The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

1. Open the Cameraor QR code scanner to scan the code.

2. If QR code scanner is not available, pleasevisit the weblinkprovided below.

https://bit.ly/3XHXhhr

The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

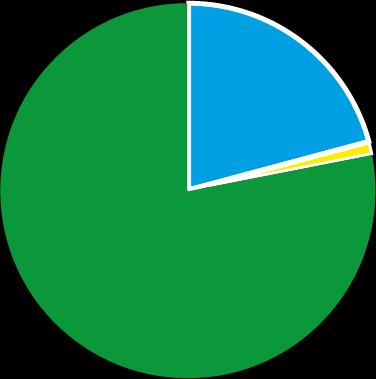

of

● Fire escapes

● Toilets

● Smoking ● Drinks

● Breaks

● Questions

● Talking over others

● Respect others’ points of view

● Timekeeping.

To improve the knowledge and awareness of learners who may work in any environment involving confined space activities during their employment

To be informative and enjoyable.

Learners will be able to understand the hazards associated with working in confined spaces, the duties of employers and employees and the requirements for a confined space rescue.

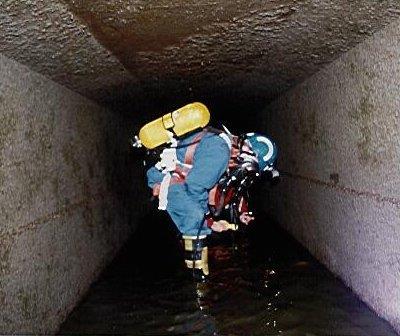

What is a confined space?

‘…a place which is substantially enclosed (though not always entirely), and where serious injury can occur from hazardous substances or conditions within the space or nearby (e.g. lack of oxygen)’

● Many people are killed each year in confined space accidents

Accidents can be caused by many factors:

