FOOD & DRINK PROCESSING & PACKAGING

The world’s largest supplier of premium perforated solutions with over a century’s experience in perforation.

Page 21

The world’s largest supplier of premium perforated solutions with over a century’s experience in perforation.

Page 21

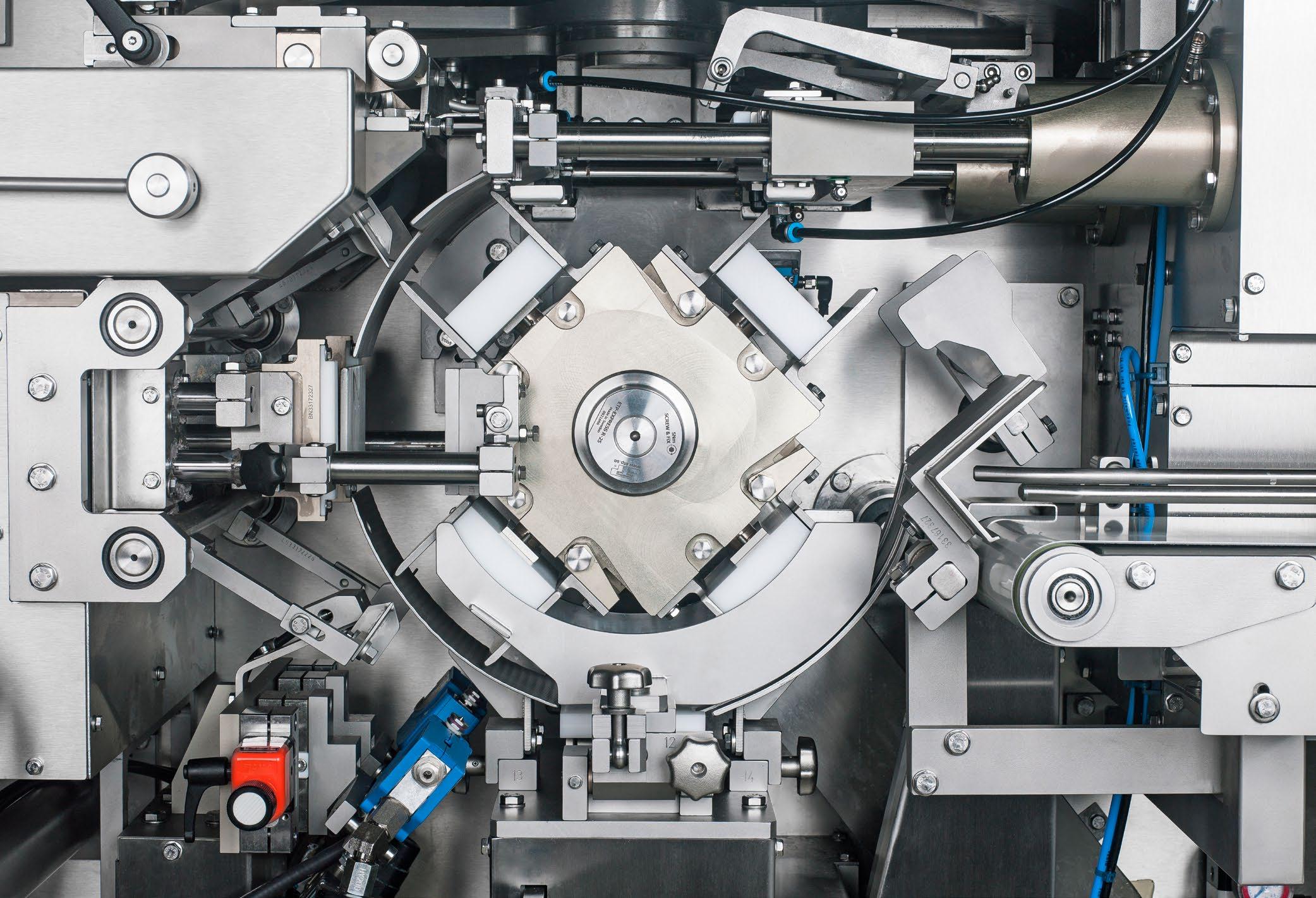

Schmersal now offers a complete range of innovative command and signalling devices specifically designed for hygiene-sensitive environments in the food processing industry.

Engineered for maximum cleanliness and reliability, these devices feature seamless transitions between sealing elements and surfaces, no protruding parts makes them exceptionally easy to clean. Their robust design withstands high-pressure washdowns and aggressive cleaning agents, meeting the highest hygiene standards.

With 147 device options available including mushroom pushbuttons, selector switches, and potentiometer-rotary switches you have the freedom to configure your control panels exactly how you need them.

Whether you are upgrading existing systems or building new equipment, this range offers the flexibility to design a safe and hygienic human-machine interface that fits your exact requirements.

For added customisation, all devices can be supplied with individual laser marking, including your company logo.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

Editor Amanda Buckingham editor@fdpp.co.uk

Business Manager Josh Holmes josh@mhmagazine.co.uk

Martin Holmes martin@fdpp.co.uk

Leila Schmitz leila@mhmagazine.co.uk The

Digital Sales Manager Jessica Bennett T: 01227 936971

Sales Manager Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971 M H Media Global Ltd. 18/20 Newington Road, Ramsgate Kent, CT12 6EE Tel 01304 806039 www.fdpp.co.uk

Harnessing the power of vibration to boost efficiency, hygiene and sustainability in modern food manufacturing.

In the world of food production, precision is everything. From handling raw ingredients to packaging the final product, every step must meet the highest standards of hygiene, efficiency, and sustainability. With roughly 15% of global food losses occurring during processing, manufacturers are under pressure to find smarter, cleaner and more reliable production methods.

Enter vibration technology—a quiet and powerful innovation transforming how food moves through production lines. By applying controlled vibrations, companies can convey, sieve, separate, dose and loosen materials with remarkable accuracy. Among the pioneers leading this shift is

NetterVibration, whose hygienic and efficient systems are helping food manufacturers worldwide cut downtime, save energy, and reduce waste.

Hygiene and Efficiency: The Twin Pillars of Modern Production In food manufacturing, hygiene isn’t negotiable. Equipment must process delicate products safely while enduring rigorous cleaning with strong detergents. NetterVibration’s stainless-steel systems, designed for corrosion resistance and easy maintenance, meet these demands head-on. Many models operate using lubrication free compressed air, removing contamination risks and reducing servicing needs.

From dairy to baked goods, powdered spices to meats, vibration solutions can be customised for nearly any environment—including high-

temperature zones or ATEXcertified areas where safety and hygiene are paramount.

Five Ways Vibration Drives Sustainable Success

1. Sieving and Separating Rosehip Seeds

A jam manufacturer needed to separate rosehip pulp from seeds and clean them for oil pressing. Using a custom vibrating sieve trough powered by electric and pneumatic vibrators, NetterVibration achieved neartotal material utilization—with minimal waste and maximum product quality.

2. Conveying and Cleaning in Meat Processing

Sticky ham strips once slowed production and cleaning. A stainless-steel linear-motion conveyor now moves the meat

smoothly without belts or moving parts, cutting energy and chemical use while simplifying sanitation.

Clumping powder caused costly downtime in snack production. By combining an impactor to loosen material with a DosyPack dosing system, paprika is applied evenly and precisely—improving consistency and extending equipment lifespan.

To reduce breakage, a biscuit producer integrated a piston vibrator that gently positioned crackers for packaging. The result: higher product integrity, fewer rejects, and reduced waste.

lower cleaning energy, and longer equipment life all contribute to a smaller environmental footprint. Automated vibration systems also enhance workplace safety, replacing manual hammering and repetitive strain tasks with precise, reliable operation.

A producer of edible oils struggled with silos blocked by product bridges. Installing an pneumatic impactor with an adhesive mount prevented clogging and manual intervention—keeping flow consistent and silos intact.

Technology

The advantages extend far beyond productivity. Reduced material loss,

In an industry where margins are tight and standards uncompromising, vibration technology delivers a rare combination of efficiency, safety, and sustainability. By rethinking how food moves through production, companies like NetterVibration are showing that innovation can be both hygienic and green—a vital harmony for the future of global food security.

www.nettervibration.com/en/

Element Logic, the world’s first and largest AutoStore® partner, is pleased to announce that it has reached an agreement to acquire BS Handling Systems, a leading provider of intralogistics solutions in the United Kingdom. This acquisition will mark a significant step in Element Logic’s strategic growth, further strengthening its footprint in the UK market, and reinforcing its position as a leading provider of fully integrated warehouse automation solutions in the UK and Ireland.

Strategic acquisition will strengthen Element Logic UK’s position with complete warehouse solutions BS Handling Systems brings over 20 years of experience delivering tailored material handling and warehouse solutions, including conveyor systems, sortation solutions, mezzanine floors, racking, and packaging. The acquisition forms part of Element Logic’s strategy to offer end-to-end warehouse automation solutions for businesses seeking to scale efficiently in an increasingly complex logistics landscape.

“We are excited to welcome BS Handling Systems to the Element Logic family,” says Scott Torrington, Managing Director of Element Logic UK and Ireland. “Their strong industry expertise and customer focus aligns well with our goal to innovate warehouse solutions, providing comprehensive inbound and out-bound services quickly and focusing on delivering value to our customers.” “We are delighted to announce the next step in BS Handling’s journey as we join forces with Element Logic UK,” says Robert BrandSmith, MD of BS Handling. “This partnership brings together our

proven expertise in conveyors, storage and automation, to merge with Element Logic’s global scale and proven innovation, providing full turnkey integrator solutions specifically for the UK and Ireland market. For our customers, it means continuity with the same trusted team, combined with even greater capability, resources, and technology with Element Logic UK. For our staff, it opens up exciting new opportunities to grow and develop within one of the top automaton companies in the world. We’re proud of what we’ve built to date, and the future with Element is going to be extraordinary. We are all very excited for the journey ahead!”

“The acquisition of BS Handling Systems marks an exciting step forward for Element Logic in the UK,” says Ankush Malhotra, Group CEO of Element Logic.

“With their complementary capabilities and shared customerobsessed mindset, the combined business provides innovative and complete solutions that unlock new ways to serve customers and deliver streamlined, cuttingedge warehouse solutions. It is a perfect fit, built on trust, driven by expertise, and powered by people passionate about transforming logistics.”

Combined strengths unlock scalable, future-ready solutions for UK and Ireland warehouses The logistics world is evolving rapidly, and so are the needs of customers. More and more, businesses are looking for end-toend solutions – automation that is not just intelligent but seamlessly integrated into the broader warehouse environment.

