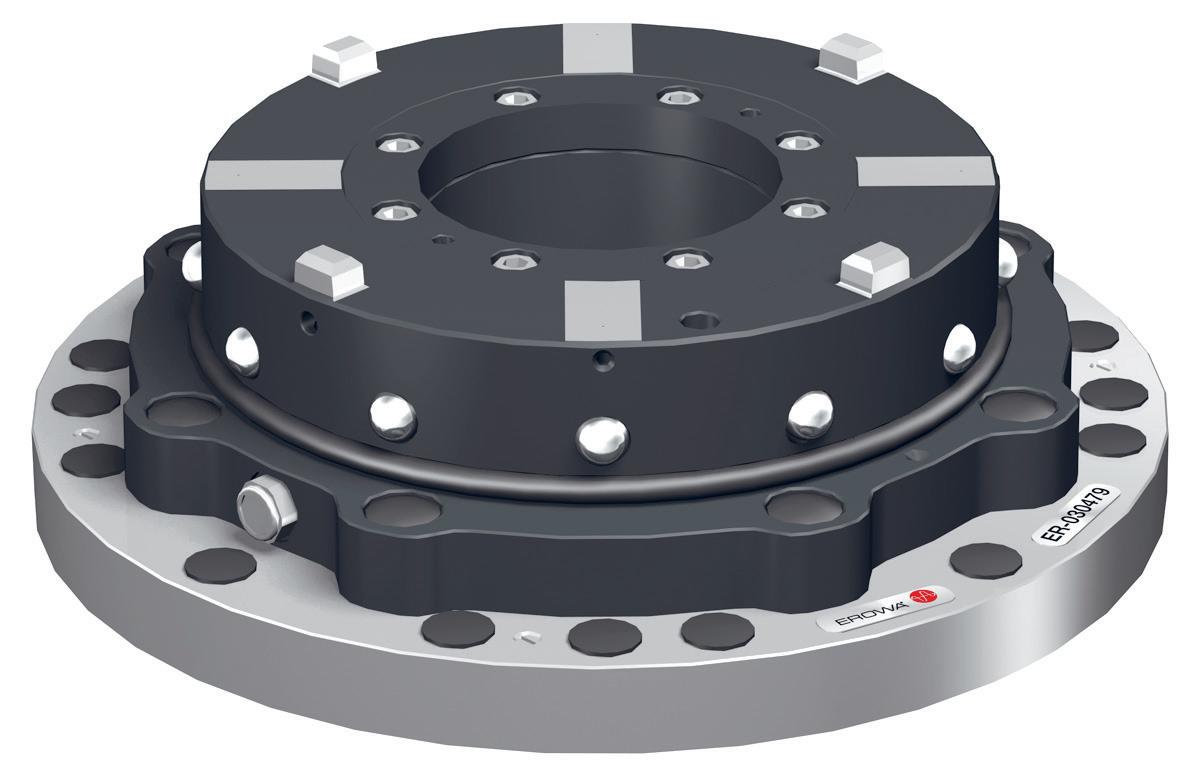

ProductionChuck 210

The tooling system for 5-axis machining

Maximum flexibility, highest precision, efficient automation

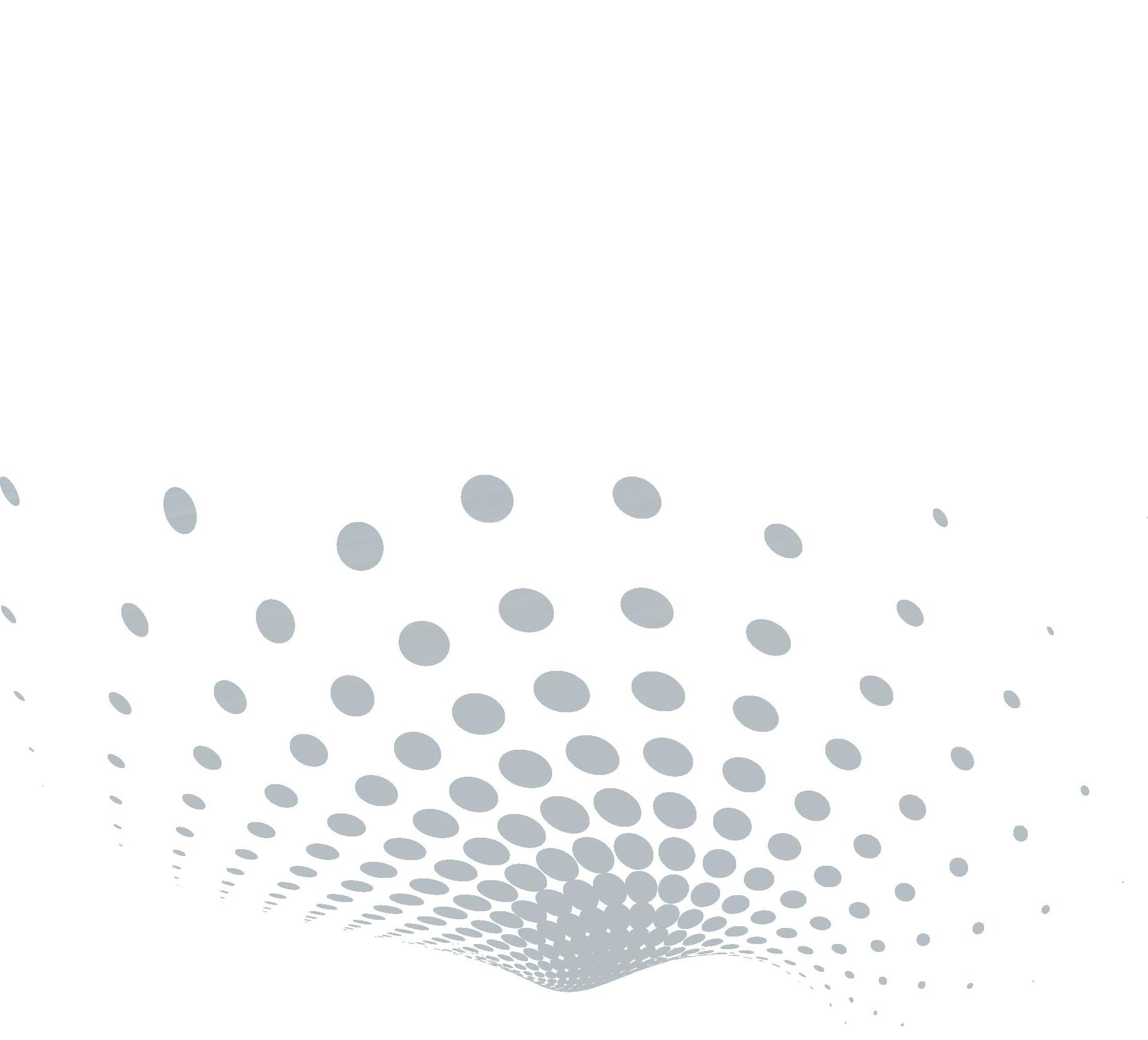

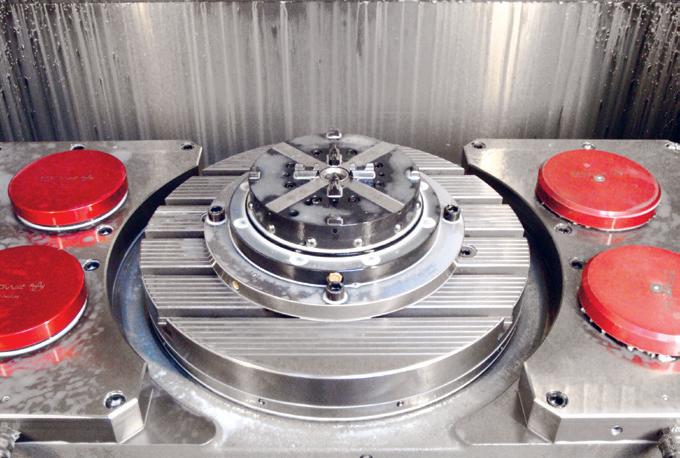

The ProductionChuck 210 is the perfect solution for your automated manufacturing. With its compact, robust design and sophisticated functionality, it takes your 5-axis machining to a whole new level.

The clamping mechanism located around the circumference ensures a stable connection between the chuck and the pallet for high precision – even with large workpieces.

PC 210 chucks are robust and compact in design. The low profile design offers plenty of space for workpieces and optimum accessibility for 5-axis machining.

