International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Haoyi Ren1 , Shilong Wang2

1,2School of Civil Engineering and Architecture, Anhui University of Science and Technology, Anhui, China

Abstract - To investigate the influence of rice husk ash (RHA) on the compressive strength and freeze-thaw resistance of cement mortar, the WAW-1000 universal testing machine was conducted to analyze the compressive mechanical properties of cement mortar specimens under varying RHA replacement ratios and freeze-thaw cycles. Scanning Electron Microscope (SEM) was further used to analyzethechangesinthemicrostructure ofcementmortar The results demonstrated that the compressive strength of cement mortar increased with the increased of RHA replacement ratios. After curing for 28 days, the compressive strength of specimens with 5% RHA replacementforsilicafumeincreasedby70.4%comparedto the control group. With an increasing number of freezethaw cycles, the rate of compressive strength reduction in cementmortar containingricehuskashandsilicafumewas significantly slower than the control group. SEM microstructural analysis revealed that RHA effectively mitigates damage induced by freeze-thaw cycles, thereby improvingthedurabilityofcementmortar.

Key Words: Rice husk ash; Cement mortar; Freeze-thaw cycles;Freeze-thawresistance;Compressivestrength

Thecoldregionsarewidelydistributed inthenorthernof China [1] With the shift of China's social economy and infrastructure construction towards the western region, the development of cold region engineering has progressedrapidly.However,buildingsincoldregionsare inevitably affected by freeze-thaw cycles [2], which can cause significant harm to the projects. According to relevantdatastatistics[3],thecementindustryhasalarge energy consumption, leading to the greenhouse gas emissionsaccountfor8%to10%oftheglobaltotal.Atthe same time, natural resources are becoming scarcer, and theuseofindustrialwasteincementconcreteisbecoming morecommon[4].Forexample,theuseofslagandflyash in concrete can not only reduce resource waste and the pollutioncausedbywasteaccumulation,butalsopromote the development of new low-carbon and environmentally friendlybuildingmaterials,generating excellenteconomic andenvironmentalbenefits[5-6].

China, the world's largest rice-growing country, produces about 40 million tons of rice husks every year [7]. However, due to high hardness and difficult

decomposition of rice husks, serious environmental pollution has arisen. Researchers from around the world have actively discussed and conducted experimental studies on the utilization of rice husk ash.Countries, such as the United States, the former Soviet Union, Japan, and India,begantostudyitspropertiesatanearlystage.China hascarriedoutmoresystematicresearchsincethe1980s. Through research, it has been found that the chemical compositionof ricehuskscalcinedbyhightemperature is similar to silica fume, containing a large amount of highly active silica. Incorporating it into cement-based composites can significantly improve the mechanical properties[8],workability[9],anddurability[10].

Therefore, this study uses the rice husk ash calcined at a controlled temperature of 600°C to replaces part of the silica fume, investigating its influence on the compressive mechanical properties and frost resistance of cement mortar. The results will provide a reference for the widespreadapplicationofricehuskashinconcrete.

In this study, the rice husk is calcined into ash at a controlled temperature of 600°C. The grade of cement is ordinaryPortlandcementof42.5.Thefinenessmodulusof thesandis1.69,andthesilicacontentofthesilicafumeis 96%. The mixing and curing water used are distilled water.

Firstly, Put the rice husks into the hydrochloric acid solution, stir thoroughly, and soak for 1 hour. Then, repeatedly rinse the acid-soaked rice husks with distilled water until the rinsing solution is in a neutral state. Next, put the rinsed rice husks into an oven for drying. Subsequently, put the dried rice husks into a muffle furnace and calcine them at a stability temperature of 600°Cfor3hours.Finally,putthecalcinedricehusksinto an ice-water mixture at 0°C for rapid cooling. After cooling,grindthemintoafinepowderandsieveitthrough a180-meshsieve.

The mix proportion in this studyis basedon the research findings from existing references [11-13]. The materials mix proportions (kg/m³) are as follows: cement: sand: water=330:1210:160

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

In the experiment, the cement mortar mixture is mechanically stirred and then fabricated the specimens with6mixproportions.Thedetailprogressisasfollow.

