Using the Sea as a Fast Lane

CONNECTING TRADE PROFESSIONALS WITH INDUSTRY INTELLIGENCE MARITIME

TRANSPORT On Track for a Smarter City

Using the Sea as a Fast Lane

CONNECTING TRADE PROFESSIONALS WITH INDUSTRY INTELLIGENCE MARITIME

TRANSPORT On Track for a Smarter City

SUPPLY CHAIN

The Disruption Gap

JANUARY 2026

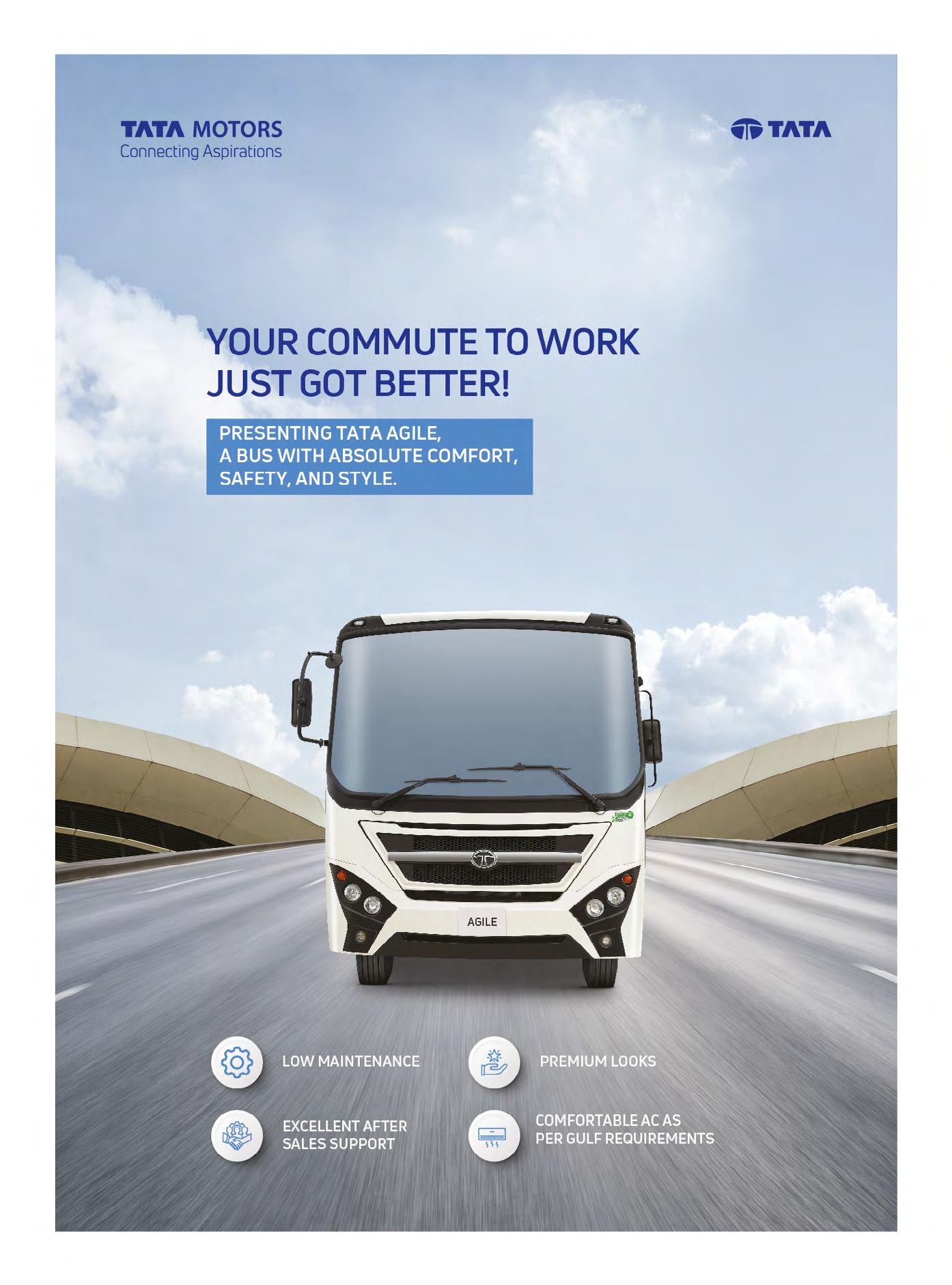

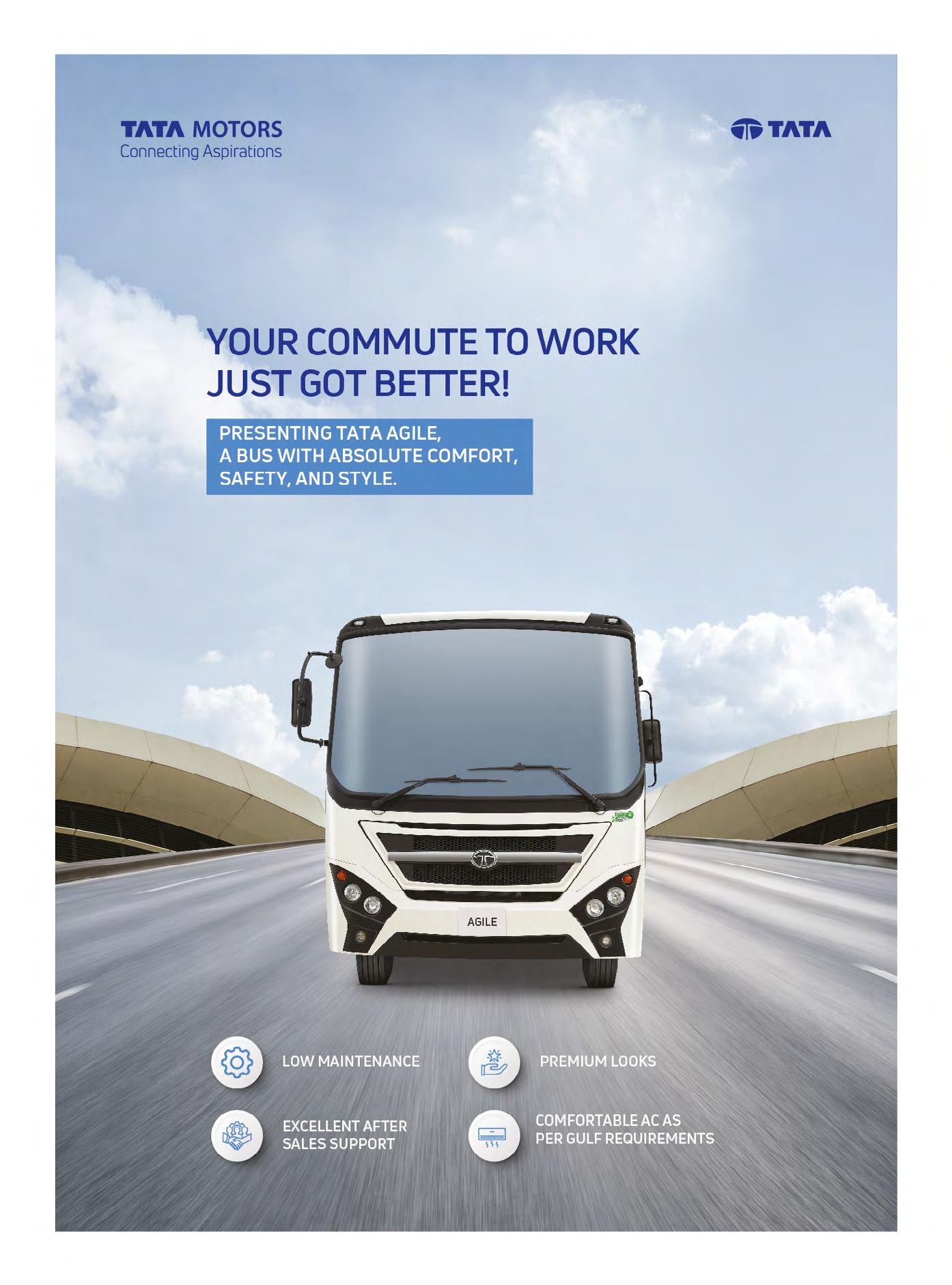

With the launch of the Kuzer in the UAE, UD Trucks targets the heart of urban distribution, where uptime, flexibility, and everyday performance matter most

New IVECO S-Way: high technology and efficiency on all missions

A wide choice of Euro III / V diesel engines, delivering class-leading power from 360 hp to 560 hp Euro III / 570 hp Euro V and superior fuel economy. 12-speed HI-TRONIX automated transmission with the most advanced technology in its category, electronic clutch and best-in-class torque-to-weight ratio. Full range of fuel-saving devices, such as anti-idling feature, EcoSwitch, Ecoroll and Smart Alternator. Top levels of comfort and safety, with a completely redesigned and reinforced cab, featuring enhanced direct visibility and enlarged cab livability.

