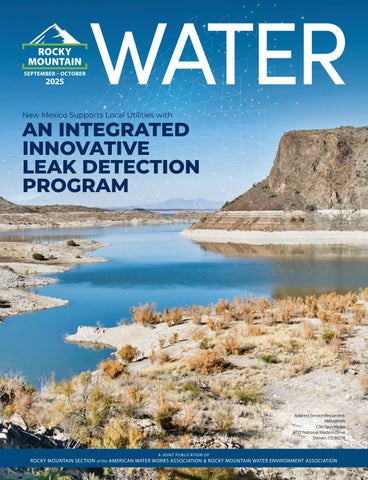

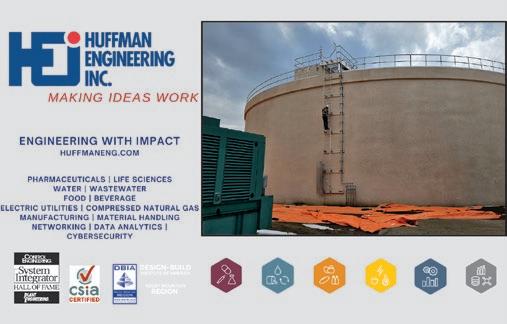

Conquer your engineering and construction challenges with our design-build solutions

EXPLORE OUR SOLUTIONS

Conquer your engineering and construction challenges with our design-build solutions

EXPLORE OUR SOLUTIONS

Orthos has repeatedly demonstrated a long track record of granular media filtration applications, and with our Centurion™ monolithic design repeatedly responds to utilities’ demands of resiliency, reliability, and permanency. scan

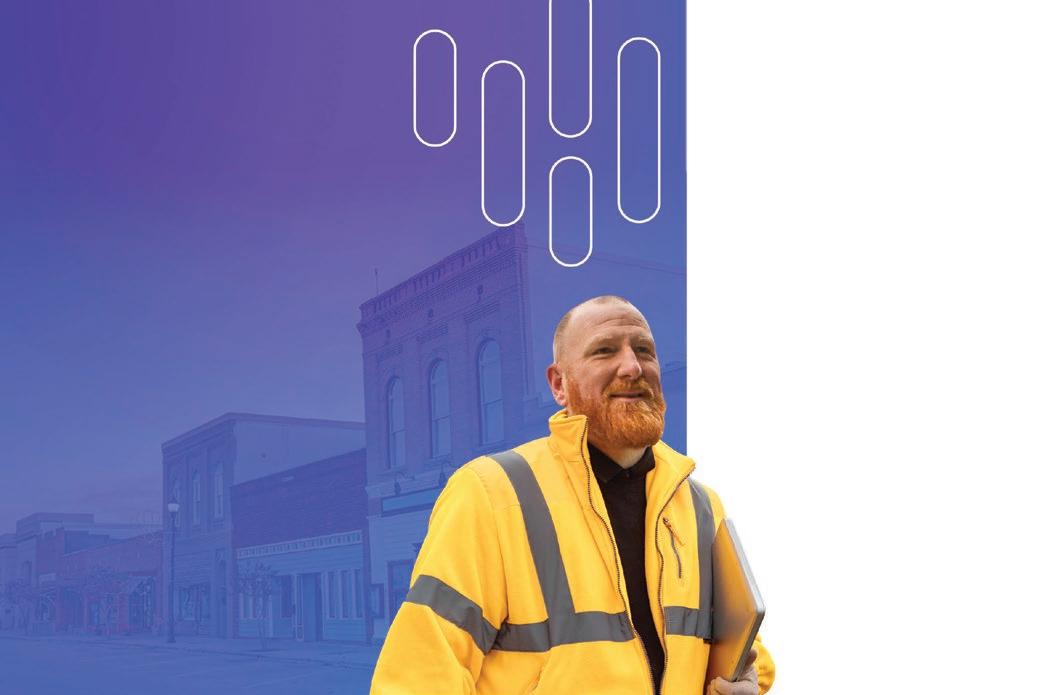

At the cutting edge of water technology, Derek Belka is transforming wastewater treatment through data-driven innovation and applied research. As part of our Water Technology Team in Colorado, he’s tackling the toughest challenges with smart, sustainable solutions — shaping a cleaner, more efficient future for water management.

Derek Belka, PhD, PE Water and Wastewater

Treatment Technologist

Rocky Mountain Water Magazine Group

The following volunteers support RMSAWWA and RMWEA with content collection, management, editing, and reviewing the magazine.

BLAIR CORNING bcorning@englewoodco.gov

ANDREW DUGAN andrew.dugan@waterwrites.co

KARI LARESE klarese@hrwater.org

RMSAWWA Communications Committee

KARI LARESE, Chair klarese@hrwater.org

ERIN RIDOLFO, eNewsletter Editor eridolfo@rmsawwa.org

RMWEA Communications Committee

ELIZABETH DEWAARD, Co-Chair edewaard@englewoodco.gov

JORI NELSON, Co-Chair jori.nelson@hdrinc.com

NATALIE COOK, eNewsletter Reviewer ncook@auroragov.org

ANDREW DUGAN, eNewsletter Reviewer andrew.dugan@waterwrites.co

ROCKY MOUNTAIN VIEW

14

Tel: 866-985-9780 Fax: 866-985-9799 info@kelman.ca www.kelman.ca

Managing Editor: Mathias Leiendecker

Marketing Manager: Chad Morrison Design/Layout: Jackie Magat

Advertising Coordinator: Sabrina Simmonds

17

New Mexico Supports Local Utilities with An Integrated Innovative Leak Detection Program

Brewing Innovation: South Platte Renew Partners to Turn Wastewater into Lager

21

From the RMSAWWA Chair 7 From the RMWEA President 9

COMMITTEE SPOTLIGHT

A YP Takeover in Denver: ACE 2025 11

HOT TOPICS

Northern Water’s Water Efficiency Team Debuts New Conservation Garden Demonstrations 24

PFAS Treatment

Technology Landscape 27

A Tale of Three Cities: How Front Range Utilities Are Rethinking Water 31

SCIENCE, RESEARCH, AND TECHNOLOGY

Boxelder WWTF Decouples Aeration from Mixing to Meet Stringent Effluent Discharge Limits 35

How Operations Can Take It to the Next Level With AI-Based Decision Support Tools

Preparing for the Lead and Copper Rule Improvements (LCRI) Compliance Journey 38 A Roadmap for Artificial Intelligence Adoption in Water Utilities................................... 41

COMMITTEE CORNER

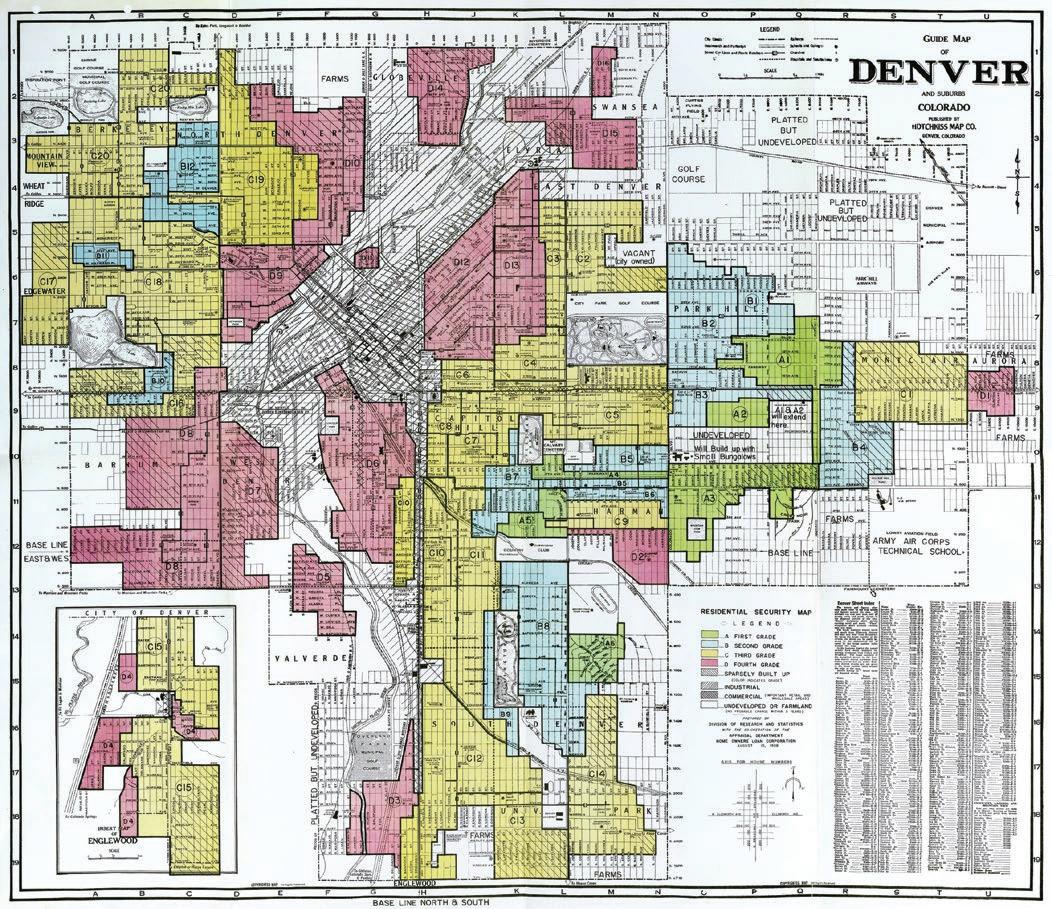

DEI Committee Redlining: A Brief History and Discussion of Its Impacts in the Rocky Mountain Region 45

OPERATIONS

The A2O Paradox: A Wastewater Operator Guide to A2O/MBR 49

RMSAWWA Unveils New Logo as Part of National AWWA Branding Refresh 55

ADVERTISER PRODUCT & SERVICE CENTER 57

At HDR, our One Water approach brings people together to plan and manage water resources holistically. By combining both natural and infrastucture solutions, we assist clients with sustainable, resilient, and adaptable water management innovations to future challenges.

hdrinc.com/one-water-approach

FROM THE RMSAWWA CHAIR

Stephanie Elliot, RMSAWWA Chair, Senior Project Manager, Stantec

And that’s a wrap for my term as Chair of RMSAWWA! As I take my final bow, i.e. being this final column, as Chair of RMSAWWA, I am filled with gratitude for having had this opportunity to lead this organization and work alongside its members, volunteers, staff and our collaborative partners, RMWEA. Serving in this position has provided me with an opportunity to continue to grow personally and professionally. It continues to show me how effective collaboration, creativity, and connection continue to drive both the water industry and RMSAWWA forward.

