Binnie LAB

Redefining Recreation Across Canada

Contact us to discuss how Elevate Roofing Systems can enhance your next project:

Asia's largest urban rooftop garden at Thailand’s Thammasat University protected by UltraPly TPO

5

RAIC PERSPECTIVE

The blueprint for successful urban design.

6

REIMAGINING THE LANDSCAPE OF CIVIL ENGINEERING

With the launch of Binnie LAB this year, Binnie continues its mission to offer versatile services that meet the unique needs of every client.

9

FINDING THE CURE

The impact of rising investments and 3D printing on the world of precast concrete. 17

ROOTED IN VISION

Uncovering the ever-evolving palette of landscape products.

Escalating demand and cutting-edge R&D is transforming Canada’s engineered wood industry.

Roofing and cladding are being inspired by everything from Passive House to techniques from Japan.

Technology and statement-making styles are at the forefront of this year’s door and hardware trends.

Trailblazing trends and bold visions in sustainable design.

Innovative

A

dive into revolutionary waterproofing products

Dan

dchapman@canadawide.com

604.473.0316

EDITOR

Bruckner nbruckner@canadawide.com

SENIOR

Scott Laurie slaurie@canadawide.com

CONTRIBUTING

Robin

Stacey McLachlan

604.299.2116

by GIOVANNA BONIFACE Chief Implementation Officer, RAIC

The Blueprint For Successful Urban Design

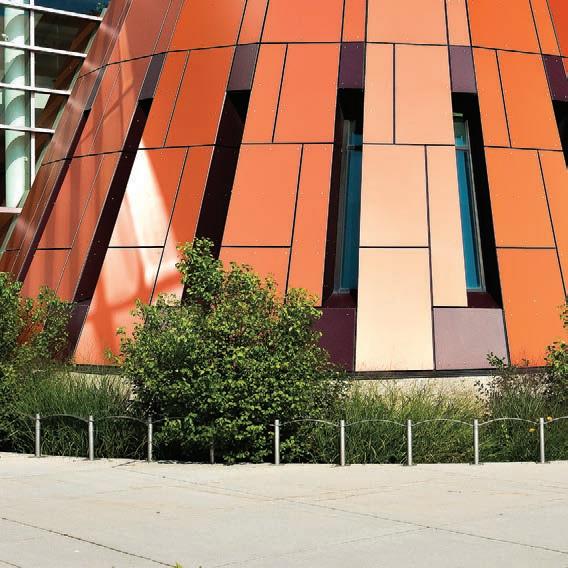

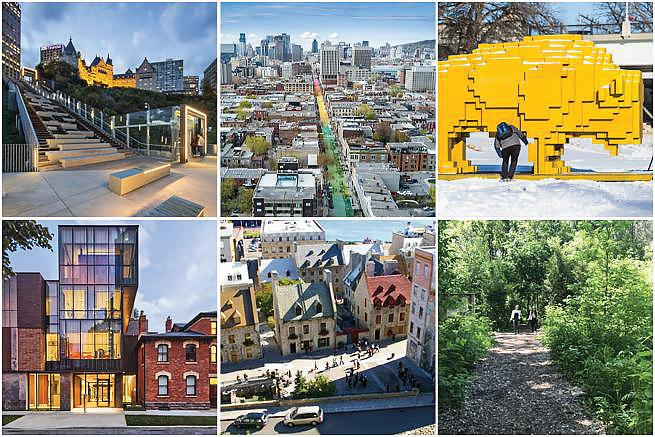

The Royal Architectural Institute of Canada (RAIC), the Canadian Institute of Planners (CIP), and the Canadian Society of Landscape Architects (CSLA) recently announced the recipients of the 2024 National Urban Design Awards.

The National Urban Design Awards are awarded every two years and recognize the important link between architects, planners, and landscape architects in achieving successful urban design. They strive to raise awareness of the crucial role that urban design plays in maintaining and improving the quality of life in Canadian cities and acknowledge the efforts of individuals, organizations, firms, and projects in this field.

According to the jury, “The submissions were consistently very high quality, and focused on many of the topics we as designers are all focusing on in our ever-changing world – justice, equity, diversity and inclusion, on climate change, on resiliency, and as always, on high quality design for the many end-users we strive to serve.

“Projects were described in the submissions with high quality graphics, photos of built projects and evidence that these projects have made significant changes to the quality of life of Canadians across the country.”

Twelve recipients have been selected from the six National Urban Design Award categories:

• Esplanade Tranquille, Les architectes FABG (Civic Design Projects)

• sθәqәlxenәm ts’exwts’áxwi7 – Rainbow Park, DIALOG BC Architecture Engineering Interior Design Planning Inc. (Civic Design Projects)

• Kids Reimagine School Streets, SPECTACLE Bureau for Architecture and Urbanism (Community Initiatives)

• Fields and Flows: Harmonizing Township Development with Riverine Health Through the Local Industrial Use and Cycling of Sedimentary Materials, Preston Stronach (Student Projects)

• Maisonneuve Library Restoration and Extension, EVOQ Architecture + civiliti (Urban Architecture)

• Stadium Station, GEC Architecture (Urban Architecture)

• Queen’s Marque, MacKay-Lyons Sweetapple Architects (Design Architects) in association with FBM (Prime Consultants), (Urban Architecture)

• Downsview Framework Plan, Henning Larsen, KPMB Architects, SLA, Urban Strategies Inc., Northcrest Developments, Canada Lands Company (Urban Design Plans)

• Exchange: Realizing RiverWalk West, groundcubed + HEREBY (Urban Design Plans)

• Skeena Terrace Community Plan, Perkins&Will (Urban Design Plans) Bentway Staging Grounds, SHEEEP in partnership with Agency—Agency, and The Bentway Conservancy (Urban Fragments)

• The Ring / L’Anneau, CCxA Architectes paysagistes Inc. (Urban Fragments)

To learn more about the award recipients, see pictures of their work and read jury comments, check out the recipient webpages.

2024 National Urban Design Awards Jury members:

• Martin Brière, oaq, mirac

• Audrey Farias, rpp, mcip, pmp, muds, barch, leed ap

• Trevor McIntyre, mla, fcsla, oala, aala, apala, asla

About the Canadian Institute of Planners

The Canadian Institute of Planners (CIP) works on behalf of over 9,000 diverse planning professionals and has served as the voice of Canada’s planning community since 1919. Planners safeguard the health and wellbeing of urban and rural communities by addressing the use of land, resources, facilities, and services with consideration to physical, economic, and social efficiency.

About the Canadian Society of Landscape Architects

The Canadian Society of Landscape Architects (CSLA) is a non-profit, national members-based professional organization. It is dedicated to advancing the art, the science and the practice of landscape architecture and celebrates 90 years of support to and advancement of the profession in 2024.

Reimagining The Landscape Of Civil Engineering

With the launch of Binnie LAB this year, Binnie continues its mission

to offer versatile services that meet the unique needs of every client

by NATALIE BRUCKNER | photography courtesy BINNIE LAB

The realm of civil engineering carries a legacy steeped in tradition, offering stability and reliability through centuries-old practices. Venturing beyond these conventional boundaries demands more than just resolve; it necessitates a readiness to challenge the norm and cultivate lasting client relationships.

Binnie, a versatile civil engineering firm, embodies this spirit while placing a paramount focus on client relations. With an unwavering commitment to understanding their clients’ needs, the team at Binnie fearlessly embark on a journey of continual improvement, standing steadfastly alongside those they serve.

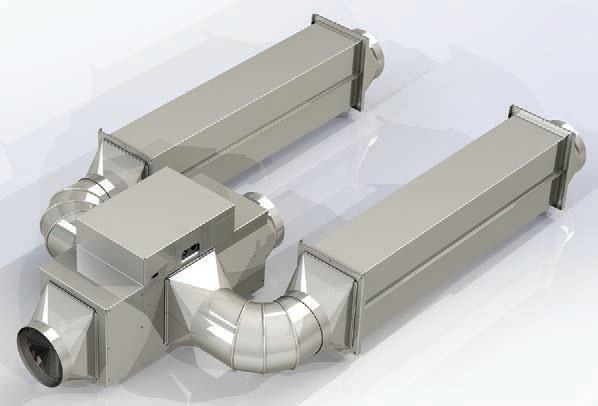

This year marked a pivotal moment in their journey with the launch of Binnie LAB – an innovative initiative poised to revolutionize integrated landscape

architecture. Serving as a testament to their forward-thinking approach, the Binnie LAB – led by Blair Arbuthnot and Catherine Eiswerth – offers a trifecta of design solutions: sports, recreation, and open spaces. Its inception reflects Binnie’s relentless pursuit of reimagining the landscape of civil engineering.

Bolstered by a team of dedicated professionals, Binnie LAB is an integrated team comprising landscape architects, civil engineers, irrigation specialists, arborists, site inspectors, and world-renowned artificial turf field specialists. As a multi-disciplinary firm, Binnie takes pride in offering versatile services to meet diverse needs. The Binnie LAB aspires to create spaces that not only inspire but also nurture a sense of belonging and well-being for generations to come.

To better understand how the company landed at this point, we need to step back to its humble beginnings. Binnie started as a husband-and-wife team in

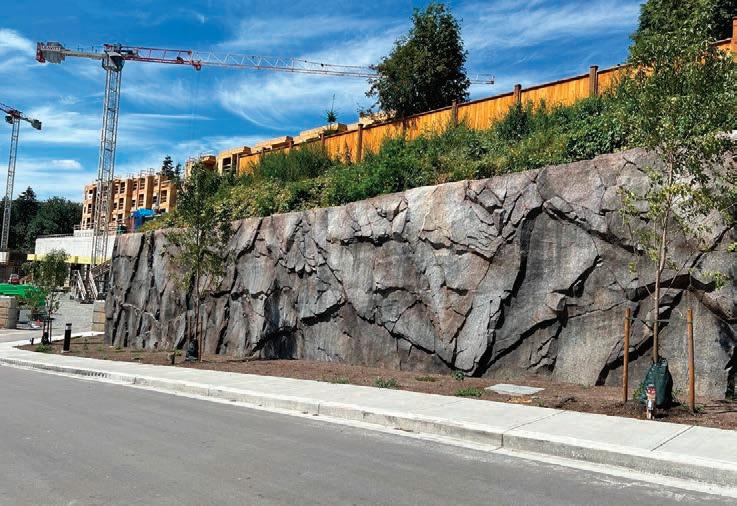

Seylynn Park, North Vancouver, B.C.

