Tariffs have reshaped the global supply chain, upending long-established networks of materials, vendors, and labor.

This disruption poses real challenges — but also unveils a critical opportunity: the chance to reimagine and rebuild American manufacturing from the ground up.

At Automation Alley, we believe disruption fuels innovation. The decoupling of global trade is a call to action to reignite domestic production and strengthen our industrial foundation here at home. We won’t sugarcoat it; this realignment won’t be easy. It will take time. It will be painful in places. But the longterm gains — economic resilience, job creation, and national security — are worth the effort if we stick the landing.

This shift also opens a door for regional collaboration like never before. For too long, manufacturers have competed in silos at home and abroad. Now, we’re being challenged to break down those walls and build partnerships that serve a greater purpose. The future belongs to those who collaborate, adapt, and evolve together.

That’s where our members come in. As an Automation Alley member, your insight, experience, and ingenuity are critical to this effort. You don’t need to have all the answers — you just need to bring your expertise and voice to the table.

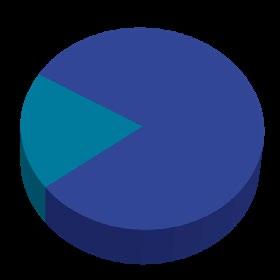

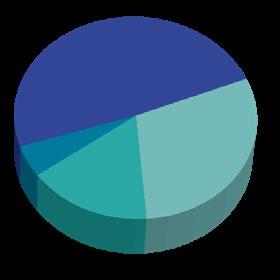

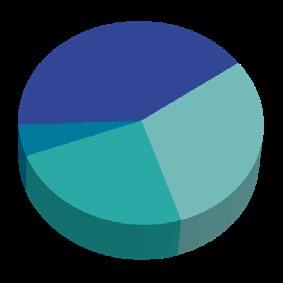

This series on Global Trends and Supply chain needs your candid input and perspectives. To achieve this, we asked our members questions around three key topics: tariffs, the definition of digital transformation, and workforce challenges. We need to understand where the momentum is on each of these topics, and how to be proactive in them.

These discussions are encapsulated accurately with supporting data in this Integr8 Playbook. It is a privilege to be the outlet for so many voices representing the breadth of industry at the table. Together, we can embrace change and lay the groundwork for reshoring manufacturing — stronger, smarter, and closer to home.

Let’s get to work.

Tom Kelly Executive Director & Chief Executive Officer Automation Alley

Roundtable Attendee List: Sponsors, Supporters and Participants

Main Feature:

Global Trends & Supply Chain: Planning for a Shifting World

Expert Insights:

Rebuilding Resilience: How Innovation Is Reshaping Automotive Supply Chains Rockwell Automation

Expert Insights:

The Design-to-Source Era Has Arrived Samsung SDS

Expert Insights:

Key Global Manufacturing Trends Heading into 2026 Wipfli

Expert Insights:

Building AI-Ready Supply Chains: Structuring Data and Navigating Legal Frameworks in an Era of Intelligent Operations

DataOps and Foley & Lardner LLP

Expert Insights:

Retaining Skilled Workers in an AI-Driven World: A Call to Action for Michigan’s Workforce Oakland Schools

Industry Pulse: Ecosystem Insights at a Glance

Future Trends: Global Trends & Supply Chain

Industry Insights: Leading the Lean Way: Transforming Supply Chains with Leadership and Lean Thinking Lean Fox Solutions

Case Study:

Juise Mobility Reimagines e-Mobility Infrastructure

Key

State

and Supply Chain

SPONSORED BY: Rockwell Automation, Samsung, WIPFLI, Oakland Schools and DataOps

Ed Bonnell - Account Manager, Rockwell Automation

Misty Goodman - Strategic Account Manager, Rockwell Automation

Rodney Rusk - Global Account Leader-Stellantis, Rockwell Automation

Annisha Vaughn - Industry Sales Manager, Rockwell Automation

George Stasiw - Senior Account Executive, Samsung

Tarah Ablett - Senior Manager, Wipfli

Rob Cheyne - Manager, Wipfli

Tim Finerty - Partner, Wipfli

Paul Galbenski - Career Readiness Supervisor, Oakland Schools

Jarrad Grandy - Executive Director of Student Services, Oakland Schools

Jennifer Kluesner - K-12 Career Readiness Consultant, Oakland Schools

Lauren Marchelletta - STEM Consultant, Oakland Schools

Paige Rutkowski - K-12 Career Readiness Consultant, Oakland Schools

Rene Sommers - Career Readiness Consultant,Oakland Schools

SUPPORTED BY AND PARTNERS WITH: BMP Media, ARM Institue and Michigan Economic Development Corporation

Jack Johns - Program Director, Macomb County Planning & Economic Development

Michael Leonard - Publisher, Food Engineering/BNP Media

Kelley Rodriguez - Editor in Chief, Refrigerated & Frozen Foods/BNP Media

Alyse Thompson-Richards - Editor-in-Chief, BNP Media

John Zappa - Director of Product Management, ARM Institute

ADDITIONAL LEADERS IN INDUSTRY, ACADEMIA AND GOVERNMENT IN ATTENDANCE:

Tom Kelly - CEO & Executive Director, Automation Alley

Pavan Muzumdar - COO, Automation Alley and CEO, Project DIAMOnD

Brian Breuhan - Sr. Manufacturing Engineer, Advanced Technology, General Motors

Justin Bruno - Territory Sales Manager, Midwest, Markforged

Bella Brykalski - Sr. Search Consultant, CPI

Brendan Cherry - Sr. Manufacturing Engineer, Advanced Technology, Michigan Economic Development Corporation

Devansh Chowdhary - Director FTE Microlearning, FTE Microlearning

Guillaume Dutripon - Purchasing & IT Manager North America, AdduXi Inc.

Angel Fonseca - Professor, Jackson College

Scott Goddard - Sales Executive, Campfire Interactive

Jason Hamp - AI Technologist - Manufacturing, Lenovo

Sam Hoff - President/CEO, Patti Engineering, Inc

Tina Hurite - Vice President of Operations, Michigan Manufacturing Technology Center

Wesam Iwas - Managing Director, Ankercloud Inc.

Amy Kitchen - Director - Strategic Growth, MetaOps

Tom Krent - Planning Commissioner, Education Planning Resources

Maribel Lopezruiz - Program Manager for Business Development, Peak One

Michael Luzi - Vice President of Strategic Partnerships, BenePro/HRPro

Vanessa Miller - Partner & Chair Manufacturing Sector – Automotive, Foley & Lardner LLP

Noel Nevshehir - Director of International Business Services and Global Strategic Partnerships, Automation Alley

Julie Oldham - Business Growth Consultant, Small Business Consulting Services

Tim Ross - Senior Sales Account Executive, Campfire Interactive

Adel Saldana - Logistics Manager, AdduXi Inc.

Robert Stauffer - Manager of Operational Excellence, Michigan Manufacturing Technology Center

Dan Stewart - Relationship Manager, Automation Alley

Samuel Thompson - CTO, Ulendo Technologies, Inc.

