METAFOR

*(CPCQA) CERTIFICATION PROGRAM BY PROCESS OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

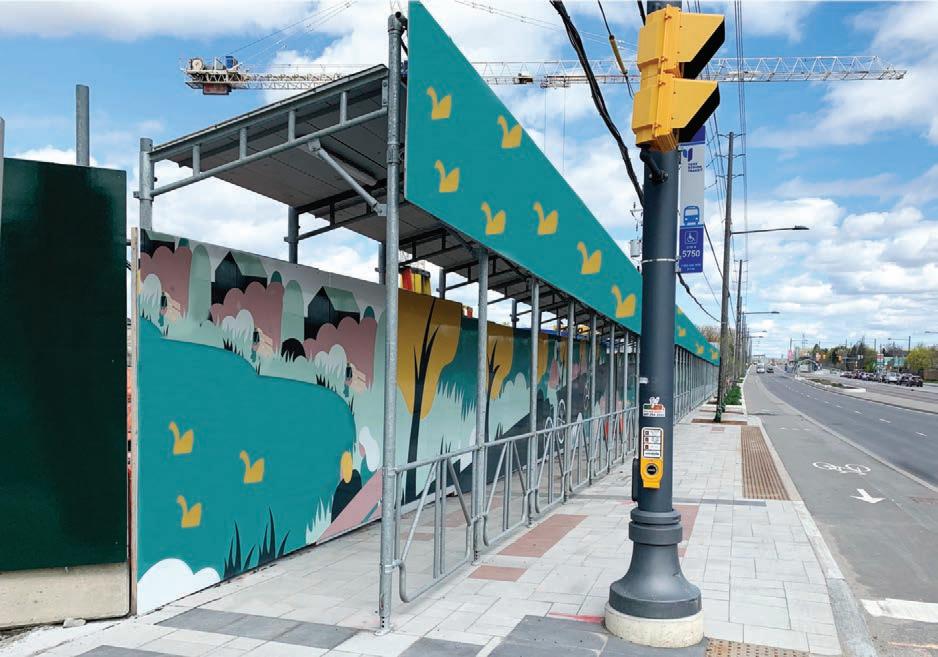

Project: Champagne Quarry Park, Calgary, AB Architect: Gibbs Gage Architects

5 RAIC PERSPECTIVE

Tackling equitable housing solutions. 6

MAKING TOMORROW BETTER THAN TODAY

With its new rebrand, Metafor honours its past while embracing a brighter future.

9

THE BUILDING BLOCKS OF CONSTRUCTION

Precast concrete industry advances sustainability with innovative techniques and partnerships. 19

AIM HIGH

Roofing and cladding trends for 2023 and beyond.

AGAINST THE GRAIN

The rise of engineered wood products following an unpredictable market.

A GAME CHANGER FOR THE ENVIRONMENT

Emerging topics and groundbreaking studies influencing tomorrow’s sustainable design decisions.

OPPORTUNITY KNOCKS

The door industry continues to evolve and shape building design.

Waterproofing solutions that rise above nature’s challenges.

YOUR OUTDOOR SPACE

Innovative landscape products thrive despite inflation challenges.

Revolutionary

The Fence People Limited has been a Southern Ontario fence contractor since 1986. Conveniently located in Brampton, Ontario, we service the Commercial, Industrial and Institutional Industries. We bring to market unique modular plywood hoarding systems, covered walkways and overhead gate protection.

Due to the modular nature of our components we have the capability of constructing various structures and offer solutions to many special requirements. Our in house manufacturing facility allows us to respond quickly to customized requirements.

We have a large stock of wire mesh panels ready to be deployed. Three different heights are available; 4, 6 and 8 feet high.

Our ability to produce our many variety of gates makes us capable of delivering and installing our products rapidly.

We have a large range of solutions for any site . These options can be quickly installed to close off your site for safety, aesthetics and privacy. They can also be modified or relocated to accomodate

Tackling Equitable Housing Solutions

The RAIC is proud to be sponsoring the exhibition Architects Against Housing Alienation (AAHA), which will represent Canada in the 18th International Architecture Exhibition – La Biennale di Venezia, from May 20 to November 26, 2023. The project is led by a group of architects and designers who have come together to address housing affordability and accessibility in Canada. AAHA recognizes that the housing crisis is not just an issue of economics, but also a social and political issue that requires a collective response.

Housing alienation refers to the condition of being separated from our fundamental connections to home, the result of the transformation of land and homes into profit-generating commodities. Luugigyoo Patrick Stewart’s backslashes in c\a\n\a\d\a refer to the originating land divisions and separations that were put in place when settlers came to Canada. Through this process, land became conceptualized as private property, reserved for the exclusive use of its owner, and yet easily exchanged, throwing something as rooted as land into circulation and leading to trends such as real estate speculation and financialization.

Those with the least advantage have felt the impact of these changes most – Indigenous peoples, women, the working class, and people with disabilities. AAHA’s manifesto, “End Housing Alienation Now!” lays out their key principles and goals for creating a more equitable and inclusive housing system.

To end housing alienation in c\a\n\a\d\a, AAHA demands:

Land Back: We demand that all land c\a\n\a\d\a claims for the “crown” be returned to First Nations, Métis, and Inuit Peoples as Indigenous land in the form of co-ownership trusts.

