@CPN_mag cpnonline.co.uk

cpn@hamerville.co.uk e

Construction Plant News, Regal House, Regal Way, Watford, Herts, WD24 4YF.

PartsForMachines.com tells CPN how its approach to aftermarket parts supply marks a departure from the norm

17 This month The Dig travels forwards and backwards in JCB’s Dual Drive backhoe.

20 The CPN team gets its hands on Hyundai’s new HD130A dozer and brings you its first impressions.

22 CPN goes on patrol with the Metropolitan police’s commercial vehicle unit to check the safety of abnormal and indivisible loads.

With PlantWorx 2025 very much on the horizon ( go to page 12 for the beginning of our preview), curiosity got the better of us, and we decided to have a look at the last iteration of PlantWorx two years ago.

Our review of the event painted a lively picture with visitors galore, unimaginably good British weather and a slew of new machine and equipment introductions. Significant among those newly launched and unveiled machines were the number of battery-electric models – wheeled loaders, mini excavators, telehandlers – all promising diesel-like productivity without the noise, emissions and disapproving looks from local authorities.

The buzz was very much of a new golden age of quiet, efficient, productive equipment that operators would learn to love, having mastered the charging routines and/or working with an electric cable tethered to their machines.

Fast forward two years and that buzz seems to have diminished as buyers and operators come to terms with the high cost of the machines themselves - often three times that of diesel models – along with the limited charging infrastructure. Figures from the Construction Equipment Association (CEA) would seem to support this. Electric equipment sales, once hailed as a major growth area, have slipped. After a strong showing in 2022 and 2023, sales dropped significantly in 2024, falling further than the rest of the market.

The UK is not alone in this lukewarm embrace of everything electric though. Even China, which is apparently the largest market for this equipment, and is more accepting of battery/electric technology, in part due to being manufacturers of the batteries themselves, only registers a 2% market share for electric machines. And for the record the EU’s figure is about 1.5% of the overall market.

So, returning to the PlantWorx theme, it will be interesting to hear the views of exhibiting manufacturers, of operators, of owners, of dealers, this time round. What will prime the pump in terms of sales of battery/electric machines? Are people convinced by their green credentials? Are operators prepared to adopt new working routines? Are we relying on city authorities to impose zero emission construction sites and mandate quiet, non-intrusive machinery?

Maybe the answer lies in producing battery/electric construction equipment that mimics the diesel equivalents ie. a truly full day’s work with no interruptions? Or awarding authorities incentivising contractors to use environmentally friendly machines, a more carrot than stick approach?

The upsides of electric machines are huge, but as yet, we seem not to be making the most of them. Perhaps it is only a matter of time. Maybe we got our hopes up too early back in 2023 and that 2025 will bring a more sanguine and realistic view.

That aside, we are looking forward to PlantWorx, taking in the new kit and experiencing all the action. It’s a new venue too, so an added incentive to attend.

We’ll see you there!

Happy reading

The CPN Team

Editor JOHNNY DOBBYN JOHN LEVICK cpn@hamerville.co.uk

Advertising Manager

MATTHEW BOASE mboase@hamerville.co.uk

Group Manager ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer DONNA BOOTH

Production Assistant CLAIRE PICTON

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2025

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

LATEST DATA FROM THE CONSTRUCTION SECTOR POINTS TO A MODEST RECOVERY IN OUTPUT AND MACHINERY SALES, WITH CAUTIOUS OPTIMISM FOR THE YEAR AHEAD, SAYS THE CEA.

IN A DEAL WITH THE ADMINISTRATORS AFI RENTALS HAS CONFIRMED THE ACQUISITION OF MORE THAN 500 ASSETS FROM THE FORMER QUICK REACH FLEET.

The purchase, made for an undisclosed sum, reflects AFI’s ongoing commitment to fleet investment and availability across the UK market.

A portion of the powered access machines will be integrated into AFI’s rental fleet. The remaining units will be added to stock at AJ Access Platforms and made available for sale.

David McNicholas, AFI Group CEO, commented: “The addition of these machines will support the ongoing growth of our rental and resale businesses. In particular, the fleet additions provide an extended number and range of Superset booms and scissors to support our customers.” The deal includes machines from leading manufacturers.

WWW.RDR.LINK/CBD002 i

QUATTRO GROUP HAS SOLD ITS SCOTTISH-BASED SUBSIDIARY, AB2K, IN A MANAGEMENT BUYOUT THAT FORMS PART OF A SECTOR-LED SEPARATION.

The move enables both businesses to specialise in their respective core industries, says the company.

In a statement, John Murphy, managing director of Quattro Group, said: “AB2K has been a valued part of the Quattro Group for the past six years. However, as our core focus on rail plant has increasingly diverged from AB2K’s construction plant operations, we recognised that it was the right time to part ways.

“In a mutually beneficial agreement, we have completed the successful sale of AB2K through a management buyout by Stuart Gardner and Mark Kirkwood, who will take the reins as joint managing directors in Scotland. Their deep sector knowledge and leadership experience make them ideally placed to guide AB2K through its next chapter.”

WWW.RDR.LINK/CBD003 i

and Caterpillar’s centennial year, we are offering everyone the opportunity to own a part of its heritage, whether by integrating the Cat 301.6 excavator into their operations or utilising a Cat DE110E2 genset to power essential infrastructure.”

WWW.RDR.LINK/CBD004 i

For more information

IN A MOVE TO HELP CUSTOMERS THAT PREFER TO DO THEIR OWN MAINTENANCE AND REPAIRS CATERPILLAR HAS LAUNCHED A COMPREHENSIVE LIBRARY OF HOW-TO VIDEOS AND ARTICLES. The library includes a new series of do-it-yourself videos designed to help customers confidently maintain Cat equipment.

“Customers can view these short how-to videos with the goal of making it simple, clear, and easy for them to maintain their Cat equipment,” said Jay Ramasamy, vice president, sales and marketing for Caterpillar’s Construction Industries Services Division (CISD).”

According to Caterpillar the video series serves as a supplement to the machine’s operation and maintenance manual (OMM) and boosts the confidence of visual learners to get the job done right. The current library includes nearly 60 how-to videos produced in English with subtitles in 23 different languages, and Caterpillar continues to expand the variety of videos offered.

FOLLOWING INCREASED USE OF HUMAN FORM RECOGNITION SYSTEMS (HFRS) IN CONSTRUCTION, THE CONSTRUCTION INDUSTRY PLANT SAFETY GROUP HAS LAUNCHED A NEW PUBLICATION ENTITLED GOOD PRACTICE GUIDANCE FOR THE USE OF MACHINE-MOUNTED HUMAN FORM RECOGNITION SYSTEMS.

This is the latest publication produced by the Construction Industry Plant Safety Group, a pan-sector group managed by the Construction Plant-hire Association (CPA) and set up through the Health & Safety Executive (HSE) a number of years ago to provide guidance on specific construction plant safety topics. The new guidance document can be downloaded free of charge from the CPA website at https://cpa.uk.net/plant-safetygroup/

The comprehensive publication extends to just over 50 pages and aims to advise and inform plant owners, users, operators, managers, OEMs and third-party suppliers about considerations for the fitment, use and management of human form recognition systems installed on plant to detect and warn of human presence in defined danger zones.

WWW.RDR.LINK/CBD006 i

For more information

WWW.RDR.LINK/CBD005 i

ONE OF THE UK’S LEADING SPIDER CRANE COMPANIES IS WARNING THE INDUSTRY TO PREPARE FOR A SIGNIFICANT CHANGE IN COMPLIANCE.

Jekko Cranes says major contractors are starting to specify that spider cranes brought onto their sites must be compliant with the mobile crane standard EN 13000. However, most spider cranes in the UK do not meet these requirements.

“We are already receiving enquiries from Tier One contractors, stipulating that spider cranes must meet EN 13000,” said Andrew Foster, managing director of Jekko Cranes UK. “It is only a matter of time before this shift becomes mainstream practice in the market. It is therefore vital that the industry starts preparing now to meet these changing customer needs.

“With contractors increasingly insisting on EN 13000 compliance, now is a good time for crane hire companies, contract lifters and steel erectors to ensure that their next investment is spider cranes that meet this standard,” he added.