With BS Handling Systems’ proven track record and Element Logic’s global expertise in AutoStore®, AMRs, software integration, and robotics; the newly combined offering enables businesses across the UK and Ireland to benefit from:

• Digital Intelligence: From smart picking algorithms to realtime performance dashboards, ElementLogic UK’s intelligent software brings speed, visibility, and precision to every part of the warehouse,turning complexity into competitive advantage.

• End-to-End Solutions: From AutoStore-powered AS/RS to advanced conveyors, AMRs, sortation andautomated packaging, customers gain a complete intralogistics solution under one roof.

• Local Expertise, Global Strength: BS Handling’s strong UK presence, now backed by Element Logic’sinternational scale, means faster support and solutions that fit local operational challenges.

• Future-Ready Automation: Intelligent, scalable, and sustainable systems designed to drive competitiveadvantage in modern warehousing.

The acquisition will be the latest step in Element Logic’s growth journey, building on previous strategic moves to create one of the most advanced, and customerfocused warehouse automation global players. Element Logic remains committed to innovation and excellence in intralogistics, and this acquisition reinforces its position as a trusted partner for warehouse automation across Europe.

Element Logic has acquired BS Handling Systems – and that’s great news for UK warehouses. With this new alliance, some of the world’s most cutting-edge systems are standing by to automate every aspect of your warehouse, from sortation to handling to packaging.

The ultimate turnkey solution!

As sustainability moves to the top of the retail agenda, reusable packaging has become a practical and proven way to cut waste, reduce costs, and improve efficiency across the supply chain. For retailers, it delivers even more: cleaner shelves, faster restocking, and more attractive displays that help sell more while complying with sustainability goals and packaging regulations.

Tosca is at the forefront of this shift. As a global leader in reusable and 100% recyclable plastic packaging and pooling solutions, Tosca provides packaging solutions that keep products moving safely, efficiently, and sustainably from factory to shop floor. Its integrated beverage solution - combining the UDP half pallet with durable plastic beverage trays - shows how reusability can drive both operational performance and commercial success.

The power of reusable plastic packaging

Reusable plastic packaging offers increased consistency, durability, and hygiene compared to single-use packaging. Made from 100% recycled

and fully recyclable plastic, Tosca’s packaging is designed for repeated use, maintaining strength and quality through every cycle. Unlike cardboard or wood, plastic doesn’t absorb moisture, warp or splinter - making it ideal for food and beverage environments where both hygiene and presentation are paramount.

By switching from single-use packaging to reusable plastic solutions, retailers and brands reduce their dependence on disposable materials, cut carbon emissions, and eliminate packaging waste. Independent analysis shows that, compared to a single-use display of 100 products, the UDP half pallet can reduce carbon emissions by 400–600 kilograms of CO2 equivalent, delivering measurable sustainability gains without compromising efficiency.

Tosca’s pooling model takes reusability one step further. Instead of owning packaging assets, customers pool them through Tosca’s managed network. Once

used, each pallet, crate, or tray is collected, inspected, washed, and redistributed by Tosca -ensuring every item remains in circulation for as long as possible.

This system reduces capital investment, eliminates storage and maintenance costs, and guarantees consistent availability, even during seasonal peaks. By keeping assets in use across multiple customers, pooling significantly reduces waste, streamlines operations, and ensures that every component of the supply chain contributes to a truly circular economy.

Within this model, Tosca’s UDP half pallet and plastic beverage tray combination provide a complete, retail-ready beverage display system that brings the benefits of reusable packaging directly to the shop floor. Built for efficiency, the UDP half pallet combines a load capacity of up to 500kg with a compact 800 × 600 mm footprint, enabling faster handling and easier movement through warehouses, distribution centres, and stores.

The beverage trays are designed to sit securely on the UDP, forming a sturdy and hygienic merchandising platform that moves seamlessly from truck to shop floor. This retailready system eliminates unpacking and shelf-stocking, saving valuable time and labour. Staff can restock quickly, keeping displays full, neat, and easy to access.

Durable and easy to clean, the trays maintain spotless shelf appeal and protect against spills or product damage - creating a consistently premium look that enhances brand image and helps attract shoppers. The result is a cleaner store environment, faster replenishment, and measurable labour and waste savings.

In-store, the UDP and trays are more than just operational tools – they’re powerful sales drivers. Their modular, space-saving design enables eye-catching end-of-aisle

and seasonal displays that can be moved, refreshed, or repositioned in minutes. Retailers can react faster to promotions or stock changes, maximising every square metre of selling space.

For customers, these displays offer a cleaner, more engaging experience. Products are wellpresented and easy to pick up, encouraging impulse purchases and reducing the clutter associated with single-use cardboard. In the UK, this approach has already proven successful for retailers: Tosca’s beverage solution is widely adopted by over 150 FMCG brands, driving efficiency and sales growth while cutting environmental impact.

“The UDP half pallet is more than a logistics tool - it is a proven driver of revenue,” says Laurent Le Mercier, EMEA President, Tosca. “By moving directly from production to the shop floor without the need for unpacking or handling, it allows

retailers to launch promotions faster, optimise every square metre of selling space, and generate additional sales even when shelf space is at capacity.’’

Following its success in the UK, Tosca’s beverage solution is expanding across Europe, helping retailers and brands enhance efficiency, improve hygiene, and embrace sustainability with a proven, circular model.

From the warehouse to the shop floor, Tosca’s reusable packaging solutions deliver measurable impact: cleaner operations, smarter merchandising, and stronger sales. With durable plastic assets, a robust pooling network, and a focus on efficiency at every stage, Tosca helps beverage retailers turn sustainability into a source of competitive advantage.

uk_sales@toscaltd.com

Contact Us - Tosca EU

Charlotte-based testing company slashes reporting times from 12 hours to five minutes with a connected, cloud-first workflow.

By combining Flir’s new i65 thermal imaging camera with the Condoit electrical data platform, the company has overhauled its asset monitoring and reporting process – cutting turnaround times from 8-12 hours to less than five minutes. The result: faster workflows, fewer errors, and smarter decision-making for customers.

Until recently, Blackmon Power’s technicians followed the same time-consuming process familiar to many in the industry: capture thermal images, store them on SD cards, transfer the data to spreadsheets back at the office, and manually generate reports.

“The biggest time constraint was always back-end reporting,” recalls Tyler Grant, Project Manager at Blackmon Power. “We knew that a more advanced thermal camera and data app could save time and money – for both us and our customers.”

A small 10-15 component inspection typically took two hours to report. Larger jobs could demand an entire workday. For some projects, reporting alone consumed up to 30% of total job time, cutting into margins and slowing response times.

The solution came in the form of Flir’s i65, a next-generation thermal camera from the iXX-Series, and Condoit, a cloud-based electrical data platform.

The i65 pairs infrared imaging with smartphone-like functionality, while Condoit offers automatic single-line diagram generation, NFPA 70B-aligned maintenance workflows, and a customer visibility portal. Together, they

enable real-time data capture, instant cloud sync, and automated reporting – a far cry from spreadsheets and manual uploads.

Blackmon Power put the new workflow to the test at the Kings Mountain Data Center Campus for T5 Data Centers, a flagship 60 MW facility billed as Carolina’s only “FOREVER ON” data center. The Phase I delivery of the new project is scheduled for 2026.

Technicians scanned electrical distribution assets using the i65, identifying temperature anomalies that could signal loose connections or faulty equipment. Each scan took just 15-20 seconds, with data uploaded automatically to the cloud.

Previously, reporting might take half a technician’s time. Now, with the Flir–Condoit platform, that figure drops close to zero.

“Using the i65 and Condoit app is a total gamechanger,” Tyler says. “I’ve been doing this job for over a decade, and it’s never been this easy. Reporting has moved from the office to the field. What used to take us 12 hours now takes five minutes.”

The Condoit integration connects wirelessly with most Flir cameras, doubling the speed of traditional thermography workflows. There’s no manual image sorting or software juggling; everything syncs instantly to the cloud.

Field teams and office engineers can collaborate in real time, while customers gain secure access to

their data through Condoit’s online portal. For clients like T5, which manage multiple facilities, this centralized visibility makes it easier to track electrical system health across entire property portfolios.

With nearly 60% of inspection teams reporting a shortage of skilled thermographers, the platform’s guided workflows help less experienced technicians perform expert-level inspections. Blackmon Power can now also collect baseline data for all components without passing on extra costs to customers.

“Before, collecting non-problematic data was too expensive for most clients,” Tyler explains. “Now, it’s simple and fast. And because field technicians can input data in real time, errors have dropped dramatically.”

For Blackmon Power, the impact goes beyond speed. The integrated platform improves data accuracy, enhances transparency through customer portals, and sets a new standard for reporting quality.

“The Flir i65/Condoit platform puts our team light years ahead of the competition,” Tyler concludes. “It’s cleaner, faster, and better for our customers, with great reporting on the back end. What’s more, with the i65 we don’t need a separate smartphone or digital camera. This is going to change our business for years to come.”

For more information, Join the free webinar organised by both Condoit and Flir Revolutionizing Asset Monitoring with Flir iXX and Condoit. Here is the registration link:

https://register.gotowebinar.com/

The iXX-Series is a new class of app-powered thermal cameras designed to make inspections faster, easier, and more consistent, no matter the skill level of your team. From experienced thermographers to technicians new to thermal imaging, iXX cameras simplify every step of the process: capturing the right data, sharing it instantly, and turning it into actionable insights.

Built on the Flir Ace platform, the i34/i35 and i64/i65 work with apps developed by Flir, customers, and trusted third-party developers—so your camera can evolve with your inspection needs.

