PlantFloor FOCUS

Flooring, equipment and everything in between

Flooring, equipment and everything in between

Welcome to our debut Plant Floor Focus

E-Edition 2025, where operational excellence, safety compliance, and technological innovation converge on the food manufacturing plant floor. This comprehensive guide explores the critical foundation elements that transform ordinary production spaces into world-class food manufacturing facilities.

The food manufacturing industry stands at a pivotal moment where every component—from flooring to packaging lines—plays a crucial role in overall success. VERNi’s Supaflor® flooring systems demonstrate how advanced materials science delivers seamless, antimicrobial surfaces that eliminate hygiene challenges while withstanding demanding thermal and chemical conditions. These represent foundational investments in food safety and operational efficiency. Modern packaging and processing equipment continues reshaping production capabilities. IJP Filling & Labelling’s custom-engineered

automation systems showcase South African leadership in precision filling and labelling solutions, while Filmatic Packaging Systems’ beverage filling technologies, including their innovative Fil8 model, achieve both volumetric accuracy and sustainability goals while meeting stringent EHEDG standards.

Behind every efficient operation lies the science of proper lubrication and maintenance. FUCHS

LUBRICANTS’ LCCP Audit tool and ISO 21469 certified CASSIDA range illustrate how lubrication practices directly impact food safety, energy efficiency, and equipment longevity.

PMD Packaging’s new range, including the Taurus mini VFFS machine and high-speed Sigma 1 system, reflects an industry responding to diverse market needs, enabling entrepreneurs across Africa to access professionalgrade packaging capabilities previously available only to largescale operations.

This e-edition addresses the fundamental question: How do we

build food manufacturing facilities that consistently deliver safe, highquality products while maintaining operational efficiency and economic viability? From antimicrobial flooring to precision packaging lines, every element contributes to manufacturing excellence.

The plant floor is where theory meets reality, where safety protocols are tested, and where operational efficiency is ultimately measured. We’ve packed this edition with insights, innovations, and practical solutions that we believe make for compelling reading—this truly is a page-turner, and we hope you enjoy diving into these stories just as much as we enjoyed bringing them together for you!

Kelebogile (Lebo) Nondzaba

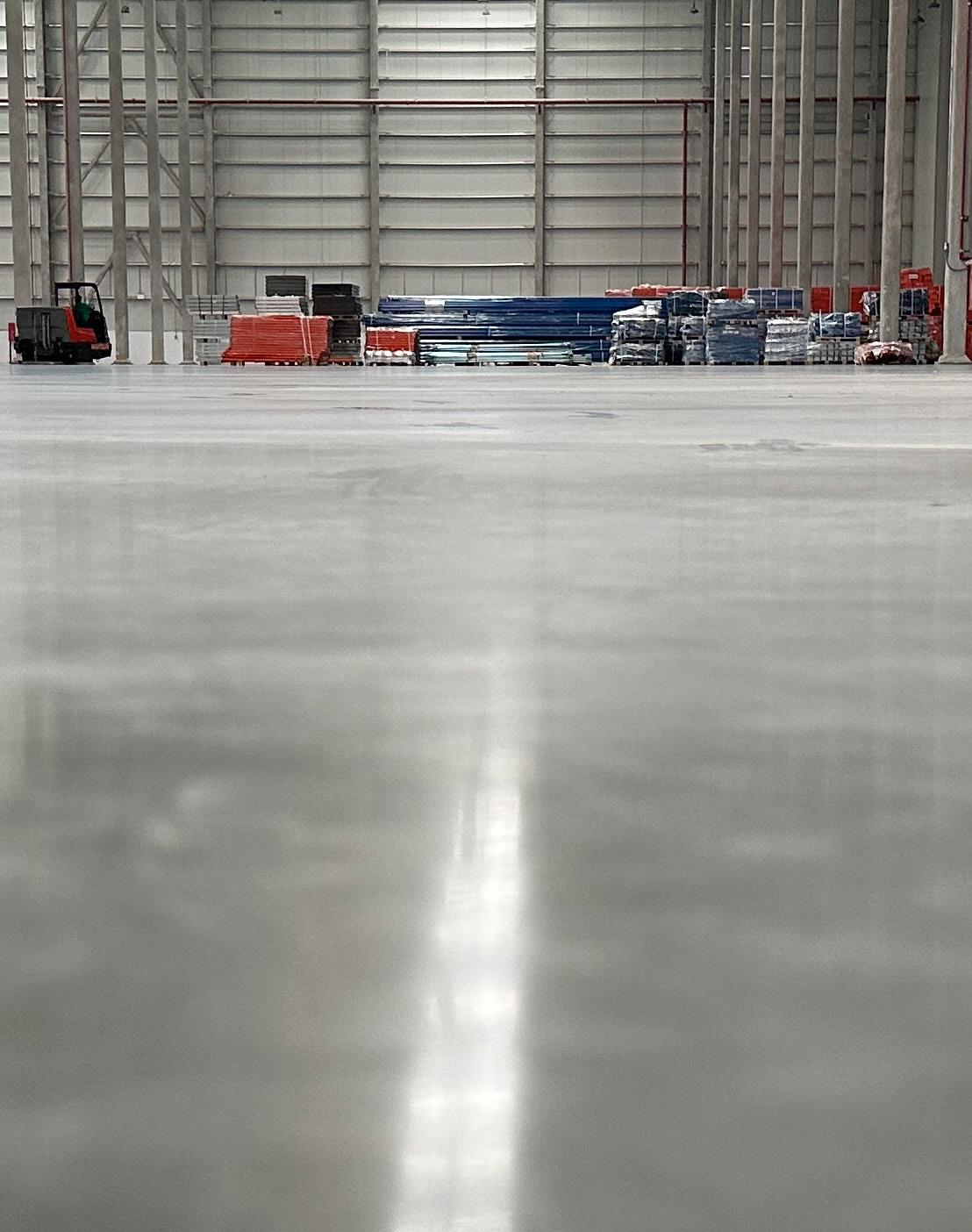

VERNi-SUPAFLOR ® delivers seamless, hygienic flooring systems engineered specifically for demanding food and beverage processing environments worldwide.