One of the best things about working in the water industry is the people, and that is why at the core of what we’ve accomplished during my tenure is connection. Whether in formal gatherings or casual conversations, whether over virtual meetings or sitting alongside during a presentation, connection and networking continue to be ranked the highest value for our members. Especially this year, the opportunity to build and maintain relationships is what I value most.

We’ve leaned into collaboration and creativity, somewhat out of necessity, yes, but also with intention. The water industry is no stranger to change. Whether it’s evolving regulations, shifting climate conditions, or workforce dynamics, we are continually challenged to rethink how we design and manage systems, recruit and retain talent, and pursue our mission and vision. I remain inspired by the ingenuity of our members, staff, and partner organizations, those who challenge the status quo and bring forward new ideas, passion, and hard work.

Communication connects our ideas to others and is essential for both success and growth. During the July Summer Planning Meeting, board members and committee chairs explored ways to enhance the Section’s communication strategies to better serve the evolving needs of our members and the water industry. I’m excited to see how initiatives like YP takeovers, Instagram stories, and/or YouTube videos will spark greater interest in water careers and deepen engagement with RMSAWWA. These new efforts will complement our magazine, newsletter, and existing social media channels. If any of this resonates with you, I encourage you to get involved with our Communication Committee so we can continue building effective communication that supports our growth and success.

I’m excited to share that our new logo was officially launched during the Business Lunch at the Rocky Mountain Water Conference this August! As we roll out this fresh look across our communications platforms, swag, and signage, we invite you to celebrate with us. Be sure to check out our website, newsletter, and social media for a special membership promotion, where you’ll have opportunities to earn entries into a prize drawing!

As my term comes to a close, I want to express my deepest gratitude for the

During the July Summer Planning Meeting, Board members and committee chairs explored ways to enhance the Section’s communication strategies to better serve the evolving needs of our members and the water industry.

opportunity to serve this incredible organization, its dedicated members, and our great staff. To our valued partners at RMWEA, thank you for being such a collaborative and forward-thinking ally as we continue to elevate the quality of our trainings, conferences, and networking events that serve both our members and the broader water industry.

It has been an honor to lead RMSAWWA with a focus on creativity, collaboration, communication, and connection –all essential pillars as we work toward our mission of providing innovative solutions to manage water, our planet’s most vital resource.

I’m confident that our incoming Chair, Brett Pugh, will bring fresh energy, insight, and strong leadership to build upon the solid foundation we’ve established. I have no doubt he will continue to strengthen our shared commitment to meeting our mission, ‘building a better world through better water’.

As I look ahead to this next chapter, I’m excited to continue collaborating boldly, connecting deeply, creating fearlessly, and communicating openly. If you’re interested in getting more involved with RMSAWWA, please visit our website at www.rmsawwa.org or feel free to reach out to me directly at chair@rmsawwa.com.

Clay Rahn, RMWEA President, Senior Water/Wastewater Project Manager, HDR, Inc.

Last summer, as I was thinking through – and admittedly freaking out about – how I could best serve RMWEA during my term as President, one realization kept surfacing: nothing lasting or meaningful will be accomplished without a great team. In other words, it will take a community of talented, dedicated, and passionate volunteers to help kick off and complete the initiatives I had in mind. I will not be able to do this on my own. Thankfully, I knew RMWEA is full of individuals who embody exactly that spirit. I’m incredibly grateful to the many volunteers who stepped up, offered their time and talents, and supported the initiatives I believed would make a positive and meaningful impact for RMWEA. I sincerely hope you know how much it’s appreciated. Together, we were able to bring three key initiatives across the finish line:

• A refreshed vision, mission, values, and strategic plan: This new strategic plan lays a strong foundation for RMWEA’s future. It aims to bolster workforce support, improve collaboration between entities, increase the public’s understanding of our work, and shine a spotlight on the cutting-edge innovations our water community is driving.

• Cloud-based hub: For years, RMWEA faced challenges with keeping our files, photos, and other important documents organized and accessible. This initiative will introduce a centralized, cloud-based file storage system that ensures better structure and strategic accessibility for both current and future volunteers.

• Facility Asset Renewal Marketplace (FARM): Born out of the 2024 Innovative Water Technology Shark Tank session at the Rocky Mountain Water Conference, FARM is an exciting new platform to facilitate the exchange of wastewater equipment between members of our utility operations and maintenance community. Again, another idea developed by a team of talented and ambitious water professionals.

It’s important to note: none of these initiatives were my original ideas. Each one was created by others and was already in motion before my term began. My role was simply to support and elevate the incredible teams leading the charge, and it’s been a privilege to do so.

As my time as President comes to a close, I’m filled with gratitude, thankfulness and yes, relief! But it truly has been an honor to serve this outstanding organization. Now, I’m thrilled (more than you know) to pass the torch to our incoming President, Kristin Johansen. She has some amazing initiatives of her own and comes in with fresh eyes and energy. I have no doubt she’ll lead with strength, vision, and heart. Thank you again for an unforgettable year and for allowing me the honor to serve as your president.

As my time as President comes to a close, I’m filled with gratitude, thankfulness and yes, relief! But it truly has been an honor to serve this outstanding organization. Now, I’m thrilled (more than you know) to pass the torch to our incoming President, Kristin Johansen. She has some amazing initiatives of her own and comes in with fresh eyes and energy. I have no doubt she’ll lead with strength, vision, and heart.

Like water itself, innovation flows through every challenge and shapes new possibilities. For over 90 years, Carollo has pioneered breakthroughs in water technology – from resilient infrastructure protecting growing communities to groundbreaking solutions safeguarding public health and ecosystems. At Carollo, innovation isn’t just about what’s new – it’s about what’s necessary. Every advancement, every improvement, and every solution flows from a single purpose: shaping a future where water enriches every community it touches.

303.635.1220 / carollo.com

FROM JASMINE’S PERSPECTIVE:

Attending ACE for the first time was one of the most fulfilling and rewarding professional experiences I’ve had so far. As a young professional (YP), this conference broadened my perspective, not just technically, but personally and professionally. From the moment I stepped in, I could feel the energy and passion of thousands of water professionals in one space. It was exciting, inspiring, and at times overwhelming, in the best way possible.

Being part of RMSAWWA has provided so many opportunities for me to grow over the years, and ACE was no exception. I had the chance to participate through multiple volunteer roles and was honored to serve on several committees: Young Professionals, Communications, the ACE Local Host Committee, and as the New Mexico Water YP Liaison. These roles allowed me to witness the behind-the-scenes effort it takes to bring ACE to life and how many people collaborate to make the conference successful. Everyone was motivated and passionate about their work, which made it even more inspiring.

One highlight was co-leading the @rmsawwa YP Instagram Takeover with Natalie. Capturing the energy of ACE25, from technical sessions and networking events to exhibitor booths, was both fun and fast paced. It was a unique opportunity to engage with our water community in real time through an online platform, sharing what was happening at ACE for those who were there and those who

couldn’t attend. We were able to highlight key events, activities, and spontaneous moments throughout the week.

I also helped with the Student and YP Scavenger Hunt, Career Fair, and Emerging Leaders Reception, where I had the chance to connect with students and early career professionals. Additionally, attending the Young Professionals (YP) Committee Meeting was great to share our perspectives on conference activities, discuss career and future opportunities, and learn more about

I reconnected with familiar faces and formed new bonds with professionals from across the country. I also met fellow Filipino engineers straight from the Philippines, which made me feel so proud and connected to my roots.

how to stay engaged through student chapters and AWWA programs.

Additionally, I attended technical sessions focused on water reuse, an area I’m deeply passionate about. Hearing about current projects, challenges, and solutions didn’t just inform me they inspired me to ask more questions, explore more solutions, and keep learning.

But more than anything, what stayed with me was the people. I reconnected with familiar faces and formed new bonds with professionals from across the country. I also met fellow Filipino engineers straight from the Philippines, which made me feel so proud and connected to my roots. At ACE, you meet people who just get it, those who share the same drive to protect, innovate, and serve our communities through water.

FROM NATALIE’S PERSPECTIVE:

My journey with ACE started in 2022 in San Antonio, when I attended as a graduate student and RMS Fresh Ideas Poster Competition winner. Back then, it was all about presenting my research and job hunting. Fast forward to this year, I’m now fully immersed in the water industry and felt a strong calling to support students the same way I was once supported. I felt fortunate to help three RMSAWWA students from the University of New Mexico attend ACE through the support of the Rocky Mountain Section. Watching them navigate the conference, make connections, introduce them to other YPs, and explore future careers brought everything full circle. One standout moment was seeing UNM student Carl Abadam present his research on Atmospheric Water Harvesting at the Fresh Ideas Poster Competition, a continuation of my research when I was studying at UNM. His work sparked real discussions about unconventional water sources and served as a reminder that great ideas aren’t limited by age or job title.