Smarter Asset Management Made Simple

Auto-Link Radiometric Images to Asset Hierarchy

Instant Report Generation with Insightful Dashboards & Trending

Simplified Workflows with In-Field Decision Support

Compatible with Flir Exx, T5xx, T8xx, iXX cameras

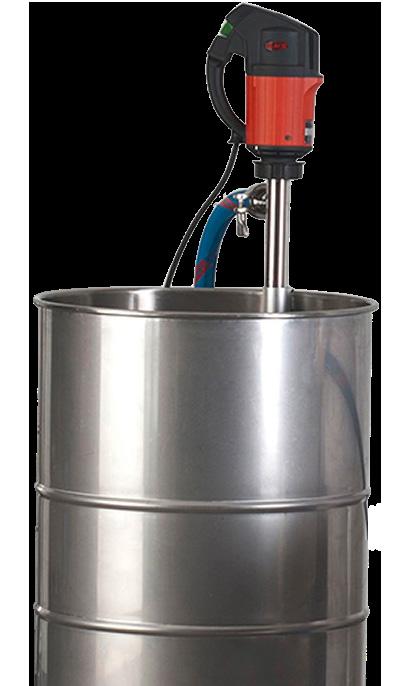

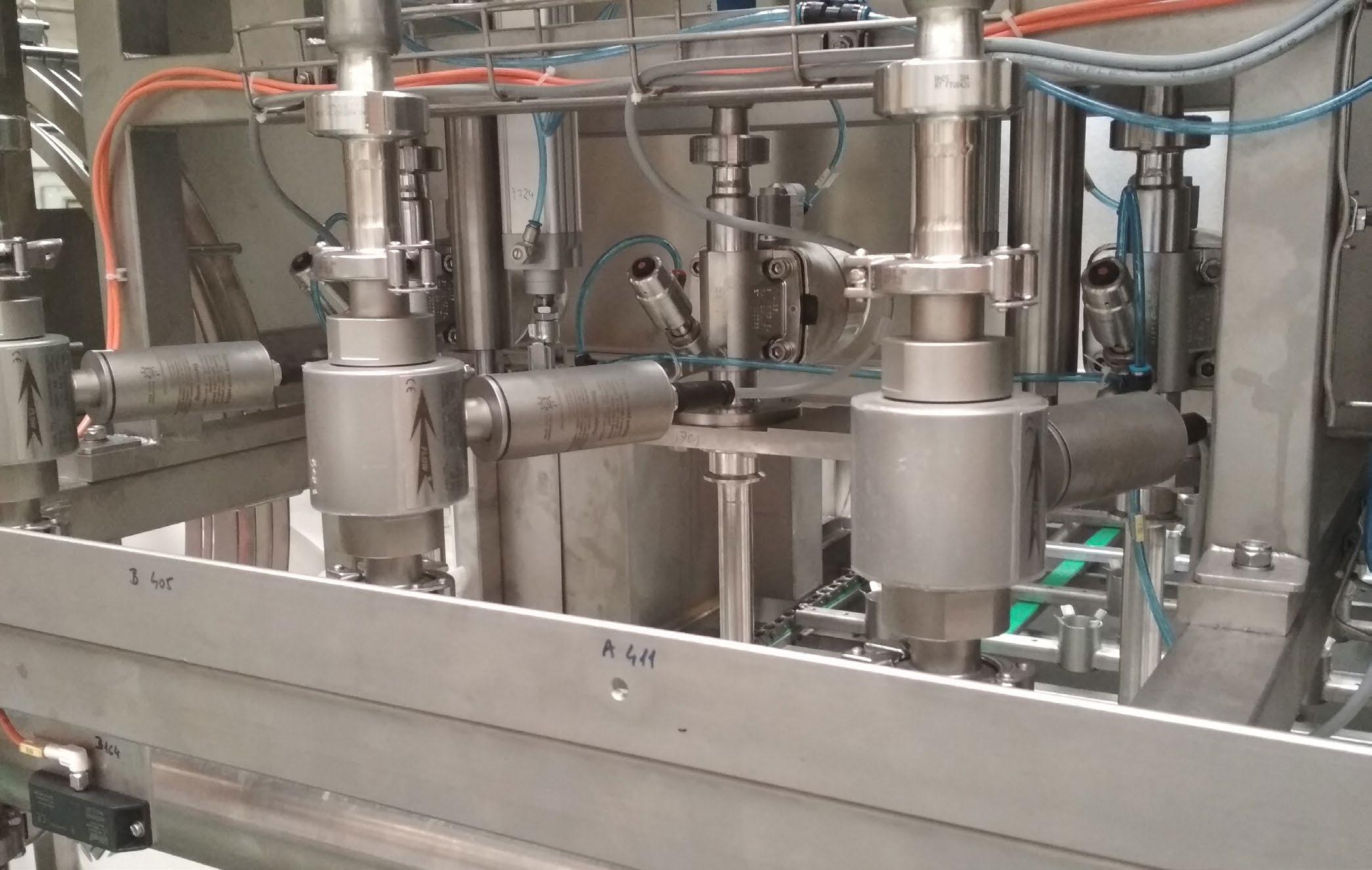

A leading global cosmetics brand chose us to supply four hygienic, ATEX-rated distilling pumps for their perfume line. These pumps now support the distillation stage, transferring heated alcohol–oil blends through a heat exchanger after kettle processing.

Distillation in perfumery

This procedure extracts volatile aromatic oils from plant materials by heating them to produce vapour, which is then condensed and collected.

Steam distillation is most common, using steam to extract fragrant molecules, later separated from water in an essencier.

Perfume is created by extracting natural or synthetic oils, blending them into top, middle, and base notes with alcohol and fixatives, then aging the mixture before filtering and bottling. Extraction methods include cold enfleurage

for delicate flowers and hot enfleurage for sturdier blooms like mimosa.

Cosmetic-grade pumps are designed to ensure product purity and skin safety through hygienic materials, bacteria-resistant construction, and compliance with strict standards. Built with closed, airless systems, they prevent contamination and protect product integrity. Manufactured from skin-safe materials like 316 stainless steel, they are easy to clean, CIP-compatible, and resistant to residues. With precise dispensing, they deliver consistent dosing that maintains quality while minimising waste.

In the US, the FDA and 3-A standards regulate pump design, requiring hygienic materials, CIP compatibility, and bacteria-free construction. In Europe, EHEDG

guidelines—focused on smooth, cleanable, and safe materials—also ensure cosmetic product safety.

ATEX certification, required under EU Directive 2014/34/ EU, ensures pumps can safely handle flammable substances like alcohol in perfume production without risk of ignition. Cosmetic pumps achieve ATEX certification through spark-proof materials and explosion-safe designs, allowing safe handling of flammable liquids in perfume production.

ATEX-rated cosmetic distilling pumps are built with safe materials suitable for direct contact with cosmetics, feature explosion-proof motors and components to prevent sparks or hot surfaces and use a sealed design that both contains internal explosions and prevents ignition of nearby flammable materials.

Our ATEX hygienic pumps ensure gentle, contamination-free transfer in cosmetics production, maintaining quality and consistency across applications from perfumes to skincare. For this client, we supplied four ATEXrated single-phase side-channel pumps, ideal for low-power use with a standard AC supply.

Side-channel pumps deliver high pressure at low flow, self-priming, and up to 50% gas handlingideal for container emptying. Our ATEX-certified 316 stainless steel models with VFDs ensure efficiency, reliability, and long service life.

Not sure which pump is best for your delicate fluids? Talk to North Ridge Pumps—we’ll guide you to the perfect solution.

Optimise performance with specialist support

Whether you’re dealing with clogging, separation, downtime, or other issueit’s costly. Time wasted troubleshooting and lower production mean missed targets and less profit. A sanitary pump is the solution but choosing the right one feels like stepping into a minefield. You know what you need it to do but with so many options, it’s difficult to know which is best for your process and parameters.

+ Accelerated stator wear

+ Clogging

+ Changes to fluid consistency

+ Clean-in-place and sterilise-in-place hygiene issues

+ Crushing of sensitive products

+ Inconsistency in finished product

+ Inaccurate transfer of flavourings or ingredients

+ Liquid separation

+ Seal wear or failure

We’ve been engineering sanitary pumps for sectors such as distilling, brewing, food manufacturing/processing, and more, for 20+ years. We understand industry-specific processes and know what it takes to optimise performance through better-suited pump design - giving you complete peace of mind.

Our expert engineers understand your process and guide you through the options, so you can confidently select the most suitable sanitary pump.

EXAMPLE PRODUCTS:

+ Abrasive mixtures

+ Creams, milk & ice cream

+ Edible oils & fats

+ Fish & meat

+ Fruits eg. cooked apples, plums, berries, grapes

+ Grains & seeds

+ Pastes & purees

+ Syrups, juices & alcohols

+ Vegetables & peelings

+ Waste eg. trimmings, packaging & offcuts

+ Sheer sensitive liquids

+ Solid laden or viscous mixtures

At impact, we are committed to helping our customers achieve their sustainability targets. So much so, that we have created a dedicated infrastructure team tasked with just that - making sure our customers’ handling fleets have the lowest possible carbon footprint.

As sustainability becomes a greater priority for businesses, material handling equipment operations are under increasing pressure to improve their environmental performance.

However, we know that in reality many businesses are faced with barriers, such as energy supply limitations or budget constraints, that may be frustrating their goals.

Good news is at hand though, as there are a surprising number of simple steps that all lift truck operators can take, many without significant changes or costs, that can bring positive and meaningful environmental benefits to their fleets.

To help highlight some of these steps we have put together a handy guide, that is available as a FREE download. You can find the link for your copy at the bottom of this page.

The guide aims to help anyone using material handling equipment to improve their green credentials, no matter how big or small their fleet, and to do so at a pace that fits comfortably with their wider business operation.

Helpfully the guide identifies opportunities to introduce environmental improvements throughout each stage of the fleet’s life-cycle.

Some of the take-aways from this include:

• Going green does not have to be expensive

• Little changes can bring big savings

• Your drivers can make your fleet greener

• You don’t have to go fully electric or all new to go green

With a little e ort, everyone can achieve a greener fleet!

With a huge variety of products needing to be handled, when it comes to the food processing industry, no two pump requirements are the same. Getting the right pump, rather than just one that “does the job” is the key to saving yourself from excessive wear, unnecessary maintenance, product waste, process failures and energy costs. This case study is an example of the importance of just that.

Castle Pumps Ltd were approached by a manufacturer of ready to drink cocktails who were looking for pumps for various stages of their cocktail production. They had already installed two pumps supplied by Castle Pumps for the transfer of flavourings, and after six months of excellent service were ready to look at all of their other transfer processes, all with differing challenges meaning differing pumps needed to be specified.

They were looking for seven pumps for the transfer of the finished

cocktail products from container to container; an individual pump for each of the premixed cocktail products they offer.

They also required a single pump for transferring 55% proof alcohol that needed to be easily transportable around the plant to dispense at various locations and two pumps for handling cleaning solutions as part of their canning machines’ Clean in Place system.

When it comes to alcohol transfer, flexible impeller pumps are a go to pump design which is what Castle Pumps specified for the seven pumps. Firstly, they are a common cost-effective solution for food transfer applications where the fluid is not being pumped at high pressures, which this application wasn’t. To satisfy the hygienic requirements of the manufacturer, they were specified with a food grade Neoprene impeller, compatible with the alcohol products and Tri-clover

connections that meet ISO 2852 standards for hygienic couplings. Secondly when it comes to the handling of drink products, it is often important that the pump applies low shear during the transfer process, which the flexible impeller design does. This is because a pump such as a centrifugal which applies force that agitates the product can lead to frothing and the impact on taste.

