Empowering your production

High customer demands and constantly changing economic conditions are challenging the supplier industry in all areas. Dynamic challenges throughout the entire production process require agile solutions. This is precisely where EROWA, as an experienced company, offers an independent yet holistic approach.

From the medical industry to aircraft construction. From the semiconductor industry to the world of automotive. The demands are high, time is short. This is precisely why it is important to take a bold step towards the future in order to manufacture even more economically and sustainably.

With needs-based solutions in the areas of workpiece clamping, presetting and measuring as well as automatic loading and data transfer, we enable you to make economical and sustainable investments in your production systems.

EROWA‘s solutions are modular and scalable: machine tools from all manufacturers and different generations can be integrated, regardless of the different manufacturing processes.

• Reduction of set-up times

• Maximization of machine running times

• Future-proof, modular solutions

• Integration into existing IT infrastructure

• Global support

Our customers achieve measurable improvements:

• Set-up time reductions of up to 70%

• Increase in machine running time by an average of 650%

• Faster amortization due to flexible expandability

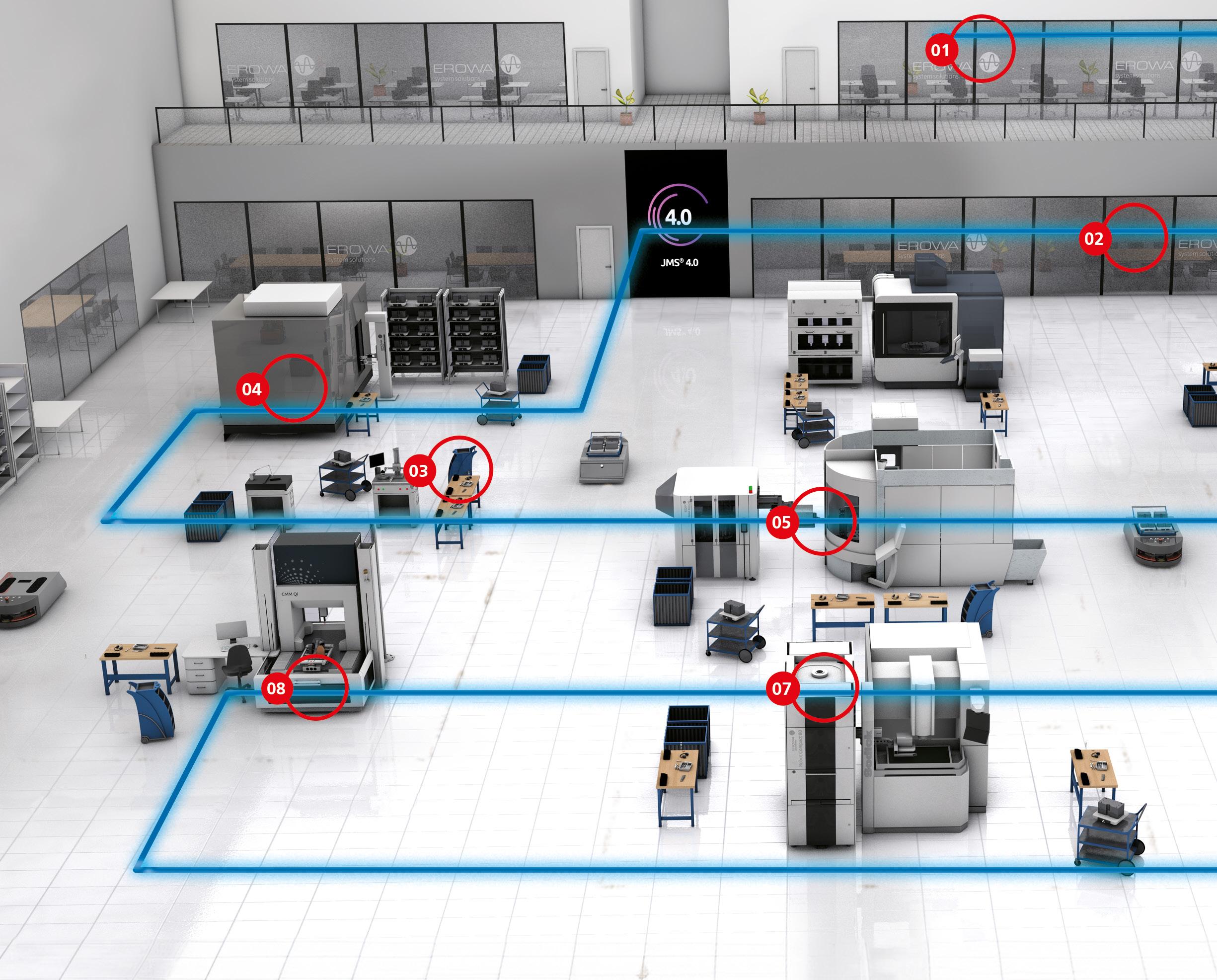

Smart networking

The EROWA JMS 4.0 process control system connects all data and controls the entire production process. Thanks to a continuous flow of information from CAD, CAM to ERP, the smart factory becomes a reality. Numerous interfaces in JMS 4.0 ensure that you can plan and work with real-time data.

01 | Order entry with ERP

02 | CAD/CAM office

03 | Main time parallel set-up and zero point detection

04 | Milling with manual loading

05 | Milling with automatic loading with monoblock robot

06 | Milling and in-process measuring with automatic loading by linear robots

07 | Eroding with automatic loading by monoblock robot

08 | Quality measurement

09 | Monitoring and reporting the production processes

The aerospace industry is confronted with the strictest quality standards, innovative material combinations and absolute traceability. Lightweight construction, engine efficiency and safety require continuous process optimization. Manufacturers and suppliers need highly flexible production systems in order to combine low quantities with maximum precision and traceability.

• Material durability and variety

• Precision and quality

• Continuous traceability

• Simple control regulations

• Supply chain security

• Certified processes

EROWA SOLUTIONS

Our EROWA Robot Dynamic systems enable the operation of multiple CNC centers with maximum flexibility - ideal for complex components such as turbine blades. Thanks to modular expandability, the investment remains flexible in the long term.

