The Pelican

Rethinking

Aeration:

Enhancing Efficiency and Biological Nutrient Removal with

Operations

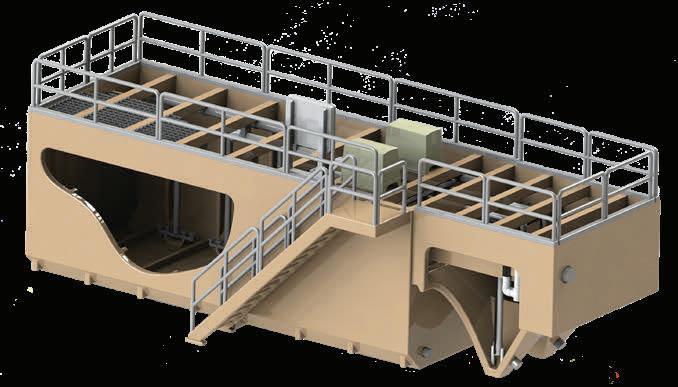

Clean Water. Clean Future. Clear Choice.

The Trusted Choice for Louisiana’s

Decentralized Wastewater Treatment Needs

From seasonal sites to high-capacity facilities, our wastewater systems meet the full range of Louisiana’s commercial needs. Whether it’s a resort, school, industrial plant, or municipal project, we deliver scalable, code-compliant solutions you can count on.

Custom-Built Wastewater Plants

• Proven wastewater solution for treating wastewater levels in a variety of applications

• Clear and odor free effluent suitable for subsurface or direct discharge

• Minimal mechanical components for low life-cycle maintenance costs

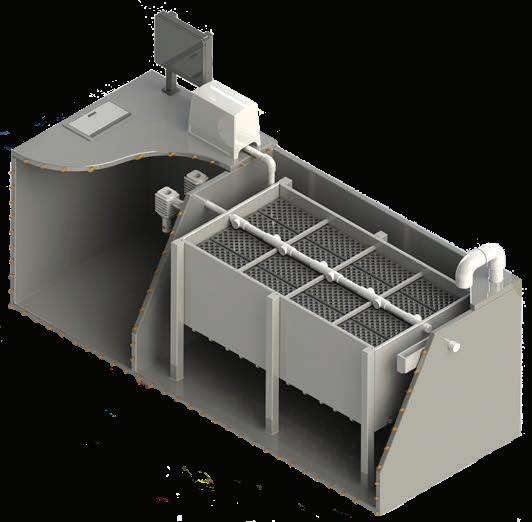

Fixed Media Wastewater Treatment

• The fixed film process provides a robust solution suitable for continuous or intermittent use

• With no mechanical parts internal to the unit, the ECOPOD is easy to maintain

• Designed specifically to minimize sludge production for fewer pump out cycles

Meet Your 2026 CWPLa Vice President

“She is passionate about strengthening the organization’s impact and ensuring that clean water professionals across the state have access to education, resources, and networking opportunities that support both personal growth and environmental protection.”

HANNAH ESPONGE ORGERON

CWPLa Vice President

Hannah Orgeron serves as Vice President of the Clean Water Professionals of Louisiana, bringing more than 12 years of industry experience, technical expertise, and a strong commitment to environmental stewardship to the organization. Throughout her career, Hannah has demonstrated a deep dedication to protecting water resources, ensuring regulatory compliance, and supporting responsible environmental practices across Louisiana. Currently, Hannah works as an Environmental Specialist IV with Providence Engineering and Environmental Group in Baton Rouge, Louisiana. In this technical role, she supports water quality and hazardous waste projects, providing critical expertise that helps clients navigate complex environmental regulations while safeguarding public health and the environment. Her work involves technical analysis, compliance support, and collaboration with multidisciplinary teams to deliver practical, effective environmental solutions.

Prior to joining Providence, Hannah held environmental and safety roles with Kinder Morgan, Inc. and Stingray Energy. These positions provided her with valuable experience in highly regulated industrial environments and helped shape her strong understanding of environmental compliance, operational safety, and risk management. This background continues to inform her approach to both her professional responsibilities and her leadership within the Clean Water Professionals of Louisiana.