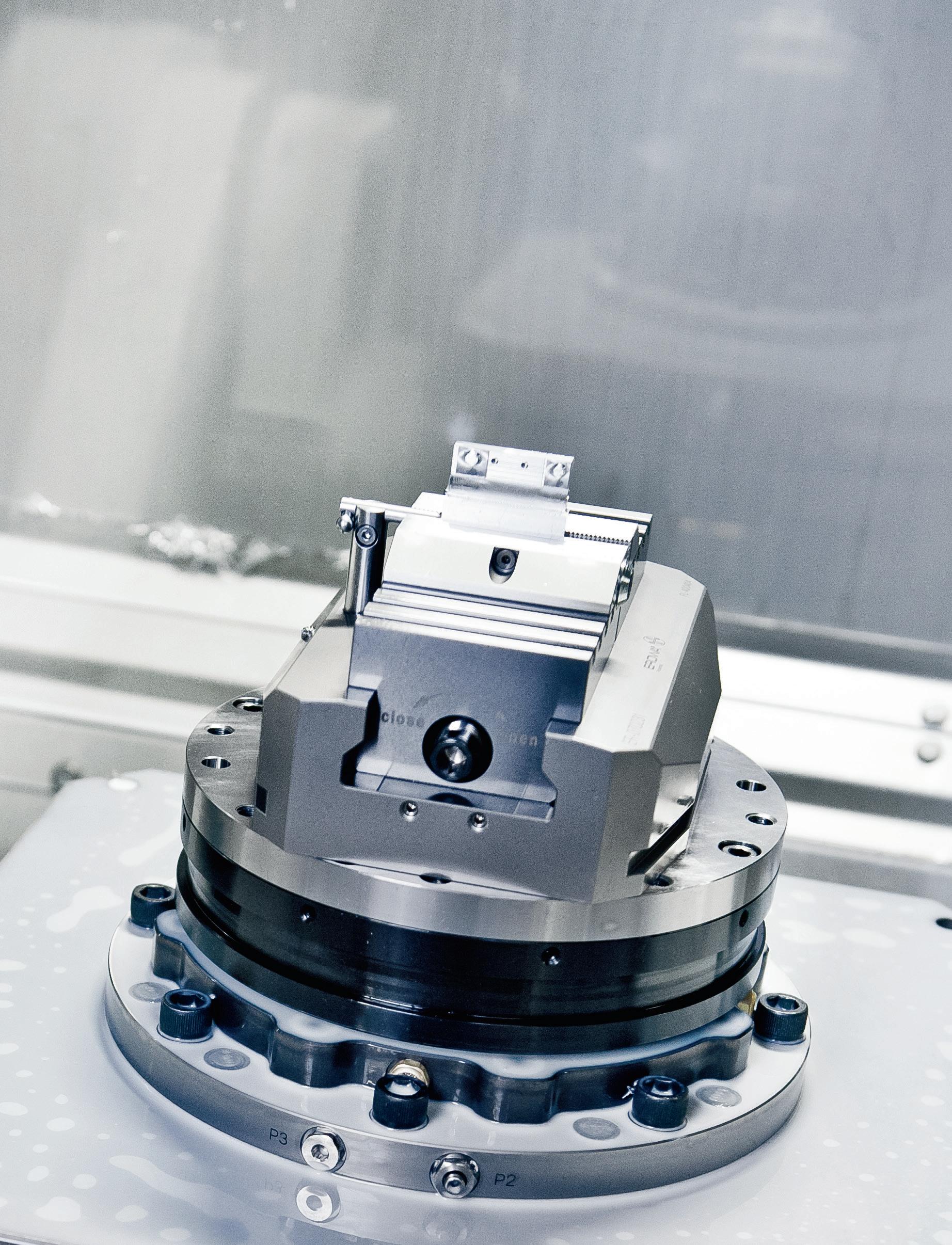

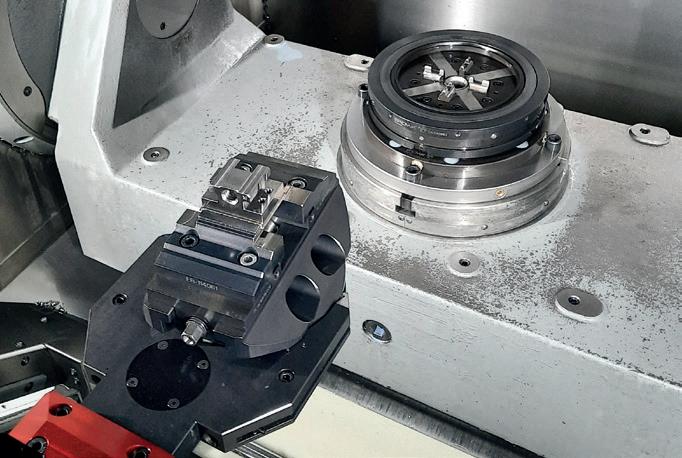

Equipped with an integrated EROWA PowerChuck P, the ProductionChuck 210 Combi handles both ITS and ProductionChuck 210 pallets effortlessly – ensuring maximum flexibility and minimal changeover time.

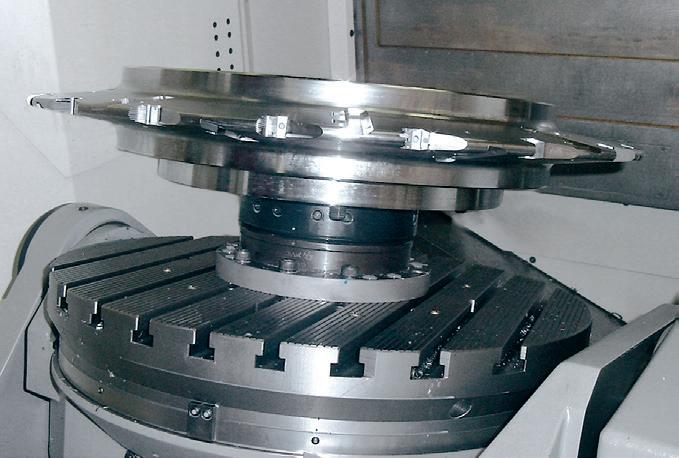