Prepare specimens with rice husk ash replacement ratios forsilicafumeof0%,10%,30%,50%,70%,and90%,and mark them with G1, G2, G3, G4, G5, and G6 respectively. According to the mix proportion and the requirements in the Test Method for Mechanical Properties of Ordinary Concrete(GB50081)toprepareandcurethespecimens

Table -1: Cementmortarratio

Groups water Sand cement Ricehuskash Silicafume

G1 0.038 0.423 0.104 0 0.011

G2 0.038 0.423 0.104 0.001 0.010

G3 0.038 0.423 0.104 0.003 0.008

G4 0.038 0.423 0.104 0.005 0.006

G5 0.038 0.423 0.104 0.008 0.004

G6 0.038 0.423 0.104 0.010 0.001

The 70.7mm×70.7mm×70.7mm cubic mold is used to make the specimens of cement mortar. Pour the raw materials for 6 groups with different mix ratios, 3 specimensineachgroup.Then,removethespecimensand soaktheminwaterat(20±2)°Cforcuringfor4days.

The freeze-thaw cycle is carried out for cement mortar specimens in accordance with the standard GB/T 500822009[14] Standard for Test methods for Long-term Performance and Durability of ordinary concrete. The freezingtemperatureis-20±2℃,thethawingtemperature is20±2℃ Thefreezingandthawingtimeareboth4hours, and one cycle lasts 8 hours The number of freeze-thaw cyclesinthis study is20,dividedinto three groups:0, 10, and 20 cycles. The specimen without freeze-thaw cycles wasusedasthecontrolgroup.

Theinstrumenttypeusedforfreeze-thawcyclesisSTDW40D high and low temperature test chamber, the temperature is set -20℃, the specimen is put in and the freezing time is set to 4 hours. At the end of 4 hours, the specimen was taken out and put into room temperature (20±2℃) for 4 hours. When the thawing time is over, one freeze-thaw cycle is completed. After reaching 0, 10 and 20 cycles, the basic physical of the specimen were measured,andcarriedoutstaticuniaxialcompressiontest toanalyzethemechanicalproperties

Static uniaxial compression test equipment is WAW-1000 universal testing machine, the test adopts the displacementloadingmethod,theloadingrateis0.01m/s, themaximumloadingforceis1000kN.

Before the static uniaxial compression experiment, the zeropointoftheforcemeasuringshouldbecorrectedand adjusted. The cross-section of specimen was measured with a vernier caliper. Then, put the specimen in the centeroftheplaten.Duringtheexperiment,applytheload slowly and evenly. Record the peak load when the specimen is compressed, and continue recording the load until the cement test block is compressed to the point of failure. After the experiment, the uniaxial compressive stress-strain curve of cement specimen is obtained accordingtotheexperimentaldata.

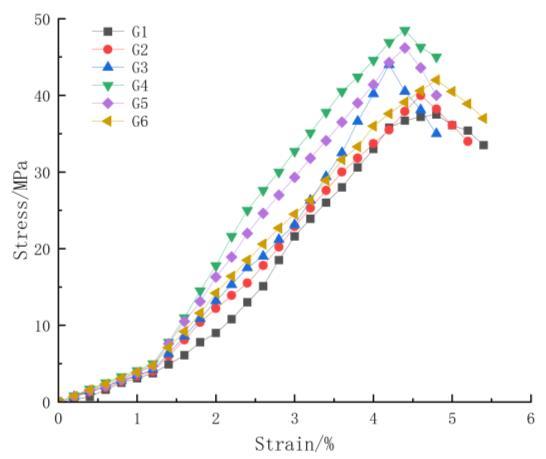

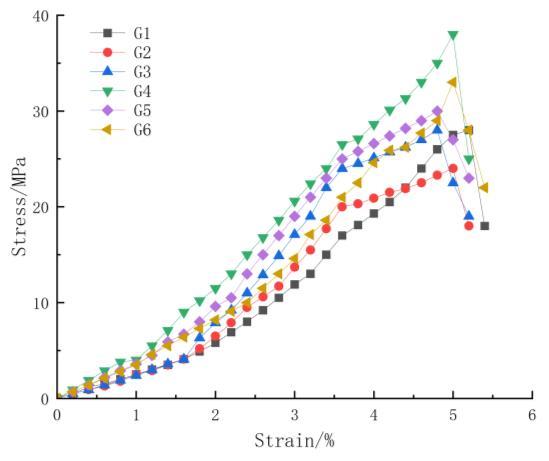

The stress-strain curves of cement mortar specimens under different freeze-thaw cycles exhibit unimodal and typical characteristics of plastic materials. In the compaction stage, the stress of the cement mortar specimen increases gradually with the increase of strain. When entering the elastic deformation stage, the stressstraincurveis basicallylinear.Withtheincreaseofstrain, the slope of stress-strain curve increases, and the deformation of the specimen is also intensified, and the specimen enters the plasticstage.After reaching the peak stress,itfinallyentersthefailurestage.Itcanbeseenfrom Fig.1,2and3thatwiththeincreaseoffreeze-thawcycles, the peak stress of rice husk ash specimens with different contents as they reach failure decreases gradually. The peak stress is at a minimum when freeze-thaw cycles reach 20. With the increase of rice husk ash replacement ratio, the peak strain of specimens with different freezethawcyclesincreasesfirstandthendecreases.