Expert Insight

A Logistics Industry

Outlook for the UAE and MENA Region

Maritime Using the Sea as a Fast Lane

Cover Story A New Force in Light Duty

Food Trade Navigating Future of Food Trade Amid Global Transformation

Transport On Track for a Smarter City

E-Commerce Logistics Beyond 30 Billion

Autonomous Logistics When Supply Chains Start Thinking for Themselves

Supply

Global

Nestled by the coast of Lusail sits the splendor of Raf es and Fairmont Doha, where luxury is rooted in even the smallest details. Open the doors to mesmerizing hospitality and make memories in a world of sophistication.

WITH INDUSTRY INTELLIGENCE

CEO

Wissam Younane wissam@bncpublishing.net

Managing Director

CEO

Rabih Najm rabih@bncpublishing.net

Wissam Younane wissam@bncpublishing.net

Group Publishing Director

Director

Joaquim D’Costa jo@bncpublishing.net

Rabih Najm rabih@bncpublishing.net

Editor

Group Publishing Director

Aya Zhang aya@bncpublishing.net

Joaquim D'Costa jo@bncpublishing.net

Commercial Director

Editor-in-Chief

Andrea Mocay andrea@bncpublishing.net

Vibha Mehta vibha@bncpublishing.net

Digital Reporter

SUBSCRIBE

subscriptions@bncpublishing.net

subscriptions@bncpublishing.net

PO Box 502511 Dubai, United Arab Emirates P +971 4 4200 506 | F +971 4 4200 196

Managing Editor Kasun Illankoon kasun@bncpublishing.net

Reeba Asghar reeba@bncpublishing.net

Creative Lead

Christian Harb chriss@bncpublishing.net

Design Christian Harb

Junior Art Director

Marketing Executive

Rizaldi Febrian

Aaron Joshua Sinanbam aj@bncpublishing.net

Marketing Executive

Digital Media Producer

Aaron Joshua Sinanbam aj@bncpublishing.net

Alexander Bungas

Videographer

Eduardo Buenagua

For all commercial enquiries, contact jo@bncpublishing.net T +971 50 440 2706

PO Box 502511 Dubai, United Arab Emirates P +971 4 4200 506 | F +971 4 4200 196

All rights reserved © 2025. Opinions expressed are solely those of the contributors. Logistics News ME and all subsidiary publications in the MENA region are officially licensed exclusively to BNC Publishing in the MENA region by Logistics News ME. No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher.

For all commercial enquiries, contact jo@bncpublishing.net T +971 50 440 2706 All rights reserved © 2023. Opinions expressed are solely those of the contributors. Logistics News ME and all subsidiary publications in the MENA region are o cially licensed exclusively to BNC Publishing in the MENA region by Logistics News ME.

Printed by United Printing and Publishing | upp.ae

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher.

Printed by United Printing and Publishing | upp.ae

Images used in Logistics News ME are credited when necessary. Attributed use of copyrighted images with permission. All images not credited courtesy Shutterstock.

In addition to our print edition, we’re bringing you all sorts of industry news on our web mediums. We’re looking forward to interacting with our readers on all of our social media and web platforms. See you on the web!

Anew year often feels like a fresh page, but in logistics, the story rarely starts from zero. The changes we see today are built on the moves made yesterday, the investments completed quietly, the processes refined before anyone noticed.

2026 is shaping up to be a year of decisions rather than surprises. Ports, networks, and technology continue to evolve, and companies that think beyond speed or cost are quietly defining what resilience and reliability look like in practice. It is not always dramatic, but it is meaningful.

In this issue, we look at the forces shaping this next chapter. From global e-commerce reaching record milestones to regional hubs positioning themselves as strategic linchpins, the stories show logistics as a complex system where infrastructure, insight, and human judgment all matter.

This is the year to watch who adapts thoughtfully and who simply reacts. The details that seem small now will determine who leads the trade routes, both regionally and globally, by the end of the year.

Here’s to understanding what comes next, and how we keep shaping it.

Aya Zhang Editor aya@bncpublishing.net

Bahri and Hadeed have signed a Letter of Intent to explore cooperation in maritime transport for iron ore shipments.

The National Shipping Company of Saudi Arabia (Bahri) and the Saudi Iron & Steel Company

(Hadeed) have signed a Letter of Intent (LOI) to explore potential cooperation in maritime transport to meet Hadeed’s Iron Ore shipping needs.

The LOI, signed in Riyadh, states that both parties intend to discuss mechanisms for utilising Bahri capabilities to meet Hadeed’s maritime transport requirements. This collaboration aims to explore potential joint opportunities between Bahri and Hadeed , including the potential development and construction of new vessels tailored to Hadeed’s operational and technical needs within the Kingdom.

On this occasion, Bahri’s Chief Executive Officer, Eng. Ahmed Al-Subaey, said: “This collaboration marks an important step toward enhancing the national maritime transport ecosystem. At Bahri, we remain committed to supporting supply chains and providing reliable and resilient shipping solutions that enhance operational efficiency for our partners.”

Meanwhile, Hadeed’s Chief Executive Officer, Mr. Abdulqader Al-Mubarak, stated:

“Hadeed is continuously working on developing its operational and logistics ecosystem. This collaboration with Bahri represents a supportive step toward securing specialised maritime transport solutions that meet our operational needs and enhance the efficiency of the industrial sector.”

The cooperation aligns with efforts to strengthen industrial and operational integration and localise value chains. Bahri serves as the Kingdom’s national maritime carrier with a global logistics footprint, while Hadeed is one of Saudi Arabia’s leading national industrial companies in the steel and iron sector.

As part of Dubai Customs‘ ongoing efforts to strengthen strategic partnerships with private sector institutions and international companies specialising in logistics services, His Excellency

Dr. Abdullah Busnad, Director General of Dubai Customs, paid an official visit to DHL facilities, one of the world’s largest shipping and logistics companies. His Excellency was accompanied by a high-level delegation of officials from the Department. His Excellency and his accompanying delegation were received by Mahmoud Haj Hussein, General Manager of DHL Express in the UAE, and several managers and officials from the company.

The visit aimed to explore ways to enhance cooperation and develop mechanisms to support logistics operations in the Emirate of Dubai in line with the Emirate’s vision and global leadership in the trade sector. The company provided a comprehensive presentation on its work system and the technical and operational infrastructure it relies on to facilitate and accelerate shipping and transportation operations, along with a detailed explanation of the global service lines on which the company relies in managing intercontinental trade traffic, especially e-commerce shipments.

During the visit, His Excellency the Director General of Dubai Customs emphasised that cooperation with leading companies such as DHL is a key factor in supporting Dubai’s competitiveness as a global hub for trade and logistics services, noting that Dubai Customs is constantly working to develop a flexible and fast customs environment that complies with the highest international standards.

His Excellency added that the partnership with the private sector enhances the emirate’s ability to attract more investments and increase the efficiency of supply chain operations, especially in light of the rapid growth in e-commerce and air and sea freight traffic.

This visit is part of a series of field visits conducted by His Excellency Dr. Abdullah Busnad, Director General of Dubai Customs, to strengthen communication with strategic partners, follow up on field developments, and to reaffirm Dubai Customs’ commitment to supporting the trade ecosystem and facilitating business in line with the emirate’s vision of strengthening Dubai’s position as a leading global trade and logistics hub.

Effective 1 January 2026, flyadeal will add Madinah as its fourth operational base in the Kingdom.

flyadeal, Saudi Arabia’s fastgrowing low-cost airline, has opened its new expanded operations control centre in a ribbon-cutting ceremony officiated by His Excellency Eng. Saleh bin Nasser AlJasser, Saudi Minister of Transport and Logistics Services, and Chairman of the airline’s parent Saudia Group.

His Excellency Eng. Ibrahim Al-Omar, Saudia Group Director General and flyadeal Chairman, was joined by flyadeal Chief Executive Officer Steven Greenway in welcoming His Excellency to mark yet another significant milestone for the budget carrier.

Located at flyadeal’s Jeddah headquarters, the new standalone Integrated Operations Control Centre (IOCC) – with a four times bigger capacity – offers additional operational monitoring screens and greater space to accommodate a growing team in line with the airline’s expansion plans.