Thanks to their wide spacing, the Z-supports deliver stable, precise support – even when handling larger workpieces.

The ProductionChuck 210 palletizing system can be seamlessly automated, with EROWA providing tailored handling solutions for any application and technology.

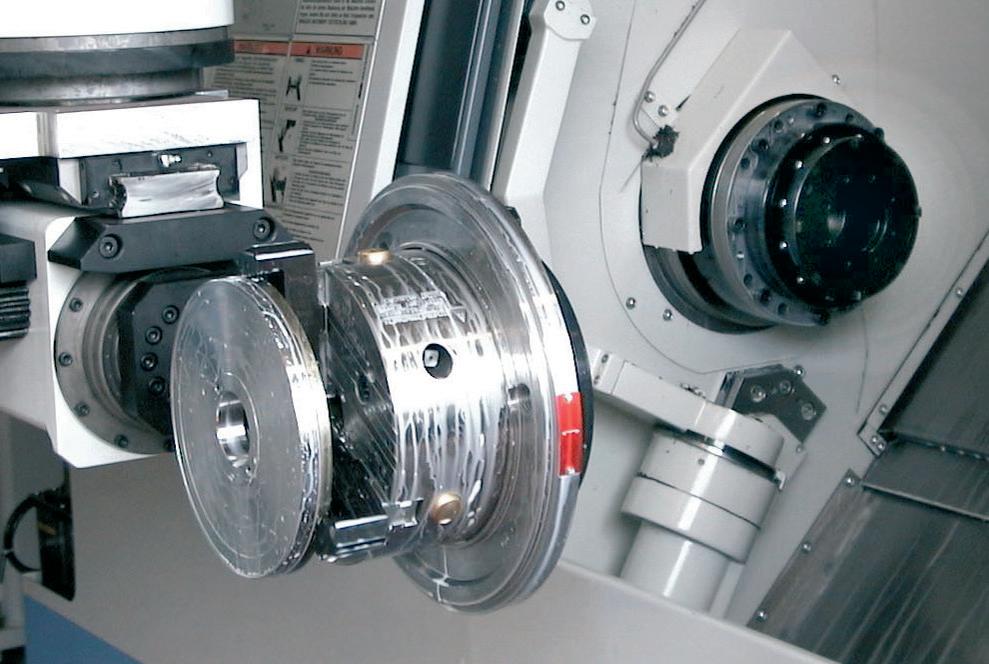

The palletizing system is also highly suitable for use on lathes and circular grinding machines.

