the splash

As a project engineer with Garver’s Water Team, Thomas Helvick brings technical expertise and a deep sense of purpose in designing and implementing vital infrastructure in his home state. With every project, he helps ensure safe reliable water for communities across Oklahoma for generations to come.

Thomas Helvick, PE Water Project Manager

GarverUSA.com

Happy New Year! This is a time of reflection and anticipation. I am so proud of the activities OWEA completed in 2025, including hosting a WEFMAX, Ops Challenge events, June Operator Short School training, May OWEA Annual Conference, and September planning retreat. I am excited about OWEA’s plans for 2026 (a few of which are described below), and we hope that you will join us in some or all of our endeavors.

In this issue, we highlight:

• Stockholm Junior Water Prize, which is the world’s most prestigious award presented to a high school student for a water-research project. Fun fact: Tulsa student Braden Milford won the national US competition and went to the international finals for his heavy metal bioremediation research in 2018.

• WEF’s Water Leadership Institute (WLI) is a program that educates, trains, and provides opportunities that enable developing and emerging leaders to build strong, lasting relationships within the water industry. OWEA has several WLI graduates, including our current Treasurer, Joy Kotey and WEF delegate, Mary Elizabeth Mach.

• Our Young Professionals is an active committee that frequently partners with similar organizations to host monthly networking events.

• The 2026 APWAOK/OWEA Joint Technical Conference & Trade Show will be held May 4-6 in Tulsa. Sponsorship and registration are anticipated to open in early April. You can find more information at www.owea.org/conference.

“OWEA’s mission seeks to “connect and enrich the expertise of Oklahoma’s water environment professionals.” Thank you for helping us achieve our mission!”

Before you move on to the rest of the issue, I want to provide an update on some of our recent Board and Committee key goals:

• Expand Ops Challenge

• The Competition Focus Area is exploring increasing from two to four Ops Challenge events and has begun to develop a brochure that describes the benefits of participating, requirements, and resources available to Ops Challenge teams.

• Conduct intentional member outreach

• The Membership Focus Area is developing an appreciation package that will be sent to all members and will contain more information about our organization, committees, and a special gift.

• Improve communications

• The Social Media Focus Area is working to re-establish the OWEA LinkedIn account and will begin making regular posts in the coming months.

• Investigate better financial investment opportunities

• The Financial Investment Ad Hoc Committee has reached out to other state member associations and a financial planner about investment experience and/or opportunities. They are developing an investment plan that will be considered by the Board in the coming months.

• We recently contracted with a virtual assistant to support the organization on several of our initiatives.

Are you interested in learning about OWEA and committees?

Join us at our next Quarterly Board Meeting in March (date/time to be determined). Email me at awooten@carollo.com for more details or to RSVP.

OWEA’s mission seeks to “connect and enrich the expertise of Oklahoma’s water environment professionals.” Our members are operators, laboratory specialists, maintenance technologists, engineers, contractors, suppliers, and managers that are “dedicated to sustaining Oklahoma’s water environment through advocacy and education.” Thank you for helping us achieve our mission!

As you would expect from Lakeside, our Raptor® Multi-Rake Bar Screen is an efficient, proven screen technology for rapid removal of inorganic solids in municipal and industrial applications. But what sets it apart is the simple fact that ours is built to Lakeside’s renowned standards and features superior quality. As with everything we do, our Raptor Multi-Rake Bar Screen is well-engineered, designed for optimum performance and durability, and is manufactured in the USA. That’s important on a lot of levels. When critical decisions are made on design and specifications, stand out with the Lakeside Raptor Multi-Rake Bar Screen, the gold standard of the industry. REPRESENTED LOCALLY BY: Offices in Houston, Austin, Dallas, Oklahoma City

Speak to one of our experts at 630.837.5640, email us at sales@lakeside-equipment.com, or visit www.lakeside-equipment.com

Frequency Curves

Optimization

Efficiency

Head

Affinity Laws

System Curve

Cavitation

Operating Range

Operations

Hydraulics

Flow

ANSI

Every community relies on critical infrastructure to stay safe, healthy, and thriving. At Sulzer, we deliver innovative pumping, mixing, and treatment solutions that safeguard what matters most.

From stormwater management that prevents flooding, to wastewater treatment that ensures clean water, to pumping systems that keep essential services running, Sulzer products are at the heart of resilient communities. Whether it is hospitals, schools, or neighborhoods, our technology works behind the scenes to keep your water pumping.

Because when it comes to your community, reliability is not optional, it is essential. go.sulzer.com/one-reliable-solution-a-time

The WEF-sponsored Junior Stockholm Water Prize serves as a significant platform for inspiring high school students to engage in innovative research addressing global water challenges. Since its inception as the US Stockholm Junior Water Prize by the Stockholm International Water Institute in 1997, the competition has highlighted the importance of research in water science and engineering, inspiring high school students to explore sustainable solutions for the world’s most pressing water resource issues.

In 2025, for the third consecutive year, members of the Oklahoma Water Environment Association served as judges at the Oklahoma State Science and Engineering Fair (OSSEF), where they identified water-related poster projects. OWEA’s involvement is a testament to the association’s commitment to promoting rigorous research and creativity among the next generation of water stewards. By carefully evaluating each project, the judges ensure that the water posters reflect both scientific excellence and innovative thinking – an essential quality for securing Oklahoma’s entry as the state’s winner for the Junior Stockholm Water Prize.

OSSEF, hosted by Oklahoma State University in Stillwater, stands as one of the state’s premier platforms for young scientists and engineers. According to the OSSEF website, the fair offers high school students a dynamic environment where they can showcase their projects, gain constructive feedback, and compete for awards and scholarships.