One of my biggest roles leading up to ACE was serving as Local Host Competitions Chair. I coordinated logistics and prepped supplies for the main ACE competitions including Hydrant Hysteria, Pipe Tapping, Top Ops, and the Meter Challenge. I volunteered during Hydrant Hysteria for a very hands-on experience where after every heat, I helped dissemble the hydrants for the next competitor. It was neat to see the mechanics behind the madness. If you’ve ever attended ACE, you understand how high-energy this event can be and it brought out the best in so many teams.

As Vice Chair of the RMSAWWA Young Professionals section and lead of our Communications Committee, I knew we had a big opportunity to show off what YPs bring to the table. With Jasmine Quiambao, our New Mexico YP Liaison, we took on an Instagram takeover of the new RMSAWWA account throughout the conference. We made sure to capture the local host committee, volunteer highlights, and exciting after-conference-receptions. One of my favorite events was the Emerging Leaders

In my opinion ACE really showcases what it looks like when YPs are given a seat at the table and the space to shine. I left feeling energized, grateful, and even more committed to creating pathways for others to join this journey.

Reception at Lucky Strike. The event consisted of arcade games, great food, and YPs from all over the country to reconnect with familiar faces and meet new ones. Having been to previous YP Summits, I loved seeing how this event brought us all together again.

In my opinion ACE really showcases what it looks like when YPs are given a seat at the table and the space to shine. I left feeling energized, grateful, and even more committed to creating pathways for others to join this journey.

Jasmine Quiambao is an Environmental Engineer at Carollo Engineers with a background in water, wastewater, stormwater, and environmental compliance. She’s actively involved in professional organizations such as RMSAWWA and RMWEA. You can reach her at jquiambao@carollo.com.

Natalie Gayoso is an Environmental Engineer at CDM Smith. She has worked on wastewater treatment, asset management, stormwater pollution prevention, and preliminary design projects. She serves as the student liaison for the New Mexico Water Committee and the Rocky Mountain YP Communication Committee. You can reach Natalie at gayosonm@cdmsmith.com or on LinkedIn.

New Mexico Supports Local Utilities with

Paul Gagliardo, MPH, PE, Independent Consultant

Governor Grisham announced New Mexico’s 50-Year Water Action Plan in 2024. Climate change is threatening the precious water resource that holds immeasurable cultural, agricultural, ecological, economic and recreational value to the state. Complex issues are affecting all aspects of water supply; precipitation is more variable, and snowpack, runoff and aquifer recharge are declining. Higher temperatures are drying landscapes, leading to increased erosion and more extreme wildfires. It is estimated that the state will have 25% less water supply over the next 50 years. It is critically important that the state takes the lead in managing this issue.

The Water Action Plan prioritizes actions related to water conservation, creating new water supplies and protecting watersheds. One of the activities proposed to address the reality of reduced water supplies in the future is to reduce leaks in municipal drinking water systems. Some local utilities have real water losses of 40-70%. Exacerbating the problem is the fact that most municipal drinking water utilities in the state are small and located in rural areas. The customer base cannot bear the cost of large capital programs to maintain aging water systems.

Jonas Armstrong, Water Protection Division Director, explains, “The water action plan contains key themes such as conservation, supply and protection. It was developed by a group of stakeholders to support innovation and advance technology in these areas, including leak detection for the over 1,000 public water systems in the state.”

The state is stepping in to help local utilities find these leaking pipes by using an innovative satellite imagery program that can survey the entire state. The Environment Department partnered with ASTERRA to provide intelligence and insight on below-ground, non-surfacing, potable water system leaks. This technology utilizes L-band radar to survey large areas of land and is the first of its kind capable of monitoring soil characteristics such as moisture levels that have a potable water signature. 30-mile by 40-mile satellite surveys

are collected, and the backscatter is analyzed using a proprietary algorithm to determine likely leak locations.

Field inspection crews are then deployed to these areas, typically less than 10% of the total system pipeline length, to pinpoint these leaks so they can be repaired. James Perry, ASTERRA CEO, states, “Our satellite-based Earth observation technology delivers actionable insights across a wide geographic area, enabling regions to address their water supply and asset management programs quickly, in a cost-effective manner.”

This is an innovative way for a state government to achieve its water supply and management goals. The state has no direct authority over the local water distribution systems. They must develop novel approaches to boost overall water availability, complementing traditional methods for increasing supply, such as dam construction or offering loans and grants for the development of new water facilities. By funding the front-end work to identify leaking pipes in local systems, ASTERRA can provide valuable information to the retail utility to repair pipes and recover lost water supply. This saves the utility money, reduces some of the need for rate increases for customers, maintains system reliability and service levels and saves water for beneficial use.

It has been shown that the marginal cost of generating effective new water supply through finding and fixing leaks is less expensive than recycling wastewater, treating brackish groundwater or constructing storage facilities. It also takes less time to implement leak repair programs than to plan and construct new, large-scale capital programs, and it has fewer negative environmental impacts. This program is usually supplied directly to utilities so that they can find and fix leaks in their system.

“ The water action plan contains key themes such as conservation, supply and protection. It was developed by a group of stakeholders to support innovation and advance technology in these areas, including leak detection for the over 1,000 public water systems in the state.”

In this case, the state stepped in and provided a comprehensive leak detection solution to small, rural utilities and municipalities so that overall water loss in the state can be reduced. This program supports local utilities by pinpointing leak locations so crews can be deployed to repair the leaks before they burst and cause serious problems. The first phase of this work was completed in May 2025 and found 82 leaks resulting in 240 gallons per minute (GPM) of water loss reduction.

A total of four satellite surveys were collected in March 2025. Five different water agency systems, Truth or Consequences, Timberon, Cloudcroft, Bernalillo and Tranquillo Pines Water Users Co-Op were analyzed. A total of 20 crew days were spent in the field pinpointing

leaks. Of the 82 leaks found, 34 were on the utility side and 48 were on the customer side of the meter. All of the utility leaks were repaired. Over 80% of the leaks found were not surfacing and would not have been found if not for the satellite survey.

Mayor of Truth or Consequences, Rolf Hechler, states, “The state has been very generous to us by funding pipeline replacements and also helping us find leaks with ASTERRA, which is a game changer. We used to find leaks the old-fashioned way, waiting for them to surface. Finding hidden leaks ahead of time saves us water, money and time. It is a perfect solution.”

This model demonstrates how state environmental water agencies can assist local utilities through direct action to reduce real water loss, save money and improve underground infrastructure. The state provided the satellite survey and field leak inspection services. The individual utilities provided the GIS maps of the system and technical and operator support to efficiently identify leak locations. Utility staff were intimately involved in this collaborative process, which involved ASTERRA, the state Environment Department and McKim and Creed (field inspectors). Through this joint effort, 345,000 gallons of water were saved for beneficial use in the first half of 2025, taking a step toward the water loss reduction goal of 25% by 2040 articulated in the Action Plan.

Paul Gagliardo is an independent consultant advising innovative water sector startup companies. He has held leadership positions in the water business for 30+ years.

Paul has been a judge for the Imagine H2O Accelerator since 2009. He is the host of

The Water Entrepreneur Podcast. He can be reached at thewaterentrepreneur@gmail.com.

Sept. 29 - Oct. 1, 2025 Chicago, IL

LOOKING FOR A SCREW PUMP UPGRADE THAT’S BABA-COMPLIANT?

Lakeside’s screw pumps offer the ideal and cost-effective “drop in” replacements for less reliable designs. Improve pumping performance and reduce maintenance costs with our superior dual upper bearing design and heavy-duty self-aligning lower bearing designs. For decades we’ve been the go-to source for replacing all screw pump brands. Replacements typically require little or no structural modifications. It’s what you expect from Lakeside Equipment—known for nearly a century for efficient and dependable operation in all wastewater, drainage and industrial applications.

REPRESENTED LOCALLY BY: Goble Sampson Associates

Speak to one of our experts at 630.837.5640, email us at sales@lakeside-equipment.com or visit lakeside-equipment.com for more product information.

stranger to innovation and creative partnerships. Since 2019, the facility’s Pilot and Research Center (PARC) has conducted numerous pilot projects testing new treatment technologies, coordinated dozens of research partnerships, and served as a hub for utility-driven innovation. While much of PARC’s focus is centered around developing and verifying these critical treatment technologies, SPR recognizes

that public outreach and education are just as crucial to advancing the industry.

In an effort to keep service area residents informed and pursue treatment technologies, SPR recently partnered with a local brewery. The result was a broad collaboration between academics, community members, and industry professionals that highlighted an advanced treatment technology while facilitating an impactful marketing and public education tool, all packed into a crisp and delicious beer.

SPR initially partnered with Breckenridge Brewery, a community discharger located within its service area, through its industrial pretreatment program, monitoring parameters like biochemical oxygen demand (BOD) and pH. This relationship evolved into a pilot project to use brewery waste as a carbon source to promote denitrification in the secondary treatment process. This pilot project was previously

successful in utilizing waste from a whiskey distillery. However, technical evaluations determined that the brewery waste was not suitable for this application.

