EMAG offers three machine series that are perfectly tailored to a wide range of manufacturing requirements: Classic, Modular and Customized. From economical entry-level solutions to highly specialized systems, EMAG can help you find the optimal solution for your production.

Complete solutions for all series

EMAG off ers comprehensive turnkey solutions for all machines. From the initial process design to successful production implementation, you will benefi t from the decades of experience of EMAG‘s experts. The range of services includes:

Detailed process and tool design for optimized machining strategies

Precision cycle time calculation with the latest simulation software

Comprehensive project support from a single source

Worldwide service and spare parts supply

With EMAG, you not only get a machine, but a well-thought-out manufacturing solution that is precisely tailored to your requirements and your budget.

COMPLETE SOLUTIONS for all series

Guaranteed system availability and production cycle times

Classic machines combine maximum efficiency with the high quality you expect from EMAG. These machines focus on the essentials and off er an optimized range of functions for typical machining requirements. The base machine is purchased from selected partners and equipped by EMAG with proven process and machining technology, such as chucks and tools. You benefi t from EMAG‘s worldwide service network and fast spare parts supply – the ideal choice for cost-efficient production without compromising on reliability.

The modular machines, such as the VL series, expand the range to include flexible manufacturing solutions. These machines and system solutions are characterized by a modular design and can be adapted to your specific requirements using a wide range of options. They combine high productivity with outstanding adaptability – ideal for companies with more specific requirements.

The customized machines, which include the VLC and VSC series, for example, represent tailor-made cutting-edge technology. Each machine is designed exactly according to customer requirements and is particularly suitable for highly complex processes that require maximum precision and specialization. These solutions off er the greatest possible fl exibility for implementing individual production concepts.

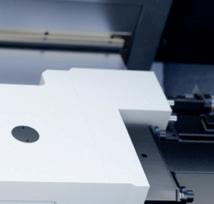

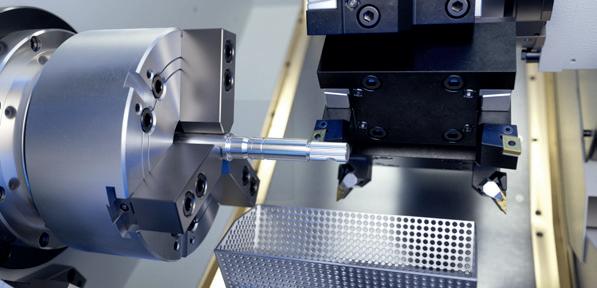

The HSC 1 is a compact CNC turning and milling center from the EMAG Classic series designed to meet the requirements of modern manufacturing companies.

The focus is on the complete machining of workpieces in two operations (OP 10 and OP 20), the integration of additional milling and drilling operations, and a high degree of automation for unmanned series production.

The core of the machine philosophy is the combination of main and counter spindles. This dual-spindle concept enables continuous complete machining: After front-side machining is completed with the main spindle, the workpiece is automatically transferred to the counter spindle. There, the rear side is machined without reclamping the workpiece. This eliminates the need for additional machines, handling effort, and sources of error during re-clamping.

ADVANTAGES:

» Throughput times are reduced thanks to complete machining in a single machine.

» Process reliability is increased by eliminating multiple clamping and manual re-clamping.

» The Y-axis and driven tools also enable flexibility for complex geometries.

» Cost-effectiveness is ensured by the compact machine design, short setup times, and high level of automation.

» The wide range of applications extends from small batches to unmanned series production.

The design of the HSC 1 is geared towards maximum rigidity, precision, and user-friendliness. The solid machine bed in monoblock construction made of high-quality cast iron is the centerpiece. This design offers several advantages:

+ High rigidity and vibration damping: The cast iron bed reliably absorbs machining forces and prevents vibrations during the process. This ensures consistently precise machining results, even during demanding cutting operations.

+ Optimized chip removal: The slanted arrangement of the turret slide allows chips to fall directly into the chip conveyor without affecting the guides or the workpiece. This increases process reliability and reduces cleaning effort.

+ Thermal stability: The monoblock design ensures consistent temperature behavior and minimizes dimensional deviations due to thermal infl uence.

EXCELLENT ACCESSIBILITY FOR SMOOTH PRODUCTION

Bar loader for material up to 50 mm in diameter

Direct adjustment of the clamping pressure

VERSATILE APPLICATIONS:

» Automotive industry: Transmission parts, brake system components

» Aerospace: Precision valve bodies, fittings

» Medical technology: Implant components, surgical instruments

» General mechanical engineering: Shafts, flanges, valves

» Energy technology: Valve components, specialized fittings

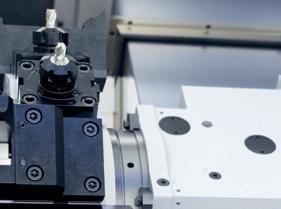

The spindle technology is the heart of the HSC 1 and is designed for high precision, fl exibility, and process reliability. The interaction of the main and counter spindles enables continuous complete-machining of the front and rear sides—without manual re-clamping.

Main spindle:

» Spindle nose: A2-6 (Ø 100 mm front bearing)

» Spindle bore: 63 mm diameter

» Bar passage: 50 mm

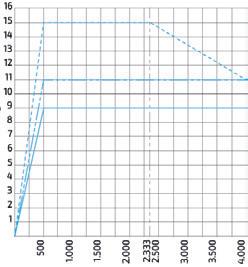

» Speed range: 50 - 4.000 min-1

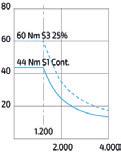

» Drive power:

Belt-driven spindle unit with 11 kW (30 min)/9 kW (continuous operation)

» C-axis: Precision positioning for milling operations

» Chuck: Hydraulically operated

+ The main spindle is belt-driven and offers a wide torque profile: from powerful rough-machining at low motor speeds to high-precision finishing at high cutting speeds.

