By Irwin Rapoport CEG CORRESPONDENT

The Massachusetts Department of Transportation’s (MassDOT) $303 million design-build project to replace the temporary Rourke Bridge over the Merrimack River in the city of Lowell is under way. The project was awarded to Skanska USA Civil in May 2025 through MassDOT’s Design-Build Program.

The new bridge will be 1,278 ft. long and 84 ft. wide, consisting of seven spans and carrying two travel lanes in each direction, with shoulders, bike paths and sidewalks. It will connect Middlesex Street to Pawtucket Boulevard, improve mobility for all users and meet current standards, including ADA accessibility.

The bridge is anticipated to open to traffic in 2029, with full project completion expected in 2030. Currently, vehicles cross the Merrimack River via a temporary two-lane bridge erected in 1983.

This ambitious project combines final design and construction into a single phase.

“The Rourke Bridge is a critical transportation link in Lowell,” said John Goggin of MassDOT Communications. “The bridge carries about 27,000

Gov. Maura Healey announced a plan to make investments in the state’s roads, bridges and regional transportation system and stabilize the finances of the MBTA, putting it on a path of stability.

The investments — representing $8 billion over the next 10 years — would be done without raising taxes and represent the largest state transportation investment in more than 20 years by maximizing Fair Share revenue and other existing resources, according to the governor.

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock

They are:

• Easy to order and ea t d t stock asy to s l

components and too

• Ideal for stocking se and trucks

Choose from the follo

• Central lubrication

• Preventive mainte

• O-Ring kits

• Electrical service k

• Hydraulic service k And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code.

Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits

NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN

When Brown University’s Ruth J. Simmons Quadrangle reopened in midOctober after a five-month closure, passersby likely noticed the newly dedicated Stephen Sondheim Amphitheater at the Providence, R.I., campus.

But behind the fences that surrounded the site during its renovation, most of the project did not involve building the amphitheater itself. Instead, roughly two-thirds of the construction project took place underground, according to Paul Dietel, Brown’s assistant vice president of planning, design and construction.

Beneath the renovated quad, he explained the university installed water storage tanks “that will accept the high volume” of rainwater produced during highintensity storms. Brown also increased the sizes of the quad’s underground pipes, which “were quite literally at capacity,” Dietel said.

The Simmons Quad renovation is just one part of the school’s growing effort to adapt aging campus infrastructure to increasingly severe storms, the Brown Daily Herald reported Dec. 5. In recent years, rainwater from these storms has flooded campus buildings, from first-year dorms to dining halls.

The quad’s new stormwater system, like other recent projects on campus, is a recognition of recent “changing conditions with heavier rainwater events,” Dietel said.

“There’s not a single campus across the country that is immune to climate-related impacts and threats to its infrastructure,” said Kim Cobb, director of the Institute of Brown for environment and society.

But at the university, these storms pose a challenge to a campus that is connected to a strained city stormwater system in Providence, Dietel explained. Many of the centuries-old buildings around campus were not built to modern waterproofing standards.

“All our infrastructure is tied directly into the city of Providence,” he said. “The city system, way back when it was built … really wasn’t designed to accommodate those microbursts [of rain].”

In the case of the centuries-old Simmons Quad, “the drainage network from the quad and the surrounding buildings was overwhelming the city system,” Dietel said.

He added that Brown University officials hope that the new storage tanks will allow stormwater to slowly dissipate into the ground or move into city pipes when Providence’s system is no longer at capacity.

Since Brown’s campus sits atop College Hill, rainwater not retained onsite can either accumulate on the hill or flow into the city’s stormwater or sewer systems. When the municipal system cannot keep up with heavy rainfall, the school’s campus becomes prone to flooding.

In urban areas like College Hill, the risk of flooding is elevated “because large portions of land are covered by impervious surfaces,” said Indrek Külaots PhD., a professor of engineering and a 2001 graduate of Brown who teaches courses on water supply and treatment systems as well as environmental engineering.

As a result of those surfaces, Külaots said that it does not take a large storm to cause flooding in many urban areas.

Anthony Vega, the press secretary of the office of Providence Mayor Brett Smiley, told the Daily Herald that the city does not collect data on Brown’s “overall stormwater impacts.” But he noted that “all areas of development with impervious surfaces place strain on the city’s stormwater system during significant or intense rain events.”