The connections between awards like the Junior Stockholm Water Prize and events like OSSEF underscore a broader goal that OWEA embraces, which is inspiring and developing future scientists, engineers, and environmental professionals. Engaging students in hands-on projects and authentic research experiences not only deepens their understanding of water management challenges but also instills the kind of innovative problem-solving skills needed in today’s evolving scientific landscape.

By encouraging research in water science, engineering, and broader scientific fields, OWEA plays a small role in developing the next generation. This year’s Oklahoma State Science and Engineering Fair is scheduled to be held at Oklahoma State on March 27, 2026. If you have any interest in participating as a judge or if you know of a student interested in participating in the competition, please contact Andy Doerflinger at andrew.doerflinger@stvinc.com

OWEA sponsors Oklahoma’s winner to participate in-person at the national competition in June. The 2025 USA National competition will be held June 19-22 at Washington University in St. Louis. The US SJWP winner receives a cash prize of $10,000, a crystal trophy, and represents the US at the international competition held each August at World Water Week in Stockholm, Sweden. For more information about the contest and the judging criteria, please see this website: www.wef.org/membership-community/students--young-professionals/sjwp.

“ The connections between awards like the Junior Stockholm Water Prize and events like OSSEF underscore a broader goal that OWEA embraces, which is inspiring and developing future scientists, engineers, and environmental professionals.”

The Oklahoma Water Young Professionals (YPs) held a series of successful networking events in 2025! Look for 2026 events on OWEA’s LinkedIn Page, email blasts, and forthcoming The Splash editorials. If you are interested in becoming more involved with the group or sponsoring an event, email Cameryn Edwards at cameryn.edwards@stvinc.com or join our WhatsApp: https://chat.whatsapp.com/LEypnHymz710ltrBOcpDPC.

November 2025 – Chicken & Pickle in OKC (Sponsored by Garver)

September 2025 – Dust Bowl Lanes in OKC (Sponsored by McWane Ductile)

May 2025 – Water’s Worth It Auction at OWEA Annual Conference

Thank you to all of our sponsors who donated items to the Water’s Worth It Auction! If you are interested in donating an item for our 2026 OWEA Annual Conference, please contact Sarah Jones at sjones@carollo.com.

April 2025 – The Big Friendly in OKC (Sponsored by STV)

Utilities across the United States are facing the challenge of maintaining aging infrastructure while meeting demands driven by population growth, climate change, and concerns about water quality and availability. The American Society of Civil Engineers (ASCE; Reston, Virginia) has rated US water infrastructure between a D and C-, which can lead to expensive, unexpected repair work for local utilities. For example, ASCE has estimated that a US water main breaks every two minutes, and the associated repair costs are approximately USD $2.6 billion annually.

Traditional methods of infrastructure management tend to overlook the unique challenges faced by economically and environmentally disadvantaged communities. A 2019 report by DigDeep (Los Angeles) and the US Water Alliance

(Washington D.C.) highlighted race as the strongest predictor of water and sanitation access across the US, with poverty also being a key obstacle. Asset management plans (AMPs) are an essential tool for managing aging infrastructure; however, many AMPs often overlook these social and economic factors during the development process. By proactively assessing these issues during both AMP data collection and project prioritization and focusing on community outreach and engagement, water sector leaders can work toward finding a solution.

There are many issues, both past and present, that have contributed to an aging and inequitable water infrastructure system in the United States, and utility

leaders should understand the history behind these decisions to avoid repeating mistakes. Population growth, climate change, and the “out of sight, out of mind” approach to infrastructure management –failing to maintain a comprehensive inventory and track conditions – also have accelerated these challenges. To overcome, utilities must adopt a modern perspective that incorporates inclusive and proactive planning. Digital master planning and consistent investment in public outreach and AMPs can help utilities plan for equitable water access for future generations.

A key aspect of developing an AMP is the thorough collection of data and the creation of a detailed asset inventory. By incorporating social and environmental justice datasets into AMP

development, utilities can better identify and address disparities in water access and infrastructure quality. Geospatial datasets, such as the locations of customer assistance calls, overflow or backup complaints, and outstanding water bills, can be overlaid to identify communities that may be disproportionately burdened. Other helpful datasets can include maps of historically redlined districts, census data, US Federal Emergency Management Agency flood maps, urban heat index maps, and air quality index maps.

Some utilities, such as DC Water (Washington, D.C.), have successfully integrated a comprehensive set of consequences of asset failure factors into their AMP and decision-making processes by including a thorough analysis of multiple parameters. These parameters encompass public health and safety, public confidence, regulatory compliance, environmental impact, system reliability, and fiscal impact. By incorporating these into an AMP, decision-makers can make informed decisions about utility rehabilitation and replacements. This holistic approach ensures that the most pressing needs are addressed while maintaining public trust and adherence to regulatory standards.

Spotlighting Community Engagement

Additionally, utilities should prioritize community engagement throughout the AMP development process. Questions that utility leaders can consider include, “What policies were in place when assets were designed and constructed, and how do they impact who benefits from the infrastructure and who does not?” “Who is missing service now, or will need service in the future?” and “Who is most impacted by failure, both now and in the future?”

These questions can guide community engagement strategies by helping utility leaders identify stakeholders and develop communication plans. Engagement methods may vary depending on the community, ranging from mailers, social media posts, and live dashboards to call centers, community forums, and listening sessions.

Regardless of the tools chosen, engaging stakeholders early and maintaining ongoing communication ensures that decision-making processes are inclusive and reflect the needs of all community members.