As the nerve centre of any airline, the IOCC is responsible for managing, dispatching and monitoring daily flights; coordinating crew resources and aircraft maintenance; and importantly, responding to disruptions while prioritising operational safety and punctuality at all times.

flyadeal now consistently operates up to 250 scheduled flights daily, recently crossed the 10 million mark for annual passengers carried for the first time this year, and has recorded the best On-Time Performance for punctuality of any Middle East low-cost airline for 11 consecutive months. flyadeal is also the region’s fastest-growing carrier.

Steven Greenway, flyadeal CEO said: “An absolute honour having Their Excellencies Eng. Saleh bin Nasser

Al-Jasser and Eng. Ibrahim Al-Omar visit flyadeal’s Jeddah headquarters to officially open our brand new operations facility.

“The Integrated Operations Control Centre is the airline’s heartbeat, the centralised command unit, the main decision-maker to implement contingencies, and the unsung hero that makes an airline tick. Not often talked about, the IOCC ensures schedules are maintained in coordination with airports across our network for what is a complex and disciplined process involving the management, tracking and resourcing of flights 24/7.”

Greenway added: “Reaching the size we are today, now operating up to 250 daily departures for the first time since our very first flight in 2017, and expansion focused on increasing our international footprint over the next few years, we needed a facility and environment fit for purpose.”

flyadeal operates scheduled flights from bases in Riyadh, Jeddah and Dammam to more than 30 domestic and international seasonal and yearround destinations in the Middle East, Europe, North Africa and South Asia with a modern fleet of 43 Airbus A320 family aircraft. The airline’s network and fleet will exceed 100 cities and aircraft respectively by 2030.

Backed by Meituan, the launch underscores Bahrain’s growing role as a hub for technology-enabled innovation and international partnerships.

In the presence of His Excellency Mr. Abdulla bin Adel Fakhro, Minister of Industry and Commerce, and His Excellency Mr. Ni Ruchi, Ambassador of the People’s Republic of China to the Kingdom of Bahrain, Keeta officially announced the launch of its on-demand food delivery operations in the Kingdom of Bahrain. The platform is backed by Meituan, a global technology company specialising in digital services.

The announcement was made during an official launch ceremony held in the capital, Manama, attended by senior officials, representatives of relevant entities, and members of the

business and restaurant community. The event underscored the importance of public–private sector collaboration in supporting economic development and expanding the adoption of advanced digital solutions across key sectors.

Keeta’s entry into the Bahraini market forms part of its regional expansion strategy, following the launch of its services in the Kingdom of Saudi Arabia, the United Arab Emirates, Kuwait, and Qatar. This expansion reflects confidence in Bahrain’s attractive investment environment, advanced digital infrastructure, and supportive regulatory frameworks.

The company stated that the launch of its operations in Bahrain aligns with its vision of providing efficient and reliable delivery services that enhance the consumer experience, while supporting local restaurants through long-term strategic partnerships aimed at improving operational performance and achieving sustainable growth.

Keeta’s services are powered by advanced technological systems supported by Meituan, which analyse multiple factors including traffic conditions, delivery distance, and order characteristics. These systems enhance the accuracy of delivery time estimates and support adherence to service commitments, while reinforcing principles of transparency and service quality through clear compensation mechanisms in cases where delivery timelines are not met.

To mark the launch, Keeta announced a range of introductory promotional offers, including meal discounts and free delivery at selected partner restaurants, without subscriptions or additional fees. These offers are designed to enable users to experience the platform through a clear and seamless service model.

The company also confirmed that it has invested in establishing a comprehensive local operational framework in Bahrain. This includes an adequate network of delivery riders, defined service standards, and a dedicated local support team backed by a 24/7 customer service centre. For restaurant partners, Keeta applies an integrated support model covering onboarding, daily operations, and performance enhancement, supported by data analysis and continuous collaboration.

As infrastructure investment, e-commerce growth, and sustainability regulation reshape supply chains, the UAE and wider MENA region are entering a decisive new phase in logistics development.

The logistics industry across the UAE and the wider MENA region is undergoing a pivotal transition. Once defined primarily by its geographic advantage at the crossroads of major global trade routes, the region has evolved into a highly interconnected logistics ecosystem. Today, ports, airports, free zones, digital trade environments, and last-mile distribution networks operate as a more coordinated and strategically aligned system than ever before. This evolution stems from sustained infrastructure

investment, the rapid growth of online commerce, and policy reforms aimed at streamlining trade and integrating transport modes. This supports the projected growth of the UAE logistics market from $30 billion in 2023 to $40 billion in 2028 (Ken Research, 2024). Other indicators of this progress are increasingly visible: DP World, for example, reported record-breaking container activity in 2024 and carried that momentum into 2025, underscoring continued strength in handling volumes and asset utilisation.

Three forces are shaping the current industry trajectory: shifts in demand patterns, ongoing modernisation of physical and digital infrastructure, and the growing emphasis on sustainability and resilience.

The first and arguably most influential driver is demand. E-commerce remains the dominant catalyst reshaping logistics planning across the region. The UAE’s online

retail sector expanded notably in 2024 and is forecast to accelerate over the medium term. This surge has amplified cross-border parcel flows, increased the complexity of returns processing, and heightened demand for technologically advanced fulfilment spaces. With consumers expecting faster and more reliable delivery, pressure on last-mile networks has intensified, presenting both operational challenges and valuecreation opportunities for logistics operators and digital solution providers.

Physical and digital Infrastructure constitutes the second major theme. Globally, infrastructure investment is critical, with many countries focusing on modernising transport networks to support logistics. This places the UAE, Saudi Arabia, and other MENA countries in a unique position, allowing them to rapidly expand their logistics capabilities, unlike in developed regions, where ageing infrastructure poses challenges. Public and private stakeholders continue to invest in multimodal connections, warehousing capacity, and port efficiency. Key hubs, including Dubai and Abu Dhabi, as well as Jebel Ali Free Zone, are expanding automated terminal infrastructure

and enhancing digital trade platforms, alongside major gateways in Saudi Arabia, Egypt, and Morocco. Dubai Trade’s transition toward fully paperless processes, for instance, has reduced administrative overheads, shortened clearance times, and contributed to lower emissions across the trade ecosystem. These reforms are improving reliability and predictability across supply chains.

Technology and automation continue to drive sectoral change. The logistics sector in the UAE and MEA is rapidly adopting advanced technologies such as AI, IoT, and blockchain to improve efficiency and transparency in supply chains. The region is also focusing on smart logistics solutions to enhance operational capabilities. Across the region, logistics players are piloting robotic systems, advanced terminal automation, and autonomous delivery solutions. From automated container-handling equipment to robotics-enabled fulfilment centres and smart-city delivery pilots, the region is positioning itself as a testbed for next-generation logistics technologies. Dubai’s initiatives to enable autonomous heavy vehicle trials on key

freight corridors highlight the regulatory commitment to shaping the future of mobility in logistics. These pilots are intended to support long-term shifts in cost structures, safety outcomes, and environmental performance.

The third significant theme in the logistics industry is triggered with the increasing demand for sustainability. Sustainability has become more strategic in relevance to the logistics industry. More logistics regulations will emerge globally. Regulations related to emissions and fuel efficiency will significantly impact the logistics industry. For example, “The expansion of EU Emission Trading System (EU-ETS) and FuelEU Maritime will mean that shipping lines face rising costs, which will impact logistics plans.” Regulations on carbon emissions are included in “UAE Federal Decree-Law No. 11 of 2024.” The law targets the management and reduction of GHG emissions in logistics, among other sectors. The laws provide countries like the UAE with a framework for addressing climaterelated environmental issues. Failure to comply with this law will result in severe penalties ranging from AED 50,000 to

AED 2,000,000. In case of repeated offences, it could be doubled,” KPMG in 2024.

Addressing compliance with these growing sustainability regulations should be done with consideration for managing disruption from geopolitical risks in the region. Organisations must mitigate risks while ensuring operational efficiency.

To foster ongoing industry growth while navigating challenges, five strategic priorities should inform future policy and action.

1. Advance multimodal connectivity

Deeper integration of ports, rail, road, and air freight systems will be essential. Enhancing multimodal corridors reduces exposure to bottlenecks and strengthens supply chain continuity, particularly in light of recurring maritime and geopolitical disruptions affecting routes such as the Red Sea and Suez Canal.

2. Accelerate digital trade interoperability

Expanding single-window platforms, scaling electronic documentation, and enabling interoperable customs data will drive down transaction costs and reduce dwell times. Public–private coordination around data standards and API frameworks will be fundamental to reinforcing the region’s competitive advantage in logistics efficiency.

