Pablo van der Lugt

Pablo van der Lugt

BUSTING THE MYTHS ABOUT THE REAL POTENTIAL OF TIMBER BUILDINGS

Timber is our oldest and newest building material. It built our frst crude shelters and now stands at the forefront of our response to the climate crisis and the housing shortage at the same time. For thousands of years, humans have drawn their homes from forests and local resources; now, after a hundred years of concrete and steel, we are rediscovering timber’s potential as a technology of renewal. In the past two decades, mass timber and engineered wood products such as glue laminated timber (glulam), cross-laminated timber (CLT) and laminated veneer lumber (LVL), has reemerged as a transformative technology in construction. These engineered timbers combine strength, precision and lightness, allowing us to build taller, faster and far more responsibly than ever before.

Yet for all its promise, timber still sits under a shadow of misunderstanding. It is still too often seen as fragile, non-durable and fammable, a material of the past and not the future, believed to cause deforestation instead of strengthening our forests. These are the myths that The Timber Truth sets out to dismantle. They obscure the simple fact that timber, responsibly sourced and intelligently used, is a contemporary material capable of delivering the performance, beauty, scale and low-carbon profle our cities urgently need.

We are at a critical moment. Across Europe, North America and Asia, the enthusiasm for mass timber is matched by hesitation. Pioneering large-scale timber projects are rising across cities such as Stockholm, Amsterdam, London and Portland, while others stall under the weight of outdated codes, conservative insurers or anxious clients. Progress slows not because timber has failed, but because our systems of regulation, fnance and habit have yet to catch up with the science.

Designing and building with timber demands a different paradigm. It replaces hierarchy with collaboration, tolerance with millimeter precision and reaction with foresight. A mass timber building is manufactured as much as it is constructed, digitally modelled, prefabricated and assembled in days to weeks, instead of months to years. This process collapses boundaries between architect, engineer and contractor; it requires shared knowledge and mutual trust. In this sense, timber is not just a material, it is a catalyst for a new culture of building.

My own fascination with timber began more than twenty years ago, when we built some of the frst CLT structures in the UK. Standing in those early buildings, I realized that something fundamental had shifted. The air felt different, cleaner; the acoustics softened; people touched the walls. It was architecture that invited intimacy instead of distance. Since then, in multiple occasions I have seen timber’s quiet strength transform not just the carbon footprint of projects but the spirit of those who live and work within them.

That is why this book matters. The Timber Truth is both a reference and a call to action, an open dialogue led by Pablo van der Lugt based on latest insights from industry and academia alike. The book tackles sixteen enduring misconceptions, from questions of strength, fre and durability to forestry, economics and climate. It also transparently addresses some of the over-optimistic myths surrounding modern timber construction.

Enriched with practical insights from the most recent and innovative mass timber projects across Europe, it offers the much-needed knowledge base that allows policymakers, investors and builders to act with conviction, not caution.

The climate emergency has forced us to rethink not only what we build but also how we build, and why. Timber offers us a route forward: a regenerative, circular approach that reconnects architecture with living systems while decarbonizing the act of construction itself. Dispelling myths is a crucial frst step towards that transformation.

We know how to build better. This book reminds us why we must.

Andrew Waugh

BUILDING QUALITY AND PERFORMANCE

Myth 1 Wooden buildings are structurally inferior

Myth 2 Timber buildings don’t last

Myth 3 Timber buildings are uncomfortable

Myth 4 Timber construction is monotone and design-limited

Myth 5 Timber is unsafe in case of fre

Myth 6 Timber solves all our problems!

ENVIRONMENT AND CLIMATE

Myth 7 Timber construction is bad for the environment

Myth 8 Timber buildings are not circular - the materials are burnt or landflled at the end of life

Myth 9 Glue negates all environmental benefts

Myth 10 Timber solves all our problems!

FORESTRY AND AVAILABILITY

Myth 11 Building more in timber will destroy our forests and accelerate climate change

Myth 12 There isn’t enough wood

Myth 13 Timber solves all our problems!

ECONOMY AND MARKET

Myth 14 Timber construction is too expensive and too complicated

Myth 15 Timber construction is hard to fnance and insure, and yields less Myth 16 Timber solves all our problems!

Timber has one of the best strength-to-weight ratios of all materials, and with fully standardized and strength classifed mass timber elements, enormous spans and even high-rise buildings can be safely constructed.

Wood is a natural and anisotropic material. That means that its strength differs according to the direction it is loaded, with far higher strength in longitudinal direction parallel to the fber. Furthermore, the strength of a board may vary depending on the growth conditions, the location of the board in the stem, as well as natural defects such as knots.