In-process control of turbine blades

• Flexible solutions for various materials

• Guaranteed precision of the workpieces

• Holistic monitoring of the manufacturing process

• Maximum process reliability through smart automation

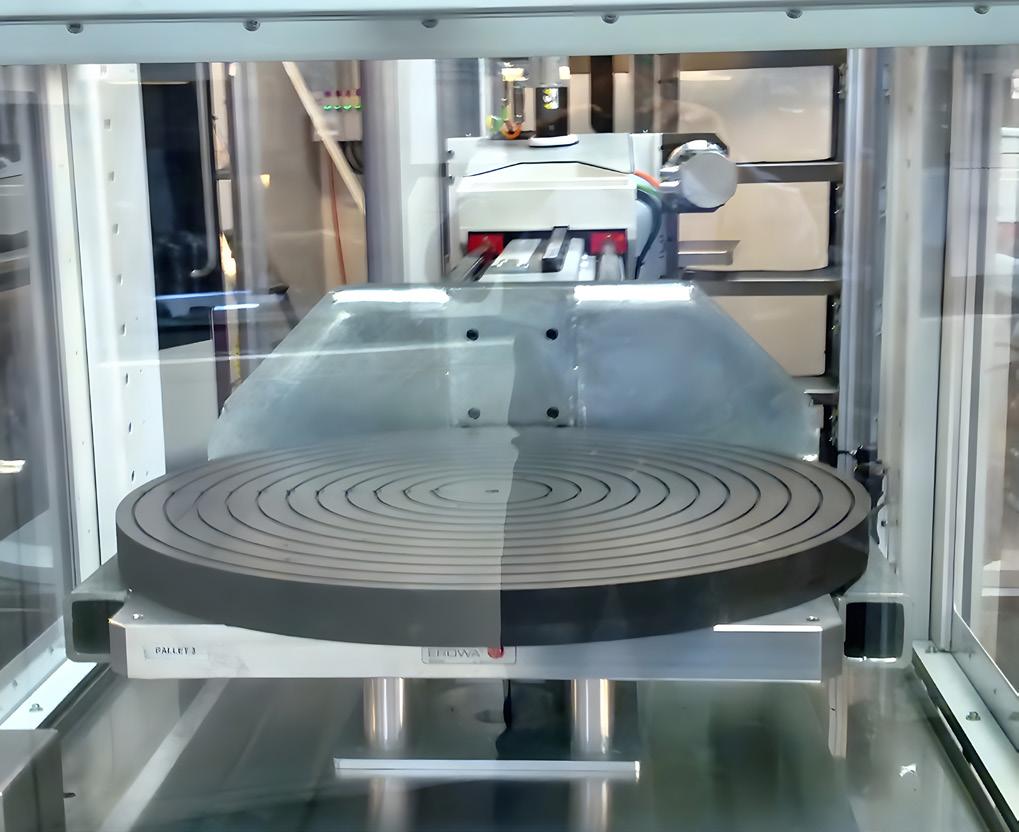

EROWA UPC palletizing systems reduce set-up times and increase efficiency in prototype and small series production. This lowers costs and increases competitiveness.

Maximum process reliability and data traceability

JMS 4.0 guarantees end-to-end control and complete traceability of all production steps. EROWA distinguishes itself here with its seamless ERP connection.

The development of medical technology is very dynamic. The medical technology industry demands absolute process reliability combined with short innovation cycles. Implant manufacturers and manufacturers of surgical instruments have to cope with small batch sizes, the strictest regulatory requirements and an increasing number of variants.

The EROWA Robot Compact 80 enables unmanned, efficient production even for the smallest series and frequent product changes. EROWA scores points here with its small footprint.

Customized solutions

THE CHALLENGES

• High precision and quality

• Compliance with regulations

• Seamless documentation and traceability

• External cost pressure

EROWA SOLUTIONS

• High reproducibility

• Complete traceability and documentation in accordance with MDR and FDA guidelines via process control system

• Fast integration of modular solutions

Part sizes from a few millimeters up to 300 mm in length with batch sizes from 1 to 10,000 pieces and a variety of up to 1,000 different parts per order - tailor-made solutions like EROWA VPC are particularly crucial for such challenges in order to adapt ideally to the process sequence.

