive (CSRD) and Europe Deforestation Regulation (EUDR) in the European Union and the anticipated UK Forest Risk Commodity Regulation (UKFRC) all offer a structure to help businesses consider and understand their relationship with nature, and many businesses are already preparing to comply. Some of these frameworks also enable businesses to better understand their interactions, impacts and reliance on nature. The TNFD’s four-step LEAP process provides a comprehensive framework on how to link technical nature assessments to real business risks and opportunities. Many of the emergent regulation is also designed to be interoperable. This means that, done correctly, companies can streamline their assessments and reporting for maximum effect. This also means that nature can be integrated alongside climate or human rights workstreams, enabling companies to develop robust and comprehensive sustainability strategies.

As an example, companies could combine their nature and climate assessments by matching up steps between the TNFD and Task Force on Climate-Related Financial Disclosures (TCFD) frameworks, which were designed to go hand-in-hand. Concurrently, they can start preparing science-based targets for nature (SBTN) because steps 1 and 2 of the SBTN framework are almost exactly aligned to the first two steps of TNFD’s LEAP process. If the business falls into scope of broader regulation such as Corporate Sustainability Reporting Directive, any nature and climate impact and risk assessments can also feed into the environmental reporting pillars.

Starting from the foundations laid by existing reporting demonstrates that many businesses already recognise the importance of working with nature and the environment. So, when thinking about taking action on nature now, many will have already made a significant start. The British Retail Consortium is offering its support to take this further by hosting events and campaigns, which I have seen many organisations passionately participating in. To start developing nature risk and opportunity reporting further, businesses can do the following.

• Under take a preliminary assessment in line with the TNFD guidelines: this can create a baseline understanding of nature and climate ‘hotspots’ across supply chains and the broad business; impacts and dependencies on natural resources and ecosystems, and risks relating to nature; and the opportunities for positive change and impact.

• Engage with stakeholders, internal and external, on the topic: this may involve working with suppliers that share your vision or working together to bring positive change with existing partners.

• Begin to understand across the company and broader value chain where issues may arise: this should include conversations with the board and procurement teams.

• Star t making commitments to develop a strategy to address identified business risk and opportunities.

• Explore setting Science-Based Targets for Nature (SBTNs), on land or water, especially if the organisation already has successful commitments to SBTNs for greenhouse gas reductions.

For retail businesses, the need to develop effective nature targets and how to measure action against them will be critical. Nature underscores much of business activity in this vital sector; getting it right is not only possible but also achievable. As we come to understand more about how closely linked core industries are to nature and the environment, it becomes clearer why action is important. Taking action on nature ensures shortterm resilience, profitability and long-term business survival. It is not just about businesses doing good but about doing good business.

Christophe Lavialle is retail, food and drink sector director at RSK Group. His knowledge and experience of the food industry spans 30 years from farm to fork in North America and Europe. Having started within livestock and crop farm management, he then held various commercial roles in the food sector, including in bakery, fresh and frozen produce, dairy, pet care and more recently shopper and retailer insights. Christophe’s expertise lies in supporting the retail and food industry transition to sustainable and regenerative practices to secure our food, build resilience in the supply chain and enhance the environment.

The beverage manufacturing sector is undergoing a period of rapid evolution, driven by shifting consumer preferences, higher quality expectations and growing pressure on producers to operate more efficiently.

From carbonated soft drinks and bottled water to beer, wine and functional beverages, manufacturers are looking closely at every stage of production to ensure consistency, safety and shelf appeal. One area receiving increased attention is the role of industrial and food-grade gases across the beverage value chain.

Often operating behind the scenes, gases are integral to how beverages are produced, protected and presented. Their application can directly influence taste, appearance, shelf life and operational performance, making them a strategic consideration rather than a simple utility.

Carbonation remains one of the most visible applications of gas in beverage production. Carbon dioxide is central to the sensory profile of carbonated drinks, influencing mouthfeel, taste perception and consumer satisfaction. Achieving consistent carbonation levels requires precise control over gas quality, pressure and integration within the production process.

Beyond production, beverage dispense systems rely on carefully managed gas solutions to maintain product integrity from storage to point of serve. Variations in gas composition or pressure can lead to issues such as excessive foaming, flat drinks or inconsistent pours. As a result, manufacturers and operators are placing greater emphasis on reliable, well-designed dispense systems that support brand consistency across different environments.

