The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

1. Open the Cameraor QR code scanner to scan the code.

2. If QR code scanner is not available, pleasevisit the weblinkprovided below.

https://bit.ly/3XHXhhr

The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

Highfield Place, Shaw Wood Business Park, Shaw Wood Way, Wheatley Hills, Doncaster, DN2 5TB UK Tel: 0845 2260350 Tel: 01302 363277

All rights reserved. No part of this publication may be reproduced, added to, stored in a retrieval system or transmitted in any form or by any means without prior written permission from Highfield Products ltd. This publication is sold subject to the condition that it shall not, by any way of trade or otherwise, be lent, re-sold, hired out or otherwise circulated without the prior consent of Highfield Products ltd.

The UK and Middle East’s leading supplier of compliance, work-based learning and apprenticeship training materials.

● Established in 1982, a family-run business with over 250 staff across the UK and Middle East

● A market leader for multiple qualifications

● Over 2,000,000 learners across more than 100+ countries use Highfield training materials

● An impressive client list including some of the world's most recognisable companies and government agencies

● Over 15,000 training centres and trainers deliver Highfield qualifications across the globe

● Over 500 unique supporting training products

● Over 250 qualifications available.

● Fire escapes ● Toilets ● Smoking

Drinks ● Breaks ● Lunch

Questions ● Talking over others ● Respect others’ points of view ● Timekeeping

As a courtesy to others please set your mobile phone to SILENT MODE.

To improve the knowledge and skills of all learners who may work at height during their employment

To be informative and enjoyable.

Learners will be able to understand the hazards from work at height and its equipment and to apply that knowledge to reduce the risk of injury to themselves and others

This course does not qualify the learners in activities such as:

• Erection of scaffolds (mobile or tower)

• Operation of mobile elevating work platforms (MEWPs)

• The statutory inspection of such equipment

• Climbing aerial towers or similar

• Rope access.

Health and safety is important for the following reasons:

Under international safety laws the employers and employees have statutory duties for health, safety and environment in the workplace.

1. What does your employer have a duty to provide for you?

2. What do you have to do for your employer?

What does an employer have a duty to provide?

● A safe workplace so far as is reasonably practicable

● Information, instruction, training and supervision

● Safe systems of work

● Safe tools and equipment, maintained and inspected as required

● A responsible competent person to look after HSE

● Emergency plans including provision for fire and first aid

● Insurance for employers

● PPE as required for tasks (free of charge to employees)

● Risk assessments and safety planning

● Safe access and egress – ways in, out, up or down for getting to the workplace.

● Look after their own safety

● Look out for the safety of others

● Report any unsafe acts or conditions

● Follow company safety rules and instructions

● Use tools, equipment and PPE correctly as trained and instructed.

Employers

Employees

Self-employed

Designers and manufacturers

Occupiers of buildings in which persons work

Governments.

● OSHAD (Abu Dhabi) Codes of Practice

● Ministry of Manpower (MOM)

● Dubai Municipality Labour Laws

● PDO (Oman O&G)

● Saudi Aramco General Instructions

● Qatar Petroleum or Qatar Construction Standards.

Avoid Work at height wherever possible

Plan

All work at height tasks correctly using a risk assessment and method statement

Provide Correct equipment, permits and training for employees carrying out the tasks

Rescue

Ensure an emergency or rescue plan is in place for all work at height.

With work permits and risk assessments

Inspect

All equipment and surfaces before use

Report

Any issue that should stop work at height.

Trained - theoretical and practical

Experience – through applying knowledge

Confidence – to carry out tasks correctly.

Which of the following is NOT a duty of the employee?

Take reasonable care of themselves

Take reasonable care of others

Cooperate with the employer

Write a risk assessment

What are the main employer’s responsibilities for WAH?

Provide fall arrest harnesses

Ensure health, safety and environment department in charge

Risk assess, plan and use competent persons and correct equipment

Ensure that a fire extinguisher is in place

ILO C155, Armaco Gls, OSHAD

Aramco, PSP, ComHSE

British, French and Spanish

PUWER, LOLER and ComHSE

Knowledge, experience and confidence

Training, assessment and competence

Language, skills and application

Certified, over 18 and skilled

What is work at height?