Palletized fixtures in the robot magazine. The PC 210 pallets are the practical basis for the accommodation of workpieces, self-centering vises and fixtures.

Optimally Accessible

The EROWA ProductionChuck 210 seamlessly blends proven EROWA precision with the flexible palletizing capabilities required in modern parts manufacturing.

• The clamping mechanism around the circumference ensures a stable connection between the chuck and the pallet.

• The 81mm diameter bore allows material to be fed through centrally. This is a major advantage when machining workpieces on lathes and dividing heads.

• All pallets can be indexed 4 x 90°.

• Operation is manual or automatic.

• The system is suitable for palletizing workpieces with dimensions up to 400 x 400 x 400 mm.

• The round design allows optimal accessibility to the workpiece with tools.

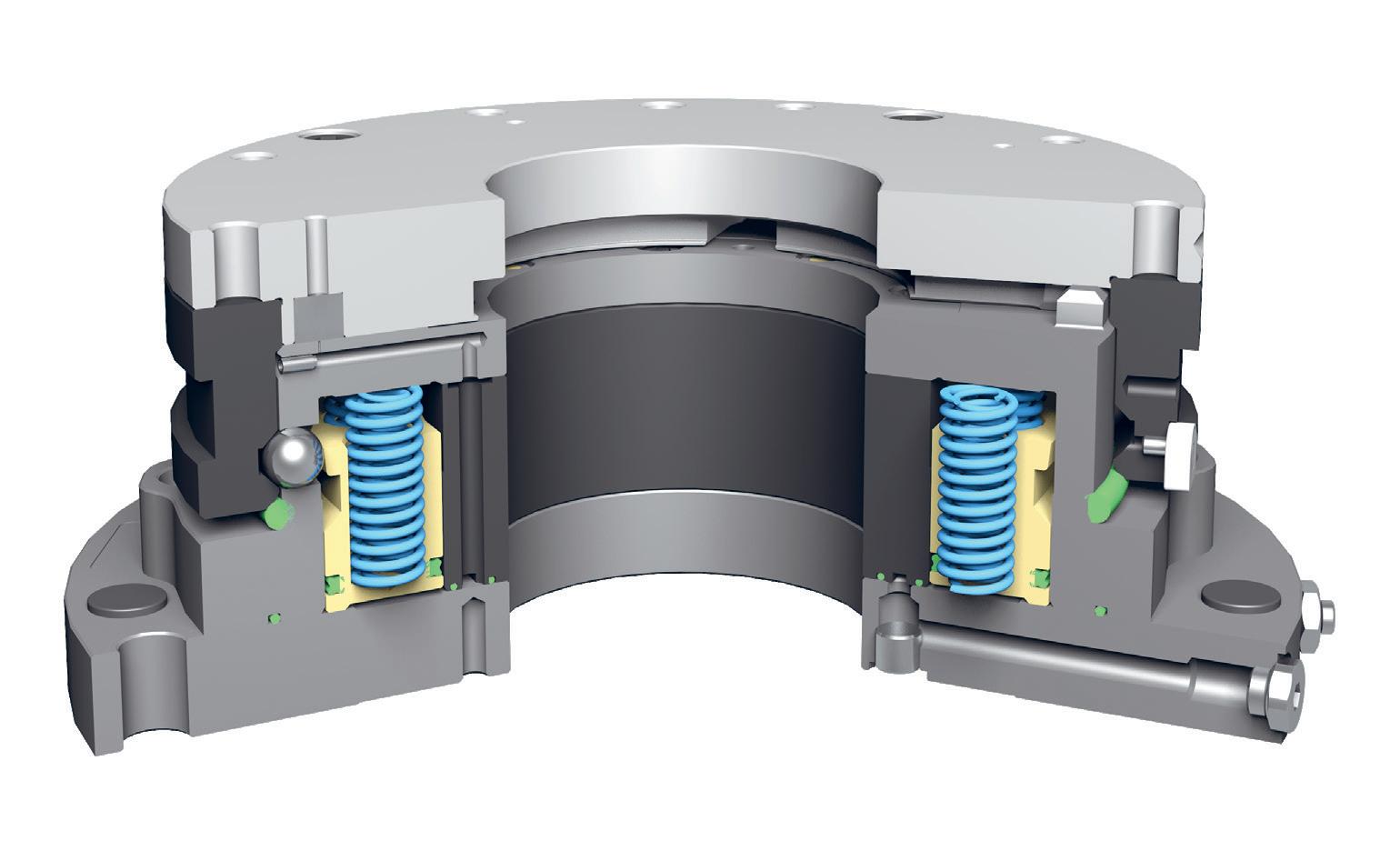

Function

01 | Mounting

Workpieces, fixtures and plates are directly mounted on the PC 210 pallet.

