EXECUTIVE SUMMARY 2025

ROUNDTABLE SERIES

Intelligence, Security, and Resilience

In 2025, the Integr8 Playbook series charted a decisive turn in manufacturing’s digital transformation. Artificial intelligence has matured beyond novelty, additive manufacturing has crossed into mainstream production, and cybersecurity has become the connective tissue of trust. Across government, academia, and industry, the message was clear: technology alone doesn’t drive progress—coordination does. The new manufacturing economy demands unified standards, agile talent pipelines, and digital infrastructure built on resilience. Below, the year’s findings distilled into seven takeaways for each pillar of the ecosystem.

Recommendations for: Government

The Catalyst for Secure and Connected Innovation

1. Standardization as Strategy. Governments are being called to lead in establishing AI, data privacy, and additive manufacturing standards—bridging regulatory fragmentation that slows global adoption and deters cross-border innovation.

2. Cybersecurity as Infrastructure. Federal and state agencies are redefining digital security as essential infrastructure, requiring deeper public-private coordination on threat sharing, breach response, and incident reporting protocols.

3. Funding the Digital Middle. Small and mid-sized manufacturers remain under-equipped for digital adoption. Expanded grant programs and tax incentives are vital to democratizing Industry 4.0 participation.

4. Reshoring with Realism. Policy leaders view reshoring and “friendshoring” as national security imperatives but must address labor and logistics gaps to make domestic production sustainable.

5. AI Governance in Motion. Governments face rising pressure to balance innovation with oversight—crafting rules around AI transparency, accountability, and intellectual property generated by algorithms.

6. Regional Collaboration as Policy Tool. Integr8 discussions reinforced that regional alliances between state agencies, universities, and accelerators can localize innovation far more efficiently than federal mandates alone.

7. Public Trust Through Competence. Effective governance now means communicating both ambition and capability—showing that cybersecurity, data ethics, and automation policy can evolve as fast as the technologies they regulate.

Recommendations for: Academia

Building the Human Infrastructure of Industry 4.0

1. Curriculum Convergence. Universities are collapsing silos between computer science, mechanical engineering, and business to produce graduates fluent in both code and production.

2. Applied AI Education. Academic programs are pivoting from theoretical AI models to industrial implementation—training students on predictive maintenance, digital twins, and secure data pipelines.

3. Cyber Literacy as Core Skill. Cybersecurity is no longer a niche discipline; it’s becoming a baseline requirement across engineering and IT curricula, reflecting its centrality to modern manufacturing.

4. Lifelong Learning Networks. Stackable credentials and micro-certifications are emerging as bridges for incumbent workers to reskill rapidly without leaving the workforce.

5. Ethics and Critical Thinking. Professors warn that AI proficiency must be paired with human judgment. “There are no shortcuts,” one participant noted—education must cultivate discernment, not dependence.

6. Partnerships Over Isolation. Joint research and co-op programs with manufacturers are replacing traditional academic isolation, aligning lab innovation with shop-floor application.

7. Inclusion in the Talent Pipeline. Expanding STEM access—especially for community colleges and underrepresented groups—is seen as essential to filling the two million manufacturing jobs projected to go unfilled by 2033.

Recommendations for: Industry

Converting Innovation into Scalable Value

1. AI Becomes Operational. Manufacturers are deploying secure, privatized AI to manage predictive maintenance, quality control, and production scheduling—turning hype into measurable productivity.

2. Cyber Resilience as Market Edge. Security has shifted from compliance burden to competitive differentiator. Firms integrating AI-driven defense and incident response outperform on both trust and uptime.

3. Additive Manufacturing Scales Up. “Vibe Manufacturing” and distributed printing networks are redefining production models—lowering cost, waste, and emissions while decentralizing capability.

4. Data as a Controlled Asset. Companies are moving from open experimentation to governed AI ecosystems, blending open-source agility with closed-source protection of intellectual property.

5. Workforce Reinvention. The greatest constraint to AI adoption is human readiness. Leaders are investing in cross-training, digital fluency, and partnerships with educators to close the capability gap.

6. Leadership and Culture Shift. Mid-level managers are emerging as the linchpins of transformation, tasked with translating digital strategy into workforce confidence and execution.

7. Innovation Through Collaboration. The Integr8 consensus: manufacturing’s next gains will come not from isolated breakthroughs but from synchronized ecosystems—where data, design, and defense move in concert.

Key Member Data Points that Defined 2025

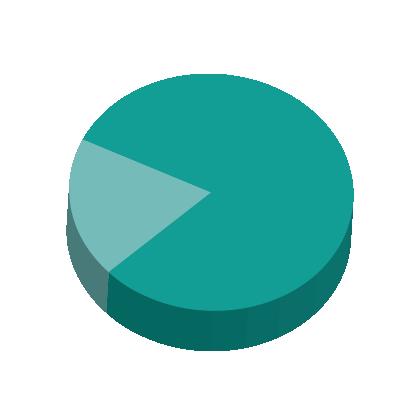

1. Is the workforce still the leading challenge of the global manufacturing industry?

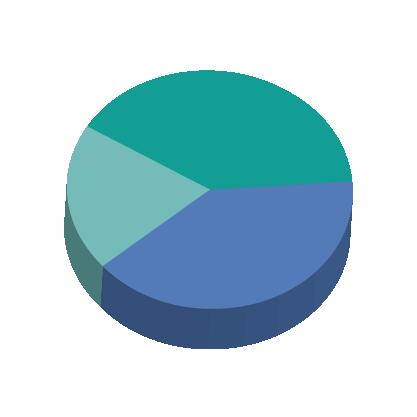

3. To what degree has AI improved your business?

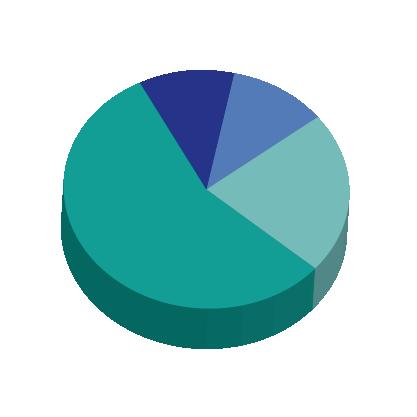

2. 3D printing adopters, what is additive manufacturing primarily used for in your facility?

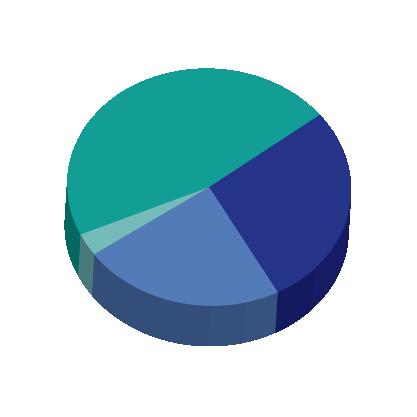

4. What is the greatest challenge in producing parts for the EV industry?

Sponsorship Opportunities Available at info@automationalley.com

Register for Integr8 2026 here https://integr8series.com/events/