Work at height means work in any place where, if precautions were not taken, a person could fall a distance liable to cause personal injury. You are working at height if you:

You are working at height if you:

● work above ground or floor level

● could fall from an edge, through an opening or fragile surface

● could fall from ground level into an opening in a floor or a hole in the ground

Work at height does not include a slip or a trip on the level, as a fall from height has to involve a fall from one level to a lower level, nor does it include walking up and down a permanent staircase in a building.

What are the most common causes of fatality to workers in the construction sector?

Falls from a height

Trapped by something collapsing/overturning

Struck by a moving vehicle.

● Planning

Supervision

Carried out in a safe manner

Risk assessment

Emergency and rescue provision

Environmental considerations

Competence levels

Equipment suitability.

The building or area we work in

● Floors (Holes through) ● Access and egress ● Space

Lighting

Temperature

Dust

Wind Environmental factors

The behaviour and ability of the individual

Lack of knowledge

Lack of concentration

Horseplay

Lack of capability.

Occupational factors

The job or task that we carry out

● Manual handling

● Use of hazardous substances

● Use of equipment.

● Falls from height ● Dropped objects

● Equipment failures

● Lack of competence

● Improper use of equipment ● Overloading ● Tipping.

Not providing a safe system to carry out work at height

Failure to recognise a problem.

Estimated figures from ILO

2012-2015, over 120 people have died from falls from height at work

Only around 40 of these fatalities were as a result of a fall from above 2 metres

Approximately 50 of these were as a result of falls from portable ladders or temporary staging

In these same years 3177 major injuries were recorded as a result of falls from height.

What are the main points to consider when carrying out work-at-height tasks?

Planning, prosecution, tipping

Use best priced equipment

Supervise all persons at height or floor

Planning, supervision, risk assessment

1.8 metres

2 metres

All of the above, any height you can fall and injure yourself from 8 metres

Main hazards at height include:

falls, poor equipment use, weather

weight of PPE

tripping on stairway or road

confidence of task requirements

Against distance or consequence of a fall

Avoid work at height wherever possible

● Can the work be carried out at ground level? E.g.

● using reach and wash window cleaning systems

● using hinged street lights so bulbs can be changed from the ground

● Can items be pre-fabricated at ground level?

● Use existing safe work at height gantry’s or walkways

● Can a control unit be positioned at ground level?

Prevent falls wherever possible

● Consider use of permanent guardrails or temporary guardrails if the duration of work is short

● Use equipment with edge protection already in place, e.g. MEWP scissor lift

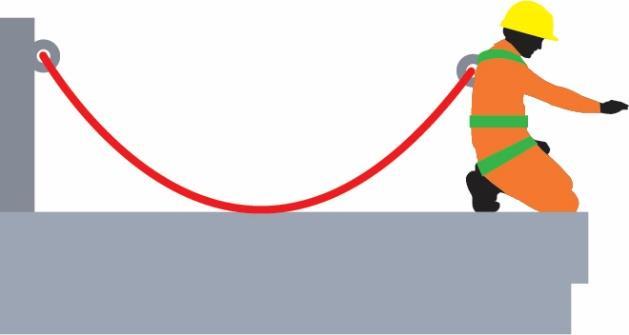

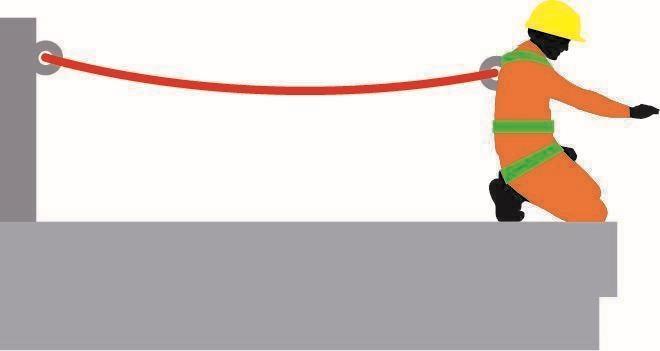

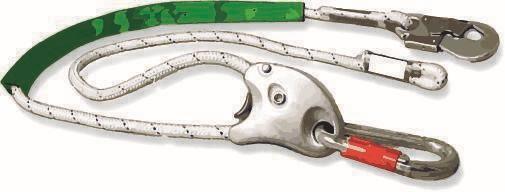

● Use ManSafe systems or restraint lanyards shorter than the distance to the unprotected edge.