1969 and by the 1980s the company had expanded to 20 employees. During that time, the world had witnessed dramatic transformations – from manual surveying and typewriters to smartphones and 3D scanning – and Binnie was evolving just as rapidly.

“From our humble beginnings to our growth into a multi-disciplinary firm with a team of dedicated professionals, our focus has always been on fostering connected communities across Western Canada, and improving our neighbourhoods and cities,” says Richard Bush, president and CEO.

The team at Binnie has indeed always had a passion for problem-solving, “and our staff feel rewarded when they see the tangible outcome of their work – whether it’s a small roadway upgrade or a large master-planned community,” adds Bush.

Today, Binnie comprises a dynamic team of more than 350 staff spread across six offices in B.C. and Alberta. As the company has grown, so has the breadth, scale, and complexity of its projects. It has added more disciplines to its established surveying and civil engineering teams, including landscape architecture, project management, water resources, highways design, and sustainable infrastructure solutions that consider climate change. “This means we are always evolving in how we use our skills and integrate our various disciplines across the company and offices to create solutions for our clients,” says Bush.

The advent of the Binnie LAB this year heralds a new chapter, positioning the company as a frontrunner in Canadian sports and recreation design solutions. “Binnie has continued to stay on the leading edge of the sports and recreation design process due to our fully integrated design process between our landscape architects and civil engineers working within a single division, and our design teams cross training on each project. By blurring the design lines between the two traditional disciplines, we can reach aesthetic design solutions backed by strong technical excellence,” says Arbuthnot.

Indeed, this isn’t a new area of expertise for the team; in fact, they have long been renowned for their pioneering sports complexes, meticulously crafted running tracks, dynamic sport courts, enchanting playgrounds, lush parks, and meandering trails.

Back in the early 1990s, the team at Binnie was involved with the Burnaby Lake Sports Complex – one of the largest artificial turf facilities in North America at the time. This ultimately led to the development of dozens of turf fields throughout the Greater Vancouver area, significantly increasing the local capacity to support sports and recreation programming through all seasons.

There are, of course, all manner of standout projects in this realm that Binnie has been involved in, including the Fen Burdett Stadium, where The City of North Vancouver retained Binnie for the full detailed design of a synthetic turf field, community recreation track, and fitness park. “Our design focused on creating a multi-use facility that emphasized inclusiveness, a feature often absent from sports-oriented complexes. By using created landforms we eliminated ball control fencing, while also creating a sense of enclosure around the field. We also prioritized passive use open space and incorporated hilly jogging trail loops into the complex to link the new fitness stations,” says Arbuthnot.

In addition to the Fen Burdett Stadium, Binnie was involved in other notable projects such as the Telosky Stadium Synthetic Turf Field Facility, which consists of two full-size soccer/softball synthetic turf fields and associated amenities including bleachers, dugouts, pathways, and a field house. Another noteworthy project is Grant Park, designed with utmost accessibility in mind – the park design includes a wheelchair-friendly synthetic baseball field and a specially designed diamond with synthetic turf that provides a perfect level playing surface. The City of Abbotsford was awarded the BC Recreation and Parks Association Award in Park Design Excellence for this project in May 2022.

“From multi-purpose sports fields to playgrounds, parks, and bike paths, we envision, design, and construct vibrant open spaces that not only enhance human interaction but also elevate the quality of life within communities,” states Bush.

As Binnie celebrates another significant milestone this year, its team maintains an unwavering focus on the core values that have always defined the company: prioritizing the needs of people and communities, regardless of the pace at which the world changes.

“It is an exciting time to be in the consulting space and shape the communities we work and live in. The rate of change and advancement in technology will further enhance and improve our ability to collaborate and execute the vast variety of projects we are involved with. Our purpose is creating connected communities that are resilient, safe, and reliable, ranging from roads and utilities to parks and public spaces. While technology, work methods, and products continue to change at an accelerated rate, Binnie will always be about people, and the communities that we serve,” concludes Bush. A

Fen Burdett Stadium, North Vancouver, B.C.

Yorkson Community Park, Langley Township, B.C.

Telosky Stadium Synthetic Turf Field Facility, Maple Ridge, B.C.

Burnaby Lake Sports Complex, Burnaby, B.C.

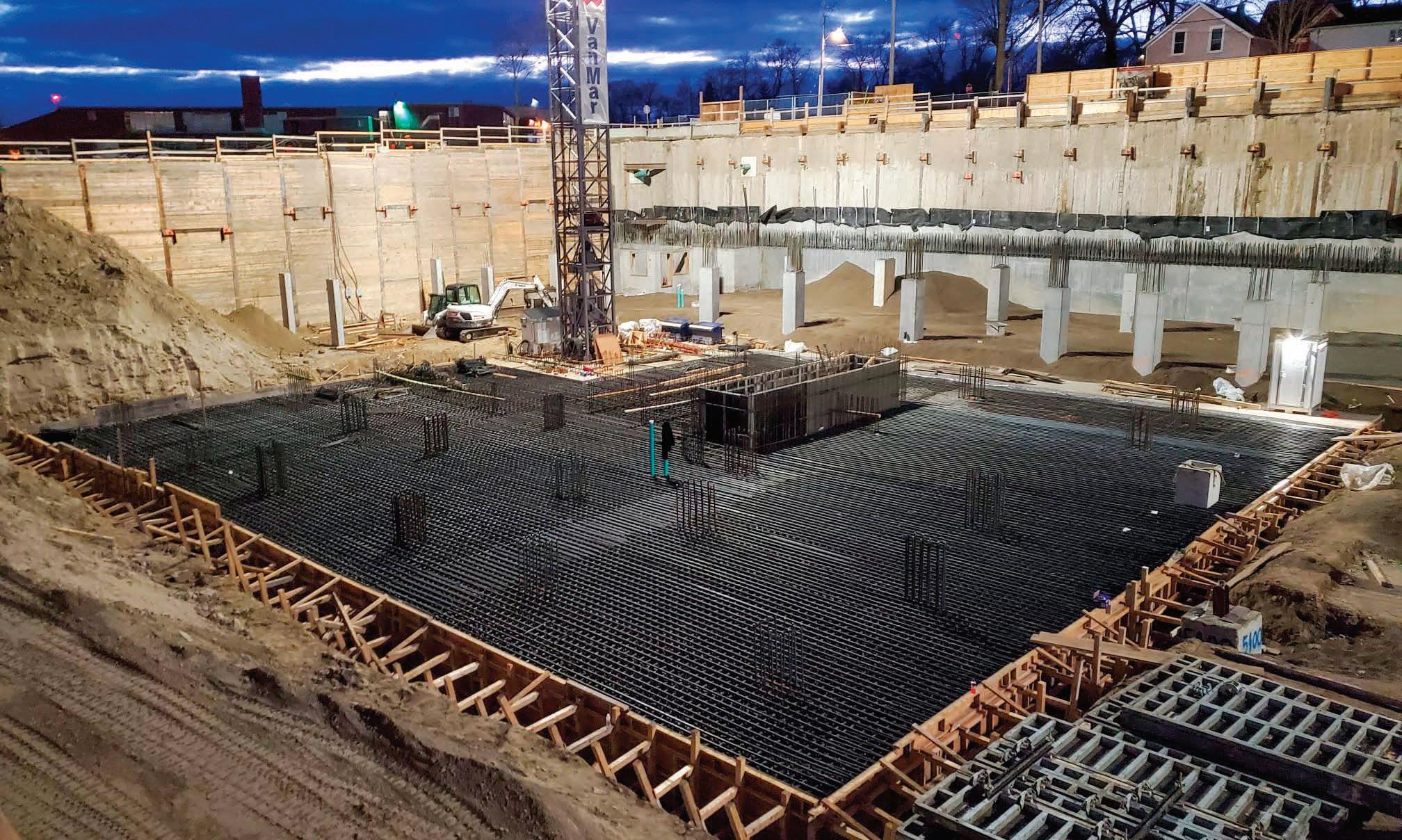

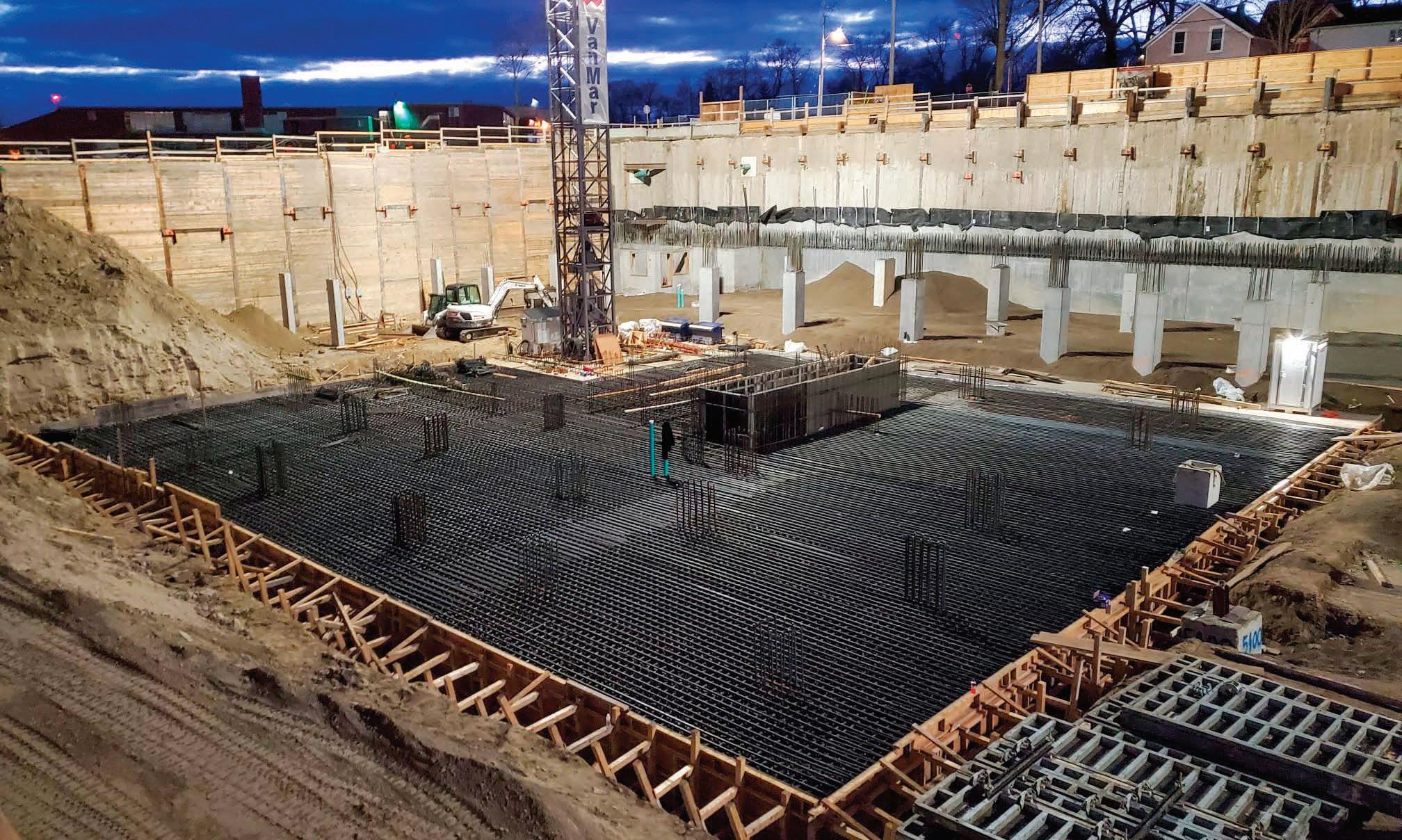

Total Precast Concrete Key Attributes to Passive House Development are:

· Manufactured in local precast facilities under controlled conditions

· The whole building envelope in one composite panel; air barrier, moisture control, insulation and the structure

· Hollowcore floor slabs allow for a much lower depth to span ratio

· Hollowcore provides the lowest GWP per m2 of concrete floor area

· Precast concrete dramatically reduces the construction schedule, site congestion, noise and environmental impacts

For more information and educational presentations check out Learn on Demand, a 24/7/365 Educational Platform. Visit: cpci-learnondemand.com/

For more information on Passive House Total Precast Concrete, visit www.cpci.ca/publications to download your free copies of the Structural Solutions Guide and the Putman Family YWCA Total Precast Concrete Case Study.

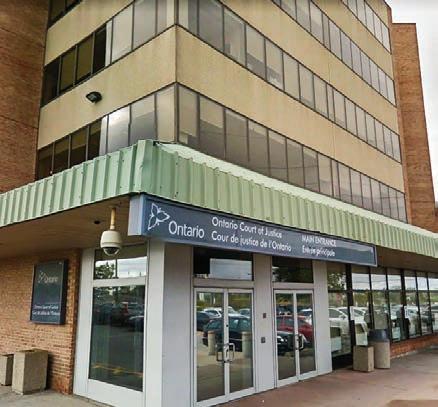

Project: The Putman Family YWCA, Hamilton, ON Architect: Kearns Mancini Architects Inc., Toronto, ON

Finding The Cure

The impact of rising investments and 3D printing on the world of precast concrete

by ROBIN BRUNET

Precast specialists are finding themselves extremely busy in many sectors across Canada in 2024, and a boom in one sector is credited directly to the problems that arose during the COVID lockdowns.

Dominic Colpron, engineering manager for Peikko North America says, “The lockdowns and resulting supply shortages taught us not to be so reliant on offshore manufacturing, and as a result governments in the U.S. and Canada are making massive investments in new facilities, which in turn is benefitting precast companies and related equipment firms.”

Colpron cites multi-billion-dollar investments made by Samsung in the Austin, Texas region for new semiconductor and microchip plants as one of many such projects Peikko is busy supplying. “The work began three years ago, there are dozens of tower cranes operating on these sites, and the work is expected to continue for the next 10 years,” he says.

Colpron adds, “We’re also involved in the second phase of the Sofidel pulp plant expansion in Columbus, Ohio.” This $185-million undertaking will expand the facility by 500,000 square feet and is expected to be completed in 2025.

For both projects, Peikko is supplying HPKM Column Shoes used to connect precast columns to

foundations and to connect columns together. The Ohio project is also using Peikko’s BECO Beam Shoes and COPRA Anchoring Couplers, a fast and economical solution for creating a moment connection between precast beams and columns.

Peikko is heavily relied upon to supply a large selection of concrete connections and composite beams for both precast and cast-in-situ situations in a wide variety of applications, and Colpron is optimistic about the volume of work coming down the turnpike due to what seems to be a concentrated push to revitalize North America’s manufacturing capabilities. “Another project soon to commence that we’re involved with is a Dow Chemical Plant in Fort Saskatchewan,” he says. “So, while opportunities in the residential sector have diminished somewhat due to inflation, industrial work is intense.”

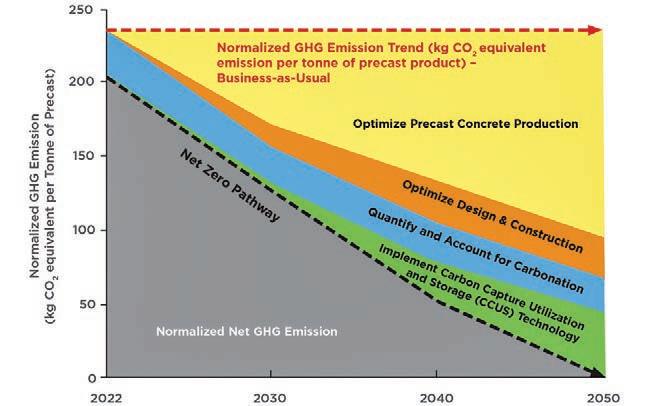

From the perspective of Brian Hall, managing director at the Canadian Precast/Prestressed Concrete Institute, a major push in his sector continues to be lowering carbon emissions. “In 2023, CPCI’s members made a solid commitment to work with our designers, producers, and suppliers to reduce the emissions of the precast concrete industry in Canada,” he says. “This requires full transparency from CPCI members during this decarbonization process to declare our emissions and commit to working together to reduce baseline emissions of the precast concrete industry. Industry experts have developed a document for CPCI members that provides a pathway toward decarbonizing our sector.”

CPCI is also working with its affiliates to provide tools and the necessary training for members to develop on-demand plant and product-specific Environmental Product Declarations (EPDs) for various precast concrete products and assemblies. “Quantifying and reporting our emissions will be very important for us in tracking and reporting the progress of our industry in the decarbonization process,” Hall says.

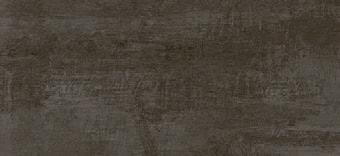

Precast concrete cladding panels at the Clayton Reservoir, Surrey, B.C.

Net Zero Pathway to 2050.

Lower the carbon footprint of your next construction project

EcoCem® was developed as part of our ongoing commitment to significantly diminish CO2.

The use of EcoCem® reduces CO2 emissions in concrete by as much as 10% to 22%. When using EcoCem®PLC or EcoCem®PLUS from Heidelberg Materials, you’re able to produce concrete with the same level of strength and durability as that manufactured with ordinary portland cement. Designed for use in the production of concrete block and pavers, concrete pavement and soil stabilization and advantageous for all ready mixed concrete applications.

Visit our website to learn more about our sustainable products:

Business in 2024 is brisk for Heidelberg Materials and Justin Arnott, Calgary-based area VP and general manager for Precast Concrete Pipe says, “While most of our market is residential development, we’re noticing a push in infrastructure projects in Western Canada, especially in B.C.”

As a result, certain processes are gaining traction to facilitate the work, and Arnott cites the increasing instances of microtunneling in situations where traditional open cut pipe laying is not feasible.

Microtunneling (also known as pipe-jacking) is a non-disruptive method of installing utility tunnels and conduits by thrusting pipes through the ground as controlled excavation is undertaken at the face. Pipes manufactured in a variety of materials to include concrete, clay, and steel can be jacked and standard pipe diameters generally range from 150 millimetres (mm) to 2,400 mm, or greater when required, and lengths can be in excess of one kilometre depending on pipe diameters, ground conditions, and excavation methods.

Arnott says, “We’ve had good success with the process in B.C., with projects including the Trans Mountain Pipeline and currently the Burnaby Lake interception project. Since an increasing number of areas are being built out and regions are become urbanized, the need for microtunneling grows.”

For the concrete and precast concrete industry in general, another evolving innovation is the use of 3D printing to facilitate construction, and one example showcasing the potential of this technology is Kakatoosoyiists, 16 one-bedroom units being built across four buildings on the Siksika Nation about 100 kilometres east of Calgary. This is the first 3D concrete-printed housing initiative in Alberta and the largest in the country, with external walls being 3D printed with concrete using a four-foot tall robotic arm to pour the substance.

Arnott says Heidelberg Materials Pipe has established an in-house 3D operation “to help solve nitpicky problems associated with the limitations of sand casting, and we use it to create custom jigs. It’s a fabulous aid to the bespoke work we do, and 3D has potential as a game-changer in the precast world.” Heidelberg Materials has vast experience in 3D concrete printing materials, supplying dry mortars in Europe to some precast operators. In North America, the 3D operations are mostly focused on single family homes and concrete furniture or landscaping elements.

As for Heidelberg Materials’ ongoing commitment to achieve and maintain sustainable standards, its Manitoba concrete pipe plant in January shifted from 30 percent production with EcoCem Plus to 100 percent, and Arnott says it’s just a matter of time before the company’s other plants across Canada follow suit. “We’re getting the same strengths from EcoCem Plus compared to normal cement and its workability is great,” he says of the blended Portland Limestone Cement that is produced by inter-grinding clinker, fly ash, limestone, and gypsum (and can lower the carbon footprint by more than 22 percent compared to General Use cement).

John Carson, executive director at AltusGroup, Inc. says, “The precast industry in North America is very strong with many significant projects in a wide mix of markets – but the future is somewhat cloudy due to high interest rates, material inflation, and other factors. In general, schedules are sliding somewhat and demand is heavily dependent on regional economic activity and growth.” AI continues to drive data centre project development.

Carson points to the recent opening of the new Knife River prestressed and precast plant in Spokane, Washington, as an example of the industry scrambling to fill the need for precast projects. One of Knife River’s early accomplishments has been

supplying a new electric car dealership with a precast roof system as an alternative to steel roof joists; the company built the system in the space of a week and finished installation in six months, hence the use of precast.

Carson, who toured the plant, says, “It’s doing lots of wall and transportation projects, and the industry overall is also adding capacity through internal capital expenditures.”

