Safe Moving and Handling

Safe Moving and Handling

1. Open the Cameraor QR code scanner to scan the code.

2. If QR code scanner is not available, pleasevisit the weblinkprovided below.

Handling

Moving and Handling

Who is…

• A family-run business, employing over 300 staff worldwide, including internationally recognised subject matter experts

• Over 2 million people are trained every year using Highfield products

• Over 45,000 trainers and training centres delivering Highfield qualifications

Our services…

Qualifications

Products

Assessments

E-learning.

• Customers include the world’s leading brands

• Internationally recognised accredited qualifications.

International brand recognition – adds value

Why choose…

Validated, relevant, up to date training materials

Quality, value and consistency

High quality trainers

Quality assurance and compliance with regulatory standards - trustworthy

Everything we do centres around our core values:

Quality, value, service & integrity

Authenticity of certificates via check cert facility

Outstanding customer service Integrity – invigilated exams

Expert technical advice

Dedicated centre managers to provide support.

Competency and CPD

• A qualification provides knowledge and assists career progression

• Applying/Implementing the knowledge leads to competency

• To maintain competency you need to keep your knowledge up to date

• This requires: continual professional development (CPD).

Further enhance your knowledge and skills

Free Highfield CPD webinars

Benefits:

• continuing professional development (CPD) certificates for live attendance

• delivered by leading SMEs

• time inconvenient? Watch later

• throughout the year

• a library of past events

To access our events:

• visit www.highfieldqualifications.com

• select ‘online solutions tab’

• select event.

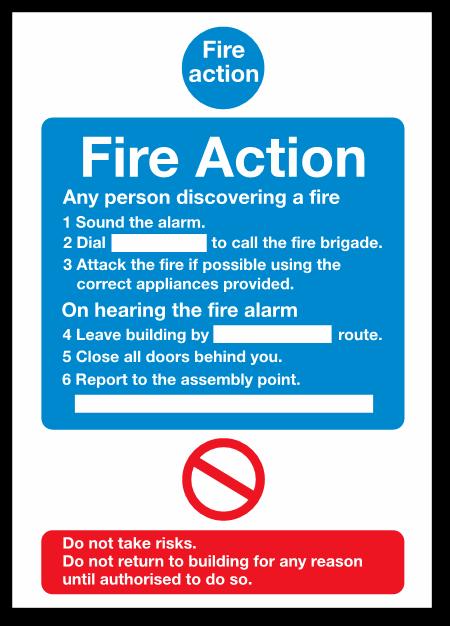

Ground rules

● Fire escapes

● Toilets

● Smoking

● Drinks

● Breaks

● Lunch

● Questions

● Talking over others

● Respect others’ points of view

● Timekeeping

As a courtesy to others, please set your mobile phone to

SILENT MODE

Mobile phones must be SWITCHED OFF and removed from the desk during the examination.

Module 1

Introduction to safe manual handling

What do you understand by the term ‘manual handling’?

The supporting and transporting of a load by hand or by bodily force

Lifting/lowering

Carrying

Pulling

Pushing.

What do you understand by the term ‘manual handling’? (cont.)

List all the manual handling tasks you do in your workplace.

Moving and handling – the bigger picture

Year on year, manual handling injuries are a significant cause of workplace injuries

Musculoskeletal disorders (MSDs) are among the leading causes of occupational ill health issues in Great Britain

There are targeted inspections by the enforcing authorities.

Outline the benefits to employers when manual handling risks are controlled

Production/contracts maintained

Quality of products maintained

Competent employees

Positive safety culture

Insurance costs maintained or reduced

Good reputation with customers.

Outline the benefits to employers when manual handling risks are controlled (cont.)

Avoid injuries at work

Avoid pain, suffering and stress (along with their families)

Retain jobs and earnings

Maintain lifestyles and leisure activities.

Costs to society

• Acute healthcare

• Rehabilitation

• Welfare Injuries caused by incorrect moving and handling place a large cost burden on society

All these are met through tax and National Insurance contributions. KEY POINT

How much do you know?

What is the legal definition of ‘manual handling’?

The supporting and transporting of a load by hand or bodily force

Any moving of objects that does not involve equipment

Lifting, carrying and lowering, but not pushing or pulling

Moving objects and equipment over long distances

How much do you know?

Every year, manual handling injuries cause a _______ number of workplace injuries.

Minor

How much do you know?