Simmons Quad is not the only site where Brown is trying to collect and store stormwater on its campus.

Local and state regulations require large property owners like Brown to take steps to filter and contain stormwater. Brown’s 2023 Stormwater Master Plan, for instance, established a three-way stormwater credit system between the university, the city of Providence and the Narragansett Bay Commission. The system incentivizes Brown to reduce its stormwater footprint through measures like rain gardens and enhanced filtration.

Last summer, the university also excavated the side of Rhode Island Hall and installed exterior water pumps that would divert water to a municipal drain on George Street — a project that Dietel called one of the more “extreme” examples.

In 2020, Brown completed a similar project on the exterior of the Sciences Library, he added.

Cobb welcomed sensible efforts to fortify campus buildings and mitigate rainwater accumulation. She sees such steps as a necessary part of climate resilience.

The impacts of climate change on College Hill have “been a long time coming,” Cobb said. “You often do need to wait to see those impacts on the ground before you make the deep investments.”

A century-old research home for generations of leading MDI Biological Laboratory scientists in Maine is currently being fully modernized and winterized.

The renovation of the Neal Laboratory in Bar Harbor will update the historic structure to include a 21st century research lab, offices, meeting space and innovation hub, the research facility announced.

The project is made possible by a $1.6 million federal appropriation request secured by Maine Senators Susan Collins and Angus King.

MDI Laboratory President Hermann Haller, M.D., calls the project a major step forward for the research and bioscience complex.

Located on the shores of Frenchman Bay, MDI Bio Labs was founded in 1898 as a summer research and education facility along the rocky Maine coastline in order to have access to countless and diverse sea animal species.

The Neal building was the first permanent structure that MDI Biological Laboratory built on Bar Harbor’s Frenchman Bay.

Over the last decade, MDI Bio Labs began “a dramatic transformation to become a growing and rising independent biomedical research, development and education institution,” according to a news release.

MDI Bioscience was launched to accelerate early-stage development of new therapies for human health and provide industrygrade research capabilities. As projects and collaborations take shape, they require more modern and flexible labs capable of supporting complex workflows and partnerships.

The Neal laboratory renovation is tailored for that mission, the Mount Desert Islander in Ellsworth learned, and will add nearly 2,000 sq. ft. of research space to complement more than 10,000 sq. ft. of existing infrastructure at the Kathryn W. Davis Center for Regenerative Biology and Aging and other facilities on the coastal Maine campus.

“MDI Bioscience is filling an important need at the MDI Bio Lab as our faculty apply their original research and expertise to real-world problems in human health,” Haller said. “When the Neal Laboratory reopens it will honor MDI Bio Lab’s historic contributions to science while forging ahead in the new age of biomedical innovation.”

The Neal Laboratory has long supported seasonal research, but its layout and infrastructure had become limiting due to small, compartmentalized labs on the first floor and a half-story upstairs with low ceilings

and minimal meeting space, not to mention a striking but impractical spiral staircase.

Designed by gbArchitecture & Planning of Burlington, Vt., and carried out by E.L Shea Builders & Engineers of Ellsworth, Maine, the renovation will completely reimagine the space for year-round science.

The first floor will become a 900-sq.-ft. open-plan laboratory with room for roughly a dozen staff, significantly expanded bench space and a bio-secure procedure room for sensitive experimental work. A welcoming entry area, common space and restroom will support the rhythms of daily lab life.

Upstairs, crews are removing the existing structure entirely and rebuilding it with full headroom, which will double the usable space to nearly 1,000 sq. ft. The second floor also will feature two private offices, a large conference room overlooking the bay and a break room with a kitchenette – spaces designed to foster collaboration and facilitate efficiency.

According to Mark Hanscome, MDI Bio Lab’s facilities manager, a dedicated and standalone HVAC system will supply the laboratory with controlled air exchange and negative pressure to safeguard research integrity. Energy-efficient heat

pumps, now proven reliable even in brutal Maine winters, will serve the upper floor and common areas.

In addition, he said the project includes extensive structural reinforcements that will be hidden from view but essential to supporting the expanded second story and ensuring long-term durability.