In the past, this non-uniformity of timber made for large-scale replacement with fossil-based materials in the industrial revolution, such as steel and concrete. However, with the introduction of (often automized) strength grading, it is no longer necessary to guess. Each wooden board intended for structural use is graded following EN 14081 and classifed in strength classes following EN 338, see also box 1.

Actually, because of its lightweight and relatively high strength, (engineered) timber is one of the most effcient building materials available on the global market from a structural perspective, with mechanical properties such as strength or stiffness that can easily meet European building regulation requirements.

This is especially true for mass timber products: during production, weaker sections of the boards are either removed or placed in structurally less critical inner layers, while the fault-free boards for input in cross-laminated timber (CLT), glue-laminated timber (glulam) or veneers for input in laminated veneer lumber (LVL) are glued together and positioned on the outside to form an assembled component that is much stronger than the individual boards.

Additionally, timber buildings have lightweight and elastic structures - allowing them to bend under shock loads and making them more resilient to earthquakes. Building with wood is therefore often preferred in earthquake-prone areas.

As a result of the high structural effciency, it may come as no surprise that mass timber products such as glulam and LVL offer bending strength and stiffness suffcient for major span applications.

For regular multi-story mid-size domestic and offce buildings, usually a post-beam glulam system in combination with CLT fooring is deployed. CLT fooring is most effcient in foor spans between 4 and 7 meters, and about 5 meters in residential

Different properties in different directions

Non-destructive timber strength grading, in addition to visual grading, is primarily achieved through bending tests or measurements using specialized machines that utilize vibration or radiation. This automated process is vital for selecting wood with optimized properties, particularly in the development of engineered wood products. The European standard EN 338 classifes timber into softwood (C-class) and hardwood (D-class) based on these grading results, with classifcations ranging from C14 to C50 for softwood and D18 to D70 for hardwood, allowing structural engineers to accurately calculate timber structure performance.

Strength grading

Automated strenght scanning of input boards in the CLT factory of DERIX in Westerkappeln, Germany.

As a rule of thumb in softwood used for CLT (strength class C24) allowable stresses parallel to the grain are 24 N/mm2. Compression perpendicular to the grain is around 10% of this value (2.4 N/mm2) while tension perpendicular to the grain is around 1% of the parallel value (0.24 N/mm2).

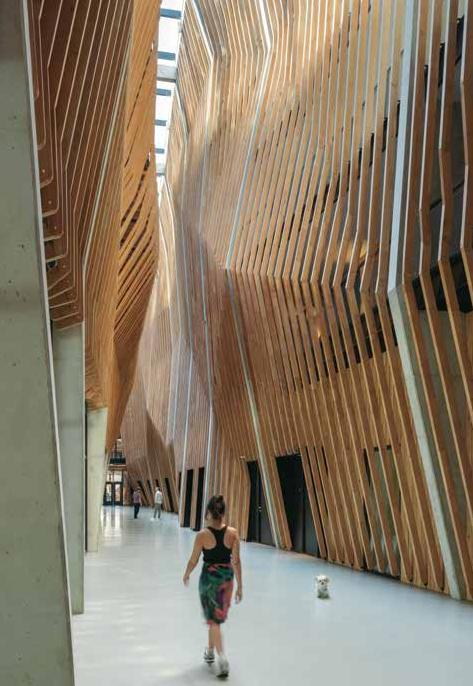

With mass timber, a new and exciting architectural form language is possible, both in complex 3D parabolic and rectangular forms. And although it is perhaps a lost opportunity, a building with a complete timber shell, can still resemble an ‘ordinary’ concrete building.

YOU CAN’T CREATE MODERN ARCHITECTURE WITH TIMBER - IT OFFERS LITTLE DESIGN FREEDOM

Modern architecture is often associated with clean lines, long spans, cantilevers, and sculptural forms, a language historically dominated by concrete and steel. The perception that timber cannot achieve such qualities stems largely from outdated associations with conventional timber-frame construction. Today, engineered timber systems enable architects to realize comparable spatial and formal ambitions while dramatically reducing carbon impact.

Mass timber’s lightweight consistency and precise workability open new opportunities. Engineered panels and beams can span long distances and enable complex forms. When combined with computational design, parametric modeling and digital fabrication, these designs can be translated with millimeter precision into reality via CNC or robotic manufacturing.

This precision enables large-scale freeform components to be fabricated off-site and assembled effciently on site. Architects such as Shigeru Ban have pioneered this approach, demonstrating that

timber can serve not only as a sustainable substitute for conventional materials, but also as a medium for developing entirely new spectacular architectural languages.