Which of the following is a benefit to the employee of using safe moving and handling techniques?

Cost of personal injury claim

Time lost to physiotherapy appointments

Good reputation

Retain lifestyle and employment

How much do you know?

Which of the following is a consequence to a business of incorrect manual handling?

Loss of production

Better reputation

Potential hazards, injuries and ill health Module 2

Manual handling

Which parts of the body are injured by unsafe manual handling?

Back

Fingers and thumbs

Arm

Hand/wrist

Rest of torso

Other.

What

are sprains and strains?

Sprain

Injury to a ligament that has been stretched too far, for example, a twisted ankle

Strain

Injury to a tendon/muscle that has been pulled too far, for example, a back injury caused by poor technique.

What are the functions of the spine?

Allows movement Provides support and stability

Protects the internal organs

Provides the attachment of muscles and ligaments.

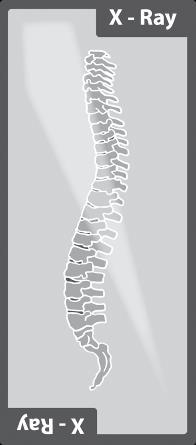

Anatomy of the spine

Cervical spine (neck)

Thoracic spine (mid back)

Lumbar spine (low back)

Sacrum (tail bone).

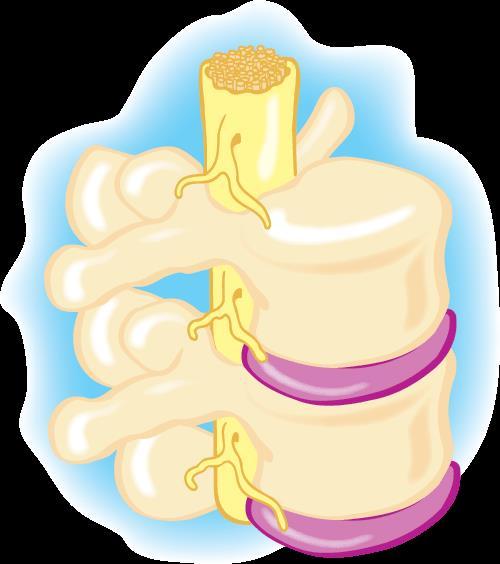

The vertebrae

Facet joints in motion

Flexion (bending forward) Extension (bending backward).

Vertebral body Disc

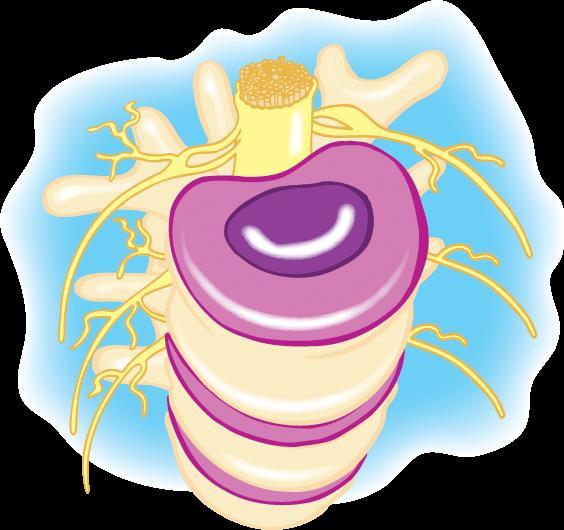

The spinal joint and intervertebral disc

Nerve root

Spinal cord

Vertebrae

Spinal nerves

Intervertebral disc

Facet joints.

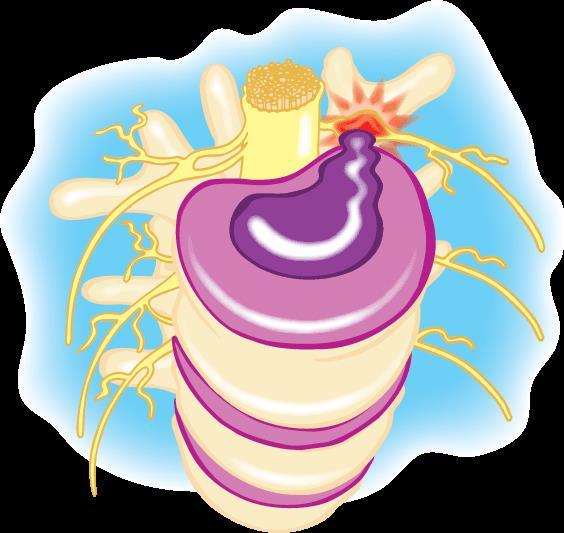

The spinal joint and intervertebral disc

The spinal unit, showing the Intervertebral disc in good health

The spinal unit showing a prolapsed intervertebral disc.