Alyssa Ramsey is a Water Resources Engineer at Jacobs (Dallas). Amro Hassanein is a Bioenergy and Biosolids Technology Strategist at Yokogawa Corporation of

America (Sugar Land, Texas). Anna Hermes is a Senior Watershed Scientist at Northern Colorado Water Conservancy District (Berthoud, Colorado). Grace Vogel Sanders is a Landscape Architect at the Sewerage and Water Board of New Orleans. Miguel Miranda is a Senior Process Engineer at DC Water. Razhan Kareem is a Senior Principal Engineer at Hazen and Sawyer (New York City). Woinshet Tegegne is a Project Manager at DC Water.

Public utilities, such as water and wastewater treatment systems, are typically owned and maintained by local municipalities. However, public-private partnerships (PPPs) are often forged between thirdparty contractors and government entities to assist with operations and maintenance (O&M) of their facilities for a multitude of reasons.

Managing and operating these essential systems has never been more complex. Aging assets, evolving regulations, staffing challenges, and budget constraints have placed unprecedented demands on municipal teams. Even the most dedicated in-house staff can struggle to keep up with the requirements of today’s utility environment. Partnering with a specialized contract operator enables municipalities to improve system reliability, reduce risks, deliver enhanced service, and ultimately protect public health.

Sometimes local governments lack the knowledge and training to operate these complex systems effectively. Sometimes they don’t have the financial resources or expertise to make critical repairs, allowing water infrastructure to deteriorate over time. In some communities, their plants may be out of compliance, or they may need industry experts to develop a solution to improve system performance and protect public health.

As a result, public-sector organizations seek to outsource this work to established private contractors that can maintain proper asset management and environmental compliance, thereby minimizing risks.

Outsourcing water treatment and management provides several benefits, including:

• Implementing proven processes and procedures.

• Providing dedicated, educated and experienced staff.

• Giving access to cross-functional services and people.

• Mitigating and transferring risk to an accountable partner.

• Enabling predictable expenses.

• Allocating resources where they are needed most.

“Our team has developed a successful track record of supporting communities for over 40 years because we approach it as a true partnership with the communities we’re serving –and that mindset is essential. Because our team lives in the communities, we have families and friends who are directly impacted by our work. That results in an extreme level of commitment. We really care about the job we do.”

Whether it’s a small town or a large city, public works organizations will initiate a request for proposal process to solicit competitive bids from multiple private firms. The proposal process provides municipalities with the opportunity to compare operating options, and it allows the potential third-party contractors the opportunity to understand what is most important to the municipality. Companies submit their qualifications and work through a curated, multi-step selection process to highlight their operations experience, knowledge, resources, and the cost to the municipality.

Inframark is a trusted water and wastewater operator that has supported Oklahoma communities for years and is the largest American-owned, dedicated contract O&M company in the country, managing over 550 wastewater and water infrastructure systems in 30+ states.

Check out this recent interview with Inframark’s client in Jasper, Georgia, on how their decision to outsource has improved operations and maintenance and protected the health and environment for communities on the Inframark YouTube channel.

When being accepted into the Water Leadership Institute (WLI), most people have a general idea of what a leadership development program offers, but with the WLI, the attendees quickly learned that WLI is far more than the typical leadership training.

“The WLI is a fantastic opportunity to connect with peers and make professional connections that will serve you throughout your career,” said Wes Cardwell, a business team leader at Garver and WLI alum. “The program challenges you in multiple areas to get outside of your comfort zone and to grow in areas that you may not have otherwise had opportunities to.”

From the kickoff in May through graduation at WEFTEC, the program weaves together monthly classes, team meetings, and a capstone project that pushes participants to explore the industry’s future through a leadership lens. Participants are shuffled groups.

“We had opportunities to meet with and discuss key leadership issues with people from all over the world,” said Andrew Doerflinger, STV Oklahoma City water group practice leader. “One other neat aspect was that the groups consisted of folks with a variety of backgrounds. Our group specifically included a regulator, several engineers who worked in both a consulting and municipality environment and a plant operator.”

The WLI stands apart because it takes universal concepts and reframes them in the context of water. The sessions focused on the realities those in the industry face every day, such as recruiting and training the next generation of skilled workers, navigating industrywide challenges, and learning how to build teams that reflect the diverse communities they serve.

“The WLI stands apart because it takes universal concepts and reframes them in the context of water.”

“WLI allowed me to learn from people with different perspectives and different responsibilities within the industry,” said 2025 alum Afiya Wilkins, attorney for the Oklahoma Department of Environmental Quality. “It was interesting to hear from plant managers and operators how they handle things, learn from consultants about how they support plant operations and planning, and brainstorm with nonprofit champions about their research and projects that highlight the same challenges.”

The program offers development opportunities for professionals at every phase of their career. Krysten Marshall, who serves Garver as its Director of Strategic Growth, attended the institute in 2025. She built industry relationships that blossomed into something more akin to friendships.

“I have several engineers that I’ve made really good friends with, and I know I can call these people up if I have, just like, a weird question,” Marshall said. “It makes a really big, daunting industry feel small, and it humanizes it to a point where I know I can call this person if I have a question about this thing, or that person if I have a question about that thing.”

A major highlight of the program was the final group project. Each of the small teams, organized at the beginning of the program by their compatible skill sets, was assigned a broad industry

Distribution Systems • Pumping Systems • Rural Water Districts • Sewer Collection Systems

• Land Development Services

• Utility GIS Mapping Services

• MS-4 Stormwater NPDES Permit Compliance Services • Municipal Services

• Streets and Storm Sewers • Treatment Facilities • Water Storage Systems • Water Well Design • Drainage Design • Landscape Architecture Services

“The relationships built during the program are perhaps among the most valuable outcomes. The connections established will last for the rest of their careers, and likely would not have been possible without the WLI program.”

challenge and asked to look at the challenge through each person’s contrasting lens. The project required the teams to develop a video and accompanying article, which will be available on YouTube and the articles published on WE&T over the coming year.