The renovation is part of a coordinated plan for the lower MDI Lab campus that includes the recently upgraded Halsey Building. That structure is dedicated to support animal husbandry for zebrafish, African Turquoise Killifish, and other comparative models for human health that MDI Bioscience uses in its quest to accelerate drug discovery.

“We are expanding capacity, attracting new investigators and equipping the lab to pursue innovative solutions to challenges in human health with greater precision and efficiency,” said Haller.

Demolition on the Neal Lab site began in November and its upgrades are expected to be completed in September 2026.

Hanscome said his chief goal is to “get the project in on time and on or under budget, and I am confident we will.”

CHOOSE ABLE TOOL and EQUIPMENT...

dumpers are impressive for their simple operation and powerful functions!

• Local Ownership with flexible approach

• Trained staff for repairs and maintenance

• Dedicated Parts personnel on site

Combining power and maneuverability with uncompromising off-road capability!

• Focused on the Heavy Construction Industry

• Providing the BEST support equipment available

• Experienced outside sales staff

Among other improvements, the funding will include a $1.4 billion investment in the MBTA for new commuter rail coaches.

photo PLAN from page 1

The plan will be filed as legislation as part of the Governor’s Fiscal Year 2026 budget proposal and an accompanying supplemental budget. It puts into action many of the recommendations made by the Transportation Funding Task Force, which delivered its final report to the governor outlining multiple steps for stabilizing and enhancing transportation while setting the stage for ongoing discussion about how best to finance transformative investments in transportation into the future.

“This historic transportation proposal represents smart, forward-thinking fiscal management, and it will have an impact on people in all regions of our state,” said Governor Healey. “We’re going to invest billions of dollars to deliver better roads, less traffic, safer bridges and a transit system that works in every region. We’ll close the MBTA’s budget gap, improving service and upgrad-

ing stations, and we’ll move forward on regional projects like West-East Rail. And we’ll do this all without raising taxes. I’m grateful for the insights of the Transportation Funding Task Force, which shaped this proposal, and for the strong leadership of Secretary Tibbits-Nutt and Gorzkowicz.”

“This plan will not only stabilize the finances of the MBTA but also dedicate new and critical resources to our Regional Transit Authorities and municipalities, accelerate our efforts to repair crumbling bridges, fix our culverts and advance important projects throughout the state,” said Lieutenant Governor Kim Driscoll. “Our administration knows the role a safe, reliable and efficient transportation system plays in the future of Massachusetts and this plan represents a gigantic step forward.”

The proposal would:

• immediately direct $857 million in surplus Fair Share revenue from FY24 to public

transportation;

• dedicate $765 million in Fair Share resources from FY26 to the Commonwealth Transportation Fund, building on a strategy developed by the Healey-Driscoll administration to maximize Fair Share through borrowing to yield $5 billion over the next 10 years for capital investment bonds in rail, roads, bridges, Regional Transit Authorities and culverts; and

• more than double support for the MBTA’s operating budget to $687 million in FY26 and immediately address the agency’s budget shortfall, putting the MBTA on a path of long-term stability.

As part of this capital expansion, Governor Healey filed a multi-year Chapter 90 bill that will grow the size of the funding pool directed to cities and towns to $300 million per year for five years, the highest amount in the history of funding for local roads and sidewalks, according to the gover-

nor. This additional $100 million annual investment represents a 50 percent increase to support the repair of municipal roads, bridges and infrastructure.

The combined impact of the governor’s House 1 budget proposal for FY26 and the supplemental budget to spend surplus Fair Share revenue from FY24 will achieve a 5050 percent split between Fair Share resources dedicated to transportation and education since enacted of the voterapproved surtax, according to the governor. This was one of the key recommendations included in the Transportation Funding Task Force report.

Among the improvements that this funding will allow include:

• a $1.4 billion investment in the MBTA for new commuter rail coaches, red and orange line cars, station accessibility and resilience, track improvements and power

Monroe Tractor welcomes Garth Field to its team as an equipment sales representative serving all of Rhode Island and most of Bristol County, Mass.

Field brings 20 years of experience in equipment sales, rentals and customer support, with a strong foundation in heavy equipment. His career has been built around understanding customer needs and matching them with the right equipment — quickly, efficiently and with complete transparency.