Hannah holds a Bachelor of Science in Occupational Safety and Health, as well as an Associate of Science in Petroleum Safety. Her educational background, combined with hands-on industry experience, enables her to approach environmental challenges with a well-rounded perspective that balances technical requirements, regulatory expectations, and real-world application.

As Vice President, Hannah is committed to advancing the mission of the Clean Water Professionals of Louisiana by supporting member engagement, professional development, and industry collaboration. She is passionate about strengthening the organization’s impact and ensuring that clean water professionals across the state have access to education, resources, and networking opportunities that support both personal growth and environmental protection.

Outside of her professional and volunteer work, Hannah is a devoted wife and mother. She is married to her best friend, Chase, and together they are raising three children: Siddalie, Dominic, and Jade. Her family remains a constant source of inspiration and motivation, reinforcing her dedication to building a strong, sustainable future for Louisiana’s communities.

Through her leadership, experience, and commitment to service, Hannah Orgeron continues to play a vital role in supporting the Clean Water Professionals of Louisiana and protecting the state’s most critical natural resource, clean water.

YOUR TRUSTED PARTNER

WORKING HARD 24/7

Introducing the MevaScreen ® RSM Monster! Our progressive step fine screen works in facilities with extreme grit or high screening loads in difficult operating conditions. The new screen’s patented process provides ease of maintenance and can be tailored to the facility’s specific application needs. With a greater than 80% debris removal rate, it’s an excellent choice to protect sites with high solids removal requirements. 800.331.2277 | jwce.com

March 22-24, 2026 | Charlotte, North Carolina

Join the 2026 YP Summit: The Next Wave

Registration is officially open for the WEF/AWWA Young Professionals (YP) Summit at www.wef.org.

Take advantage of Super Saver rates by registering early for YP Summit 2026. This event brings together peers from drinking water, wastewater, stormwater, academia, engineering, consulting, and more to build leadership capabilities and foster lasting connections.

Under the theme The Next Wave: Navigating Water Sector Currents, participants will develop practical leadership and communication skills, learn from innovative sector professionals, expand their national network of young professionals, and gain the confidence to lead through change, preparing them to shape the future of the water sector.

Space is limited, and the YP Summit sells out every year. Don’t miss your chance to join this one-of-a-kind experience. Register early to get a discounted rate!

Build America, Buy America A Partner

You Can Count On.

You need equipment that works and works within the rules. Sulzer’s XFP submersible sewage pumps deliver clog-resistant performance and long-term reliability, all while meeting full Build America, Buy America (BABA) compliance.

That means peace of mind for your operations and access to funding your project relies on, without compromising performance.

We don’t just meet standards. We help you move forward with confidence.

Built here. Built to last. Built for you.