What are acute and chronic conditions?

Acute

Sharp and of short duration. Illnesses that are acute appear quickly and can be serious or life-threatening. When the illness ends, the patient usually recovers fully

Chronic

Of long duration and slow progression. Illnesses that are chronic develop slowly over time and do not end. Symptoms may be continual or intermittent, but the patient usually has the condition for life.

High-risk activities

High-risk activities

Stretching upwards

Poor posture.

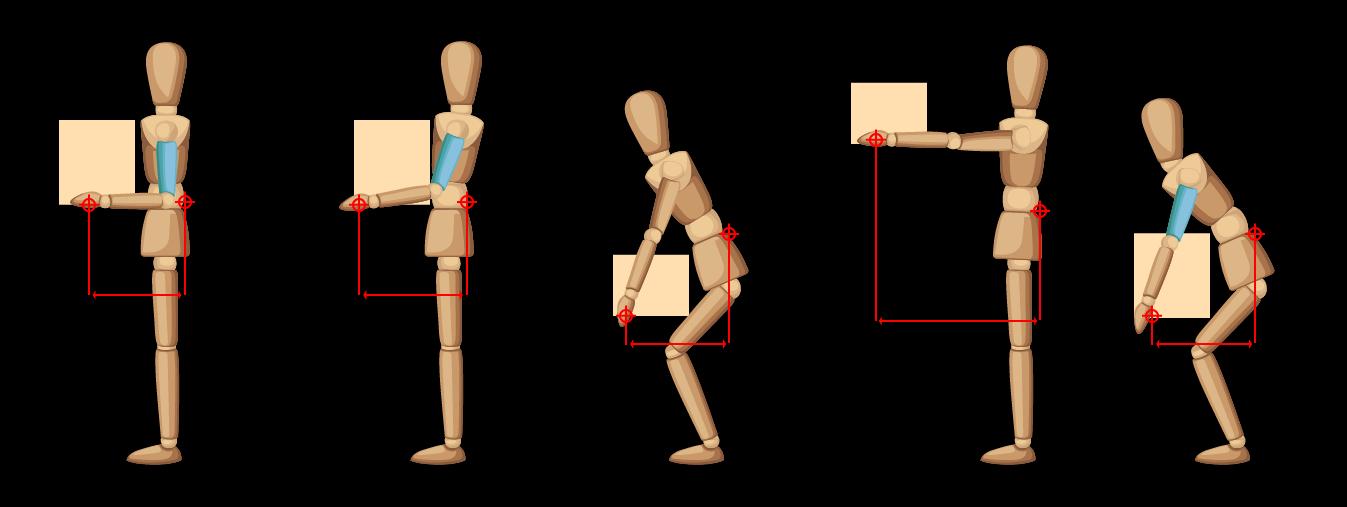

Guideline for maximum handling loads (HSE)

How much do you know?

What could cause an intervertebral disc to rupture?

Carrying a load

Lifting a load to shoulder height

Repetitive lifting and carrying

Holding a load close to the trunk

How much do you know?

Which type of injury is a twisted ankle?

How much do you know?

What is the name of the interlocking joint found in the spine?

Interspinal

Compound

Disc

Facet

How much do you know?

Which of the following is a high-risk activity?

Reaching above head height

Carrying a load

Moving a load at chest height

Pushing a handcart

Legal duties and responsibilities Module 3

Health and Safety at Work etc. Act 1974

“

Every employer must ensure, so far as is reasonably practicable, the health, safety and welfare at work of all employees Health and Safety at Work etc. Act 1974.

”

Number of people exposed What is ‘reasonably practicable’?

Reduction in risk

Severity

Likelihood

Materials

Health and Safety at Work etc. Act 1974 (HASWA)

An employer’s duties are to:

• provide and maintain safe equipment

• provide safe systems of work

• provide information, instruction, supervision and training

• provide a safe place of work

• provide a safe working environment

• consult employees

• have a health and safety policy (written when there are 5 or more employees).