Maximum precision and reproducibility

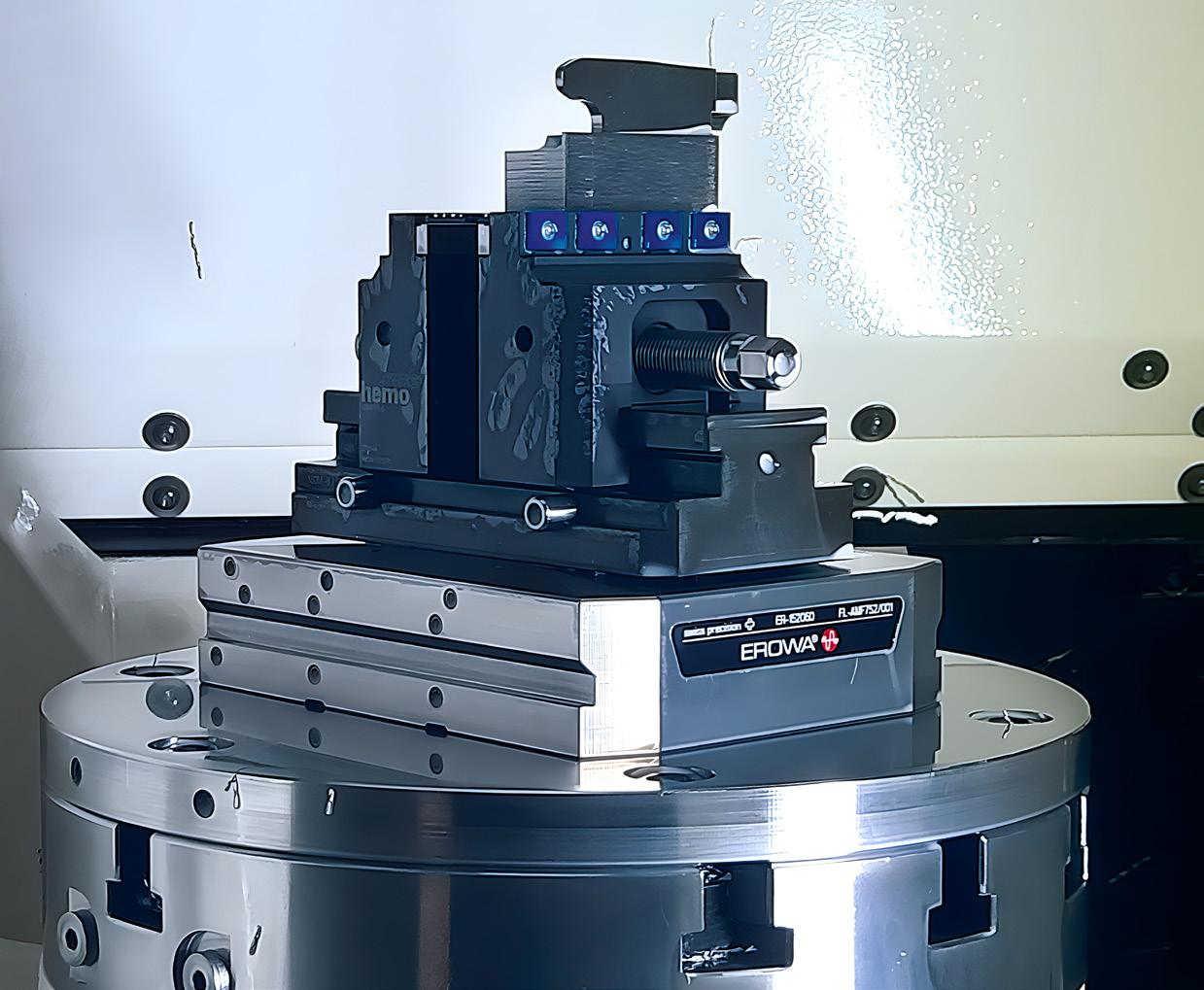

EROWA ITS and MTS clamping systems offer maximum precision and reproducibility - crucial for the manufacture of endoprostheses and dental components. They reduce inspection effort and error rates.

The automotive industry is transforming rapidly. Electromobility, lightweight construction and increasing model diversity require flexible production. Suppliers and OEMs must efficiently manage increasing quality requirements and fluctuating batch sizes. Flexibility in production and targeted risk management are essential in order to successfully navigate this challenging industrial landscape.

Automation optimizes production processes and increases the efficiency of machines. Scalable and flexible systems help to adapt the various processes and grow step by step as required, including high process reliability.

• New technology and greater complexity of products

• Overall production in transition

• Sustainability

• Quality requirements

EROWA SOLUTIONS

• Modular systems for high production flexibility

• User-friendly handling for employees

• Smart automation for maximum machine autonomy

• Optimization of production and logistics processes

Depending on size and weight, workpieces and clamping devices are attached to the appropriate EROWA system size. Adapter pallets create maximum modularity and enable fast product changes without compromising quality. This improves the OEE (Overall Equipment Effectiveness).

Our Robot Dynamic 500 linear production cells adapt dynamically to changing production requirements - e.g. when processing battery module housings. The modular scalability reduces investment risks.

Mechanical engineering combines one-off and small series production of large, complex components. Customer-specific solutions, tight delivery deadlines and increasing cost pressure demand efficient, flexible production systems. Manufacturers are forced to push ahead with the integration of digital technologies as well as the automation and networking of production.

EROWA Robot Six flexibly expands existing production cells, supports different machining processes and combines raw/semifinished parts with pallet handling.

EROWA offers exceptional compatibility with third-party systems.

EROWA LoadMaster Compact enables the precise handling of heavy components weighing up to 5 tons - e.g. machine beds or large mould inserts. Less manpower required, greater safety.