Ben Wixson - Group Manager, Automation Solutions of America

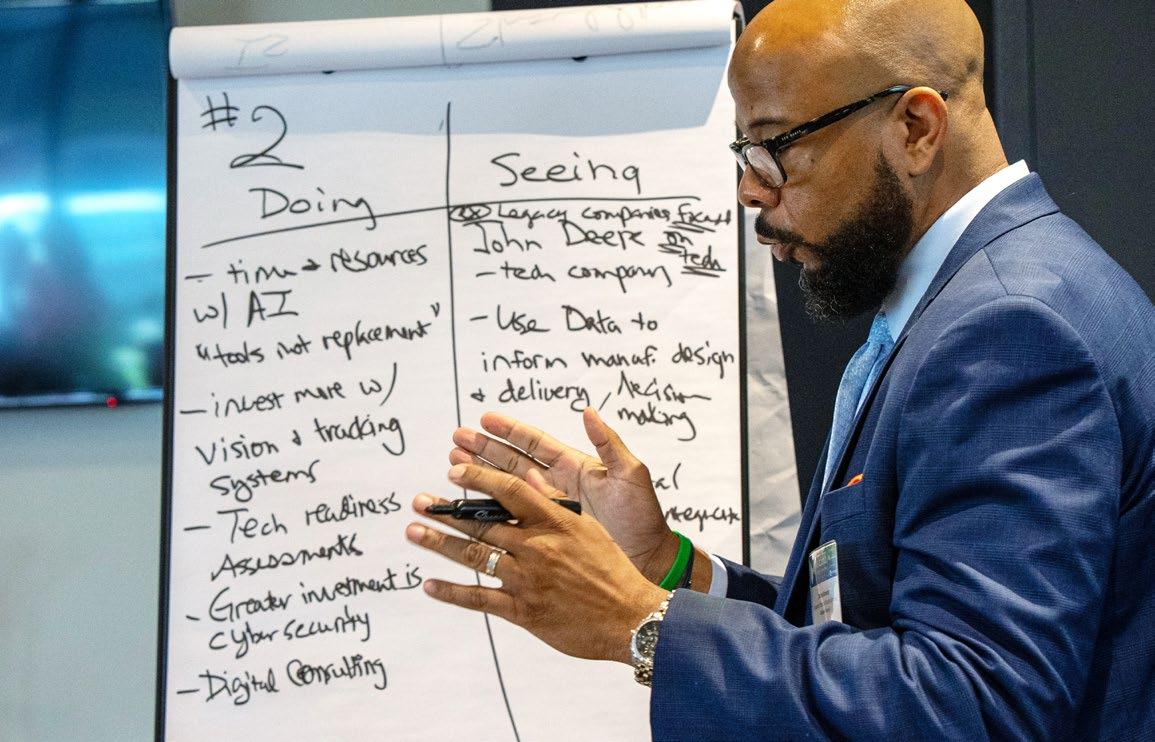

Manufacturing is contending with the largest disruption in global trade since the pandemic. Moving target tariffs, changing political relationships, a push for onshoring and the AI juggernaut are all jostling the traditional manufacturing order. So, what does industry, academia, and government agree on as the best course for manufacturing at this time in history? The answer from our roundtable was clear: Innovate, diversify and digitize to survive.

Automation Alley’s latest roundtable on top trends influencing global manufacturing in 2025 focused heavily on the opportunities, challenges, and workforce issues shaping the sector this year. The discussions revealed a manufacturing industry grappling with uncertainty while cautiously optimistic about innovation.

The manufacturing landscape is undergoing a profound transformation, presenting forwardthinking companies with opportunities to enhance efficiency, reduce costs, and create innovative products. Two areas stand out for their potential to revolutionize production in 2025: AI-powered design and personalization at scale

Generative design software now allows engineers to input specific parameters such as material restrictions, weight limitations, and performance requirements and receive dozens of optimized design alternatives in minutes rather than weeks. According to a study by MIT, highly skilled workers improved performance by nearly 40% when using generative AI, compared to those without AI support.

Supporting this data is also Rockwell Automation’s 2025 State of Smart Manufacturing Report , which surveyed 1,500 worldwide manufacturing leaders. Forty-one percent plan on deploying AI and machine learning technology to fill in skills gaps and labor shortages.

According to a study by MIT, highly skilled workers improved performance by nearly 40% when using generative AI, compared to those without AI support.

“Many people think ‘AI in and jobs out’. We have a lot of conversations about that not being true, but that perception is prevalent in the manufacturing segment. We also heard a lot about keeping pace—or exceeding pace—with China.” Michael Leonard Group Publisher

Meanwhile, spending on new manufacturing construction surged to new heights over the last two years despite recent cooling, signaling an overall renewed push toward domestic capacity. That investment dovetails with emerging digital transformation tools, which are democratizing technologies once reserved for the largest manufacturers.

Michael Leonard, group publisher at BNP Media, said there is also growing attention among industry partners on how these opportunities intersect with global competition. “Many people think ‘AI in and jobs out’,” Leonard said. “We have a lot of conversations about that not being true, but that perception is prevalent in the manufacturing segment. We also heard a lot about keeping pace— or exceeding pace—with China.”

Despite the promise of technology, manufacturers face a convergence of economic, technological, and geopolitical hurdles. Chief among them are tariffs, AI accuracy, and the slow pace of digital transformation.

Though the science of diagnosing the health of the manufacturing industry is difficult, there are several statistics that underscore the current uncertainty in the manufacturing sector: The Institute for Supply Management’s Manufacturing PMI dropped to 48% in July, down from 49% in June—marking contraction territory after months of sluggish growth. Additionally, construction on new manufacturing facilities is down 6.7% in comparison to last year.

Leonard noted the deep uncertainty surrounding trade policy as an important factor. “Most importantly, there are concerns of delays with tariffs and the idea of fluctuation of tariff rates,” he said. “This is forcing companies to speculate and try to stay ahead of tariffs. There is also a fear of inflation of what these tariffs may cause.”

Tim Finerty, partner and CPA at Wipfli, said nearshoring and onshoring are natural responses, but progress is slow. “There is uncertainty with these tariffs, but nearshoring and onshoring are great opportunities,” Finerty said. “Unfortunately, it is hard to do that in the short term.”

Rodney Rusk, global account manager of Stellantis at Rockwell Automation, said tariffs are already forcing companies into tough decisions. “Many companies that were thinking to adapt are now forced to adapt,” he said. “Do we or do we not pass on tariff costs to customers? Everyone has to make a choice.”

The Institute for Supply Management’s Manufacturing PMI dropped to 48% in July, down from 49% in June—marking contraction territory after months of sluggish growth.

“Many companies that were thinking to adapt are now forced to adapt. Do we or do we not pass on tariff costs to customers? Everyone has to make a choice.”

Rodney Rusk Global Account Leader-Stellantis Rockwell Automation

Jarrad Grandy, executive director of student services at Oakland Schools, added that tariffs are increasingly hidden within overall pricing. “Tariffs are becoming more baked into the price of goods and less transparent,” Grandy said. “It’s a fluid environment.”

Further illustrating this push and pull between onshoring growth and a timid market comes from Federal Reserve data. Overall manufacturing output is up 2% at an annual rate. However, more complex manufacturing like appliances and parts related to motor vehicle production fell by 2.6%. The production of primary metals leads all gains in manufacturing at 3.1% growth.

“Digital transformation is a lot of information coming out very fast, but the actual implementation is slow,” Leonard said.

The restructuring of global supply chains remains a dominant theme. Leonard said reshoring is now the industry’s instinctive response. “Reshoring is obviously the answer, at least today,” he said. “Everybody around this table is saying we need to bring manufacturing back to the United States.”

However, the web of the global supply chain is complex. The rise of white-labeling products and obscuring the origin of manufactured goods provides confusion on the sourcing of key materials in the supply chain.

“That means identifying China and changing sources on secondary suppliers,” Leonard said. “But sometimes it is difficult for tier ones to find out where those suppliers are.”

John Zappa, director of product management at the ARM Institute, said companies must diversify beyond reshoring. “There is this whole notion of offshoring and nearshoring, but what we should be looking at is diversifying our supplier base,” Zappa said. “We need to look at friendshoring, countries with lower taxes and tariffs.”

“There is this whole notion of offshoring and nearshoring, but what we should be looking at is diversifying our supplier base. We need to look at friendshoring, countries with lower taxes and tariffs.”

John

Zappa

Director of Product Management ARM Institute

The workforce challenge is both an opportunity and a risk. According to the Manufacturing Institute, nearly 2.1 million jobs could go unfilled by 2030 due to a skills mismatch, potentially costing the U.S. economy $1 trillion. Nearly a quarter of the manufacturing workforce is also over age 55, raising fears of a “silver tsunami” of retirements. Federal labor statistics show employment in manufacturing has edged higher in recent years, yet the need for advanced technical skills continues to outpace supply.

Leonard warned that much of the burden of digital change falls on employees rather than executives.

“A lot of the digital transformation comes from the C-suite, but the actual workforce is very stressed with these changes,” he said. “There are people working for companies for 15-20 years, and when you start throwing in new acronyms and systems it will be hard.”

This gap can be illustrated with data from a Gallup Poll on AI in the workplace. According to Gallup, “46% of leaders, compared with 36% of individual contributors, indicate they use AI in their roles to consolidate information or data.”