02 | Centering system

The widely spaced centering system enables the transfer of maximum torque.

03 | Z-supports

The Z-supports minimize the tilting moment and are automatically cleaned with air. Stagnation pressure is then used to verify that the pallet is properly clamped.

04 | Ball lock

The self-locking ball lock generates a clamping power of 20,000 N. The chuck is clamped via spring pressure. Compressed air is needed to open the chuck.

05 | Material pass-through

Round material of up to ø 81 mm can be led directly through the chuck. The ø 81 mm boreholes also provides for air, hydraulic and vacuum lines to operate the fixtures that are clamped on pallets.

Pallet size ø 210 mm

Chuck dimensions H = 55 mm x ø 224 mm H = 75 mm x ø 254 mm

System height (chuck and pallet) 80 mm / 100 mm

Recommended workpiece size up to 400 x 400 x 400 mm

Repeatability < 0.002 mm

Pallet indexation 4 x 90°

Clamping power 20,000 N / 29,000 N

Clamping power (central PowerChuck P) 9,000 N generated by spring power

Opening pressure min. 7.5 bar (pneumatically)

Chuck fits directly to:

– machine tables with T-slots

50, 63, 100 mm

– round tables with T-slots 4 x 90°, 45°

ProductionChuck 210

Technical data - ProductionChuck 210

The components

EROWA provides you with a full range of products – everything fits together!

To make it easier for you to find your way about the fields of application for EROWA products, we use the following symbols in all our documents:

1. Manual operation

2. Operate with compressed air jet

3. Operate with manual valve

4. Operate with manual control unit

5. Operate with electropneumatic control unit

6. With central flushing clearance

7. Suited for submerged operation

8. Corrosion-resistant material

9. Suited for automatic operation

10. Handling with EROWA Robot gripper S

11. Handling with EROWA Robot gripper Combi

12. Handling with EROWA Robot gripper C

13. Handling with EROWA Robot gripper 72

14. Handling with EROWA Robot gripper 115

15. Handling with EROWA Robot gripper 148

16. Handling with EROWA Robot gripper RN PC 210

17. Handling with EROWA Robot gripper RCS

18. Handling with EROWA Robot gripper WGS-500

Technical data

EROWA ProductionChuck 210 Chucks

ProductionChuck 210

Repeatability < 0.002 mm

Indexing 4 x 90°

Clamping power 20,000 N

Clamping power (central PowerChuck P) 9,000 N

Clamping with spring tension (clamped without pressure)

Opening pressure min. 7.5 bar (pneumatic)

Max. permitted speed 4,500 min -1

ER-030479 ProductionChuck 210

Version Chuck for high machining forces in chip cutting. Low-profile. Through-borehole ø 81 mm.

Connections Laterally or from below with two lines.

Operation With air gun, laterally. With control unit, through the two connections laterally or from below.

Application On milling machines, lathes and grinding machines. To clamp pallets PC 210.

ER-032964 ProductionChuck 210 without base plate

Version Chuck for high machining forces in chip cutting. Low-profile. Through-borehole ø 81 mm.

Application On milling machines, lathes and grinding machines. To clamp pallets PC 210.

Connections 2 air connections: on the sides and from below through customized base plate.

Operation With air gun or control unit.

Note Base plate must be customized.

Version Chuck for strong machining forces in chip-cutting operations. PC 210 with integrated PowerChuck P.

Connections Laterally or from below with two lines.

Operation With air gun, laterally. With control unit, through the two connections laterally or from below.

Application On milling machines, lathes, grinding machines and EDM centers. To clamp pallets PC 210, pallets ø 148, ø 115, ITS holder ø 72 and 50 C.