Just across the plant at the PARC liquid site, another pilot was underway: the PureWater Colorado Direct Potable Reuse (DPR) trailer. Operated by Colorado School of Mines (CSM) faculty and students, this pilot was designed to progress innovative technologies, develop quantitative metrics, and create protocols to reclaim wastewater effluent to meet drinking water standards. The trailer’s focus was not just on developing the technology but on making the technology accessible to the public in a

way that dispelled uncertainty and created confidence in a water reuse strategy that will be key to addressing future water demands. As the DPR trailer travelled around utilities in the state of Colorado, it also created a knowledge-sharing opportunity for the local community. SPR saw this potential for widespread public education and engagement and wanted to make sure that the opportunity was fully realized. SPR approached Breckenridge Brewery with the idea of creating a beer using the recycled water generated from the trailer. Given their passion for sustainability and innovation, Breckenridge was quick to jump on board.

By April of 2025, CSM operated the DPR trailer to produce 2,600 gallons of potable water through reverse osmosis treatment. The recycled water was tested by a thirdparty laboratory and confirmed to meet all Colorado Department of Public Health and Environment (CDPHE) drinking water standards. The water was then delivered to Breckenridge Brewery, where they used their own pilot-brew system to create a small-batch Helles Lager.

The public education efforts continued from there. Communications teams from both SPR and Breckenridge Brewery coordinated to create a logo, outreach strategy, and media releases to showcase the safety, reliability, and sustainability of this water

renewal technology. A key part of this outreach strategy was through SPR’s PARC Innovation Flow Podcast. Hosted by Blair Corning, SPR’s Deputy Director of Environmental Programs, each episode features in-depth conversations with industry experts and leaders. Together, they delve into pioneering projects and research that are helping to shape a sustainable future for our communities and the environment. In a special episode highlighting this partnership, Blair sat down with Justin Fisher, Innovation Brewer at Breckenridge Brewery, to discuss the science and strategy behind brewing with recycled water, why Helles Lager was the perfect pick, and how sustainability flows through

every step of their brewing process. This episode, as well as all other, can be found at southplatterenewco.gov or the QR code.

This partnership culminated in a release party held at Breckenridge on June 5, celebrating World Environment Day. City leadership, SPR staff, CSM students and faculty, and members of the public celebrated the successful partnership and experienced the true taste of sustainability.

This collaboration between South Platte Renew, Breckenridge Brewery, and the Colorado School of Mines demonstrates the power of integrating public outreach with technical research. By engaging the public through a tangible product, this partnership created an exciting and educational experience to build trust and foster a deeper understanding of water reuse technologies. These partnerships not only advance technical understanding but also serve a crucial role in fostering public trust, a foundational element for the future expansion of direct potable reuse projects both locally and nationally. By enhancing public awareness and engagement it can help to dispel misconceptions and build confidence in these innovative methods that are vital for addressing growing water scarcity challenges.

Shannon Harney is an Engineer II at South Platte Renew. She works on the development and implementation of the facility’s Asset Management Program, as well as serves as a project engineer on several capital projects and pilots. She also works on the development of several plant-wide programs, including Safety, Energy and Sustainability, and the Analytical Instrumentation Program. Shannon has her bachelor’s in Environmental Engineering with minors in Sustainable Watersheds and Global Environmental Sustainability from Colorado State University.

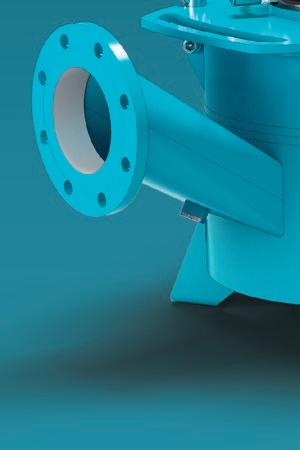

Your job is demanding, but your pumps shouldn’t be. The Sulzer XFP with Contrablock Evo impeller is designed to maintain smooth operations with the clog-resistant performance you can rely on.

Whether you’re operating a plant, managing a facility, or overseeing upgrades, our pump helps you stay on track, stay compliant, and avoid unplanned downtime.

With full BABA compliance, it helps you meet today’s infrastructure requirements while giving you back what matters most, your quality time.

Learn more about Sulzer’s HST go.sulzer.com/trusted-xfp

At Johnston Pump, reliability isn’t a feature, it’s our foundation. Since 1907, we’ve delivered rugged, high-performance pumps that keep systems running smoothly and customers worry-free.

We understand what’s at stake, which is why every Johnston pump is engineered for durability, backed by expert support, and available as Build America, Buy America compliant so you can move forward with confidence and compliance from day one.

Learn more about Johnston Pump trusted-johnston

Excellent raw water quality does not mean that water treatment operations are easy or straightforward. The operations team at Louisville, Colorado, knew this firsthand when they began exploring digital tools to assist them in providing the highest quality drinking water possible for their community.

Situated between Denver and Boulder on the Front Range of the Colorado Rockies, Louisville has benefitted from some natural advantages in water supply. Sourced from either South Boulder Creek or the Colorado River, Louisville benefits from the “snowcapto-tap” water systems that supply many of the communities along the Front Range. While life next to the mountains presents its own watershed risks (wildfires devastated the

Dr. Peter S. Fiske, Chief Strategy Officer, Fontus Blue, Inc., Executive Director, National Alliance for Water Innovation (NAWI)

community in 2021, destroying more than 500 homes and displacing most of the town), Utilities Director Greg Venette and his team have always maintained a policy of excellent operations and data-driven decisions. Louisville’s raw water is naturally low in organics. But this sometimes poses significant treatment challenges, including weak coagulation, which can lead to pin floc and early filter breakthrough. Venette and the team knew that optimizing coagulant dosing and allowing filters to run for as long as possible between backwashes would save water and money in the long run. A member of the utility’s IT team had a background in data science and built a regression analysis tool based on historic

data that the operations team utilized to dial in coagulation. “Our source water is really good, so in order to achieve better performance, you need real accuracy in your data and your model,” notes Venette. Unfortunately, the in-house model was complex to utilize and hard to update, so they began searching for a digital tool that would be usable by the entire team and easy to maintain and sustain as new team members joined the utility. The IT department was also wary of software that was directly connected to SCADA. “SCADA is sacred,” notes Venette, “You really have to be careful about cybersecurity.” Having a cloud-hosted option that was disconnected to SCADA seemed like the best approach.

Louisville learned about a new option in April 2023. Virtual Jar® is a cloud-hosted software system that enables operators to accurately model the treatment processes in their plant and perform thousands of “virtual jar tests” to explore the broadest range of treatment chemical combinations. Venette and his team liked what they saw and asked for a demo in August. They kicked off use of the software in October 2023.

The Louisville team knew that operators needed to embrace the tool if it was ever going to be adopted successfully, so they assigned two up-and-coming operators to work directly with the team from Fontus Blue to get the model built and perform the first simulations. They we’re then assigned the job of training the rest of the operations team. “If you get the champions online early, everyone else comes along sooner,” notes Venette.

The operations team started by replicating current plant operations in the new software. “There’s no ‘breaking it’ because it’s a computer model; you just play and play. It’s really a collaborative tool,” notes Venette. Rather than dictating specific recommendations to the operations team, the software invited the operators to explore combinations of chemicals and dosage ratios that were outside their normal operations. Senior operators often have decades of experience with a specific treatment plant, but also favor treatment combinations they have experience with. “That’s the way we’ve always done it’ is actually NOT okay,”

notes Venette. It helps operators to be able to see not only what they’ve done in the past but also what the future could look like with different treatment strategies.

“Organics treatment was a big mindset change for us,” notes Venette. The team had historically prioritized turbidity reduction because organic levels were generally low in their raw water. But certain turbidity reduction strategies also help reduce organic levels, and the Louisville team soon found that different ratios of aluminum sulfate and ACH (aluminum chlorohydrate) produced better results for both treatment objectives. The software also helped the team appreciate how mixed coagulants needed to be adjusted for temperature: for colder water, higher ratios of ACH produced the best results, whereas when water temperatures were warmer, higher ratios of alum produced better results.

“We have always been cautious in our approach to treatment changes,”

explained Venette. “Changing only one variable at a time and evaluating the results.” But with software that can accurately predict plant performance over a wide range of conditions and chemical combinations, the operations team was able to evaluate simultaneous changes in multiple chemicals, discovering some “hidden islands” of optimal performance.

“Changing both alum and ACH simultaneously made us a bit nervous at first,” notes Venette. “But in water, everything is changing all the time, so operators need to be more dynamic in their thinking.” The software tool is also able to reveal the exact cost of each treatment strategy, allowing the operations team to choose the best treatment scenario for a given cost objective.

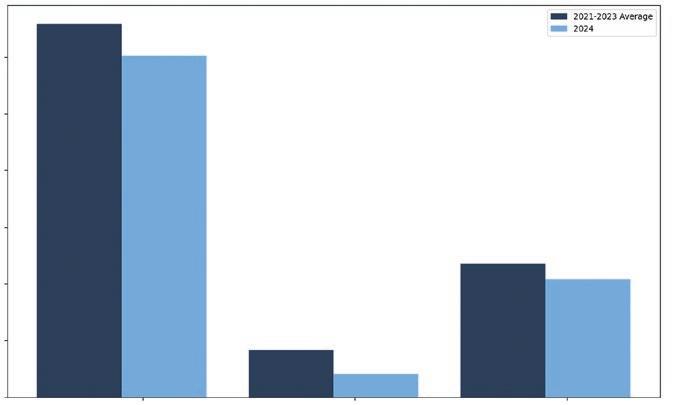

After the first full year of using the optimization software, the Louisville operations team was gratified to see the results. Throughout the year, they were able to meet or exceed their water quality

objectives 100% of the time, but at a cost reduction of $37,000 in chemicals (Figure 2) and a savings of over 18 million gallons of water. “That’s a real win for us,” explains Venette. “It’s equivalent to a nine-to12-day water supply for the entire town.”