Grandy echoed this, noting the difficulty of matching reshoring with talent capacity. “Companies are encouraging onshoring, but don’t necessarily have the talent that is needed to complete the extra work,” he said.

Finerty emphasized that universities and trades must align more closely with industry. “We are trying to figure out how to use these universities to focus on what manufacturers need,” he said. “Also, how do you use the trades to support this?”

Rusk called for a broader conversation between industry and government. “We need a new dialogue on talent and resources, whether this is looking at how the government and industry can partner up or how to capture opportunities,” he said.

Zappa stressed that leadership must manage the human side of change. “This is not something that happens by itself,” he said. “As with all change, consider the emotional response from people whether you are talking about AI, robotics or automation.”

According to Harvard Business Impact, mid-level leadership is key to driving institutional change in the future of work. These leaders must be transparent and forge a “compelling vision” for employees to understand the goals of digital transformation.

Rusk added that leadership is already reshaping organizational cultures. “We need to take a leadership role to control our own destiny,” he said. “In some cases we are seeing leadership leaning into this and creating a new culture. We want to see more of that.”

Grandy said legacy manufacturers are evolving into tech-driven organizations. “Legacy companies are becoming more and more like tech companies, using data to inform their decisions,” he said. “Human and AI capital becoming truly collaborative is the next step.”

Rusk noted that the long-term goal is to make AI a partner, not a threat. “Overall, we want the workforce to be involved in AI, not fearful of it,” he said.

Despite deep uncertainty, manufacturers agree on one path forward: innovate, diversify, and digitize. AI-powered design, personalization at scale, and rising investment in domestic capacity are reshaping production, while leadership and culture shifts are turning legacy manufacturers into tech-driven organizations. Success will hinge on leaders who manage the human side of change and foster collaboration between people and AI.

Challenges, however, remain significant. Tariff volatility, uneven digital adoption, and a widening skills gap complicate reshoring and supply chain diversification. With talent pipelines struggling to keep pace, universities, trades, and mid-level leaders must align more closely with industry needs. Those who pair resilience with bold innovation will be best positioned to shape the future of manufacturing.

Although many of these trends are still in flux, manufacturers that balance innovation with resilience will be best positioned to thrive. As Leonard put it, equilibrium will eventually be “delivered by the market, where it will organically happen.”

Rodney Rusk Global Account Leader

Stellantis, Rockwell Automation

The automotive industry is at a crossroads. After decades of refining internal combustion engine vehicles, manufacturers now face a global imperative to embrace electrification. This shift isn’t just about changing the powertrain—it’s about rethinking the entire supply chain.

Pressure is mounting to deliver smarter, more sustainable, and flexible operations. Innovation is no longer optional—it’s now the engine driving the future of automotive manufacturing, offering a clear path amid uncertainty.

Electrification is reshaping consumer expectations. Hybrids and fully electric vehicles are no longer niche—they’re mainstream. But the transition hasn’t been smooth. Faltering EV sales growth in recent years has forced OEMs to revise forecasts and scale back expansion plans. This volatility is cascading through the supply chain, creating new challenges for Tier 1 suppliers and component manufacturers.

These suppliers must support a wider range of drivetrains and adapt to unpredictable demand, making supply chains more agile, intelligent, and resilient than ever.

Labor shortages are compounding the pressure. In the U.S., Tier 1 suppliers are competing for workers in crowded industrial corridors, where multiple global manufacturers operate side by side. Retaining talent is a daily battle.

Technology offers a way forward. Automation and robotics help mitigate workforce gaps, improve productivity, and maintain continuity. Persistent workforce challenges are addressed through investments in digital and flexible automation systems.

This isn’t about replacing people. It’s about empowering them. Automation enables workers to focus on higher-value tasks, reduces physical strain, and creates safer, more efficient workplaces. Automation enhances, not replaces, the workforce.

Battery manufacturing is at the heart of the EV revolution. But scaling production to meet demand is no small feat. Manufacturers must balance speed, quality, and cost while navigating complex chemistries and evolving technologies.

Innovation is helping bridge the gap. Advanced automation systems are streamlining cell assembly, improving traceability, and enabling real-time quality control. These tools are critical for meeting the demands of next-generation vehicles, which require higher energy density, faster charging, and longer lifespans. Key takeaway: Advanced automation is crucial for competitive battery manufacturing.

As battery plants scale up, the ability to replicate success across multiple sites becomes essential. Standardized automation platforms and digital twins are making this possible, allowing manufacturers to launch new facilities faster and with greater confidence.

Tire production is another area ripe for transformation. Historically, it’s been a labor-intensive process with limited flexibility. But as vehicle designs evolve and consumer preferences shift, tire manufacturers must adapt quickly.

Automation is simplifying complexity. From material handling to curing and inspection, digital tools are improving consistency, reducing waste, and enabling mass customization. Manufacturers can now produce a wider range of SKUs without sacrificing efficiency.

This flexibility is critical in a market where performance, sustainability, and personalization are becoming key differentiators. By embracing innovation, tire manufacturers are staying competitive and future ready.

The road ahead will require collaboration. OEMs, suppliers, and technology partners must collaborate to build smarter, more interconnected supply chains. This means sharing data, aligning standards, and investing in scalable solutions.

It also means rethinking how we measure success. Efficiency alone is no longer enough. Manufacturers must consider sustainability, adaptability, and workforce empowerment as key performance metrics.

Innovation isn’t just about technology—it’s about mindset. It’s about refusing to settle for “good enough” and imagining what’s next. At Rockwell Automation, we’re committed to helping our partners navigate this transformation with confidence, clarity, and purpose.

Innovation isn’t just about technology—it’s about mindset.

Rockwell Automation is the largest company in the world that is dedicated to industrial automation and digital transformation. Across the globe, our flagship Allen Bradley ® and FactoryTalk ® product brands are recognized for excellence. Our singular focus on automation, combined with our deep automotive manufacturing experience, means that we understand your world and how to improve on it. We bring a passion for connecting people’s imaginations with machines’ potential to make your plant work smarter today and tomorrow.

George Stasiw Senior Account Executive Samsung

For modern manufacturers, supply chain costs are rising from every direction: raw materials, logistics, compliance, labor, and financing. For companies managing complex bills of materials (BOMs), especially in high-precision and engineered- to-order sectors, the margin for error is shrinking while the cost of inefficiency is growing.

At the same time, innovation cycles are accelerating. Customer demands shift quickly, product designs evolve rapidly, and expectations around delivery speed and customization rise continuously. This is placing unprecedented pressure on procurement and supply chain teams to balance agility with cost control.

The solution lies in rethinking the traditional linear model and embracing a smarter, more connected approach that starts not at the point of purchase, but at the very beginning: design.

Welcome to the era of design-to-source powered by data, driven by collaboration, and increasingly enabled by artificial intelligence.

Historically, product design and procurement teams have operated in silos. Engineers build what they envision and procurement teams are expected to source it, often with limited visibility into part availability, cost implications, supplier capacity, geopolitical risk, or potential market disruptions.

This disconnection leads to:

• Over-engineered components that drive up cost

• Missed opportunities to standardize or consolidate suppliers

• Reactive sourcing under pressure

• Expensive last-minute changes or supply chain delays

Issues like these get amplified when the unexpected happens, as seen with recent tariff changes. More and more teams are seeing the need to collaborate sooner to bring tariff awareness into the early design and sourcing process before parts are locked in. When many products contain thousands of components sourced from all over the world, this collaboration enables teams to think strategically about viable alternative options that will keep a project on budget and on time.

In today’s rising-cost environment, inefficiencies stemming from disconnection are no longer acceptable. More importantly, they’re no longer necessary.

Design-to-source represents a transformational shift: integrating sourcing intelligence into the product design process so that engineering and procurement teams make decisions collaboratively, informed by real-time supply data.

When engineering can see the full picture—pricing trends, lead times, supplier performance, geographic risk, ESG compliance—at the point of initial product design, it empowers smarter part selection, faster time to market, and measurable cost savings. Likewise, when procurement is looped into the design phase, it can guide decisions that avoid single-source bottlenecks or recommend pre-qualified, lower-cost alternatives.

This is where AI is becoming a game changer.