Management of Health and Safety at Work Regulations 1999

Employers must provide comprehensible and relevant information on:

• risks to their employees’ health and safety

• control measures

• emergency procedures

KEY POINT

This must be done using a language that is understood.

Management of Health and Safety at Work Regulations 1999

Employers must take into account the capability of any employee before giving them a task to complete.

Management of Health and Safety at Work Regulations 1999

KEY POINT

Employers must ensure that employees are provided with adequate health and safety training:

• on recruitment

• on being exposed to increased risk

• on a change of job or equipment

• from time to time (refresher training).

Employers’ responsibilities under the Manual Handling Operations Regulations 1992

AVOID manual handling operations where possible

ASSESS the risk of injury from any manual handling operation that can’t be avoided

REDUCE the risk of injury from manual handling operations, so far as is reasonably practicable.

Employers’ responsibilities under the Manual Handling Operations Regulations 1992

REVIEW all manual handling assessments according to the risk or whenever any significant change occurs

RECORD significant assessments. These must be recorded when there are 5 or more employees.

Employees’ duties and responsibilities

• Cooperate with the employer

• Take reasonable care of themselves and others

• Do not alter the equipment provided and use it as instructed

• Report any faults or defects

• Inform the employer if they identify hazardous handling activities

• Health and Safety at Work etc. Act 1974 (HASWA)

• Management of Health and Safety at Work Regulations 1999

• Manual Handling Operations Regulations 1992.

Enforcement of the law

Local authority environmental health officers

• Shops, offices, residential homes, warehousing and entertainment

Health and Safety Executive (HSE)

• Factories, hospitals, nursing homes, mines, schools and construction sites.

Consequences and penalties of non-compliance

Enforcement action hierarchy

Informal advice given during an inspection

A formal letter or advice issued after an inspection

An improvement notice is served

A prohibition notice is served

Prosecution commences.

How much do you know?

Which regulations provide guidance on how to reduce the risks associated with manual handling activities?

Handling and movement regulations

Manual handling in the workplace regulations

Lifting, lowering and carrying regulations

Manual Handling Operations Regulations 1992

How much do you know?

According to the Health and Safety at Work etc. Act 1974, the employee must take _________ care of themselves and others.

How much do you know?

Who must provide a safe place of work as defined in the Health and Safety at Work etc. Act 1974?

The employer

The employee

The safety officer

The competent person

Risk assessments

What is a hazard?

Hazard Something that has the potential to cause harm.

What is a risk?

Risk

The likelihood of harm occurring.

Who undertakes a manual handling assessment?

A competent person

Competent person

Has appropriate skills, knowledge and experience

Knowledge

Skills

Has qualifications in health and safety relating to that type of workplace Is able to implement that knowledge in the workplace effectively

Experience

Has experience in the employer’s type of work

Other qualities

Has good communication skills and attitude.

Load

What would you need to know about a load before moving it?

Is the load:

• heavy?

• difficult to manage?

• bulky?

• unstable or likely to move unexpectedly, for example, if it contains animals or liquids?

• harmful, for example, hot or sharp?

• awkwardly stacked?

• too large to see over?

Individual capability (you)

What do you need to consider about yourself before

carrying out manual

handling?

• Are you fit enough (fatigue level)?

• Are you ill?

• Any past/present injuries to consider?

• Have you been trained with this load?

• What are your handling skills like?

• Are you pregnant?

• Are you familiar with the equipment?

• Do you know the ability of your partner for team lifting?

• Do you need a particular level of strength or other physical requirements?

What you need to know before attempting manual handling

Does it involve:

• holding loads away from the trunk?

• introducing unsatisfactory body movements, such as twisting, reaching upwards or stooping?

• excessive lifting distances?

• moving the load a considerable distance?

• strenuous pushing or pulling?

• a risk of sudden movement?

• frequent or prolonged physical effort?

• a process-imposed work rate?

Environment

What you should know before manual handling

Are there:

• space constraints preventing good posture?

• floors that are uneven, slippery or unstable?

• obstructed floors and traffic routes?

• extremely hot or cold working conditions?

• changes in levels due to steps or ramps?

• chances of strong gusts of wind?

• poor lighting conditions?

• surfaces at different heights?

• any other hazardous conditions?

Equipment and work organisation

What are the other factors to be considered before manual handling?

• Is movement hindered by work equipment?

• Is the work equipment being used unsuitable?

• Is movement hindered by personal protective equipment?