For the pump required to pump the 55% proof alcohol there were some additional requirements. The first point Castle Pumps recognised was that we needed to supply the flexible impeller pump with an ATEX motor due to the flammable nature of the fluid. In addition, dry run protection was specified to prevent any overheating to further limit the risk of potential sparks in the environment. With portability a key factor, the pump was supplied trolley mounted for ease of transportation and supplied with an inverter to allow it to be run at different speeds when transferring different quantities from different tanks.

For the two pumps that were being used to transfer cleaning chemicals, the main factor was ensuring material compatibility with the solutions in question. The pumps were also supplied with a reverse operating switch to allow retrieval of any excess chemical in the delivery hose back to the tank.

If you’re looking for the right pump to deliver your process or perhaps have a challenging fluid you need to transfer, contact the pump exerts at Castle Pumps.

For further information, please visit www.castlepumps.com

Pump smarter, not harder. Use our 15 years’ experience to save excessive wear, process failures, product waste & operator time.

✓ Solid-laden, viscous fluids without clogging/wear

✓ Safe handling of chemicals, fuels & flammables

✓ Highly accurate dosing of chemicals & ingredients

✓ Difficult to pump or delicate, shear sensitive fluids

✓ 99.98% barrel emptying to prevent product waste

✓ FDA & 3A models for food and hygienic applications

Contact our technical sales engineers now!

In food and drink production, packaging lines are the heartbeat of the factory. Yet they are only as strong as their weakest link –and for many manufacturers, that link is keeping lines stocked with consumables. Reels of film, trays, cartons, bottles or caps: if materials don’t arrive on time, the entire line stops.

Day to day, this challenge is inconvenient. But at peak times – Christmas, Easter, summer BBQ season, or during supermarket promotions – the stakes rise dramatically. With output targets stretched, more frequent changeovers, and deadlines immovable, even a short delay in replenishment can cost thousands in lost throughput and risk critical supply relationships.

The reality on most factory floors

Traditionally, packaging lines are

supplied in three ways. Forklift drivers shuttle pallets back and forth from storage, often navigating through busy or hygiene-sensitive areas. Operators themselves leave their machines to fetch supplies when they run low, breaking their focus on monitoring and quality. Or managers overstock by the line as a buffer, trading valuable space, safety, and hygiene for short-term reassurance.

None of these methods are efficient. Forklift time is expensive and creates congestion. Operators lose productive minutes every time they step away. Overstocking adds clutter and compliance headaches. During quieter periods, these inefficiencies are tolerated. But during peak production, they can bring lines grinding to a halt.

The pressure of peaks and promotions

Seasonal demand and promotional surges amplify every weak point in packaging supply. Consumables are used up more quickly, meaning replenishment must happen more often. More SKUs and shorter production runs create a constant demand for different trays, films, or cartons. Many food and drink production lines are designed to handle multiple products throughout the year, not just during peak periods, so efficient changeovers become critical for maintaining output, saving time, and controlling costs.

Every stoppage chips away at Overall Equipment Effectiveness (OEE) – reducing availability, slowing throughput, and adding delays at the very moment when efficiency matters most.

At the same time, labour is stretched. Recruiting and training seasonal staff is increasingly difficult, and existing teams are already working at capacity. Relying on people to fetch and carry packaging materials is no longer sustainable. When lines stop, so does production – and in peak season, every lost minute counts.

Automation that flexes with demand

There is a smarter way to keep packaging lines moving. Autonomous vehicles can take on the repetitive, low-value task of delivering packaging materials to the line. They operate safely around people and equipment, carrying supplies – from reels to cartons – from storage to where they are needed – exactly when they are needed.

Better still, with models like Autonomous GO - Automation by the Hour, manufacturers can introduce automation with confidence and expand as their needs change. Additional vehicles can be integrated smoothly to support higher volumes, seasonal peaks, or new product lines – all without capital investment, long contracts, or licence fees. You simply pay for the hours a robot works. With ROI achievable within an hour and risk-free trials available, Autonomous GO delivers

long-term reliability with none of the upfront risk.

To suit different packaging environments, Guidance Automation offers applicationready autonomous vehicles tailored to specific tasks. iNcaart is engineered for lighter loads and maximum flexibility, designed as a base vehicle that works in combination with bespoke top modules such as conveyor units, tote lifters, trolleys, or fully custom-built solutions. For more demanding transport duties, briNgbot is an autonomous forked vehicle that delivers the same durability and reliability while handling heavier loads, ensuring that every packaging line – large or small – can be supported effectively.

By automating packaging supply, manufacturers can:

• Eliminate downtime: lines stay stocked, with consumables arriving just in time

• Protect Overall Equipment Effectiveness (OEE): fewer stoppages and delays mean higher availability and throughput, even under peak pressure

• Free skilled staff: operators

briNgbot autonomous forked vehicle positions palletised loads for transfer onto conveyors, supporting smooth and efficient packaging operations.

remain focused on monitoring, quality, and efficiency, rather than fetching materials

• Use space more effectively: no more cluttered buffer stocks stacked around machines, reducing trip hazards and improving safety as well as hygiene

• Scale with confidence: seasonal demand can be met without relying on extra labour, thanks to Autonomous GO’s flexible pay-asyou-go model

Ready for the next peak

When seasonal peaks or supermarket promotions hit, production lines can’t afford to wait for their next delivery of consumables. With an autonomous supply system that flexes on demand, every line keeps running smoothly – whatever the workload.

It’s time to stop accepting stoppages as part of the job. With the right automation in place, packaging operations can stay resilient, efficient, and always ready for the next challenge.

Discover how flexible automation could keep your packaging lines stocked and stress-free:

Tel: +44 116 243 6250 enquiries@guidanceautomation.com www.guidanceautomation.com/ autonomous-go

In today’s fast-paced food and beverage packaging industry, hygiene, efficiency, and reliability are essential. Noblelight® BlueLight Flash systems from Excelitas® offer a cutting-edge, chemicalfree disinfection solution that is transforming how manufacturers disinfect products and packaging in food and beverage production facilities. These systems are designed to meet the rigorous demands of modern production environments, delivering consistent, high-level microbial reduction without harsh chemicals like peracetic acid and hydrogen peroxide.

Powered by pulsed xenon technology, BlueLight Flash systems emit intense ultraviolet light that inactivates pathogens by disrupting their cellular structure. This results in significant log reduction rates across a wide variety of packaging formats, from beverage bottle caps and food containers to direct irradiation of organic products such as poultry portions.

The BlueLight Flash product family includes two systems tailored to different application needs.

The BlueLight® Flash System has been reengineered for high throughput disinfection of compact packaging substrates and organic products. It performs reliably in cold, damp, and demanding environments such as poultry processing plants, with integrated monitoring mechanisms that enable the system to operate safely. With processing speeds of up to 500 square meters per hour, it consistently achieves microbial reductions greater than 4 log (99.99 percent). In recent microbiological studies, the system demonstrated exceptional efficacy across various substrates, including plastic bottle caps and aluminum lids and tins. On a glass slide reference sample, the system achieved greater than 6 log reductions of Aspergillus brasiliensis.

The BlueLight Flash Large Area System is engineered for broadsurface applications, such as those

in dairy production. It delivers uniform, high-intensity irradiation and supports both cell plate and sealing film carrier treatment. Its modular, cartridge-style lamp design streamlines maintenance, minimizes downtime, and enhances adaptability across diverse use cases. With a compact footprint, the system integrates easily into space-limited environments and is ideal for retrofitting applications.

Both systems feature intuitive human machine interfaces, IP69rated enclosures for washdown protocol compatibility, and quartz glass breakage sensors to ensure safe operation. As a noncontact disinfection solution, BlueLight Flash is ideal for emerging packaging trends that favor thinner, more delicate materials unsuited to wet chemical disinfection.

To support optimal implementation, Excelitas provides disinfection modeling and simulation services, helping customers configure the most effective system for their specific needs. For manufacturers seeking high-performance disinfection, BlueLight Flash systems offer unmatched safety, power, and peace of mind.

https://bit.ly/4ntEKR4

Email: julian.priddle@excelitas.com Office Phone: +44 1223 429822 Mobile: +44 7912 379865