THE CHALLENGES

• Technical complexity

• Customer-specific requirements

• High quality

• Cost efficiency

EROWA SOLUTIONS

• Flexible automation solutions

• Standardized pallet system

• Modular concepts for individual challenges

• Clear process control system

Large workpieces positioned quickly Reducing set-up times is also a key issue when setting up and repositioning large workpieces. The EROWA Giant Tooling System (GTS) guarantees reliable clamping of large and difficultto-fix workpieces. The high repeat accuracy reduces rework.

The semiconductor industry is characterized by extreme precision requirements and short innovation cycles. Manufacturers of wafer, MEMS and optoelectronic components require ultra-precise, flexible and highly automated production processes in order to reduce costs and improve process reliability at the same time.

Optimal planning to optimize complex manufacturing processes, produce efficiently and make reliable statements about delivery dates is essential to meet the required quality and adherence to delivery dates. JMS 4.0 centralizes order management and enables precise in-process measurements for maximum process control. The platform is future-proof and scalable.

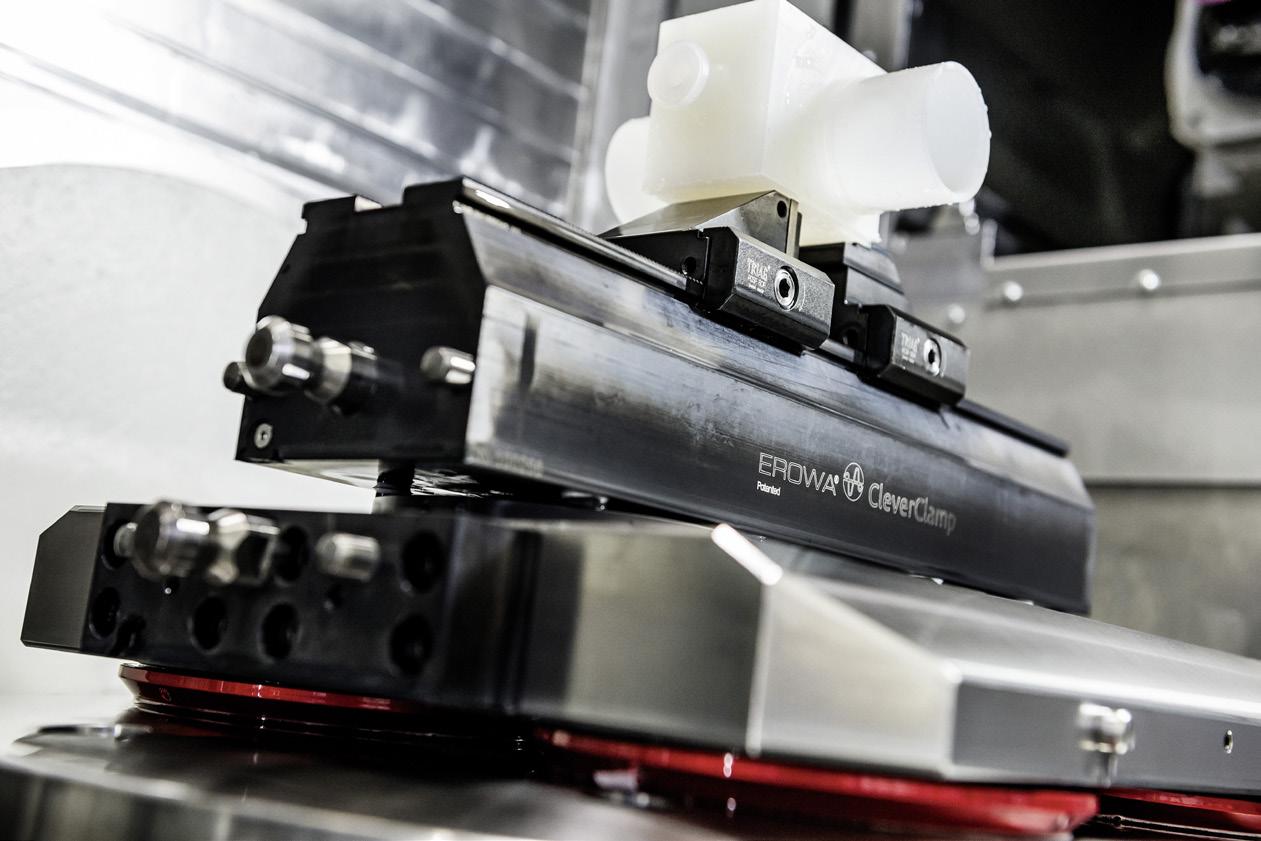

Vacuum clamping technology

Vacuum clamping plates with EROWA MTS pallets enable the precise clamping of sensitive, thin or structured components. Advantage: Stresses are minimized.

THE CHALLENGES

• Precise and complex manufacturing processes

• New materials and technologies

• High quality requirements

• Sustainability and environmental impact

EROWA SOLUTIONS

• High-precision clamping systems

• Customized automation

• Integrated measurement technology solutions

• Scalable process control system

Standardized interface for all machines