Learn more about Sulzer’s BABA go.sulzer.com/trusted-baba

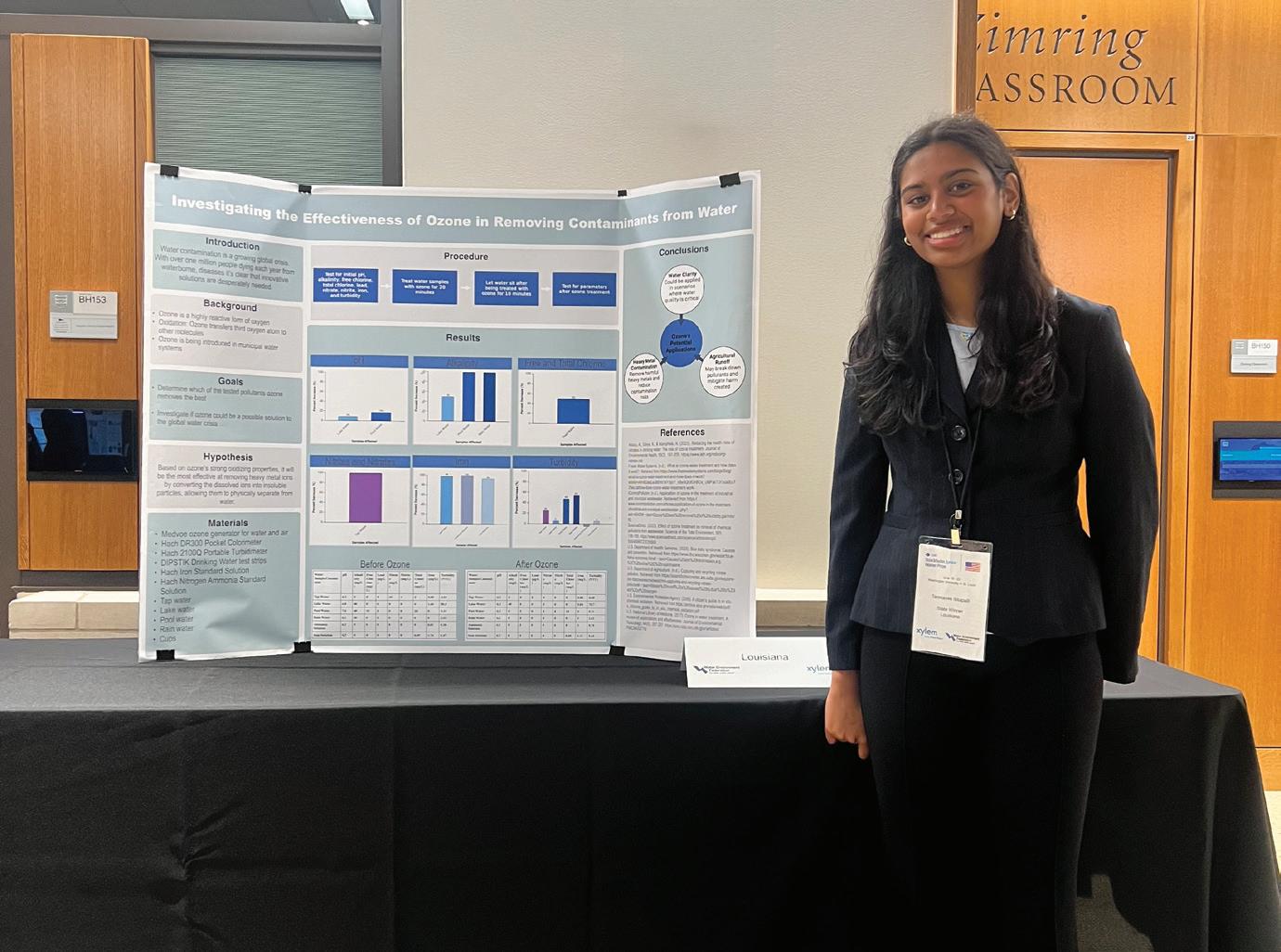

Tanmayee Iskapalli, Louisiana Representative for the US Stockholm Junior Water Prize

“Hearing how my work paralleled real-world applications helped me see how ideas like mine can evolve into tangible solutions.”

This past June, I had the honor of representing the state of Louisiana at the US Stockholm Junior Water Prize, a national competition focused on the innovative water research of high school students. This event selects the United States representative for the Stockholm Junior Water Prize, one of the most prestigious awards for youth researchers in the water field. It was an incredible opportunity that allowed me to see how science was being used to tackle challenges in the water industry. My research project, “Investigating the Effectiveness of Ozone in Removing

Contaminants from Water,” began from one simple observation: water quality issues are everywhere, but cost-effective, practical solutions remain limited. I looked into ozone because it was a naturally occurring element that had promising water purifying capabilities due to its being a powerful oxidizer. I was able to complete my project with the help of a water equipment grant I received from HACH, which helped me have access to industry-standard equipment at no cost. My project showed that ozone held a lot of promise in cleaning out contaminants from water, especially nitrogen-based ones and heavy metals. After competing in my state science fair,

a peer encouraged me to apply to the Louisiana Stockholm Junior Water Prize. I submitted my paper and was thrilled to learn that I had won the state competition and would go on to compete at the national level.