Food-Grade Gases and Product ProtectionFoodgrade gases play a vital role in protecting beverages during processing and packaging. Oxygen exposure can negatively affect flavour, colour and shelf life, particularly for products such as beer, wine and sensitive functional drinks. Nitrogen is widely used to displace oxygen in tanks, pipelines and packaging, helping to preserve freshness and reduce spoilage.

The use of certified food-grade gases also supports hygiene and compliance requirements. As food safety standards continue to tighten, beverage manufacturers must demonstrate control over all inputs, including gases used during production. This has elevated the importance of traceability, purity and documented handling procedures within gas supply and usage.

As packaging formats diversify and branding becomes increasingly important, surface treatment has emerged as a critical step in beverage manufacturing. Corona treatment is used to modify the surface energy of packaging materials such as PET bottles, cans and films, ensuring inks, coatings and labels adhere effectively.

Without adequate surface treatment, manufacturers risk poor print quality, label failure and reduced shelf impact. Gas-based corona treatment processes allow these surfaces to be treated efficiently without compromising material integrity, supporting high-speed production lines while minimising waste and rework. Efficiency, Sustainability and the Bigger Picture

The role of gases in beverage manufacturing extends beyond quality and presentation. Optimised gas usage can improve line efficiency, reduce product losses and support cleaner operations. At the same time, manufacturers are under increasing pressure to demonstrate environmental responsibility, driving interest in more efficient processes and reduced emissions across the supply chain.

As the beverage sector continues to innovate, the effective use of gases is becoming a key enabler of performance, compliance and sustainability. When managed strategically, gases support not only the technical requirements of production, but also the broader commercial goals of modern beverage manufacturing.

In today’s fast-paced and constantly evolving beverage manufacturing landscape, efficiency, product integrity and consumer satisfaction remain paramount. Whether producing soft drinks, juices, RTDs, dairy-based beverages, carbonated drinks or alcoholic products, manufacturers rely on gas solutions that not only streamline operations but also elevate product quality, ultimately delivering value to both business stakeholders and end consumers.

Air Products supports beverage producers of every scale with a comprehensive portfolio of food-grade gases and services engineered to meet the industry’s most demanding challenges.

For manufacturers transitioning to lighter, more sustainable packaging formats, Air Products’ liquid nitrogen plays a vital role. Suitable for both medium-sized producers and highvolume operations, each precise drop of liquid nitrogen expands and strengthens bottles, ensuring they maintain their integrity throughout transport and handling.

Air Products’ specialists can evaluate your operational needs and develop a tailored solution covering gas storage, tank configuration and delivery models. Air Products experts can also estimate liquid nitrogen consumption for the dosing system and when required, support this with trials to validate actual usage. This delivers a streamlined, reliable dosing system that supports your sustainability goals and initiatives.

For businesses aiming to extend shelf-life, Air Products provides the expertise needed to protect sensitive beverages from oxidation. Our gases, when used for purging, help maintain flavour, colour and aroma by effectively reducing oxygen exposure. From craft beverages to premium nutraceutical drinks, controlled oxygen levels ensure a cleaner taste profile and improved shelf stability.

Whether producing sparkling wines or large-scale soft drinks, Air Products’ carbonisation solutions ensure the perfect level of fizz and effervescence. We proudly serve a broad customer base, from small producers using food-grade CO₂ cylinders to high-volume manufacturers relying on robust bulk CO₂ supply. Regardless of scale, our carbon dioxide solutions support consistency, operational efficiency and cost-effective production.

For on-site CO₂ drinks dispense, the CarboStore™ system provides a smart, modern alternative to traditional cylinder setups. The Fit & Forget feature uses remote, automated gas-level monitoring to ensure a constant and reliable supply, eliminating manual checks and reducing the need for staff to access the cellar.

Because you only pay for the gas you use, the system helps lower operational costs, with automated refill deliveries arranged outside trading hours and requiring no staff presence. The removal of bulky cylinders also frees valuable cellar space and improves on-site safety by reducing manual handling.

For processes requiring maximum product protection, nitrogen can be used to create low-oxygen environments throughout storage, transfer and packaging. Air Products supplies high purity nitrogen and application expertise to support inerting approaches that safeguard sensitive ingredients, reduce spoilage risks and help maintain product quality. Our experts work with you to build an inerting approach that fits seamlessly into your operations.