● lack of safety awareness

● lack of training

● inadequate supervision

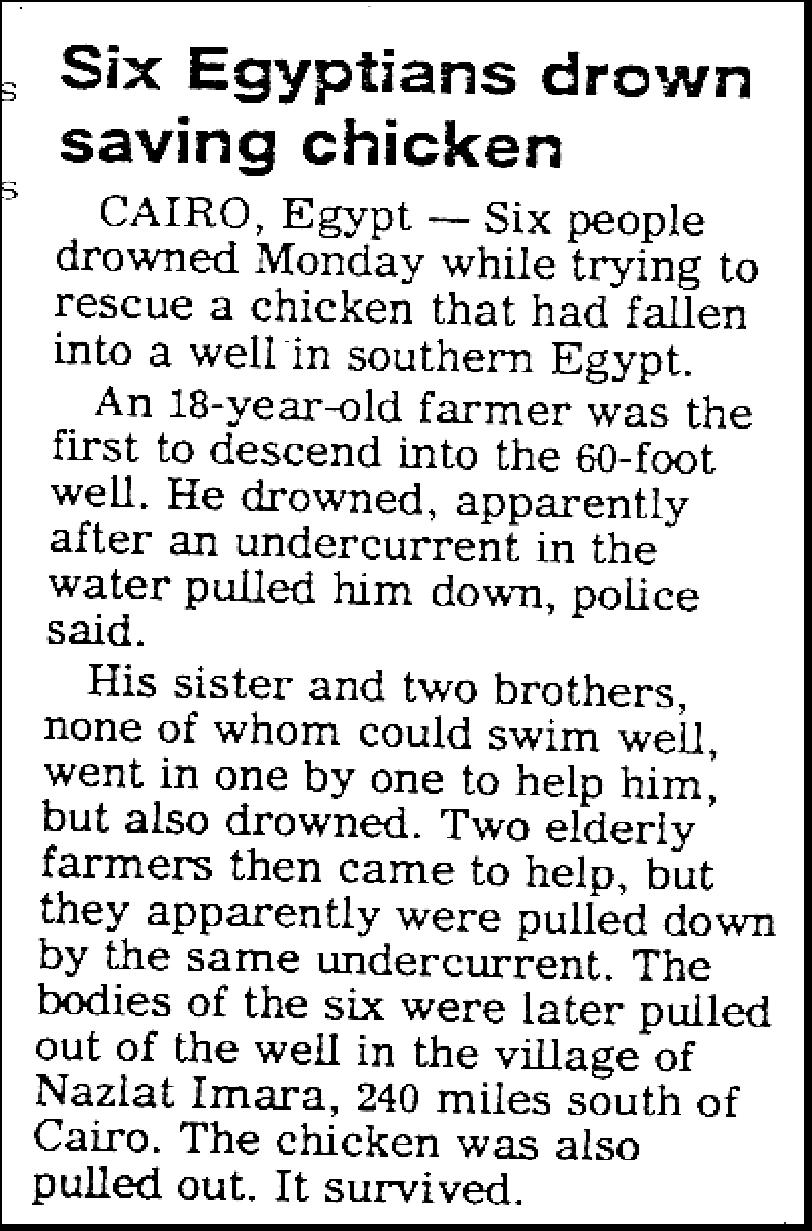

● Situations can be made worse by heroic but ill-conceived rescue attempts which can result in multiple fatalities

● It is essential to be able to identify confined spaces and their hazards when entering and working in them.

A confined space can also be described as:

● space large enough to enter

● with limited or restricted entry or exit

● not designed for continuous occupancy.

In summary confined spaces are spaces that are enclosed or largely enclosed. Unfavourable conditions in a confined space can threaten the health and safety of workers e.g.

● a lack of oxygen and asphyxiation

● risk of explosion

● risk of fire

● risk of drowning

● increased temperature in enclosed working conditions causing loss of consciousness.

of

● Entry with permit

● Entry without permit

● Confined space rescue

Common mistakes

● No means of testing the atmosphere

● No planned rescue procedures

● No retrieval device at the site for confined space rescue

Confined Spaces come in all shapes and sizes

● Storage tanks

● Silos

● Drains

● Sewers

● Industrial vats

● Poorly ventilated rooms.

You will require a permit to enter if you have:

● a hazardous atmosphere

● an engulfment or entrapment hazard

● any configuration hazard

● any foreseeable recognised serious hazard.

Permit required confined space

Is the space large enough to enter, has limited/restricted entry or exit and is not designed for continuous occupancy? Not a confined space

Hazardous atmosphere?

Configuration hazard?

Engulfment hazard?

Any other foreseeable serious hazard?

Non-permit required confined space

● Oxygen deprivation

● Gas leaks, oxidisation

● People at work

● Combustion

● Toxic atmospheres

● Exhaust gases, LPG fumes

● Natural gas from soils

● Chemical vapours. GAS

● Welding or cutting fumes

● Excess heat or cold

● Inflow of substances through leakage, etc.

● Poor access and egress

● Projections and obstructions

● Atmospheric testing and monitoring.

15-19% Decreased ability to work strenuously. May impair coordination and induce early symptoms in persons with coronary, pulmonary, or circulatory problems.

12-14% Respiration increases on exertion, pulse up, impaired coordination, perception, and judgement.

10-12% Respiration further increases in rate and depth, poor judgment, lips blue.

8-10% Mental failure, fainting, unconsciousness, ashen face, blueness of lips, nausea, and vomiting.

6-8% 8 min., 100% fatal; 6 min., 50% fatal; 4-5 min., recovery with treatment.

4-6% Coma in 40 sec., convulsions, respiration ceases, death.

NOTE: Exposure to atmospheres containing 12% or less oxygen will bring about unconsciousness without warning and so quickly that individuals cannot help or protect themselves.

(Source: Compressed Gas Association Bulletin SB2)

● These are the hydrogen sulphide (H2S) exposure limits

● Permissible exposure limit: 10ppm for an average 8 hour period

● Short-term exposure limit: 15ppm for an average of 15 minutes

● Immediately dangerous to life or health: 100ppm.

Concentration levels

Concentration Health Effects

10 ppm Beginning eye irritation.

50-100 ppm Slight respiratory tract irritation after 1 hour exposure.

100 ppm

200-300 ppm

Coughing, eye irritation, loss of sense of smell after 2-15 minutes. Altered respiration, pain in the eyes, and drowsiness after 15-30 minutes followed by throat irritation after 1 hour. Several hours exposure results in gradual increase in severity of these symptoms and death may occur within the next 48 hours.

Severe respiratory tract irritation after 1 hour of exposure. Possible pulmonary oedema (fluid in the lungs).