WWW.RDR.LINK/CBD007 i

FOR THE SECOND YEAR IN SUCCESSION, METSO UK AND IRELAND DISTRIBUTOR, MCHALE PLANT SALES HAS BEEN FETED BY THE FINNISH CRUSHERS MANUFACTURER, THIS TIME AS RECIPIENTS OF ITS COVETED ‘DISTRIBUTOR OF THE YEAR 2025’ AWARD CHOSEN FROM ITS WORLDWIDE DISTRIBUTOR NETWORK.

First appointed Metso distributors in Ireland and Northern Ireland some 10 years ago, McHale received a major boost when, in April 2023, its brief was extended to include the English, Scottish and Welsh markets.

Describing it as an ‘honour’ at having been chosen Metso Distributor of the Year 2025 from amongst its global distributor network, managing director, Tim Shanahan described the award as “a tribute to all within the company – in Tamworth, Edinburgh, Rathcoole, and at our headquarters in Birdhill – whose round-the-clock commitment has been the key factor in helping us to strengthen our presence in all markets”.

WWW.RDR.LINK/CBD008 i

For more information

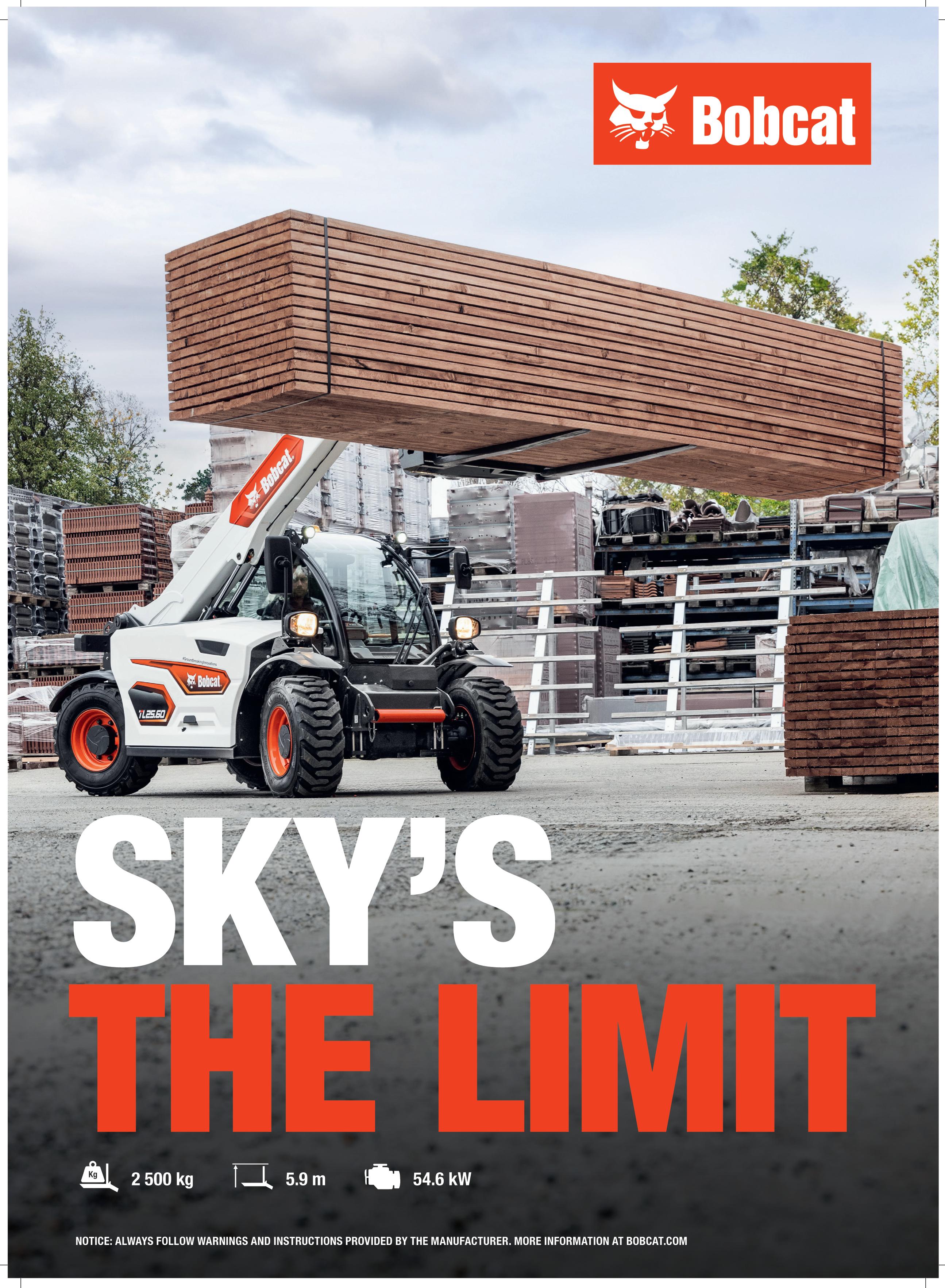

BOBCAT HAS APPOINTED LIVERPOOL-BASED HUSKISSON LTD AS THE COMPANY’S NEW AUTHORISED DEALER FOR MERSEYSIDE, CHESHIRE AND GREATER MANCHESTER, CLWYD IN NORTH WALES AND THE ISLE OF MAN. HUSKISSON REPLACES THE PREVIOUS DEALER FOR THIS AREA, NORWEST PLANT LTD.

Dealer principal, Dave Parr, said: “We are delighted to be appointed as the new authorised Bobcat dealer for the Northwest and North Wales. As a company, we have had well over 40 years of success with the Bobcat brand, with our first dealership dating back to 1981. We are enjoying selling an expanded range of equipment at Bobcat, where the world-famous compact equipment, excavators, telehandlers and attachments, light compaction and ground maintenance products are complemented by the sister dealer network offering forklifts and warehouse equipment and portable power.”

WWW.RDR.LINK/CBD009 i

the reputation we’ve established. Now, with Sussex and Surrey added to our territory, we’re ready to bring that same level of support and professionalism to even more businesses in construction, utilities, landscaping and civil engineering.”

FOR

For more information

WWW.RDR.LINK/CBD010 i

THE CONSTRUCTION PLANTHIRE ASSOCIATION (CPA) HAS ANNOUNCED A BRAND-NEW HIGHLIGHT ON THE CPA CALENDAR, THE CPA GALA DINNER 2025.

The prestigious black-tie event is set to take place in St George’s Hall in Liverpool on Thursday 6th November 2025.

According to the association it promises to be an unforgettable night of fine dining, legendary speakers, and industry celebration, with a three-course menu prepared by a team of 5* Michelin experienced chefs. Standard tables of 11 can be booked online at www.cpa.uk.net/cpa-gala-dinner-2025 at a cost of £3,000 plus VAT.

Steve Mulholland, CPA CEO, said: “We thought it was fitting to get everyone together to celebrate what a wonderful industry we work in. There have been testing times for the sector over the last few years, and the gala dinner will allow us all to enjoy an evening of great company and excellent food in the stunning surroundings of St George’s Hall in the heart of Liverpool.”

For more information WWW.RDR.LINK/CBD011 i

This new partnership expands GGR Group’s product portfolio with cutting-edge load levelling technology, available to UK customers for both hire and purchase.

When lifting heavy, imbalanced, or irregularly shaped loads, precision and control are critical. Ganterud’s levelling yokes, also known as lifting yokes, are designed to maintain load stability by enabling operators to adjust the centre of gravity at the touch of a button. These high-performance tools are ideal for safely handling items such as precast concrete elements, stair units, and steel structures.

Graeme Riley, CEO of GGR Group, commented: “We’re always looking for ways to help our customers work more safely and efficiently. The addition of Ganterud levelling yokes provides a practical solution for complex lifts, ensuring greater control and reducing time spent on crane operations.”

GGR Group offers five models from the Ganterud range, each engineered to meet specific lifting challenges.

WWW.RDR.LINK/CBD012 i

Abhishek Tanwar, the inspiration behind the first digital all-parts aftermarket parts platform, cut his teeth in the machinery sector selling parts to copper mines in Zambia. This began a life-long education about what makes various manufacturing companies tick –and some of the opportunities and challenges they face.

Overtime he identified major deficiencies in their ways of supporting small machinery owners in their operations. For example, he believes that large manufacturers are suited to dealing with large businesses. It is often challenging for them to effectively support small business owners and entrepreneurs.

He cites how OEM profit margins are small, with their parts, therefore, often carrying the heavier burden of profitability – which means escalating maintenance costs for end-users.