950mm min 150mm 470mm max 470mm max

Only prevents the individual from a fall

Work Restraint systems use a fixed or adjustable lanyard, which may be of rope, webbing or steel wire, anchored back to a suitable anchor point. The lanyard is of a length that will prevent the user from falling.

When using work restraint, very careful attention must be paid to corners and edges of rooftops, where a sideways step could place the worker at risk of a fall.

Mitigate/minimise against distance or consequence of a fall

● Ensure all work at height has an emergency or rescue plan

● Consider use of safety nets to reduce distance, or air bags to reduce impact of a fall

● Use second line for rope access work with positioning lanyard

● Provide fall arrest lanyards with shock absorbers for any tasks where falls may occur.

Collective fall protection

Collective fall protection, systems such as:

● Ensure all work at height has an emergency or rescue plan

● Air bags and safety nets can be used when a number of people are working in one location

● Where the risk of a fall cannot be eliminated, work equipment and the correct type of Personal Fall Protection should be used

These will minimise the distance and consequence of a fall.

Minimise the consequences of a fall by the use of

PFPE is to be considered the last resort.

● Where there is a risk to others from falling objects, then the danger area should be cordoned off and warning notices prominently displayed

● All loose tools and equipment should be secured by means of a tether to the person or structure

● Personnel working within the drop zone should wear appropriate PPE.

Minimise, avoid, protect

Prevent, protect, avoid

Avoid, prevent, minimise

Avoid, minimise, prevent

The identification of hazards, calculation of risk and reduction of risk either completely or to an acceptable level.

● Slipping/tripping hazards (floors and stairs)

● Fire

● Chemicals and hot liquids

● Vehicles

● Moving parts of machinery

● Tools and equipment

● Dusts, fumes and poor ventilation

● Human factors

● Electricity

● Working at height

● Manual handling

● Noise

● Poor lighting

● High or low temperatures

Cleaners

Contractors

Disabled people

Expectant mothers

Inexperienced staff

Lone workers Visitors

Are existing precautions and control measures satisfactory? If not… can they be improved?

Do they:

● reduce the risk?

comply with the law?

represent good practice?

Are existing precautions and control measures satisfactory? If not… can they be improved?

Have the staff:

● received training ● received information

received procedures

been advised about risk assessments

been provided with PPE?

Can risks be controlled by other means?

Substitution

Control/contain

Alter

Protect

Educate/Ensure.

Necessary to prove you did everything that was reasonably practicable.

Regularly

If

After an accident or near miss

If new information becomes known.

All work at height requires a risk assessment which includes a practised rescue plan in the case of an emergency

Think about:

● the work being carried out

● the difficulty of accessing the worker by the rescue team

Specific rescue training must be carried out at regular intervals to keep skills to an acceptable level

Training should not be carried out with live persons, a life-sized dummy should always be used.

● Stay calm and quickly assess the situation. Identify the hazards present

● Do not put yourself at risk

● Raise the alarm

● Establish the status of the casualty

● Assess the need for a rescue

● Perform the rescue if possible

● Do you need emergency services? If so call them

● Administer first aid (only if qualified to do so)

● How long have they been suspended?

● Report the incident.

Perform a risk assessment in teams using the sheets provided

hazards

who

evaluate

record

review/revise.

Record the findings

Evaluate the risk

Identify who may be harmed

Identify the hazards

What does a work at height risk assessment have to include?