3. Reimagine urban last-mile delivery

As regional cities grow denser, urban logistics must evolve. Solutions such as consolidation hubs, micro-fulfilment centres, parcel locker networks, and low-emission delivery fleets can decompress congestion and improve reliability. Integrating logistics considerations

into municipal planning will help reduce environmental and social impacts.

4. Strengthen workforce capabilities and regulatory agility

The shift toward automation and digitalisation demands new competencies in data analytics, software integration, and robotics maintenance. Partnerships between industry, government, and higher education will be crucial for upskilling. At the same time, regulatory frameworks must accommodate innovation, such as autonomous vehicle technologies, while ensuring safety and supporting workforce transitions.

5. Embed sustainability and resilience.

The movement toward net-zero operations requires targeted investment in energyefficient port assets, greener fleets, and sustainable warehousing. Simultaneously, enhanced resilience planning against cyber threats, climate risks, and geopolitical supply chain shocks must become integral to corporate strategy. Expanding routing options and improving inventory transparency are prudent steps that raise system-wide resilience.

For logistics businesses, the implications are clear. Companies that pair upgraded physical assets with strong digital capabilities, customer-focused fulfilment solutions, and sustainable operations will be best positioned to capture future growth. Investors in specialised real estate such as cold-chain facilities or automated warehouses will benefit from shifting fulfilment models. Yet challenges remain, including potential asset overcapacity, rising capital costs, regulatory fragmentation across markets, and ongoing geopolitical volatility.

The UAE and the broader MENA region have reached a point at which logistics is no longer merely a facilitator of trade but an independent strategic industry. The convergence of e-commerce expansion, advanced digital platforms, infrastructure upgrades, and technological adoption creates a robust foundation for the next decade. Realising this potential, however, requires intentional policy choices, coordinated multimodal investment, a skilled workforce, and a steadfast commitment to sustainability and resilience. For industry leaders and academics alike, the coming years offer a unique opportunity to shape logistics systems that are more efficient, greener, and more inclusive than ever before.

Using the Sea as a Fast Lane

Fly-Box CEO Alain Thébault explains why existing port transport models no longer meet express demand, and how automated coastal shuttles could offer ports a faster, cleaner alternative for short-distance container moves.

What problem does Fly-Box solve for ports today?

Ports deal with two hard challenges: move more containers, faster and more agile, while cutting CO2 drastically. Many express short distance moves inside port areas or between nearby ports end up on trucks as the default option. It feels simple because you load once, you drive, you unload, done. But the side effects are getting harder to accept, both for the real total transit time and for the footprint: gate congestion, queues, noise, local air pollution, and dependency on drivers.

On the water, classic feeders are great for volume, but not reactive. They run fixed schedules and often wait to fill, it’s impossible for express needs. Barges could be more flexible but they can’t face open sea segments. Fly-Box is a fast, low-emission container shuttle designed to operate in open sea conditions with automation rooted in its software design. It uses the sea as an extra lane for express single moves. It empowers underused waterfronts to reduce pressure on the main terminal and gates, and bring

containers closer to their final destination, keeping trucks for a true last-mile job.

How is a Fly-Box route faster or cheaper than using trucks or feeder ships?

We reduce waiting time in port and shuttle time on routes. We do not compete against inland barges. We operate on coastal open sea legs. Versus trucks, we can win when gate congestion is high and the sea route is direct while the road route is long, tortuous,or regularly jammed. Our full-scale platform targets 1 ×

“Fly-Box is a fast, lowemission container shuttle designed to operate in open sea conditions with automation rooted in its software design.”

40 ft on a ~20 m craft, cruising around 25 kn (about 45 km/h), for routes up to 150 nm (about 250 km).

On costs, early work suggests that on premium express service when we are radically faster in total time from A to B, our OPEX can catch up because the asset can rotate more. Also, time savings are not linear with price: on specific routes and for time-sensitive products, twice faster can justify way more than twice the cost. We are running a techno economic assessment to model total cost per move, including energy, port fees, maintenance, and crewing, plus the real savings from avoiding congestion and reducing idle time. One point that matters a lot for ports is infrastructure: we offer low-CAPEX port interfaces. A small quay plus a reachstacker and you can operate. This can generate value from underused port zones that do not produce much today and most port

operators look at how to intensify their operations, without new land consumption.

Finally, our solution truly scales when automation comes into the game. Naval drones are progressing fast and the sea is a less crowded environment than roads. We believe container shuttles can progressively move from 1 unit = 1 pilot, to several units in a platoon supervised by one pilot, and then toward remote control with a control tower.

Which types of ports benefit most from Fly-Box and why?

The best fit is a major hub where interterminal transport (ITT) has become a real bottleneck and hubs surrounded by multiple secondary ports within a few hours of navigation, especially where roads around terminals are structurally saturated. Dense coastlines, gulfs, deltas, and industrial port clusters are typical sweet spots.

The Gulf is a natural beachhead market for our solution: many ports fall within Fly-Box range, road congestion is severe with strong political pressure to regulate truck flows, and there is a clear appetite for innovation. Sea and weather conditions can also support operations on most days of the year. We have already established very positive contacts there with port operators, port authorities, political networks, and shipbuilding providers.

As said, Fly-Box is designed for simple infrastructure: shallow-draft access, a short quay, and standard cargo-handling equipment such as a reach stacker. That opens up underused waterfronts inside large ports, and can also reactivate smaller ports that lost container calls over time, including ports that never considered handling containers. We also see strong interest from island regions where logistics are complex and expensive. In places such as the Maldives, faster and more agile sea logistics can be a real game changer, and traction is strong in these niche markets as well.

What does success look like at the end of your current industry assessment?

Success means we end the assessment with an operator-grade view of operations and business, not just a concept story. It consists

of a shortlist of priority routes with volumes, service-level targets, constraints, and port interfaces. Also a clear model with CAPEX and OPEX for the operator, including a port integration plan (how we connect with TOS and planning tools, how container handover works, with safety procedures, energy and maintenance setups). If the assessment ends with one corridor where the numbers make sense and the execution plan is realistic, we

believe this will naturally trigger the next stage.

How much can operators realistically cut emissions by shifting cargo to FlyBox?

It depends on what you replace and how you power the vessel, so we avoid one magic percentage. The platform is designed to be fully electric for ITT-type operations, so on corridors where ports can

supply low-carbon electricity, operational emissions can drop sharply. For longer routes and early deployments, we also consider hybrid architectures, and operators can choose their own balance between cost and footprint. What is clear is that hydrofoils reduce drag, which reduces energy demand.

Our design direction targets about 30%–40% less energy than a conventional barge hull for comparable payload on the same route, with the additional benefit of keeping speed and schedule in moderate open sea (up to 1.5 m wave height). But the honest answer is route by route: electricity mix, port dwell time, truck detours, and the replaced mode all matter. The purpose of the current assessment is also to quantify emissions with an operatorgrade methodology that can be used in ESG reporting.

When will Fly-Box move from pilots to commercial operations?

We made our 8m demonstrator take off on Lake Geneva this fall. Next steps are phased: complete the industry assessment and lock pilot routes, while upgrading our demonstrator to its next version with more autonomous and remote-operation features. A big part of our value is in software. We then aim to secure the funding to build the first 2 full-scale units and run pilots with an operator under real conditions. Commercial operations come after successful pilots and the normal certification path, not before. If funding and industrial execution stay on track, we believe pilots can start in the 18–24 month window after we freeze the full-scale design.

With the launch of the Kuzer in the UAE, UD Trucks targets the heart of urban distribution, where uptime, flexibility, and everyday performance matter most

Urban logistics in the UAE is changing rapidly. As cities grow denser and delivery windows tighten, fleet operators are under mounting pressure to do more with less, less time, less space, and less margin for downtime. In this environment, light-duty trucks are no longer supporting players. They are becoming the backbone of last-mile distribution, municipal services, retail replenishment, and construction support.

It is into this space that UD Trucks has introduced the new Kuzer, marking the brand’s formal entry into the UAE’s light-duty segment and completing its commercial vehicle portfolio across light, medium, and heavy-duty operations.

The launch reflects more than a product expansion. It signals a deliberate response to how goods move through modern cities, and what fleet operators now demand from vehicles that operate at the sharp end of daily logistics.

The new Kuzer has been developed to meet the operational realities of urban and regional

distribution, where stop-and-go driving, tight access points, and long operating hours define performance expectations. Offered in 6.5-ton, 7.5-ton, and 8.5-ton GVW variants, the truck gives operators flexibility across a wide range of applications, from FMCG distribution and retail delivery to service and municipal use.

Depending on configuration, the Kuzer is powered by either a 3.0-litre or 5.2-litre Euro 4-compliant engine, paired with a six-speed manual or Automated Manual Transmission. This drivetrain setup is engineered to balance payload capability with fuel efficiency, particularly in congested urban environments where smooth drivability and reliability directly affect operating costs.