Until recently, the vision of a fully integrated design-to-source workflow was difficult to achieve at scale. The data existed, but it was scattered across ERPs, spreadsheets, emails, and siloed systems. Human decision making was limited by time, scope, and visibility.

Now, AI is closing the gap by turning fragmented data into predictive insights and enabling smarter, faster decisions across the entire product lifecycle. AI technology in design-to-source procurement workflows enables:

AI can forecast the cost impact of design choices in real time, drawing from historical data, market pricing, and supplier benchmarks, helping teams stay within budget from day one.

AI can use machine learning to analyze BOMs and suggest functionally equivalent components based on availability, lead time, or cost, improving resilience without sacrificing quality.

AI aggregates external and internal data to assess supplier risk profiles, financial health, geopolitical exposure, and ESG alignment, helping procurement teams mitigate risk proactively.

AI can generate and distribute RFQs, recommend optimal price points, and even analyze contract terms, accelerating the sourcing process without compromising compliance.

AI can simulate and model hundreds of scenarios simultaneously, informing better planning by testing what-if situations like tariff changes, raw material shortages, or supplier shutdowns.

Design-to-source capabilities aren’t just ideas. They’re tangible, essential tools for manufacturers who must balance cost, complexity, and speed in volatile markets. Consider a real-world use case:

A top-10 global automotive manufacturer wanted to enhance the cost competitiveness of its vehicle trim components, including wipers, mirrors, visors, consoles, and more. The difficulty was that sourcing these items required the validation of spreadsheet files containing 200-900 line items per component with little consistency from line to line.

By applying AI algorithms to organize historical quote databases and calculate should-cost analysis, the automaker standardized quotes, sped up sourcing cycles (quote analysis alone went from taking one week to just hours), and reduced purchasing costs for interior components by 5-10%. This saved millions while improving stability in procurement and supply chain planning functions.

There are many more examples of AI-powered technology enabling the design-to-source process in the real world. Whether it’s analyzing BOMs that contain thousands of line items, flagging components at risk of near-future unavailability during the design phase, or identifying hundreds of components eligible for substitution quickly, companies are avoiding launch delays and meeting their financial targets more easily than ever before. These aren’t just efficiency wins— they’re strategic, competitive advantages.

When every cost is under scrutiny and every delay is magnified, the old model of procurement as a late-stage, reactive function no longer serves manufacturers. The future belongs to those who integrate design and sourcing from the start by leveraging AI to drive transparency, speed, and strategic alignment.

Lastly, it’s essential to understand that AI doesn’t replace human expertise; it augments it. Engineers still design, and procurement still negotiates, but AI empowers both functions with insights at the speed and scale that today’s manufacturing environment demands. To realize the full benefits of design-to-source, companies must ultimately foster a new culture where data flows freely, collaboration is rewarded, and product lifecycle decisions are made with total cost and supply resilience in mind.

At Samsung SDS Caidentia, we believe that the most competitive supply chains aren’t just lean—they’re intelligent by design. As we join the Integr8 Supply Chain Roundtable and contribute to the Playbook, we look forward to advancing a vision that empowers manufacturers to thrive in complexity, not just survive it.

After all, the smartest way to cut costs isn’t after the fact. It’s to build smarter from the very beginning.

Samsung SDS America (SDSA) is the North American subsidiary of Samsung SDS, a global leader in cloud and digital transformation. We help organizations boost productivity, strengthen security, and make smarter decisions with enterprise-grade technologies, including secure mobility, generative AI, cloud services, and procurement solutions with full design-to-source-to-pay capabilities through platforms like Caidentia.

Serving industries from government, financial services, retail, and healthcare to manufacturing and technology, SDSA uses data-driven insights and automation to help businesses thrive in today’s connected world. As part of Samsung SDS, a globally recognized ICT leader, we deliver innovative solutions that shape the future of business across North America.

Caidentia is Samsung SDS’s AI-driven procurement platform covering the full design-to-source-to-pay process. It connects engineering, sourcing, and supplier teams to streamline collaboration and decisionmaking. The platform delivers real-time cost analysis, alternative part options, and supplier insights while using AI to automate sourcing tasks, forecast pricing, and improve contract compliance. Designed for manufacturing, high tech, automotive, and consumer electronics, Caidentia helps organizations make faster, more cost-effective sourcing decisions and strengthen supply chain resilience.

TTim Finerty Partner Wipfli

he global manufacturing sector is changing. Drivers like uncertainty, political instability and new tariffs are rerouting supply chains and forcing business leaders to adapt.

What do you need to know as a manufacturer as you look toward 2026? From a high level, the answer is that businesses willing to embrace flexibility and evolving tech like automation will be better able to overcome the challenges of the moment.

But let’s drill down on specifics. Keep reading to understand where the manufacturing sector is going and how you can better compete.

Uncertainty is the biggest factor influencing manufacturing today. After navigating challenges associated with post-pandemic inflation, the business climate has felt an additional wave of pressure since the Trump administration took office and began taking a markedly different approach to economic policy than its predecessors.

At home, unpredictable tariffs make it harder for businesses to plan for the long term. Many manufacturing firms are holding off on making major strategic decisions or big investments because leaders simply don’t know whether what makes financial sense today will still do so tomorrow.

However, tariffs are also raising current costs. Manufacturers importing materials or unfinished products now often have to pay tariffs when those goods arrive at ports of entry. And as those tariffs are subject to change without warning, they create an additional layer of financial friction.

Tariffs aren’t the only factor driving uncertainty either. The One Big Beautiful Bill Act has been signed into law, but the effects will play out in the months and years to come. How will the huge changes in energy policy, for example, affect manufacturers?

No one has a full answer yet.

And the ongoing war between Ukraine and Russia, plus smoldering tensions between Israel and Iran, create an additional element of instability that affects global trade. While conflict may spur demand for defense manufacturers,

an Iranian decision to say, close the Strait of Hormuz could create a dramatic rise in oil prices that ripples through the broader economy and increases the cost of doing business.

All of this adds up to a fundamental question: Where is everything going to be built? Most manufacturing that has left the U.S. won’t be coming back, but tariffs and international conflicts make it more challenging to invest in expanding manufacturing capacity overseas.

Both tariffs and international conflict have had a particular impact on supply chains. American manufacturers often rely on supply chains that source from all over the world, and those supply chains are now under threat.

Let’s look at the automotive industry as an example. American car companies may build their finished products at plants in Michigan or Georgia, but they have often relied heavily on parts imported from Mexico or Canada.

In the previous free-trade environment under USMCA, these tightly integrated supply chains helped auto manufacturers build in the U.S. while managing costs. However, tariffs on imports from both Mexico and Canada create a significant headache that threatens production.

For now, auto manufacturers may simply find it harder to get parts, as overseas partners shift to new buyers. Parts left sitting in port due to tariffs can also affect the availability of key supplies.

It’s not just auto, of course. Manufacturers of all stripes face similar challenges. What we don’t yet know is exactly how this shakes out.

Sustainability was a hot word a few years ago. While that luster has faded a little, it’s still an essential factor for businesses to address.

Consider battery technology. Batteries have evolved by leaps and bounds, and despite new changes in tax law to phase out the EV vehicle credit, will likely only continue to be more broadly adopted as a means for storing renewable energy and powering electric vehicles.

But those big lithium-ion batteries eventually wear out, and when they do, they’re an environmental mess. Battery manufacturers are frequently responsible for recycling their products at the end of their useful lifespan, which makes figuring out safer, more efficient ways to do so not just an issue of social responsibility, but financial good sense.

This holds true across products and industries. Manufacturers who prioritize sustainability will often discover new opportunities to innovate that drive their businesses forward.

Speaking of innovation, new tech may hold the key to solving some of the thorniest challenges facing manufacturers today. Here are some areas where manufacturing firms are working to move the ball forward.

In industries like food and beverage, auto and even pharma, automation is a tool to speed up production time. A fully or nearly automated plant can essentially run 24/7, which can allow it to produce more of a given product than a less automated facility.

Automation is one way manufacturers looking to navigate tariffs can try to bring down the cost of making things domestically. The upfront investment can be significant, but once an automated plant is up to speed, your overall manufacturing costs will often be lower.