Implementation

Copies of competence certification

Replacement equipment

An emergency or rescue plan

How

The chance of harm occurring

Calculation and reduction of harm

Assessment of harm

Podium steps

Scaffold and towers

Rooftop harness

MEWPs

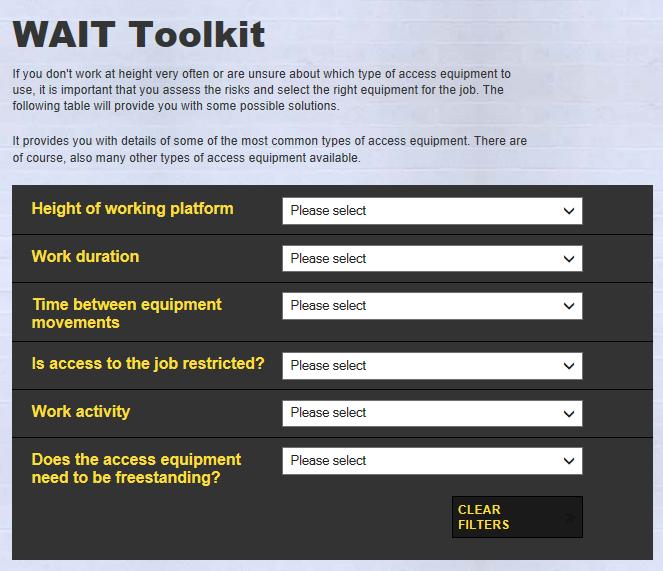

www.hse.gov.uk/work-at-height/wait/wait-tool.htm

Only use a ladder or stepladder:

for access purposes only for light work (if risk assessed) when a ‘handhold’ is available on the ladder or stepladder (or a point above for mini-steps) when three points of contact can be maintained.

Considerations:

● do not be complacent, think about the risks

● ladders are not safe for long-term use (30 mins max)

● cheap in price and mobile

● can be used if a risk assessment has been carried out

Factors to think about before use:

● securely fixed to stop slipping outwards or sideways

● site conditions – exposed element, ground and wall or structure used against

● can you safely stand on ladder and do the job required

● the ability, training and experience of the user

● the type of work required to be carried out and what tools will need to be used.

Must be Industrial rated BS EN131 or similar (no personal ladders allowed)

Able to extend 1m higher than access point

Support maximum load imposed

Must comply with below mentioned lengths

Must be inspected daily

Metal ladders or reinforced GRP plastic

• 6.1m for industrial stepladder

• 9m for a single industrial ladder

• 15m for an industrial extension ladder

Wooden ladders

• 5.5m for platform stepladder

• 5.5m for industrial pole ladder.

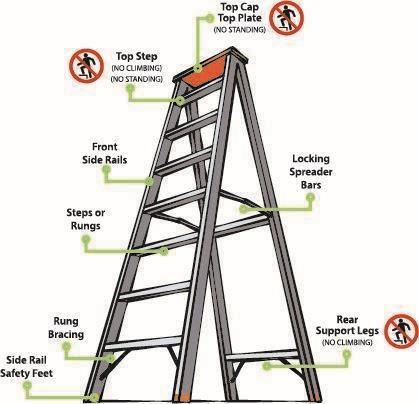

● Overload it (check safe working load)

● Over reach or stretch

● Rest ladders against weak upper surfaces

● Work above top three rungs

● Move ladder while it is being used.

● Ladder rungs must be level

● Worker must be healthy and fit to carry out the task

● Tie or foot ladder properly

● 3 points of contact at all times

● Ladders must lean at angle of approx 75º (4 up 1 out)

● Ladder should extend 1m above landing

● Point for handhold.

1m min above access point

To avoid slips of ladder you must secure it

● Tie ladder to proper point and make sure both stiles are tied

● Use a stability device that is safe such as a ladder strap

● Securely fix the ladder to the wall wherever possible above 3m.

● Foot the ladder as a last resort if unable to tie in

● Overload (check safe working load)

● Use where restraint devices cannot be fully opened

● Don’t use top two steps of stepladder

● Don’t use top three steps of swing-back or double-sided stepladders.

While working on stepladders always face the activity to avoid side loads and keep stability e.g. drilling in solid materials

Where side-on loadings cannot be avoided you should prevent the steps from tipping over by tying in.

Before using a ladder or stepladder you must check whether it is safe. You must check the following:

Have no visible defects

Detailed visual inspection

Suitable ladders or step ladders for work

Maintained and stored safely

Must be inspected daily.

Inspection:

Feet are in good condition

Screws, bolts and hinges are secure

On a stepladder, the ‘spreaders’ can be locked into place

No obvious signs of damage (cracks/splits)

Storage:

Ladders or step ladders must be stored in a well-ventilated area.

Straight ladders in flat racks or wall brackets

Step ladders in closed, vertical position.

● Podium steps are a safe alternative to step ladders to gain access to a high level

● They are built from a framework of aluminium tube and snap lock/hook locking type fittings

● Should be erected by competent experienced operators

● They provide heights ranging from 0.42m to 1.9m.