Industry also faces challenges of capital inefficiency, where large stock is kept at every stage of the supply chain, in theory, to ensure availability. However, parts are nevertheless often unavailable, which leads to costly downtime for the business owner.

Identifying the right part for machinery is difficult - and this vital information rests with a select few. And, even when available, there is a

thinks it has found the recipe for success when it comes to supplying aftermarket parts. CPN caught up with founder Abhishek Tanwar to hear his story.

Abhishek and his co-founders got their collective heads together and created a business from the ground up that is built to support owner-operators for all their needs related to parts, consumables and tools. They felt that the best, most efficient way to build this business would be online only – but, crucially, backed up by great support and service. “And then,” he declares, “we imaginatively decided to call it PartsForMachines! “

They decided on some key operating principles. They would create a one stop shop catering to the needs of small businesses and owner operators of machinery

They also sought to create an ecosystem of industry experts with deep expertise in one product area - such as turbochargers, radiators, or side view mirrors – linked with a mature manufacturing or supply chain and then, in turn, link them with customers

They determined to use e-commerce to make the process of identifying and buying tools seamless and cost-effective.

There would be extensive use of digital tools

to build and create a low-cost, low-capitalintensive business and transfer these benefits to PartsForMachines’ customer base through lowering their costs.

Starting as an e-commerce business with one brand and 1000 product references in 2021 PartsForMachines now has over 250,000 products and 60 supplier partners. It anticipates growing to over one million part references by the middle of next year, and well over 100 supplier partners –such is the strength of the response it is now seeing.

Technology driven

PartsForMachines believes it is at the forefront of the technological changes happening in the industry. However, the company sees the manufacturing, construction and agricultural sectors all lagging behind in embracing change.

“For example, e-commerce is now ubiquitous in our daily lives,” explains Abhishek, “but it’s yet to fully penetrate our sector. We note, with some degree of alarm, a similar trend relating to AI and the machinery sector. AI will likely render many roles, that are knowledge or servicebased, obsolete but, at the same time, it will also help make the roles of tradesmen and woman future-proof.

“AI has helped us reduce our time onboarding new suppliers on the site by 75%

over the past year. We are also embracing AI in customer service and anticipate a 90% reduction in costs while offering better service for our customers’ needs. Our 4.9/5.0 trust pilot ratings clearly demonstrate that we can provide a great customer service at lower cost.”

Having launched in the UK, it has always been the intention to make PartsForMachines.com an

“... e-commerce is now ubiquitous in our daily lives, but it's yet to fully penetrate our sector...”

international platform. The first steps came recently with the launch of PartsForMachines for Ireland and, here again, with the help of AI, PartsForMachines, in foreign countries will launch, language-native, in the near future.

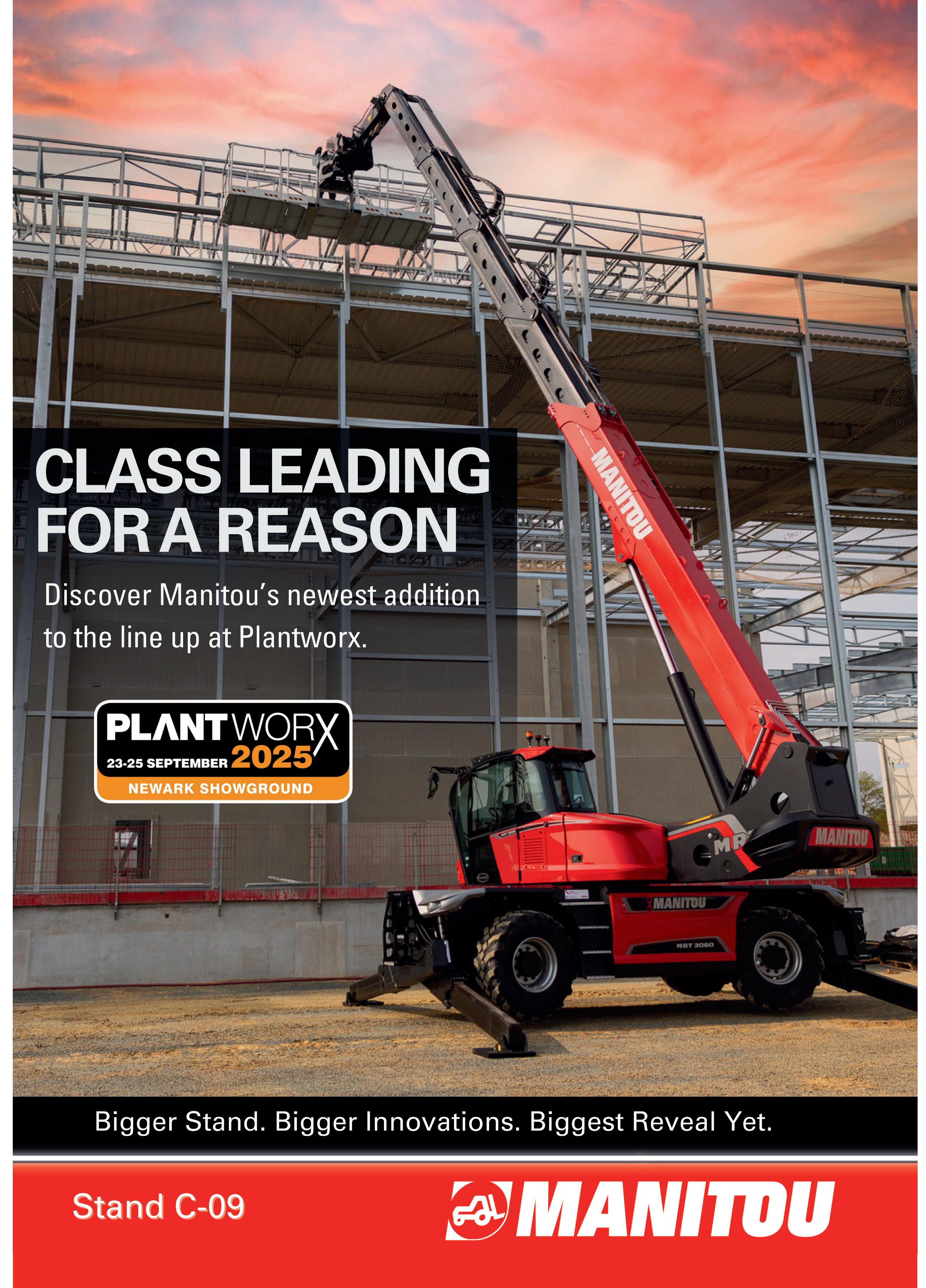

If you’re in construction and want to see where the industry is headed, you need to be at PlantWorx 2025. From 23–25 September, Newark Showground will host over 300 exhibitors, including leading OEMs and specialist suppliers—this is where machines are put through their paces, new ideas are shared, and business gets done.

See the industry in action with live demonstrations across a working showground. Test drive the latest machines, explore cuttingedge safety systems, and speak directly to the teams behind the technology. Inside the indoor pavilion, a dedicated tech zone will showcase automation, connectivity and control systems designed to transform how construction sites operate.

Watch some of the UK’s top operators compete in the Awesome Earthmovers Operators Challenge in association with JCB. Visit the brand-new Site Sustainability Showcase—an initiative focused on practical, lower-carbon solutions, from battery storage to hydrogen-powered machinery.

This year’s exhibitors include 16 of the world’s top 50 construction equipment

manufacturers—an impressive show of strength for the UK’s largest working construction exhibition. Big names like Caterpillar (represented by Finning), JCB, XCMG, Kubota, HD Hyundai and SANY are all confirmed, alongside Manitou, Fayat, Shantui, Takeuchi, Lonking, Sunward, Hidromek, Merlo, Yanmar— and most recently, Zoomlion, the fast-rising Chinese OEM. Collectively, these brands represent over 30% of the global Yellow Table— underlining PlantWorx’s growing international relevance and its reputation as a serious platform for business.

The attachments sector is also turning out in force, with confirmed names including Rototilt, Miller, Auger Torque, Worsley Plant, Holp, OKB Attachments, Attach UK Ltd, BPH Attachments, Arden Equipment, Digga Europe, Con Mech Engineers and Movax. Watson & Hillhouse will also be on site, showcasing the latest in piledriving equipment. Whether you’re looking for earthmoving tools, demolition gear or compact solutions for tight-access sites, you’ll find the latest developments right across the showground.

Takeuchi returns to Plantworx with a stand full of new machines, including the latest from its 3-Series excavator line-up. Making its show debut is the 2-tonne TB320, built for contractors using multiple attachments, with up to four auxiliary ports as standard.