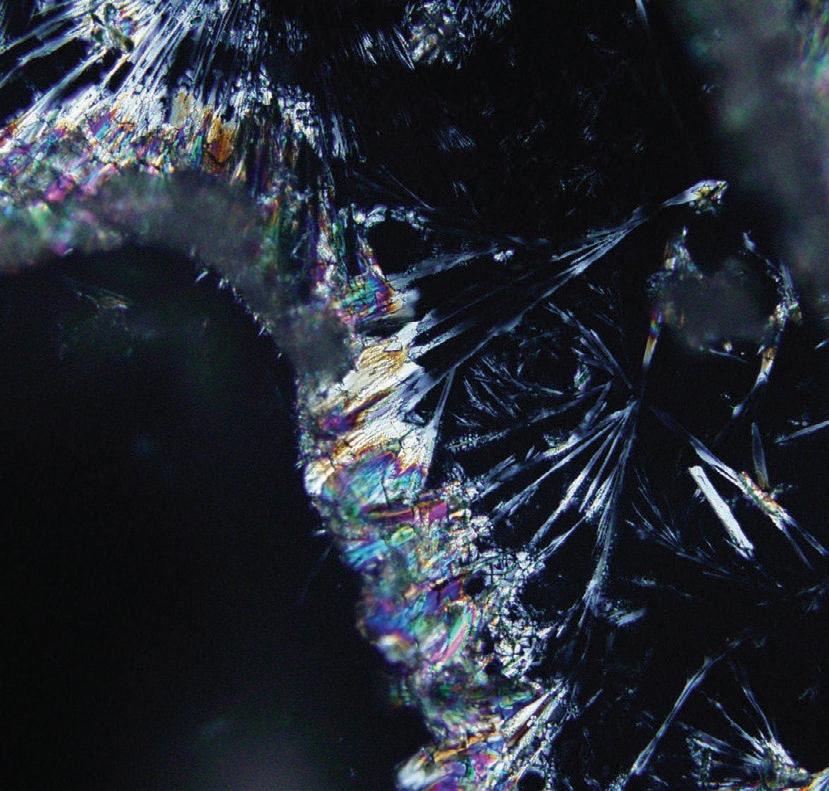

Carson notes that in addition to manufacturers continuing to seek ways to improve productivity, achieve footprint reduction, and manage labour shortages, technological innovations continue to inform their work. “New fibre reinforced polymer connection systems and design methodologies like CarbonCast and the use of composite design in wall assembly makes precast a desirable selection for builders and GC’s,” he says. “Ultra and high-performance concrete admix technology continues to gain attention, and less cement and lighter weight elements are drivers for new sustainable systems.”

CarbonCast High Performance Insulated Wall Panels are composed of two concrete wythes separated by continuous insulation. With very low thermal conductivity, the high-strength C-GRID connectors help deliver insulation values up to R-37 depending on the thickness and type of board foam insulation used.

Twin precast box culvert line installation, Bonnybrook Wastewater Treatment Facility Outfall, Calgary, AB.

Oil/Grit Separator installation, Balzac, AB.

CarbonCast High Performance Insulated Wall Panels, Boys Town School, Omaha, NE.

*(CPCQA) CERTIFICATION PROGRAM BY PROCESS OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

Project: Champagne Quarry Park, Calgary, AB Architect: Gibbs Gage Architects

However, precast is not exclusively about sustainability or even efficiency, as crucial as these factors are. The best precast manufacturers have a keen ability to produce structures that are aesthetically pleasing, and Lafarge in Western Canada (where the company’s precast services are focused) extends this value to projects that would otherwise be considered utilitarian.

Case in point: for the Clayton Reservoir in Surrey, B.C., Lafarge Precast Edmonton created 161 white and charcoal precast concrete cladding panels, curved in a 3D circular/wave effect to maintain the natural ambiance of the area. A more traditional example of precast’s aesthetic appeal is the Eagle Ridge affordable housing project in the Fort McMurray region. Eagle Ridge was notable for its use of precast concrete as the primary building material, including the superstructure, flooring, and exterior cladding. “The use of precast allowed for expedited construction, high-quality finishes, and affordable housing in the Fort McMurray area,” says Kristen Marston, communications and marketing manager for Lafarge Canada Inc.

Marston adds, “By prioritizing our goals in precast, including integrating modern technology, such as our newest hollowcore extruder, we’ve successfully minimized cross-sections while preserving strength, thus reducing cement usage and our environmental footprint. Innovation isn’t a buzzword; it’s ingrained in our processes and products, defining our commitment to building a more sustainable future.”

Coreslab Structures is well known in the precast sector for its structural and architectural expertise, facilitated by 17 manufacturing facilities across North America. Its strength for developers lies in the fact that it works with clients from initial design and planning to fabrication and installation, thus helping to ensure that projects are completed to the highest standards.

One example of Coreslab’s materials capability in Canada is Blendtek Ingredients Inc.’s 85,000-square-foot headquarters in Cambridge, Ontario. Built by Jackman Construction Ltd., the facility required 21,915 square feet of precast hollowcore and solid slabs, as well as 32,258 square feet (150 pieces) of insulated precast walls each measuring 42 feet (’) by 7’, to meet both SQF and organic certifications.

Coreslab’s work on the 10th & Wyandotte Parking Garage in Kansas City, MO is a showcase for the aesthetic benefits of precast structure. The five-storey design features unique blackouts in its precast exterior panels, which were achieved using custom moulds and ceramic artwork. Also, thanks to precast the project was able to cover 72,000 square feet with 281 pieces in just 10 months.

Finally, the general contractor NZ Builders is unique in that it pushes the envelope of design and building science by building a variety of high-performance passive solar homes on Vancouver Island.

One such home in Victoria is especially noteworthy in that it boasts a diverse array of concrete finishes, including one entire exterior panel featuring a life-size image of a Garry oak tree, etched permanently into the concrete. The flooring is polished concrete, and mixed media and textured walls are throughout the build. The entire home required Concrete Insulated Panels (CIP), R-16 effective wall assembly, R-40 slab insulated footings, and an R-40 roof assembly. A

Peikko BESISTA® tension rod and compression bar systems set the standard for seamlessly bracing buildings and other load-bearing structures. With detailed aesthetics and patented safety and installation features, BESISTA is your first choice for load-carrying connections that boldly stand out.

Precast construction at the Eagle Ridge affordable housing project, Fort McMurray, AB.

Rooted In Vision

Uncovering the ever-evolving palette of landscape products

by ROBIN BRUNET

When it comes to landscaping products, regardless of the properties they’re intended for, design and colour trends are subtle rather than seismic, and everything old eventually becomes new again.

Vito Lore, sales manager, Canada, at family-owned Mutual Materials (whose 13 manufacturing plants and 18 branch offices provide high-quality masonry and hardscape products to a wide range of customers), says, “The preference for larger format slab sizes, which began some years ago, is still a trend. We carry 120 inch [”] by 24” and 24” by 24” units, but we also have 8” by 12” and 16” by 24” units, because a lot of the standard sizes are still popular too.”

Mutual’s masonry offerings include brick, blended brick, structural brick, and concrete masonry units in many colours, shapes, and textures. Its hardscape products include paving stone, patio slabs, and garden and retaining walls.

Lore notes that elsewhere, “There seems to be a new interest in different shapes such as geometric shaped pavers and larger slabs. Conversely, Romanstyled, tumbled worn pavers were very popular for a number of years, but now the move is towards cleaner and more linear; it’s a matter of evolving aesthetics.”

Belgard remains at the forefront of product design innovation. The hardscapes company recently launched several new paver styles within its already extensive portfolio of offerings, ensuring there is a style that goes with each and every project, no matter the design or aesthetic.

Belgard has a dedicated focus on modularity, which makes design and installation easier. Modular design uses individual parts to create a holistic plan more efficiently; modular pavers work off nominal sizes, which allows contractors to play more with shape, size, and texture within the design.

The company also understands the importance of combining aesthetics and function and has introduced new textured paver designs that offer depth and dimension without compromising quality.

Part of Belgard’s Artisan collection, the Papyrus paver, offers a unique, organic textural experience with a touch of modern elegance. It features clean edges with a unique face that mimics the look of hand-tooled striations and the texture of organic textiles. It comes in true three-inch increments for optimized pallet layouts and job site efficiencies, which delivers reduced cuts, installation time, and waste. In addition, its modular format allows for increased options for creative patterns, simplified quoting, and design of projects.

The Basalt paver is also part of Belgard’s Artisan collection and features the distinctive character of flame-textured stone. It has the same modular benefits as Papyrus and is compatible with other Belgard modular paver lines.

Large slab pavers from Mutual Materials.

The Basalt paver from Belgard’s Artisan collection.

Landscape Forms, North America’s leading designer and manufacturer of high-design site furniture, structure, LED lighting, and accessories, recently released the new Plains & Pods – two complementary systems of modular seating, surfaces, and planters created with London-based design studio, Industrial Facility. Plains & Pods are sibling products that work elegantly either together or separately, with a minimalist, non-prescriptive design to enhance its versatility.

Rectilinear and architectural, Plains are comprised of large format platforms and a trestle, varying in height and width to create customizable settings of layered seating and surfaces. Constructed of naturally weathering wood, powdercoated metal, or a combination thereof, Plains are offered in four widths each with short and tall heights, as well as optional metalbacks and attaching side tables, thus providing a level of detail only rivalled by custom solutions.

Pods are seating and planters designed to be grouped together in multilayered clusters of respite space and attractive greenery. Different groupings of Pods modules give users the opportunity to determine how they interact with space – from large and open communal zones and areas for privacy to single seating and quick individual touch-down points.

Interplay between Plains’ crisp right angles and Pods’ friendly curves offers added aesthetic richness, and combination installations create a variety of opportunities for different social experiences. “Together, these two products are all about layering space and experiences to create pockets of recognizable design DNA that are totally non-prescriptive,” says Ryan Heiser, director of design for Landscape Forms. “People can approach a Plains & Pods installation from 360-degrees and determine exactly how they want to use it.”

Holger Rust, head and founder of South Africa-based Terraforce, continues to offer the Canadian market what it is famous for in its home country and across the world: the original, reversible, hollowcore retaining block.

Versatility is one key to Terraforce’s prominence in so many countries: its interlocking Terraforce 4x4 steps blocks can be used for stairs or seating arrangements, depending on which way they’re laid.