The US Stockholm Junior Water Prize took place from June 19-22 at Washington University in St Louis, Missouri. The two days leading up to judging were filled with learning more about the water industry from professionals and connecting with my peers who also shared a passion for innovation. My favorite event was touring the Chain of Rock Water Facility. It was incredible seeing water technology that I had spent so much time researching up close and in action. The judging took place on the morning of the 21st, and the environment was filled with a professional and collaborative atmosphere. The judges were truly invested in our projects and took the time to connect their feedback to real experiences from their work in the water industry. I was especially excited to learn that one judge was testing out ozone-based water treatment in New Orleans. Hearing how my work paralleled real-world applications helped me see how ideas like mine can evolve into tangible solutions.

The encouragement I received throughout this process made this experience extremely meaningful. I’m so grateful for the Louisiana Water Environment Association’s support through the whole process and to Aimee Kileen for her guidance. Being part of this year’s US Stockholm Junior Water Prize cohort showed me how important it is for students to have the chance to share their ideas. It also reminded me how powerful it is to explore and ask questions, as it opens the door to being part of solutions that really matter.

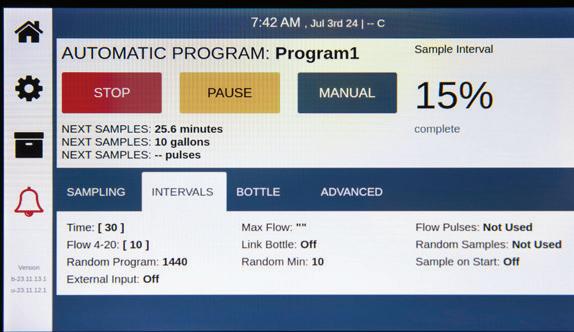

Vacuum Wastewater Sampler

• Fully Programmable Sampling

• 7" Color Touchscreen

• High-Impact, Acrylic/ABS Enclosure

• Heavy Duty, Piston Vacuum Pump

• Modular Refrigeration

The WAVE™ by Emerald Coast Manufacturing is an electronically controlled, heavy duty vacuum wastewater sampler capable of fully programmable composite sampling with a high level of accuracy.

The WAVE’s powerful vacuum system generates stronger purges that remove contamination and can draw samples from greater distances than other samplers on the market, up to 200 Feet.

The WAVE’s integrated touch screen and userfriendly interface provide for straightforward control of sample volume, time and temperature, and the high impact acrylic/ABS body make this all-climate unit able to withstand even the harshest outdoor environments.

Rethinking Aeration:

Enhancing Efficiency and Biological Nutrient Removal with Low Dissolved Oxygen Operations