Also new is the TB370W – a compact, roadready 7.5-tonne wheeled excavator marking Takeuchi’s return to the rubber duck market.

XCMG is set to make a strong impression at PlantWorx with the UK launch of two new compact machines: the XC7-TV12 compact track loader and the XC908HST compact wheel loader.

With a focus on operator experience, durability, and flexibility, these two new models mark a significant step in XCMG’s growing presence in the UK compact equipment market.

SANY UK is showcasing several UK product debuts. Making their first appearance are the SY10U micro excavator, SANY’s first 1-tonne digger with zero tail swing, the compact 2-tonne SY20C with air conditioning as standard, and the reduced tail swing SY60U – all designed for tight job sites and demanding applications.

Six excavators, including the SY80U, will be available in a hands-on demo zone. Visitors can also take part in the SANY Operator Challenge using the SY19E, with prizes on offer. Hyundai Construction Equipment will unveil

three UK-firsts on stand A-32: the HX360L crawler excavator, the company’s first batteryelectric mini – the HX19e, and its debut dozer, the HD130A.

The HX360L, part of Hyundai’s Next Generation range, features full electro-hydraulic (FEH) control for faster response and fuel savings, with up to 8% efficiency gains and extended service intervals. Its DX08 Stage V engine delivers a 23% power boost, and safety is upgraded with AAVM+ and AI-assisted radar detection. Inside, a premium cab includes cooled/heated leather seats and a 12.8in touchscreen.

The HX19e 2-tonne mini is Hyundai’s first electric model, available with a 32kWh or 40kWh battery offering 6–10 hours of operation. Fast DC charging (2–2.5 hrs) and the same breakout forces as its diesel counterpart make it a standout in its class.

The new HD130A dozer brings Hyundai into a fresh market, offering the highest power-to-

weight ratio in its class, six-way blade adjustability, and 2D blade assist for easy grading.

JCB has a packed line-up targeting civil engineering, housebuilding, highways and utilities – including several exciting product debuts.

One of these is the brand new 8008E CTS electric micro excavator. Designed for confined and urban job sites, this sub-1-tonne machine matches the performance of its diesel counterpart, with zero emissions, low noise, and a full day’s battery life.

Also on show: the recently launched 145XR reduced tailswing excavator, the JCB Pothole Pro, the powerful 558 260R Pro rotating telehandler, and the versatile 4CX PRO DualDrive backhoe loader.

Away from the stand, JCB is headline sponsor of the Plantworx Operator Challenge –an eight-part, game-themed competition designed to test precision and operator skill. Merlo UK is back with its most comprehensive

range yet, showcasing performance, safety, comfort, and sustainability on an expanded stand on Avenue B.

Leading the line-up is the Gold awardwinning eWorker 25.5 – Merlo’s fully electric telehandler with a 2.5-tonne lift capacity, 5m lift height, and 8-hour runtime. With zero emissions and whisper-quiet operation, it’s ideal for urban, indoor and low-noise zones.

Visitors can explore compact telehandlers like the P27.6PLUS and TF33.7G, plus heavy-duty models including the P40.13PLUS, P40.17, and 12-tonne P120.10HM. Merlo’s flagship ROTO 50.30SPLUS high-reach model (30m lift height, 5-tonne capacity) will be on display with hydraulic winch.

Merlo’s dumpers include the compact CINGO M700TD Hi-Tip, just 750mm wide, and the 9-tonne dual-view DM9 with 180° swivel seat and rotating skip for safer site handling.

Shantui will bring its mid-range DH20M crawler dozer to PlantWorx, offering UK visitors a closeup look at a machine built for performance, reliability and operator comfort. Designed for the demands of European contractors, the DH20M features a powerful Cummins L9 engine delivering over 220hp precision blade control, and a comfortable, modern cab—making it ideal for road construction, heavy-duty earthmoving and site prep.

Xwatch Safety Solutions, part of Hexagon, debuts its new MK2 system at the event – the UK’s first chance to see this next-generation safety solution in action following its international launch at Bauma.

MK2 is a significant upgrade from the original system, combining smarter engineering and an industry-first PL d-rated architecture to deliver trusted safety performance. Designed from the ground up, it features a 30% faster installation time, fewer components and a simpler system layout for improved reliability and easier integration.

New to MK2 is patent-pending proportional motion control for smoother, more accurate hydraulic movement – and a multilingual interface to reduce operator error across global sites.

Zoomlion will present three machines, combining operator comfort, precision control, and reliable performance across its latest excavator and compact loader models.

The ZE55GU is a high-powered compact excavator offering 5% improved digging capacity and excellent climbing and bulldozing performance, thanks to its large-displacement travel motor.

For tight site conditions, the ZE27GU mini excavator offers zero-tail swing, swingable work equipment, and a removable cab for added flexibility. Built with an 8,000-hour structural lifespan and four-track roller undercarriage for improved stability, it comes with a factory-fitted air-conditioned cab as standard.

Also on display is the ZS090V compact loader with vertical lift geometry, delivering a 14% performance gain.

Rototilt will be showcasing a wide selection of its tiltrotator systems and attachments covering machines from 1.5 to 43 tonnes. Visitors can explore everything from plug-and-play models to the flagship Quick Change system – part of the Open-S Alliance, a global standard that ensures compatibility across brands, helping users reduce downtime and get more value from attachments.

On display will be tiltrotators including the RC2 and above, all featuring Pulse (for controlled material discharge, ideal for aggregate) and Return to Home, which brings the unit back to a pre-set position for greater precision. GPS compatibility is also available.

Con Mech Engineers return with an expanded line-up, strengthened by new distribution deals with BS Track Undercarriage and Dozco Rock Breakers. The move adds undercarriage systems and a full range of rock breakers to Con Mech’s offering, broadening the appeal for contractors working across infrastructure, civils, and heavy plant.

The company’s Blademaster range remains front and centre. Manufactured in the UK using British steel, these cutting edges and groundengaging tools are engineered for durability and minimal downtime. Con Mech’s team will be on hand to explain what sets their blades apart— from consistent ‘through hardness’ to the importance of steel chemistry and quenching methods.

Worsley Plant will introduce two new products to the UK market, both designed to improve efficiency on site and reduce handling time.

Making their debut are the Rotar RSSXSeries Scrap Shears, engineered for demanding demolition and scrap processing work. With reinforced nose blades, improved jaw alignment and high cutting force, the X-Series can operate at pressures up to 380 bar. Models are available to suit carriers from 9 to over 75 tonnes, offering strength and reliability across a wide range of applications.

Also on show is the Dynaset HRVB hydraulic recycling vacuum bucket, a compact attachment that transforms hydraulic power into a vacuum and air blow system. It’s designed for collecting lightweight waste such as plastic, insulation, or packaging debris, making it ideal for site clean-up, railway and road maintenance.

LWC Group will present its Lite Guard trench shoring systems at PlantWorx, featuring lightweight aluminium trench boxes, manhole shields, edge protection, soldier sets, and accessories tailored for utility, groundwork, and civil engineering sites.

Visitors will see how Lite Guard helps minimise manpower and downtime, making it particularly suitable for restricted environments and live utility projects across the UK. LWC

Group’s team will be on hand to demonstrate the versatility and strength built into the company’s engineering-led trench shoring range.

Demarec will introduce its new pulversiers, to its dedicated demolition line, designed for flexibility and performance across a wide range of applications.

The DLP range features a modular design with easily replaceable wear parts, allowing the same tool to be adapted for both primary and secondary demolition. With models available for excavators from 55 tonnes down to 3 tonnes, the Pro-Line series is built to serve both new and existing customers with varied fleet sizes.

The focus on durability and reliability, combined with Demarec’s established design principles, makes the DLP range a practical solution for demanding demolition work.

Red Rhino is bringing two brand-new machines — both designed to meet the needs of today’s demolition, recycling, and compact quarrying sectors.

The Red Rhino 8000 is the biggest crusher in the company’s line-up to date. Weighing in at 18 tonnes and boasting an 800mm x 500mm jaw aperture, it fills a long-standing gap in the midsized crusher market. With a deep crushing chamber and a bespoke crusher box, it’s capable of outputs up to 100 tonnes per hour, making it ideal for high-volume applications.

Also on show will be the Trommel, a fully electric, compact screening unit with synchronised feed and drum speeds for accurate material separation. Lightweight and hook-lift compatible, it’s designed for clean, efficient, and mobile operation, with two output sizes and zero emissions.