While Terraforce’s full potential is yet to be realized in Canada, Rust notes that his company is busy “with some very interesting projects that demonstrate the effectiveness of our retaining walls, including a significant airport project in India.”

Rust is referring to India’s Kempegowda International Airport at Bengaluru, for which Terraforce supplied over 110,000 L12 blocks for the construction of retaining walls on both sides of Terminal Boulevard, a new 10-lane thoroughfare that feeds directly into the airport.

Plains & Pods from Landscape Forms.

Terraforce retaining wall at the Kempegowda International Airport.

Approximately 1.2 kilometres (km) of the road has been lined with retaining walls on both sides, covering a total surface area of 9,000 square metres. The Terraforce retaining wall system was chosen for several reasons, aesthetics being a major consideration. The blocks also allowed the planting of flowers and other vegetation, and the inclusion of hume pipes facilitated the planting of trees. In addition, the Terraforce option required less soil excavation and was more cost-effective than reinforced concrete or reinforced earthen walls would have been.

One of the main challenges of this project was that additional cutting into the embankments for the installation of geogrid reinforcement was not possible. So, soil nailing was specified and involved drilling 115-millimetre (mm) diameter holes of up to 9 metres (m) in length, perpendicular to the slope of the embankment. Nails were inserted into the holes and grouted, then PVC drainage pipes up to 2.5-m long and wrapped in a geotextile membrane were installed in pre-drilled holes. The slopes were then covered with a geodrain membrane, two layers of 8mm steel mesh and 100mm of shotcrete.

More procedures followed, then reinforced concrete shear-key blocks were cast to form the foundations of the Terraforce walls. A mock-up section of the embankment was built to identify constraints and improve the installation process.

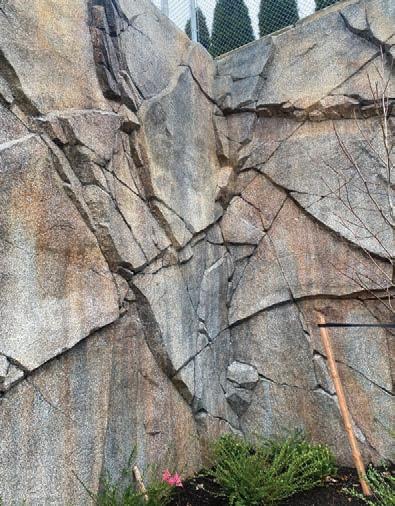

Aside from its value as a reinforcing material in infrastructure projects, shotcrete is increasingly becoming sought as a solution for elaborate retaining wall systems. In 2005, Vancouver Shotcrete & Shoring Inc. (VSS) debuted to provide customers with viable and sustainable options for their construction needs. VSS has serviced various municipalities and private companies while completing over 850 top-tier shotcrete projects.

Jesse Ebenal, general manager at Vancouver Shotcrete & Shoring Inc., says, “Business is great, and there are lots of large-scale retaining wall projects in the residential, commercial, and infrastructure fronts. Nevertheless, several recent projects are showcases for the level of quality we provide, one being the Highline at Garibaldi Springs rockscape retaining wall for a townhouse development in Squamish, B.C.”

According to Ebenal, the shotcrete retaining wall was designed to be anchored by Titan 40 IBO anchors with a test load capacity of 52,000lbs each, spaced every two metres on centre. Temporary shotcrete was reinforced with welded wire mesh; the permanent, structural shotcrete layer was reinforced with one layer of 15mm rebar placed 300mm apart, in order to span the load between anchors and bridge the joint between the shotcrete and bedrock interface.

Ebenal says the construction team faced numerous challenges due to poor ground conditions, including loose rock and sand backfill, blasting of adjacent bedrock, running sands, and underground water. The procedure of applying a structurally reinforced shotcrete coat was time sensitive, and after many other steps a decorative rockscape finish was applied, hand shaped, and carved by VSS’s in-house finishing crews.

Rockscape retaining wall at Garibaldi Springs, Squamish, B.C.

Design Without Limits Plains & Pods : Outdoor experiences open to interpretation.

Designed by Industrial Facility

Landscape Forms

At VSS, we specialize in crafting bespoke, hand-carved faux rock shotcrete retaining walls, each one a testament to our commitment to blending artistry with functionality.

From cascading water features to intricately carved rock formations, our designs are as diverse as the landscapes they inhabit. We believe in harnessing the beauty of nature to create spaces that are visually stunning.

With VSS, you’re not just getting a retaining wall; you’re getting a work of art that harmonizes seamlessly with its surroundings. Let us help you transform your space— constructing nature, one retaining wall at a time.”

Reach out to one of our highly skilled team members to begin constructing the retaining wall of your dreams.

Finally, in the realm of landscape maintenance, ensuring that trees are healthy is often a tricky and costly business, and as more and more areas become built up, trees become more valued as an environmental asset.

Enter Cohen & Master Tree and Shrub Services Ltd., which has always placed great importance on a proactive method of tree care. “Most recently we took big steps in analyzing and evaluating mature trees with specialized equipment known as Sonic Tomography and Resistograph drilling,” says Cohen & Master director Tait Sala.

Sala goes on to explain this relatively new deployment of technology in North America is an advanced level of tree inspection. “The thing about mature trees, especially in urban areas, is that the outer wood can cover old injuries and defects. With Sonic Tomography we place sensors around the trunk and penetrate it with sound waves, and the rate by which they penetrate reveals defects.”

With Resistograph drilling, a digital drill with a very fine bit penetrates the tree, and fluctuations in the velocity of the bit reveals defects and decay. “By overlaying the data from both devices we can learn a lot about what’s going on, and we’ve saved a lot of heritage trees in this manner that may look damaged on the outside due to lightning strikes or other phenomena but are in fact sound on the inside,” Sala says.

Sala adds, “The information allows us to make critical decisions about vital preservation and retrenchment pruning and or tree removal when the defect and level of risk are too high. This is the future of advanced level tree assessment, and we’re excited about spearheading a science-based approach to preserving the urban canopy.”

Mature tree inspection using Sonic Tomography.

Shiver Me Timbers

The forecast for the global engineered wood market between 2024 and 2031 indicates a substantial upward trajectory. In Canada, this surge is notably fuelled by government initiatives, increased acceptance of engineered wood, and heightened education regarding its versatility.

Rory Koska, program director of Alberta Wood WORKS!, agrees that the demand being seen is due in part to a significant surge in the acceptance and utilization of engineered wood, now widely recognized as a credible and sustainable complement to traditional materials. “It’s no longer viewed as a

boutique solution,” emphasizes Koska. “We’re witnessing a shift towards considering it a viable and reliable option, backed by education, data, and increased experience.”

Koska highlights the growing interest in residential projects surpassing four storeys, where engineered wood offers both construction efficiency and design flexibility. Furthermore, its incorporation into educational facilities and Indigenous community buildings underscores a commitment to holistic well-being and eco-conscious practices.

Projects like Métis Crossing’s community centre and The Boutique Lodge in Smoky Lake, Alberta, showcase a blend of traditional methods like heavy timber and stud framing with newer engineered

Escalating demand and cutting-edge R&D is transforming Canada’s engineered wood industry

by NATALIE BRUCKNER

wood products such as glulam and engineered lumber. This combination serves as an excellent example of what can be achieved. As Koska says, understanding that engineered wood, when used in conjunction with other materials like steel and concrete, can offer the most efficient and cost-effective building solutions.

One of the most impactful developments, according to Shawn Keyes, executive director at WoodWorks BC/Canadian Wood Council, is the recent implementation of mass timber incentives by the City of Vancouver. Keyes explains, “This policy offers an additional two or three storeys for mass timber projects over eight storeys, effectively incentivizing more sustainable construction practices.”

The Boutique Lodge, Smoky Lake, AB

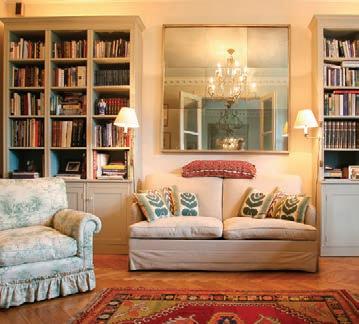

WHAT’S YOUR Colour Narrative?

Urban or Rustic?

Neutral or Colourful?

Modern or Classic?

Find your Colour Narrative in our fullspectrum palette that captures more of the widely specified paint colours from across Canada, determined by our Customers and Colour Experts.

He further elaborates that “such initiatives help developers mitigate cost and risk premiums associated with newer construction methods, fostering the growth of the mass timber market.”

B.C., Quebec, and Ontario have also announced plans to expand their building codes to permit 18-storey Encapsulated Mass Timber Construction (EMTC) with additional occupancies and reduced encapsulation requirements. Keyes notes, “This alignment with the International Building Code [IBC] in the U.S. opens up new markets for mass timber, simplifying code compliance pathways processes previously limited to alternative solutions.”

Keyes highlights The Hive, a 10-storey mass timber commercial office building in Vancouver, as an exemplary project. Notably, it employs a lateral system comprising CLT shear walls and timber braced frames. Once completed, it will stand as North America’s tallest timber-braced frame building, showcasing the possibilities of engineered wood products, particularly in seismic regions like Vancouver.

Looking ahead, Keyes anticipates a growing demand for affordable rental properties in the seven to 18 storey range, presenting a significant opportunity for mass timber. He also notes that engineered wood products, including I-joists, excel in mid-rise applications for five or six storey buildings, offering affordable construction options with low embodied carbon.

ESCALATING DEMAND

This heightened interest spans across diverse sectors, as evidenced by the experiences of Beam Craft, which is witnessing a significant uptick in demand.

Jason Beamish, partner, sales and marketing at Beam Craft, elaborates on this trend: “We’re now seeing the emergence of multi-storey structures,” he explains. “This year, we’re embarking on a five-storey condo project in Saskatoon, marking our first multi-storey endeavour in Saskatchewan. Previously, our focus in the region had been primarily institutional projects. Additionally, we’re undertaking another multi-storey project at the

University of the Fraser Valley, and of course educational institutions have been instrumental in driving mass timber initiatives.”

Like Koska, Beamish notes the rise in hybrid structures, where combining materials presents both opportunities and challenges. “While ‘hybrid’ is the buzzword in our sector, we must address challenges such as quality assurance. Ensuring precision in bearing locations when transitioning between mass timber, steel, and concrete is crucial. Although we possess the techniques and technology, continual improvement is imperative for the industry.”