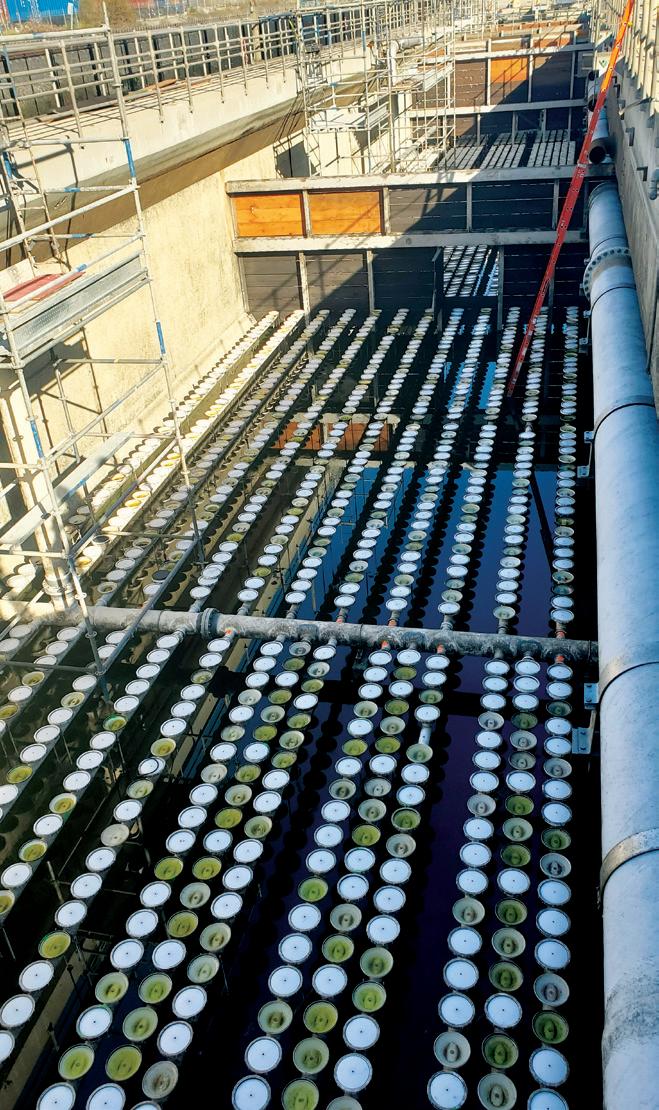

Many Water Resource Recovery Facilities (WRRFs) use biological nutrient removal (BNR) as a crucial secondary treatment process to remove nitrogen (N) and phosphorus (P). Traditional activated sludge processes are effective at transforming ammonia to nitrate, but typically operate at high dissolved oxygen (DO) concentrations above 2 mg/L. Because conventional aeration processes use 45-60% of a plant’s energy demand

for aeration, low dissolved oxygen (DO) treatment, i.e. below 1.0 mg/L, has emerged as a successful strategy for reducing energy consumption while simultaneously providing effective BNR. Low DO BNR can provide consistent nutrient removal performance by applying selective pressure on microbial communities involved in nitrification, N removal, and biological P removal to adapt and perform effectively at low DO concentrations.

Natalie Beach, Lead Technologist, Carollo Engineers, Inc.

Michelle Young , Senior Technologist, Carollo Engineers, Inc.

While several plants across the US have implemented low DO with varying levels of success, there is limited guidance on designing and operating full-scale systems. As part of the Department of Energy project DE-EE0009509, “Transforming Aeration Energy in Water Resource Recovery Facilities (WRRFs) through Suboxic Nitrogen Removal,” Carollo Engineers led a team to gain better insights into low DO BNR. This DOE project is the first application where state-of-the-art high-efficiency blowers and controls were combined with a focused design to reach low DO operations while maintaining or improving nitrogen and phosphorus removal.

The Sanitation Districts of Los Angeles County’s (LACSD) Pomona

“While several plants across the US have implemented low DO with varying levels of success, there is limited guidance on designing and operating fullscale systems.”

Aeration grid upgrades included blanking about 25% of diffusers to help maintain low DO operations while providing flexibility to operate at DOs as high as 2 mg/L for extreme events.

The DOE project integrated team members from utilities, consultants, and vendors to identify key design parameters and operational approaches for low DO operation. Back row (L-R): Sam Reifsnyder (Carollo), Tanja Rauch-Williams (Metro Water Recovery), Tom Weiland (LACSD). Front row (L-R): Alex Ekster (Ekster & Associates), Natalie Beach (Carollo), Michelle Young (Carollo), Phil Ackman (LACSD).

Water Reclamation Plant (WRP) provided an opportunity to gain valuable information on low DO design and implementation. Pomona WRP is a 15-MGD modified Ludzack-Ettinger activated sludge plant that includes primary clarification, three parallel activated sludge tanks, and secondary clarification. Each activated sludge train has one anoxic zone followed by two aeration zones. The plant serves as a scalping facility that removes load from a larger downstream treatment plant. Pomona WRP receives high diurnal influent total Kjeldahl nitrogen (TKN) and biochemical oxygen demand (BOD) load spikes. Solids from Pomona WRP are discharged to a downstream treatment facility for treatment.

Pomona WRP pursued low DO BNR for several reasons. The facility was approaching a major aeration system upgrade, as the existing 50+ year-old centrifugal blowers had minimal airflow turndown. The inefficiencies associated with the aging blowers meant that the plant was using more than 1,300 kWh/MG of influent treated, which is at the upper end of the typical industry range (approximately 850 to 1,300 kWh/MG influent). This level of energy intensity is challenging in a state where electricity is at a premium and supply is sometimes undependable. Process air control was

limited, using Proportional Integral Derivative (PID) control of two air header valves to maintain the target DO in the selected aeration zones. Plant operators wanted more precise and responsive airflow control to better support stable operation and achieve consistent effluent nutrient concentrations.