Robustrack returns to Plantworx for its fifth show with a stand packed full of innovation and favourite hydraulic attachments. Visitors can expect to see popular kit including Femac flails and mulchers, Agriforest tree shears and log grabs, Malaguti compaction attachments, and Sima concrete mixing buckets.

Making its Plantworx debut is Idrobenne’s range of multi-purpose grapples, launched earlier this year. The 4/3 open finger configuration has proved a firm favourite for handling brash and clearing debris.

Autumn’s at hand and the leaves are turning. Some say he’s got a sunny disposition, others that he can have a frosty attitude. All we know is that we call him The Dig. This month he reconnects with his youth as he hops aboard a JCB 4CX Pro Dual Drive.

There can be no more iconic machine than JCB’s backhoe loader. Over the years, it’s become synonymous with the brand name. Just last year the Staffordshire based manufacturer celebrated 70 years of producing them, and as mentioned in these pages last month, the millionth machine rolled off the production line earlier this year.

The 3C, in particular, has always had a special place in my affections, as I grew up around them as a child, with my late father who was a passionate operator of them for his entire working career.

Always innovating, JCB has introduced a number of significant upgrades to the machines

to simplify the operational experience, making it easier for the operator with increased levels of comfort and functionality.

One of the most exciting developments is the all-new Dual Drive function that is available as standard on all 3CX Pro and 4CX Pro machines with servo controls. Put simply this feature enables the operator to drive and operate the machine whether they are facing forwards or to the rear.

This ability has been present on Swedish Huddig and Finnish Lannen machines for over 25 years, but those big multi-functional machines are somewhat different in the fact that they feature central articulation for steering

and the backhoe is the centre mount style. The JCB Dual Drive is believed to be the first time a conventional side shift backhoe has been set up like this.

Anyone who has spent time on a backhoe loader knows that it can be a time-consuming exercise when excavating with the back-end, the constant need to move the machine requiring you to raise the jack legs, spin around to face the front, and lift the loader arms before moving forward, then having to repeat the exercise in reverse - it can all be a bit of a faff. But with the Dual Drive, the whole operation is

speeded up and makes the machine more user friendly for the operator and ultimately saves time on projects where the machine is working.

I climbed on board a 4CX Pro Dual Drive to experience it for myself. It certainly felt strange being invited to take to the seat facing to the rear at first, for as long as I can remember, you took your seat in a backhoe facing towards the front of the machine, before spinning around to the rear to undertake backhoe work.

With the flick of a switch on the dashboard to my left facing to the rear, I was in control of the travel options. On the underside of the right-hand joystick, I found a forward and reverse rocker switch, whilst a roller switch on the underside of the left joystick controls the steering.

On the floor in front of me there were twofoot pedals which intuitively are a brake pedal on the left and throttle on the right. Selecting reverse on the switch I gently dabbed the throttle pedal and gingerly moved off. Initially it felt quite strange and I learned quickly that only light movements on the steering rocker are required as its very responsive. The longer I spent on it the more natural it felt, I likened it to the way a rubber duck reacts when you are driving with the steering wheels to the rear, it takes a bit of mind training and was a little bit daunting to start with, but it very quickly becomes second nature.

As a safety feature a 7in monitor is nicely positioned to the operator’s left (when rear facing) to enable you to have a wide-angle view of the front of the machine when travelling forwards, but facing the rear.

The hydraulics are so well tuned I quickly learnt that I could travel and work the backhoe at the same time, and I immediately thought about how useful this machine would be, when for instance, placing concrete for kerb layers, dropping kerbs in place, and indeed other similar lift and carry scenarios.

It’s a bit of a cliché, but I do feel this could be a game changer for the backhoe loader, increasing the versatility and ability of what has always been a versatile machine but taking it to another level and one that will appeal to younger operators who are coming into the industry.

The Dual Drive feature opens up a whole new way of operating a backhoe loader, bringing it bang up to date in the 21st century. Once mastered an operator will never look back to the old traditional ways of backhoe loader operation.

Other upgrades to the range include a return to grade function on all machines fitted with servo controls. Using this system enables the operator to set up the 6-in-1 front bucket for grading work. To set this up, the operator activates it via a switch on the console, opens the clam shovel, before sharply moving the loader lever to the right like you would say on a return to dig function. By using this feature the bucket automatically stops the shovel rotation at its optimum angle for fine grading work.

With the uptake of laser levelling systems

on sites up and down the country, JCB has come up with a 2D laser receiver mount, which is fitted to the front loader arms. This was being demonstrated mounted on a 3CX Pro. The pole can be adjusted to suit a wide range of receivers but on this occasion was fitted with a Leica system. The operator sets the grade depth required and receives feedback visually via the red/green lights on the receiver which is facing the cab.

JCB has also upgraded its integrated quick hitch with forks. As we all know using bucket mounted flip-over forks can be a painful experience, especially when trying to use them at ground level where visibility is virtually impossible, and you are effectively relying on guess work to enter the forks into a pallet.

Talking of visibility, JCB is now offering a twin camera and screen option with the integrated fork system. An anti-misting camera mounted within the quick-hitch frame provides superb visibility of the forks and the load to be moved, much needed when at ground level. A second second camera mounted in the roof provides a view of the quick hitch bar, and a 7in colour screen inside the cab offers the operator the option to view either camera as it suits him.

With the quick hitch you can drop off the shovel and use the machine for dedicated fork work. Capable of a load capacity of 2,000kg, the fork carrier has been widened by 220mm to improve stability when carrying wider loads. The forks now sit outside of the carrier frame, making it easier to reach them, and stow them after use, something I have always struggled with in the past!

Hydraulic pipework couplings have also been relocated for improved access when changing, and rubber mounts have been introduced between the forks and the frame to eliminate that all too familiar rattling that we have all had to listen to over the years, a simple but very effective and welcome addition.

JCB has always been at the forefront of innovation over the years, and that mindset will surely continue in future years. It’s always exciting when I visit the Staffordshire based facility to see what latest features are going to be revealed.

“... the Dual Drive feature opens up a whole new way of operating a backhoe loader...”

CPN climbs into the cab of Hyundai’s new mid-weight dozer, the HD130A, and is impressed with its versatility, functionality and all-round performance.

Hyundai CE expanded its range of machinery at the recent Bauma exhibition in Munich, launching a host of new equipment, that will take the company into additional business sectors. New models included a materials handler, two skid steer loaders and a compact tracked loader, along with the firm’s first mid-weight bulldozer, the HD130A.

This 15-tonne machine is available in both standard XL and LGP low ground pressure layouts and is powered by a 117kW (157hp) Stage V diesel engine. The dozer drives through a two-speed hydrostatic transmission, that delivers up to 22,000kgf of drawbar pull, with 35° gradeability. An eco mode, auto idle and auto shutdown, all aim to minimise fuel consumption, with eco mode alone promising up to a 5% fuel efficiency gain in lighter grading tasks.

The ROPS/FOPS cab is a comfortable place to spend the day. It sits on CabSus mounts that suppress vibrations and help to keep internal noise to a minimum. A slim engine canopy, with the air filter pre-cleaner positioned inside, along with floor to roof glazing, provide a clear view to the front of the machine and there is a touchscreen monitor mounted below the windscreen that displays the rear-view camera when reversing.

There is a hands-free Bluetooth audio system with smartphone connectivity and, though not as large as the screens in Hyundai’s latest excavators, the main display is easy to use and offers clear access to function menus and diagnostic tools. An automatic-shut-off feature will stop the machine if the operator leaves the seat and the machine has

a seatbelt warning alarm.

Travel is controlled through the left-hand electro-hydraulic proportional joystick, with a pedal on the floor limiting how much drive reaches the tracks. It works more as a brake or clutch than a throttle, in that the more you push down, the slower the dozer will move. Lift up and the machine will track forward at full speed. Nudge the joystick to the front for forward travel and pull back for reverse. This same lever controls the steering, by tilting to the left or right. Push the lever fully to one side or the other and the machine’s tracks will counterrotate, to allow the dozer to virtually turn on the spot. Travel speeds are controlled by a thumbwheel on the lever head.