500-700 ppm Loss of consciousness and possibly death in 30 minutes to 1 hour.

700-1,000 ppm Rapid unconsciousness, loss of respiration, and death after 1-3 minutes.

1,000-2,000ppm Unconsciousness at once, loss of respiration and death in a few minutes. Death may occur even if individual is removed to fresh air at once.

● Colourless, odourless non-combustible gas

● Heavier than air

By-product of: ● carbonation ● organic decay ● grain silos, sewers, storage bins, wells ● fermentation ● digesters.

● Colourless, odourless gas

● Slightly lighter than air

● Chemical asphyxiant

● Primary source: incomplete combustion of organic material

● Petrol-fuelled combustion engines.

Percent* Symptoms

0-10 Shortness of breath on exertion

10-20 Tightness across forehead, slight headache

20-30 Throbbing headache

30-40 Severe headache, nausea, vomiting, collapse on exertion

40-50 All symptoms increased, pulse rate and breathing increased

50-70 Coma, interrupted breathing (Cheyne-Stokes), death

Percent saturation of Haemoglobin with CO [Blood Levels]

(Adapted from Dubois and Geiling)

● Thermal effects (heat and cold)

● Moving machine parts

● Noise

● Vibration

● Radiation

● Fatigue while working in a confined space.

● Restricted means of entry/exit

● Large enough for employee to enter and work

● Not designed for continuous occupancy

Permit-required confined space

● Potential for hazardous atmosphere

● Potential of material engulfing worker

● Configuration that may trap worker

● Contains other foreseeable hazards.

By removing the hazard, it is possible to change a permit required space as a non-permit required space.

● Evaluate workplace

● Inform employees of

● existence, location and danger

● If employees enter:

● develop a written plan

● train and educate employees.

● Know what hazards are present and their consequences

● Verify emergency plans are in place

● Test procedures carried out prior to entry

● Proper equipment available at all times

● Cancel permits upon completion or change

● Remove any unauthorised personnel

● Ensure entry permit conditions are complied with.

● Not to perform any other duties while on watch

● Be aware of any existing and potential hazards

● Summon rescue and emergency service if necessary

● Keep all unauthorised personnel out of the area

● Order immediate evacuation if conditions change

● Must remain outside to monitor the workers

● Must under go special training to recognise hazards

● Maintain effective contact with entrants at all times.

● Know what hazards are present and their consequences

● Use all appropriate PPE as instructed and training

● Maintain contact with attendant at all times

● Exit immediately when instructed or hazard is observed

● Inform attendant of any changes or symptoms of exposure.

● Entrant and attendant must maintain contact at all times

● Must have a backup communication system

● Written plan of action for rescue is required

● Forced ventilation is necessary if there is the potential for atmosphere to move out of the acceptable range.

Standards state that a Safe System of Work for confined spaces must be implemented and written down to serve as a formal record that all hazards have been considered in advance. This Safe System of Work should take into account all appropriate precautions in their correct sequence.

What do you need to consider when creating a safe system of work?

● Identify and evaluate space

● Test for atmospheric hazards and monitor

● Prevention of any unauthorised entry

● Establish/implement procedures and rules

● Identify the employees duties

● Provide and maintain all required PPE

● At least one attendant at all times

● Procedures for calling rescue and emergency service.

● Permit signed by supervisor Entry permits include:

● test results with testers initials or signature

● supervisor name and signature

● name or number of space and personnel (by duty)

● purpose and control measures in place

● name and number of rescue/emergency service

● that acceptable entry conditions exist

● any special equipment and communication procedures

Identifies by name:

● attendant

● entrants.

Supervisor, entrant and attendant depend on each other!

● calibrated air testing monitor

● rescue equipment to hand

● full rescue type body harness

● communication equipment

● protective eyewear (goggles)

● protective helmet

● protective boots

● protective gloves.

Gas detector

● Oxygen content

Flammability ● Explosion potential ● Carbon monoxide ● Hydrogen sulphide

Critical issues

● Training

● Procedures

● Calibration.

Samples can be drawn without entering the space!

At times a simple fan could ventilate the permit-required confined space enough to eliminate the hazard.

At first sign of trouble notify attendant and begin evacuation

Rescue team notified if necessary.