To facilitate the transition to low DO operations, Pomona WRP underwent several critical upgrades, including:

• Replacement of the existing centrifugal blowers with APG Neuros dual-core turbo blowers for sufficient turndown.

• Implementation of DO/Nmaster™, a novel machine learning ammoniabased aeration control (ABAC) system.

• Re-sizing and installation of electrically actuated, precision control valves in each aerated zone for improved airflow control.

• Installation of new online probes to monitor DO, total suspended solids, and ammonia for better process feedback in each tank.

Through coordinated planning among operations, engineering, research and development, laboratory staff, and outside consultants, Pomona WRP adopted a phased approach to lowering DO focused first on confirming that the control system would meet a narrow accuracy around DO setpoint and then to gradually reduce DOs to low DO

conditions. Important steps in building team confidence included providing simulations of anticipated controller performance based on existing diurnal loading patterns, defining acceptable operational boundary conditions (e.g., minimum aerobic solid retention times (aSRTs), maximum and minimum DOs, etc.), and developing a structured plan for progressively lowering DO setpoints using ABAC. This systematic approach minimized the risk of process upsets while maintaining regulatory compliance.

For the low DO transition, ABAC was configured using ammonia setpoints as the primary control variable and DO setpoints as a secondary constraint. The DO setpoints functioned to maintain DO within an acceptable band and were used to force the system to lower operational DOs over time. Adaptation was rapid above 1.1 mg DO/L, requiring between two to seven days DOs greater than 1.2 mg DO/. For DOs below 1.0 mg/L, a minimum of three aSRTs were required between DO changes for consistent system performance and adaptation.

Through a combination of ABAC controls on ammonia and limiting the DO operating range, Pomona WRP was able to maintain ammonia discharge limits at levels comparable to historical plant performance at the same aSRT (6.5 d) and total SRT (9 d), demonstrating that process capacity was not compromised by low DO operations. At the same time, aeration energy consumption was reduced from 1,300 kWh/MG baseline to 550 kWh/MG, well below the industry standard.

One operational challenge experienced during daily operations was recurring periods of high influent TKN loading every morning. During these four-to-six-hour loading surges, the ABAC system alone was insufficient to fully prevent ammonia breakthrough, with effluent ammonia concentrations peaking between 10 and 18 mg/L. To address this, the plant introduced a load-responsive DO override

“Pomona WRP’s successful transition to low DO operations provides a compelling case study in energy-efficient wastewater treatment.”

Average DO

NH3 Maximum Grid B Setpoint

Average DO

Maximum Grid B Setpoint

Monthly Average Effluent NH3 Limit

Grid C Setpoint

Effluent NH3

Maximum Grid C Setpoint

Pomona gradually lowered operating dissolved oxygen (DO) concentrations from 3.0 to 0.75 mg/L, achieving consistent nitrification to less than 2.4 mg/L ammonia.

Pomona

Typical Industry Operations

Average DO Blower Energy Use

DOE project goal

Installing new, more efficient blowers improved energy efficiency by 40 percent, but reducing from a maximum aeration DO of 3 mg/L in Phase 1 to a maximum aeration DO of 1.0 mg/L in Phase 10 further decreased energy usage by 20 percent.

strategy within the aeration control framework where DO was temporarily allowed increase to 1.3 mg/L in the first zone. During the non-peak period, DO was constrained to a maximum of 0.6 to 1.0 mg/L, resulting in a daily DO average of around 0.75 mg/L, while reducing effluent ammonia concentrations to as low as 1.2 mg/L.

Pomona WRP’s successful transition to low DO operations provides a compelling case study in energy-efficient

wastewater treatment. The facility has significantly reduced its energy consumption while maintaining high effluent quality by integrating advanced aeration controls, targeted retrofits, and systematic process optimization. The insights gained from Pomona WRP’s experience can help guide future implementations as more WRRFs explore low DO as a means of reducing operational costs and improving sustainability.

Cap$on: Pomona gradually lowered opera$ng dissolved oxygen (DO) concentra$ons from 3.0 to 0.75 mg/L, achieving consistent nitrifica$on

WHAT’S THE VALUE OF WATER?