Prefabrication is often associated with dull, repetitive architecture. Yet industrialized timber systems provide not uniformity, but a platform for customization. The more advanced the parametric design and production tools, the greater the variation in form, façade expression, and spatial organization that can be achieved. With thoughtful architectural design, repetitive components can be combined into distinctive façades, hybrid systems, and diverse building typologies.

Current practice already demonstrates this. Prefab timber can be organized as 2D systems (walls, façades, foors, and roofs assembled on site) or as 3D volumetric modules (complete units with services and fnishes). Both approaches have been applied in multi-story housing, ranging from expressive midrise apartments to light-weight rooftop extensions. The adaptability of timber, with its workability and low weight, makes it especially suited to modular

This 22,000 m² experience center in Göteborg, Sweden (designed by Henning Larsen), is constructed largely in timber, with glulam columns and beams forming towering tree-like trunks up to 15 meter high, and CLT foor slabs throughout. The curved structural ribs span up to 35 meter and are produced with high-precision CNC fabrication, underscoring a new benchmark in large-scale timber architecture.

Although timber is combustible, mass timber behaves quite predictably in case of fre, and many measures can be taken to safeguard fre safety in a timber building. However, knowledge on this topic is still evolving so a precautionary approach is advisable.

It is often assumed that timber must always be concealed behind layers of gypsum board to achieve fre safety. In reality, mass timber can be designed to meet fre requirements in two passive pathways: charring, where oversized members form a protective char layer in case of fre, or encapsulation, where timber is covered with gypsum or other frerated boards. The choice depends on factors such as building height, occupancy, costs, risk level, but also sustainability, health and circularity considerations.

Encapsulation makes it straightforward to meet combustibility requirements, but it also hides timber’s aesthetic and indoor climate qualities. To balance these aspects, modern building codes offer fexible pathways. For instance, the International Building Code (IBC) in the United States defnes three categories of mass timber construction: Type IV-A (up to 18 foors, full encapsulation), Type IV-B (12 foors, partial exposure allowed), and Type IV-C (9 foors, signifcant exposure permitted). Similarly, the forthcoming Dutch NTA 6125 allows combinations of encapsulation, sprinklers, and charring performance to achieve equivalent safety levels.

Large-scale fre tests by institutes such as RISE confrm that exposed timber can safely remain visible if certain precautions are taken. These include limiting exposed surface areas, avoiding intersecting exposed corners, and providing robust fre-stopping at junctions. Such measures are increasingly refected in evolving codes and design guidance.

Façade requirements are set separately. In the EU, most countries apply the EN 13501-1 Euroclass system to the complete façade system in its socalled ‘end-use’ application, meaning the tested assembly including cladding, substructure, membranes, insulation, and fxings.

For low-rise buildings, Euroclass D cladding materials may still be permitted, while high-rise projects (typically over 20 meters) usually require Class B or stricter. Some countries, such as the UK, now mandate A2 or better for certain high-rise façades. Importantly, because ratings apply to the full tested assembly, individual product classifcations do not guarantee the same performance once combined.

Thus, full plasterboard encapsulation is one valid fre safety strategy, but far from the only one. Modern

Modern understanding of fre safety recognizes that material properties, design strategies, and system integration are far more important than combustibility alone. Fire protection design either involves active, often preventive systems (such as sprinklers, alert systems, fre extinguishers, etcetera) or passive systems (design and materialization measures to limit the damage in the event of fre).

The table in fgure 1.08 lists – in a nonexclusive manner - the most common used standards to demonstrate the fre performance of building materials and elements.

Figure 1.08

Commonly used standards to demonstrate fre performance

Classifcation Description

Reaction to fre

Fire resistance (R/E/I)

Class describing ignition and surface fame spread properties both for façades and indoor application; used to select fnishes that limit rapid fre growth.

Ability of building components to maintain load-bearing capacity (R), integrity (E), and insulation (I) for a specifed time (e.g., EI90 = 90 min).

K-class Classifcation for protective layers over combustible substrates indicating how long they remain effective under fre exposure.

Façade class Resistance of façade assemblies to vertical fre spread, tested at large scale; evaluated under national methods.

Relevant standards Notes

EN 13501-1

EN 13501-2

EN 13501-2 (Annexes)

No harmonized EN standard; country specifc, i.e. SP Fire 105 (SE), BS 8414-1/2 (UK), DIN 4102-20 (DE), NPR6999 (NL)

SAWA

The apartment building SAWA in Rotterdam, the Netherlands (designed by Mei Architects & Planners), combines several fre safety strategies, including sprinklers, overdimensioned mass timber elements designed for charring, and partial encap-sulation of selected CLT slabs.