The food and beverage processing industry operates under unprecedented pressure to maintain the highest standards of hygiene, safety, and operational efficiency. Traditional flooring solutions often fall short in these demanding environments, where seamless surfaces, chemical resistance, and easy maintenance are not just preferences—they’re regulatory requirements. VERNi-SUPAFLOR® flooring systems represent a breakthrough in industrial flooring technology, specifically engineered from epoxy and polyurethane resins to address the unique challenges faced by food production facilities.

Bacterial resistance technology: VERNiSUPAFLOR® creates completely seamless, non-porous surfaces that actively resist bacterial growth. The integrated coved skirtings and wall upturns work in harmony to support comprehensive washdown protocols while preventing bacteria build-up in joints and cracks—common problem areas in traditional flooring systems.

These advanced flooring systems enhance support for increasingly strict global certification and compliance standards, ensuring facilities can meet and exceed regulatory requirements across different international markets.

Heavy-duty traffic resistance: The flooring withstands continuous heavy

Seamless, non-porous surfaces resist bacterial growth and make cleaning more efficient while supporting washdown protocols. “ “

traffic, impact, and abrasion from forklifts, production equipment, and constant foot traffic. Unlike conventional surfaces, VERNi-SUPAFLOR® prevents delamination, cracking, and erosion even under the most demanding operational conditions.

Thermal shock protection: Engineered to handle extreme temperature fluctuations from ovens to freezers, steam cleaning operations, and rapid temperature cycling without compromising structural integrity.

CHEMICAL AND ENVIRONMENTAL RESILIENCE

The specialised resin formulation provides exceptional resistance to the full spectrum of food-processing chemicals, including acids, alkalis, and aggressive cleaning agents. This comprehensive chemical resistance ensures longevity and maintains surface integrity throughout years of intensive use.

Transform your facility with VERNi-SUPAFLOR ® and discover how 24 years of flooring innovation can transform your food production environment.

for both wet and dry operational zones, significantly reducing workplace accidents and liability risks.

Colour zoning integration: The system supports strategic color zoning for workflow organization and hazard alerts, creating visual guidance systems that enhance operational safety and efficiency.

Slip resistance customisation: VERNiSUPAFLOR® offers customisable slip resistance properties specifically calibrated

Long-term value proposition: The seamless flooring design eliminates dirt traps, reduces cleaning costs, minimizes downtime, and ultimately delivers significantly lower lifecycle costs compared to traditional flooring solutions.

Fast Fact

24 years of proven performance across diverse food & beverage production facilities, from abattoirs to breweries throughout Africa

Expert technical support: VERNi provides comprehensive technical support throughout the specification and installation process, ensuring each flooring system perfectly aligns with facility goals and regulatory requirements.

Customised system design: VERNi flooring systems are engineered to meet specific operational, environmental, and safety requirements across various food production environments—from abattoirs and bakeries to complex cold-chain facilities.

PRODUCTS (PTY) LTD

info@verni.co.za

www.verni.co.za

+27 (0)11 552 8393

5 Midley Road, Hughes, Boksburg, Johannesburg, Gauteng, South Africa 1459

Minimal maintenance requirements: Compared to tiled, vinyl, or concrete finishes, VERNi-SUPAFLOR® requires minimal upkeep, dramatically reducing ongoing maintenance costs and operational downtime.

(011) 552 8393 www.verni.co.za

Improve your plant’s safety and efficiency with a FUCHS LUBRICANTS SOUTH AFRICA LCCP Audit.

In the highly scrutinised business of food and beverage manufacturing, keeping your production line running smoothly is critical. Balancing operational efficiency, product quality, and adherence to stringent safety standards leaves little room for error.

FUCHS LUBRICANTS SOUTH AFRICA understands these challenges and now, in addition to their extensive range of foodgrade lubrications they are also to help optimise your lubrication application and bring significant improvements to your plant with their new LCCP Audit tool.

The Lubrication Critical Control Point (LCCP) Audit by FUCHS LUBRICANTS SOUTH

AFRICA is an in-depth study designed to assess lubrication risks and identify opportunities for improvement in food safety, maintenance efficiency, and energy cost savings. By conducting the LCCP Audit, FUCHS LUBRICANTS SOUTH AFRICA helps

you avoid costs associated with the rejection of defective products, crosscontamination, or damage to your brand image.

Whether you’re managing high-speed conveyors, heavy-duty mixers, or complex packaging machinery, the FUCHS LUBRICANTS SOUTH

AFRICA LCCP Audit takes it all into account, providing tailored solutions for your specific needs.

Ready to take control of your plant’s efficiency and safety? Request your FREE FUCHS LUBRICANTS SOUTH AFRICA LCCP Audit today and experience a world of difference. For inquiries, orders, or to book a LCCP Audit, contact them and follow FUCHS LUBRICANTS SOUTH AFRICA on Instagram, Facebook, and LinkedIn for more.

BENEFITS

1. Reduced downtime: By identifying and addressing lubrication issues, the audit minimises equipment downtime, ensuring consistent production flow.

2. Improved efficiency: Optimised lubrication practices lead to smoother operations and increased output.

3. Cost savings: The audit helps reduce lubricant consumption and maintenance costs, directly impacting your bottom line.

4. Ensured food safety: Proper lubrication safeguards against contamination, protecting consumer health and maintaining your brand reputation.

5. Energy savings: Efficient lubrication reduces friction, leading to significant energy cost reductions.

THE LCCP AUDIT

PROCESS - WHAT TO EXPECT?

When you request a FUCHS LUBRICANTS SOUTH AFRICA LCCP Audit, here’s what happens next:

• Expert visit: One of our seasoned Sales or Technical experts will visit your facility for a detailed assessment of your lubrication practices.

• Evaluation: All lubrication points will be thoroughly evaluated, and current products will be reviewed for effectiveness and safety.