Address: 161 Cambridge Science Park, Milton Road, Cambridge CB4 0GQ

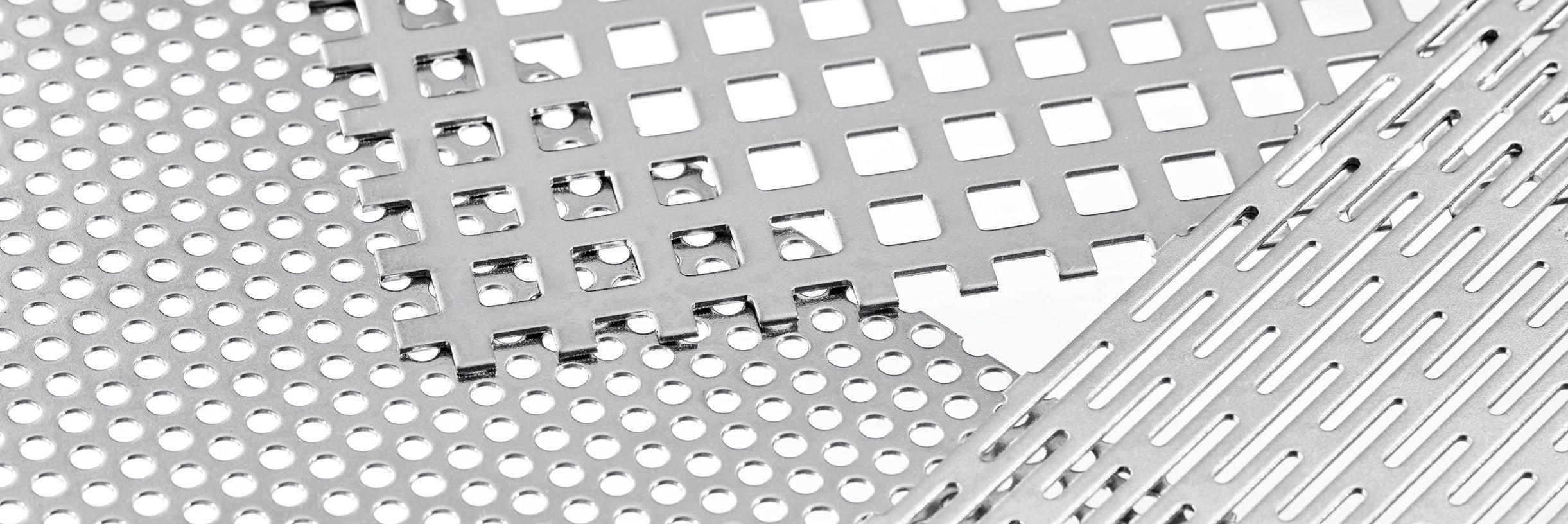

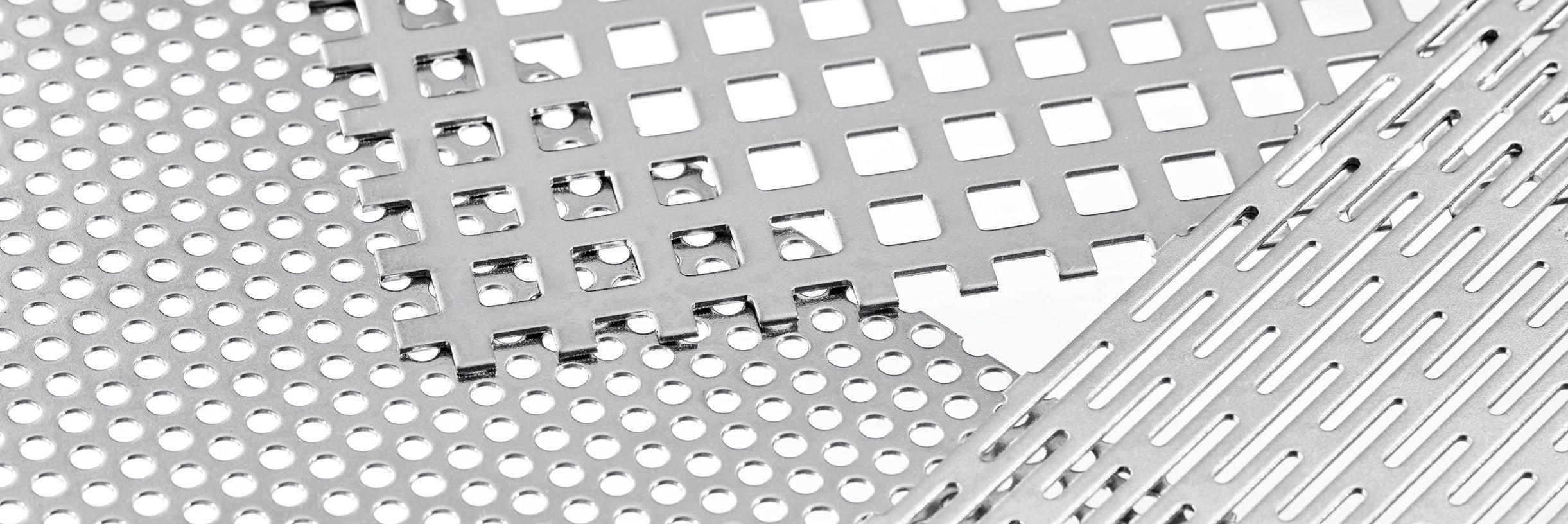

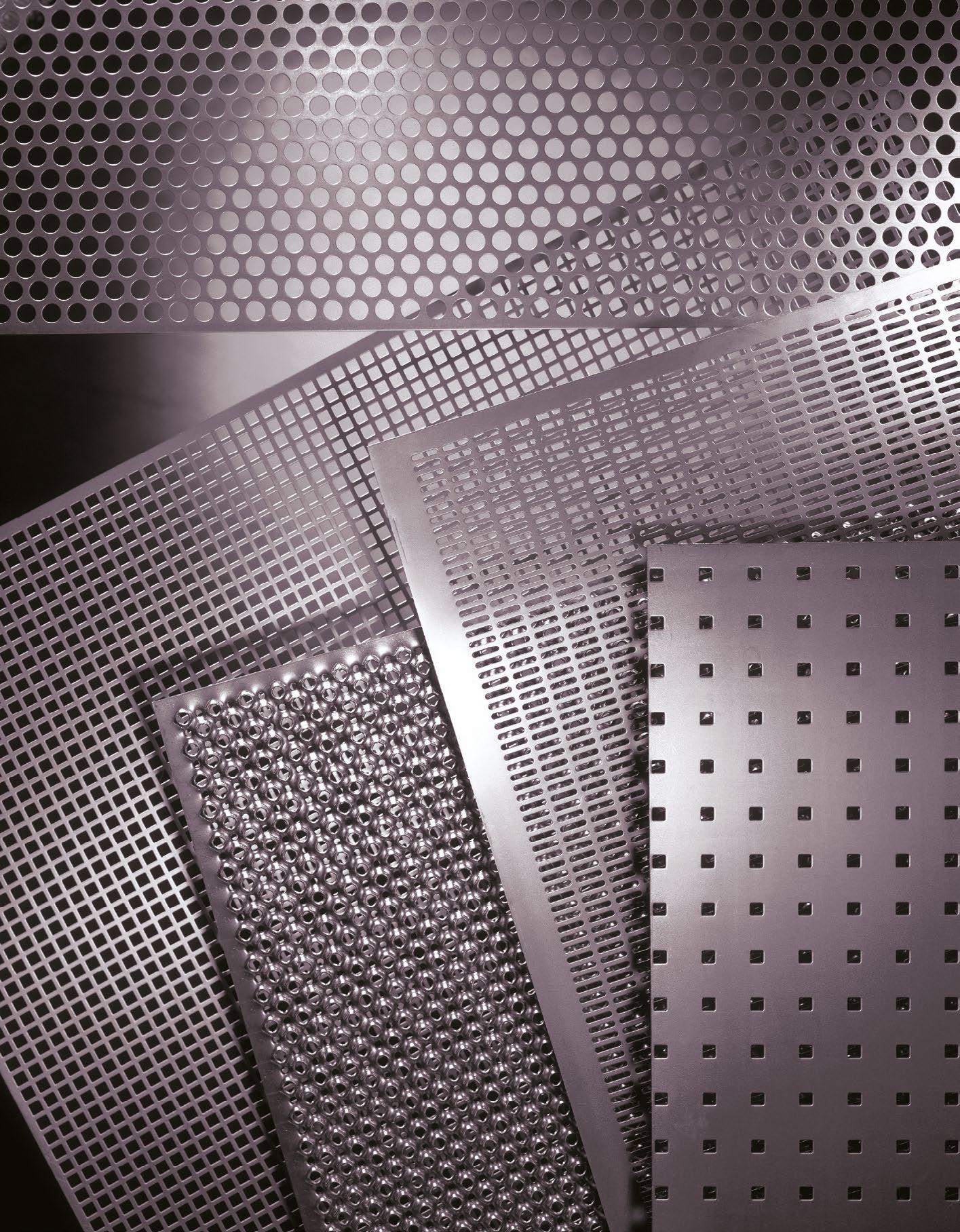

Perforation ideal for food processing

Perforated sheets from RMIG Solutions meets the high levels of hygiene demanded by the food processing industry. Perforated screens are also strong with important thermal capabilities, making them useful for a wide range of food processing applications. RMIG Solutions tailor-made perforated solutions are ideal for cleaning, heating and steaming in food production environments. Whether it’s baking trays, cereal cleaning or ingredient conveyors, all of RMIG Solutions perforated materials can be customised for each application.

RMIG Solutions ability to work with different grades of stainless steel, aluminium and galvanised mild steel at very high perforation specifications, allows us to provide the

food industry with perforated materials that give high air and fluid flows through burr-free open area designs.

This provides ideal solutions for cleaning, heating and steaming in food production environments. So wether it’s baking trays, helical feeding drums or ingredient conveyance, all our perforated materials can be tailormade for fabricating and finishing in applications to meet customer’s exacting requirements.

RMIG Solutions also deliver a wide variety of stock sheets in various materials and hole configurations, which we can deliver within 24/48 hours for those urgent requirements.

Quality and consistency sit at the heart of every food and beverage brand. They shape reputation, build trust, and decide whether a product earns a place on the shelf. As the sector adapts to new ingredients, regulations, and consumer expectations, particle size analysis has become a core part of quality control and product development.

Endecotts has specialised in this field for more than 80 years. Its equipment helps manufacturers monitor performance, meet compliance standards, and maintain the quality that customers expect, from laboratory testing to production.

Endecotts designs and builds instruments for one purpose: dependable, repeatable results. The company’s products are used across food and beverage production, including baking, dairy, beverages, confectionery, and other process industries.

Made from high-grade stainless steel and supplied with Calibration Certificates to ISO 3310 or ASTM E11, Endecotts sieves provide full traceability. Each is measured and

inspected to confirm accuracy before it leaves the factory.

Electromagnetic drive systems automate the sieving process. They remove much of the variation found in manual testing and ensure consistent outcomes over long production runs.

Used to measure viscosity and flow rate in sauces, dressings, and spreads. These instruments help food producers maintain uniform texture and appearance across every batch.

Accurate sampling is vital for representative testing. Endecotts dividers ensure powders, grains, and other bulk materials are split precisely, giving reliable data for process control.

Together, these instruments form a complete solution for measuring and managing particle size, from incoming ingredients through to the finished product.

Particle size influences nearly every characteristic of a food or drink, be it flavour, texture, solubility, or stability.

• In baking, flour size affects dough formation, structure, and crumb.

• In coffee and tea, grind size governs extraction and taste.

• Spice and seasoning producers depend on uniformity for even blending.

• Powdered dairy products rely on correct sizing for solubility and flow.

• Chocolate and confectionery require precise control to achieve a smooth finish.

• In beverages, sieving prevents sedimentation and ensures a consistent mouthfeel.

Accurate particle analysis helps producers maintain these qualities, reduce waste, and keep every batch within specification.

Manufacturing excellence depends on reliable measurement. Endecotts instruments support that aim by giving clear, repeatable results that stand up to scrutiny. Decades of engineering experience have shaped the company’s range, which continues to evolve with new materials and production techniques.

Whether testing ingredients in a development lab or monitoring production in a busy factory, Endecotts equipment helps ensure every batch meets the same standard of quality and consistency.

For more information or to speak with a specialist:

www.endecotts.com

sales@endecotts.com

ENDECOTTS delivers premium particle analysis equipment for the food and beverage industry. Our equipment is precision-engineered and EU-made for unbeatable quality.

There are several trends in the food and beverage industry that are influencing the growing importance of advanced particle analysis, such as:

Health & Nutrition Focus

Clean Label & Natural Products

Plant-Based & Alternative Proteins

Food Safety & Quality Assurance

Sustainability & Waste Reduction

Automation is transforming how food and drink manufacturers handle their end-of-line processes. From packing to palletising, intelligent robotic systems are helping businesses improve consistency, throughput, and workplace safety, whilst reducing operating costs.