They must be erected on firm level ground

Check all components are free from damages and used correctly

Podium must be erected in accordance with manufacturer’s instructions

Climb in using steps provided only

Castor breaks must be ON when steps are in use

Check safe working load of platform

Guardrail gate fully closed in position; do not stand on frame to gain extra height

Must be erected following manufacturers instructions.

● Scaffolds should be assembled, moved, inspected and dismantled by a competent person

● PASMA (Prefabricated Access Suppliers and Manufacturers Association)

● CISRS OSTS (Construction Industry Scaffolders Record Scheme)

● Overseas Scaffolders Training Scheme.

Scaffold must only be assembled by competent person

In date inspection tag (at least every 7 days) Access areas and working areas should be clear and safe

Toe boards should be attached minimum height of 150mm Every platform should have guard rails at all sides to prevent a fall All components should be fixed properly and not loose.

Isolate tag and report any issues

● Rooftops should only be accessed by qualified and competent person

● Caution must be taken when working on rooftops as there are many risks associated with this activity

Fall hazards:

Roof edges

Through gaps and holes in roof

Through fragile roof material and roof lights

Falling objects from roof.

● To avoid falls from rooftops or leading edges we need proper protection. Guard rails should be provided as per OSHAD standards in UAE

● Collective fall protection preferred over personal

● Any temporary guard rails should be installed and regularly inspected by a competent person every 7 days.

● Fragile surfaces will not support your weight

● Approx. 20% of fatal accidents at height due to fragile surfaces

Thickness

Design and support structures

Age of material

Roofs can become fragile after time

Prevent unauthorised access.

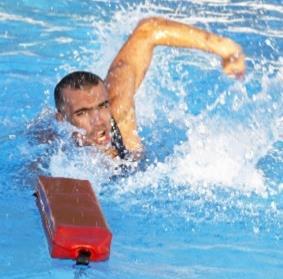

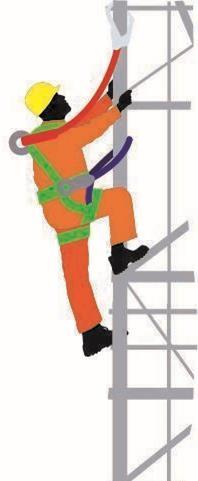

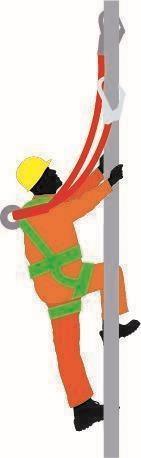

● Short-duration work means working for minutes rather than hours

Minimum requirements for short-duration work:

● A safe means of access on to the roof and for work at roof level

● Proper safety harness (measured lanyard) and anchorage point

● Appropriate for user and in good condition.

● Securely attached to anchor point.

● Mobile elevating work platforms

● Used for working at height in various places

● IPAF PAL card allows you to operate the class you have been trained in

● You can work from a MEWP but not operate unless you hold a licence

● Licence by category

● 1a, 1b + 3a, 3b

● Must have a valid licence to operate a MEWP

● The machine must have an in-date 3rd party inspection certificate. Carried out every 6 months

● Pre-use inspection by operator

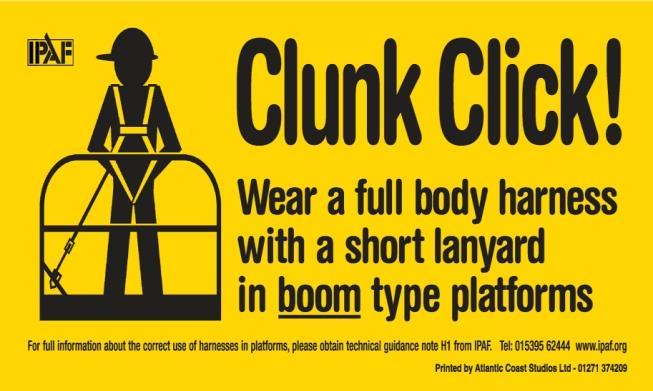

● Adjustable restraint harness in all boom-type machines(3b) and anchor at designated points

● In vertical machines(3a), safety harness is not recommended by IPAF but it can be used depending upon risk assessment

● A rescue plan should be in place.

What distance should be above the access when using a ladder?

0.5m 0m 1m 2m

A MEWP needs a 3rd party inspection done every:

6 months

1 year

7 days

1 month

Which 2 pieces of work at height equipment need an additional licence?