• Comprehensive report: A detailed

lubrication report will be compiled and shared with you within a few days, outlining findings and recommendations for improvement.

Beyond the audit, FUCHS LUBRICANTS

SOUTH AFRICA offers the ISO 21469 certified CASSIDA range of food-grade products that meet the rigorous demands of industry. “Whether in gear units, hydraulic systems, or compressors, our products prevent contamination ensuring the highest standards of safety, efficiency and regulatory compliance.” explains Ashleigh Pollen, National Sales Manager - Industrial and Specialty at FUCHS LUBRICANTS SOUTH AFRICA. “This also applies to sprays and

Unlock the benefits of optimised lubrication practices with the FUCHS LUBRICANTS SOUTH AFRICA range of food-grade products and their expert LCCP Audit tool and services. Ensure your production line runs smoothly, translating to consistent quality and an improved bottom line.

A robust focus on food safety is essential not only for protecting public health but also for ensuring business viability and fostering a positive reputation in the competitive market “ “

single point lubricators, where FUCHS LUBRICANTS SOUTH AFRICA is one of very few companies entitled to use the strict ISO 21469 mark. Also, kosher and halal certificates ensure that the lubricants meet stringent cleanliness requirements for Jewish and Islamic dietary laws” Pollen concludes.

FUCHS LUBRICANTS SOUTH AFRICA

www.fuchs.com/za

ZA-contact-za@fuchs.om

+27 (0) 11 565 9600

PMD Packaging launches innovative small pack machinery range targeting African entrepreneurs and addressing portion control hygiene challenges across diverse markets.

PMD is constantly investing in new solutions for packaging systems to suit the Food and Beverage market and others including Pharmaceutical, Nutriceutical, et al. Furthermore the company wants to pay attention to the economic profile of Africa. Many end users of common domestic products just don’t have the resources to purchase the big

packs and the result is often Please change to manual intervention in order to satisfy the need for small packs. Small entrepreneurs have no choice but to do their best and measure portion size as best they can and manage their hygiene issues accordingly. This naturally introduces the consumer to hygiene

For all your Packing; Filling; Weighing; Grouping requirements.

risks and also risk of being over charged. Thus there is more pressure to make small packs available and that they are produced in compliance with health and safety requirements of the modern world.

PMD has now launched a new range of machines to complement a very successful range of VFFS machines with a multitude

PMD Packaging has been manufacturing high-quality packaging machinery, since inception in 1966. The Sigma range of vertical form fill and seal packaging machines complies with world class standards. Under the guidance of Mike Spencer, the company has expanded, to offer a wide range of packaging and processing machinery by partnering with a number of international brands. PMD services a loyal client base globally and throughout Africa, with local representation in Johannesburg, Cape Town and Durban.

Our success is based on our work ethic, as well as an excellent track record of successful installations and back up service for many leading multi-national companies. Throughout the years PMD has put technical development at the top of its agenda with the result that its products are widely recognised as leaders in the field of food packaging machinery, and now has many machines installed in a broad cross section of industries and countries throughout the world. We represent a number of suppliers including, Matcon, Delfin, Velteko, New Projects, Proxes, Symach. Pat Galleymore, Technical Director heads up PMD’s manufacturing and demo facility in Northriding, Johannesburg, supported by an experienced and qualified team.

We design them, we build them, we maintain them, we improve them, we develop them. And above all we have technical support for everything we make.

of special dosing systems, plus Auto Baling, Shrink-wrap, and many other special solutions where the company enjoys assistance from our European partners.

This move is designed to satisfy many markets including, small entrepreneurs, and also big companies that need to offer small portions.

PMD HAS DEVELOPED AND INTRODUCED TO THE MARKET, A RANGE OF SMALL PACK MACHINES:

Taurus: Mini VFFS machine for 3 side seal or pillow pack. Taurus is available with quick change over dosing capability for liquids, powders or granules.

Sigma 1: High speed VFFS machine for small packs up to 100 packs / min

Apollo: Horizontal sachet machine for 3 or 4 side seal in single or twin lane format.

PMD

www.pmdpackaging.co.za

Southern Storage Solutions – DEXION, has installed numerous mobile rack installations in conjunction with Barpro Storage which has increased the storage capacity of each facility without the expensive task of increasing the room size.

Traditionally pallets of packed fruit were stored by securing steel corner posts to each pallet and then storing another level of pallets on top. While doubling store capacity, this form of block storage effectively prevented stock rotation, increased stock damage and in some situations prevented adequate cooling. As fruit packaging became further differentiated, accessing stock quickly for an order became practically impossible. Pallet racking was introduced into existing fruit stores to solve these problems. “DriveIn” racking made better theoretical use of the

chilled space and reduced product damage. However, the accessibility problem was not solved leading to “drive-in” lanes being only partially utilised for immediate access to individual product lines. The alternative was to use fixed selective racking, giving immediate access to every pallet but greatly reducing storage capacity. Mobile racking was first used in 1997 in a fruit store outside Grabouw in the Western Cape.

Mobile racking consists of special rails that are laid in the floor during construction. Rails can

also be retrofitted in existing rooms provided the floor is suitable by levelling the rails on the existing surface and pouring a 150mm reinforced slab. A low ramp is needed at the entrance. The mobile bases run on the rails and support pallet racking which is specially designed for use in a mobile application. The bases are motorised and energy efficient. Maximum tonnage per base varies but should not exceed 360 tons. In larger stores mobiles are arranged in banks of up to 10 bases, each with its own moving aisle. The bases are controlled either by push buttons, remote control, or by an interface with the warehouse management system. An access aisle is created at the push of a button.

www.dexionrackingandshelving.co.za

Filmatic Packaging Systems delivers precision turnkey bottling solutions across Africa with over 45 years of proven manufacturing excellence.

In the beverage industry, where precision and efficiency directly determine profitability, the filling process represents the critical junction between quality control and operational success. Errors in filling can cascade into product loss, contamination risks, or costly operational downtime, ultimately undermining competitive advantage in an increasingly demanding marketplace.