MEETING THAT DEMAND

As engineered wood’s popularity continues to soar, evidenced by Kalesnikoff Mass Timber’s expansion plans, meeting that demand is imperative. With the announcement of a third facility and new product lines, expected to open at the end of this year, Kalesnikoff aims to solidify its position as a leader and innovator in meeting the evolving needs of the construction industry.

“We have experienced consistently strong interest and demand in our initial mass timber investment announced almost exactly five years ago,” said Chris Kalesnikoff, COO of Kalesnikoff Mass Timber. “This additional offering of leading mass timber products and services for the North American construction industry will support mass timber buildings including student and workforce housing, prefabricated housing, and other mass timber projects.”

The expansion includes offerings such as modular construction, prefabricated mass timber, and light frame components, catering to the increasing demand for sustainable building materials.“This new initiative creates more opportunity to work in partnership with current and new construction industry customers to create and manufacture customized pre-fabricated solutions and products for growing and evolving housing types and needs.”

PROJECTS HIGHLIGHT VERSATILITY

The innovative use of engineered wood in projects like the City of Sunnyvale’s mass timber building exemplifies the remarkable versatility of this sustainable construction material. Kinsol Timber Systems was involved in the construction of the building that was spearheaded by XL. Together, the design-build team completed the five-storey office structure in a remarkable 12 weeks.

This project stands as a pioneering endeavour in the Bay Area, utilizing the emerging sustainable construction material. The 92-foot-tall fully electric office building features exposed timber beams, wooden ceilings, and concrete flooring.

Moreover, the project underscores the significance of collaborative partnerships in advancing sustainable initiatives. Achieving LEED Platinum certification, the building boasts a compelling narrative of co-operation – from the City’s commitment to sustainability to the visionary designs by Michael Green Architecture and SERA Architects, supported by the structural expertise of Equilibrium, and the dedication to excellence of mass timber innovators like Kinsol Timber Systems and Elevated Construction Services.

EMERGING TRENDS

When it comes to trends, one that is being observed by the experts at Western Archrib is a growing interest in Spruce glulam. According to Andre Lema, manager of business development, this trend is attributed to its light and bright wood tones, offering a consistent look and colour across laminations. He notes that the product is also receptive to stains/ custom finishes.

Since joining the Northland Group of Companies in 2021, Western Archrib has experienced remarkable growth. Lema emphasizes the synergy between the two entities and the role Spruce Pine has to play: “Our collaboration with Northland has been instrumental in meeting the growing demand. Their focus on producing Spruce aligns perfectly with our needs, providing the highest quality input fibre and guaranteed supply,” explains Lema, speaking from the International Mass Timber Conference in Portland.

CLT shear wall installation at The Hive, Vancouver, B.C.

PHOTOGRAPHY BY UPPER LEFT PHOTOGRAPHY/COURTESY NOVACOM BUILDING PARTNERS

Waap Sa’mn (House of Spruce), Coast Mountain College, Terrace, B.C.

Spruce Pine glulam on display at Saddle Lake Elementary School, Saddle Lake, AB.

Western Archrib’s recent expansion includes the acquisition of a 130,000-square-foot facility, with an additional 40,000 square feet added. Lema adds, “We’re in the process of commissioning the new manufacturing facility with state-of-the-art machinery and it is scheduled to be fully operational in about 18 months. This will significantly enhance our production capacity to meet the increasing demand for mass timber across North America.”

Amidst a flurry of projects, Western Archrib is involved in several exciting endeavours, such as a 14-storey academic wood tower at the University of Toronto and the Ādisōke facility, a hybrid steel structure housing the Ottawa Public Library and Archives Canada. Lema remarks on the company’s busy schedule and the challenges of meeting demand in this high growth industry, expected to grow at an annual rate of around 14.5 percent annually. “Now more than ever it is important for architects and general contractors to engage early with mass timber manufacturers if they are considering building with mass timber.”

Another trend being seen is an interest in Dowel Laminated Timber (DLT), as witnessed by International Timberframes, which leads the way in this realm with its Wood100 DLT, a glue and nail-free 100 percent wood product. The recent introduction of a custom-built DLT production line not only boosts capacity but also underscores the company’s dedication to innovation.

Swiss Master Timberframer and founder, Sigi Liebmann, notes a surge in activity over the

past year, citing increased recognition of mass timber’s significance among architects and engineers. “Architects and engineers are contacting us early in the design process as they recognize the importance of the expertise upfront,” he says.

Primarily focused on environmentallyfriendly, healthy residential projects, the company is also engaged in larger commercial ventures, combining DLT with traditional timber framing and other mass timber.

Despite industry challenges like fluctuating lumber prices and skilled manpower shortages, Liebmann emphasizes their proactive approach: “We invest constantly in team training to handle complex projects and meet demand.”

SOUND CHOICE

Staying ahead of the curve in innovation is a fundamental strategy adopted by industry leaders, exemplified by companies such as AcoustiTech.

André Rioux, co-owner and VP of sales and marketing, underscores how the recent housing shortage has catalyzed the construction sector to expedite the delivery of more units while exploring innovative solutions to meet escalating demand. For instance, the increasing popularity of prefabricated and modular wood structures offers a rapid and durable alternative to traditional construction methods.

However, as occupants’ expectations for acoustic quality continue to rise, significant innovations have emerged. “Dry systems tailored for light wood frame and mass timber structures incorporate advanced soundproofing materials, ensuring

effective sound insulation while streamlining construction timelines and reducing overall weight, thereby leading to cost savings,” explains Rioux.

He adds that, simultaneously, new standards focused on reducing carbon footprints are dictating the future of construction. “Upcoming new building codes emphasize low-carbon materials, encourage the use of eco-friendly and sustainable solutions, while guaranteeing optimal acoustic performance,” he says.

PROTECTING EWP

With more than 35 years of success in largescale wood construction, Sansin’s Precision Coat line is tailored for pre-finishing and machine application. KP-12 is one of the most effective products for engineered wood in the Precision Coat line. It is a penetrating protective undercoat that enhances dimensional stability and protects wood from UV degradation and moisture absorption. KP-12 protects wood during the manufacturing and construction process, and dramatically improves topcoat performance.

“Mass timber manufacturers, architects, and builders have come to rely on KP-12 as an ‘insurance policy’ to ensure their engineered wood is protected against damage from weather,” explains Sjoerd Bos, Sansin’s managing director. “Construction sites can be wet and dirty, and projects are often delayed. The best practice is to apply a penetrating, breathable protective treatment like KP-12 in the factory as part of a comprehensive coating system to protect the investment in wood.”

Your masterpiece deserves the best wood protection.

Sansin Precision Coat products offer unparalleled beauty and durability in an environmentally friendly formula. Contact us about our specification program so we can help you achieve the perfect finish and protection, every time. Warrantied for up to 20 years, Precision Coat factory finishes deliver the color, transparency and performance that architects, engineers and builders can count on.

Toronto Montessori School | Richmond Hill, Ontario

Photography Courtesy of Timber Systems | © Tom Arban Photography Inc.

PLAYING TOGETHER TO GIVE SUPPORT FOR BC’S KIDS

As we eagerly anticipate the 29th Annual Building for Kids Charity Golf Classic on July 18, 2024, BC Children’s Hospital Foundation extends its deepest gratitude to our sponsors and participants for their unwavering support.

Join us at Morgan Creek Golf Club for an even more impactful event this year, uniting BC's construction and development industry to support children in need.

TOURNAMENT SPONSORS

THEME SPONSORS

Last year’s tournament successfully raised $472,000, adding

the tournament’s cumulative total of $4.1 million to date. Funds raised will help us enhance the physical space of the Heart Centre to create a more comfortable and healing environment for patients and their families.

Below is a list of our 2023 supporters and sponsors -- to learn more about the event please contact golf committee chair Gavin Yee GYee@ventanaconstruction.com or visit bcchf.ca/bfk.

Because KP-12 is imperceptible, it is ideal for projects where beautiful clear or light wood tones are desired. An example is the Churchill Meadows Community Centre, designed by MJMA Architecture & Design, which uses Canadian-made mass timber products as the focal point of the structure. The

glulam columns and CLT timber beams, manufactured by Sansin partner Nordic, run along the full length of the park side of the building.

Inside, the glulam and CLT showcase stairway is protected with a complete system of Sansin’s architectural finishes, including: KP-12 UVW, SDF Topcoat (in washed white), and Precision Coat Topcoat (clear).

RESEARCH & DEVELOPMENT

In an era where innovation is paramount, the engineered wood industry faces an imperative to push boundaries, a commitment embodied by StructureCraft’s unwavering dedication to pioneering research and development. During an international engineering conference, StructureCraft’s Ben Moerman presented findings from an experimental study on three types of balloon-framed cross-laminated timber (CLT) shear wall configurations: a single wall; a coupled wall with a half-lap joint between wall piers; and a coupled wall with steel link beams between wall piers.

Three-storey, two-thirds-scale CLT wall specimens were cyclically tested to failure at the University of Canterbury, and the beam coupled wall demonstrated the best seismic performance among the wall configurations, showcasing its feasibility to be designed for lateral load resisting systems in buildings.

The firm has also pioneered software development with Branch, a next-generation software platform for building structure design which cuts across traditional boundaries between design and manufacturing in AEC. Branch seamlessly

integrates real-time structural analysis and design, 3D modelling/detailing, and fabrication into a single, integrated design environment.

StructureCraft believes in an intensely practical, efficient approach to engineering – showcased through their built work such as the KF Aerospace Spiral Stair in Kelowna, B.C., which uses doublycurved CLT composite with concrete to create a 70’ free-spanning spiral staircase. Thorough structural testing was required to achieve this world-first design, pushing the boundaries of what is possible with material design.

INNOVATIONS IN ADHESIVES

The significance of adhesives in engineered wood cannot be overstated, and Henkel remains at the forefront of sustainability in construction with its bio-based PUR adhesives designed for load-bearing timber. These innovative solutions significantly reduce CO2 emissions, with the new Loctite ECO variants cutting emissions by over 60 percent. Developed with bio-based materials, they maintain high performance standards while promoting environmental responsibility.