“Our utility isn’t small, but it isn’t medium. It’s ‘smedium’,” notes Venette. “We have resources and a strong drive to produce optimal quality water, but we sometimes don’t have all the people. Virtual Jar® helps level the playing field.”

Peter Fiske is the Chief Strategy Officer for Fontus Blue, Inc. He is also the Executive Director of the National Alliance for Water Innovation (NAWI). Prior to founding NAWI, Fiske was the CEO of PAX Water Technologies, Inc.

Northern Water

In fall 2024, Northern Water wrapped up phase II of the Berthoud Campus Development project at its headquarters, which included a focus on conservation and sustainability. As part of this campus expansion, the Water Efficiency team has been working diligently to install new water-wise demonstrations in the Conservation Gardens.

These new demonstrations feature plants and trees native to Colorado and the Southwest region of the United States, creatively displayed to represent five unique landscape scenarios:

• Medians

• Shaded street strips

• Slopes

• Low maintenance

• Prairie ecosystems

Water Efficiency Specialist Lindsay Nerad said, “Ultimately, we wanted to make these new demonstrations attractive so not just using one or two plants that might suit the purpose of each, but really having a wide plant palette for each situation; plants that are going to retain a slope, that are going to be low maintenance and obviously having a diverse system for our prairie ecosystem since we do have so much plant diversity around us here in Northern Colorado.”

The Water Efficiency department is at the forefront of promoting water conservation in Northern Colorado through its various programs, services and educational opportunities, including the following.

COLLABORATIVE WATER-EFFICIENT LANDSCAPE GRANTS

The Water-Efficiency Landscape Grant Program promotes water-efficient Colorado climate-friendly landscapes that serve

as regional demonstration and outreach efforts. Grants awarded provide financial support for commercial-scale landscape projects aimed at reducing water use while expanding ecosystem services.

AND ASSESSMENTS

We know the importance of designing the perfect landscape while being efficient with water use. That’s why we offer landscape consultations and irrigation assessments through our qualified staff and partnership agencies.

Northern Water Provided Landscape Consultations – Designed for our commercial customers, landscape consultations address issues of concern, including water usage, management and design, irrigation system performance, landscape plans and expectations, and ideas. Water Efficiency Landscape Grant applicants are required to complete a consultation in advance of submitting an application.

Partner Provided Assessments –Outdoor irrigation assessments provide a foundation for assessing outdoor water use. Assessments are designed to help identify water waste and offer direction for optimal water use. Indoor assessments support commercial water users like office buildings, schools, hotels, restaurants and more by identifying water and cost-saving opportunities in their operations.

Indoor Assessments – The Commercial, Industrial, Institutional (CII) Assessment program offers no-cost indoor water-use assessments for commercial properties.

Landscape templates are a great tool to start a landscape transition or a new installation. Whether you’re starting with a blank slate or want to reduce water use and add some color, using a template can ease the burden of design costs and time-consuming research. Northern Water offers two types of templates:

• Waterwise Landscape Templates are fun, colorful designs supporting transitions to a sustainable, more beneficial waterwise landscape. The designs reduce water use while building a colorful and pollinatorfriendly landscape.

• Sustainable Landscape Templates are comprised of six sets of comprehensive landscape plans and supplemental information designed to assist the communities impacted by the Marshall Fire of 2021. The templates accommodate corner, middle, cul-de-sac and large lots for maximum adoptability. They also include full landscape plans, irrigation plans, water-wise low flammability plant lists, cost opinions and more.

Classes and training aim to give attendees a deeper understanding of many topics, including the plant-soil-water relationship, plant water requirements, landscape water budgeting and irrigation management, among others.

We provide education and outreach through a variety of opportunities, including Conservation Garden tours, presentations, sponsoring programs and events, staffing booths, writing educational content and partnering with others in order to advance water efficiency.

The fastest-growing program is the Collaborative Water Efficient Landscape Grants, with $1.2 million awarded to 80 projects and 8.2 million square feet of landscapes since its inception in 2019. It has also saved 8.7 million gallons of water within Northern Water’s boundaries.

The Water Efficiency Department also offers numerous other resources to Northern Colorado residents and property owners. To learn more about water conservation, get involved, or simply enjoy the beautiful Conservation Garden, Northern Water offers monthly tours from April to October, and the annual Conservation Gardens Fair each June at our Berthoud headquarters.

Free and open to the public, the Gardens Fair features educational seminars,

demonstrations of irrigation technologies, fun and engaging kid-friendly activities, informational booths, food trucks, giveaways and more. Throughout the day, roam the gardens to view examples of plants, trees and grasses to learn how to conserve water in your landscaping and understand ways to increase water efficiency at home without sacrificing curb appeal.

The Water Efficiency team provides water efficiency information, inspiration and investment for Northern Water allottees. Visit www.northernwater.org for more information.

Introducing the MevaScreen® RSM Monster! Our progressive step fine screen works in facilities with extreme grit or high screening loads in difficult operating conditions. The new screen’s patented process provides ease of maintenance and can be tailored to the facility’s specific application needs. With a greater than 80% debris removal rate, it’s an excellent choice to protect sites with high solids removal requirements.

Authorized Representative

Phone: 303-309-6150

Website: www.miscowater.com

Email: nlucas@miscowter.com

Mirka Wilderer, CEO and President, AqueoUS Vets

Given the ubiquity of per- and polyfluoroalkyl substances (PFAS) contamination, there is much interest in exploring the growing landscape of treatment technologies positioned to remove PFAS from the environment. These technologies broadly fit into two main categories: concentration and destruction. Concentration methods remove PFAS from water and isolate them, while destruction technologies break the carbon-fluorine (C–F) bonds to eliminate the compounds permanently. This article aims to summarize the landscape of these technologies at a high level.

H2:

Concentration technologies separate PFAS from water, such that they are safely removed from the environment and stored in some other form. The most established concentration methods are granular activated carbon (GAC), ion exchange (IX), and reverse osmosis (RO). Of these, GAC and IX are

considered the gold standard due to their reliability and cost-efficiency. Both work via adsorption and are commonly used in drinking water, remediation, and industrial settings. GAC and IX media must be removed and disposed of after they become saturated with PFAS, whereas RO produces a highly concentrated PFAS brine that historically has been discharged to wastewater treatment plants, surface water, or deep well injection sites.

Foam fractionation (FF) is an emerging technology that leverages PFAS’s hydrophobic nature to separate them via foam. It’s especially promising for highconcentration waste streams, where GAC or IX may become expensive due to frequent media changes. FF produces a highly concentrated PFAS stream that must be destroyed or discharged. Unlike RO, FF selectively removes PFAS. As a result, the FF concentrate is much “cleaner” than RO brine, and therefore more amendable to PFAS destruction techniques. Table 1 summarizes concentration technologies.

After PFAS is separated from the environment, the C-F bonds that make up these compounds must be broken to prevent re-contamination. With a bond strength of 130 kcal per mole, C-F bonds are extremely stable and require a lot of energy to break down. Traditional methods include thermal desorption with oxidation (i.e., reactivation) and incineration. Newer methods include supercritical water oxidation (SCWO), hydrothermal alkaline treatment (HALT), electrochemical oxidation (EOx), plasma, advanced oxidation processes (AOPs), and photocatalysis. Table 2 summarizes the landscape of PFAS destruction technologies.

Thermal Desorption with Oxidation heats solid waste to ~600°C, volatilizing contaminants, which are then destroyed at ~1000°C. Incineration, already used for PCB disposal, burns PFAS-laden media at >1000°C to destroy PFAS.

TABLE 1: Summary of PFAS concentration technologies. (P) Indicates proven technologies approved broadly for use today, whereas (E) indicates an emerging technology.

TABLE 2: Summary of PFAS destruction technologies. (P) Indicates proven technologies approved broadly for use today, whereas (E) indicates an emerging technology.

HALT (E)

EOx (E)

fomate Simple, effective for long-chain PFAS Energy use, byproducts

Plasma (E) Ionized gas Brines, fomate Electrode-free, compact Slower kinetics

AOPs (E) Chemical oxidation Brines, fomate Familiar, scalable

Photocatalysis (E) UV + catalyst Brines, fomate Theoretical potential

Limited PFAS degradation

High cost, low efficiency

Through thoughtful selection of concentration and destruction technologies tailored to specific site conditions, PFAS can be effectively removed and destroyed, helping to minimize long-term environmental risks and treatment costs.

Both technologies are currently accepted by the EPA for the disposal of IX and GAC media; however, the fate of products of incomplete combustion (PICs) is uncertain.

SCWO brings waste to supercritical conditions, dissolving organic compounds and oxidizing them. It’s highly effective but energy-intensive and susceptible to scaling, which can cause dangerous reactor plugging. HALT is similar to SCWO; however, the process avoids supercritical conditions by using hydroxide reagents to chemically break PFAS bonds. This method keeps salts soluble and mitigates plugging issues.

Electrochemical Oxidation uses electric current to create radicals that break down PFAS, particularly effective on long-chain variants. It’s compact but less efficient

on short-chain PFAS unless retention time or energy input is increased. Plasma treatment uses ionized gas to generate oxidants and electrons. It’s energy efficient and avoids electrode fouling, though reaction kinetics can be slow.

AOPs (e.g., UV with peroxide or ozone) and photocatalysis use oxidative methods to degrade PFAS. While these are well known in water treatment, they show limited effectiveness against PFAS due to the stability of the C–F bond.