With global demand for ready-to-drink beverages surging—propelled by rapid urbanisation and evolving consumer preferences—manufacturers urgently require reliable, high-performance solutions that can scale with market demands.

Four decades of manufacturing excellence:

Established in 1979 in Paarl, nestled within South Africa’s prestigious Western Cape winelands district, Filmatic Packaging Systems has evolved into a continental leader in beverage filling technology. As a cornerstone company within the Trepko Group, Filmatic has successfully installed equipment across 28 African countries while building a global client base exceeding

7,000 manufacturers worldwide.

Engineering for challenging environments: The company specializes in developing durable machinery specifically engineered for demanding

Equipment installed in the 1990s continues operating reliably today, often exceeding 20 years of service life across demanding production environments.

operational environments, including regions with power instability and facilities requiring consistent high-output operations. This focus on resilience has proven invaluable across diverse African markets where infrastructure challenges demand robust, dependable solutions.

Versatile filling capabilities: Filmatic’s advanced filling systems accommodate an impressive range of liquid products, from highly carbonated beverages and viscous fruit juices to specialised applications

like edible oils and motor lubricants.

The flagship Fil8 model, featuring eight precision filling heads, ensures exceptional volumetric accuracy while systematically minimising product waste—a critical factor in maintaining profit margins. Integrated manufacturing approach:

We help shape the future of the packaging & filling industry with innovative & cuttingedge machines designed for maximum efficiency. “ “

Complete integrated production lines include blow-molding capabilities, comprehensive capping systems (ROPP, screw, or sports caps), precision labelling, and automated palletising—all manufactured in-house to ensure seamless compatibility and optimal performance integration.

International compliance leadership: As a distinguished member of the European Hygienic Engineering & Design Group (EHEDG), Filmatic prioritizes compliance with the most stringent international standards. The company incorporates premium stainless-steel construction throughout its equipment designs and implements advanced Clean-In-Place (CIP) systems to exceed food-safety requirements across all applications. Extended shelf-life technology: Stateof-the-art Extended Shelf Life (ESL) filling machines achieve remarkable production rates of 7,500–9,000 bottles per hour for 1-liter containers. The modular design philosophy enables seamless scalability, accommodating both small-scale boutique producers and large-volume commercial manufacturers.

Filmatic’s equipment serves diverse industries including dairy, cream, water, beer, fruit juice, jam, honey, shampoo, dish washing liquid, ketchup, vinegar, motor oil, edible oil, wine, and cider production. This versatility demonstrates the robust engineering principles underlying every system design.

Transform your production capabilities with Filmatic’s proven filling systems and discover how 45+ years of African engineering innovation can revolutionize your beverage manufacturing operations.

Environmental responsibility: Sustainability remains embedded throughout Filmatic’s engineering philosophy. Energy-efficient components systematically reduce power consumption, while precision filling technology significantly limits product loss— delivering both environmental and economic benefits to manufacturers.

24-Hour global support commitment: The company provides comprehensive support services, from initial facility audits and system design through operator training and ongoing maintenance. Highly skilled technicians and maintenance teams deliver round-the-clock service support, ensuring long-term performance optimization for clients worldwide.

Continental market leadership: As Africa’s beverage market continues its rapid expansion, Filmatic enables local manufacturers to compete effectively on global scales. By prioritising exceptional durability, uncompromising hygiene standards, and operational adaptability, the company establishes new benchmarks for efficient, sustainable bottling solutions. Future-ready innovation: Through continuous investment in cuttingedge technology and engineering excellence, Filmatic positions African manufacturers at the forefront of global beverage production capabilities, ensuring long-term competitiveness and market growth.