Fire Station Reinbek

An increasing number of fre stations are now built in timber; a powerful demonstration that well-designed mass timber buildings can fully meet strict fre safety requirements. The photo shows the Reinbek Fire Station in Germany (designed by Rimpau Bauer Derveaux).

Euroclass A (non-combustible) to F (highly combustible). Most wood >350 kg/m³ = D-s2-d0; highdensity species can reach C; fre-retardant treatment can help achieve B.

Partly related to combustibility class, but mainly infuenced by design, thickness (sacrifcial layer) and protection measures such as coatings.

Typically used for timber protection layers such as gypsum.

Describing the overall performance of façadeelements, using end-use test strategies as well as more realistic fre loads.

Timber is a powerful low-carbon material, but it’s not the answer to every engineering challenge. Each material has distinct strengths: wood for lightness and prefabrication, steel for tension, concrete for compression and water resistance. Smart hybrid design combines them where they perform best, with steel often supporting demountable joints in mass-timber buildings - complementing, not competing with wood.

EVERYTHING SHOULD BE MADE OUT OF WOOD, INCLUDING FOUNDATIONS AND ALL CIVIL WORKS

Timber is increasingly embraced as a low-carbon structural material, and its popularity has led some to suggest using it in nearly every element of the built environment, including foundations, ground slabs, and civil works. Yet not all applications beneft from timber in terms of durability and material effciency.

Although European forests provide a large supply of wood (see Myth 12), this valuable resource should be used as effciently as possible. For some applications, other materials can be more suitable: concrete for compression and water resistance, steel for tension and strength per volume. Especially in high-rise construction, hybrid structures often provide the best balance of performance and resource effciency (see also Myth 1).

From an engineering perspective, outdoor structures in ground-water contact in many cases still favor concrete, due to its resistance to moisture and high compressive strength. For example, engineering frm ABT1 calculated that if the Jonas residential housing project in Amsterdam had been built on timber piles instead of concrete, it would have required 25 times more piles, plus a concrete “head” at the groundwater level to prevent decay from oxygen exposure (below the water table, timber can last indefnitely).

Civil timber structures above ground are possible, but they fall under the demanding use classes 3 and 4. Here, durable wood species, protective detailing, and proper ventilation are essential (see Myth 2). Without these measures, long-term performance cannot be guaranteed.

Jonas

The Jonas residential project in Amsterdam, the Netherlands (designed by Orange Architects), features extensive timber cladding. If timber piles had been used instead of concrete ones, the building would have required around 8,250 piles rather than the 330 concrete piles actually installed.

The iconic Krúsrak heavytraffc bridge in Sneek, the Netherlands (designed by Onix and Achterbosch), was built in 2008 from laminated acetylated wood (Accoya). During 2025 maintenance, superfcial delamination and cracking were observeda result of exposure and coating wear rather than material failure, underscoring the importance of regular maintenance for timber in exposed conditions.

Timber construction is bad for the environment

As timber construction gains momentum, so do questions about its true environmental performance. How sustainable is it once we account for production, adhesives, and endof-life scenarios?

This chapter examines the full climate footprint of building with wood - from embodied carbon and circular reuse to material composition and realistic limits - showing that timber can only deliver genuine climate benefts when applied thoughtfully and within a balanced system perspective.

SAWA

This 16-story, 50-meter tall residential tower in Rotterdam, the Netherlands (designed by Mei Architects & Planners), is built almost entirely in CLT and glulam, is clad with pressure treated spruce and features a stepped profle with generous green terraces, see also page 47. MYTH Timber solves all our problems!

The European forests are a net carbon sink, and building with mass timber can actually substitute carbon intensive building materials and store carbon in buildings, making the built environment an additional carbon sink.