• Is there an indication of a lack of training or information from employees?

• Is the job boring?

• Is the job repetitive?

• Is communication between management and staff failing?

HSE Manual Handling Assessment

Chart ‘MAC’ tool

Hand distance from the lower back

Observe the task and examine the horizontal distance between the operative’s hands and their lower back. Always assess the worst-case scenario. Use the following to guide your assessment

Upper arms vertical AND torso upright

Hands close to the low back G/0

Hands at moderate distance from the low back

Upper arms angled away from torso Torso bent forward G/0

Torso upright. Arms fully outstretched

Hands far from the low back

Upper arms angled away from torso AND torso bent forward R/6

HSE Manual Handling Assessment

Chart ‘MAC’ tool

Vertical lift region

Observe the position of the operative’s hands at the start of the lift and as the lift progresses. Always assess the worst-case scenario. Use the following illustrations as a guide Hands

HSE Manual Handling Assessment

Chart ‘MAC’ tool

Torso twisting and sideways bending

B. Hand distance from the lower back

Observe the task and examine the horizontal distance between the operative’s hands and their lower back. Always assess the ‘worst case scenario’. Use the following to guide your assessment:

Observe the operative’s torso as the load is lifted. If the torso twists in relation to the hips and thighs or the operative leans to 1 side as the load is lifted, the colour band is amber and the numerical score is 1. If the torso both twists and bends to the side as the load is lifted, the colour band is red and the numerical score is 2 Little or no torso

HSE Manual Handling Assessment

Chart ‘MAC’ tool

G = green – low level of risk

Although the risk is low, consider the exposure levels for vulnerable groups, such as pregnant women or young workers, where appropriate.

A = amber – medium level of risk

Examine tasks closely.

R = red – high level of risk

Prompt action is needed. This may expose a significant proportion of the working population to a risk of injury.

P = purple – very high level of risk

Such operations may represent a serious risk of injury and should come under close scrutiny, particularly when the entire weight of the load is supported by 1 person.

The colour-coding helps to identify the level of risk. Which colour requires immediate action to reduce risk?

How much do you know?

Which of the following is a manual handling hazard?

How much do you know?

A _________ is something with the potential to cause harm.

Warning Danger

Hazard

Risk

How much do you know?

What is meant by the word ‘risk’?

The potential to cause harm

The danger presented by an activity

The lack of safety

The likelihood of harm occurring

How much do you know?

Before asking an individual to undertake a work activity, the employer must take into account their:

Manual handling controls Module 5

How can we reduce the risk?

The load

Can the load be made:

• lighter?

• less bulky?

• easier to grasp?

• more stable?

• less damaging to hold?

KEY POINT

Employers must ensure that employees are provided with adequate health and safety training.

How can we reduce the risk?

The individual

• Individuals’ capabilities must always be given priority

• Employees must be given full details on the tasks they will be expected to undertake

• Where higher risks of manual handling injuries are identified, specific training must be given

• Procedures to protect new or expectant mothers must be in place

• Employees must be given information on the tasks they are likely to face in the workplace

• Policies and procedures must be adjusted to address temporary capability issues

• Work clothing and personal protective equipment, when worn, must be suitable for manual handling activities.

How can we reduce the risk?

The task

• Use appropriate equipment designed to assist with lifting/handling

• Make amendments to the workplace’s layout o reduce high-risk movements, such as twisting and stooping

• Improve efficiency in the workplace by introducing changes to the layout and processes

• Avoid lifting from floor level

• Avoid lifting above shoulder height

• Vary work routines

• Reduce the activities that require repetitive handling

• Push rather than pull.

How can we reduce the risk?

The environment

• Make the workplace obstruction-free to allow a full range of movement

• Ensure flooring is suitable and does not cause slips or trips

• Improve environmental conditions, such as lighting, heating and ventilation

• Redesign work processes and procedures to avoid steps or steep ramps

• Ensure staff maintain correct posture by redesigning the workplace if necessary.

How can we reduce the risk?

Other factors

Work organisation

• Rotate tasks or make adjustments to the work routine to reduce boredom

• Reduce the number or frequency of mundane tasks where practicable

• Utilise individuals’ skills more effectively

• Make deadlines and targets achievable and safe

• Involve the entire workforce in communication and assessments

• Make manual handling training relevant to the manual handling activities carried out in the workplace.

How can we reduce the risk?