Fig -1:The0thfreeze-thawcycle

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

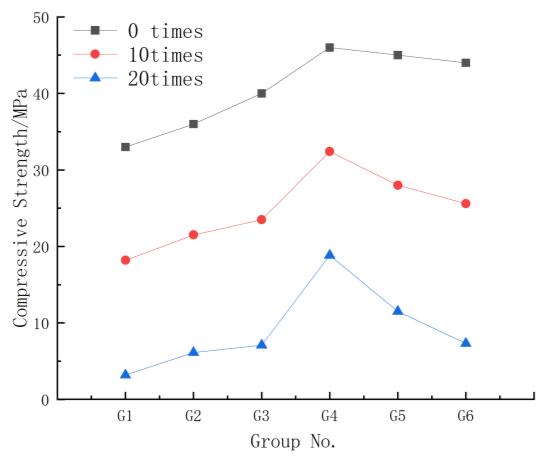

-4: Compressivestrengthcementmortarafter differentfreeze-thawcycles

Figure 4 shows the compressive strength test results of specimenscontainingdifferentcontentsricehuskashand silica fume after curing 28d. The specimens contained 30% and 50% of rice husk ash replacing silica fume is higher compressive strength than the 100% silica fume. Therefore,whentheproportionofricehuskashreplacing

silica fume is less than 50%, the compressive strength of cement mortar can be improved. The compressive strength of the cement mortar specimens with 70% and 90%ricehuskashreplacingsilicafumeis higherthanthe 100% silica fume Moreover, under equivalent dosage conditions, the specimens incorporating only SF demonstratedlowercompressivestrengththanthosewith combined incorporation of RHA and SF. This is because whentheparticlesizeandthemassfractionofSiO2 arenot much different, the existence form of SiO2 will cause the differenceinhydrationreaction,leadingtovarying effects on compressive strength [15]. In addition to amorphous SiO2, rice husk ash also contains a certain amount of crystalline phase SiO2, which cannot promote hydration [16]. With the increase of freeze-thaw cycles, the compressive strength of ricehusk ashand cementmortar specimenswithdifferentdosagedecreasesgradually. This is because the volume of water inside the specimen increaseswhenitfreezes,causingstressanddeformation. During the thawing process, the water penetrates the interior, leading to further damage, which reduces the compressive strength of the specimen. After 20 freezethaw cycles, the compressive strength decreased significantly. Due to significant internal damage to the mortar, obvious cracks appeared on the surface, and granularmaterialbegantofalloff.Asaresult,thestrength ofthemortardecreasedsignificantlyatthisstage.

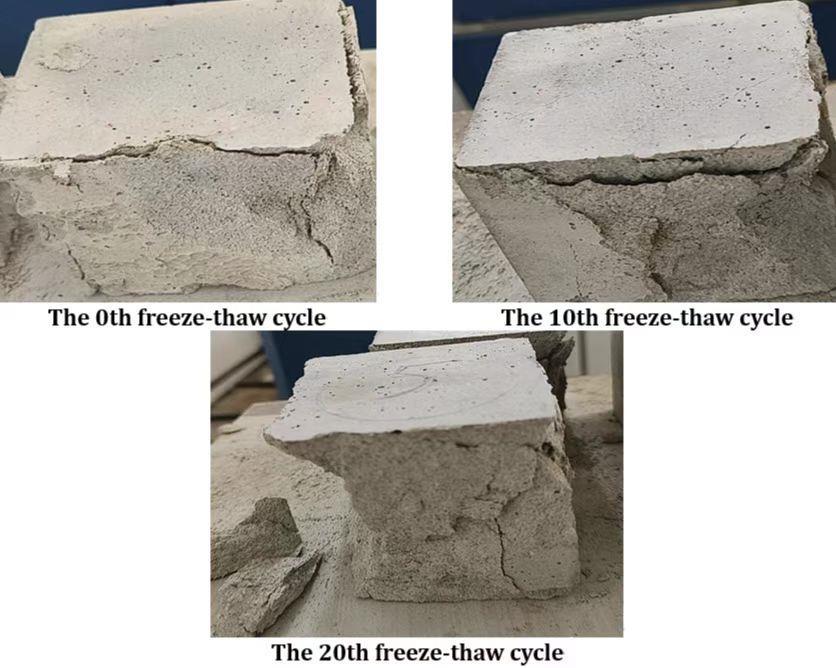

ItcanbeseenfromFig -5thatwiththeincreaseoffreezethaw cycles of cement mortar, the surface erosion holes increaseandthesurroundingcornersarepassivated.This phenomenon shows that with the same dosage, the surface damage of the specimen contained different rice husk ash and silica fume will be more serious with the increaseoffreeze-thawfrequency.