While concentration and destruction technologies are often pitted against one another, they are typically symbiotic, where concentration technologies are used prior to destruction to minimize the cost of destruction. Through thoughtful selection of concentration and destruction technologies

tailored to specific site conditions, PFAS can be effectively removed and destroyed, helping to minimize long-term environmental risks and treatment costs.

Dr. Mirka Wilderer is recognized as one of the leading female executives in the water industry with deep experience in corporate strategies, business transformation, and cross-functional leadership in global organizations. Mirka is a seasoned executive with two decades of experience in the water industry. Prior to Aqueous Vets, Mirka was the CEO of De Nora Water Technologies.

WE DON’T JUST MAKE PIPE. WE PROVIDE SOLUTIONS.

EVERY DAY, WE MAKE AMERICAN BETTER AMERICAN never stops innovating. We’re always breaking new ground in our technology, processes, and quality. This commitment to the future means ever-higher reliability, confidence, and sustainability – aligning with your needs. Throughout our history, the Right Way has meant giving you confidence in our products and our expertise. And, above all, your future.

Have you been looking for a solution that will optimize your operations, enhance customer service and drive smart decisions? CORE+ brings together local expertise and smart technology to support utilities in becoming more efficient and future-ready.

Ashwin Dhanasekar, Principal, Brown & Caldwell

Colorado’s water story is changing fast. The Front Range, like much of the West, is feeling the squeeze of growing populations, longer droughts, and the realities of climate change. To meet these challenges, three local water utilities –Denver Water, Fort Collins Utilities, and the Town of Windsor – are each testing new ways to conserve, reuse, and rethink how we handle water.

This isn’t just about high-tech fixes or big infrastructure projects. It’s about a shift in mindset: doing more with less, designing smarter systems, and building a more resilient water future from the ground up. Here’s a look at how these communities are stepping up.

DENVER WATER: A SMALL BUILDING WITH BIG IMPACTS

Denver Water has turned its own administration building into a live experiment in how we might manage

water differently in the future. The “ReUse For US” (RUFUS) system, tucked inside its six-story office, captures water from sinks, toilets, urinals, and even the cafeteria. After treatment, that same water gets reused to flush toilets and urinals again –a closed-loop that saves a lot of potable water from being flushed away. At the

heart of RUFUS is a small team and a big community of microbes. These “adorable microorganisms” (as staff call them) help clean the water, doing the heavy lifting with surprisingly minimal fuss. The system uses two separate plumbing lines – one for drinking water and one for recycled water –to keep things safe and efficient.

Getting state approval for RUFUS wasn’t easy. In fact, it was the first setup of its kind in Colorado to get the green light from health officials. That win opened the door for others: now, developers across the state have a tested model and a clear regulatory path if they want to build with onsite water reuse in mind. This project fits squarely into Denver Water’s bigger “One Water” philosophy (see illustration) – the idea that not every use needs drinking-quality water, and that we should match water quality to its purpose. The building itself, which aims for LEED Platinum and Net Zero Energy, takes this approach seriously. Solar panels, radiant heating, and even wetland planters in the lobby all work together as part of

an integrated, sustainable system. It’s a glimpse into what water-wise buildings might look like in the years ahead – places where water is reused, energy is conserved, and design choices reflect a new way of thinking about resources.

As someone who’s lived in Fort Collins for a long time, I’ve seen how this city tackles challenges with practicality and a strong sense of community, especially when it comes to water. The city’s new Water Efficiency Plan (WEP) is ambitious, but not flashy. It charts a clear course to reduce

treated water use by 4% annually through 2040 – that’s about 320 million gallons a year below what we’d otherwise expect. But what sets Fort Collins apart isn’t just the numbers. It’s how the community shaped the plan.

Hundreds of residents weighed in, and the utility made a real effort to include voices often left out, like renters, non-English speakers, and low-income residents. That equity focus isn’t just talk; it’s guiding how programs are built and prioritized. The message is clear: water efficiency isn’t only technical – it’s people-centered. The plan features diverse strategies: educational efforts like school programs and neighborhood “Garden Parties”; infrastructure upgrades like advanced metering and real-time leak detection; and financial tools like appliance rebates, tiered rates, and discounted “Garden In A Box” kits.

Fort Collins knows the climate’s getting hotter – by about 1°F by 2040 – and it’s planning accordingly. Rather than react during the next drought, the city is investing now in systems and habits that build resilience. In the end, Fort Collins isn’t just conserving water. It’s showing how a utility can truly partner with its residents – listening, adapting, and planning together to ensure benefits for all. It’s not flashy, but it’s exactly the kind of approach we need more of.

TOWN OF WINDSOR: BALANCING BIG PROJECTS WITH LOCAL ACTIONS

I live in Windsor now, and it’s been fascinating to watch how this small but fast-growing town is planning for its water future. Like many Front Range communities, Windsor is trying to balance rapid growth with water security, all while facing longer dry spells and rising temperatures. A key part of the plan is the Northern Integrated Supply Project (NISP), a major regional water storage effort involving 15 Northern Colorado providers. Windsor’s share – 3,300 acre-feet of raw water – will be critical as demand rises. Though NISP has had a long, winding journey, the town sees it as essential to long-term resilience.

But Windsor isn’t just waiting on big projects. Its Municipal Water Efficiency Plan helps unlock state funding and lays out a roadmap for smarter local use. Community

programs like the “Home Water Works” tracker, discounted xeriscaping kits, and the “Windsor Water Wagon” bring conservation directly to residents. Behind the scenes, the town is tackling leaks, installing rain sensors, and enforcing summer watering rules. One standout: many new developments now install non-potable irrigation systems –a second set of pipes that saves treated drinking water for where it’s really needed.

Windsor is also investing in wastewater infrastructure. Its treatment plant, which handles up to 2.8 million gallons a day, is undergoing an $8.5 million upgrade to its headworks – the first step in treating wastewater. It may sound technical, but improving grit removal early makes the system more efficient and helps return cleaner water to the Cache la Poudre River. Windsor’s strategy isn’t flashy, but it’s smart. It shows that in Colorado, managing water takes many coordinated steps, not just one big solution.

What’s happening in Denver, Fort Collins, and Windsor isn’t just about technology or infrastructure – it’s about a shift in mindset. Each of these communities is taking a slightly different path (see illustration), but they’re all moving in the same direction: toward a future where water is used more thoughtfully, managed more efficiently, and valued as the critical resource it is.

In the end, what ties these stories together isn’t the technology or even the water. It’s the people – the engineers, planners, operators, residents, and leaders, who are working together to figure out how to do better with less. It’s not always flashy, and it’s definitely not simple. But it’s happening, one thoughtful decision at a time. The challenges are big, but so is the opportunity.

So, the real question is: how do we keep that momentum going? How do we keep learning from each other,

AECOM’s objective is to provide water clients with access to globally sustainable technologies, delivered locally. AECOM continues to remain committed to the world’s need for safe, reliable water while protecting this critical natural resource for the future.

With offices across the Rocky Mountain Region, our professionals work in and across the major markets to deliver comprehensive solutions that safeguard human health and the environment. aecom.com

borrowing the best ideas, and staying curious about what’s possible? Because if there’s one thing Colorado’s water story makes clear, it’s this: progress doesn’t come all at once. It comes in steady flows, and every drop counts.

Ashwin Dhanasekar serves as a strategic leader in Brown and Caldwell’s Research and Innovation and Digital Solutions teams. He has over 15 years of experience working on a variety of topics, including the energy-water nexus, research and innovation in the water sector, biosolids, climate change and resilience. He has a B.S in Chemical Engineering and a M.S. in Environmental Engineering from Colorado State University. Contact him at adhanasekar@brwncald.com.

Most see a water tower.

We see a thirst-quenching drink.

Taylor Jordan, Process and Innovation Engineer, EnviroMix

Organized in 1965, the Boxelder Sanitation District provides sanitary sewer services to customers near Fort Collins, Colorado. The district constructed a state-of-the-art enhanced biological phosphorus removal (EBPR) wastewater treatment facility (WWTF) in 2014 to keep pace with the rapid growth of the area.

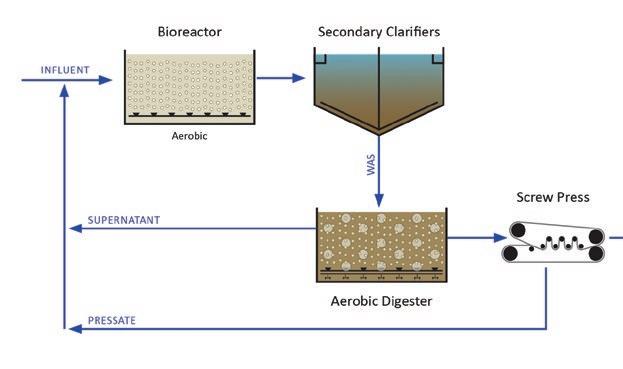

In 2021, Boxelder expanded and upgraded the WWTF to accommodate future population growth and new stringent effluent discharge limits on nitrogen and phosphorus. Increasing capacity from 3.0 MGD to 4.6 MGD (million gallons per day), the comprehensive project encompassed many process improvements, including: UV equipment upgrades, headworks modifications, an additional oxidation ditch, two new secondary clarifiers, and two new aerobic digesters. The upgraded

facility was designed to produce effluent containing less than seven mg/L total inorganic nitrogen.

After evaluating conventional aerobic digestion alongside alternative technologies, Boxelder’s design team ultimately selected EnviroMix’s BioCycle-D Optimized Aerobic Digestion Process to provide volatile sludge destruction and stabilization in the new aerobic digesters.