For more information, our expert team is ready to help: Call 0800 389 0202 or E-mail APUKINFO@airproducts.com Or scan the QR code to learn more:

A range of products and modes of supply for all business sizes and operations…

As food and beverage manufacturers respond to changing market demands, packaging formats are being asked to deliver more than ever before. Sleeving and cartoning continue to play a central role in this evolution, offering manufacturers the flexibility, consistency and visual impact required in an increasingly competitive environment.

Product ranges are expanding, promotions are more frequent and regulatory information is constantly evolving. In this context, packaging formats that allow change without disrupting production have become especially valuable. Sleeving offers a practical route to refreshing branding, introducing limited editions or creating multipacks without altering the primary container. For many manufacturers, this adaptability supports faster decision-making and reduces the complexity of managing multiple SKUs.

Cartoning remains a dependable choice where protection, handling and presentation are priorities. Whether used for retail display, transport or foodservice supply, cartons provide structure and reassurance throughout the supply chain. Their broad printable surface also allows manufacturers to communicate product information clearly while maintaining a consistent brand presence across markets.

Operational considerations increasingly shape how these formats are deployed. Packaging teams are focused on reducing downtime, simplifying changeovers and maintaining reliable output across long production runs. Equipment that supports smooth material handling, consistent application and straightforward operation helps minimise interruptions and maintain efficiency, particularly in facilities producing a wide variety of products.

Hygiene and quality assurance are also key factors. Both sleeving and cartoning must support cleaning regimes, inspection requirements and traceability expectations without slowing production. Clear visibility, controlled handling and dependable pack integrity all contribute to meeting food safety standards while protecting product quality.

Sustainability is another important driver behind packaging decisions. Manufacturers are under pressure to reduce waste, improve recyclability and demonstrate responsible material use. Sleeving and cartoning formats can support these goals by enabling efficient use of materials, reducing overpackaging and offering alternatives that align with evolving environmental targets.

Increasingly, the conversation around sleeving and cartoning is less about individual machines and more about how packaging formats fit within wider production strategies. When aligned with operational priorities, marketing objectives and sustainability goals, both formats continue to provide reliable, adaptable solutions for modern manufacturing.

For food and beverage producers navigating complex packaging demands, sleeving and cartoning remain proven options because they continue to evolve alongside the industry itself.

The S01 Compact sleever is a patentprotected design demonstrating everything good British engineering should represent. With its innovative, simplistic design removing the reoccurring issue of machine footprint for Food & Drink businesses worldwide, the S01 boasts the smallest footprint of any preglued sleever on the market.

30 years of sleeving experience means we can now proudly share a design-led solution that simply removes common pain points for our customers surrounding space-limiting site layouts, offering them a compact, upgraded solution that solves all their problems.

Our market-leading edge and the focus we give our customers’ needs for maximised efficiency, quicker changeovers, easy access and, of course, reduced footprint have never been more pivotal to the machine design and innovation we aspire to bring to the market.

Compact but capable of speeds of up to 60ppm on a single rotary

and throughput of 120ppm on a double, it sleeves, it codes, it checks, it rejects and it collates, all in a footprint around 1m².

This compact design is super practical and has proven performance reliability with a wide variety of preglued sleeves such as a full watchstrap, band and five-panel sleeve, all on the same machine. Its easy-access acrylic doors ensure full visibility and access to all moving parts, delivering the most hygienic and easy-maintenance machine on the market.

There is also the advantage of reduced changeover times with 100% accurate, repeatable setup. When the machine is in operation, the product pusher allows for maximum flexibility and there is also the incorporated option of finished pack collation for easy outer packing. A further notable improvement to the design is that it even minimises air usage when idle with its improved vacuum system.

This S01 preglued sleever does everything you would want it to do and more and is designed to incorporate a date coder, barcode reader with inbuilt inspection and reject system within the machine.

Book to come and see it at T Freemantle for an on-site demo today.