Stepladder and MEWP

Scaffold/tower and rooftop

Ladder and step ladder

Scaffold/tower and MEWP

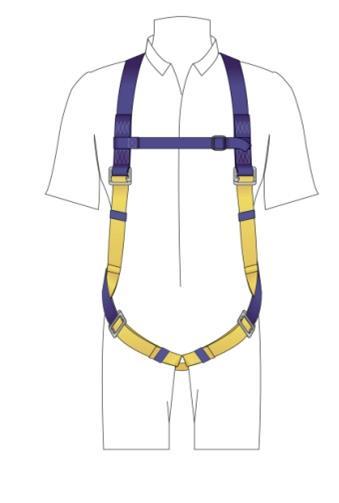

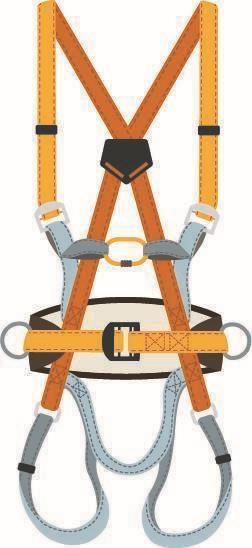

● Personal fall protection equipment (PFPE) is divided into three categories, which are (in order of increasing risk)

Work restraint

Work positioning

Fall arrest.

Restraint, positioning and fall arrest equipment is deemed PFPE

Should only be considered as a last resort when there is no alternative means of protection

● Only approved fall protection equipment may be used when working at height

● Equipment must be CE / ANSI marked (certified European)

● Equipment must comply with the appropriate European (EN) or National (BS) standard.

● Always refer to the manufacturer’s guidelines before use

● Those using PFPE must use an approved hard hat fitted with a suitable chin strap.

Fall arrest and restraint

Fall arrest, vertical climbing and restraint

Work positioning, fall arrest and restraint

Fall arrest and vertical climbing, rope access and work positioning.

This is the safest option when using PFPE

Equipment:

Lanyard too long

The worker is unable to fall from the edge due to the length of the lanyard

You should use a full body harness

Attachment method –accurately measured lanyard or rope

During work positioning activities the worker is supported by their equipment.

During this type of activity workers must ensure they maintain both a primary and secondary attachment point (AP)

Attachment method - twin ropes/lanyard EN 355/354 and pole strap

Harness – full body or sit EN 361/358 ANSI Z359 (US) CSA Z259 (CAN).

They connect between the anchor and harness

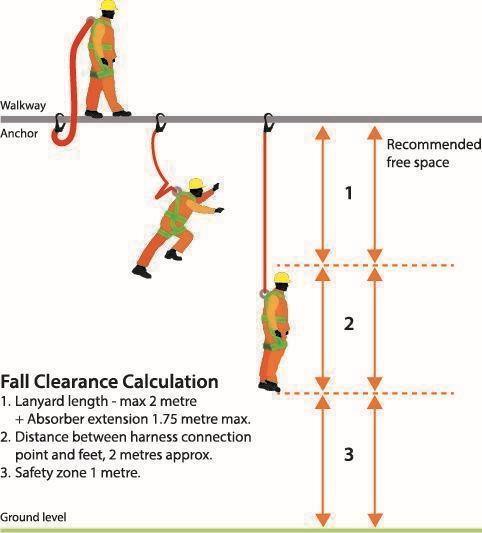

They have integral shock absorption to limit the arrest forces to below 6kN They can be a maximum of 2m in length

Most common types of fall arrest lanyard are single, twin or retractable

Fall clearances allowing for shock absorber extension must be considered.