Loctite HB S ECO and CR 821 ECO offer excellent safety, durability, and productivity, crucial for modern wood construction. These adhesives continue Henkel’s legacy of success in wood construction while significantly lowering environmental impact. With certifications and documentation ensuring sustainability throughout the supply chain, Henkel’s commitment to innovation drives a greener future for the industry. A

Churchill Meadows Community Centre, Churchill, MB

Under The Covers

Roofing and cladding are being inspired by everything from Passive House to techniques from Japan

by ROBIN BRUNET

In this era, where lowering carbon footprints on one hand and dealing with steadily escalating costs on the other dominate building development, it’s no surprise that companies involved with roofing and cladding continue to be focused on achieving sustainability as well as surpassing traditional energy efficiency standards.

In the cladding realm, the fact that Engineered Assemblies (EA) recently achieved Passive House certification from Germany for its TcLip system inspires EA’s senior technical advisor, Jeff Ker, to talk about his company’s approach to encouraging the Passive House movement across North America.

“Even though genuine, 100 percent passive houses are still extremely few in number in Canada, we think the movement is really about applying Passive House integrity to as many projects as possible.”

Ker adds, “There’s no question that a growing number of architects only want to deal with Passive House-certified products, partly because such certification speaks to their resiliency and superior performance. It was a long and involved process for us to get our TcLip certified, but well worth it.”

EA’s patented TcLip is a contractor-preferred thermal clip for façade installations; it is one of the highest performers among leading systems, is adjustable for sub-wall misalignment, and often requires half the number of clips compared to other systems.

When asked what else EA is venturing into in 2024, Ker replies, “We’re taking a big stand on Indigenous construction in Canada.” Indigenous design and art in the building development realm is something EA has long been interested and involved in, and a good example is the kindergarten to grade 9 school built

on the Paul First Nation Reserve, 70 kilometres west of Edmonton. EA was able to transfer a student-created beadwork design pattern onto exterior grade phenolic panels that became the outside face of the new school. The company’s technical team provided early guidance to the architects to ensure they could achieve the desired scale and effect of the artwork utilizing a large-format custom panel building façade system; the team also assisted the fabricator with conversion of the shop drawings to artwork files needed by the phenolic laminate process.

Ker says, “We are placing special focus moving forward on integrating Indigenous art into facades using customizable material that is also high performance, which is in keeping with the Indigenous value of not harming the environment.” He cites the Elsie Fabian Fort McKay First Nation School as a current work in progress: “First Nation beadwork art was chosen as the exterior phenolic panel pattern on a feature area of the school.”

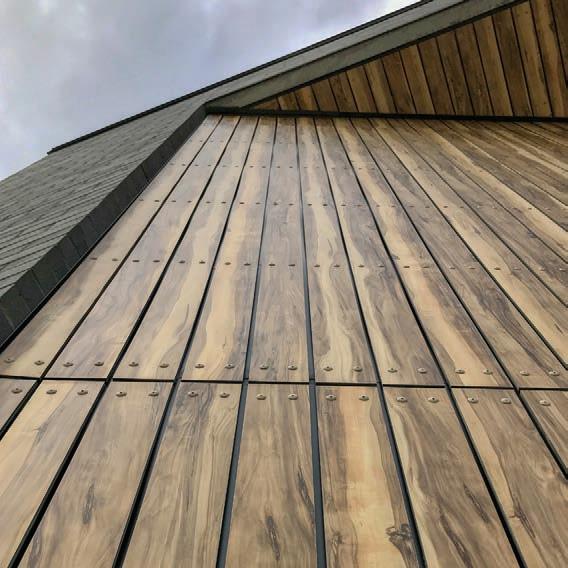

Denise Barcia, marketing director at NewTechWood Canada, says, “Since launching our Shou Sugi Ban profile last year we’ve been getting tremendous feedback on the product, and we continue to receive an equal amount of enthusiasm from the architectural and design community for our Norwegian and exterior fluted siding, which are our best-selling products.”

The Shou Sugi Ban, or ‘burnt cedar’ siding replicates a Japanese technique popular in architecture; like fluted wood it is a unique look, and while NewTechWood doesn’t actually burn the wood (a process that increases resistance to wear, mould, and insects) comparable high strength qualities are inherent in the wood composites.

Exterior grade phenolic panels, Paul First Nation School, Edmonton, AB.

Shou Sugi Ban is a fully finished product, meaning it doesn’t need to be treated with a moisture barrier. Being fully capped, the boards are impervious to water absorption, and the timber-look cladding will stand up to all weather conditions, without requiring maintenance.

NewTechWood’s fluted composite wall panels can, thanks to the company’s UltraShield technology, withstand even the constant humidity and salt air of coastal B.C. These panels make stunning facades and beautiful accent walls, among other applications, and are available in large strips (Belgian), and thin strips (Norwegian).

The roofing sector in 2024 is characterized by an equally vigorous display of new product development. Building Products of Canada’s Signature series is the latest example of the innovation and creativity that are hallmarks of the company. These shingles, launched at the end of 2023, are designed to resist even the worst weather conditions (including winds up to 135 miles per hour, with no special installation required) and come in 12 colours in Eastern Canada and 10 in the West, intended to reflect both modern and traditional aesthetics (the colours, developed by BP’s Chroma Color Lab, pair well with any type of exterior finish).

Elevating the colour offering is Chroma Color Lab’s proprietary new Profusio design patterns that merge two shingle colours and alternates them over successive rows to create a third colour to produce a complementary or contrasting visual effect.

The Signature series shingles have a high resistance to nail pullthrough and were made with BP’s WeatherTite technology, a patented roofing shingle system featuring two sealant bands. While the continuous band ensures maximum adhesion, the discontinuous dotted band increases the shingle’s adhesion, keeping winddriven rain flowing off the roof.

BP Canada marketing director Nathalie Lambert says, “The Signature line brings new life and a modern twist to traditional shingles, which have barely seen a change in tints in decades. We’re giving homeowners a first-of-its-kind opportunity to affix their signature to their roofs with unique natural looks that set their

properties apart and blend into a home’s facade like never before.”

Polyglass, which is part of the Mapei Group, has led the industry in the development of high-quality modified bitumen roofing and accessories; its APP and SBS membranes provide outstanding protection, durability, and life expectancy, and are also environmentally friendly, energy efficient, UV-resistant, and of course visually pleasing.

March was a busy month for Polyglass in the U.S. with the unveiling of two new breakthrough products. PolyVap SA S is engineered for superior performance in commercial low-slope roofing applications and features a high-strength polypropylene sheet with an aggressive acrylic based adhesive on the bottom, ensuring a bond with most substrates. This carrier-less membrane is surfaced with a slip-resistant top surface to enhance walkability and can serve as a temporary roof for up to 180 days.

PolyVap SA S is an ideal air/vapour barrier in low-slope roofing applications, for use on steel, OSB, plywood, gypsum, and thermal boards. Its top surface is compatible with approved coverboards and Polytherm insulation, allowing for mechanical attachment or adhesion with Polyglass LRF CR (low-rise foam) adhesive. It is impermeable to air, moisture, and water, and the aggressive self-adhesive makes for exceptional wind uplift performance.

Also in March, Polyglass launched Modifleece, a revolutionary fleece-backed Styrene-Butadiene-Styrene (SBS) modified bitumen roofing membrane base sheet. Designed for the use in multi-ply low-slope roofing systems, Modifleece, thanks to an innovative laminating process, integrates a specially formulated dual compound into the polyester fabric, creating a seamless bond between the two components. The self-adhered side laps are safeguarded by a protective release film; the film is removed during application to reveal the aggressive selfadhered SBS compound, ensuring watertight seams.

Modifleece serves as a strong and durable waterproofing substrate for additional roofing membrane plies, ensuring long-lasting protection. It is suitable for application directly over irregular or semi-rough substrates, including Lightweight Concrete (LWC), and as a recover option over existing modified bitumen roofing systems.

Shou Sugi Ban timber-look cladding.

Wood Composite

Siding · Decking

Fencing · Beams

95% recycled materials

Maintenance-free

Sustainable · Fade resistant

Jasmeet Deol, senior manager, product marketing at Holcim Building Envelope, says Elevate’s ISOGARD polyiso insulation continues to be recognized as among the very best thermal insulation products for commercial and other projects. “ISOGARD provides the highest R-value per inch in colder mean temperatures,” he says.

Drilling down into ISOGARD’s unique properties, Deol, explains, “The product is tested at an average of 24 degrees Celsius; when the mean temperature is on the low side the R-value actually increases from 5.7 to 6.2. So, if a building is prone to wide temperature variations, the same level of ISOGARD insulation gives better performance, resulting in cost savings.”

This is possible partly because polyisocyanurate, or polyiso, is a thermosetting type of plastic, closed-cell foam that contains a low-conductivity, hydrochlorofluorocarbon-free gas in its cells. In short, it is a rigid foam board insulation made up of closed cells pressed together so tightly that air and moisture can’t squeeze between them or into the foam. Elevate’s ISOGARD takes things a step further by being the first insulation product on the market that meets ASTM C1289 required and recommended thermal performance values.

Deol also reports that Holcim Building Envelope “continues to make headway with our Roofing Waste Diversion program, whose purpose is to look at ways to reduce waste in the construction process and is focused on the waste generated from the over 400 million square feet of commercial roofing systems installed annually.”

In partnership with Geocycle Canada, Holcim Building Envelope is supporting landfill diversion options for commercial roofing materials from retrofit and re-roofing projects (a lot of the roofing waste is co-processed in cement kilns).

“Also, old roofing ballast that would traditionally end up in landfill is instead collected and reused as granular A road base,” Deol says.

Finally, Carlisle SynTec Systems has not only been a leader in the commercial single-ply roofing industry for more than 50 years (with products including Sure-Seal EPDM, Sure-Weld TPO, Sure-Flex PVC, and FleeceBACK membranes), the company is also dedicated to the advancement of people in the industry through training and education.

This is evident with its blog, TecTopics, whose goal is to provide applicators, installers, building owners, and architects with information and guidance on matters such as material installation, system detailing, roof maintenance, and current roofing industry issues. Proper installation, maintenance, and warranties of single-ply roofing systems are also covered.

Another blog, SpecTopics, focuses on industry-wide topics that affect building product specifications, code approvals, and technical information for roofing, insulation, and air and vapour barrier products. It provides design solutions for common architectural problems utilizing new and innovative products and systems as well as the necessary language to incorporate those products and systems into project specifications. A

Installation of Elevate’s ISOGARD polyiso insulation.

WEST COAST CONTEMPORARY LINE

A custom home build is quite often the single largest investment in one’s life. This is a tremendous responsibility to entrust to the construction community.