Leading this transformation is Spider Robots, one of Europe’s foremost suppliers of palletisers with more than 30 years’ experience in automatic packing and palletising lines. PALpack is proud to be the UK agent for Spider Robots, supplying fully integrated systems with comprehensive technical support and turnkey delivery.

Versatile packing and palletising systems

Spider Robots’ automation systems are designed for efficiency, flexibility, and ease of use. Built using high-end components, each machine is engineered for long-term reliability in demanding production environments.

Key features include:

• Modular construction – easily scaled from a single to multiple production lines

• Quick change grippers: simply release four clamps to swap grippers, allowing one palletiser to handle multiple product types.

• Remote access and monitoring –built-in cameras store up to three months of footage for faster fault diagnosis

• Universal components – common motors and sensors minimise spares and simplify maintenance

Spider Robots are particularly well suited to food and beverage operations handling multiple product types, where flexibility, reliability, and hygiene are critical.

Modular systems engineered for efficiency and ease of use

Spider’s modular palletiser design allows the system to serve a single production line or be extended to handle multiple lines within the same frame. When one head can manage several lines, a single unit is used; if higher throughput is required, additional robot gantries can be added to increase capacity.

This multi-line capability means multiple production lines can feed into a single palletiser system, providing an efficient setup that

reduces footprint, maximises throughput, and scales easily.

With PALpack’s turnkey capability, each system can be supplied as a complete line solution, including infeed conveyors, labelling, wrapping, and pallet outfeed, configured to fit your existing layout.

High-performance palletising systems

By replacing manual handling with robotic palletising, food and drink manufacturers can reduce labour requirements, improve accuracy, and keep pace with growing demand. Spider palletising systems, available through PALpack in the UK, can manage high volumes with minimal supervision.

Programming a new pallet pattern for a different pallet size or new product is straight forward. Through an intuitive animated interface, operators can create or modify pallet patterns directly on screen, with no specialist coding required. Once a configuration is saved, it can be recalled at any time, streamlining product changeovers and reducing downtime.

Spider’s case and tray loading systems share the same proven design principles as their palletisers. They provide fast, accurate product handling across a wide range of packaging formats.

The method of feeding product into the case or tray depends on the type of item being handled. For flexible packs such as pouches or bags, consistency and orientation are crucial. Spider’s Delta robot uses a vision system to identify each pack, correct its orientation, and place it precisely into the carton.

For heavier or rigid products, or where items are already in a fixed orientation, Spider employs a pickand-place system which ensures reliable loading even at higher speeds.

Quick-change tooling lets operators switch between pack types within minutes using an interchangeable block and four easy-release clamps. All electrical and pneumatic connections are housed within the vertical axis, making changeovers fast, safe, and completely tool-free.

One of the greatest advantages of working with Spider Robots and PALpack is their ability to deliver complete turnkey end-of-line systems. Each solution is designed to complement the existing production flow and make the best use of available space, without requiring major layout changes or reconfiguration.

Spider can supply all connecting conveyors, carton and tray handling, labelling, and pallet wrapping. This integrated approach ensures that every stage of the process works together efficiently and reliably.

Every Spider system supplied by PALpack includes remote VPN access and onboard cameras, allowing the support team to review operational footage and diagnose issues without delay. When a site visit is required, engineers arrive fully prepared with any necessary parts, ensuring most issues are resolved in a single visit.

All Spider machines use standardised motors, inverters,

and sensors, keeping spare part requirements to a minimum and reducing overall operating costs. For food and drink producers, the benefits include higher throughput, lower labour needs, and improved safety and traceability.

As the UK agent for Spider Robots, PALpack provides complete support from consultation and system design to installation and ongoing service.

For more information or to discuss your requirements, contact PALpack on 07946 454188 or sales@palpack.co.uk

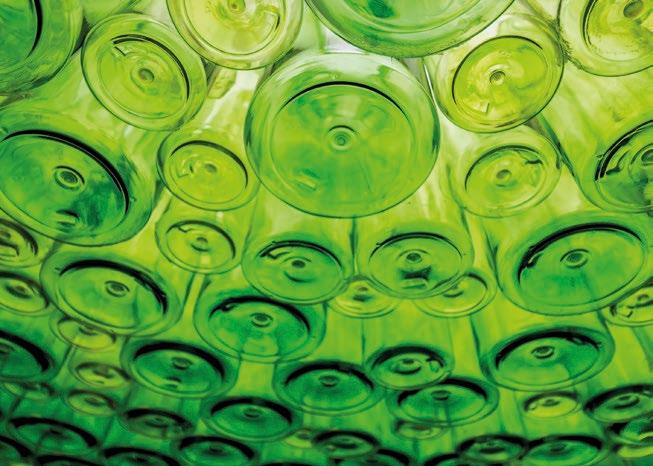

Faced with fierce competition and rising consumer expectations, the drink manufacturing and bottling industries

need to find ways to deliver products faster and at lower costs than ever before, without compromising on either quality or production standards. If they’re going to meet these challenges, they need to partner with equipment manufacturers that can offer smarter, more reliable, and more efficient solutions.

Regal Rexnord™ is playing a key role in this move towards heightened efficiency and reliability. It offers a comprehensive portfolio of component products from trusted brands designed to meet the diverse challenges of modern production lines.

From gear motors and conveyors to precision motion control and braking systems, Regal Rexnord’s integrated suite of products delivers unparalleled performance and ease of integration, making it the go-to partner for original equipment manufacturers (OEMs) and plant engineers seeking a tailored solution for the beverage sector. From single components to fully integrated powertrain, Regal Rexnord can deliver new solutions to address your business challenges, while reducing the complexity of existing infrastructure.

More hygienic, more durable, more accurate

Bottling lines rely heavily on highperformance conveyor systems built on Bauer Gear Motor™ solutions. These compact, efficient gear motors out-perform the competition when it comes to durability and deliver outstanding resistance to the harsh washdown environments needed to keep lines hygienic. These are often complemented by robust enclosed

gear drives and motion control components engineered by Boston Gear™, ensuring smooth, dependable operation throughout the plant.

Bearing systems also play a key role in high-speed bottling operations. Here, Sealmaster™ PN Gold series ball bearings offer IP69K-certified resistance to ingress – ensuring the highest level of protection against the effects of repeated high pressure washdowns and other contaminates.

Elsewhere on the line, precision linear actuators and guides from Thomson™ ensure accurate, repeatable movement, helping manufacturers achieve consistent fill levels and label alignment.

Smarter conveying materials

Conveying chains are a critical factor in ensuring smooth, efficient, and hygienic product flow in beverage production. Regal Rexnord’s premium material offerings for conveyor chains and wear strips are engineered to outperform standard acetal or polyethylene materials, particularly in high-speed bottling and canning lines.

Options such as HP™ (High Performance Acetal), PSX™, NG Evo™, and Dry-PT™ deliver lower friction, improved chemical and temperature resistance, and exceptional wear life, all while reducing or even eliminating the need for external lubrication. Combined with advanced wear materials like Nolu-S™, these solutions enable quieter, cleaner operation, extend equipment lifespan, and support higher throughput with less downtime.

Stopping power

Maintaining precise control and safety is essential on fastpaced bottling lines, especially where stop–start cycles happen frequently. Regal Rexnord’s braking solutions, including electromagnetic clutches and brakes, deliver rapid, reliable stopping with minimal

maintenance requirements. These components support key applications such as conveyor indexing, cap handling, and labelling, helping to maximise uptime while protecting both operators and equipment.

At the far end of the line, robotics now are playing a larger role in tasks like packaging and palletising. Here, Regal Rexnord’s Kollmorgen™ brand provides robotic solutions required for agile, high-speed automation. Its advanced servo motors, drives, and motion controllers enable coordinated, repeatable performance – ideal for robotic arms managing demanding, repetitive operations such as case packing or shrink-wrapping.

When combined with Regal Rexnord’s wider range of clutches, actuators, and brakes, manufacturers can achieve seamless, synchronised motion that enhances productivity and accuracy across the plant.

The Regal Rexnord advantage

Working with Regal Rexnord means access to a unified network of leading motion control and power transmission technologies. OEMs and plant operators can simplify procurement and maintenance by working with a single, trusted partner – ensuring full system compatibility, reduced complexity, and coordinated support from design through to operation.

Whether the goal is to modernise existing lines or develop new systems from the ground up, Regal Rexnord provides complete, factory-tested powertrain and automation solutions tailored to the exact needs of the beverage industry. From the first gear motor to the last robotic palletiser, every component is engineered for durability, efficiency, and performance – backed by a global team dedicated to keeping production running smoothly.

www.regalrexnord.com

Engineered to perform in the toughest food and beverage environments.

From processing to packaging, every component in a powertrain system needs to meet the highest standards of hygiene and reliability. Regal Rexnord provides stainless steel drives, washdown motors, and precision conveying systems designed to keep production lines running safely and efficiently while meeting strict hygiene standards.

Our technologies are trusted by global food and beverage manufacturers to maximise uptime, minimise product waste, and simplify maintenance.

Built on decades of expertise and innovation, we help you see beyond individual parts to build a powertrain with unlimited possibilities.

CopriSystems have always offered a turnkey service but clients are often surprised to hear that they can do all the groundworks and internal fit-out, on top of the building design and installation.

Turnkey means that one company will handle everything in a construction project from the initial consultation to handing over the keys. In many ways, it is a collaborative arrangement in which CopriSystems act as the principal contractor and subcontract specific jobs out to other businesses until the facility is fully ready to operate. This means that communication is streamlined to one consistent point of contact and there are no complications with constant changes to the project management.

With turnkey projects

CopriSystems like to work with suppliers and businesses that are local to the project, not only so that they are able to reduce their carbon footprint but they have found that this strategy helps to create a more cohesive

team. A team that is flexible and readily on hand to make any necessary changes quickly and efficiently. A team that can offer specific expertise not only in their specialised field of work but also in their knowledge of local regulations and building codes. A team that is more likely to deliver the highest quality service because their business depends on them protecting their reputation in the local area.

Turnkey projects can reduce the financial unknowns and help to condense timelines. Sticking to a schedule is critical for successful delivery but during the lifecycle of a project, there are times when unforeseen delays can occur and additional costs are incurred. Extreme weather conditions cannot be avoided but miscommunication can and with all turnkey projects, CopriSystems are able to ensure that everyone is on the same page from the offset.

Turnkey projects are also great for setting high quality standards upfront to ensure consistency

throughout the project lifecycle across design, fabrication, build and finish.