EROWA clamping systems and the palletizing of workpieces are crucial for ensuring and even optimizing flexibility in automation. The zero point is seamlessly transferred to the next machining process.

The packaging industry is under increasing pressure to efficiently combine variant diversity, short delivery times and sustainability requirements. Manufacturers have to implement frequent format changes without sacrificing productivity.

Flexibility and a high degree of automation are two decisive factors that contribute significantly to increasing efficiency and competitiveness in a challenging production environment. EROWA loading systems can be adapted to suit any production environment. Competitive advantage: short amortization times.

THE CHALLENGES

Powerful and precise positioning

The compact EROWA MTS clamping system offers flexible solutions for a wide range of packaging formats - from consumer goods to pharmaceutical applications. EROWA impresses here with minimal space requirements.

• High flexibility required in production

• Fast delivery times expected

• High quality and reliability

• Sustainable and cost-efficient

EROWA LÖSUNGEN

• Smart automation for maximum process reliability

• Flexible and modularly expandable automation solutions

• Standardized interface for maximum flexibility

Reduce delivery times

The great potential for shortening throughput times lies in the unused off-peak and night-time hours. By automatically loading the machines with an EROWA loading system, they can also be used unmanned, reliably and productively.

The EROWA process control system JMS 4.0 connects all data and controls the entire production process. It automates the data flow from the ERP and CAD/ CAM through to the production cells.

JMS 4.0 takes over the control of the robots and the data transfer and control of the connected machines.