Understanding this concept and exceeding customers’ expectations are what Westeck strives for and is at the core of the Westeck culture.

BIG PRODUCTS FOR ALL SIZES EMBRACE THE PATIO EXPERIENCE INDOOR/ OUTDOOR LIVING VANCOUVER 1480 Kootenay St, 1‑877‑606‑1166 CHILLIWACK 8104 Evans Rd 1‑877‑606‑1166

westeckwindows.com sales@westeckwindows.com

UNLOCKING ACCESS ALLURE

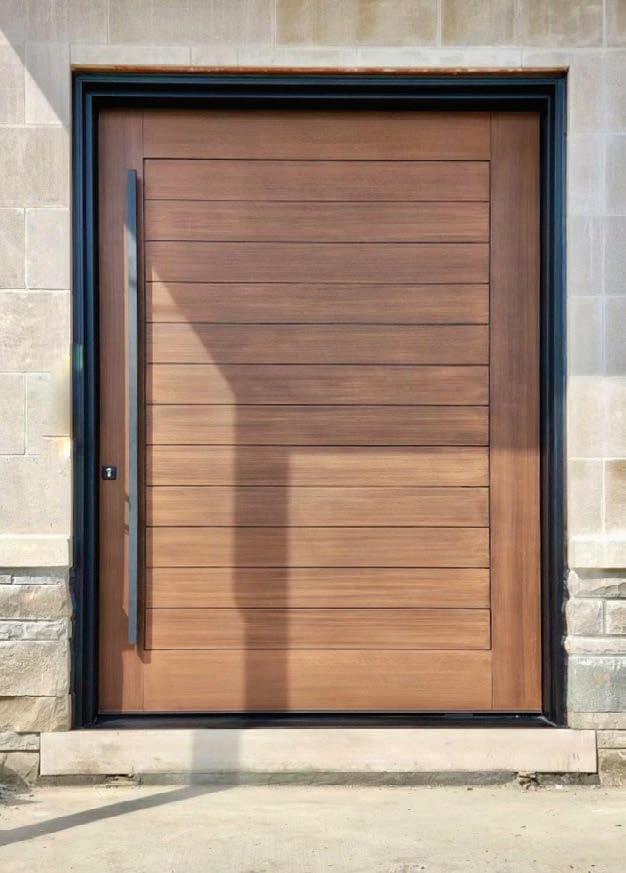

Technology and statement-making styles are at the forefront of this year’s

door and hardware trends

by STACEY MCLACHLAN

From the bold, expressive colours adorning today’s residential entrances to the high-tech security systems that feel straight out of a sci-fi movie, the doors and hardware on the market today have something for everybody.

The industry’s offerings hinge on a striking fusion of aesthetics and technology. If you’re looking for inspiration for your next project, you’ll find it here: door manufacturers are creating innovative options like high-performance products, advanced access systems, and finishing touches perfect for selfexpression. Read on as we open the door on this year’s most compelling industry trends.

PERSONAL TOUCH

Doors aren’t just an entrance or exit: they’re an opportunity to make a statement. No wonder there’s a continued consumer demand for aesthetic customization options for commercial doors – such as colour variations – as businesses prioritize the visual appeal of their properties.

“The visual appeal of doors and hardware plays a significant role in consumer decision-making, with a growing emphasis on enhancing the overall look of

their property or business,” says Lana Winterfield, manager of marketing and communications for Creative Door. That being said, she also points to the importance of affordability in the door market: “It’s a primary concern for consumers, alongside quality and durability.”

For residential projects, black doors are a popular choice; it’s a look that emphasizes a sleek and modern aesthetic. Geoff Mainprize, principal of Trillium Architectural Products notes that white hardware is on the rise, commonly specified these days for levers and hinges. “It looks like the next hot trend,” says Mainprize. He also points to the rising relevance of ‘colour contrast’ as a design/accessibility requirement. “Spaces where doors have a dark stain or paint finish are being specified with lighter toned hardware, and vice versa,” he notes. But it’s not just an aesthetic choice: “Colour and brightness contrast is important to provide more visibility and make the operation of doors more accessible for everyone.”

Commercial customers are also shifting away from standard colour options, preferring to choose colours that seamlessly integrate with the rest of the building. Lilac, for instance, has emerged as a highly sought-after option, complemented by a

variety of architectural styles and colour palettes. Navy blue, sage, and terracotta are hot for 2024, too, reflecting a trend toward natural and earthy tones. Hardware, meanwhile, runs the gamut, reflecting a diversity in personal tastes: vintage bronze adds an element of elegance and warmth, matte black offers a bold and modern appeal, and satin brass provides versatility and a touch of sophistication.

Wayne Dalton residential garage doors from Creative Door. Colour contrast provides visibility and accessibility.

Elevate Your Building with SILEX Fiberglass Windows and Doors

Proudly Canadian. Unmatched Durability. Custom Contemporary Design.

Superior Strength: Built to endure the toughest weather conditions. Energy Efficient: Keeps your home comfortable and reduces energy costs. Elegant Styles: Modern designs to enhance any architectural aesthetic.

WI-FI OH MY

Increasingly, consumers are seeking smart door solutions with Wi-Fi connectivity for added convenience and control. “Wi-Fi access is becoming increasingly prevalent in commercial door electric openers, enabling seamless connectivity and control for enhanced convenience and security,” says Winterfield. “Innovations in smart technology for residential applications are transforming door operations, enabling features such as remote access for delivery companies to safely deposit orders inside homes, enhancing both convenience and security.”

Homeowners are looking for products that offer convenience, peace of mind, security, and energy efficiency, and want to have the ability to control conditions at home even when they are away. Smart home technology is top-of-mind with an increased desire for automation to improve convenience.

“We are witnessing an exciting era driven by advancements in smart technology and security systems,” says Michael Hicks, operations manager for Silex Fiberglass Windows and Doors. Companies around the globe are incorporating features such as biometric authentication, keyless entry systems, and advanced access control technologies to enhance both convenience and security for customers.

Over at Silex, the team has been particularly focused on integrating innovative solutions, such as the Danalock smart lock system, into a product lineup that includes a multipoint locking system. Danalock offers smartphone control, keyless entry options, and seamless integration with popular smart home platforms like Apple HomeKit.

“Imagine having the ability to assign temporary digital keys that expire to a babysitter or house sitter, providing enhanced peace of mind,” says Hicks.

(Marvin’s recently unveiled Marvin Connected Home is another high-tech hardware product – a first-to-market smart solution that makes it easy for homeowners to operate doors with a home automation system, voice assistants, the Marvin Home app, a wall switch, or on-unit control buttons.)

SETTING THE ENERGY BAR HIGH

There’s an ever-increasing interest in building envelope energy efficiency, and doors and hardware are a huge part of that puzzle. The industry is in the process of transitioning from R-value to U-factor as per DASMA testing standards, signifying a major change in how insulation efficiency is measured.

Wayne Dalton (one of the brands carried by Creative Door) stands out with the best U-factor in the industry, emphasizing superior thermal performance and energy efficiency.

Wayne Dalton Garage Doors.

Danalock smart lock system.

Innotech Windows and Doors, a B.C.-based manufacturer of high-performance windows and doors, is one company leading the way in passive house design and energy efficiency with its Defender 88PH+ system. The product represents a significant advancement in the North American fenestration industry, delivering the performance needed to meet the pinnacle of energy-efficient design and construction. The Passive House Institute (PHI) certified component stands out for its exceptional thermal insulation, enhanced resistance to air, water, and sound, and demonstrated long-lasting quality.

It’s also worth noting that the door manufacturing industry has taken significant strides towards sustainability in the past few years. Embracing environmentally friendly practices, manufacturers are now heavily investing in materials that minimize ecological impact. This shift is evident in the increased use of recycled materials like steel and aluminum, and sustainable sources like bamboo and FSC-certified wood. Production processes have evolved, too, with reduced waste and energy consumption, and advanced techniques in manufacturing now ensure that the carbon footprint of door production is significantly lowered.

It all signifies a commitment by the industry to the well-being of the planet, while meeting the needs of modern construction and design – a move that warms our homes and hearts.

OPEN UP

The trend towards large doors has not slowed in

drawn to expansive glass panels that allow for uninterrupted views and a seamless transition between indoor and outdoor spaces,” says Michael Wandschneider, director of product management at Marvin. It’s not surprising, given the growing popularity of indoor-outdoor living. “They’re blurring the

boundaries between their interior and exterior environments, prioritizing connection with nature and maximizing natural light in their homes,” he adds.

Luckily, ever-improving technology enables larger high-performance windows and doors that address this demand. Increased glass, expansive views and enhanced access to natural light within residential spaces is now easily achievable. For instance, there’s Marvin’s latest sliding glass door innovations: the Ultimate Sliding Door and the Ultimate Sliding French Door G2, products intended to elevate the aesthetic appeal of a space, while offering practicality for long term use.

Sectional doors have long been a popular option for creating indoor-outdoor spaces in residential projects, but we’re seeing more and more in commercial spaces now, too. Bars, event centres, and restaurants are utilizing sectional doors to enhance both the aesthetics and functionality of their dining and event areas. “By incorporating various types of full-view doors, these establishments create versatile spaces that seamlessly blend indoor and outdoor environments, catering to evolving consumer preferences for open, airy atmospheres, and dynamic event experiences,” explains Winterfield.

Commercially speaking, “people are trying to push the limits of what can be done,” says Zach Campbell, an engineer with PowerLift Doors. “They’re getting more creative.” His company has recently produced glass-panel doors in size ranges as large as 110feet wide and 25- or 30-feet tall. (Even at this scale, however, efficiency is still high. “These designs are very thermally efficient,” Campbell explains.

Windows + Doors for Passive House Projects

Innotech Windows + Doors is a Canadian manufacturer of high-performance windows and doors. The Defender 88PH+ System combines decades of fenestration knowledge to deliver a robust window and door system that is not only Passive House Institute certi ed, but that also delivers the air, water and structural performance required for highly sustainable housing developments.

Defender 88PH+ door certified by the Passive House Institute.

EVOLVE IN VANCOUVER, BC

Passive House Multi-Family Project by ZGF Architects and Peak Construction.

FUTURE-PROOFED FUNCTIONALITY

According to a recent U.S. News and World Report study, 93 percent of aging adults intend to age in place – and the door industry has taken note, with a renewed focus on ergonomic door handles and architectural hardware for ease of aging in place.