Employer responsibilities:

● Rescuers provided with ALL required PPE

● Fully trained to perform rescue duties

● including authorised entrant’s training

● Practice rescue exercises completed yearly or when changes are made within the team

● Provide any mechanical devices needed for rescue

● Provide full breathing apparatus set for entry.

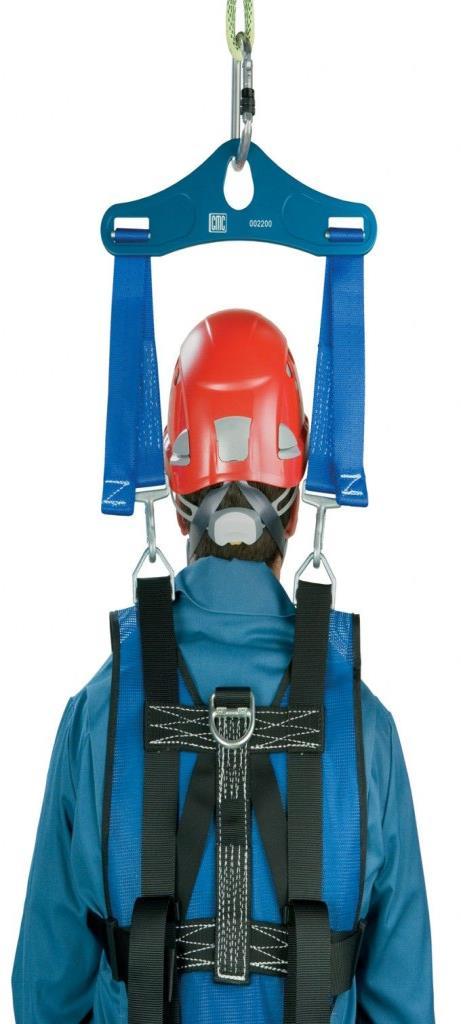

Entrant to wear a rescue harness

Cable attached to the shoulder points

Use a hand winch

Wristlets may be used.

Confined space rescue teams must practise annually at each confined space they may provide rescue from

The employer must be able to verify that the rescue team can perform rescue missions.

Additional training when:

● job duties change

● change in work programme

● new hazard identified

● employee’s job performance is deficient.

As a minimum, training must include:

● recognition of permit space hazards

● control of permit space hazards

● use of atmospheric monitoring equipment

● use and maintenance of PPE such as respirators

● use and maintenance of rescue equipment

● annual practice of permit space rescues

● proficient in first aid and cardiopulmonary resuscitation (CPR)

● all training should be documented.

● During scheduled preventive maintenance at an indoor theme park, a maintenance technician is instructed to enter a ride machinery pit located beneath a roller-coaster track. The pit is partially enclosed, approximately 2.5 meters deep, with limited entry via a ladder. The space is not designed for continuous occupancy.

● The pit has been closed overnight and contains residual nitrogen from a fire-suppression system test conducted earlier in the week. No atmospheric testing is carried out before entry.

● Ten minutes after entering, the technician reports dizziness and shortness of breath over the radio. Moments later, communication stops.

● Is this a permit-required confined space? Why?

● What atmospheric tests should have been conducted?

● What mistakes were made by the supervisor and attendant?

● How could forced ventilation have reduced the risk?

Permit-to-Work system implemented

Pre-entry atmospheric testing (O₂, CO, H₂S)

Continuous monitoring during entry

Forced mechanical ventilation

Trained attendant positioned outside

Non-entry rescue plan using harness and winch

● A contractor is assigned to inspect a balance tank beneath a water-based attraction at a theme park. The tank collects recycled water and organic debris. Access is via a top manway with vertical descent.

● Upon opening the hatch, a strong rotten-egg smell is briefly noticed but ignored. The contractor enters without respiratory protection. Within minutes, he collapses.

● A second worker attempts to enter the tank to assist and also becomes unresponsive.

What caused the domino effect?

What rescue method should have been used?

domino effect

●

● The next worker goes to help

● A third worker goes to help...

1. Open the Cameraor QR code scanner to scan the code.

2. If QR code scanner is not available, pleasevisit the weblinkprovided below.

https://bit.ly/4egSxXb

“NowIt’sATimeForYourGenuineReviews”

HadaGreat TrainingExperience?

ScantheQRCodeand leaveusareviewon