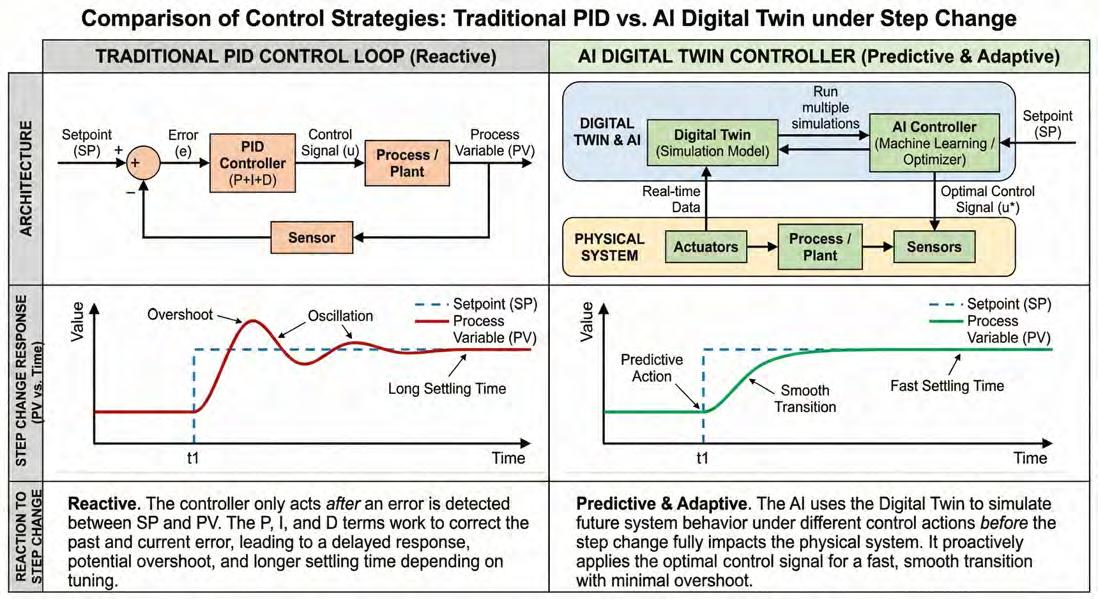

UK thermal engineering specialist EnerTherm Engineering deploys intelligent control systems that turn waste streams into energy assets, delivering fuel savings of up to 50% while positioning manufacturers for a decarbonised future

In an era where food manufacturers face relentless pressure to reduce emissions while maintaining productivity, a quiet revolution is taking place in factory boiler rooms and process halls. At its centre: artificial intelligence that can predict, optimise, and control thermal energy flows with unprecedented precision.

EnerTherm Engineering, a specialist in industrial thermal systems, is at the forefront of applying AI-powered digital twin technology to transform how food manufacturers manage heat, the single largest energy cost in most production facilities. Through an exclusive partnership with Energiency by EPSA, the Industry 5.0 energy analytics platform trusted by global manufacturers including SKF, L’Oréal, and Stellantis, EnerTherm now offers a combination of proven thermal engineering hardware and real-time intelligent software that sets them apart from conventional equipment suppliers. Their integrated approach creates systems that learn, adapt, and continuously improve.

“The food industry doesn’t have a technology problem, it has an integration problem. We see factories with excellent individual systems that don’t communicate with each other. Digital twin

technology allows us to model the entire thermal ecosystem, predict behaviour before it happens, and optimise in ways that were simply impossible five years ago.”

Unlike conventional industrial controls that react to changes after they occur, EnerTherm’s digital twin approach creates a virtual replica of a facility’s entire thermal system. This digital model runs continuously alongside the physical equipment, processing data from sensors throughout the plant to predict outcomes and optimise settings before problems develop.

Integrated with major PLC platforms including Rockwell and Siemens, the system monitors critical parameters such as oil temperature, product colour, moisture content, and throughput rates, continuously adjusting to maintain peak efficiency. The controller does not just respond to conditions; it learns from them, building increasingly sophisticated models of how each facility behaves under different operating scenarios.

For food manufacturers, this translates directly to the bottom line. Ovens that anticipate product load changes maintain tighter temperature bands, reducing both energy consumption and quality variations. Frying systems automatically adjust oil temperature and throughput to match product characteristics. The result is consistent product quality with measurably lower energy input.

EnerTherm’s comprehensive approach addresses thermal energy across four interconnected domains, each enhanced by intelligent digital control.