There are two dozer blade options, a standard 3.45m3 for the XL machine and a 4.18m3 blade with the wider low ground pressure tracks. In both cases the operator has six-way angle-tilt control, with the right-hand proportional lever providing up and down movement and rotation to the left or right. A proportional roller switch on the lever head controls blade tilt and there is a button to activate blade float, allowing the dozer to follow the contours of the ground as the machine reverses. There is also a two-way mechanical adjustment, that allows the operator to pre-set

“... the availability of a dozer from the same dealer will no doubt be a welcome addition....”

blade pitch, from 54-58°, to meet individual operating requirements.

Hyundai claims a best-in-class power output for the 15-tonne machine and the HD130A certainly has plenty of pushing capability. Even with the larger LPG dozer blade, the machine is capable of cutting into new ground and digging in with each pass. The six-way adjustable blade provides plenty of options for the operator, allowing contours and gradients that would not be possible with a fixed blade. The machine is capable of working with a range of machine guidance and control systems and there is a standard 2D blade dozing assist function that makes it easier for less experienced operators to get to grips with the controls. At the rear, there is a choice of a towing drawbar or an optional ripper attachment, which is also controlled from the right-hand lever head. Here too, the machine has the power to dig deep with the three-tine ripper, breaking up compacted ground without losing traction at all.

Service engineers should be equally happy with the machine, with all daily service points easily reached from ground level, through side access doors in the engine canopy. For more indepth maintenance work, the entire cab can be tilted to the rear, providing clear access to hydraulic and driveline components. Customers can specify Hyundai’s Hi-MATE telematic monitoring system, for real-time operating data and location information.

Whether working in haul road construction and maintenance, topsoil stripping or site reinstatement, the manoeuvrability of a machine of this size, combined with the versatility of the six-way adjustable blade, should make this a highly productive addition to the Hyundai lineup. For those customers already operating the firm’s loaders, excavators and dump trucks, the availability of a dozer from the same dealer, will no doubt be a welcome addition to the line-up.

London’s Commercial Vehicle Unit (CVU) is a special, round-the-clock police force dedicated to keeping the capital’s roads safe by monitoring abnormal loads and heavy goods vehicles, while educating drivers and enforcing safety standards. CPN spent the day with it.

It’s 05:50 on a Thursday morning, and officers from the Metropolitan Police’s CVU are assembling at a depot in south east London. The CVU is the largest dedicated commercial vehicle unit in Europe and the only one in the UK operating 24/7. The team includes one inspector, six sergeants, and 58 officers spread across Chadwell Heath, Alperton, Catford, and Merton.

Leading the charge is Inspector Rik Wenham, a former soldier with an impressive résumé.

‘You never know who’s driving!’

He’s an advanced police driver, motorcyclist, examiner, and collision investigator. He holds HGV qualifications across multiple classes, is ADR certified for all hazardous materials, and is a tachograph and crane operator and examiner. Not bad for a traffic cop!

Before joining his team on patrol, Rik heads out early on a solo mission to spread the word about vehicle and road safety. Rik’s so-called ‘Toolbox Talk’ is primairly aimed at new drivers and those needing refreshers. Today’s audience is from Holcim (formerly Aggregate Industries), gathered over coffee and croissants. Rik’s talk has reached around 70,000 drivers to date.

The presentation is pragmatic and educational. Rik stresses that the CVU isn’t out to penalize minor infractions – such as an abnormal indivisible load (AIL) actually being under-length on the paperwork – but is seeking to ensure the smooth running of London’s roads and the safety of all its users. Mentioning no names here, he is quick to point to other regional forces who enforce movement orders to the letter, even when the safety situation is improved – like being under-length, under-width or lighter.

Driver responsibilities are a key theme, especially regarding vehicle condition and load security. Rik reminds attendees that in the event of an accident, legal consequences often fall squarely on the driver, not necessarily the operator. He also highlights the ‘fatal four’ prime causes of road deaths: speeding, mobile phone use, drink and drug driving, and failure to wear seatbelts. Each fatality costs the economy £2 million, not to mention the devastating human toll.

The CVU’s performance is measured by reductions in fatalities and serious injuries, with an ambitious goal: Vision Zero – no deaths on

London’s roads. Interestingly, AILs haven’t been involved in recent road deaths, a testament to improved safety practices.

Rik shares sobering stories of lives lost due to unsecured loads. “Gravity is not an approved load restraint,” he warns, recounting incidents where flying debris caused fatal accidents.

Indeed, a friend of this author’s infant sister was killed by a piece of metal from a wagon entering her parents’ vehicle through the windscreen.

One shocking statistic is that possibly 40% of deaths relevant to the sector are “enabled suicides”, where individuals use plant or HGVs as their preferred means of exit and the effect on drivers, initially thinking they were responsible, is unimaginable.

Rik is also campaigning to scrap London’s embargo on heavy-duty vehicle movements. He argues that modern safety systems, improved vehicle design, and 20mph speed limits make the restrictions outdated. In areas with overlapping noise abatement orders, construction traffic is effectively barred altogether. He believes staggered vehicle entry would be safer than releasing multiple HGVs simultaneously.

Though the embargo falls under the Met Commissioner’s authority, Rik is lobbying stakeholders – such as the London Mayor’s Office and Transport for London – for change.

With the talk complete, the CVU hits the road. Unusually, all four depots converge in south London. Mobile units include an unmarked DAF tractor, vans, and Rik’s car. Though they specialise in plant and HGV matters, they’re traffic cops first.

The first stop is a van riding suspiciously low. It’s 56% overweight on both axles, prompting officers to demand half the load be removed. Worse, the van’s contents – fresh seafood stacked on fresh chicken stacked on fresh vegetables – are unrefrigerated in 70o heat, triggering a call to environmental health.

Meanwhile, mobile phone users are being pulled over in numbers on the A2 – a significantly busy, and quick, route into London. It’s truly amazing how many people are caught –and it’s also amazing how many people seem to be totally oblivious to either a police van or car sat on their tail, all lights flashing and sirens blaring. Mirror use, it seems, is a lost art.

After an hour of ticketing and warnings, the team moves to a static site in Greenwich. Officers direct wagons off the A2 into a layby for inspection. Selection criteria are vague – one officer cites his “copper’s nose.”

The most common fault found on the day are tacho infringements. Generally, these aren’t serious and – as might be expected – are often a result of heavy London traffic. It comes as a surprise to the drivers that the police can see more on the tacho than they can and the few that try to game it – by activating rest mode when stationary but not resting – get a rude surprise.

When the conversation reveals they ran out of time because of traffic jams, the unit’s pragmatic approach comes into play and firm words are deemed preferable to tickets.

The final ‘pull’ of the day is the driver of a plant hire low loader delivering a cherry picker and scissor lift. For the purposes of journalism, the stop is disappointingly uneventful. For the driver and the hire firm, this is a good thing. The driver’s admin is in order; the traffic has pushed his hours close to, but not over, his limit and –with a few straps and chains made a bit tidier –he is soon on his way.

This day in the life of the CVU reveals a unit that blends enforcement with education, pragmatism with precision, all in the service of safer streets. London’s CVU proves that smart policing, technical expertise, and a human touch can make a real difference in keeping the capital’s roads safe for everyone.

When a Norfolk company wanted to revitalize an old camping site and give it a new lease of life, it turned to SANY machinery for help. CPN reports.

Kiwi Farm Partnership is a King’s Lynnbased arable farming and contracting business that’s run by husband-and-wife team Will and Alex Chapman. It also develops recreational outdoor spaces, such as glamping and camping sites.

One of the company’s most recent projects is the renovation of Holt Hollow, a 15-acre lakeside camping and glamping site that’s nestled in woodland and surrounded by beautiful North Norfolk countryside near Cromer.

Although Holt Hollow was a previously established site, it hadn’t been in use for years and had become very overgrown. The natural lake was also full of silt, leaves and wood and couldn’t be seen for brambles. Will and Alex wanted to bring the site back to its former glory and develop it even further with a new parking area, pathways and island for a hot tub.

The woodland also needed managing, and the dense conifers eventually replanted with native species to protect the local habitat.

Will was first introduced to Global Machinery Solutions’ Vic Mallett at the nearby Royal Norfolk Show. Will was so impressed with Vic’s industry knowledge and technical expertise, he decided to invest in a SANY SY35U mini excavator.

This small but mighty powerhouse’s short tail swing allowed the team to work in between the tight rows of trees, where the machine’s ability to do neat 360o turns was invaluable. Logs are easily lifted and moved around the site – and with the tree shear and flail head attachments, the machine can also cut hedges and clear undergrowth with ease.

