Vertical Turning and Grinding Centers

VSC 250 DS

VSC 400 DS

VSC 400 DDS

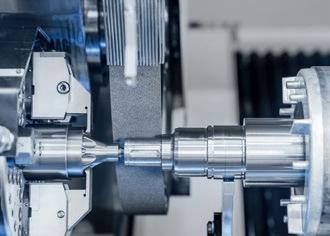

Vertical turning and grinding- The turning and grinding centers

VSC 250 DS, VSC 400 DS and VSC 400 DDS combine the advantages of vertical hard turning with the advantages of grinding – on a single machine, in a single set-up.

VSC 250 DS

VSC 400 DS

VSC 400 DDS

VERTICAL TURNING AND GRINDING CENTERS

Efficient flexibility.

Quality requirements are steadily increasing, particularly for components in the automotive industry and its sub-contractors. To fulfill the quality requirements, EMAG relies on complete-machining in a single set-up. The use of different technologies – such as turning and grinding, for example –leads to a considerable shortening of the process stream, with all its advantages for the user. These include less

capital outlay and lower unit production costs, shorter throughput times, a better quality component and a higher degree of process integrity, a smaller footprint and less maintenance.

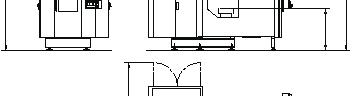

VSC 250 DS

VSC 400 DS

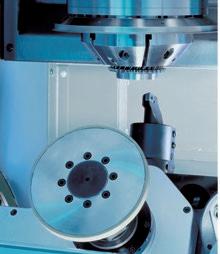

Disc-type turret for 12 turning tools and one fixed spindle for internal grinding work.

Hard turning and grind-finishing.

Hard turning, scroll-free turning, grinding.

The VSC DS series is specially designed for the low-cost, process capable, precision machining of medium to large component batches. Typical examples of such workpieces are: gearwheels, chain wheels, sliding sleeves, parts for CVTs, link pins, con-rods, rocker arms, bearing rings and piston rings. In each case, workpiece and quality requirements decide which of the available machining processes is the best and the most economical. The advantage for the

customer is in the flexibility that allows them to select the best technology for every application: hard turning, scroll-free turning and grinding – and all on a single machine.

VSC 400 DDS

VSC 400 DDS with linear Y-axis and laterally aligned turning tools.

Internal polygon grinding

Peel-grinding with CBN wheel

Hard turning

Complete manufacturing processes – VSC DS.

Whether the job includes the high metal removal rates of turning and milling or a gentler grinding process – the VTC machine series offers the possibility to integrate most metal cutting processes on the machine. Depending on production requirements the VSC DS can be equipped with turning, milling, drilling, grinding and even honing or hardening modules – it could also use combinations of them, of course. For each requirement the best possible technology is available. The advantages are obvious. One main advantage is that complete machining in a single set-up eliminates reclamping errors.

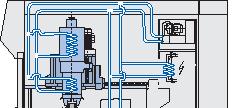

Measuring is also included in the machine, making quality control an integral part of the process. The measuring probe is located between the machining area and the pick-up station and is well protected. The workpiece is measured in its original set-up, outside the machining area. It can also be checked and measured anytime between machining operations.

VSC 250 DS

VSC 400 DS

VSC 400 DDS

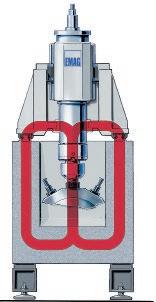

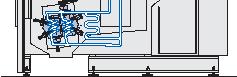

All accuracy defining machine elements are connected to the fluid-cooling

The symmetrical force distribution of the closed-loop construction is a necessary prerequisite for high static and dynamic rigidity

The hydrostatic guideway principle.

circuit.

The vertical arrangement of the work spindle and the fact that the tools are located below the workpiece ensure optimal chip flow conditions during both hard turning and grinding. All machine modules are mechanically stable and particularly vibration resistant. This is helped by the MINERALIT® polymer concrete machine base. The polymer granite base has excellent vibration damping properties and the sturdy design of the work spindle also helps. The work spindle forms an integral part of a sturdy quill with high-precision,

hydrostatic guideway in Z – a construction that adds to the vibration damping quality.

The tooling systems are firmly integrated into the machine base and provide a stable basis for demanding turning and grinding work. This is an important requirement for time-saving hard pre-turning operations and ensures that good surface finishes are generated with the hard finish-turning or grinding operations. The number and type of fixed tooling systems employed can vary according to machining requirements.

VSC 250 DS

VSC 400 DS

VSC 400 DDS

The whole machine is thermally stable, because the work spindle, grinding spindles, turret and machine base are all fluid-cooled. The operating temperature is quickly reached and then maintained within the limits of the ambient temperature by a powerful cooling unit.

As on all machines of the VSC series, the pick-up principle ensures that the EMAG REINECKER VSC DS turning and grinding center loads itself. There is consequently no need for cost-intensive, space-devouring gantry loaders or other loading devices that necessitate time consuming resetting work.