Compact exterior dimensions and a maximum overall height of up to 2,294 mm support manoeuvrability and visibility in dense city settings. Multiple wheelbase and rear frame configurations allow the Kuzer to accommodate a broad range of body types, with body lengths ranging from 4,300 mm to 6,130 mm. This adaptability positions the truck as a versatile platform rather than a single-purpose vehicle.

For drivers, light-duty trucks often mean long hours, frequent stops, and high fatigue levels. UD Trucks has placed clear emphasis on comfort and usability in the Kuzer’s cab design. Climate control, an adjustable tilt and telescopic steering column, and a clear instrument cluster contribute to a working environment that supports focus and consistency throughout the day.

Practical in-cab features including USB charging ports, a 24-volt power outlet, cup holders, and durable seating are designed around real-world usage rather than showroom appeal. The result is a cab that supports productivity without unnecessary complexity.

Safety remains central to the Kuzer’s design philosophy. The truck is equipped with Anti-lock Braking System, traction control with Anti-Slip Regulator, and Electronic Brakeforce Distribution.

“The introduction of the new Kuzer marks a truly significant milestone for UD Trucks in the UAE.”

Mourad Hedna President of UD Trucks MEENA

Driver and passenger airbags are available as an option, reinforcing a layered approach to safety.

Additional features such as a reverse buzzer, steering lock, and central locking enhance operational security, particularly in highfrequency delivery environments.

To support durability in demanding conditions, the Kuzer is fitted with front and rear fog lamps, an HD air filter with pre-cleaner, fuel pre-

filter, fuel tank lock, electric disc horn, and position lamps.

These elements reflect a vehicle designed not just to perform on launch day, but to withstand the cumulative wear of daily commercial use.

A full-range offering, backed locally

The introduction of the Kuzer completes UD Trucks’ model

range in the UAE, spanning light-duty, medium-duty through the Croner, and heavy-duty through the Quester. This fullspectrum offering allows fleet customers to standardise across vehicle classes while remaining within a single brand ecosystem.

Crucially, the launch is supported by UD Trucks’ long-standing UAE partners, Al Masaood CV&E and United Diesel, part of the Al Masaood Group and Al Rostamani Group respectively. Together, they bring more than six decades of local commercial vehicle experience, providing nationwide sales, service, and parts support.

Over the past two years, extensive preparation has gone into building the infrastructure required to support the Kuzer, from technician training to parts availability. This groundwork underpins the brand’s emphasis on uptime, a critical metric for light-duty fleet operators.

After-sales as a strategic differentiator

Beyond the vehicle itself, UD Trucks is positioning after-sales support as a core part of the Kuzer proposition. The truck

comes with a competitive warranty of three years or 150,000 kilometres, whichever comes first. Customers also gain access to UD Genuine Parts, covered by a standard two-year fitted parts warranty.

UD Trust maintenance plans offer fixed pricing, priority service scheduling for fleet customers, and roadside assistance. Service support has been structured specifically for light-duty operations, with quicker response times and flexible walk-in servicing options designed to minimise disruption.

This focus reflects an understanding that in light-duty logistics, downtime carries an outsized cost.

A strategic milestone

“The introduction of the new Kuzer marks a truly significant milestone for UD Trucks in the UAE,” said Mourad Hedna, President of UD Trucks MEENA. “A strategic market for us with its well-connected network and rapidly developing infrastructure, the UAE

demonstrates a strong demand for reliable and robust light-duty trucks.”

“With the Kuzer, we now have a complete range offering from 6T to 100T. Along with our trusted partners, we are proud to keep supporting UAE prosperity and our customers’ success.”

As urban logistics continues to evolve, the role of the light-duty truck is being redefined. With the Kuzer, UD Trucks is making a clear statement of intent, entering the segment not as a peripheral player, but as a serious contender focused on productivity, reliability, and longterm fleet value.

For UAE operators navigating tighter delivery windows and growing urban complexity, that proposition arrives at a timely moment.

“With the Kuzer, we now have a complete range offering from 6T to 100T. Along with our trusted partners, we are proud to keep supporting UAE prosperity and our customers’ success.”

From drones to digital supply chains, the way food moves globally is evolving. Climate, tech, and changing consumer habits are forcing logistics to rethink speed, sustainability, and resilience.

The global food trade is entering one of its most transformative eras. Climate change and evolving consumer expectations are converging to redefine how nations produce, move, and secure their food. At the same time, new technologies and trade policies are opening pathways toward greater transparency, efficiency, and resilience.

Navigating this complex landscape requires a delicate balance between domestic production, regional collaboration, and technological innovation, all while adapting to shifting global trade regulations, market access challenges, and sustainability imperatives. Key strategies for this include investing in modern infrastructure, fostering technological innovation in

agriculture, and building collaborative platforms for food security and innovation.

Reflecting these key trends, the upcoming global event Gulfood 2026, scheduled to be held in Dubai from January 26 to 30, 2026, will provide a platform for dialogue and collaboration on the future of food trade. The event will bring together global policymakers and leaders to explore how innovation, sustainability, and trade diversification can work in tandem to build resilient

food trade systems. The central theme will be food security as a global priority, a topic that is set to spark discussions among industry figures, decisionmakers, and investors.

In addition, the event’s Grocery Trade Zone, a dedicated sourcing platform for high-volume private label and FMCG products from around the world, will offer companies a significant opportunity to expand their portfolios and forge new partnerships that meet

rising demand for cost-effective, high-quality consumer goods.

According to the Agricultural & Food Markets: Trends & Prospects 2025-2034 report (July 2025) by the Organisation for Economic Co-operation and Development (OECD) & Food and Agriculture Organisation (FAO), global food and agricultural trade reached $1.9 trillion in 2023, underscoring the integral role of trade in linking producers and consumers worldwide. As food security becomes a top national priority, many countries are adopting protectionist policies alongside efforts to build regional resilience through robust collaboration and diversified sourcing strategies.

Technology: Backbone of Food Systems

Technological innovation is rapidly becoming the cornerstone of future-ready food systems. For instance, precision agriculture utilises AI-driven farming, robotics, and the Internet of Things (IoT) to optimise water and nutrient use, reduce waste, and improve yields. Furthermore, blockchain technology is revolutionising traceability and transparency in supply chains, allowing stakeholders to ensure food safety and strengthen consumer trust.

In the Thomson Reuters Institute’s supply chain survey, 52% of trade professionals stated that they had been impacted by cross-border dynamics and retaliatory tariffs impacting export control laws, while 74% cited challenges related to supply chain due diligence. These disruptions are prompting greater investment in digital tools and automation to reduce costs, improve efficiency and risk management, and drive decision-making, even as many organisations proceed cautiously with generative AI adoption across their operations. Growing investment in alternative protein sources, such as plant-based and lab-grown meats, also reflects a shift toward more sustainable diets and reduced environmental impact.

Climate change continues to exert profound pressure on global food supply chains.

Extreme weather and water scarcity are intensifying volatility in the food sector, while consumers and regulators alike demand more sustainable and ethically produced food. Future trade policies are increasingly shaped by environmental standards, carbon footprint regulations, and circular economy principles. Nations and businesses are being challenged to reduce emissions from long-distance transport, promote low-impact ingredients, and invest in regenerative agriculture and waste reduction strategies.

A white paper by the Stockholm Environment Institute (SEI) and Mistra Geopolitics highlights how cross-border dynamics and climate risks are directly impacting food production and trade, posing significant risks to global food security. In response to this, the study urges governments to strengthen national production, encourage resilient agriculture, minimise food waste, and enhance cooperation.

To thrive in this new era, countries must take a multi-faceted approach, investing in resilient infrastructure, strengthening domestic agricultural capacity, diversifying supply chains, enabling tech-driven farming, and building balanced trade partnerships that align with evolving consumer preferences for healthier and sustainable diets. Businesses are being challenged to rethink traditional models and build more resilient, sustainable strategies for the future. Cross-border collaboration, regulatory adaptability, and continuous innovation will be essential to ensuring stable, equitable, and future-ready food systems.

As 2026 approaches, the food industry is at a critical juncture, driven by challenges of rising tariffs, stricter sourcing requirements, evolving food security standards, and new trade frameworks. Success will hinge on strategic adaptation, including diversifying suppliers, fostering resilient supply chains, and prioritising sustainability and ethical practices to meet changing consumer and regulatory demands.

Vikas Sardana on leadership, technology, and why modern rail networks must move in rhythm with people, not just schedules.