A persistent concern around timber construction is the perceived risk of deforestation. While this concern is not unfounded in cases of poorly regulated land-use change, particularly in tropical regions driven by soy, palm oil, or cattle ranching, it does not apply to forestry where sustainable practices are in place (see also Myth 11). In fact, Europe’s forest area has been expanding for decades, supported by responsible management and certifcation schemes such as FSC and PEFC. However, climate change is putting growing pressure on these forests, underscoring the need for more ‘Climate Smart Forestry’ practices (see Myth 11). Timber construction, when sourced from sustainably managed forests, does not deplete resources. Managed harvesting followed by regrowth maintains or even increases forest carbon stocks. Once established, young, well-managed stands typically sequester more carbon than old-growth forests, showing that sustainable harvesting and replanting can enhance rather than diminish forests’ role as carbon sinks1

1 ASBP (2023)

2 Schouten et al. (2023)

Climate scientist Professor Hans Joachim Schellnhuber introduced the concept of the Forestry Construction Pump to describe the three levers through which timber construction mitigates climate change: 1) carbon sequestration in forests, 2) carbon stored in wood products including cascading use (see Myth 8), and 3) substitution of high-carbon materials like steel and concrete. See also box 3.

Through these levers, scaling up timber use could signifcantly cut CO2 emissions. In Europe, replacing 50% of new residential construction with biobased typologies by 2030 could reduce annual CO2 emissions by 18% (≈37 Mton) while providing an additional 69 Mton of long-term carbon storageeffectively halving embodied carbon of the building industry when sequestration is included.2

It is important to note, however, that this carbon was sequestered over the past 30+ years. Sustaining such benefts depends on continuous afforestation and reforestation to replenish harvested wood (see also Myth 11), while maintaining sustainable forest management. Under the right conditions, timber construction can be a crucial part of the pathway toward a carbon-neutral society.

CO2 emission and CO2-sequestration and net missions in 2030 from construction of new residential buildings in various scenarios

Adapted from Schouten et al. (2023)

Author Pablo van der Lugt – Green Matters

Supervision & fnal editing Sigrid Lussenburg – MaterialDistrict

Technical Supervision Gert-Jan Rozemeijer – Lüning

Saskia Hegeman – Nieman

Arjan van Timmeren – Delft University of Technology

Gert-Jan Nabuurs & Bas Lerink - Wageningen University & Research

Maarten Willemen, Patricia Dolman & Marten de Groot - PEFC

Djordy van Laar, Jip van Grinsven & Jim Teunizen - Alba Concepts

Graphic design vanRixtelvanderPut ontwerpers

Schemes vanRixtelvanderPut ontwerpers

Illustrations Jakob Lagerweij – Broertjes Lagerweij

Picture management Sigrid Lussenburg – MaterialDistrict

Printing Wilco B.V.

Paper 120 g/m2 uncoated (writable) paper

Paper (Cover) 280 g/m2 single sided coated sulphate board

Publisher Jeroen van Oostveen – MaterialDistrict

This publication is printed on certifed paper.

Special thanks to the following parties for making this publication possible LÜNING Engineers www.luning.nl

Metropoolregio Amsterdam www.metropoolregioamsterdam.nl

NICE Developers www.nicedevelopers.nl

PEFC Netherlands www.pefc.org

Publisher MaterialDistrict B.V. The Netherlands +31 (0)20 71 30 650 info@materialdistrict.com www.materialdistrict.com

© 2025 MaterialDistrict B.V.

No part of this publication may be reproduced or transmitted in any form or by any means without prior permission in writing from the publisher.

In the selection of text fragments and illustrations, the publisher has tried to comply with and honor existing copyrights as much as possible. Persons who feel that they have copyright claims are requested to contact the publisher.

All books published by MaterialDistrict are available at books.materialdistrict.com

Timber is often hailed as the material of the future — renewable, low-carbon, and beautiful. Yet despite growing enthusiasm for timber construction, persistent myths continue to shape how architects, policymakers, and builders perceive wood. Is it really less durable? Too fammable? Limited in design? Or environmentally overrated?

The Timber Truth dismantles sixteen of the most common misconceptions about timber — from concerns about fre safety, strength, and lifespan, to debates on carbon storage, circularity, and sustainable forestry. Drawing on the latest scientifc research, European building practice, and policy developments, the book reveals what the data actually show — and where the real challenges lie.

Structured around four themes — Building Quality & Performance, Environment & Climate, Forestry & Availability, and Economy & Market — The Timber Truth combines rigorous analysis with inspiring visuals, including stunning examples of the most innovative mass timber and biobased projects from around the world. Written in a clear, accessible style, it offers professionals the knowledge and perspective to move beyond opinion and ideology — toward evidencebased, nature-positive construction.

Dr. Pablo van der Lugt is an architectural engineer and leading voice in mass timber and biobased construction. Author of Tomorrow’s Timber and Booming Bamboo, he bridges science and practice to show how building with nature can combat climate change. As a keynote and TEDx speaker, he inspires audiences worldwide with his vision of a sustainable built environment.

Cover photo: Ossip van Duivenbode

ISBN: 978-90-834293-1-1