“I take pride in answering the phone within a few rings and getting back to customers in a timely manner,” said Field. “I’m all about making the sales and rental process as seamless as possible, with consistent communication updates. I believe in acknowledging customers with positive energy, getting them the information they need fast and following up with excellent serv-

ice after the sale.”

In his role, Field oversees sales of new and used equipment across all brands, supporting contractors, municipalities and agricultural customers throughout his territory. His mainline

products include Case Construction and Case IH equipment, rollers — including Case and Dynapac — Screen Machine, paving and crushing equipment and Okada hydraulic hammers.

Known for his responsiveness, positive attitude and customer-first approach, Field is committed to building longterm relationships and being a reliable resource that customers can count on.

“Garth’s experience, energy and commitment to service align perfectly with our values,” said Richard Longbottom, branch manager. “He understands that communication and follow-through are just as important as the equipment itself, and our customers will benefit greatly from his approach.”

For more information, visit monroetractor.com.

PLAN from page 8

system resiliency;

• $2.5 billion for road and bridge repairs across the state through MassDOT, with money set aside for culverts, small bridge repairs and safety and congestion hot spots;

• close the funding gap for the Allston I90 Multimodal Project; and

• allow for projects advancing West-East Rail to continue to move forward, including capacity improvements near Pittsfield, trackwork and accessibility improvements in Springfield and station planning in Palmer.

“Governor Healey and Lt. Governor Driscoll have stressed that transportation systems must work if we want our communities to thrive, and the announcements today further the state’s vision to improve infrastructure by recommending significant financing initiatives for the short and longterm,” said Monica Tibbits-Nutt, Massachusetts Transportation secretary and CEO. “With the Governor’s plan, we are taking very actionable steps to increase the use of Fair Share revenue, offer municipalities more money through the Chapter 90 program, double support for the MBTA’s operating budget, and expand microtransit

services.”

After covering $100 million in debt service on new borrowing, the FY26 budget will propose to invest:

• $687 million to stabilize MBTA operations, including $500 million from Fair Share to to fund programs such as the MBTA Workforce Academy, low-income fares and water transportation programs;

• $110 million for Regional Transit Authorities, including $66 million for formula-based transit improvements, $30 million for Fare Free service and $10 million to facilitate interconnectivity between RTAs; and

• $55 million for MassDOT operations, including workforce investments and enhanced capital project delivery.

The surplus Fair Share supplemental budget to be filed by Governor Healey will propose to invest $857 million of the $1.3 billion surplus available for spending in transportation, including:

• $400 million to address workforce and safety initiatives identified as necessary by the Federal Transit Authority;

• $300 million to replenish MBTA reserves;

• $25 million for a Winter Resilience

Assistance Program for municipalities;

• $25 million for RTA workforce recruitment and retention; and

• $10 million for microtransit.

The multi-pronged financing plan leans on Fair Share, which has performed exceedingly well as a revenue source for Massachusetts, according to the governor. In FY24, the state collected $2.46 billion from the surtax, nearly $1.5 billion above what had been budgeted.

The financing plan also calls for using $170 million available from the administration’s pool of federal matching funds to retire the MBTA’s legacy debt ($89 million), freeing up operating capacity at the agency. These matching funds also will continue to support the administration’s strategy of aggressively pursuing federal funding, with matching dollars committed to the Green Line Central Tunnel project as well as local technical assistance and local project matches.

Lastly, the administration plans to use $1.2 billion in Grant Anticipation Notes (GANs) to borrow against future federal highway grants to finance priority Highway Division projects statewide.

The financing plan was heavily informed by the work of the Transportation Funding

Task Force, which was created by Governor Healey through executive order in January 2025. The Task Force spent the past year reviewing current and projected revenue sources, comparing those sources to benchmarks and trends in peer and neighboring states and exploring innovative financing approaches and alternative pricing mechanisms.

The Task Force developed a framework focused first on stabilizing the transportation system’s finances and addressing critical infrastructure repair needs. Additional recommendations looked at how to “enhance and transform” the system.