FILMATIC

+27(0)21 862 2192 sales@filmatic.com

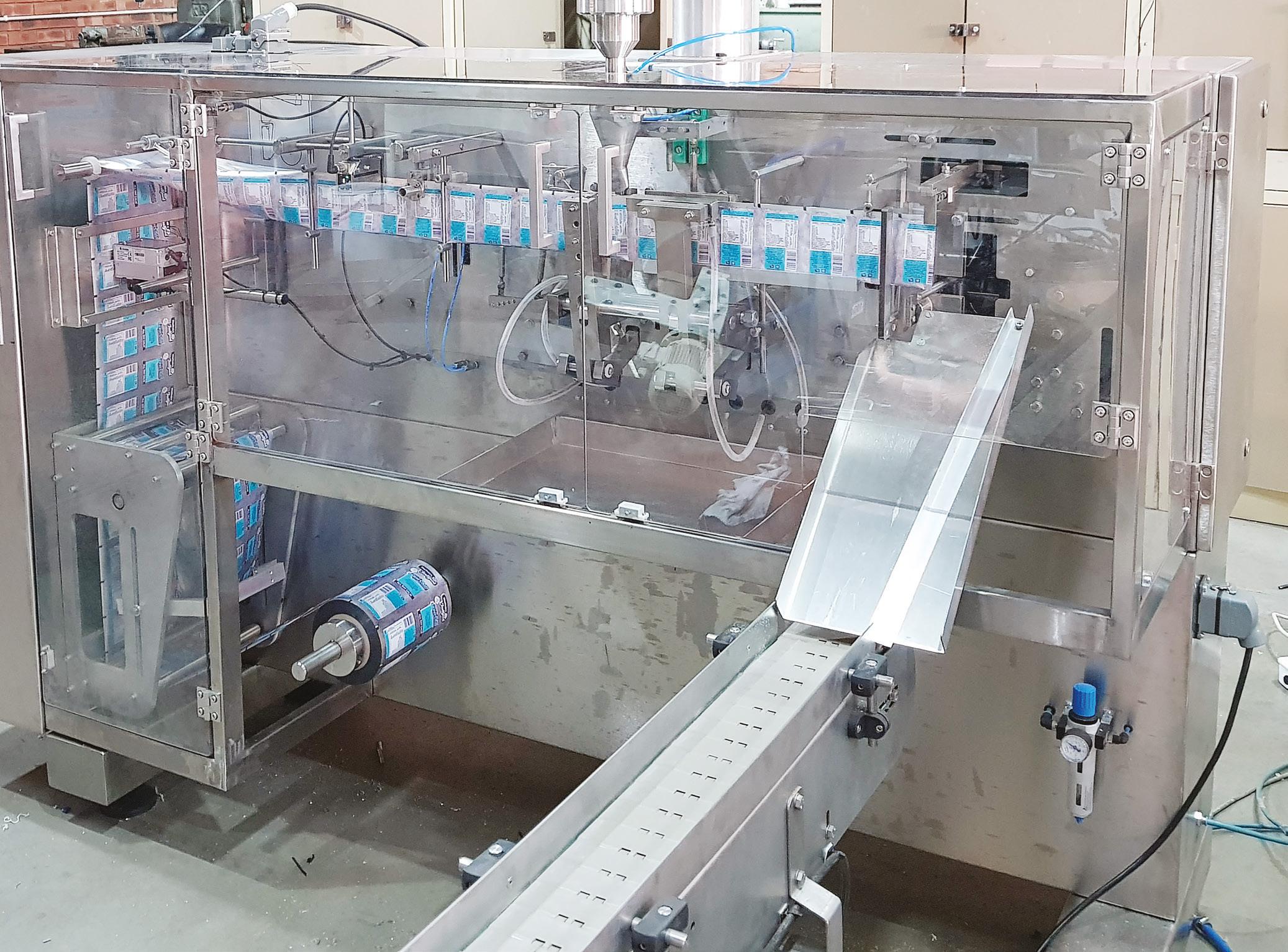

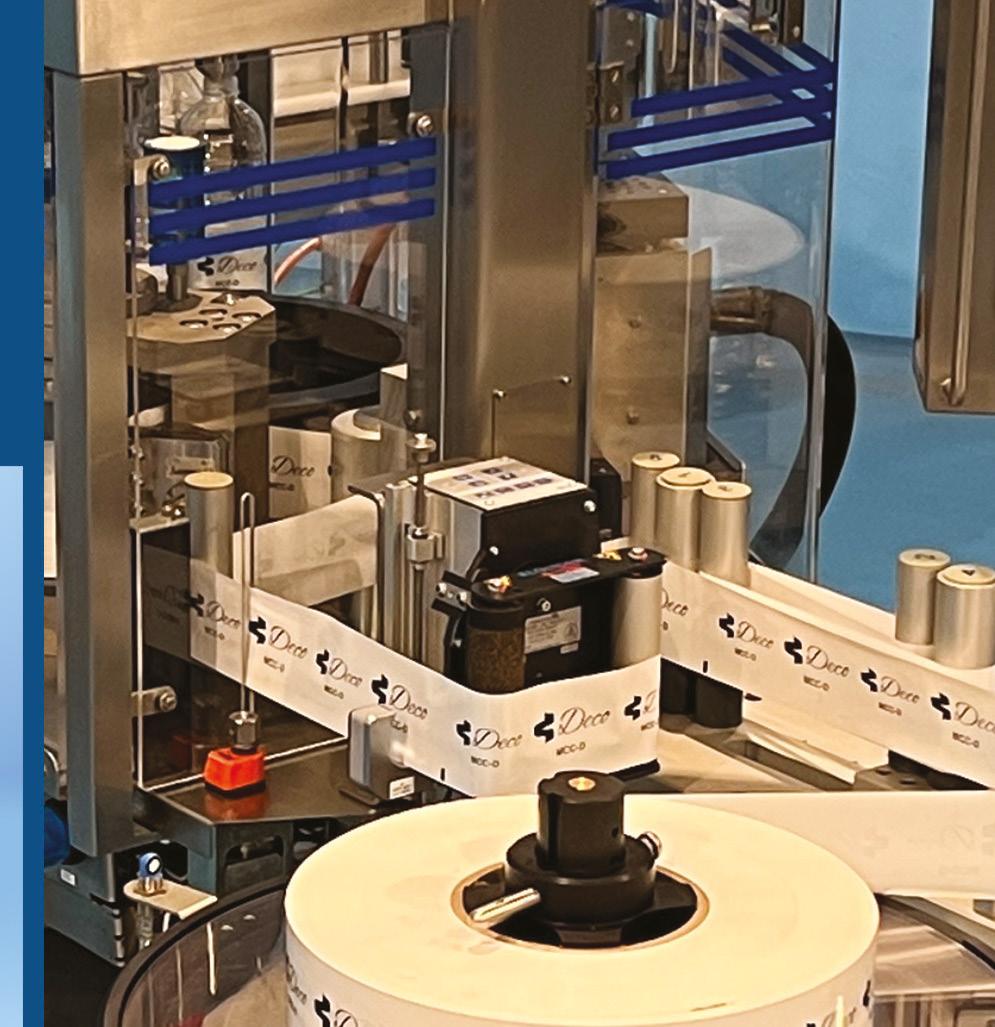

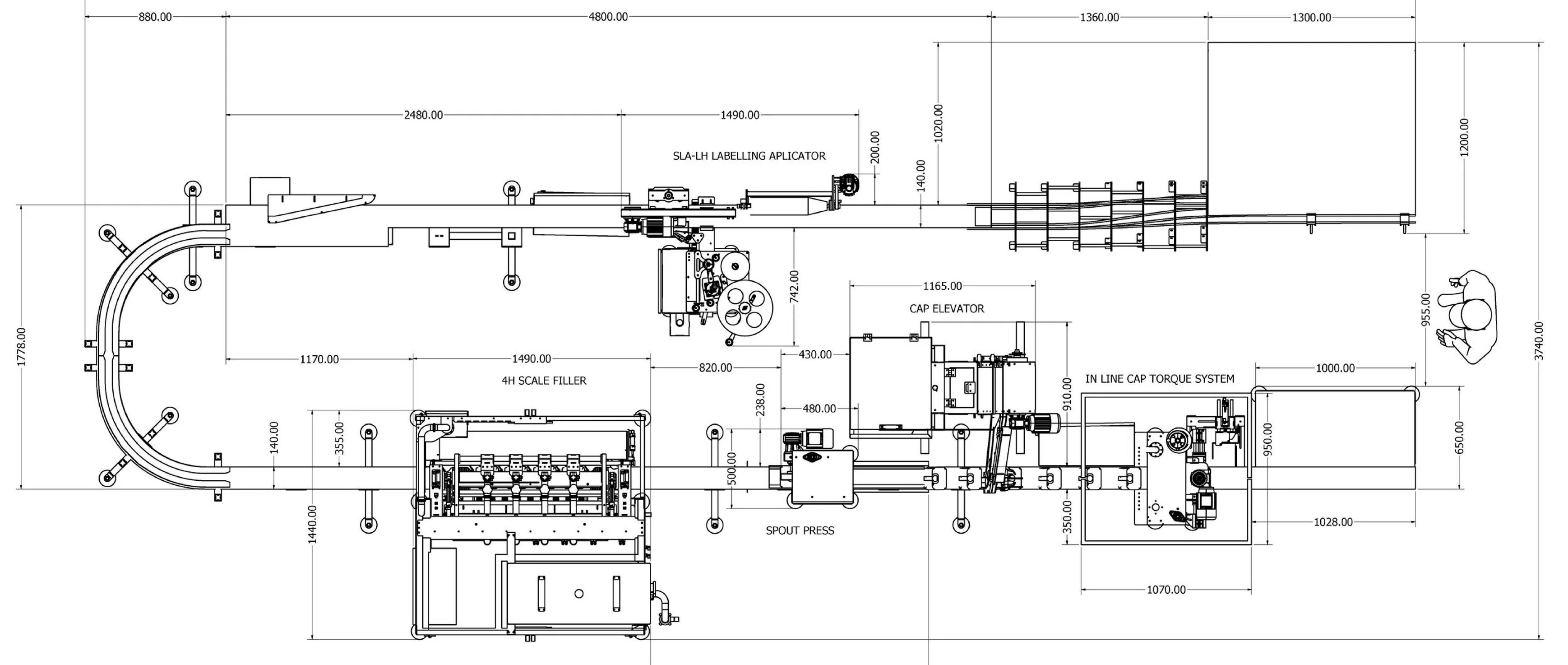

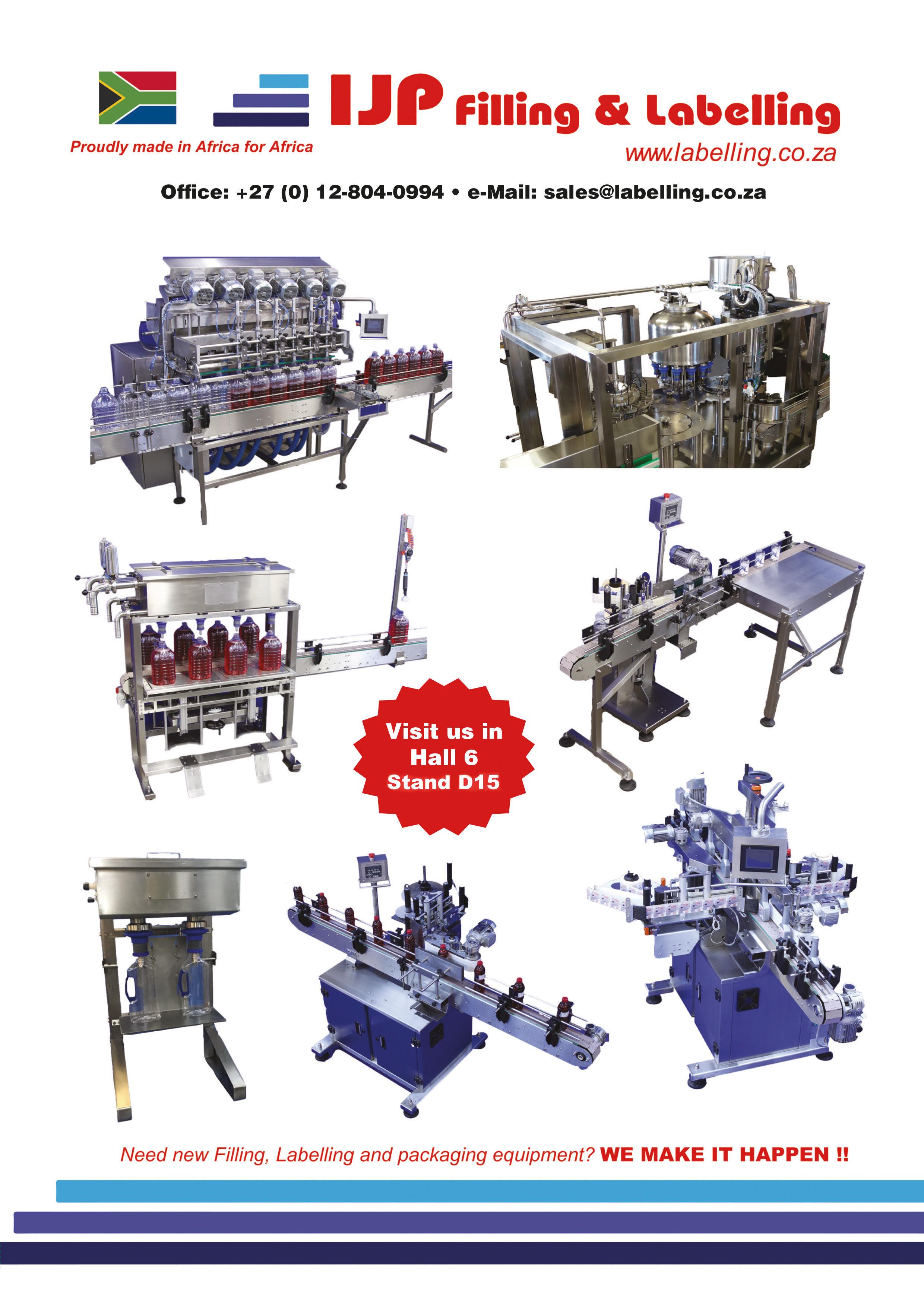

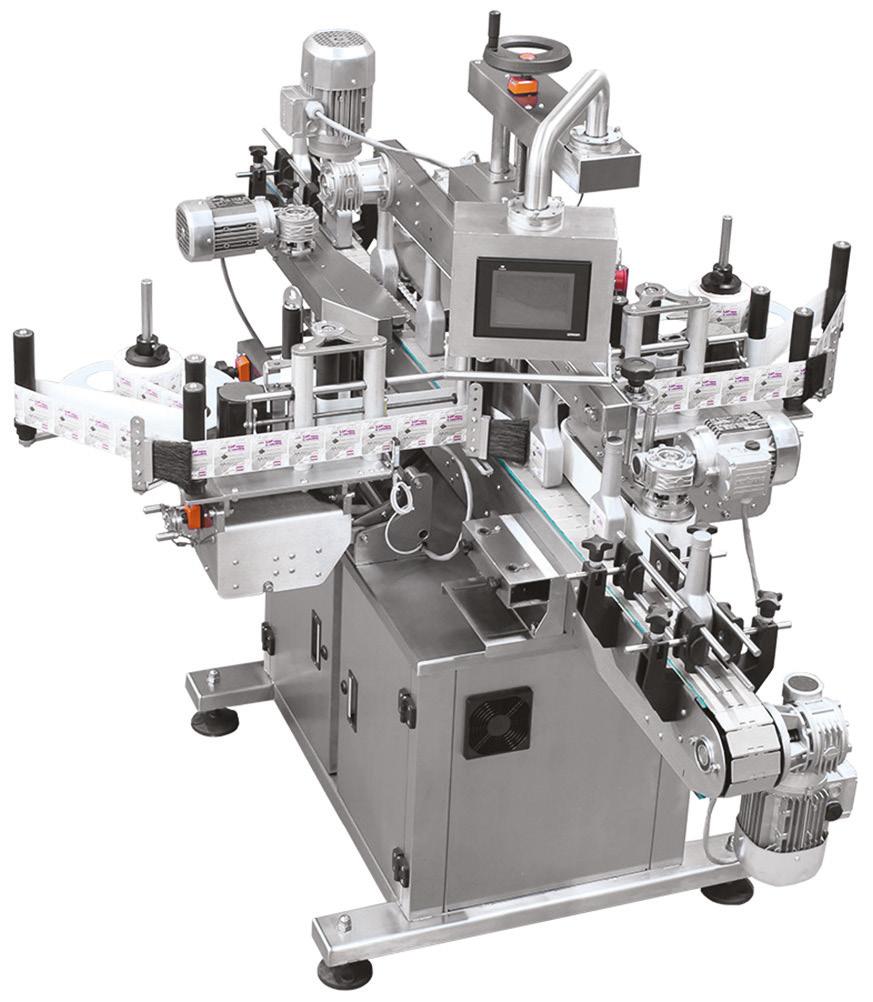

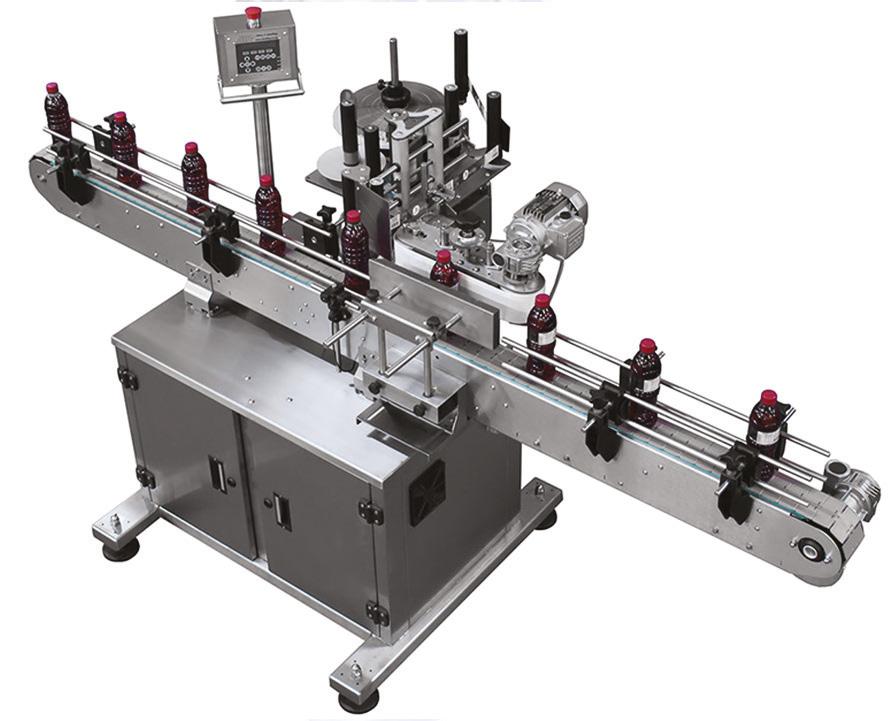

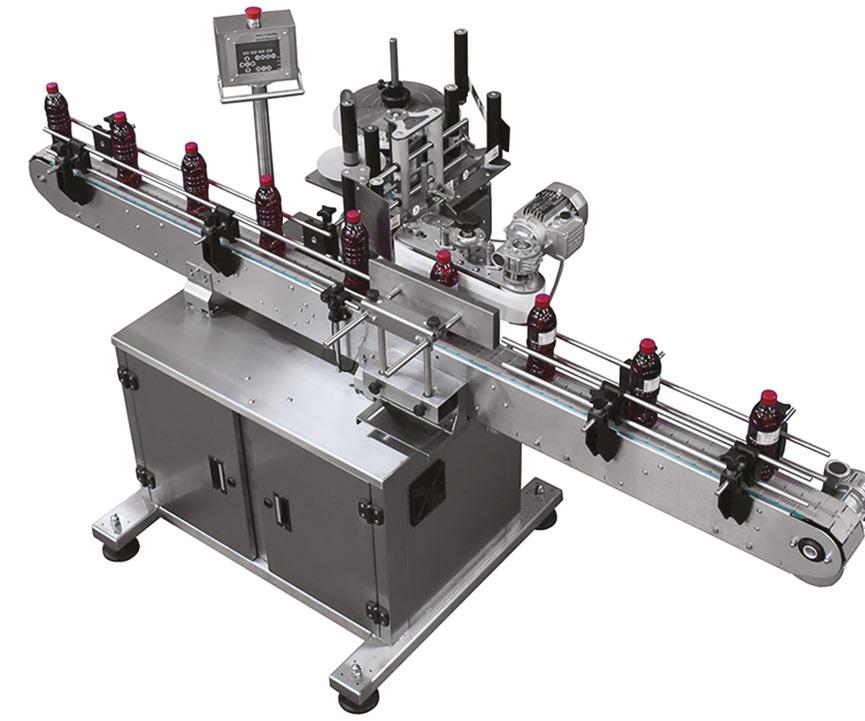

At IJP Filling & Labelling, we bring over 30 years of proven expertise in the packaging and automation industry.

As a trusted South African manufacturer, we specialise in the design, engineering, and installation of advanced filling, capping, labelling, and conveyor systems all built for maximum efficiency, precision, and reliability in your production line.

Our dedicated technical team partners closely with system integrators, equipment suppliers, and component manufacturers to deliver custom-engineered packaging automation solutions that perfectly match

your business requirements. From smallscale production setups to large industrial manufacturing environments, IJP ensures seamless integration and optimized performance at every stage of the process.

We take pride in helping clients streamline operations, minimise downtime, and boost productivity through intelligent system design and top-tier engineering. Whether

you’re launching a new production facility or upgrading an existing line, our experts provide comprehensive factory layout planning and workflow optimisation to ensure smooth, continuous operation.