Recently, CopriSystems have completed work on a multi-sport facility for Welland Park Academy in Market Harborough. This was a fantastic example of a turnkey project that was fully reliant on us getting the best people involved to deliver a state-of-the-art sports hall. As our site manager perfectly said, “Construction projects run smoother when you have the right selection of contractors supporting our own team of experts.

Contractors that can utilise years of experience to react to any given situation. Each contractor has exceeded expectations and their attention to detail was relentless. We were all one team together and the professionalism of everyone involved stayed continuously above the bar.”

For more information, a quick quote or site visit, please contact us: sales@coprisystems.com 01380 830 697

• Materials & machinery for the complete solution

• Transit & display packaging

• Fully-recyclable, sustainable, anti-fog, barrier, MAP packaging and more...

• High-speed equipment for demanding environments

• Supported by expert engineers, across the UK & Ireland

DISCOVER THE RIGHT INGREDIENTS FOR FOOD PACKAGING SUCCESS.

Reviewing your packaging system’s setting can result in material and power savings.

The new pEPR regulations are shining a light on the environmental footprint of manufacturers’ packaging practices. The focus of the regulations is on materials use and specification, however operators can also make improvements toward their sustainability goals by reviewing the equipment they operate.

Below, Jonny Braithwaite, Director at Yorkshire Packaging Systems (YPS) talks through some of the ways manufacturers can reduce their environmental impact, improving their production performance while simultaneously lowering their plastic usage and also decreasing their power use.

When looking to invest in new or upgraded packaging equipment there are some key features now available that result in reduced materials use. For existing equipment, our engineers also attend customers’ sites for machinery maintenance visits, where optimisation of settings can lead to a reduction in power

consumption. For high-volume operations, these gains can mount up to serious savings.

At YPS, we supply shrink wrapping machines and horizontal bagging machines that are designed with low gauge, highly-recycled content materials in mind, that in turn lead to higher throughput and a reduction in power requirements.

Features to look out for in this respect include:

Vacuum belts – The vacuum belt pulls the product and film through the machine, reducing the pressure on the film when compared with machines without this feature. This means that a much thinner film can be utilised, reducing film consumption by downgauging material specification. A vacuum belt also allows for a closer cut to the product, improving the pack aesthetic as well as reducing material consumption.

Continuous motion sealing jawThe sealing head moves with the product, rather than remaining static. This means it can start to close around the product earlier which creates a much tighter seal.

Thinner sealing jaw – A finer sealing jaw results in a narrower seal, resulting in small material reductions per pack. It can also activate closer to the product, again creating a tighter finished pack.

Side sealing first – Where the side seal is created first, the machine effectively creates a tube of material around the products as they pass through the machine and then cross cuts to separate each pack. This produces a tighter seal than processes which crossseal and then side-seal. It also creates significantly less material waste from trimming of the side seal.

Programmable start-stop –Machines which include startstop scheduling power off

automatically, ensuring that they are not running any longer than needed, therefore preventing unnecessary power use.

Power monitoring – Some models can include continuous power monitoring. This ensures that any issues that are causing a rise in consumption are highlighted and corrected as soon as possible, preventing wastage.

operation of any line

Our in-house team of dedicated packaging engineers carry out service contract and routine maintenance work for our customers and also perform Sustainable Site Surveys, which review existing set-ups with the specific aim of reducing environmental impacts.

A few of the key settings they review include:

Sealing jaw temperature and dwell time – Ensuring that these settings are ideal for the operation confirms that the system isn’t using additional, unnecessary power. Reducing unnecessary dwell time also speeds up throughput for increased packs per minute and lessens machine wear and tear over the long term.

Heat shrink tunnel temperature – For shrink wrapping systems, shrink tunnel temperature should be matched to the material specification in use. Where customers have moved to the use of thinner films, reducing plastics use, they can also lower their tunnel temperature, realising a saving in power consumption.

Shrink tunnel operation – Our engineers always check that shrink tunnels are functioning as they should. If a heating element is down for any reason, the remaining elements use an increased power load overall to ensure the required temperature is reached.

For manufacturers and contract packers who would like to explore investment or upgrade options or who would like our engineering team to help optimise their current packaging system in line with their environmental goals, our team are always happy to help.

www.yps.co.uk

New automated packaging models can include features for significant reductions in plastic use.

In modern food and beverage manufacturing, precision and hygiene are everything. Whether it’s controlling ingredient dosing, monitoring water use, or managing CIP cycles, accurate flow measurement plays a critical role in maintaining quality, efficiency, and compliance.

The Comac Cal FLOW 33 Inductive (Electromagnetic) Flow Meter, supplied in the UK by iCenta Controls, offers a robust and costeffective solution for liquid flow applications across the industry. Designed for reliable performance in demanding environments, the FLOW 33 provides high accuracy and stability without the complexity or maintenance of mechanical meters.

Built with no moving parts, it’s ideal for use with conductive liquids such as water, juices, syrups, and cleaning fluids. The smooth internal bore eliminates areas

where residue could accumulate, making it suitable for hygienic or CIP-cleaned systems. Compact and corrosion-resistant, the FLOW 33 can be easily integrated into process lines and automated control systems, offering a variety of output signals compatible with modern PLC and SCADA networks.

For food and beverage producers under pressure to improve resource efficiency and reduce downtime, this meter combines dependable measurement with straightforward installation and long service life.

As with all iCenta-supplied instrumentation, the FLOW 33 is backed by technical expertise, calibration support, and tailored advice — ensuring every installation delivers precise and traceable results.

“Our partnership with Comac Cal enables us to offer proven

European-built technology supported by local service and calibration expertise,” says the iCenta Controls team. “It’s a combination that provides real value for process engineers and plant managers alike.”

From breweries and dairies to water utilities and energy recovery systems, the FLOW 33 provides the accuracy and dependability that modern production demands — helping keep operations flowing smoothly.

Learn more at iCenta Controls

Expanding its already extensive range of colour label printers, AM Labels Limited has added the Neuralabel Callisto Colour Label Printer to its portfolio. It was showcased for the first time at the PPMA Show 2025.

The Neuralabel Callisto is an affordable, high-speed, colour label printer. It is durable and lightweight, due to its aluminium construction, and its small footprint makes it ideal not only for the factory floor, but also it can be accommodated in a small office.

The printer is able to produce BS5609 compliant labels, which are designed to withstand extreme conditions, including sunlight, prolonged exposure to water and abrasion. Using durable aqueous pigment inks, it is suitable for printing chemical and waterresistant labels due to their high resistance to alcohol and solvents. Additionally, these labels are GHS compliant, which means that the

labels meet global safety standards, which ensures that the labels can withstand hazardous material and chemical applications.

A large, seven inch intuitive, touch screen, with built-in help options, make the printer easy to operate as well as to maintain. In addition, the printer supports a variety of label design software such as Bartender, NiceLabel and SAP, adding to its versatility and ease of use.

What’s more, the high capacity, individual, CMYK ink cartridges1 and the generous media width, from one to 12 inches (25.4 to 304.8 mm), and a print width of 11.7 inches (297.2 mm) extends operational productivity. A print resolution up to 1200 x 4800 dpi guarantees that the labels look clear and sharp regardless of the application.

The portfolio from AM Labels continues to grow, with the addition to the range of the Neuralabel

Callisto. The Callisto is an ideal option for businesses looking to expand and enhance their in-house printing systems.

Brendon Bass, Sales and Marketing Manager, AM Labels Limited comments: “The Neuralabel Callisto colour label printer is an excellent solution for companies seeking to enhance and expand their in-house label printing operations. Having showcased it at the PPMA 2025 Show, visitors were impressed by its capability. It is designed to create high-quality labels, as well as being GHS compliant, which gives companies that added peace of mind. We are proud to add it to our portfolio, as part of our commitment to delivering high performance, business ready technology.”

For more information on labelling solutions from AM Labels, please call the sales team on 01536 414222 or email: sales@amlabels.co.uk

If your organisation generates a significant amount of waste, which is very likely in a processing and packaging environment, exploring baling as a waste management solution is a key sustainable action for your organisation.

Don’t just think about waste, think about your effectiveness as an organisation, storage optimisation, transportation efficiency, recycling facilitation, reduced handling and ultimately cost savings.

At Kadant PAAL we offer a multitude of solutions which are tailored to your needs for now and also into your waste handling future.

Waste materials generated such as cardboard, cartons, paper and aluminium can all be baled effectively with our extensive range of products and we also take the major factor of quantity /

throughput into consideration before providing your organisation a solution. We are strong believers that we will only recommend a product that is suitable for you individually and we have the distinct advantage of choice from our vast range of baler and compaction products.

The Kadant PAAL baling and compaction equipment resource incorporates our PAAL range of Channel Balers and the DICOM product range of Compaction Equipment. Take the indecision and risk out of your waste processing requirements, partner with Kadant

PAAL who will provide established designs, tried and tested in thousands of installations. Our robust construction combined with the latest cutting-edge technology at Kadant PAAL will give you our tradition meeting technology formula.

In short, Kadant PAAL does not just supply machinery – we deliver you strategic value and growth through innovation, sustainability and operational excellence.

www.kadantpaal.com www.dicompaal.co.uk

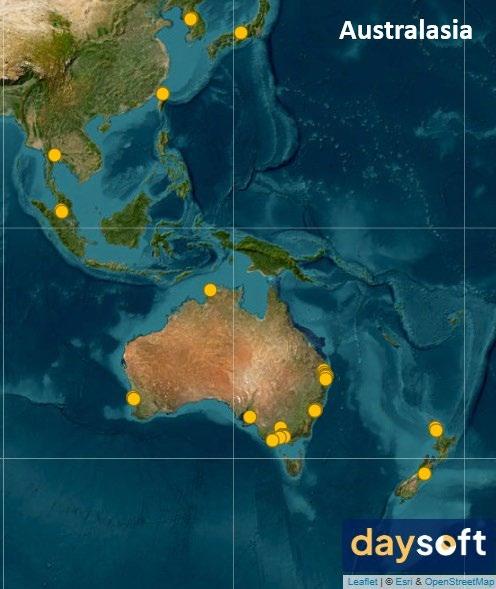

one day all contacts will be daily-disposable and one day they will all be sold the daysoft-direct way making healthier eyes affordable for everyone, every day, everywhere

Daysoft® successfully replaces other soft spherical contact lens brands without refitting and ships direct to you at half the price

Every day, my company, Daysoft Limited, prevents contact lens wearers around the world suffering from excruciatingly painful visionloss. The causes of this distressing condition to which I am referring is directly related to the wearing of contacts prescribed for overnight wear (ON) or those prescribed for repeated use with daily cleaning (RU).