In a conventional aerobic digestion process, aeration is used to both provide the oxygen needed for digestion and completely mix the tank contents. Automated process control and instrumentation feedback are rarely incorporated. This approach results in over-aerating the digester, leading to high energy consumption and excessive amounts of nitrogen recycled back to the secondary process.

BioCycle-D is designed with a diffused aeration system to satisfy process oxygen demand and a compressed gas mixing system to satisfy mixing requirements. This decoupling of aeration from mixing facilitates independent control over oxygen delivery and mixing operation.

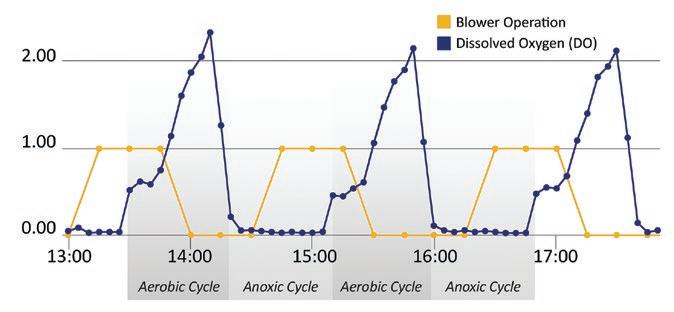

Through online sensor feedback, the controller automatically transitions between an aerobic cycle for volatile solids destruction and nitrification to an anoxic cycle for denitrification, alkalinity recovery, and energy savings. Alternating aerobic and anoxic conditions optimize digestion and prevent over-aeration.

Prior to 2021, Boxelder utilized a sludge storage lagoon that recycled high amounts of nutrients to the secondary process, reducing efficiency and necessitating expensive sludge removal. Before the upgrade, Boxelder was spending around $400,000 annually to dredge out its waste stabilization pond.

The EPA estimates that typical side-stream nitrogen loads are between 15 and 50% of the load on the secondary process (Bilyk, Taylor, Pitt, and Wankmuller 2011). Boxelder successfully reduces the ammonia and nitrate concentrations in the digester supernatant and pressate return streams sent back to the head of the plant.

Figure 2 displays levels of ammonia and nitrate in Boxelder’s pressate return. For comparison, anaerobic digestion return streams typically contain ammonia concentrations of 300-900 mg/L, while conventional aerobic digestion return streams typically contain nitrate concentrations of 50-200 mg/L.

“Very shortly after [BioCycle-D] startup, it was clear that nitrate in the return stream was really low – like less than one part –and it didn’t require much effort,” stated Craig Hibbard, plant manager. “Having low concentrations of both ammonia and nitrate in our return streams has helped us achieve the lowest total nitrogen discharge levels in the state of Colorado for a couple of years now.”

In Figure 3, blower operation is indicated by the yellow curve in the graph – 1.00 indicates the blower is enabled; 0.00 indicates the blower is off. Controlled on a time cycle, the blower is running for one hour and then off for 30 minutes.

The DO concentration, shown in dark blue, indicates when the digester is in an aerobic or an anoxic environment. When conditions in the digester are aerobic, nitrification occurs, and ammonia is converted to nitrate. When conditions in the digester are anoxic, denitrification occurs and nitrate is converted to nitrogen gas, which leaves the system.

is based on automatically rotating aerobic and anoxic cycles.

The cycling between aerobic and anoxic conditions not only reduces nitrogen in return streams, but it also maximizes volatile solids destruction, which is required for class B biosolids suitable for land application. Boxelder meets its class B biosolids permit year over year with a fecal coliforms geomean of ~35,000 CFU/g, far below the limit of two million CFU/g. Figure 1. Boxelder’s secondary process configuration.

Dan Widdel has become the new President of Illinois-based Lakeside Equipment Corporation, who since their formation back in 1928, have become a highly renowned provider of wastewater treatment systems, including screens, grit collectors, clarifiers, screw pumps, and biological processes.

With Lakeside for 25 years, Dan steps up to replace retiring President, Karen Wolk, who served the employee-owned company for 40 years. Karen had been in the head role for the past three years, following the sudden passing away of Lakeside’s much-admired President, Steve Eckstein.

“This is a huge honour for me to follow in the footsteps of those who have led Lakeside Equipment Corporation so diligently for almost a century,” said Dan Widdel.

“Despite some challenging times in our long history, including the Pandemic, and the tragic loss of our former President, we have stuck together as a very solid team, determined, no matter what, to deliver the very best solutions for our customers. I would like to sincerely thank Karen Wolk for her huge contribution in pushing Lakeside forward”.

Jim Snyder (Lakeside’s Production Manager), who has been with the business for 43 years, moves up to become joint Vice President, sharing the new mantle with Jim McKee (National Sales Manager), who has been at Lakeside for 25 years.

Meanwhile, Jamie Marshall has joined Lakeside as its new Controller. She recently completed her Master of Business Administration, together with achieving a human resources graduate certificate.

The cyclic aeration controls substantially reduces ammonia and nitrate levels in both the digester supernatant and pressate return streams, preventing nitrogen spikes in the secondary process. By utilizing the decoupled system, Boxelder reduced energy consumption by 75% versus conventional aerobic digestion.

“I’m very pleased with the energy use. The power needed for the digesters is much less than we were anticipating,” Mr. Hibbard commented. Regarding maintenance, he added, “We don’t have any subsurface mixers we have to haul out of there that could get fouled. 90% of the repairs are doable above ground.”

By choosing this technology instead of conventional diffused aeration to mix the new aerobic digesters, it is estimated that Boxelder and the community it serves are saving $175,000 annually.

Taylor Jordan is a process and innovation engineer at EnviroMix. Taylor focuses on biological nutrient removal and secondary treatment biology at the design, modeling, controls, operations, and startup phases of a project.

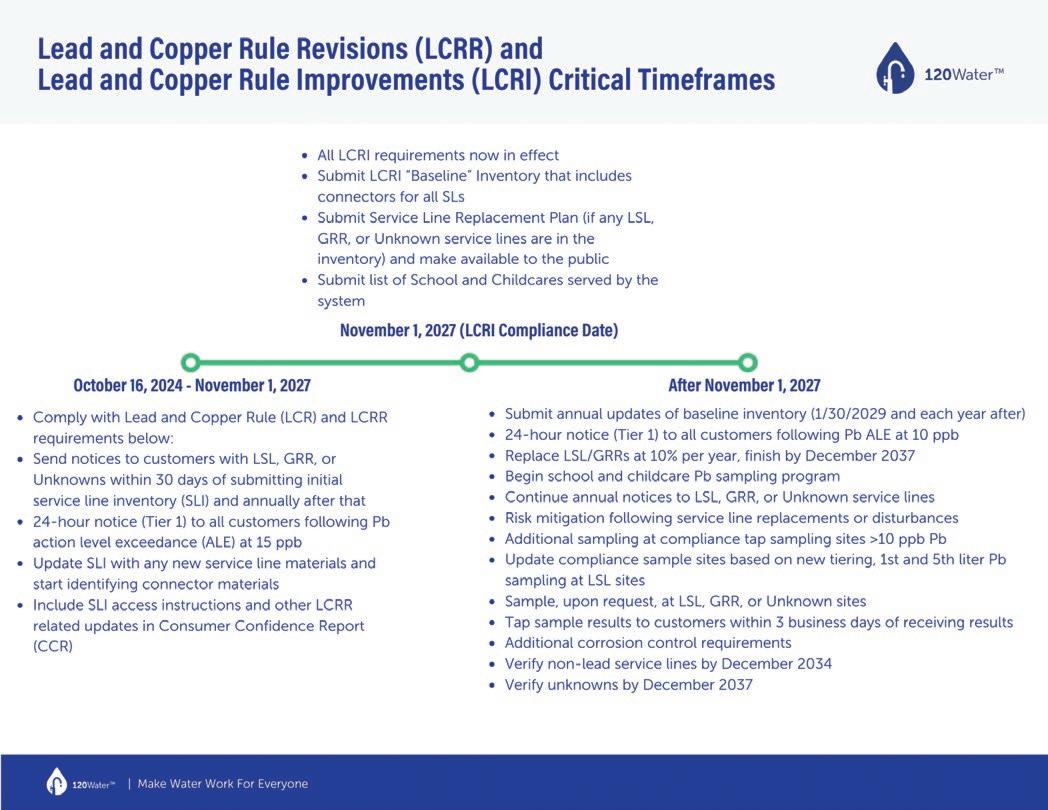

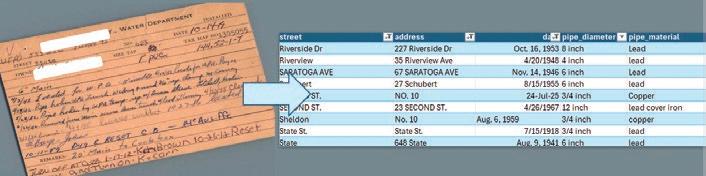

Jonathan Cuppett, Director of Water Quality Compliance, 120Water

As the November 1, 2027, deadline for the Lead and Copper Rule Improvements (LCRI) approaches, water systems are actively evaluating and strategizing their next steps –balancing near-term obligations with the need to build long-term, data-driven compliance programs. While the 2024 Lead and Copper Rule Revisions (LCRR) service line inventory marked the first major milestone, the journey is far from over. The upcoming requirements demand more than just compliance – they require careful planning, continued inventory verification, integration of new elements like connector material classification and non-lead validation, and robust data management. Though each system’s path will vary, those who start now will be better positioned to meet regulatory expectations and avoid additional burdens after 2027.