At its most advanced, automation is a major component of what’s called the 4th Industrial Revolution or Industry 4.0: manufacturing built around automated factories, autonomous robots, 3D printing, and other advanced practices expected to revolutionize the sector in the coming years.

AI is also seen as part of Industry 4.0. As manufacturing firms continue to gather more data through technologies like IIoT, leaders have opportunities to use AI to analyze vast new datasets to glean insights that can boost productivity and performance.

But manufacturers have to focus on one area here: data integrity. With AI, garbage in equals garbage out.

You don’t just need large, inclusive datasets but also data that is clean and properly categorized. Making an effort here will significantly raise the ceiling on what you can accomplish by implementing AI tools in your business.

For manufacturers, a ransomware attack is less a matter of if than when. And when one does happen, it may shut down production at an affected plant.

With cybersecurity, prevention is always cheaper and more effective than trying to deal with an attack after it has occurred. Start with the basics. Hire a cybersecurity firm to do penetration testing on your facilities.

What you want is to get answers to questions like: How easily can someone hack into your system? How strong are your existing defenses?

Once you know where you stand, you can upgrade accordingly.

Sales for many consumer goods moved online a long time ago. But this is increasingly the case for even expensive products that have long relied on an in-person sales journey.

Let’s return to the auto industry here. Dealer showrooms are increasingly empty due to tariffs. But this is less of a problem than you might think, because huge swaths of consumers, especially millennials and Gen-Z, would rather not go to the showroom in the first place.

Those consumers would rather buy a car online. Online sales allows buyers to customize their purchase, compare prices and even get a car delivered to their front door — all from the comfort of home. Small wonder many people prefer that.

So, companies that invest in creating a smooth, attractive online sales journey will often gain a leg up on those that don’t. Even something as simple as having a website that’s easier to use than your competitor can make a real difference here.

In the coming months, manufacturers will work to understand how big global trends apply to their specific circumstances. This is essential to meeting the moment.

It’s also a lot for you to tackle alone, so consulting an advisor can help. Wipfli works with manufacturing firms to identify challenges and introduce solutions in areas like automation, AI and operational performance.

Wipfli Description: Business is more fluid than ever. Helping manufacturers achieve their goals takes imagination, discipline and a process that delivers results today while anticipating tomorrow’s demands. That’s Wipfli. With more than 7,500 manufacturing, retail and distribution clients and over 300 industry-focused professionals, Wipfli ranks among the top 25 advisory and accounting firms in the nation. From operational improvements and performance enhancements to large-scale digital transformation, they help clients achieve lasting results and set their sights on new goals. With their dedicated specialists, you benefit from insightful thinking across critical areas of your business — gaining greater financial success, tax optimization, operational excellence and an engaged workforce. wipfli.com/manufacturing

Paul Marcus CEO, DataOps

TCTO & President, DataOps

oday’s supply chains face unrelenting pressure to deliver faster, smarter, and with greater resiliency. From global disruptions and labor shortages to rising customer expectations around transparency and agility, traditional supply chain models are no longer sufficient. The next frontier isn’t just digital; it’s an intelligent neural network armed with predictive capabilities.

To get there, supply chains must be structured, shared and AI-ready. This demands a number of foundational capabilities including:

• Structured, integrated data environments,

• Intelligent predictive / prescriptive capabilities, and

• Proactive and customized legal frameworks to govern AI deployment, cybersecurity, and data collaboration.

This article outlines how organizations can future-proof their supply chains by aligning modern data architecture with emerging legal considerations, paving the way for responsible, intelligent automation.

The case for urgency is clear. The convergence of supply chain disruptions, labor volatility, and rising demand for speed and visibility has created an inflection point. AI is no longer an experimental tool; it is an operational imperative.

The power of intelligent and predictive networks lay in their ability to forecast demand, optimize inventory, detect anomalies, and execute decisions autonomously. But none of this works without clean, connected, and contextualized data. In other words: AI-readiness starts with data-readiness.

Unstructured spreadsheets, siloed ERP systems, and fragmented supplier data can’t support machine learning models or real-time agents. Material providers, manufacturers and logistics leaders must modernize their data operations to unlock the true potential of intelligent automation.

To build an AI-ready supply chain, organizations must first establish a robust and flexible data architecture. This begins with a unified, cloudbased platform that centralizes operational, customer, supplier, and machine-level data.

These platforms typically leverage modern tools like data lakes or data warehouses. However, centralization alone is not enough. AI-readiness also demands system interoperability, achieved through APIs and integration layers that harmonize ERP, MES, IoT, and logistics platforms into a consistent, accessible data ecosystem. Metadata-driven governance such as clear data lineage, permissioning, and version control ensures both traceability and trust across internal teams and external partners. Organizations typically move through a maturity continuum: starting with ad hoc, siloed reporting (Stage 1), progressing to basic dashboarding via partial integrations (Stage 2), enabling predictive models and automation (Stage 3), and eventually reaching agentic systems that make real-time decisions autonomously (Stage 4). Key enabling technologies include cloud infrastructure, machine learning pipelines, IoT-edge integration, business intelligence tools, and data fabric or mesh architecture. The foundation of intelligent supply chains lies not only in what data is collected, but how it is structured, shared, and governed for scale.

As AI transforms supply chains, legal and compliance risks are evolving in parallel. A futureready legal framework must address three core areas: data ownership and use rights, regulatory compliance for AI deployment, and intellectual property protection. As companies scale intelligent operations, the contracts that define rights around data and AI models become as critical as the technology itself.

AI depends on training data, much of which comes from internal operations, suppliers, or customer touchpoints. But who owns the data? And who has the right to use, commercialize or combine it with other datasets? Supply chain contracts must define these rights clearly, particularly in joint ventures and other supply partnerships. Without clear provisions, disputes can arise over derived insights, model outputs, or access to historical datasets. Key contract elements include data licensing rights, anonymization protocols, restrictions on secondary use, and post-termination obligations.

As jurisdictions introduce AI-specific legislation (such as the EU AI Act, and proposed U.S. and state-level laws), companies must align their supply chain AI systems with evolving legal requirements. These may include transparency obligations, risk classification of AI systems, documentation requirements, or limits on automated decision-making. In many cases, regulatory compliance is no longer limited to product safety or import/export rules, it now includes algorithmic accountability, fairness, and human oversight.

AI models, especially those trained on proprietary operational or supply chain data, can become a critical competitive asset. But if not protected, they can be replicated or reverse-engineered. Legal teams should review how intellectual property laws including trade secrets, copyright, and patents—apply to both AI models and the data that fuels them. Additionally, contract terms should define who retains ownership of models developed during collaborations, whether co-development IP is jointly or severally owned, and how IP is protected after a relationship ends.

As supply chains adopt AI and automation, the rules of the game change. Decisions are happening faster and often with less human intervention, which means governance isn’t just a good idea … it’s critical. Organizations need to think about governance across three dimensions: data, models, and cybersecurity. Each plays a unique role in ensuring that intelligent ecosystems are both effective and trustworthy.

Good AI starts with good data, and that means knowing exactly where your data comes from, how it’s used, and who has access to it. Data governance frameworks ensure that information flowing through your systems is reliable, consistent, and protected. This includes formal roles for data stewards, clear documentation of data lineage, versioning to track changes over time, and robust permissioning; especially across multiple business units or external partners. When data governance is done right, it builds a foundation of trust for every AI application that follows.

Once data is in place, the next layer of governance focuses on the AI models themselves. These models need to be explainable, auditable, and continuously monitored to ensure they’re doing what they’re supposed to do especially as conditions change. That means keeping a record of how models were trained, who approved them, when they were last updated, and how their performance is being tracked. As AI becomes more embedded in day-to-day operations, model governance helps maintain accountability and provides guardrails for ethical and effective use.

With more data and decision-making centralized in digital platforms, the supply chain becomes a bigger target for cyber threats. And as AI systems get smarter, so do the attackers. Cybersecurity must evolve to protect not just traditional IT infrastructure, but also data pipelines, AI models, and real-time edge devices. That includes securing APIs, encrypting data at rest and in motion, monitoring for anomalies, and having contingency plans in place. In intelligent ecosystems, a single breach could disrupt operations across the globe, making proactive security measures essential.