Heat Recovery. Every industrial process generates surplus heat from exhaust gases, cooling systems, and process equipment. Left unaddressed, this thermal energy simply escapes through exhaust stacks, representing both wasted fuel and unnecessary emissions. EnerTherm’s heat recovery portfolio captures this energy and redirects it to productive use. The company’s Thermstack shell-andtube economisers extract heat from flue gases and transfer it directly into water circuits for process use. Air-to-air heat exchangers capture exhaust energy to preheat incoming combustion air, reducing the fuel required to reach operating temperatures. Stack recovery systems, pollution abatement preheat units, and exhaust heat systems for heating and ventilation round out a portfolio designed to ensure no thermal energy leaves a facility unnecessarily.

Process Heating. Under the EcoHeat banner, EnerTherm delivers process heating solutions engineered specifically for food manufacturing environments. Direct and indirect industrial air heaters deliver clean, contaminant-free process air at 80 to 90 percent efficiency, critical for applications where product quality depends on precise, consistent thermal profiles. Combustion preheated air systems take efficiency further by using recovered exhaust heat to warm incoming combustion air before it reaches the burner. This reduces the fuel required to achieve target temperatures, delivering immediate savings while extending equipment service life. Multi-fuel flexibility allows facilities to adapt to changing energy markets and

availability. The integration of AI-driven controls allows these systems to learn product-specific thermal profiles, anticipating the heat demand of different recipes and production runs. Bakeries, drying operations, steaming processes, and potato processing lines all benefit from controls that adapt to their unique requirements.

Thermal Oxidation. Food manufacturing generates significant waste streams, both solid residuals and volatile organic compounds from cooking, frying, and baking processes. These foul gas streams contain oil mist, steam, and combustible compounds that represent both an environmental compliance challenge and an untapped energy resource. EnerTherm’s thermal oxidation systems transform these waste streams through controlled high-temperature combustion. Volatile compounds and odour compounds are completely destroyed, eliminating emissions concerns, while the combustion process itself releases substantial thermal energy. This energy is captured and returned to the production process rather than being allowed to escape.

CycloTherm. EnerTherm’s flagship CycloTherm technology represents the convergence of all four thermal disciplines into a single, unified system. Designed for manufacturers seeking maximum environmental and economic benefit, CycloTherm creates a true circular energy economy within a single installation. The system captures foul gas from frying or cooking processes, the contaminated air stream containing oil mist, steam, carbon dioxide, and nitrogen, and routes it through a high-efficiency thermal oxidiser. Complete destruction of volatile compounds and odour compounds occurs at temperatures exceeding 750 degrees Celsius, ensuring environmental compliance while releasing the chemical energy contained in the waste stream.

What happens after thermal destruction is where CycloTherm distinguishes itself from conventional oxidation systems. Rather than simply venting hot combustion gases, the system captures this highgrade thermal energy through a multi-stage recovery cascade.

In the primary recovery stage, high-grade heat from the oxidation chamber transfers directly to the process oil circuit, reducing the fuel required by the primary heater. In frying applications, this recovered energy maintains oil temperature with significantly reduced burner input.

In the secondary recovery stage, economiser-stage heat exchangers extract additional thermal energy from the gas stream, transferring it to process water circuits. This preheated water serves cleaning systems, ingredient preparation, or boiler feedwater, displacing energy that would otherwise come from dedicated water heating systems.

In the tertiary recovery stage, lower-grade residual heat preheats incoming combustion air for the oxidiser itself, creating a selfreinforcing efficiency loop. Additional recovery serves space heating requirements or preheats process air for adjacent operations. Beyond thermal recovery, advanced CycloTherm configurations can extract additional value streams from the combustion products themselves. Condensers recover water from the steam content of foul gas, reducing site water consumption and providing feedstock for onsite hydrogen generation. Membrane separation captures nitrogen for food packaging applications and carbon dioxide for beverage carbonation, transforming what was once a waste stream into a source of revenue.

CycloTherm’s modular architecture allows manufacturers to invest progressively as requirements evolve and budgets permit. A bakery might begin with thermal oxidation and primary heat recovery,

then add secondary water heating as the first system demonstrates returns. Additional recovery stages, resource capture modules, and hydrogen-ready combustion systems can integrate seamlessly as decarbonisation roadmaps advance.

This flexibility extends to fuel sources. CycloTherm systems accommodate natural gas, biogas, biomethane, LPG, and hydrogen blends, with combustion chambers designed for eventual 100 percent hydrogen operation. Electric hybrid heating elements provide additional flexibility during peak demand or as grid carbon intensity continues to fall. The result is infrastructure that adapts to the energy landscape rather than constraining it.