Version Chuck for high machining forces in chip-cutting operations. PC 210 with integrated PowerChuck P.

Application On milling machines, lathes, grinding machines and EDM centers. To clamp pallets PC 210, ITS pallets ø 148, ø 115, ITS ø 72 and 50 C holders.

Connections 2 air connections: on the sides and from below through customized base plate.

Operation With air gun or control unit.

Note Base plate must be customized.

ER-030478 ProductionChuck 210 Combi

ER-032388 ProductionChuck 210 Combi without base plate

EROWA ProductionChuck 210 Pallets

ER-046473 Clamping ring RN PC 210

Version Steel, hardened.

Application Clamping ring for centering pallet PC 210 and centering pallet PC 210 / ø 81. Can be automated with gripper PC 210 RN (option).

ER-042865 PC Centering pallet 210

Version Steel, without clamping ring (option ER-046473).

Fitting 8 x M10 attachment threads and two ø 10 boreholes.

Application To accommodate workpieces, clamping jigs and plates PC 210.

ER-042866 PC Centering pallet 210 ø 81

Version Steel, without clamping ring (option ER-046473).

Fitting 8 x M10 attachment threads and two ø 10 boreholes.

Application To accommodate workpieces, clamping jigs and plates PC 210.

ER-046009 Pallet RN PC 210

Version Steel. Centering segments integrated.

Assembly 8 x M10 attachment threads and two ø 10 boreholes. Application To clamp workpieces, clamping jigs and pallets PC 210. Can be automated with gripper RN PC 210 (option).

ER-046474 Pallet RN PC 210 ø 81

Version Steel. Centering segments integrated. Through borehole ø 81 mm.

Fitting 8 x M10 attachment threads and two ø 10 boreholes.

Application To accommodate workpieces, clamping jigs and plates PC 210.

Can be automated with gripper RN PC 210 (Option).

ER-116634

pallet RN PC 210

Version Pallet PC 210 with ground alignment rail and four Z-measuring surfaces.

Application Alignment of the angle position and determination of the Z-values of PC 210 chucks.

P

Version Pallet P ø 148 with ground alignment rail and four Z-measuring surfaces, including chucking spigot F/M Production.

Application Alignment of the angle position and determination of the Z-values of ITS Chucks 100 P, PowerChucks P and PC 210 Combi chucks.

Version Steel, rust-resistant. Centering integrated in the pallet. With optimized center of mass.

Application To accommodate workpieces and fixtures for chip-cutting production.

Fitting a blank Through the pallet with M8 bolts or through the blank with M10 bolts.

Please note Compatible with EROWA ProductionChuck 210 Combi.

Version Fixed type, manual. 1 spigot.

Application In pallets PC 210 for chip-cutting machining processes.

Please note: For additional pallets and electrode holders for the ProductionChuck 210, see EROWA General Catalog.

Alignment

ER-138950 Alignment pallet ø 148

ER-115521 Pallet ø 148 P

ER-045541 Chucking spigot for PC 210

EROWA ProductionChuck 210 Operation

ER-157413 Control box 1-fold with booster

Version Manual control box for 1 chuck. Integrated booster with a maximum loading ratio of 1:2. To control the opening / reclamping / cleaning functions. Pressure adjustable, display through a manometer. Includes a set of tubes.

Connections 1 input (P IN) and 3 outputs (P2 Open / P3 Clean / P4 Reclamp).

Application To operate chuck types ITS, ITS Compact, CombiChuck, PowerChuck P, VPC, UPC or PM Tooling.

ER-070445 Control unit with monitoring

Version Electropneumatic valve. Outputs for chucks: opening/cleaning/reclamping. 24 V, incl. mounting accessories and 3 m connection hose.

Application Operation and monitoring of machine-integrated chucks, for instance through the CNC M-function.

Air jet

Version Plastic, smooth regulation of air flow, connection 1/4’’, inside thread.

Application Operation of manual chucks.

Note Not suitable for operating MTS+ and MTS81.

Option Volume and pressure reduction to air jet (ER-087668). Pressure build up is reduced if Air Jet is not pushed against an air valve.

Booster box

Version Booster with a maximum loading ratio of 1:2. Pressure adjustable, display through a manometer.

Connections 1 input (P IN) and 2 outputs (P OUT High (boosted) / P OUT Low (network pressure)). All connections with fast couplings for tube inside ø mm.