Since September 2021, Keolis MHI — a joint venture led by global transport operator Keolis together with Mitsubishi Heavy Industries Engineering and Mitsubishi Corporation — has been responsible for operating and maintaining the Dubai Metro and Tram networks under a multiyear contract with the Roads & Transport Authority (RTA). The company oversees one of the world’s longest fully automated metro systems, including the Red and Green lines, as well as the city’s tram network, delivering high standards of safety, punctuality and passenger experience while supporting the emirate’s smart mobility goals.

In this interview, Vikas Sardana, Acting Managing Director of Keolis MHI, reflects on the organisation’s leadership philosophy, its approach to innovation and sustainability, and how advanced technologies and a passenger-centric culture are shaping the future of rail transport in Dubai.

How would you define your leadership vision for guiding

the rail transport network at this pivotal stage of its development?

Our vision is built on a clear principle: to make the transport ecosystem smarter, more sustainable, and more deeply connected to people’s daily lives. We are not simply operating trains and stations-we are redefining the role of public transport in the city so that it becomes a natural part of the urban rhythm and a seamless element of everyday mobility.

We adopt a “think like a passenger” culture, meaning that every operational or technical decision starts with the user’s needs-comfort, convenience, and safety.

How does the partnership between Keolis and Mitsubishi Heavy Industries translate into day-to-day performance across your projects?

This partnership brings together world-class operational expertise and engineering excellence. Keolis contributes extensive global experience in managing the networks, while Mitsubishi Heavy Industries brings deep

technical and engineering capabilities, having been involved in the development of the core infrastructure from the start. This synergy results in operations that meet the highest standards of safety and quality, meticulous maintenance, and data-driven asset management-ensuring exceptionally high availability, reliability, and overall network harmony.

What makes the Keolis–MHI team the backbone of your success?

Our people are our true success factor. We rely on over 1,700 well-trained professionals, equipped with the competencies needed to run a modern mobility system, and guided by a culture that places safety first and the passenger at the center of every operational decision. We also place strong emphasis on Emiratisation, having successfully attracted and trained young Emirati talents, including field and administrative leaders. This reflects our commitment to supporting the national vision of building local expertise in one of the most sensitive and significant sectors.

What makes the passenger experience in this system more than just a means of transportation?

Air-conditioned stations, punctual services, seamless integration with buses and marine transport, and the speed and fluidity of movement all create a calm, safe, and reliable travel experience.

Our goal is for every user to feel that their trip is part of a city run professionally and

designed to make their day smoother and more organised.

Something which comes before everything else is the safety and happiness of our passengers, which we are focusing on in all our activities.

What are the key technologies you rely on to enhance safety and reliability?

The metro operates on a fully automated, advanced train control system that ensures precise movement and coordination. We also employ predictive maintenance, using continuous data streams to detect potential issues before they occur-reducing disruptions and extending asset life. In addition, we adhere to strict standards for safety, asset management, and cybersecurity, supported by a “zero harm” policy that forms the backbone of our operational culture.

To what extent does smart data analysis help you understand ridership patterns and anticipate demand?

We use advanced analytics systems that draw near real-time data from stations and trains, enabling us to understand daily mobility

patterns and forecast peak-hour demand.

This allows us to adjust train distribution, refine timetables, plan maintenance, and continuously enhance the passenger experience. It is a system that makes operations more agile and more capable of adapting to the needs of a fastgrowing city like Dubai.

What are the biggest challenges you face in managing a network of this scale and precision?

The main challenge is maintaining perfect alignment between technical performance and the passenger experience. Even minor disruptions can affect thousands of passengers within minutes.

Managing a network of this size requires complex coordination between operations, maintenance, asset management, and workforce training-all while strictly adhering to safety standards and ensuring service regularity.

Is there a human moment that has stayed with you during your daily management of the network?

The moments that touch me most are when passengers express their appreciation for the comfort and safety they feel while using the metro every day.

Seeing a student, an employee, a mother with her child, or an elderly passenger relying with full confidence on the system reminds me that our work is not just about running trains—it is about improving people’s quality of life. This human dimension accompanies me every day.

How have your previous experiences-including your work in India-shaped the way you manage this advanced system?

Working in countries with high population density and complex transport systems provides valuable

insights into managing heavy passenger flows and long-term planning.

These experiences helped me develop an approach based on operational discipline, flexibility, risk management, and adapting global best practices to Dubai’s culture and the needs of its diverse users.

How do you expect the concept of “smart mobility” to evolve in the emirate in the coming years?

I believe the future will bring greater integration between all modes of transport, deeper reliance on data and smart analytics, and a shift toward a fully connected city where different systems operate in harmony. The metro and tram will remain central to this shift, supported by the

growing role of Emirati talent in leading this vital sector.

We also expect sustainable mobility to expand, reducing emissions and strengthening Dubai’s position as a global model for environmentally friendly cities.

What message would you share with today’s passengers about the future of this network and its role in urban life?

My message is simple: this network was designed for you to make your daily life easier, safer, and more convenient.

Its future will be even more advanced, intelligent, and sustainable, and it will continue to be an essential part of Dubai’s heartbeat and its path toward becoming the city of the future.

“We invite everyone to embrace public transport as a partner in creating better urban living and more connected, human-centered cities.”

J&T Express closes 2025 with record-breaking parcel volumes, powered by automation, network expansion, and unstoppable e-commerce growth.

J&T Express, the global integrated logistics operator, has capped 2025 with a milestone that few in the industry can match. The company announced that its total parcel volume for the year surpassed 30 billion for the first time, reaching 30.13 billion, up 22.2% year-on-year, while its average daily parcel volume hit 82.5 million, a 22.6% increase. The momentum carried through the fourth quarter, where J&T delivered 8.46 billion parcels, a 14.5% increase from the same period in 2024, averaging 92 million parcels per day.

Driving this growth were strong performances in Southeast Asia and the company’s New Markets, alongside consistent contributions from China. In Southeast Asia, the fourth quarter saw 2.44 billion parcels, up 73.6% year-on-year, bringing the full-year total to 7.66 billion, an impressive 67.8% increase. Across J&T’s New Markets—Saudi Arabia, UAE, Mexico, Brazil, and Egypt—parcel volume in Q4 reached 130 million, a 79.7% rise year-on-year, with full-year volumes hitting 400 million, up 43.6%. China maintained steady quality growth, delivering 5.89 billion parcels in Q4, with a full-year total of 22.07 billion, marking an 11.4% increase.

Beyond the raw numbers, J&T Express invested heavily in infrastructure and operational

efficiency to support this expansion. The company strategically optimised its network partners and outlets across markets, while upgrading sorting centers to streamline operations. In China, automation and cloud warehouse initiatives accelerated, resulting in a 26% increase in automated equipment by year-end compared to June, alongside the deployment of 1,000 unmanned vehicles to enhance last-mile delivery efficiency.

Reflecting on the year, Charles Junyi Hou, Group Vice President of J&T Express, said: “Benefiting from the rapid development of e-commerce and a diversified customer base, J&T maintained robust growth in Southeast Asia and New Markets. In China, we actively pursue higher-quality growth, and the more than 30 billion parcels delivered globally by 2025 will be a new starting point for us. Looking ahead, we will continue to strengthen our global network, drive growth through innovation, and consistently meet market demands.”

With record-breaking volumes, strategic investment in automation, and a growing global footprint, J&T Express is not just keeping pace with the evolving logistics landscape—it is shaping it.

Yahyah Pandor, VP and GM – MENAT at Blue Yonder, explains why the next phase of supply chain transformation is not about visibility or automation, but about AI-driven systems that can sense, decide, and act with minimal human intervention.

Supply chain digitisation has been on every boardroom agenda for years, but what do you think will define the next frontier of transformation beyond visibility and automation?

We’ve now reached a point where having visibility over your supply chain and using automation is no longer “advanced,” it’s simply expected. What comes next is supply chains that can make smart decisions on their own. Instead of systems that only show what’s happening or predict what might happen, the next stage is technology that can recommend and take actions automatically.

Our latest Supply Chain Compass report shows that nearly 47% of companies are already using machine learning and predictive AI, while another 40% say AI is transforming the way they operate. This is a clear signal that the shift from reactive to autonomous systems is underway.

The goal is to evolve toward an ecosystem where data continuously informs and optimises every decision, from sourcing to delivery. We’re building toward a state of continuous intelligence that allows supply chains not only to sense and respond but also self-correct and learn. This is where supply chains evolve from being responsive to being truly self-driving ecosystems, capable of learning, adapting, and executing with minimal human intervention.