“Collaborating with my team on the WLI article showed me what’s possible,” said Oklahoma Department of Environmental Quality Lead & Copper Manager Lisa Stewart, a 2024 WLI alum.

“We were able to meet consistently, work together effectively and, ultimately, host a webinar and submit a research article on the topic.

Realizing that we could accomplish all of that gave me a strong sense of confidence in myself and my peers.”

Beyond the technical content, WLI taught everyone just as much about time management and collaboration as it did about population shifts and leadership theory. The relationships built during the program are perhaps among the most valuable outcomes.

The connections established will last for the rest of their careers, and likely would not have been possible without the WLI program.

“We became mentors, cheerleaders, and a support group for each other,” Wilkins said. “It was a great relationship-building experience for me, and I continue to be in contact with many of my teammates.”

What WLI ultimately gives attendees is a sense of community. It makes a massive, complex industry feel surprisingly small and incredibly connected. And that, more than anything, is what makes the Water Leadership Institute such a powerful experience.

About 120 candidates have submitted applications for the 2026 WLI, which will close January 15. The course will run from April through October, which will formally end in presentations by each group at the annual WEFTEC on September 26-30, 2026, at the Ernest N. Morial Convention Center, in New Orleans, LA.

Like water itself, innovation flows through every challenge and shapes new possibilities. For over 90 years, Carollo has pioneered breakthroughs in water technology – from resilient infrastructure protecting growing communities to groundbreaking solutions safeguarding public health and ecosystems. At Carollo, innovation isn’t just about what’s new – it’s about what’s necessary. Every advancement, every improvement, and every solution flows from a single purpose: shaping a future where water enriches every community it touches.

Utilities nationwide are leaning on partners who can blend regional expertise with long-term stability and modern technology support.

United Systems & Software, Inc. announces that it has acquired Mountain States Pipe & Supply, a trusted name in utility metering since 1955. Moving forward, the company will operate as Mountain States Systems, a wholly owned subsidiary of United Systems.

Mountain States has been a family-run business for nearly 70 years, guided by three families across two generations: from the Sonnyborn family to the Wilcox family, and most recently the Carroll family. Along the way, they built long-standing relationships with utilities in 11 states by doing the basics exceptionally well: reliable products, technical expertise, and follow-through.

They’ve also helped shape the metering landscape in the West. Mountain States began selling water meters in 1960 and has been a gas meter distributor for more than 50 years. In 1988, they became the fourth Itron distributor nationwide, and the only distributor at the time selling both water and gas meters.

The track record speaks plainly:

• More than 1 million water meters sold from the Rocky Mountains to the West Coast.

• Over 400,000 gas meters sold across the Rocky Mountain states.

• More than 1 million water, gas, and electric meters have been installed since 2004.

The combined customer footprint now spans coast to coast and supports metering infrastructure across water, gas, and electric utilities across two-thirds of the nation.

“This opportunity aligns directly with our expansion plans by building on the strong foundation Mountain States has established,” says Scott Waldrop, President of United Systems.

Mountain States will continue operating with the same team, the same service mindset, and the same customer-first approach – now with added resources behind them. For customers and partners, this is about continuity with momentum.

“Together, we will deliver more integrated, data-driven capabilities to utilities nationwide while maintaining the service and reliability our customers expect,” says Waldrop.

For nearly 50 years, United Systems & Software has provided quality solutions, services, and equipment for utilities and municipalities. United Systems offers innovative technology to help organizations optimize and sustain the delivery of water and energy, including but not limited to Advanced Metering Infrastructure (AMI), software and web products, and managed IT. United Systems complements these advanced solutions by offering project and process management services, helping utilities and municipalities modernize and streamline operations with the most complete product and service offering in the industry. For more, visit united-systems.com.

Even the best performing AC drives need protection. DrivePro® Extended Warranty offers a wide range of warranty options and provides the longest coverage in the industry.

Given the rigors and challenges faced in today’s facilities, even the bestperforming AC drives need protection. The reliability of Danfoss products helps ensure maximum uptime and when combined with DrivePro® Extended Warranty, you can take control of your budget and reduce unplanned expenses.

Flexible coverage you can rely on

A wide variety of coverage programs are available, tailored to meet the support needs of various VFD applications.

In the event of a failure, local experts will be on their way to get you up and running as quickly as possible

Rest easy knowing that in the event of a failure local experts will be on their way to get you up and running as quickly as possible.

Longest coverage

Get the longest coverage available in the industry, with up to 10 years warranty coverage when you pair a Danfoss warranty with a DrivePro® Service Contract.

Reduce downtime

With a DrivePro® Extended Warranty, you can improve productivity. Downtime is typically reduced by 60% due to direct support. Your plant is up and running faster after an unscheduled shutdown –a concrete productivity boost that will improve your bottom line.