Splashing in a pool, tossing a water balloon—water is one of life’s great pleasures.

Most of us never think about how water gets to us or where it goes when it swirls down the drain. Luckily, we don’t have to. Pumps, treatment plants, and pipes bring us clean water and remove wastewater.

But our water systems are aging. They need investment so they can continue to deliver life’s most precious resource. All day, every day.

Learn how water works for you. Visit TheValueofWater.org.

Water—Essential. Reliable. Invaluable. #ValueWater

Presented in cooperation with the Value of Water coalition

Upartners who can blend regional expertise with long-term stability and modern technology support.

United Systems & Software, Inc. announces that it has acquired Mountain States Pipe & Supply, a trusted name in utility metering since 1955.

both water and gas meters.

The track record speaks plainly:

• More than one million water meters sold from the Rocky Mountains to the West Coast.

Over 400,000 gas meters sold across

this is about continuity with momentum. “Together, we will deliver more integrated, data-driven capabilities to utilities nationwide while maintaining the service and reliability our customers expect,” says Waldrop.

Call for Articles!

CWPLa is looking for articles for future issues of The Pelican. We want to highlight people, projects, and facilities in the State of Louisiana. Please get in touch with Mathias Leiendecker at mathias@kelman.ca for more information or to submit your article for consideration. Thank you so much for your contribution to The Pelican!

Water shapes every facet of our daily lives, but the infrastructure we depend on to make safe, reliable water for people and the environment possible is under mounting stress.

Water shapes every facet of our daily lives, but the infrastructure we depend on to make safe, reliable water for people and the environment possible is under mounting stress.

. The costs of inaction compound over time: every year that needed investments are deferred, the price tag grows, and what isn’t covered by federal or state funding ultimately falls on local ratepayers.

. The costs of inaction compound over time: every year that needed investments are deferred, the price tag grows, and what isn’t covered by federal or state funding ultimately falls on local ratepayers.

$20,440,509

$82,073,050

$1,059,307,966

Over the next 20 years, the state requires $75 billion in investment to bring its water and wastewater infrastructure to a state of good repair. This equals roughly $3.7 billion each year or $810 per resident per year.

Over the next 20 years, the state requires $75 billion in investment to bring its water and wastewater infrastructure to a state of good repair. This equals roughly $3.7 billion each year or $810 per resident per year.

$2,579,256,645

Economic Benefits of Investing in Water Infrastructure: Louisiana

When water infrastructure fails, it disrupts basic needs safe homes, clean drinking water, and healthy ecosystems and can stall growth and the economy. Just a 24-hour disruption in water and wastewater services would mean significant losses to key industries in Louisiana.

When water infrastructure fails, it disrupts basic needs safe homes, clean drinking water, and healthy ecosystems and can stall growth and the economy. Just a 24-hour disruption in water and wastewater services would mean significant losses to key industries in Louisiana

These aren’t just unavoidable costs for an essential service closing the nation’s water infrastructure investment gap represents a major opportunity to strengthen Louisiana’s economy, workforce, and communities for the long term.

These aren’t just unavoidable costs for an essential service closing the nation’s water infrastructure investment gap represents a major opportunity to strengthen Louisiana’s economy, workforce, and communities for the long term.

Every $1 invested in water infrastructure in Louisiana supports $1.97 in economic output nationally. Meeting the national funding need over a 20-year period would support $1,560 per capita in economic output, contribute $3.71 billion to state GDP, create 33,300 jobs, and generate $1.75 billion in wages for Louisiana annually.

Every $1 invested in water infrastructure in Louisiana supports $1.97 in economic output nationally. Meeting the national funding need over a 20-year period would support $1,560 per capita in economic output, contribute $3.71 billion to state GDP, create 33,300 jobs, and generate $1.75 billion in wages for Louisiana annually.

Sectors that are key to Louisiana’s economy would also stand to gain.

Sectors that are key to Louisiana’s economy would also stand to gain.