Being able to easily move timber means larch from the wood is being milled for cladding the shepherds’ huts and other wood is processed for the fire-heated hot tub, showers and firepits.

With the lake being full of silt, Will and Alex needed a larger excavator to make good the existing hard standing area and improve the roads and paths around the site, leading from the entrance and winding down the hill to the shepherds’ huts.

They were so happy with the SY35U and Vic’s aftersales support, they approached him again and after a demo, decided on the 7.2 tonne SY75C, one of the most powerful SANY compact excavators.

This machine has been used to remove the silt from the lake, dig paths for the roads and car park. Earth from the roads has been used to create an island, which will be an idyllic spot for a hot tub!

The SANY excavator has also shifted more than 1,000 tonnes of crushed granite for the roads and car park.

Talking about the project, Will Chapman said: “The SANY excavators tick all the boxes for us.

“... the SANY excavators tick all the boxes for us...”

They do everything we need and are fantastic value for money. They’ve been instrumental in the development of the site and we are delighted at how they’ve performed

“What’s also impressed us is the ongoing support Vic – and the rest of the Global Machinery Solutions team – provides. When we had a niggle with the smaller machine, Vic organised the repair straight away through the warranty and we were back in action in no time. Having this backup is priceless and I know Vic’s always there to help.

“The SANY machines do exactly what they say on the tin, they’re high performing, powerful, comfortable, versatile – and very affordable. We’re looking forward to using them on our next project.”

In the words of Will’s grandad: “if it’s got a heater and a wireless, it’s a good ‘ol tool!”

Vic Mallet, SANY Equipment sales manager, added: “It’s fantastic to see how the SANY machines have been so instrumental in developing Holt Hollow. Working on hilly and uneven terrain shows how well these machines perform even on tricky sites.

“It’s a pleasure working with Will, Alex and the rest of the Kiwi Partnership team and I look forward to continuing to support them as they renovate and redevelop future sites.”

manufacturer could satisfy its high expectations on build quality, reliability and back-up. CPN reports.

Manchester contractor Bethell

Group had been operating a hired Liebherr excavator with shaft sinking equipment for 18 months but with an increase in contracts calling for the specialist machines, it was time to go to market. The company knew exactly what it needed and as other manufacturers and specialist conversion companies came up short, just one supplier remained.

After two years of negotiation and finetuning the specifications, a deal was signed for two shaft diggers and a telescopic crawler crane. Rónan Kilroe, Bethell’s plant operations manager, explained: “The package Liebherr put together impressed us immensely with its quality. Nothing was too much of an issue. And having the entire package manufactured, supplied and warranted by one company gives us peace of mind.”

Joining a substantial plant fleet including all the usual ‘standard’ excavating equipment, the new shaft sinkers are built around the German manufacturer’s R 930 G8 excavator template and the comprehensive specification sees each machine tip the scales at nearly 40 tonnes (standard R 930s weigh from 30.4 to 36.3 tonnes). Sitting on a standard long undercarriage, the upper structure is fitted with Liebherr’s hydraulically elevating cabin that raises the operator’s eye-level to five metres above ground for clearer views into excavations or tipper bodies.

Front end equipment includes Liebherr’s standard two-piece boom and an extending dipper stick for additional reach. Safety standards are met by a full high-visibility boxing ring, halo lighting to define the working radius and a full 360° camera system. An additional camera gives a clear view into the excavation for applications when the machine is digging under water. Bethell also opted for a slew and height restrictor.

The shaft sinkers were not the only new Liebherrs to join the fleet, with an LTR 1060 telescopic crawler crane also coming on board. With a maximum lifting capacity of 60 tonnes,

the compact unit has a maximum hoist height of 55m and a maximum working radius of 50m and adds a further level of versatility to Bethell’s operations.

Valuable contribution

The crane’s compact dimensions are ideally suited to the tight spaces where Bethell can often be found working. “If we encounter harder material as we dig deeper, we will have to lower a mini excavator with a rock wheel attachment,” said Kilroe. “The Liebherr will be able to handle

this task safely and is also the ideal machine for feeding in our pipe-jacking equipment as a tunnel progresses.” The machine will also be a valuable tool on shaft sinking contracts where it will handle large concrete ring segments as a shaft is developed.

“...Liebherr impressed us with its can-do attitude of happily building something different...”

Delivery of the three machines came after detailed discussions over two years with Liebherr-GB. “It has been a long process to get here,’ added Kilroe, “but it’s one that we feel has worked out well for us. We have three excellent products which will give us a good few years of service. While the crane is relatively standard, the bespoke nature of the two shaft diggers has impressed us with Liebherr’s can-do attitude of happily building something different.”

Bethell was established in Manchester in 1865 to meet the infrastructure demands of the rapidly growing city and is now a leading contractor in the utilities and highways sector. It was acquired in 1991 by tunnelling and shaft sinking specialists Kilroe Group. Originally founded in 1967 by Tim Kilroe Sr, the group is now headed by second and third generations of the family.

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

Manchester-based Bethell Group is the first civil engineering company in the UK to receive Takeuchi’s newest model, the new TB370W wheeled excavator.

The machine is already helping deliver phase two of the Market Street regeneration project in Farnworth, Bolton. The new wheely (rubber-duck) is set to provide a powerful yet compact utility vehicle with site-ready features designed for

utilities / streetworks and civils job. With up to four auxiliary ports for a variety of attachments, everything from grabs, pallet forks, breakers to buckets can get to work.

As one of the most compact sized wheeled excavators on the market Takeuchi has high expectations for the machine. It has been designed especially for working in reduced spaces, compact housing developments and the narrowest streetworks or utilities. With a compact footprint of just 2.1x2.9m coupled with a 2-piece boom as standard, the TB370W offers the most economic size while moving in and around site. It’s considered nimble and highly productive for a 7.5 tonne weight class.

Longstanding relationship

“Bethell have been looking for a rubber duck of this size for some time,” explained Ronan Kilroe, plant operations manager. “There have been projects where we required the versatility of our TB295W or TB395W, but the machines were just that touch too big. We explored other options from other manufacturers before the launch of the TB370W, but I just couldn’t bring myself to get something other than a Takeuchi. So, when Takeuchi exhibited the TB370W at Hillhead, I was delighted! I was very keen to try and get our hands on a unit and luckily enough we were able to do just that, investing in the first unit in the Northwest and one of the first in the UK.

“We have a long-standing relationship with Takeuchi, and we favour them for their Japanese engineering, power, reliability, fuel efficiency, innovation and strong residual values. The new TB370W will prove an invaluable tool on a wide array of civils and highways jobs for us, providing

all the benefits Takeuchi offers as well as the versality of it being wheeled while remaining compact in size.”

Takeuchi’s return to the 7.5-tonne weight class has proven a successful move with plenty of interest in the new model. The TB370W joins six other new styled 3-Series or 3rd generation Takeuchi excavators launched in recent years. WWW.RDR.LINK/CBD022 GOTO

RJ McLeod (Contractors) Ltd, one of Scotland’s largest privately owned civil engineering and building contractors, has taken delivery of 16 new machines from Develon.

The order comprises 12 Develon DA30-7 articulated dump trucks (ADTs), together with six crawler excavators, including four DX225LC7 models, a DX300LC-7 and a DX300SLR-7 super long reach machine.

Acting as both replacement and fleet expansion units, the new Develon equipment has joined RJ McLeod’s in-house plant and transport fleet, part of the sizeable in-house resources at the company, which has a workforce of around 450 employees.

Jamie Corser, director responsible for business development at RJ McLeod, commented: “For more than 70 years, RJ McLeod has excelled in delivering solutions for clients, often in logistically demanding locations. It is essential that the machinery we use is of the highest quality and we chose Develon, because our research showed that this brand of machinery provides the reliability, productivity, lower emissions and reduced running costs that we need.”

Righa Gauld, RJ McLeod’s plant yard manager,

added: “We’re delighted to take delivery of these new machines which is the first stage of significant investment in our expanding fleet.”

The new equipment has been supplied by Castle Douglas-based James Gordon Ltd (Gordons), Develon’s authorised dealer for Scotland.

FOR MORE ON DEVELON, PLEASE WWW.RDR.LINK/CBD023 GOTO

A groundworks and plant hire specialist is bringing in new business thanks to the purchase of a JCB Pothole Pro.

Purchased by Blackburn-based AJ Bretherton, the JCB Pothole Pro is being used to fix potholes on contract to Blackburn Borough Council as well as private work on local car parks.