Coverage of up to 10 years when paired with a service contract

Pre-agreed conditions

Fixed Price

Original Danfoss spare parts

Predictable long-term business case

Ensure maximum uptime with reliably fast reaction time

Save precious cost for emergency AC drive support

Certified factory and local technicians

Save costs

Reduce unexpected cost for emergency AC drive support

World´s most reliable AC drive components, with TS 16949 approval 100% compatibility and durability Best protection for your other equipment

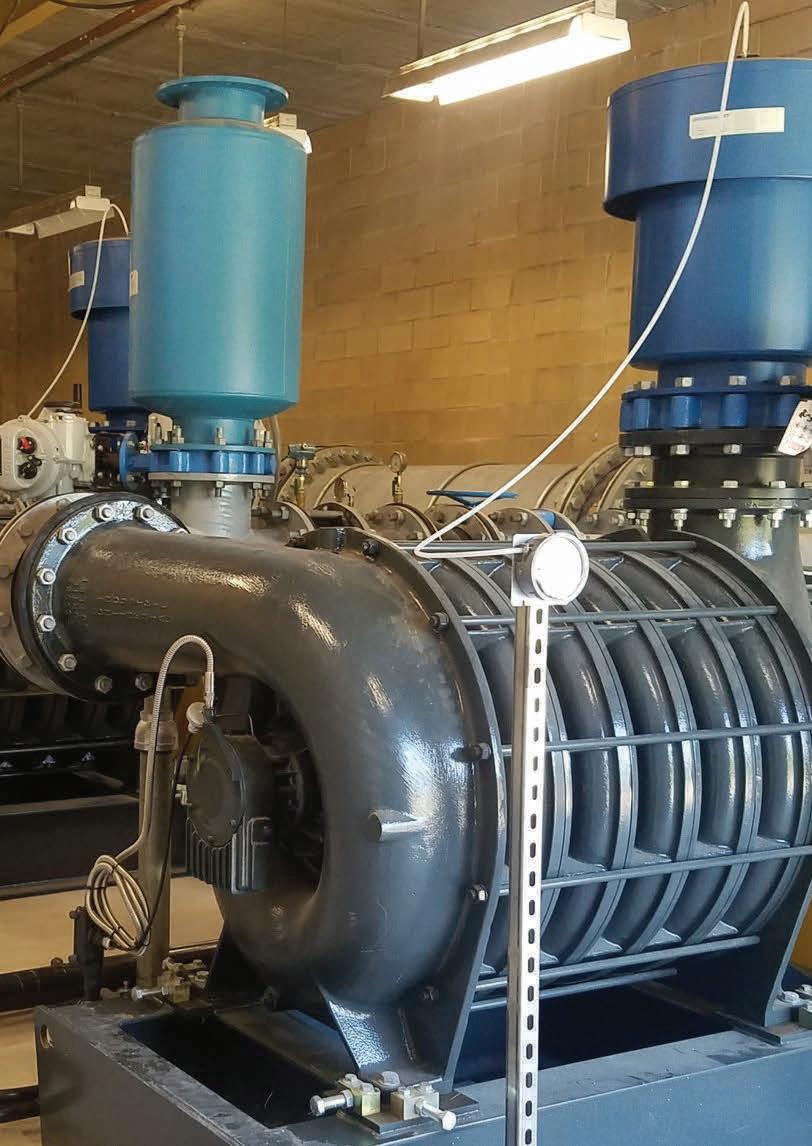

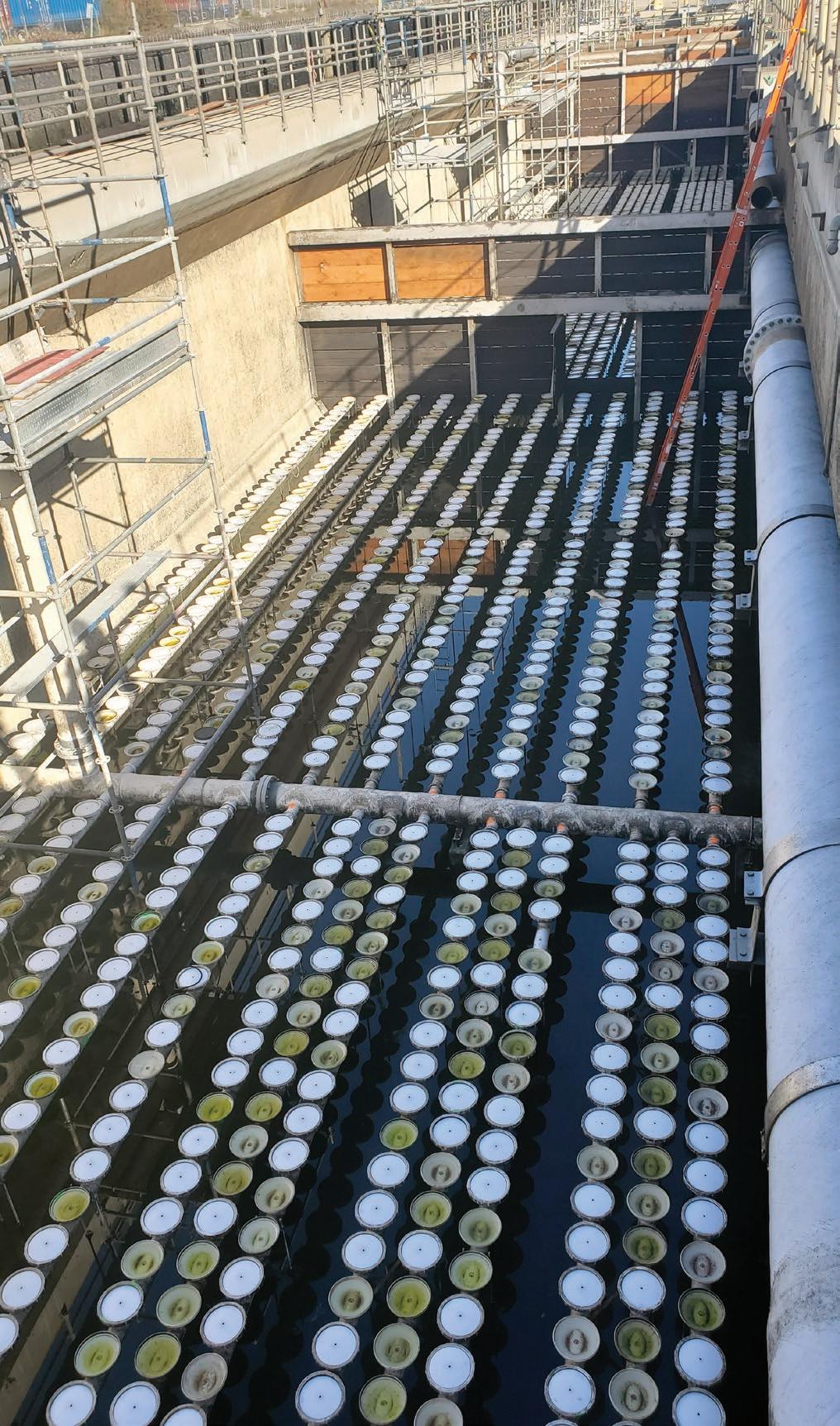

Many Water Resource Recovery Facilities (WRRFs) use biological nutrient removal (BNR) as a crucial secondary treatment process to remove nitrogen (N) and phosphorus (P). Traditional activated sludge processes are effective at transforming ammonia to nitrate, but typically operate at high dissolved oxygen (DO) concentrations above 2 mg/L. Because conventional aeration processes use 45-60% of a plant’s energy demand for aeration, low dissolved oxygen (DO) treatment, i.e. below 1.0 mg/L, has emerged as a successful strategy for reducing energy consumption while simultaneously providing effective BNR. Low DO BNR can provide consistent nutrient removal performance by applying selective pressure on microbial communities involved in nitrification, N removal, and biological P removal to adapt and perform effectively at low DO concentrations.

While several plants across the US have implemented low DO with varying levels of success, there is limited guidance on designing and operating full-scale systems. As part of the Department of Energy project DE-EE0009509, “Transforming Aeration Energy in Water Resource Recovery Facilities (WRRFs) through Suboxic Nitrogen Removal”, Carollo Engineers led a team to gain better insights into low DO BNR. This DOE project is the first application where state-of-the-art high-efficiency blowers and controls were combined with a focused design to reach low DO operations while maintaining or improving nitrogen and phosphorus removal.

The Sanitation Districts of Los Angeles County’s (LACSD) Pomona Water Reclamation Plant (WRP) provided an opportunity to gain valuable information on low DO design and implementation. Pomona WRP is a 15-MGD modified Ludzack-Ettinger activated sludge plant that includes primary clarification, three parallel activated sludge tanks, and secondary clarification. Each activated sludge train has one anoxic zone followed by two aeration zones. The plant serves as a scalping facility that removes load from a larger downstream treatment plant. Pomona WRP receives high diurnal influent total Kjeldahl nitrogen (TKN) and biochemical oxygen demand (BOD) load spikes. Solids from Pomona WRP are discharged to a downstream treatment facility for treatment.