Some of the recommendations included:

• allocating half of Fair Share revenues to transportation over time;

• expanding capital capacity for transportation by dedicating a significant portion of Fair Share revenue to the CTF;

• using Fair Share to stabilize public transportation agency operations;

• maintaining predictable and stable funding for investments in Regional Transit Authorities and microtransit providers; and

• increasing investment in the Chapter 90 local roads programs by at least 50 percent to improve local transportation infrastructure condition.

vehicles per day. Its vehicle capacity is deficient, and its bicycle and pedestrian features do not meet current multimodal and ADA standards. It is nearing the end of its useful service life, and its supporting substructure is showing signs of deterioration.”

Goggin noted that a Corridor Study and Feasibility Analysis conducted in 2013 examined replacement options and the suitability of the existing location. The study developed a series of recommendations to improve mobility for residents, businesses and visitors.

The new bridge will feature improved traffic operations, sidewalks, shared-use paths on both sides for pedestrians and cyclists, enhanced safety features, landscaping and hardscaping improvements and better connections between Middlesex Street and Pawtucket Boulevard. Intersections at either end of the bridge will be reconstructed, along with portions of Wood Street, Pawtucket Boulevard and Old Ferry Road.

Once traffic is shifted to the new bridge, the existing approximately 1,100-ft.-long temporary bridge will be demolished. The new bridge will be located west of the existing structure, with an alignment that angles diagonally across the river.

“The bridge will be built in stages while crossing the river, in ways that are environmentally sensitive and that maintain available rowing lanes,” Goggin said.

Serious planning for the project began in 2019 with data collection, followed by conceptual design, preliminary engineering, environmental permitting, right-of-way acquisition, design-build procurement and issuance of a notice to proceed.

Crews perform soil boring for the Rourke

Prior to construction, MassDOT held a series of public meetings, which have continued during the construction phase. To date, traffic impacts — limited to temporary lane closures and detours — have been minimal.

ROURKE from page 1 see ROURKE page 18

Jacobs Engineering Group is Skanska’s lead designer and is responsible for the bridge and roadway design.

“The new bridge is a technically complex structure engineered to meet modern design standards, including seismic and scour requirements, while complying with all applicable environmental regulations,” said Rob Pine, vice president of operations of Skanska USA Civil. “These challenges are being addressed through comprehensive engineering analysis, close collaboration with MassDOT and careful coordination with environmental agencies. The selected bridge design is essentially the same as the one MassDOT vetted during preliminary design, with improvements implemented during design development.”

The new bridge is expected to have a lifespan of 75 years.

While no new or unique construction materials are being used, Pine said the bridge will include aesthetic enhancements.

“The bridge will feature overlook areas with architectural trellises and benches, allowing the public to enjoy views of the Merrimack River and observe recreational activities and rowing events. It will also include aesthetic lighting on and below the bridge.”

The structure will consist of seven spans, each with seven steel plate girders and a cast-in-place reinforced concrete deck. It will be supported on drilled shaft foundations with granite-faced, cast-in-place concrete piers.

According to MassDOT’s January update, vegetation and

has the most fatal falls of all industries 51% representing more than ½ of all work-related falls nationally

In 2017, fatal falls accounted for 366 of 971

total construction fatalities

Small construction companies 10 or fewer employees ( ( account for of all fatal falls 61%