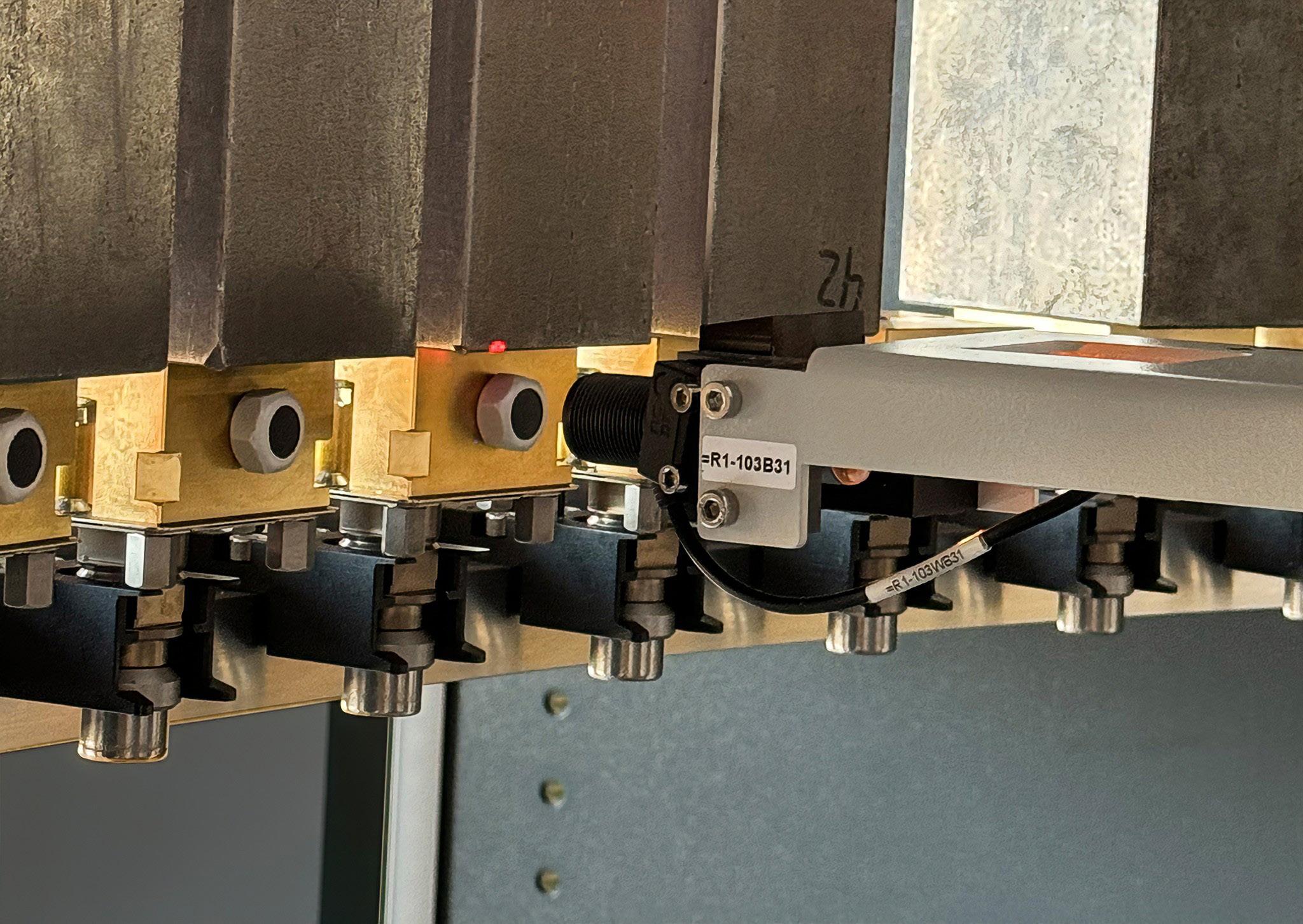

You determine the level of integration yourself. With or without automation, whether connecting a single machine or a fully integrated workshop solution. The EROWA EWIS handheld reader uses identification chips to record all pallet/workpiece data and transmit it to the JMS® 4.0 process control system. Simple, safe, fast!

JMS 4.0 provides a clear overview. All productionrelevant data is displayed in a user-friendly way. Current status and status messages support the operator.

Identification with RIFD chips can also be automated. When a magazine is loaded with workpieces or electrodes, the magazine is automatically identified by sensors and the information is transmitted to the process control system. Automatic identification guarantees a high level of process reliability.

Dashboard and supervision applications show the efficiency key figures in real time and the current status of the production cells. These can also be viewed on the EROWA mobile app.

The EROWA process control system controls and monitors production systems. The complete consistency of the data allows truly comprehensive control and process reliability.

EROWA AG, founded in Switzerland in 1971, is now a global organization for the development, production, consulting, and distribution of state-of-the-art manufacturing technology in tool and mold making, as well as in production and precision mechanics. EROWA is one of the world‘s leading companies in its main areas of activity: clamping technology and automation. EROWA‘s headquarters are located in central Switzerland. With its 13 subsidiaries and 22 agencies, EROWA offers international contacts and worldwide customer service.

The next step toward greater efficiency, precision, and productivity starts now. With EROWA, you have a partner who optimizes your entire production process – from clamping technology and automation to process control. Our innovative solutions adapt flexibly to your requirements and grow with you – for production that is ready for tomorrow. Get in touch with us – we will be happy to assist you.