What truly sets EnerTherm apart from conventional thermal equipment suppliers is their exclusive UK partnership with Energiency by EPSA, the pioneering Industry 5.0 energy analytics platform. This is not a casual reseller arrangement; it represents a strategic collaboration that fundamentally transforms what EnerTherm can deliver to customers. While competitors supply hardware and walk away, EnerTherm now provides a complete energy intelligence ecosystem that continues to generate value long after installation.

Energiency by EPSA’s technology is already trusted by some of the world’s most demanding manufacturers. SKF, the global bearing manufacturer, uses the platform across their production facilities. DS Smith, L’Oréal, Stellantis, and ArcelorMittal have all adopted the system to drive measurable energy reductions. This is proven technology deployed in over 30 countries, now available to UK food manufacturers through EnerTherm’s integrated service offering.

At the heart of the partnership is Energiency by EPSA’s comprehensive live dashboard, giving customers a front seat view of their entire energy ecosystem in real time. Production managers, maintenance teams, energy managers, and financial directors can all access tailored views configured to their specific responsibilities. The platform displays energy consumption in granular detail, highlights where spending is concentrated, and identifies the next key actions for making savings. Automated notifications alert operators immediately when consumption deviates from targets, enabling rapid response before waste accumulates.

The system goes far beyond simple monitoring. Energiency by EPSA’s algorithms model the specific factors influencing each facility’s energy consumption, from production orders and product references to maintenance schedules and process cycles. This creates a dynamic digital twin that separates and weighs how each variable affects energy use, enabling optimisation that accounts for operational,

safety, and quality requirements simultaneously. Customers can instantly view the results of energy optimisation scenarios, follow AIdriven recommendations, and track the gains achieved.

Through their combined capabilities, EnerTherm provides comprehensive data acquisition and instrumentation services, connecting existing meters, sensors, and production systems into this unified analytics platform. The result is a complete service package encompassing data collection, secure cloud-based storage and modelling, and actionable insights delivered through intuitive interfaces. For facilities pursuing ISO 50001 certification, the platform provides the monitoring and documentation framework to support compliance.

For manufacturers, this data-driven approach transforms the investment conversation entirely. Energy savings are no longer estimates based on industry averages; they are predictions grounded in facility-specific analysis. Customers gain better predictability of project outcomes, clearer visibility of sustainability improvements, and precise identification of cost saving opportunities across their operations. Most importantly, they can proceed with complete confidence that their investment with EnerTherm is fully recoupable, because the numbers have already demonstrated exactly where the returns will come from.

For food manufacturers facing increasingly stringent environmental regulations and mounting pressure from retailers and consumers alike, the path forward can seem uncertain. Regulations evolve, energy markets shift, and technologies advance at an accelerating pace. Systems designed only for today’s requirements risk obsolescence before they deliver their full value.

EnerTherm’s Future Ready approach addresses this uncertainty directly. Rather than optimising for current regulations alone, their systems are engineered for the trajectory of change: hydrogencompatible combustion systems, AI controls that improve with operational data, and modular architectures that accommodate technologies not yet commercially available. Manufacturers invest once and adapt continuously.

The digital twin serves as both the analytical foundation for identifying opportunities and the operational backbone for realising savings. By modelling current performance against theoretical optima, the system quantifies improvement potential with precision, transforming sustainability from aspiration to engineering specification. Documented fuel savings of up to 50 percent and payback periods under three years make the business case as compelling as the environmental one.

As AI capabilities continue to advance, the potential for intelligent thermal management grows correspondingly. EnerTherm’s ongoing development explores machine learning models that predict maintenance requirements before failures occur, optimise energy purchasing against real-time grid conditions, and coordinate multiple production lines for minimum overall energy consumption.

For an industry where energy costs can determine competitive viability, these capabilities represent more than incremental improvement. They signal a fundamental shift in what is possible. The factories of tomorrow will not simply consume less energy; they will consume it more intelligently, adapting in real time to changing conditions and continuously optimising toward theoretical limits.

The digital twin is not just a control system. It is the foundation of the future ready factory.