Water infrastructure investments rely on national supply chains for materials, equipment, and specialized services. When other states invest in water, Louisiana benefits—and vice versa. Closing the national gap also means other states’ water infrastructure investments benefit Louisiana. The

growth would be:

S h a r e d P r o s p e r i t y Water infrastructure investments rely on national supply chains for materials, equipment, and specialized services. When other states invest in water, Louisiana benefits—and vice versa. Closing the national gap also means other states’ water infrastructure investments benefit Louisiana. The top three indirect sources of GDP growth would be: The Economic Benefits of Investing in Water Infrastructure: Louisiana

S h a r e d P r o s p e r i t y

Water infrastructure investments rely on national supply chains for materials, equipment, and specialized services. When other states invest in water, Louisiana benefits—and vice versa. Closing the national gap also means other states’ water infrastructure investments benefit Louisiana. The top three indirect sources of GDP growth would be:

- F l o r i d a : $44 million in GDP gains from investment in Florida, largely to Louisiana’s Petroleum and Coal Products Manufacturing industry ($12.2 million GDP impact).

- T e x a s : $44 million in GDP gains from investment in Texas, largely to Louisiana’s Wood Product Manufacturing industry ($10.6 million GDP impact).

- M i s s i s s i p p i : $35 million in GDP gains from investment in Mississippi, largely to Louisiana’s Professional, Scientific, and Technical Services industry ($5.0 million GDP impact).

Likewise, investment in Louisiana benefits other states’ GDPs. The top three beneficiaries by state GDP growth would be:

- T e x a s : $227 million in GDP gains to Texas, led by Louisiana’s connections to Texas’s Wholesale Trade industry ($41.2 million GDP impact).

- C a l i f o r n i a : $87 million in GDP gains to California, led by Louisiana’s connections to California’s Professional, Scientific, and Technical Services industry ($13.3 million GDP impact).

- F l o r i d a : $39 million in GDP gains to Florida, led by Louisiana’s connections to Florida’s Professional, Scientific, and Technical Services industry ($4.9 million GDP impact).

Read the full report, The Economic Benefits of Investing in Water Infrastructure, at www.thevalueofwater.org

“Water infrastructure investments rely on national supply chains for materials, equipment, and specialized services. When other states invest in water, Louisiana benefits—and vice versa. Closing the national gap also means other states’ water infrastructure investments benefit Louisiana.”

Our Mission

Inspiring the water community in pursuit of human and environmental well-being

Our Vision

Life free of water challenges

Our Three-Year Outcome Statement

Amplify the stories of water to grow, strengthen, and diversify the water community

Our Strategic Goals

Goal 1

Attract and develop a diverse and passionate water workforce

Goal 1 Strategies

1. Raise public awareness about the importance of water and the water workforce

2. Reduce barriers to workforce entry and retention

3. Provide extraordinary opportunities for connection, growth, and education

4. Cultivate strategic partnerships

Goal 2

Cultivate a purposedriven community to sustainably solve water challenges for all

Goal 2 Strategies

1. Drive connection and collaboration for the development of innovative solutions

2. Deliver best-in-class member experience

3. Creatively develop and deliver content and programming

Our Core Values

Goal 3

Lead the transformation to the Circular Water Economy

Goal 3 Strategies

1. Convene stakeholders to craft WEF’s Circular Water Economy framework and best practices

2. Proliferate WEF’s Circular Water Economy framework and best practices

3. Champion adoption of Circular Water Economy

4. Eliminate barriers to Circular Water Economy adoption

Lead boldly with purpose and agility

Focus on our customers through empathy and service

Collaborate for collective impact

Integrate Diversity, Equity, and Inclusion in all we do

The Pelican is made possible by the companies below who convey their important messages on our pages. We thank them for their support of the CWPLa and its publication and encourage you to contact them when making your purchasing decisions. To make it easier to contact these companies, we have included the page number of their advertisement, their phone number, and, where applicable, their website. To reach professionals through The Pelican and its

your

Looking for the level?

Measuring the

impossible with radar.

Scan here to learn more

Everything is possible. With VEGA.

No matter whether your products are liquid or solid, hot, cold, or corrosive – for decades, our radar technology has been setting the standards in level measurement for drinking water supply. We deliver precise, reliable measured values exactly where they’re needed, resulting in more stable processes, greater safety, and maximum product quality. With our radar solutions, innovation knows no limits.