+ The counter spindle automatically takes the workpiece from the main spindle to machining the reverse side. This eliminates the need for manual re-clamping – a significant improvement in terms of time and quality.

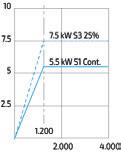

Counter spindle:

» Spindle nose: Centering diameter 110 mm (Flat Nose)

» C-axis: Integrated, for precision positioning and milling operations

» Speed range: 50 – 4.000 min-1

» Drive power: Motor spindle with 7,5 kW (S2, 30 Min. duty cycle), 5,5 kW (continuous operation)

» Workpiece transfer: Directly from main spindle chuck – no re-clamping necessary, ejector for unloading into the parts catcher

» Clamping system: Hydraulic chuck

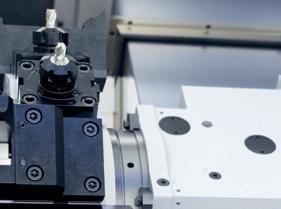

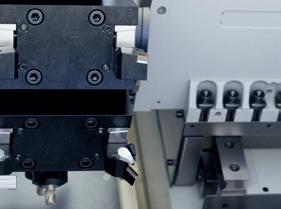

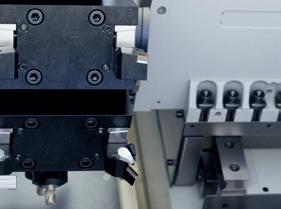

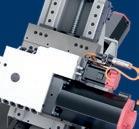

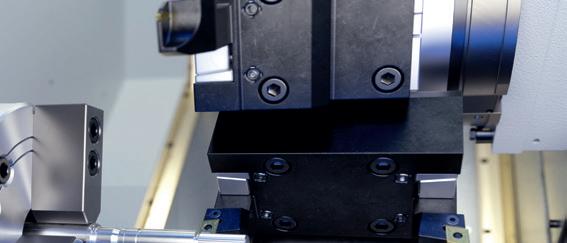

The tool system of the HSC 1 is designed for fl exibility and productivity. At its heart is the servo tool turret in BMT-55 design with twelve stations. It is also available with 16 stations (VDI-30 or BMT-45) as an option.

+ 12 stations (standard), servo-driven

+ Option: 16 stations for more tools or the use of sister tools

+ Mounting: BMT-55 (optional VDI-30 or BMT-45)

+ Locking: form-fi tting, for high rigidity and repeatability

All stations are prepared for the use of powered tools. This significantly expands the range of machining operations— drilling, milling, and threading operations can be integrated directly into the turning process.

The Y-axis enables off-center machining that would not be possible with conventional 2-axis lathes. This includes:

+ Cross holes

+ Feather key grooves

+ Surface machining on the circumference

+ Eccentric hole patterns

+ Contours outside the center of rotation.

Performance characteristics of the driven tools

» Power: 4,5 kW

» Motor speeds: bis 5.000 min-1

» Torque: 18 Nm

» Application examples:

- Cross holes

- Feather key grooves

- Thread milling and drilling

- Face milling operations

- Contour milling

Motor speed-torque characteristic curve

Intermittierender Betrieb

Dauerbetrieb

This enables machining operations that would otherwise require the use of an additional milling machine. Integrating these steps into the turning process eliminates the need for retooling and significantly reduces lead times.

(min-1)

For fast and precise measurement of tools in the work area.

Advantage: Precise tool length compensation, reduced setup times.

The HSC 1 is designed from the ground up for integration into automated production environments. This makes the machine suitable for both medium-series production and high-productivity large-series machining, right up to unmanned operation in multi-shift systems.

An essential element is the bar loader, which automatically feeds bar material with diameters ranging from 6 to 50 mm. This enables the batch production of turned parts without manual intervention.

Customer benefit: continuous machining of bar material with minimal operating effort – ideal for high quantities.

The parts catcher automatically removes the finished workpiece from the work area after cutting. This reduces operating times and enables continuous production.

The workpiece is transferred automatically from the main spindle to the counter spindle without manual reclamping. This integrates rear-side machining into the overall process.

Customer benefit: Complete OP 10/OP 20 machining without interruption and with maximum process reliability.

+ Bar loader: A utomatic feeding of bar stock (Ø 6–50 mm, length 600–1,500 mm).

+ Advantage: Unmanned batch production with a high degree of automation.

CNC control

Main spindle

Fanuc 0i-TF Plus

» Main spindle nose A2-6 (Ø 100 mm front bearing)

» Motor speeds 1/min 50–4.000

» Drive power kW 11 (30 min)/9 (duration)

Counter spindle

» Counter spindle nose Flange Ø 110 (Flat Nose)

» Motor speeds 1/min

50–4.000

» Drive power kW 7,5 (10 min)/5,5 (duration)

Turret

» Turret 12 stations, servo drive, BMT-55 mount

» Turning tool max. 25 x 25 (insert holder)

» Drill rod diameter, max. mm in 32 1.25

» Motor-speed driven tools 1/min up to 4.000

» Power-driven tools kW 4,5

Dimensions

» Machine weight kg approx. 5.500

»

(L×B×H)

with manual loading, max.

diameter with bar loader, max.

2.020 mm 2.400 mm

mm

The latest generation of Fanuc 0i TF Plus control offers extensive possibilities for process optimization. While machining is in progress, programs that follow can be created or optimized. Standardized interfaces make it easy to integrate the machine into existing production lines.

The control is specially designed for turning operations. With control of up to 15 axes in single-channel mode and 18 axes in dual-channel mode, the 0i-TF Plus offers the essential functions required for efficient turning operations, making it the ideal choice for batch producers seeking reliable performance.