The risks aren’t hypothetical, they’re already playing out. Imagine a forecasting model that overorders raw materials, leading to massive overstock and financial loss. Or an automated agent that unknowingly routes a shipment to a restricted country, triggering a compliance violation.

What if a supplier’s data is used to train an AI model without authorization, and that model is later monetized in a different industry? Or what if regulators require proof that an automated system’s decisions are explainable and your model can’t show how it arrived at its recommendations? Other real-world risks include AI-generated procurement decisions that inadvertently violate regulations or dynamic pricing algorithms that trigger antitrust scrutiny when interacting with competitor’s systems in real-time. These examples underscore the need for legal involvement not just in response to AI deployments, but in the initial design of the AIenabled supply chain ecosystems.

The future of global supply chains will look less like a linear series of steps and more like a neural network; interconnected, adaptive, and intelligent. Data will flow seamlessly across partners and platforms, enabling real-time decisions that drive speed, resilience, visibility and prescriptive insights. But achieving this vision isn’t just about technology … it’s about creating new types of partnerships between operations, IT, and legal teams. When integrated data environments are paired with strong governance and forward-thinking legal frameworks, organizations can unlock the full potential of intelligent operations while staying compliant, secure, and competitive.

For Operations & Tech Leaders:

• Conduct a data readiness assessment

• Identify 3–5 high-value AI use cases

• Build a cloud migration and integration roadmap

• Stand up a data governance council with business and IT

For Legal & Compliance Teams:

• Audit data-sharing agreements and AI usage policies

• Review regulatory exposure across jurisdictions

• Update vendor and supplier contracts to cover AI deployment

• Establish internal AI ethics and compliance guidelines

• Evaluate cybersecurity insurance coverage to address AI-specific exposures

• Collaborate cross-functionally to map AI system lifecycles (from data ingestion to model deployment

DataOps partners with organizations to build modern data ecosystems that translate strategic goals into aligned operating systems, integrated data architectures, streamlined workflows, and agentic technologies. Our mission is to futureproof our clients by embedding dynamic, decision-ready intelligence across the enterprise driving not only operational excellence but also cultural transformation toward a truly adaptive, data driven way of working.

Foley & Lardner LLP provides innovative legal solutions across Energy, Health Care, Tech, and Manufacturing with 1,100 lawyers in 26 offices, delivering trusted counsel worldwide.

Jarrad Grandy Executive Director of Student Services Oakland Schools

Across Michigan, employers are facing the same dilemma: skilled workers are increasingly hard to find, and once hired, they are even harder to keep. On top of that, the very nature of work is changing. Automation, artificial intelligence, and other exponential technologies are transforming shop floors, production lines, and offices alike. It’s no longer enough to fill today’s roles— we need a strategy to build and retain a workforce that will thrive in the future.

The truth is, retention doesn’t begin on the first day of employment. It starts the first time a young person can picture themselves in your industry. That spark might happen during a fifth- grade STEM challenge, a middle school career exploration project, or a high school visit to a technical lab. Employers who wait until the hiring stage to engage with talent are already behind.

Early engagement matters because it creates a pipeline of students who recognize your industry, understand the work, and feel a sense of belonging before they ever set foot in your facility. Those students are more likely to pursue the relevant courses, develop the needed skills, and—most importantly—stay in the field once they enter it. Employers who connect with schools early see higher retention, stronger loyalty, and employees who arrive prepared for both the technical and professional demands of the job.

The need for this alignment is even greater as exponential technologies reshape Michigan’s economy. Exponential technologies are innovations that accelerate in their growth and impact, redefining industries at a pace that feels sudden to the unprepared. These technologies, such as artificial intelligence, nanotechnology, and synthetic biology, are not far- off concepts—they are here now, and the workforce needs to be ready.

K-12 schools have a unique opportunity to help solve this problem, but only if they move beyond the old model of “covering material.” When educators focus solely on coverage, that’s all we achieve: a fleeting pass over content. True engagement comes from giving students real-world, developmentally appropriate problems to solve, problems that connect classroom learning to authentic industry applications. Employers are the ones who can provide those problems and the context that makes them meaningful.

For their part, employers need to move past another outdated narrative: “We can teach the technical skills; schools need to teach the soft skills.” In practice, the workforce demands both. Employers expect employees to arrive with a baseline of technical proficiency and the ability to communicate, collaborate, and think critically. Schools can deliver both—but only when they work hand-in-hand with industry to make learning experiences authentic.

This is where partnerships become transformative.

Across the county, technical campuses provide high school students with hands- on experiences in fields like automotive technology, construction, welding, cybersecurity, health sciences, and culinary arts. Industry partners shape the experiences in these labs by offering site visits, mentoring, and authentic project challenges. Soon, a new NAIS Lab—focused on nanotechnology, artificial intelligence, and synthetic biology—will extend that work to all grades K-12. Students will rotate through the lab for immersive experiences lasting up to a week, engaging in experiments and challenges that introduce them to technologies that will define the next generation of Michigan manufacturing and innovation.

When schools and employers fully commit to this type of collaboration, the results are not just powerful, but transformative. Students are more engaged and retain more of what they learn; employers influence the development of future talent; and communities benefit from a workforce that is both prepared and invested in staying local. A shared ecosystem like this doesn’t emerge by accident. It’s built through relationships where time and expertise are exchanged, where schools bring authentic problems into classrooms, and where employers open doors to the world students will enter.

The path forward is clear. Retention in an AI- driven world won’t come from wages alone. It will come from the connections we forge between classrooms and careers, between students and industries, and between today’s learning and tomorrow’s work. Michigan has always thrived when its schools and employers innovate together. The challenge now is to do it at scale, ensuring that every student can see themselves in the future of work and every employer has a workforce ready to grow alongside the technologies that will define it. Together, these strategies create a talent ecosystem where students thrive, employers retain skilled workers, and Michigan’s economy grows stronger.

Host Real-World Challenges:

Share authentic problems your teams are solving. Even a one - day design challenge for students builds connection and loyalty.

Open Your Doors:

Offer job shadows, plant tours, and short internships for high school students.

Serve as a Mentor or Guest Expert:

Send engineers, designers, and technicians into classrooms to talk about real projects and tools.

Collaborate on Curriculum:

Join advisory groups or co - create projects that reflect your industry’s emerging needs.

Bring in Authentic Problems:

Replace “coverage” with hands- on problem solving tied to local industries.

Leverage Employer Expertise:

Partner with companies to co - design projects or labs that mirror real workflows.

Focus on Dual Skill Development:

Help students gain technical proficiency while strengthening collaboration, communication, and critical thinking.

Connect Learning to Purpose:

Show students how the skills they develop today lead to tangible opportunities tomorrow.

Oakland Schools is one of Michigan’s 56 intermediate school districts (ISDs). It was established by the Michigan Legislature in 1962. ISDs are regional service agencies that offer support services to school personnel that are best delivered regionally, as measured by cost, size and quality advantages. Oakland Schools is an autonomous, tax-supported public school district governed by Michigan General School Laws.

We polled leaders in industry, academia and government for their input on these questions many face. Here’s what they said:

Which strategies are most critical for building a resilient supply chain in your industry?

Corporate assets include proprietary data, which is more valuable than replaceable equipment or raw materials. Stolen data can damage a company’s standing in the market. Continual cybersecurity upgrades, including implementing AI, are not optional; they’re mandatory.

With everyone having the same tools, such as AI, the data used is vital. Superior data gives a company the edge over the competition. On the global stage, it’s about knowing the people with the best information.

As tariffs are added, increased, or decreased seemingly every day, companies must be adaptive and resilient. They can either ask, “What can I do about it?” or ask, “What do I need to do to make this work?”

The future is here – no surprise, it’s AI

AI is the driving force behind supply chain improvements through inventory optimization, weather forecasts, route planning, predictive maintenance, risk management, and more. AI is capable of creating “what-if?” simulations such as shutdowns, port closures, and fuel price spikes and provide strategies to overcome those obstacles.

Professionals need to understand the supply chain’s full scope and influence on a company’s finances, logistics, risk control, supplier selection, regulations, technology integration, inventory, and flexibility.