International Research

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

The failure patterns of specimens under different freezethawcyclescanbeseenfromFigure6.Figure6showsthe shear failure occurs gradually with the increase of the number of freeze-thaw cycles of the specimen. The more freeze-thawcyclesofthespecimen,themoremacroscopic cracks will be generated during failure. The water inside themortar graduallypenetrated intotheentire specimen. Because of thermal expansion and contraction, the water inside the specimen continuously transforms from liquid statetosolidstate,resultinginmoreandmorecracksand pores inside the specimen. At this time, the mortar specimens have started to become brittle and exhibit peeling after loading, leading to a reduction in the compressivestrengthofthespecimen.

4. MICROSTRUCTURAL ANALYSIS

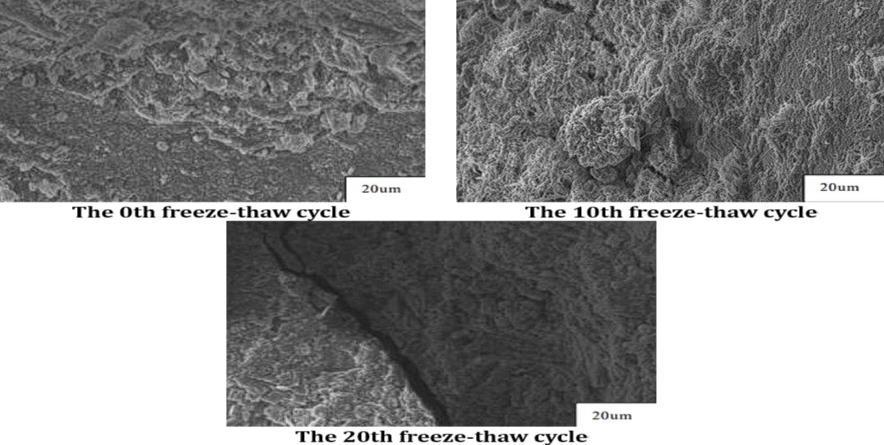

In order to investigate the microstructure changes of the specimen containing the different rice husk ash and silica fume content under different freeze-thaw cycles, the SEM testwascarriedouttoanalyzetheinternalmicrostructure ofthespecimen.

Select proper and small fragments from the broken specimen and soak them with ethanol. After soaking, put the small fragments into the drying oven at 60℃ and lasting for 24 hours. After drying, the fragments were conductedtothediffractiongoldsprayingandthenplaced in a Flex SEM 1000 electron microscope scanner for SEM testing.

As shown in Figure 7, during the initial stages of freezethaw cycles, the G4 group specimens exhibited minimal damage to the binder caused by frost heave forces [17], owing to their denser internal structure, larger contact area,andincreasedbinderthickness.

With the increase of freeze-thaw cycle, the expansion pressure from freeze-thaw cycles gradually damages the intergranular cement. Under the periodic expansion pressure, the internal crack initiate, expand, and eventuallycausefracture.Theinternalwaterisalsointhe process of "liquid - solid - liquid" transformation brings thetwomainlydamagesonthespecimen.Ontheonehand, when the water freezes into ice, the volume of the specimenincreasesandfurtherexpandtheinternalcracks angpores.Ontheotherhand,whentheiceistransformed into water, it continuously penetrates into the specimen anderodesthecracksandpores.Otherwise,underfreezethaw conditions, the cement is dissolved by water and migrates with water. As a result, the connection between the particles of the specimen with large water content is completely destroyed, and some particles become loose. Macroscopically, the internal pores of the specimen graduallyexpandedandthesurfaceparticlesfelloff.