The way of avoiding this vision-loss is to wear daily-disposable (DD) soft contacts.

This is why Daysoft has only ever designed, made and sold dailydisposable soft spherical contacts. Our direct to consumer (D2C) supply business-model reduces the cost-per-contact to a few pence including delivery, direct through post boxes anywhere in the world. This provides a really affordable contact lens system with great consumer convenience. It is also the reason why Daysoft’s contacts are designed to be direct replacements for the soft

spherical contacts of all types including ON or RU brands made by the four major contact lens manufacturers; Bausch & Lomb (B+L), CooperVision (CV), Johnson & Johnson (J&J) and Alcon.

Data-driven confidence from 1-billion lens sales

Of course, it’s easy to say; “Daysoft successfully replaces other brands for half the price” (which has been out tag-line for over 20 years) but in that time, we have meticulously amassed customer data relating to the sale and supply for over 1 billion daysoft contacts

Delivered direct for the ultimate convenience and safety

We ship direct to your home or office address straight from the end of our production lines based here in Scotland to wearers around the world. No resellers, no middlemen. This gives us the most comprehensive source of contact lens wearer experience available anywhere … we know for every Lot Number shipped who actually received these actual contacts. This direct-to-you model keeps our family business close to you, our customer, wherever you live with tupically 95% repeat purchase and 5% new wearers ordering every month.

Dr Ronald S Hamilton CBE, Founder and Owner of Daysoft Limited is the Inventor of the world’s first daily-disposable contact lens. These have transformed vision-care by eliminating the vision loss problems associated with cleaning and reusing contacts (RU) or wearing contacts continuously including overnight wear (ON).

Having sold his first contact lens business and related technology to Bausch & Lomb, Ron went on to form the world’s first Direct to Consumer (D2C) brand by integrating a new advanced manufacturing process with a unique e-commerce ordering capability.

In 2006 www.daysoft.com was launched at the British Contact Lens Association Conference (BCLA) and is now an increasingly accepted system of direct to consumer (D2C) sale and supply. The Daysoft Team is proud to be shipping over 1,000 orders every day now with over 1 Billion contacts already made and sold direct to contact lens wearers around the world, without refitting.

www.daysoft.com

Location of daysoft® orders despatched direct to wearers around the world in a typical 7-day period.

Hart Door System’s wind-resistant, high-speed, industrial rolling door, Speedor Storm, is ready for business be it a factory, warehouse, storage facility or any kind of plant operation writes Chris Dobson.

With wind resistance available up to ‘wind class 5’, as defined by DIN EN 12424, in the closed position this high-speed door is ready for openings to a maximum 8 metres width or height subject to 48 square metres.

The ability to withstand substantial wind pressure means major entrances open/close automatically so avoiding a less-than-optimal working environment and the escape of heated air important with Winter on its way.

Speedor Storm helps industry specifically by;

• Aiding productivity – because entering and leaving a building can be done more rapidly.

• Helping to create a better working environment through its highspeed operation which means there are no unnecessary open periods.

• By saving on the substantial cost of heating.

Made in the UK at Hart’s Newcastle upon Tyne headquarters from where its teams of engineers are available throughout the UK for installation of Speedor Storms and subsequent servicing and maintenance thereafter. Speedor Storm’s strength and wind resistance comes from its multilayer PVC and textile, both longlasting and tear-resistant and its inbuilt horizontal curtain braces and no external cumbersome and noisy external wind bars.

There is a colour choice as well as ‘a with or without vision panel’ which combine to deliver a good appearance, operational effectiveness and a performance product.

Safety features are of course paramount, and here they include a state-of-the-art safety light curtain, anti-fall protection and sensors to activate the door. There is a range of operating methods that include hands free, floor loops, radar, photo beam, radio operation, movement sensors, handheld or vehicle-

mounted radio transmitters, or simple push button and pull cords.

The automatic operation can be set to include or exclude pedestrians as desired. If warning lights or klaxons are required, these can be incorporated in a complete door system and control panel which are designed for any conceivable need including integration into a Building Management System if necessary. This is delivered via its unique guide system in combination with other carefully designed features.

www.hartdoors.com

Gellert freeze dryers are the perfect solution for manufacturers looking for a reliable and scalable option for regulated food production. With a notable shift towards the freeze-dried product market, manufacturers and consumers alike are recognizing the benefits of this process. By reducing, or removing, the need for cold chain handling, manufacturers can reduce transportation and storage costs, and as freeze-dried material is much lighter than frozen or refrigerated product, this further lowers costs. Additionally, freeze dried products not only take less energy and cost to store, but they also maintain the biological benefits and flavours of the raw product whilst extending shelf life.

Gellert freeze dryers offer a controlled and repeatable manner for in-situ freeze drying directly on the shelves, ensuring the product maintains its shape, structure, and nutritional value. Gellert has developed a range of freeze dryers with ease of scale-up, user requirements, and operation in mind, making them versatile and popular in the industry.

Some of the beneficial features of Gellert equipment include

AutoDry, an intuitive feature that allows users to input their desired temperature differential between the product, sample, and shelves, ensuring the sample can be dried using the AutoDry feedback mechanism, optimizing drying cycles. The chamber, condenser, shelves, and shelf stack can all be constructed from 316L stainless steel for product contact, and a hybrid cooling system is also available on larger equipment, to utilize defrost water by re-heating via the freeze dryer compressors, saving energy and costs.

The most common applications that Gellert’s freeze dryers are used for include: -

• smart foods e.g., supplements and nutraceuticals

• food and beverages

• dairy products

• fruits and vegetables

• pet food and pet treats

All Gellert systems are manufactured in Europe and strictly adhere to compliance regulations such as F-gas.

Biopharma Group is the exclusive distributor of Gellert freeze dryers across the UK, Ireland, and France. Both Biopharma Group and Gellert well respected and renowned companies, combining years of lyo industry experience. This winning combination allows the Biopharma group team to help you select the best freeze dryer to meet your specific need and Gellert has accrued a high level of practical experience and in-house expertise, developing an array of different models and configurations to satisfy a broad range of food production purposes.

Contact Biopharma Group’s product specialists to discuss your requirements or request more information.

www.biopharma.co.uk

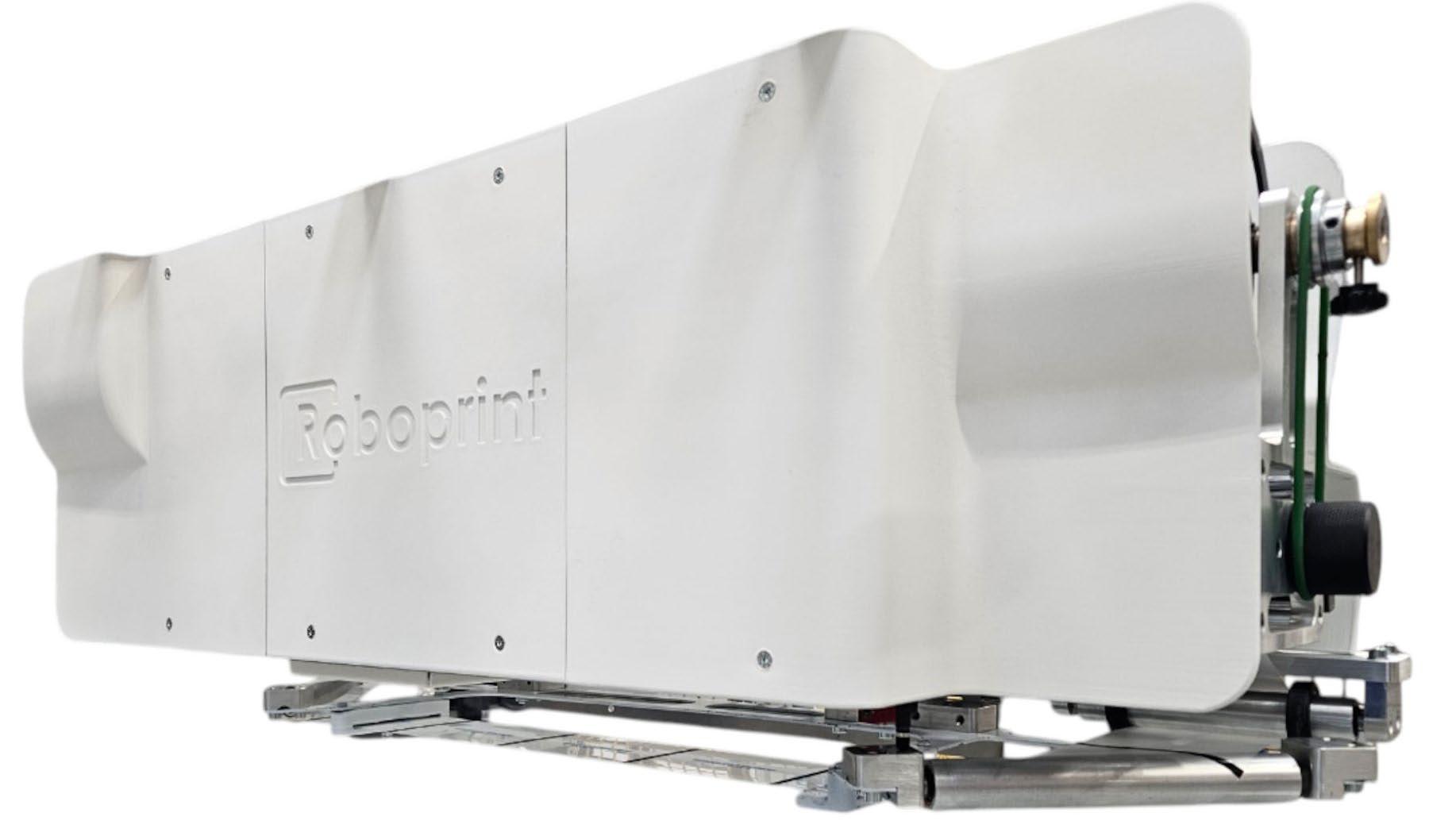

Plastics decoration has long depended on pad and screen printing — reliable but hindered by solvents, labour-intensive changeovers and downtime for design changes. In fast-moving markets with shifting consumer expectations and shorter product lifecycles, these methods are under strain. Italian start-up Roboprint, in partnership with Shibaura Machine and European distributor TM Robotics, has developed T-TRANSFER, a system that combines pre-printed transfer reels with robotic automation to overcome many of these limitations.

Consumer interest in personalisation is reshaping manufacturing. A Deloitte survey in 2024 found that one in five consumers interested in personalised products or services are willing to pay a 20 per cent price premium. This demand has

accelerated adoption of digital printing technologies, which allow shorter runs and customised designs.