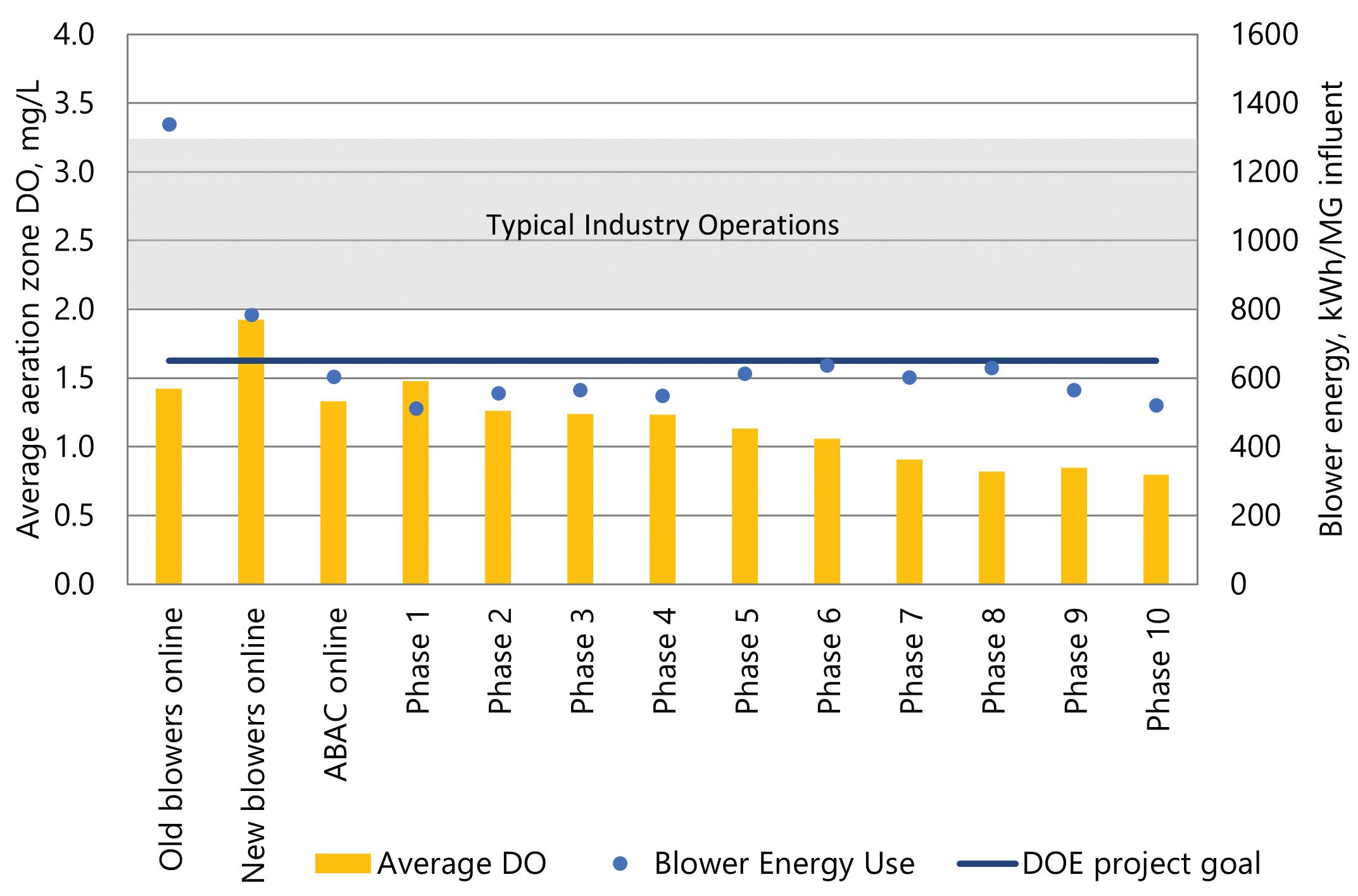

Pomona WRP pursued low DO BNR for several reasons. The facility was approaching a major aeration system upgrade, as the existing 50+ year-old centrifugal blowers had minimal airflow turndown. The inefficiencies associated with the aging blowers meant that the plant was using more than 1,300 kWh/MG of influent treated, which is at the upper end of the typical industry range (approximately 850 to 1,300 kWh/MG influent). This level of energy intensity is challenging in a state where electricity is at a premium and supply is sometimes undependable. Process air control was limited, using Proportional Integral Derivative (PID) control of two air header valves to maintain the target DO in the selected aeration zones. Plant operators wanted more precise and responsive airflow control to better support stable operation and achieve consistent effluent nutrient concentrations.

To facilitate the transition to low DO operations, Pomona WRP underwent several critical upgrades, including:

• Replacement of the existing centrifugal blowers with APG Neuros dual-core turbo blowers for sufficient turndown.

• Implementation of DO/Nmaster™, a novel machine learning ammonia-based aeration control (ABAC) system.

• Re-sizing and installation of electrically actuated, precision control valves in each aerated zone for improved airflow control.

• Installation of new online probes to monitor DO, total suspended solids, and ammonia for better process feedback in each tank. Through coordinated planning among operations, engineering, research and development, laboratory staff, and outside consultants, Pomona WRP adopted a phased approach to lowering DO focused first on confirming that the control system would meet a narrow accuracy around DO setpoint and then to gradually reduce DOs to low DO conditions. Important steps in building team confidence included providing simulations of anticipated controller performance based on existing diurnal loading patterns, defining acceptable operational boundary conditions (e.g., minimum aerobic solid retention times (aSRTs), maximum and minimum DOs, etc.), and developing a structured plan for progressively lowering DO

setpoints using ABAC. This systematic approach minimized the risk of process upsets while maintaining regulatory compliance.