Inthisstudy,ricehusk ash, cement,silica fume, sand,and waterareusedasrawmaterialstopreparecementmortar specimens containing different amounts of rice husk ash. The rice husk ash is mixed into the cement mortar to replacepartofthesilicafume,whichnotonlyreducesthe amountofsilicafumerequiredbutalsodecreasesthecost ofthecementmortar.Thishelpstoprepareenergy-saving, environmentally friendly building materials and achieve the goals of energy conservation and environmental protection in green building construction. The properties of rice husk ash cement mortar were studied experimentally,withthedosageofricehuskashusedasa variable in the compressive strength tests. Additionally, compressive tests were conducted on cement mortar specimens subjected to different freeze-thaw cycles, followed by macro-structural and micro-structural comparativeanalysis.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

As the proportion of rice husk ash replacing silica fume increases,thedamagetothespecimensinitiallydecreases, thenincreases,causingthe structuretobecomelooseand resultinginadecreaseincompressivestrength

ThisworkwasfundedbyAnhuiProvincialinnovationand entrepreneurship training program for college students (No.202310361107)

[1] W. Ma, D. Wang, "Review and prospect of permafrost mechanics research in China over the past 50 years," Chinese Journal of Geotechnical Engineering, vol. 34, no.04,2012,pp.625-640.

[2] W. Fang, "Fractal study on mechanical properties and damage characteristics of sandstone under freezethaw cycles," Ph.D. dissertation, China University of Geosciences, 2019, doi:10.27492/d.cnki.gzdzu.2019.000053.

[3] S. Lu, "Study on pretreatment of rice husk and calcination conditions affecting the activity of rice husk ash," Master's thesis, Shenyang University of Chemical Technology, 2019, doi:10.27905/d.cnki.gsghy.2019.000025.

[4] X. Wu, J. Liu, H. Peng, et al., "Effect of rice husk ash calcined at different temperatures on cement mortar properties," Journal of Wuhan Polytechnic University, vol.40,no.04,2021,pp.55-59.

[5] T. Shi, Z. Wang, Z. Liu, H. Wu, "Research status on the application of biomass ash and silica fume in concrete," Building Materials Technology and Application,no.4,2021,pp.11-14.

[6] T. Shi, Z. Wang, Z. Liu, et al., "Research status on the application of biomass ash and silica fume in concrete," Building Materials Technology and Application, no. 04, 2021, pp. 11-14, doi:10.13923/j.cnki.cn14-1291/tu.2021.04.003.

[7] C.Zhang,Z.Lou,"Researchstatusofricehuskandrice husk ash in cement concrete," Shaanxi Journal of Agricultural Sciences, vol. 56, no. 06, 2010, pp. 124126.

[8] Q. Feng, Y. Yang, Z. Tong, et al., "Frost resistance characteristics of concrete incorporating highly reactive rice husk ash (in Chinese with English abstract)," Journal of the ChineseCeramicSociety, no. S1,2008,pp.136-139.

[9] H. K. Venkatanarayanan, P. R. Rangaraju, "Effect of grinding of low-carbon rice husk ash on the

microstructure and performance properties of blended cement concrete," Cement and Concrete Composites,vol.55,2015,pp.348-363.

[10] M. H. Zhang, R. Lastra, V. M. Malhotra, "Some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste," Cement and ConcreteResearch,vol.26,no.6,1996,pp.963-977.

[11] S. Zhang, D. Huang, B. Yang, et al., "Effect of blast furnace slag content on capillary pore structure of concrete under different water-cement ratios and curingages,"JournalofJinlingInstituteofTechnology, vol. 38, no. 01, 2022, pp. 79-84, doi:10.16515/j.cnki.32-1722/n.2022.01.013.

[12] J. Wan, A. Zhu, "Study on the influence of lithium slag on the mechanical properties of cement mortar," Concrete,no.07,2022,pp.130-133.

[13] J.Tang,L.Ning,Z.Zhang,etal.,"Researchonrepeated thermal damage of cement mortar based on low-field nuclear magnetic resonance technology," Bulletin of theChineseCeramicSociety,vol.41, no.10,2022, pp. 3403-3412, doi:10.16552/j.cnki.issn10011625.2022.10.013.

[14] GB/T50082-2009,Standardfortestmethodsoflongtermperformanceanddurabilityofordinaryconcrete [S],2009.

[15] Y.Hamzeh,K. P.Ziabari,J. Torkaman,etal.,"Studyon theeffectsofwhitericehuskashandfibrousmaterials additions on some properties of fiber-cement composites," Journal of Environmental Management, vol.117C,2013,pp.263-267.

[16] D. Chopra, R. Siddique, K. Kunal, "Strength, permeability and microstructure of self-compacting concrete containing rice husk ash," Biosystems Engineering,vol.130,2015,pp.72-80.

[17] H. Jia, Q. Liu, W. Xiang, et al, "Research on damage propagation model of saturated sandstone under freeze-thaw cycles," Chinese Journal of Rock Mechanics and Engineering, vol. 32, no. S2, 2013, pp. 3049-3055.