Blue Yonder’s platform is built on AI and predictive analytics, yet true success often depends on people using that intelligence effectively. How do you see the relationship between human judgment and machine-driven insights evolving inside modern logistics organisations? This is not a story of humans versus machines, it’s about creating

symbiotic intelligence. AI brings the scale, speed, and precision that no human can match, while people bring intuition, context, and ethics.

Our research reveals that 79% of supply chain leaders expect AI to redefine workforce roles, and most see its greatest value in improving planning, predictability, and decisionmaking speed. However, they also cite challenges around data quality, fragmented systems, and skills development, which is why human oversight remains essential.

Blue Yonder’s new Cognitive Solutions address these barriers by unifying supplychain data into a continuously learning environment powered by AI Agents. These agents act as specialised digital teammates that monitor operations, surface real-time insights, and recommend next-best actions based on actual conditions. Because users can interact with AI Agents in natural language, teams gain instant clarity without needing technical expertise, making adoption smoother and building trust across planning, logistics, and operations teams.

The future lies to human-inthe-loop systems where AI handles the heavy data lifting, and people focus on strategic, ethical, and contextual decisions that technology alone cannot replicate.

Companies often measure supply chain performance by speed and cost, but increasingly, it’s about adaptability and foresight. How is Blue Yonder helping its customers in MENAT

VP and GM – MENAT, Blue Yonder

move from efficient supply chains to intelligent ones?

Efficiency will always matter, but the real measure of supply chain strength today is resilience built on foresight. Our latest Supply Chain Compass research found that 84% of leaders are prioritising agility and end-to-end connectivity as top objectives for the next two years. At Blue Yonder, we help organisations embed predictive intelligence and autonomous decision-making through our

new Cognitive Solutions, which use AI Agents to continuously analyse data, detect risks, and recommend or execute actions across the end-to-end supply chain. These solutions are built on a modern, true cloud architecture powered by the Blue Yonder Platform and Snowflake AI Data Cloud, with access to a multi-enterprise network and end-to-end interoperability that enables unified decision-making.

The recent acquisitions of Optoro and Pledge have expanded this ecosystem, strengthening our returns management and logistics emissions reporting capabilities. Optoro’s AI-powered returns management solution helps companies optimise the end-to-end returns lifecycle, while Pledge

underpins our accredited logistics emissions measurement and management as part of everyday supply chain planning. Together, these solutions enable businesses to evolve toward intelligent and sustainable supply chains, where adaptability is measurable and continuous.

MENAT markets can be complex, fastgrowing, fragmented, and digitally uneven. What have you learned about the unique operational DNA of this region that global models often underestimate or overlook?

MENAT’s strength lies in its diversity. You have economies that are scaling advanced logistics and AI infrastructure alongside frontier markets leapfrogging

into digital maturity, highlighting organisations’ entrepreneurship and agility.

In addition, our Compass report highlights that collaboration and shared visibility are among the top two enablers of transformation, especially in regions with varied digital readiness. Due to the region’s culture, co-creation is essential in MENAT, and business here thrives on partnership, trust, and alignment with government priorities. And we’ve learned that transformation sticks when technology adapts to culture, not the other way around. The most successful implementations in MENAT are those built collaboratively and locally, rather than imported wholesale.

We often hear about “digital transformation,” but that phrase is starting to feel overused. What, in your view, are the most misunderstood truths about what real transformation actually looks like inside a supply chain organisation?

The biggest misconception is that transformation is a technology project when in fact, it is a change-management journey. According to our Compass insights, while most organisations have a digital roadmap, many still struggle to scale transformation due to skill gaps, legacy systems, and cultural inertia. Meaningful change only occurs when people, processes, and platforms evolve simultaneously together.

At Blue Yonder, we view transformation as a continuous process rather than a one-off initiative. The adoption of solutions like our AI-driven Transportation and Warehouse Management systems shows that technology creates value only when paired with the right mindset and ways of working, such as empowering employees to act on AI-driven insights and updating company processes to support real-time responses. Therefore,

transformation is ultimately about cultivating a culture of adaptability, where data empowers teams to make faster, more informed decisions. When technology aligns with human capability and organisational purpose, that’s when transformation becomes real, measurable, and enduring.

Looking ahead, how do you define success for yourself and for Blue Yonder’s presence in MENAT over the next five years?

For me, success over the next five years is defined first and foremost by our customers’ success. I want Blue Yonder in MENAT to be recognised not only as a technology provider, but as a strategic partner to our customers, helping them shape the future of supply chain intelligence in the region. That is where Blue Yonder Services plays a critical role from implementation and change management to continuous optimisation, our services teams help customers turn vision into measurable outcomes across resilience, efficiency, and sustainability.

At the same time, our Blue Yonder advisory boards, including our Partner Advisory Board, are central to how we listen, co-innovate, and shape our roadmap together with customers and partners.

“If in five years our MENAT customers can point to stronger, more intelligent, and more sustainable operations that they built in partnership with Blue Yonder then I would consider that a true success for both myself and the business.”

lobal trade is operating under permanent strain, with new research showing that companies in parts of the Global South are losing months of productivity, millions of dollars and long-term customer trust as supply chain disruption shifts from episodic shock to a defining feature of today’s operating environment.

New research from DP World shows that while supply chain disruption is now a constant worldwide, its cost in lost time, revenue, and customer trust falls far more heavily on emerging and growth markets.

The Without Logistics report from DP World, based on a global study of 680 senior logistics and supply chain decision-makers across eight industries and nine regions, finds that disruption is now commonplace. However, its impact is deeply uneven, with firms in SubSaharan Africa (SSA), the Middle East and North Africa (MENA) and the Gulf (GCC) experiencing the longest downtime, the highest costs and the most severe customer fallout. In these regions, disruption routinely wipes out more than a month of operational capacity every year. The study shows that 83% of firms in SSA, 72% in MENA, and 61% in the GCC lose more than a month of operational time in years affected by major logistics disruption, compared with 50% of firms in North America, 41% in Germany and 36% in the UK.

The financial consequences are equally stark. High-value disruption is concentrated in the same corridors, with nearly half of companies in the GCC (47%) and more than four in ten in MENA (43%) reporting annual disruption costs of $1 million or more. These regions also sit at the top of the range globally for customer complaints, lost business and brand damage,

underlining how logistics challenges are now directly eroding commercial performance and reputation.

Beat Simon, Chief Operating Officer – Logistics, DP World, said: “This data shows that supply chain disruption is no longer a temporary shock, it is a recurring drain on growth, profitability and customer trust. In some regions, businesses are effectively planning around the loss of weeks or months of productive time each year.

“What is striking, however, is that the regions under the most pressure are also responding with the greatest urgency. In Sub-Saharan Africa and the GCC, more than nine in ten businesses expect to increase investment in logistics over the next year, and it’s 86% in the Middle East and North Africa. That reflects a clear understanding that resilience is now a competitive necessity, not an optional upgrade.”

The findings also expose two distinct disruption realities across global industries. High-volume sectors such as retail, healthcare and perishables are operating under near-constant turbulence, with retail and healthcare businesses each experiencing around 18,000 disruption events every year.

By contrast, automotive companies face fewer incidents, but when disruption hits, the impact is far more destructive. The average cost per disruption in automotive approaches $1 million, with annual losses estimated at $13 billion, and recovery times stretching far longer than in high-frequency sectors.

The research further shows that resilience is not driven by technology alone, but by the breadth of investment across the supply chain. Companies that strengthen multiple logistics capabilities, from factory logistics and inbound flows to

warehousing and digital coordination, report dramatically lower disruption costs than peers with narrower investment strategies. In consumer goods, firms investing in four or more logistics areas report disruption costs around 76% lower than low-investment competitors.

Customer pain is now close to universal. Across most regions and sectors, 80% to 95% of respondents say logistics disruptions have led to increased customer complaints. However, the study shows that lasting reputational damage is concentrated in specific markets, with Sub-Saharan Africa and France reporting some of the highest levels of brand impact, while firms in North America and the UK report rising complaints but relatively more resilient brand perceptions.

Despite the scale of the challenge, the research finds rare alignment across boardrooms and operations. More than 80% of respondents expect logistics to become a more strategic focus at board level, and nearly 90% agree that businesses with resilient supply chains will significantly outperform their peers in the years ahead.

Overall, the findings point to a clear conclusion: as disruption becomes a permanent feature of global trade, companies that fail to build end-to-end resilience risk falling structurally behind, whilst those that invest decisively stand to protect growth, customer trust and long-term competitiveness.

By Aya Zhang

The world of logistics is splitting into many paths. Some lead to risk, some to reward. In the Middle East, infrastructure, policy, and ambition are drawing the map of the trade routes of tomorrow.