In today’s volatile global economy, manufacturers face unprecedented supply chain complexity. Labor shortages, cost pressures, and unpredictable demand have become everyday challenges. Amid this turbulence, Lean Thinking continues to offer clarity, stability, and strategic advantage. Yet Lean tools alone won’t drive transformation. What fuels sustainable change is leadership—visionary, accountability, and grounded in continuous improvement.

This article explores how the fusion of Lean Thinking and leadership transforms not only supply chains, but entire organizations.

Lean Thinking focuses on maximizing value while minimizing waste. In supply chains, this translates to:

• Shorter lead times

• Increased agility and responsiveness

• Greater visibility across operations

• Stronger supplier partnerships

Tools like value stream mapping, 5S, and kanban provide tactical value. But without leadership embedding these tools into the organization’s culture, Lean risks becoming transactional rather than transformational.

Lean thrives where leadership is actively modeling the behaviors and mindset needed for success. Here are four key leadership practices that elevate Lean supply chain performance:

1. Articulating a Strategic Vision. Leaders must tie Lean initiatives directly to business goals. When teams understand the strategic relevance, Lean becomes a growth enabler— not a cost-cutting exercise.

Through the Herman Miller Performance System (HMPS), the company embedded Lean into its supply chain, guided by leadership focused on sustainability and responsiveness. They reduced lead times by over 50%, cut inventory, and improved customer service, enabling faster adaptation to market shifts.

2. Empowering People at Every Level. Lean is built on respect for people. Leaders who create psychological safety and value frontline insights unlock problem-solving and innovation.

Leadership implemented tiered daily management and visual dashboards. This empowered teams to escalate issues quickly and resolve bottlenecks in real time. Material shortages dropped by 43%, and visibility in supplier performance increased significantly.

3. Optimizing for Flow Through Systems Thinking. Supply chains are networks, not silos. Leaders must zoom out and manage interdependencies to drive end-to-end flow.

Facing global chip shortages, Toyota relied on “Obeya” rooms—cross-functional collaboration spaces—to maintain production. Systems thinking allowed teams to visualize the supply chain, reallocate resources, and sustain output while competitors faltered.

4. Creating a Culture of Daily Accountability. Lean leaders build rhythm through structured daily management. This drives visibility, faster decisions, and continuous learning. Whether it’s huddle boards, layered communications, or Gemba walks, daily accountability keeps the supply chain aligned—from shop floor to executive suite.

When Lean tools are used through the lens of leadership, they become transformative:

Value Stream Mapping (VSM)

A3 Thinking

Leadership Role

Sponsors collaboration and prioritization

Builds shared understanding

A heavy equipment OEM used VSM to cut global shipment times by 19 days

A Michigan medical device firm reduced stockouts by 85% by identifying unclear triggers through A3 analysis

Supplier Development

Extends Lean beyond the walls

A leading manufacturer coached suppliers on setup reduction—resulting in 70% faster changeovers and JIT delivery readiness

These tools aren’t just methods—they’re expressions of leadership.

Recent events—from COVID-19 to supply chain shocks—have shown which companies were built to adapt.

Study: Illinois Tool Works (ITW)

With Lean deeply embedded via the ITW Business Model, decentralized teams made fast, confident decisions under pressure. Leadership empowered flexibility and responsiveness without waiting for top-down directives.

For organizations looking to embed Lean into supply chain strategy, here are five starter actions:

1. Start Small

Map a single product family’s supply chain to identify flow and waste.

2. Invest in Learning

Train cross-functional teams in Lean tools and create peer-led learning opportunities.

3. Engage at the Gemba (the place where work is done)

Leaders should regularly visit shop floors and suppliers—not just to observe, but to ask, listen, and learn.

4. Celebrate Micro-Wins

Acknowledge efforts and breakthroughs. Small wins reinforce the Lean mindset.

5. Implement Daily Management

Create structured communication from frontline to executive levels. Use visual tools to drive accountability.

These steps build culture, not just capability.

Lean Thinking offers tactical efficiency—but when led with vision, it delivers transformation. The most resilient supply chains aren’t reactive, they’re prepared. They’re flexible. And they’re led with intention.

As Taiichi Ohno said:“Progress cannot be generated when we are satisfied with existing situations.”

The question for manufacturing leaders isn’t whether Lean works. It’s whether you’re ready to lead it boldly.

Privately owned e-bikes and e-scooters are transforming how people move across university and corporate campuses, as well as metropolitan communities around the globe. As adoption grows, so does the risk. Indoor charging of lithium-ion batteries has led to a rising number of fires, often caused by damaged components, overcharging, or mismatched third-party chargers. As a result, outdoor charging is gaining popularity.

Meet Juise Mobility, a company that’s reimagining e-mobility infrastructure. The company’s suite of hardware and software solutions provide smart, safe, and connected outdoor charging to empower universities, developers, and operators to foster a safe and secure community while embracing eco-friendly, last mile transportation.

Founded in April 2025 by two former General Motors venture capital alumni, Sherwin Prior (CEO) and Jason Nolte (President & CTO), Juise Mobility has enjoyed early success with orders from several university campuses and multi-family housing communities across the U.S. spanning from San Diego to Florida to South Dakota.

“Ever since I helped launch GM Ventures, I have worked with startups that were trying to change the world,” Sherwin said. “Reimagining e-mobility infrastructure is a compelling opportunity to

reduce fire risks and promote fun, safe, environmentally friendly personal transportation.” To help bring the vision to life, Prior called on Jason Nolte, a mechanical engineer and former colleague at GM Ventures, to spearhead product development.

“Jason’s technical vision, passion for mobility, and experience as a patented innovator made him the ideal partner. Our solution needed to go beyond charging ports, it needed a scalable platform,” explained Prior.

“We spent nearly four months conducting product and market discovery with prospective customers and technical experts, strategically formulating our product strategy and building our brand,” said Nolte. “Now, we offer a range of products and services to simplify and address the biggest opportunities in e-mobility infrastructure.”

“We don’t make mobility devices, we make device use better.” Nolte said. “Our focus is to improve engagement, enforcement, and entertainment across the e-mobility ecosystem.”

Unlike most startups these days, Juise Mobility took a hardware-first approach to developing its competitive advantage. Juise Mobility currently offers two platforms: the Juise Bar and Juise Pack.

The Juise Bar is an IoT connected platform providing hands-free docking, locking and charging. This solution works well for resorts, housing communities, and multi-family apartment units that want to encourage community exploration or sustainable modes of transportation.

Juise’s software enhances conventional fleet management functionality through the addition of its connected outdoor charging products to IoT enabled e-mobility fleets. For new fleet operators Juise offers sourcing, setup and management services to streamline the launch of new privately owned and operated fleets. Fleet riders enjoy a simple, sleek rental process fully facilitated through the Juise Fleet App and automated locking and docking from the Juise Bar. Gone are the days of fleet operators collecting devices or replacing batteries to recharge devices. The Juise Bar and Fleet Management Software enables fully automated secure outdoor charging and device management.

The Juise Pack allows for university and corporate campuses to accommodate individuals who own their own e-mobility devices to safely store, lock and charge their devices outside of living or working spaces. Users simply bring their own charger and lock. The Juise Pack provides weatherproof storage and charging for devices and enhances any campus’s outdoor device parking infrastruc-

“

“ We don’t make mobility devices, we make device use better. Our focus is to improve engagement, enforcement, and entertainment across the e-mobility ecosystem.

ture with integrated lighting and signage options. This solution is perfect for organizations that want to provide brand-agnostic charging for electric mobility devices, while allowing riders the flexibility of using their own chargers and locks.

Universities and colleges like Juise Mobility’s weather-protected outdoor charging infrastructure for e-scooters and e-bike of all kinds, not just the expensive IoT connected devices. Providing users safe and secure outdoor infrastructure to lock and charge devices enables administrators to mitigate fire risks and enact supportive e-mobility policies on their campuses.

Several schools ban electric mobility devices because they are a fire hazard when charged indoors. Kansas State University reported statistics from the National Fire Protection Association that United States fire departments respond to approximately 3,400 campus housing fires each year. Of those, 20% involve electrical distribution and power transfer equipment. The Center for Campus Fire Safety reports that 46% of e-mobility fires are from e-bikes and e-scooters, with damages costing as much as $200,000 per incident.