Owner, Alan Bretherton, said: “We like to support British manufacturing, which is one of the reasons we choose JCB. It’s also a comfort thing for us – the cab in a JCB is second to none. Our operators love them.

“When it comes to the JCB Pothole Pro, there’s simply nothing else like it on the market. For our type of work, it’s the only choice and is helping us land more contracts of this nature. It’s been brilliant for our surfacing work.”

Supplied by dealer Gunn JCB, AJ Bretherton’s new Pothole Pro joins an entirely JCB fleet including TM320s, a JCB 403 Plus, JS130 tracked excavators, a JCB compaction roller and two JCB Fastrac 4220s, which also support the company’s 350-acre beef and sheep farm.

GOTO

WWW.RDR.LINK/CBD024

Tasked with a complex job of lowering one roof and lifting its replacement, Hoist & Winch came up with a clever solution. CPN reports

When a landmark building in Nottingham required the replacement of its fabric tensile roof covering, the subcontractor tasked with this critical work turned to the expertise of Hoist & Winch Ltd for the roof lowering and lifting solution. The eye-catching building, a former HMRC complex similar in design to London’s O2 Arena, is today part of Nottingham University’s Castle Meadow Campus.

The leaking tensile roof covering had reached the end of its 30-year lifespan and required replacement. To ensure the optimal solution to this technically complex challenge, the specialist subcontractor responsible for the job approached Hoist & Winch. The objective for Hoist & Winch was to specify and supply a complete hoisting solution that would enable

safe, even lowering of the original fabric roof to ground level and raising of the replacement fabric roof to its final installation height.

Following a number of site meetings and consultations with both designers and roof installation personnel, Hoist & Winch was able to propose a complete package of equipment and technical support.

At the centre of the proposal were 12 Yale/CM Lodestar electric chain hoists. These 2t swl (safe working load), 110V top-hook suspension hoists were coupled with correctly sized 30m long power feed/control cables. The idea was to operate the hoists simultaneously in sets of four while suspended from the customer’s specially designed lifting beams. Hoist & Winch also provided three separate single free-standing control stations of bespoke design to manage hoist unit motion, either individually or in sets of four, during lowering of the original fabric roof and lifting of its replacement.

Another aspect of the project saw Hoist & Winch supply a combination of 15t and 6.3t swl William Hackett lever hoists to assist with de-tensioning the original fabric roof prior to lowering operations and re-tensioning the new fabric once lifted into its final position.

As always, technical consultancy proved a core element of the overall package from Hoist & Winch. The company’s highly professional approach ensured the specialist roofing subcontractor received guidance on projectcritical factors such as lifting equipment legislation, lifting operation planning and management, overall design and sizing of two bespoke portable electrical transformers, electronic load cell selection, selecting loose lifting tackle, and site examination and testing procedures prior to the commencement of lifting operations.

“The outcome was the safe and successful removal of the original fabric roof and the installation of its replacement as part of a finely controlled, smooth process,” explained Hoist & Winch director Andy Allen. “The customer was delighted with the professionalism of our expert team and the solutions we proposed. Taking projects like this from concept to fruition is where we excel, ensuring our customers meet all of their objectives in a safe, competent and timely manner.”

Such was the impression made on the specialist roofing subcontractor that it subsequently engaged Hoist & Winch in further work to adapt the already acquired lifting system and used the knowledge gained from the Nottingham project to bid successfully for another multi-point lifting project in Copenhagen.

“... the customer was delighted with the professionalism of our expert team...”

Develon has announced a number of upgrades for wheel excavators from 14-21 tonne which, it says, significantly boost performance, improve safety and enhance operator convenience. The upgrades have been introduced on the five medium-heavy models, all of which are now new ‘K’ class models, including the DX140W-7K, DX160W-7K, DX165WR-7K, DX170W-7K, DX190W-7K and the DX210W-7K 21 tonne wheel excavator.

Like the DX170W-7K, engine power for both the DX140W-7K and DX160W-7K models is now provided by the Develon DL06V Stage V engine, resulting in an 11% increase in output to 113.6kW (152hp) at 2000rpm, matching that in the DX170W-7K.

The DX165WR-7K reduced radius model is powered by the Perkins 1204J engine, offering 102.1kW (137hp). Completing the range, the DX190W-7K and DX210W-7K are again powered by the Develon DL06V Stage V engine, providing 129.8kW (174hp) and 141kW (189hp) at 1900rpm, respectively.

In the new DX140W-7K and DX160W-7K models, there is an updated main pump system, increasing the flow supplied to the travel components. In these models and the DX165WR-7K, there is also an improved travel motor for a wider range of displacement and an enhanced transmission system to release more torque to the axles. This has raised the travel speeds possible on roads and hills and also an improved overall travel acceleration and traction force.

Inside the new cab space, operators now benefit from a larger 12in gauge panel. Featuring a full HD resolution of 1920 x 1080 pixels and powered by the Android 10 operating system, the display offers crisp, high-clarity visual images. The new split-screen functionality enables the integration of multiple functions on a single interface, improving operational efficiency.

To meet the EN474:2022 safety standard, a rear/right view is always displayed while the machine is in operation, regardless of the driving or working mode, provided that the camera offers a view to the rear/right. A side and rear-view camera option ensures both camera screens are always visible simultaneously, whether in half view or full view.

There is also a new smart all-around viewing monitor (SAVM) option, whereby the top view is always displayed simultaneously when selecting rear, right and right corner views to comply with EN474 legislation. The term ‘smart’ indicates an improved AVM specification with added person detection for enhanced safety on top of the existing AVM option specification, utilising footage captured by four cameras, to reveal workers on site close to the machine.

TheAI-based technology in the SAVM system is able to effectively identify both moving and stationary individuals in close proximity to the machine. Upon detection, the system promptly alerts operators through a combination of visual signals and audible alarms on the monitor, ensuring a heightened awareness of the surrounding environment.

CASE continues to expand its compact crawler excavator range. The latest additions to a line-up that includes more than 20 individual models, are the E- Series midi models that cover the 8-10 tonne operating weight market.

Those customers looking for a zero-tail swing design with a fixed mono boom, similar to a full-size crawler model, can opt for the CX85E, with an operating weight of 8,830kg. For operators that prefer a boom swing solution like a mini excavator, for improved access on constricted sites, the CX90E weighs in at 9,210kg. The ultimate flexibility, with a longer horizontal reach and higher dump height, comes with the CX100E. This 10,080kg model offers a zero-tail swing design, with a two-piece articulating boom (TAB) and boom swing.

For additional stability and lifting capacity, the CX85E and CX90E can be ordered with an additional 440kg counterweight, which is standard on the CX100E. Mounted internally, the additional weight does not impact the zero-tail swing overhang, maintaining the compact dimensions of these 8-10 tonne class machines. All three of the machines can also be equipped with an external 900kg additional counterweight if required.

All three models are powered by a 53.7kW (73hp) diesel engine. With a variable

displacement hydraulic pump, there are three operating modes available, including economy for maximum fuel efficiency. Along with the three factory presets -economy, standard and power - it is possible for the operator to program an Individual setting, adjusting the speed of each hydraulic function to suit their preference.

The machines benefit from up to three auxiliary circuits, that can be set to match the flow requirements of different attachments, to provide maximum operating efficiency and performance. Electroproportional roller switches in the joysticks provide fingertip control of auxiliary functions.

CASE has also introduced a joystick travel mode, allowing the operator to control all tracking functions from the lefthand joystick. This is particularly useful when using the dozer blade for backfilling applications and travel. These three models are equipped with dual-speed transmission,

36 outside back cover) www.rdr.link/CBD100

4) www.rdr.link/CBD101

2 inside front cover) www.rdr.link/CBD102

with automatic shift-down when required, delivering optimum traction in all situations.

The premium cab environment offers three types of seating, including mechanical or pneumatic suspension and seat heating. Ergonomically-designed joystick levers with intuitive push buttons and electroproportional roller controls maximise productivity and reduce fatigue for the operator, while the multi-function computer display provides access to control menus, diagnostics and hydraulic adjustment screens.

Air conditioning components have been located within the rear roof spoiler, which rotates within the counterweight dimensions. This location maximises visibility from the cab, while rear view mirrors and cameras offer the operator an all-encompassing view around the excavator. LED lighting completes the visibility package, ensuring maximum vision in all light conditions and weather.

FOR MORE INFORMATION

WWW.RDR.LINK/CBD027 GOTO