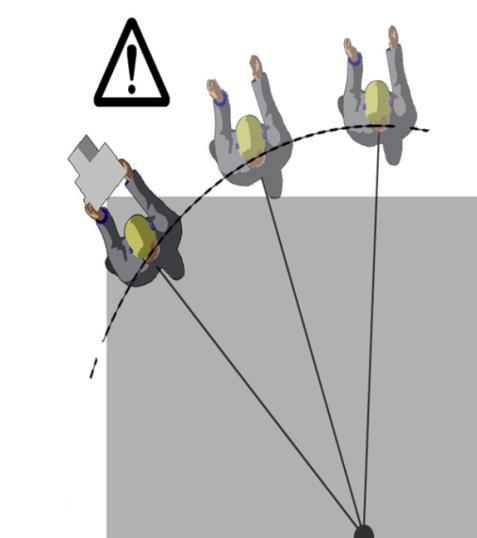

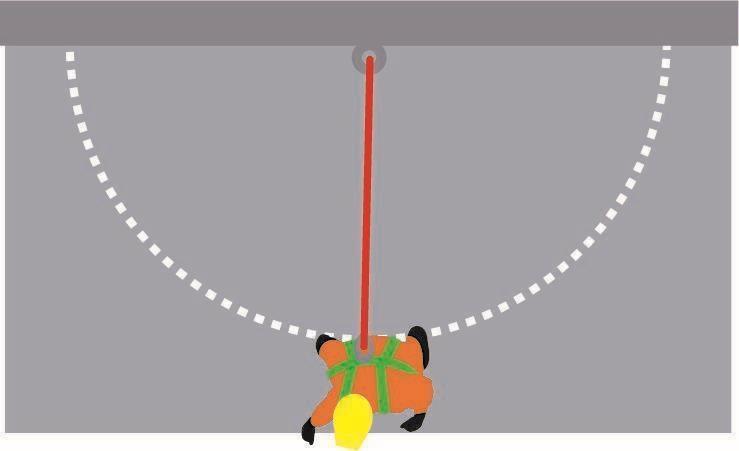

● An ill-fitted harness can cause serious injury and can be fatal

What is suspension trauma?

● Loss of consciousness due to restricted blood flow (straps between your legs)

● Can become unconscious(faint) after as little as 3 minutes

● If you can, try to keep calm and keep your legs moving. This will help to circulate your blood.

The harness MUST be worn and tightened correctly

PFPE stands for:

Personal Fall Protection Equipment

Proper Fall Protection Equipment

Personal Fall Positioning Equipment

Painful Fall Protection Equipment

Harness, rope and lanyard

Ladders, podium and MEWPs

Work restraint, work positioning and fall arrest

Single point, 2 point and 4 point harness

What is the maximum length of a fall arrest

1 hour

5 mins

30 mins 6 hours

A maintenance technician was assigned to inspect the upper framework of a roller coaster during early morning hours. The task required access at approximately 12 meters using a fixed ladder system and a short-duration work platform.

The technician accessed the structure wearing a full body harness but did not connect to a suitable anchor point. No formal work at height risk assessment or rescue plan had been prepared. While repositioning to inspect a joint, the technician lost balance and fell. The fall arrest system partially engaged, leaving the worker suspended for several minutes before help arrived, leading to suspension trauma.

Key Failures

•Failure to plan work at height properly

•Incorrect use of PFPE

•No emergency or rescue plan

•Lack of competent supervision

This incident shows that wearing PPE alone is not enough. Planning, correct anchorage, and rescue arrangements are mandatory, exactly as covered in your Core Requirements for Employers, Risk Assessment, and Rescue Plan sections.

A decorative lighting team was installing themed banners and lighting above a park entrance at approximately 4 meters. A portable ladder was used for access.

The ladder was not industrial rated and was placed on uneven ground. The worker overreached while fixing decorations, causing the ladder to slip sideways. The worker fell, sustaining fractures to the arm and shoulder.

Key Failures

•Incorrect ladder selection

•Poor inspection and setup

•Overreaching

•Failure to follow ladder use rules

This case reinforces that short-duration work still carries serious risk and must be properly assessed. It directly supports your ladder safety rules and equipment selection guidance.

Where to Incorporate This Case Study

During preparation for a live stage show, technicians were adjusting lighting fixtures mounted above the performance area. Work was carried out from a scaffold tower.

Tools were not tethered, and the drop zone below was not barricaded. A spanner slipped from the technician’s hand and fell, narrowly missing staff working below.

Key Failures

•No exclusion zone

•Failure to secure tools

•Poor supervision

•Inadequate general safety controls

This incident highlights risks not only to workers at height but also to people below, a key learning point in your General Safety and Dropped Objects content.

1. Open the Cameraor QR code scanner to scan the code.

2. If QR code scanner is not available, pleasevisit the weblinkprovided below.

https://bit.ly/4egSxXb

“NowIt’sATimeForYourGenuineReviews”

HadaGreat TrainingExperience?

ScantheQRCodeand leaveusareviewon