At IJP, we don’t just build machines we build long-term partnerships. Our commitment to innovation, quality craftsmanship, and exceptional after-sales service ensures that every client benefits from reliable performance, reduced maintenance costs, and measurable ROI.

With an expanding range of automated packaging machinery tailored for industries such as food and beverage, pharmaceuticals, chemicals, and manufacturing, IJP Filling & Labelling continues to set the benchmark for excellence in South African packaging solutions.

We specialise in custom machine design and engineering solutions created to meet the unique requirements of your packaging and production operations. With over 30 years of industry experience, our team combines innovation, precision, and practical expertise to design filling, capping, labelling, and conveyor systems that deliver unmatched performance and efficiency.

Our custom design process begins with understanding your production goals,

product specifications, and workflow challenges. Whether you require a specialised low-viscosity filling line, a highviscosity paste filler, a carbonated beverage system, or a fully integrated packaging conveyor solution, we engineer machines that fit seamlessly into your existing setup. Each design is optimised for durability, precision, and ease of operation, ensuring consistent performance even under demanding industrial conditions.

IJP’s in-house design team utilises advanced CAD modelling and 3D simulation to develop customised machinery that maximises productivity while maintaining the highest standards of quality and hygiene. From semi-automatic labelling systems for small production runs to fully automated high-speed lines, we design every machine