In light of those numbers, colleges that allow electric micromobility devices on campus often ban them from indoor spaces. However, enforcing that rule is difficult. Juise Mobility provides a solution that’s visible, intuitive to use, and policy-aligned, resulting in safer campuses with reduced fire risk and theft.

“Rather than banning e-scooters outright, campus administrators have utilized the Juise Pack to provide the charging infrastructure needed to support students’ desire to ride these devices and the need to secure and safely charge them outdoors.” Nolte said. “As simple to install as a bike rack or convenience plug, the Juise Pack can be configured to fit any campus’ needs.”

Nolte added that using Juise Mobility’s charging infrastructure will be “quite impactful” in helping to improve safety and mobility in communities surrounding college campuses.

Juise Mobility joined OU, Inc., Oakland University’s startup accelerator, and Project DIAMOnD to support its growth.

“One thing that got us to build our headquarters at OU, Inc. is Project DIAMOnD,” Prior said. “Our work with the US Center for Advanced Manufacturing and Automation Alley has proven to be helpful and both organizations are great partners.”

Project DIAMOnD provides access additive m anufacturing to training, technology, and a network of 3D printers. Through Project DIAMOnD’s resources, Juise Mobility will optimize its manufacturing capabilities moving forward.

“Additive manufacturing is an integral part of what we produce and how we produce it,” Nolte said. “The cost effectiveness of 3D printing can be measured in dollars and time. Tools like molds and dies are great for high-volume production. Scaling businesses in rapidly developing markets with exciting new products benefit from additive manufacturing to allow us to be agile, capex light, and time efficient.”

“To change those fixed tools is expensive and time consuming. Additive manufacturing allows us to quickly adapt to customer needs and design our products more efficiently for production, assembly and maintenance.”

Juise Mobility prints in house for prototypes and parts but also leverages a network of partners to support production.

“Our manufacturing partners are an extension of our team. As a growing company, this builds a better ecosystem for our small, rapidly growing startup.

Nolte explained: “We rely on reputable and knowledgeable partners to manufacture parts to meet our quality standards. In house, we primarily use virgin raw materials, no recycled powder, on production parts. We strategically designed our components for their function and fabrication method. Each product we put in the field is tested at the component and full assembly level before it leaves our facility. This gives us the confidence to back each part with warranty.”

“Our manufacturing partners are an extension of our team. As a growing company, this builds a better ecosystem for our small, rapidly growing startup.”

Juise Mobility currently manufactures and sells its products across the United States and plans to be a category leader for digital and physical e-mobility infrastructure.

“We can start with the U.S.,” Prior said, “but we will move on to the world.”

The global manufacturing sector is navigating its most disruptive period since the pandemic, with shifting tariffs, geopolitical tensions, and rapid AI adoption. Roundtable participants agreed the winning formula is to innovate aggressively, diversify operations and supply chains, and embrace digital tools to remain resilient in this volatile environment.

Manufacturers are struggling with unpredictable and fluctuating tariffs that inflate costs and complicate pricing strategies. Many companies are being forced into immediate adaptation — deciding whether to absorb costs or pass them along to customers. Tariffs are also becoming embedded into overall pricing structures, making them less transparent and more difficult to navigate.

AI is moving from concept to practice in manufacturing. Generative design tools and digital twins allow engineers to test dozens of scenarios in minutes, cutting costs and boosting speed. Personalization technologies are also democratizing customization, once limited to large firms. Early adopters are already reporting productivity increases of up to 20%, signaling a powerful competitive advantage.

While reshoring is widely viewed as the instinctive solution, it brings significant challenges. Manufacturers must also consider nearshoring and friendshoring with stable trade partners to ensure long-term resilience. Supply chain transparency remains a hurdle, especially for tier-one suppliers that struggle to identify vulnerabilities further down their networks.

The skills gap is widening, with 2.1 million jobs projected to go unfilled by 2030, potentially costing the U.S. economy $1 trillion. An aging workforce — nearly one-quarter over age 55 — heightens this risk. Industry leaders stressed the need for closer alignment between universities, trade schools, and manufacturers to prepare workers with advanced technical skills and support reshoring initiatives

Technology alone is not enough. Leaders must manage both technical adoption and the human response to change, easing workforce stress caused by rapid shifts in systems and processes. Companies that foster a culture of adaptability and resilience will be better positioned to harness AI, robotics, and automation without alienating their employees.

Legacy manufacturers are transforming into data-driven, technologyfirst organizations. Human and AI collaboration is expected to define the next era, with AI viewed not as a replacement for jobs, but as a partner in decision-making and innovation. The companies that balance innovation with resilience and workforce empowerment will set the pace for the industry’s future.

Automation Alley International Business Services

Automation Alley helps Michigan companies grow internationally through hands-on trade missions and global partnerships. Businesses can take part in Automation Alley’s annual trade missions, connecting directly with buyers, distributors, and government officials in key overseas markets. Additionally, Automation Alley offers soft-landing space and support for international companies looking to establish a U.S. presence in Michigan, creating opportunities for cross-border collaboration and business growth.

Michigan Industry 4.0 Grant: The Michigan Economic Development Corporation (MEDC) offers an Industry 4.0 Technology Implementation Grant that provides 50% reimbursement—up to $25,000—for small and medium-sized businesses investing in advanced technologies such as Additive Manufacturing. Businesses must meet eligibility requirements to apply.

Michigan Emerging Technologies Fund: In partnership with the Small Business Development Center, MEDC also supports innovation-focused companies through the Michigan Emerging Technologies Fund. This initiative helps expand access to federal innovation R&D funding, supporting tech-based business development across the state.

State of Michigan Business Resources: The State of Michigan offers a variety of support services to help businesses grow, including resources for expansion, capital access, workforce recruitment, and international market engagement.

Project DIAMOnD Digital Transformation Center: Companies participating in Project DIAMOnD can now access industrial 3D printing equipment and expert support at the Digital Transformation Center (DTC) in Auburn Hills, MI. The center enables companies to explore new applications and revenue streams using polymer and metal additive manufacturing.

Van Andel Global Trade Center (GVSU)

Since 1999, Grand Valley State University’s Van Andel Global Trade Center (VAGTC) has been a trusted resource for Michigan businesses looking to expand globally. VAGTC specializes in import and export training, international trade consulting, cultural seminars, and global market entry strategies. Whether you are exploring new markets, ensuring trade compliance, or sourcing international suppliers, VAGTC provides the expertise and connections to help Michigan companies succeed in the global economy.

U.S. Small Business Administration: The U.S. Small Business Administration (SBA) offers tools, loans, and guidance to help small businesses start or scale operations, including funding to upgrade Additive Manufacturing infrastructure and connect with potential investors.

SME Additive Manufacturing Certification: The Certified Additive Manufacturing Fundamentals (CAMF) certification from SME is a key credential for individuals pursuing careers in AM. Covering core topics like AM technologies, safety, and terminology, it’s ideal for professionals and students preparing for industry roles in sectors like automotive, aerospace, and healthcare.

National Institute of Standards and Technology (NIST): NIST leads national efforts in researching Additive Manufacturing materials, technologies, and processes. The organization also provides key benchmarks, standards, and conferences that shape the future of the AM industry.

Automation Alley is a nonprofit technology business association and Digital Transformation Insight Center focused on driving the growth and success of businesses in Michigan and beyond through innovation and automation. With a global outlook and a regional focus, we foster a vibrant community of manufacturing and technology innovators, entrepreneurs, and business leaders through opportunities for collaboration and learning. Our programs and services help businesses develop the skills and expertise needed to effectively jumpstart or accelerate digital transformation. By bringing together industry, academia, and government, we aim to create a dynamic ecosystem that drives innovation and growth across Michigan.

At Automation Alley, our mission is to help businesses thrive in the rapidly changing digital economy. We equip them with the knowledge, insights, and tools to develop a software-first mindset that leverages the power of automation, AI, and other cognitive technologies. We believe that by working together, we can build a stronger, more innovative, and more competitive economy for the future.

Wealth, prosperity and equality through technology.

To find out more about Membership visit: automationalley.com

MIT Sloan - How generative AI can boost highly skilled workers’ productivity

https://mitsloan.mit.edu/ideas-made-to-matter/how-generative-ai-can-boost-highly-skilled-workers-productivity?