Other factors

Equipment

• Utilise competent advice to ensure the correct equipment is obtained

• Ensure the type of wheels used are suitable for the workplace flooring

• Make sure grips and handles are in good order and suitable, particularly when gloves are worn

• Ensure work equipment is suitably maintained and always fit for purpose

• Brakes should be effective and easy to use.

Reducing the risk

Equipment designed to handle loads.

Reducing the risk

Equipment designed to carry people and loads.

The safety of lifting and handling equipment

Daily user checks – visual and manual checks for damage and that safety devices, wheels and brakes are working

The employer must maintain, service and test lifting equipment and hoists in accordance with manufacturers’ instructions

Equipment that is subject to the Lifting Operations and Lifting Equipment Regulations (LOLER) must be tested and examined by a competent person and have a valid certificate of ‘thorough examination’

Passenger-carrying lifts and hoists – examined every 6 months

Non-passenger-carrying lifts or hoists – examined every 12 months.

How much do you know?

Which of the following control measures would reduce the risk from the load?

Avoid lifting from floor height

Make the workplace obstruction

Ensure the wheels on the equipment are suitable for the flooring

Provide hand holds on boxes

How much do you know?

Which of the equipment listed below would MOST effectively reduce the manual handling of a load?

A bucket on wheels

A conveyor belt system

A wheelchair

A hand pallet truck

How much do you know?

Equipment that is subject to the Lifting Operations and Lifting Equipment Regulations (LOLER) requires which type of certificate?

Thorough examination

Annual examination

Six-monthly certificate

Safety certificate

How much do you know?

Which of the following control measures would reduce the risk from the TASK?