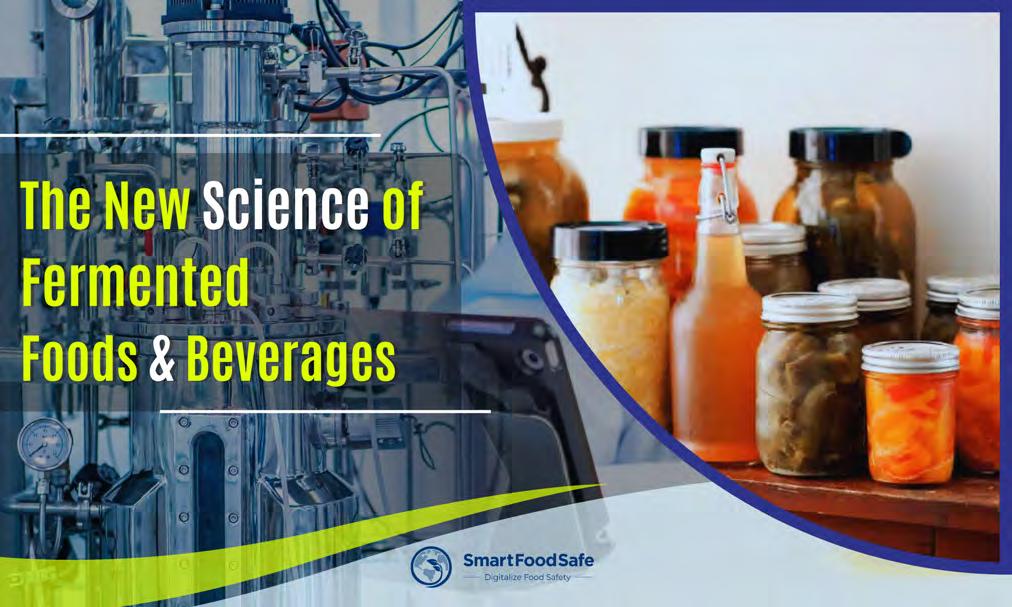

Fermentation has always lived at the crossroads of nature and nurture. For years, humans have used microbes for ages to change basic ingredients into foods that taste better, last longer, and even carry some kind of story or tradition. What has changed in recent decades is not the process itself, but our understanding of it. Modern technology is transforming fermentation from an old craft into a precise science without stripping it of its soul.

At the microbial level, the biggest shift has been visibility. Advanced microscopy, DNA sequencing, and microbial mapping now allow scientists to identify exactly which bacteria, yeasts, and fungi are present during fermentation, and how they behave over time. What was once invisible is now measurable. Producers can track how microbial communities evolve, how they respond to temperature or acidity, and how these changes influence flavour and texture.

This insight has led to the rise of effective starter cultures. Instead of relying on wild or ambient microbes, food and beverage makers increasingly use carefully selected strains designed for specific outcomes, whether that’s a sharp tang in yogurt, layered aromatics in beer, or consistent texture in fermented vegetables. The science maintains traditional profiles while enabling repeatability, a crucial requirement in today’s global food supply.

Technology has also reshaped fermentation environments. Smart fermenters equipped with sensors continuously monitor temperature, pH, oxygen levels, and fermentation rate. Realtime data enables producers to intervene early if conditions drift, reducing spoilage and safety risks. Automation preserves craftsmanship by guaranteeing that every batch satisfies quality standards rather than replacing it.

Perhaps most transformative is the role of data analytics and artificial intelligence. By analysing historical fermentation data, predictive models can forecast flavour development and fermentation outcomes. This accelerates innovation, reduces trial-and-error, and supports sustainable production by minimizing waste.

Even sensory science has evolved. Analytical tools can now identify aroma and flavour compounds at the molecular level, helping producers understand why certain fermented foods smell buttery, fruity, or earthy. This knowledge allows subtle refinement rather than blunt alteration.

Rather than redefining fermentation, modern technology has chosen the more respectful task of understanding it better. By illuminating microbial behaviour and refining the conditions in which it unfolds, science ensures fermented foods and beverages remain safe, dependable, and richly expressive. The microbes remain in charge and tradition holds steady, strengthened by knowledge that ensures their best work reaches our plates and glasses.

Like the VSRT, Fulton’s VSRT-E hybrid boiler is a revolutionary innovation in steam boilers, combining cutting-edge design with sustainability to redefine efficiency in the sector.