to align perfectly with your brand’s requirements and operational scale.

Our custom-built solutions also prioritise user-friendliness, low maintenance, and adaptability, allowing for quick product changeovers and reduced downtime. Each system is backed by our ongoing technical support, ensuring your investment remains efficient and reliable over time.

Partner with IJP Filling & Labelling for a tailor-made packaging solution that enhances your production efficiency, reduces waste, and supports long-term growth. No matter your industry, food and beverage, cosmetics, pharmaceuticals, or manufacturing we design machines that perform beyond expectations.

www.labelling.co.za sales@labelling.co.za 012 804 0994 622 Kobus Street, Silverton, Pretoria, Gauteng, 0184, South Africa

1. Filling products: IJP Filling & Labelling provides high-performance filling machines designed for precision, consistency, and efficiency in industrial production. Our advanced filling systems handle liquids, pastes, and viscous products with accuracy, minimising waste and maximising productivity. Trusted across South Africa, we deliver reliable, innovative filling solutions for diverse packaging needs.

2. Labelling: IJP Filling & Labelling offers advanced labelling machines engineered for precision, speed, and reliability. Our systems provide accurate label placement on various container types and sizes, enhancing product presentation, reducing downtime, and streamlining packaging operations across diverse industries in South Africa.

3. Capping rate per hour: The company provides high-quality capping machines designed for speed, accuracy, and consistent torque control. Our systems ensure secure, reliable sealing for a wide range of container types, enhancing production efficiency, reducing product waste, and supporting seamless operations across industrial packaging lines.

4. Conveyor types: IJP Filling & Labelling offers durable and efficient conveyor systems designed to optimise material handling and production flow. Our conveyors accommodate a variety of products and environments, ensuring smooth, reliable transport, minimising downtime, and enhancing overall efficiency across industrial packaging and manufacturing lines.

Food-safe flooring solutions : Seamless epoxy resin flooring

Antimicrobial properties with chemical and thermal resistance. Eliminates joints and grout lines where bacteria can harbour.

Automation & Robotics: AI-powered collaborative robots (Cobots)

Work safely alongside humans without protective caging, improving productivity by 35-50% while reducing repetitive strain injuries by 60-75%. Can handle packaging, palletizing, and quality inspection tasks.

Smart manufacturing equipment: AI-driven quality control systems

Detect defects, contamination, and specification deviations with 99.9% accuracy, preventing costly recalls and reducing waste before packaging.

Warehouse shelving & racking: Push-back pallet racks

Use sloped rails or carts for multiple pallets per lane, optimising storage density and improving retrieval efficiency.