www.equipmenteast.com

61 Silva Lane

Dracut, MA 01826

978-454-3320

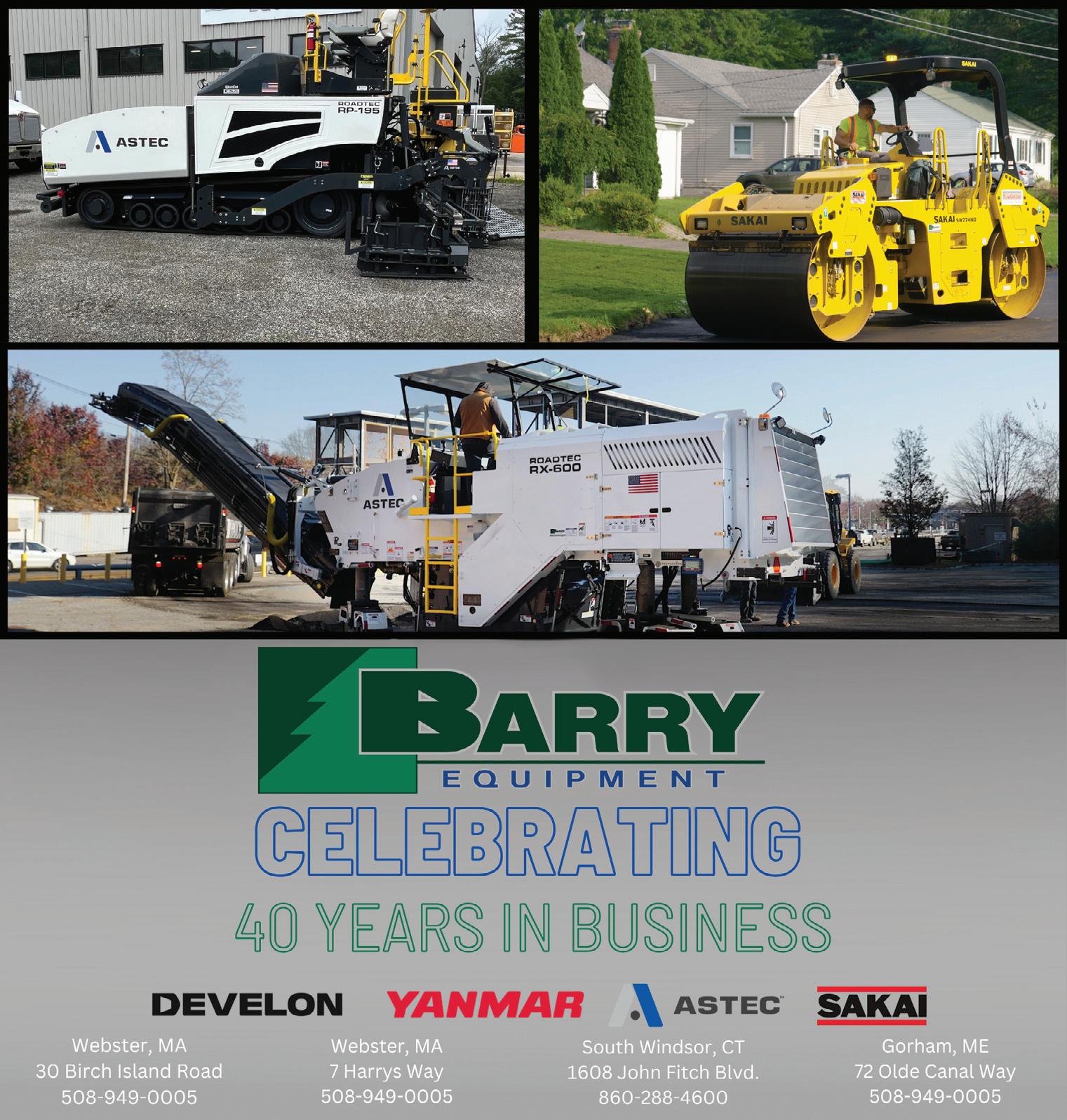

www.barryequipment.com

30 Birch Island Road

Webster, MA 01570

508-949-0005

508-949-0005 Equipment East, LLC

196 Manley Street Brockton, MA 02301

508-484-5567

1474 Route 3A Bow, NH 03304

603-410-5540

7 Harry’s Way Webster, MA 01570

508-949-0005

72 Olde Canal Way

Gorham, ME 04038

508-949-0005 1608 John Fitch Blvd South Windsor, CT 06074

860-288-4600 Rhode Island

brush clearing is under way on the south bank of the Merrimack River and along Wood Street Extension, followed by erosion control installation. Similar work, including tree removal, is occurring along the north bank near Pawtucket Boulevard to prepare bridge work zones. Excavation for test pits and drill test borings continues, along with mobilization of cranes and equipment and installation of a temporary construction access platform on the river’s north side.

A November 2025 update noted that Skanska crews refreshed painted lane markings on the existing Rourke Bridge to improve visibility and safety (now complete), installed erosion control measures in advance of vegetation removal, and established a long-term construction staging area along the shoulder of eastbound Pawtucket Boulevard near the Lowell City Water utilities building.

Construction of a temporary trestle in the Merrimack River is expected to begin in the coming months.

“The trestle will serve as access for crews constructing the new Rourke Bridge,” Goggin said.

Typical work hours are 7 a.m. to 5 p.m., Monday through Friday, although some night work will be required for select roadway and utility operations.