Avoid lifting above head height

Check the safe working load

Avoid steep steps or ramps

Check the individual’s capability

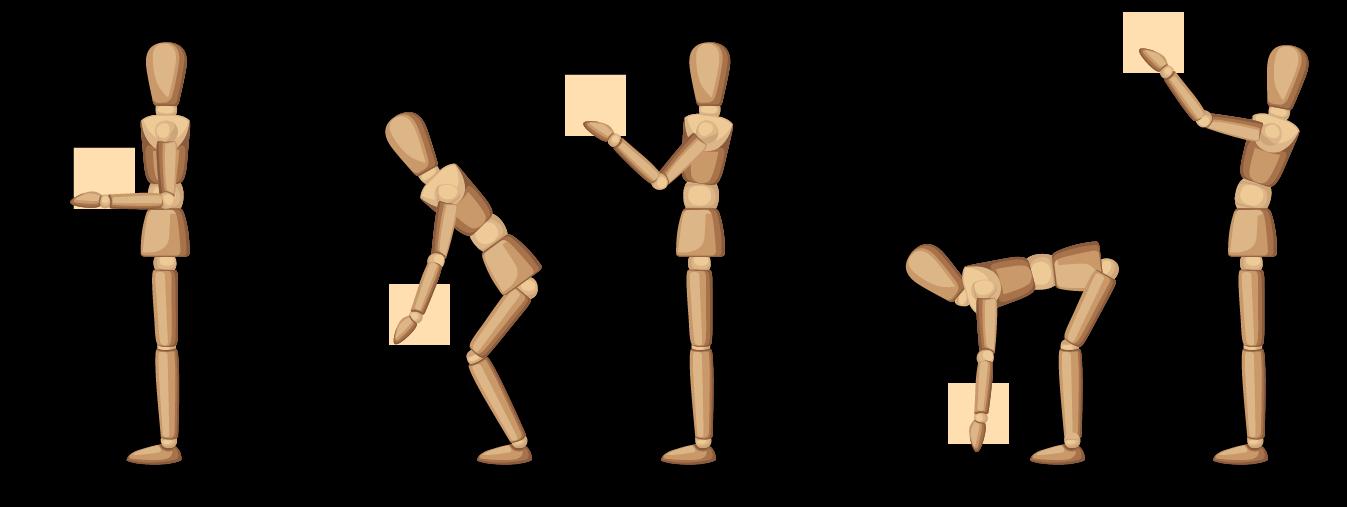

Principles of safe movement

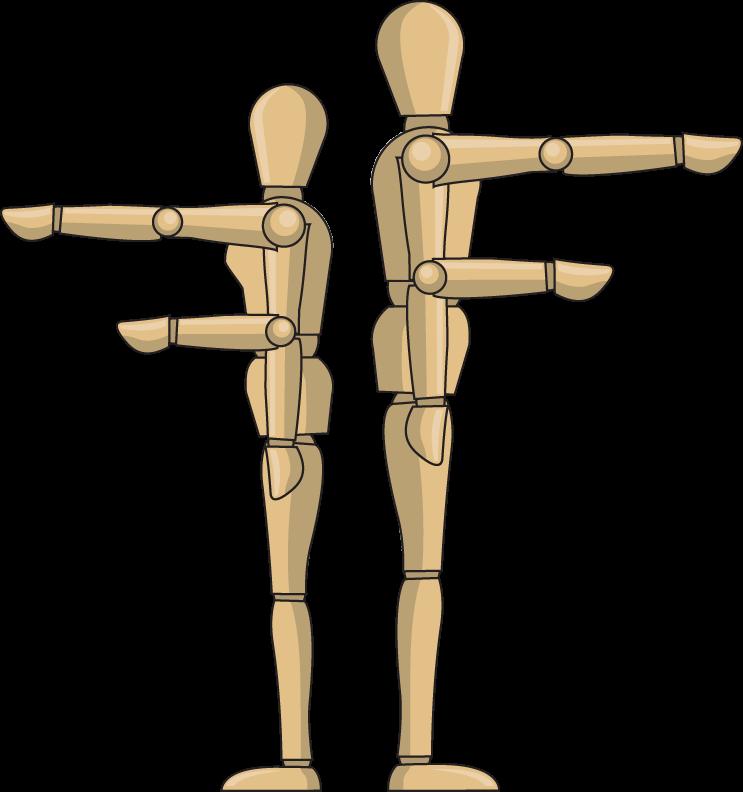

Three key safe movement principles

Safe movement principles

Warm up

Check load

Is help needed?

Plan

Clothing

Grip

Repetitive strain injuries

Storage.

Safe movement principles

Stop and think.

Safe movement principles

Position the feet.

Position of feet

Safe movement principles

Safe movement principles

Lift with a firm grip and keep the back slightly flexed. 4

Safe movement principles

Raise the load with the legs.

Safe movement principles

Keep the load close to the body.

Carrying loads

Keep the load close to the body

Avoid changing your grip

No twisting

Look where you are going

Do not obstruct your vision

Use mechanical aids.

Unloading

Keep the direction of unloading square on

Bend the knees

Allow for slight back flexion

Watch your fingers!

Rest the load

Slide Secure.

Pushing and pulling

Tips when pushing and pulling

• Use handling aids with handles between the shoulder and waist

• Ensure the movement is within the individual’s capability

• Make efforts to remove the need to push or pull when on slopes, either up or down

• Manage uneven surfaces

• Maintain correct stance

• Maintain correct pace.

Team handling

Where there is more than 1 person involved,the risk of injury goes up, so:

assess the load

plan the movement decide who will give the orders check that all of the team is ready before beginning and that all can communicate ensure instructions are clear and incisive, for example, ‘ready, steady, go’

Remember that putting down needs just as much organisation as the lift.

2 How much do you know?

What is the correct sequence of the safe movement principles?

Position the feet

Get a firm grip and keep the back slightly flexed

Stop and think

Raise with the legs

Bend the knees

Keep the load close to the body.

How much do you know?

Which of the following is a safe movement principle?

Keep the back stiff and straight

Keep the back slightly flexed

Lift with the back

Twist the back to change direction

How much do you know?

Which of the following would be the best method of reducing the risk of manual handling injuries?

Automate the process

Provide back support belts for lifting

Instruct staff in safe lifting techniques

Use manual lifting equipment

How much do you know?

Which of the following statements is true?

When there is more than 1 person involved in a task, the risk of injury goes down

When there is more than 1 person involved in a task, the risk of injury goes up

When there is more than 1 person involved in a task, the risk of injury may go up or down

When there is more than 1 person involved in a task, the risk of injury remains the same

How much do you know?

Which of the following is correct?

Loads should be carried close to the body

Loads should be carried at arm’s

length Loads should not be carried further than 25m

Loads should not be wider than the body

1. Open the Cameraor QR code scanner to scan the code.

2. If QR code scanner is not available, pleasevisit the weblinkprovided below.

https://bit.ly/4egSxXb

“NowIt’sA

ScantheQRCodeand leaveusareviewon

Thank you for listening