Application To ensure the required pneumatic pressure in case of deficient network pressure and pressure fluctuations.

Please note To be integrated in the air circuit near the user.

ER-087668

ER-001846

ER-157409

EROWA ProductionChuck 210

Auxiliary Equipment

ER-094093 Sealing ring ITS 50 C for PC 210

Version Steel hardened.

Application

Prevents penetration of chips and dirt into the ProductionChuck 210 Combi by application of EROWA electrode holders C. For automatic handling with gripper RN PC 210 (option).

ER-046460 Sealing ring holder RN ø 72 PC 210

Version Steel hardened.

Application Prevents penetration of chips and dirt into the ProductionChuck 210 Combi by application of EROWA ITS holders ø 72. For automatic handling with gripper RN PC 210 (option).

ER-046458 Sealing ring holder RN ø 85 PC 210

Version Steel hardened.

Application

Prevents penetration of chips and dirt into the ProductionChuck 210 Combi by application of EROWA ITS pallets ø 85. For automatic handling with gripper RN PC 210 (option).

ER-046456 Sealing ring holder RN ø 115 PC 210

Version Steel hardened.

Application Prevents penetration of chips and dirt into the ProductionChuck 210 Combi by application of EROWA pallets ø 115. For automatic handling with gripper RN PC 210 (option).

ER-045983 Sealing ring holder RN ø 148 PC 210

Version Steel hardened.

Application Prevents penetration of chips and dirt into the ProductionChuck 210 Combi by application of EROWA pallets ø 148. For automatic handling with gripper RN PC 210 (option).

EROWA ProductionChuck 210

Auxiliary Equipment

ER-046462 Cover RN PC 210

Version Steel hardened. Application Prevents penetration of chips and dirt into the ProductionChuck 210 and ProductionChuck 210 Combi. For automatic handling with gripper RN PC 210 (option).

ER-045243

PC 210 Sealing ring

Version Holder with wiper.

Application For use on ProductonChuck 210 Combi. To seal the outer balls if ITS 50 standard electrode holders or other workpiece carriers without PC sealing ring holders PC 210 are used.

ER-033036 Covering ring PC 210

Application Covering ring for the attachment bolts of the PC 210: ER-030479, ER-030478 (Recommended for application on lathes).

ER-035294 EWISTM Rapid chip with chip holder RCS with chip ø 3 x 13.5mm

Version Holder with built-in data carrier. EWIS chip: read only. Application To build into RCS coupling, PalletSet W holder and Basic WEDM holder.

ER-094168 EWISTM rapid chip with holder SW14 Length 8mm (grey)

Version Sleeve fitting with built-in data carrier. EWIS Rapid chip: read only.

Application In any EROWA electrode holder and pallet which has been prepared for it.

ER-119717

Repairs set ProductionChuck 210 for 030479 / 032964

Version All wear parts for ProductionChuck 210 ER-030479 and ER-032964.

Application Remove PC 210 chuck according to supplied instructions, replace parts.

ER-126696

Repairs kit ProductionChuck 210 Combi for 030478 / 032388

Version All wearing parts for the ProductionChucks 210 Combi ER-030479 and ER-032964.

Application Dismantle ProductionChuck 210 Combi according to instructions, replace parts.

EROWA - Manufacturing automation at its best

EROWA AG, founded in Switzerland in 1971, is now a globally operating organization specializing in the development, production, consulting, and distribution of state-of-the-art manufacturing technology for tool and mold making, as well as for production and precision engineering. With their headquarters located in central Switzerland, EROWA ranks among the world‘s leading companies in clamping technology and automation. Having 13 subsidiaries and 22 representatives, EROWA offers international points of contact and worldwide customer service.

EROWA Group Business Network: a member of ORENDA Holding Ltd. Subject to technical changes. Registered trademark of EROWA AG, Copyright © EROWA AG, patents are existing or pending for a number of products of EROWA AG.

Empowering Your Production

The next step towards greater efficiency, precision and productivity starts now. With EROWA, you have a partner who will optimize your production holistically - from clamping technology to automation and process control. Our innovative solutions adapt flexibly to your requirements and grow with you - for production that is ready for tomorrow. Get in touch with us - we will be happy to assist you.

EROWA - Contacts