To date, Skanska has completed geotechnical borings on land and in the Merrimack River, installed erosion controls, established a work zone on Pawtucket Avenue and cleared the north abutment area. Over the next 12 months, work will focus on trestle construction, cofferdam installation, drilled shaft foundations and pier construction.

“There will be night work associated with some select roadway and utility work,” Pine said, noting that operations will continue throughout the winter.

Investigative in-water soil borings were conducted during June, July and August using a barge-mounted drill rig, alongside on-street borings on Wood Street, Middlesex Street, Pawtucket Boulevard and Old Ferry Road. This work provided data on soil strength and composition to inform the final design.

Traffic signage was installed within the project limits in late August, followed by erosion control measures in September ahead of fall vegetation removal. Operations resumed Jan. 7, 2026, with additional clearing and erosion control installation on the south bank, followed by similar work on the north bank beginning Jan. 12, 2026.

For upcoming construction phases,

crews work on a test pit for the Rourke Bridge.

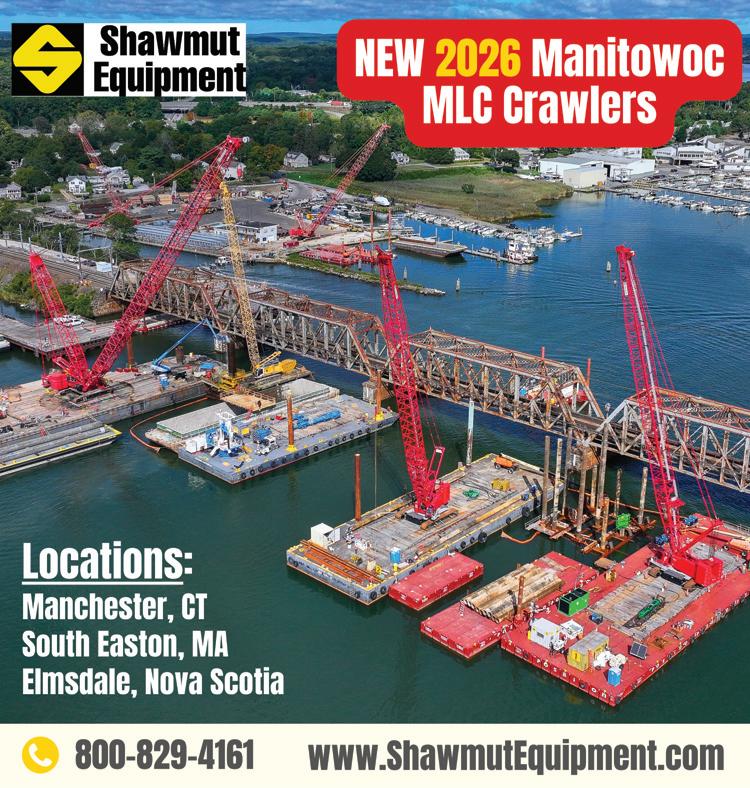

Skanska has purchased two new Liebherr LR 1300 300-ton cranes and 100 Poseidon sectional barges. Mobilization of cranes and equipment began in January, along with installation of the temporary access platform.

“The first crane has been mobilized, and the remaining equipment will be brought in over the coming months,” Pine said. Construction remains in the early stages, with much of the initial work taking place on the river.

“Drilled shafts will be installed inside cofferdams from barges,” Pine said. “Barges — including crane barges, a drill barge and multiple material barges — will be used extensively during construction.”

The temporary bridge will be demolished once traffic is transferred to the new structure, while roadway work is expected to begin later in the project timeline.

Skanska’s management team includes Project Manager Andrew Pramberger, Construction Manager Jamie Sparks and a large team of construction and engineering professionals. Staffing levels will increase significantly during peak construction, and substantial quantities of materials will be delivered to the site.

“The design is not complete yet, so final material quantities cannot be determined,” Pine said.

Skanska emphasized its commitment to equipment maintenance throughout the project.

“Mechanics will be available as needed to maintain and repair equipment,” Pine said. “Because the Merrimack River is freshwater, we don’t anticipate additional wear related to the water environment. Purchasing new equipment also helps minimize maintenance needs on a long-term project.” CEG

(All photos courtesy of MassDOT.)