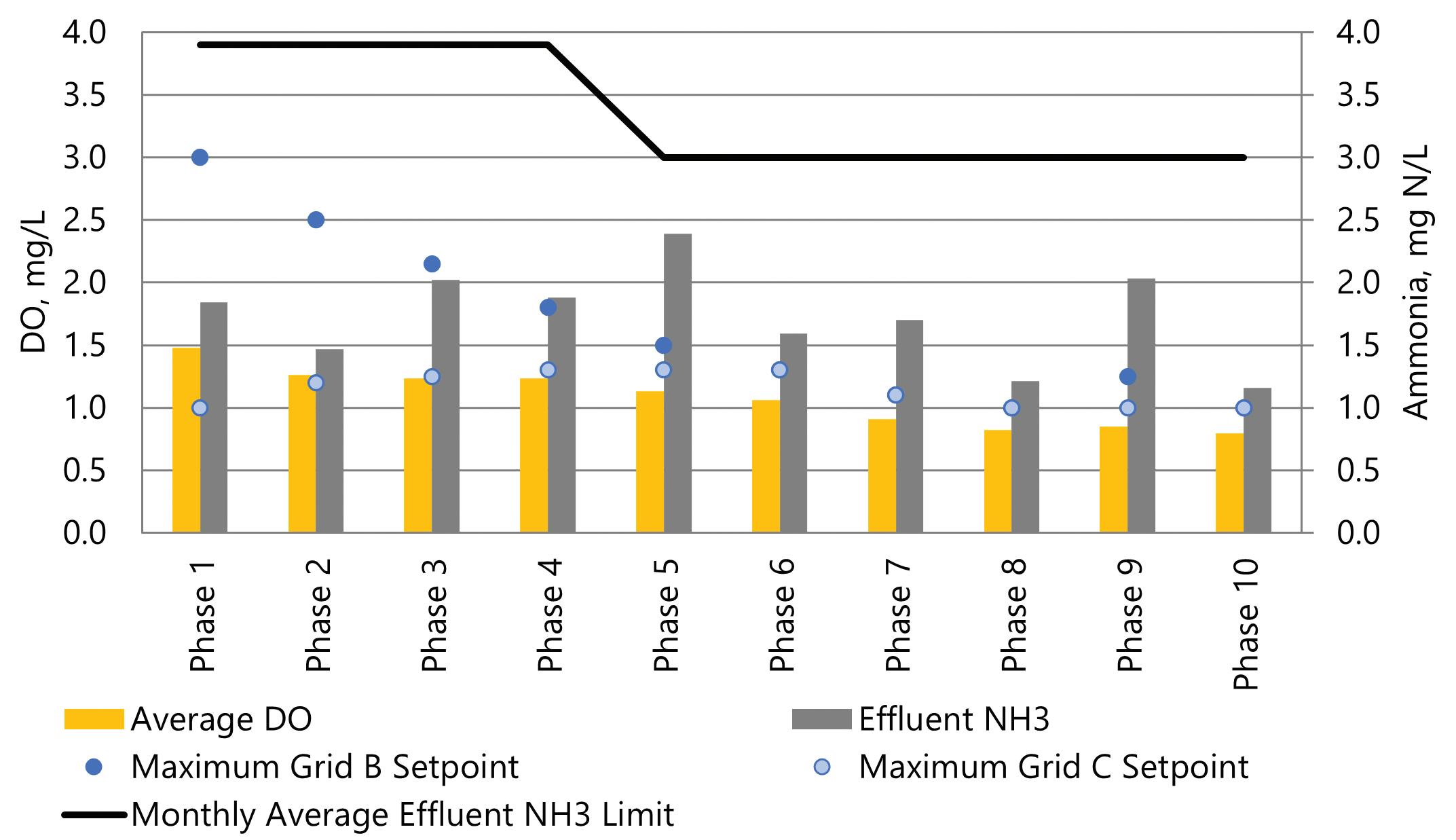

For the low DO transition, ABAC was configured using ammonia setpoints as the primary control variable and DO setpoints as a secondary constraint. The DO setpoints functioned to maintain DO

within an acceptable band and were used to force the system to lower operational DOs over time. Adaptation was rapid above 1.1 mg DO/L, requiring between two to seven days DOs greater than 1.2 mg DO/. For DOs below 1.0 mg/L, a minimum of three aSRTs were required between DO changes for consistent system performance and adaptation.

Installing new, more efficient blowers improved energy efficiency by 40 percent, but reducing from a maximum aeration DO of 3 mg/L in Phase 1 to a maximum aeration DO of 1.0 mg/L in Phase 10 further decreased energy usage by 20 percent.

Through a combination of ABAC controls on ammonia and limiting the DO operating range, Pomona WRP was able to maintain ammonia discharge limits at levels comparable to historical plant performance at the same aSRT (6.5 d) and total SRT (9 d), demonstrating that process capacity was not compromised by low DO operations. At the same time, aeration energy consumption was reduced from 1,300 kWh/MG baseline to 550 kWh/MG, well below the industry standard.

One operational challenge experienced during daily operations was recurring periods of high influent TKN loading every morning. During these four-to-six-hour loading surges, the ABAC system alone was insufficient to fully prevent ammonia breakthrough, with effluent ammonia concentrations peaking between 10 and 18 mg/L. To address this, the plant introduced a load-responsive DO override

strategy within the aeration control framework where DO was temporarily allowed increase to 1.3 mg/L in the first zone. During the non-peak period, DO was constrained to a maximum of 0.6 to 1.0 mg/L, resulting in a daily DO average of around 0.75 mg/L, while reducing effluent ammonia concentrations to as low as 1.2 mg/L.

Pomona WRP’s successful transition to low DO operations provides a compelling case study in energy-efficient wastewater treatment. The facility has significantly reduced its energy consumption while maintaining high effluent quality by integrating advanced aeration controls, targeted retrofits, and systematic process optimization. The insights gained from Pomona WRP’s experience can help guide future implementations as more WRRFs explore low DO as a means of reducing operational costs and improving sustainability.

May 4-6, 2026

Marriott Southern Hills, Tulsa, Oklahoma

The American Public Works Association Oklahoma Chapter (APWAOK) and the Oklahoma Water Environment Association (OWEA) are combining again to create an excellent conference experience for all participants, exhibitors, and sponsors. Beyond great technical sessions and a full exhibit hall, there will be several special events including a golf tournament, heavy equipment road-eo, water taste contest, operations challenges, socials, and more. We reach professionals from all areas of public works and utilities including design, management, and operations. Our attendees include utility managers and staff, public works managers and staff, state regulatory staff, private sector consultants, equipment representatives, elected officials, tribal nation staff, and many others. Up to 10 professional development hours or continuing education credits will be available for technical session attendees.

Make plans to join us at the 2026 APWAOK and OWEA Joint Technical Conference and Trade Show!

APWA Oklahoma Chapter

Devin Randall, Vice President (918) 380-8868

devin.randall@kimley-horn.com OWEA

Amber Wooten, President (918) 822-4869

awooten@carollo.com

From treatment to reuse, we’ve specialized for 46 years in cutting-edge planning, design and construction managment. Count on us for support through the full project life cycle.

March 22-24, 2026

Registration is officially open for the WEF/AWWA Young Professionals (YP) Summit at www.wef.org.

Take advantage of Super Saver rates by registering early for YP Summit 2026. This event brings together peers from drinking water, wastewater, stormwater, academia, engineering, consulting, and more to build leadership capabilities and foster lasting connections.

Under the theme The Next Wave: Navigating Water Sector Currents, participants will develop practical leadership and communication skills, learn from innovative sector professionals, expand their national network of young professionals, and gain the confidence to lead through change, preparing them to shape the future of the water sector.

Space is limited, and the YP Summit sells out every year. Don’t miss your chance to join this one-of-a-kind experience. Register early to get a discounted rate!

The Splash is made possible by the companies below who convey their important messages on our pages. We thank them for their support of OWEA and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website.