For much of the past three decades, global logistics followed a relatively simple logic. Supply chains stretched across continents, production was concentrated where costs were lowest, and efficiency was king. If disruptions occurred, they were treated as temporary shocks to be absorbed and corrected.

That logic has now fundamentally changed. What the logistics industry is facing today is not a cycle of disruption, but a structural shift. Trade volatility, geopolitical realignment, climate risk, labour constraints, and regulatory divergence have transformed logistics from an operational function into a strategic determinant of economic resilience. The world is no longer organised around a single global supply chain, but around multiple, overlapping systems shaped by politics, proximity, and risk management.

This is the new logistics world order.

From efficiency to resilience

The old model rewarded scale and cost minimisation. The new model prioritises continuity, control, and optionality. Companies are no longer asking how to move goods at the lowest possible cost, but how to ensure goods can move at all under increasingly unpredictable conditions.

Supply chains are being redesigned to absorb shocks rather than eliminate redundancy. Inventory buffers, multi-sourcing strategies, regional distribution hubs, and alternative transport routes are no longer seen as inefficiencies but as safeguards. The question is no longer whether resilience costs more, but how much disruption costs when resilience is absent.

For logistics leaders, this shift requires a different mindset. Performance is no longer measured only by speed and price, but by reliability under stress. The ability to recover quickly, reroute intelligently, and maintain service continuity has become a competitive advantage.

A fragmented trade landscape

Global trade itself is becoming more fragmented. Trade corridors are increasingly shaped by geopolitical alliances, regulatory alignment, and national security priorities. Export controls, sanctions regimes, localisation policies, and carbon

regulations are redefining how and where goods can move.

As a result, companies are building parallel supply chains to serve different markets. One network for North America. Another for Europe. A separate strategy for Asia, the Middle East, or Africa. Logistics is no longer global by default. It is regional by design.

This fragmentation places greater pressure on logistics providers to operate with precision across multiple regulatory and operational environments. It also elevates the importance of trade facilitation, customs efficiency, and corridor reliability, areas where governments and logistics operators increasingly intersect.

Why the Middle East matters more than ever

In this new order, geography matters again. And the Middle East is uniquely positioned.

Historically viewed as a transit bridge between East and West, the region is now asserting itself as a logistics command centre in its own right.

Massive investment in ports, airports, free zones, rail networks, and digital trade infrastructure is reshaping how goods flow across Asia, Europe, and Africa.

The region’s strategic value lies not only in location, but in intent. Gulf states are actively positioning logistics as a pillar of economic diversification and long-term competitiveness. This is reflected in national strategies that prioritise multimodal connectivity, customs modernisation, smart ports, and logistics-friendly regulation.

For global shippers and manufacturers, the GCC increasingly offers something rare in today’s environment: infrastructure scale combined with capital depth, policy alignment, and a stable long-term operating environment.

Ports as strategic assets

Ports are no longer passive gateways. They are strategic assets that determine the speed, cost, and resilience of trade.

Across the region, ports are expanding capacity, integrating digital systems, and diversifying services to handle

not just containers, but value-added logistics, industrial activity, and regional distribution. The focus has shifted from throughput alone to flexibility, reliability, and integration with inland transport networks.

At the same time, ports are under pressure to decarbonise operations, manage congestion, and adopt automation responsibly. The ability to balance speed, sustainability, and workforce considerations is becoming a defining challenge for port operators globally.

In the new logistics world order, ports that can offer reliability under pressure, seamless connectivity, and digital transparency will define the trade routes of the future.

Technology as infrastructure

Digitalisation is no longer an optional upgrade. It is core infrastructure.

Visibility platforms, predictive analytics, AI-driven planning tools, and automation are becoming essential for managing complexity at scale. As supply chains fragment and volatility increases,

the ability to sense disruptions early and respond quickly is critical.

However, technology alone is not the solution. Many organisations are discovering that fragmented systems, poor data quality, and skills gaps limit the value of digital investment. The next phase of transformation is less about adding tools and more about integration, governance, and decision-making capability.

The most advanced logistics operations are those where technology supports human judgment rather than replacing it. Data-driven insight, combined with operational experience and local knowledge, is what enables intelligent responses in complex environments.

Urban logistics and the pressure of proximity

The transformation of logistics is not confined to global trade routes. It is increasingly visible at street level.

Urbanisation, e-commerce growth, and rising consumer expectations are placing unprecedented pressure on last-mile delivery systems. Cities are becoming the most contested space in logistics, where speed, sustainability, and social impact collide.

Across the Middle East, logistics providers are experimenting with urban consolidation centres, microfulfilment hubs, and smarter routing to reduce congestion and emissions while meeting demand for rapid delivery. These models reflect a broader shift toward proximitybased logistics, bringing inventory closer to consumption and reducing reliance on long-haul movements.

Urban logistics is no longer a downstream concern. It is a strategic component of national mobility,

sustainability, and quality-of-life agendas.

The workforce challenge

Behind every system, there are people.

As logistics becomes more complex and technology-driven, the demand for skilled professionals is rising. At the same time, the industry faces labour shortages, skills mismatches, and increasing pressure to localise talent.

Training, safety, and workforce engagement are becoming strategic priorities. The organisations that succeed will be those that invest not only in assets and systems, but in people who can operate, adapt, and lead in an environment of constant change.

What defines success in 2026

The new logistics world order does not reward those who chase scale blindly. It rewards those

who understand risk, invest in adaptability, and think long-term.

Success will belong to organisations that build supply chains capable of absorbing shocks without breaking, that leverage technology intelligently, and that align operations with evolving trade, regulatory, and sustainability realities.

For the Middle East, the opportunity is clear. By combining infrastructure investment, policy ambition, and geographic advantage, the region can shape the future of global logistics rather than simply serve it.

Logistics is no longer a background function of global trade. It is one of its defining forces. And as 2026 approaches, the industry is not returning to the old normal. It is moving forward into a new order where resilience, control, and strategic connectivity define who leads and who follows.

Abhinav Patwa, Executive Vice President at Al Ghurair Group and Head of Zed, shared how the platform is investing in smarter fleet management, predictive ETAs, and context-aware mobility to ensure rides are effortless, efficient, and tailored to the city’s unique rhythms.

What innovations or technologies are you exploring to make urban mobility smarter and more seamless for residents and visitors alike?

At Zed, our focus is not innovation for the sake of novelty, but innovation that removes friction from everyday movement. We are investing in smarter demand–supply matching, predictive ETAs (estimated times

of arrival) and more accurate pick-up point mapping across the city.

A key area we are working on is contextaware mobility which involves understanding where, when, and why people travel, and adapting the experience accordingly. Whether it is event-driven demand, latenight travel, or routine commutes, the goal

is to make booking and riding feel effortless, predictable, and reliable. Technology should quietly work in the background while the customer experiences simplicity.

The Year in Motion suggests ride-hailing is evolving from a convenience to a daily essential. How is Zed adapting its features or services to meet this shift in lifestyle dependency?

Ride-hailing today is no longer an occasional service, it is part of how cities function daily. At Zed, we are designing the app around habitual behaviour, not just one-off rides.

This means features that support routine journeys such as faster rebooking, clearer ETAs, scheduled rides, and consistent availability during peak hours.

For example, we recently introduced a ‘one-tap booking’ feature after noticing that many riders used our services for routine commutes. This enables riders to preset their ride preferences including their pick-up point, destination, payment method and even type of ride, enabling them to re-book the exact same journey in the future in just one tap on the app and allow for future convenience.

We are also expanding ride options across taxis and limos to match different use cases from everyday commutes to business travel.

Overall, our philosophy is simple: when mobility becomes dependable, it becomes indispensable.

Beyond transport, how does Zed aim to positively impact local communities and the social fabric of Dubai?

Being a homegrown brand, community impact is not an add-on for us. It is core to how we operate. Zed actively

looks at mobility as a platform to support inclusion, accessibility, and local engagement.

From CSR-led initiatives with People of Determination to hyperlocal campaigns that support neighbourhoods, we aim to create value beyond the ride itself. Our drivers are also a vital part of the community ecosystem, and we invest time in training,

“Ride-hailing today is no longer an occasional service, it is part of how cities function daily.”

Abhinav Patwa, Executive Vice President at Al Ghurair Group and Head of Zed

incentives, and engagement to ensure they feel part of the brand journey.

Ultimately, we want Zed to feel less like an app and more like a trusted city partner.

How is Zed integrating sustainability into its operations and services, given the growing importance of eco-friendly transport solutions?

Sustainability in mobility is as much about efficiency as it is about emissions. At Zed, we focus on smarter fleet utilisation, reduced idle time, and better route planning to minimise unnecessary vehicle movement.