Before water systems can develop a compliance plan, it is critical to understand the timing of the LCR-LCRR-LCRI regulatory transition and what is required when. Figure 1 provides a timeline that captures specific deadlines for the different versions of the regulation and the associated requirements. Water systems should ensure they understand three key timeframes that are listed in Figure 1:

1. What LCR/LCRR requirements are currently in effect: October 16, 2024, to November 1, 2027

2. What LCRI elements need to be submitted on the LCRI compliance date: November 1, 2027

3. What LCRI programs may impact your system in the future: After November 1, 2027

With all the regulatory requirements and timelines, just determining where to start can be a challenge. Before systems shift their focus to the 2027 LCRI requirements, it is important to remember that notices must be sent to locations with lead service lines (LSL), galvanized requiring replacement (GRR), or unknown service lines on an annual basis (e.g. 2025, 2026, etc.) until the service line is classified as non-lead.

When preparing for LCRI requirements, continued focus on the service line inventory should remain a high priority for systems. Water systems were required to submit a service line inventory in October 2024, and the LCRI does not require another service line

inventory submission until the LCRI baseline inventory is due on November 1, 2027. However, the baseline inventory will be used as a tool to determine future compliance requirements for a variety of other LCRI elements. Continuing inventory efforts will best position systems to effectively comply with future LCRI requirements. Here are three inventory-related steps that utilities can take today to help them start their LCRI journey.

1. Identify Connector Materials:

Connectors (commonly referred to as pigtails or goosenecks) are short segments of piping not exceeding three feet that can be bent and are used for connections between service piping, typically connecting the service line to the main. Connectors are required to be added to the baseline inventory and categorized as lead, non-lead, unknown, or no connector present. While the connector material does not impact the classification for the entire service line (some states have different interpretations), water systems should review their records to classify as many connectors as possible prior to the submission deadline.

2. Start/Continue Service Line Verification: Whether you have hundreds or thousands of unknown service lines, identifying service line materials is the foundation of LCRI compliance. Unknown service lines will be assumed to be lead and included in the service line replacement rate that determines how many LSLs and GRRs need to be replaced each year. Water systems should develop a service line verification plan that assesses state-approved verification methods, evaluates opportunities to verify materials during normal field operations, and considers a data management strategy to ensure all the data is organized and accessible to various team members.

3. Initiate a Non-Lead Validation Process: Non-lead validation is a new LCRI requirement that some systems may not be familiar with. While this process is not required to be completed until December 2034, integrating the non-lead validation requirements into your current inventory verification program will result in more efficiency. The non-lead validation process requires a subset of your non-lead service lines to be visually verified at two points (e.g. one on the customer side and one on the system side) unless the service

lines were previously classified by any of the following criteria:

• Service line installed after 6/19/88 (or earlier state/local ban)

• Prior 2-point visual (e.g. one on the customer side and one on the system side)

• Previously Replaced LSL or GRR Water systems should review the EPA Inventory Validation Fact Sheet (www.epa.gov/system/files/documents/2024-10/final_lcri_factsheet_validation.pdf) to determine how the non-lead validation requirements apply to their system and how they can incorporate this process into their current service line verification efforts to reduce future efforts.

All of the LCR-LCRR-LCRI required elements may feel overwhelming. However, getting started now and continuing the inventory process should be a priority. Future compliance obligations can be minimized for those who are able to reduce unknown service lines in their system. Systems with unknowns in their baseline

inventory submission on November 1, 2027, will be forced into more requirements, including offering to sample at customer homes, submitting a service line replacement plan, and including unknowns in their service line replacement rate calculation.

The LCRI is a data-intensive regulation, with data management playing a critical role in overall compliance success. As your system works to meet LCRI’s many requirements and multiple deadlines, consider digital solutions that can help organize and manage the variety of data throughout your compliance journey.

Jonathan Cuppett is the Director of Water Quality Compliance for 120Water and has over two decades of experience in the water sector. For over 15 years, Jonathan has been active in research and policy related to Lead and Copper Rule issues and is a collaborator on various national LCR-related initiatives.

Water Technology Group is the area’s leader in the sales and service of Water and Wastewater treatment equipment and pumping systems. For over 40 years, we have dedicated ourselves to providing the most creative and innovative Water and Wastewater treatment and pumping solutions to Municipal customers. With our lineup of industry leading manufacturers, we have the resources to provide the solutions for your specif ic requirements.

Andrew Goldberg, Data Scientist, Brown and Caldwell

Artificial intelligence (AI) is rapidly reshaping many industries, including the water and environmental fields. With mounting pressures from aging infrastructure, workforce shifts, and regulatory demands, utilities across the Rocky Mountain region can significantly benefit from innovative AI technologies. This article outlines practical, real-world applications of AI, focused on a type of generative artificial intelligence, called large language models (LLMs), and provides clear steps utilities can follow to adopt this technology effectively.

LLMs are advanced AI tools that are trained to understand and generate human-like text by learning from an extensive amount of data, like books, journal articles, and websites. At their core, these models analyze language patterns to produce responses quickly. Unlike custom-built machine learning models, LLMs offer flexible solutions for many tasks “out-of-the-box,” such as summarizing documents, extracting information, analyzing data, and answering questions. These capabilities make LLMs

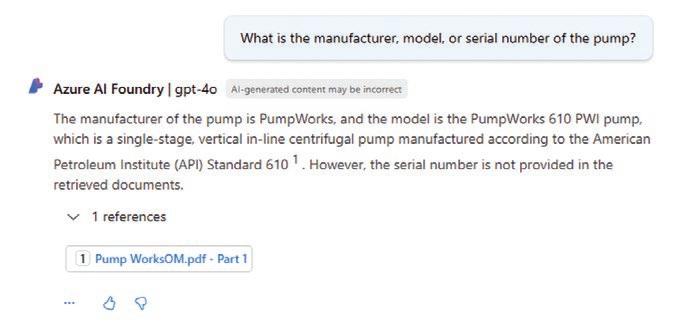

Figure 1: Sample user question focused on a facility’s asset inventory and an AI-generated response.

useful for utilities seeking efficiency and innovation without requiring substantial upfront investments.

LLMs offer productivity and efficiency in many tasks, including ones traditionally completed by water utility staff. Several water utilities have successfully piloted LLM applications to address technical challenges in operations, decision-making, capital improvement, and regulatory reporting, as described below.

A water utility in Texas piloted an AI-powered knowledge management chatbot that quickly extracts critical information from operations manuals and maintenance records. Instead of manually searching documents, which previously took several minutes per question, staff now receive accurate responses in seconds. This capability enables proactive maintenance and enhances overall facility management. An engineer at the facility involved in this pilot shared: “We constantly face complex decisions relying on fragmented documentation. AI rapidly captures and delivers institutional knowledge, helping us maintain reliability and performance.”

Utilities regularly balance service reliability against limited capital budgets. Another utility innovatively integrated AI into their asset management process, analyzing data from Geographic Information Systems (GIS) and maintenance systems to predict which assets were at risk of imminent failure.

The AI-driven insights enabled the utility to prioritize timely replacements, improving reliability and reducing unnecessary spending.

Compliance reporting can be tedious, involving data collection across numerous sources. A utility in the Northeast used AI to digitize, process, and analyze records rapidly, reducing project timelines by up to 95%.

AI tools automatically extract and organize data into required regulatory formats, freeing staff for more strategic tasks and significantly cutting costs.

PRACTICAL AI ADOPTION STRATEGIES

Adopting digital tools in the water and environmental fields requires careful planning, particularly due to risks surrounding data privacy, reliability and trustworthiness, technology integration, and responsible use. Utilities perform critical services that must be supported, rather than impeded, by technology. Below, these common concerns are described along with detailed mitigation strategies.

Innovative technology comes with understandable concerns like privacy, trustworthiness, integration, and responsible use. Utilities can mitigate these effectively:

• Data Security: Deploy AI within secure environments or private clouds. Use enterprise-grade privacy agreements to clearly outline data protection measures.

• Reliability & Trust: Regularly benchmark AI performance against defined tasks. Employ human oversight and continuous monitoring to build operational trust.

• Integration: Introduce AI gradually through manageable pilots that clearly demonstrate value. Provide role-specific training to ease technology adoption.

• Responsible Usage: Establish clear

Figure 2: AI technologies unlocked the value of data contained in thousands of scanned documents by automating data extraction and processing, increasing the efficiency of preparing regulatory reports.

governance policies limiting AI use to authorized personnel. Regular audits and user feedback loops ensure ethical compliance.

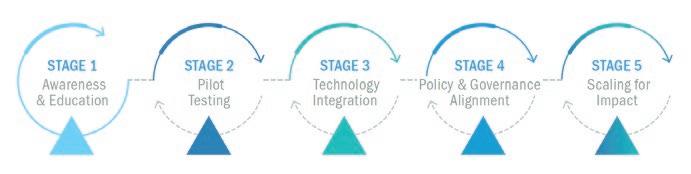

ADOPTION ROADMAP FOR UTILITIES

Successfully adopting AI requires a thoughtful, structured approach beginning with comprehensive awareness and education initiatives. We recommend a multi-stage process to advance the adoption of AI, as illustrated below:

1. Build Awareness: Educate staff about AI’s practical benefits through simple workshops or informational sessions.

2. Pilot Projects: Implement small, targeted pilot applications to demonstrate AI’s immediate value and feasibility.

3. Integration Planning: Develop detailed plans for integrating successful pilots into routine operations with minimal disruption.

4. Governance Framework: Create clear guidelines for AI use, ensuring responsible application and compliance.

5. Scale Gradually: Expand AI usage iteratively, using feedback and performance data to refine and enhance the solutions continuously. This iterative, feedback-driven approach ensures sustainable growth, continuous improvement, and broad organizational buy-in.