On the Land Housing: We demand on-the-land, off-grid, nomadic communities for Indigenous women and girls with access to safe, secure, affordable, culturally relevant wrap-around support services.

First Nations Home Building Lodges: We demand Home Building Design Lodges tied to housing manufacturing facilities on reserves, to build capacity within communities by grounding the production of houses and their components, in community values, language, and education.

Architects Against Housing Alienation takes on Venice Biennale

A Gentrification Tax: We demand a Gentrification Tax to capture the unearned increment of value to build and secure deeply affordable housing within a community land trust.

Surplus Properties for Housing: We demand that all levels of government make available surplus public property assets for the development of affordable housing and the public good that is not for sale – not now and not in the future!

Intentional Communities for Unhoused People: Across Canada, there is a rapidly expanding gap between “living rough” on the street or in self-made encampments, and gaining access to long-term housing. To support unhoused people, cities must use underutilized land to fund and build intentional communities where residents receive services, share community responsibilities, and regain agency to govern space and their lives.

Collective Ownership: We demand that municipalities incorporate guidelines that prioritize co-living, co-operative, and co-housing over speculative real estate development and that credit unions and banks remove roadblocks and create pathways to cooperative financing models.

Mutual Aid Housing: We demand housing for mutual aid in the urban core, where density and supportive programming respond to existing needs, foster community-building, and provide culturally-appropriate support to refugees. A largescale development will foster cooperative support among people of diverse backgrounds and experiences.

Ambient Ecosystem Commons: We demand a vision and participatory process for housing development that upholds ambient urban ecosystems as a continuously accessible commons necessary for social housing. This process must lead to concrete action to improve the ambient commons.

Reparative Architecture: We demand reparative architecture for the Black residents of Toronto’s Little Jamaica who have been displaced or are at the risk of being displaced due to stateled gentrification. We demand the state provide reparations by funding Black-led community land trusts for the creation of affordable housing and commercial space in Little Jamaica.

AAHA’s manifesto is a call to action for architects and designers to take an active role in addressing the housing crisis in Canada. Architects, whose work helps shape our future way of life, can use their skills and expertise to promote principles of affordability, inclusivity, and sustainability – working collaboratively to create the political will, economic and policy frameworks, and designs for housing that are socially, ecologically, and creatively empowering for all.

To learn more and join the campaign, visit www.aaha.ca

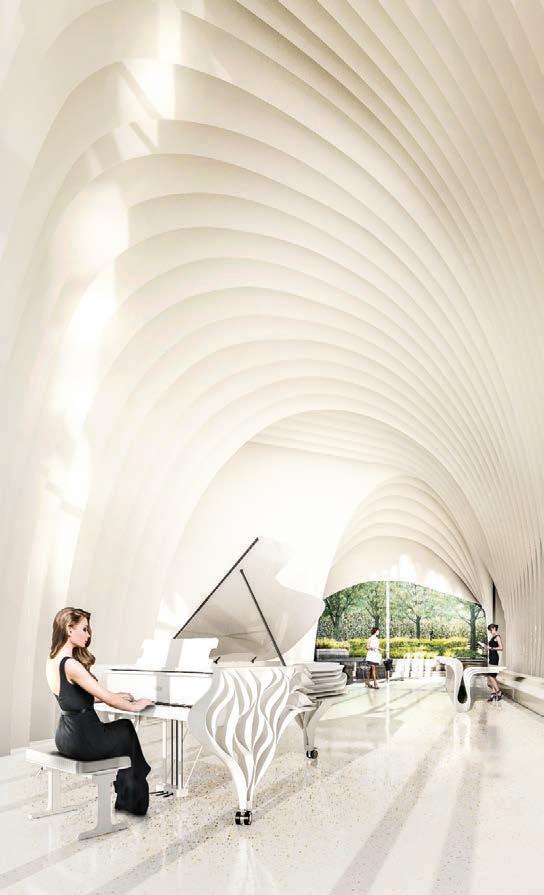

Better Than Today Making Tomorrow

With its new rebrand, Metafor honours its past while embracing a brighter future

by NATALIE BRUCKNER | photography courtesy METAFOR

Design, like everything in life, is in a constant state of evolution. It is this transformative process that enables architecture to affect society in a profound and meaningful manner, sculpting our built environment and forging deeper connections with its inhabitants. To meet the constantly evolving needs of society, architecture must constantly innovate and adapt – a sentiment that resonates deeply with Calgary-based Metafor.

Last year, Metafor (formerly MTA and Marshall Tittemore Architects, respectively) found itself at a crossroads, with a unique opportunity to leverage its extensive 22 years of experience in a variety of settings, from urban and rural areas to Indigenous lands and city districts throughout Western Canada. Moreover, the studio had forged strong partnerships over more than two decades with national and international architectural firms and clients, resulting in numerous award-winning and world-class projects.

At the core of Metafor’s human-centric approach lies a deep sense of responsibility to create a more inclusive and accessible society for all, while simultaneously ensuring the longevity and resilience of their designs. Metafor is dedicated to utilizing their craft as a means of shaping a socially just, more sustainable future for generations to come.

Upon getting to know the team at Metafor, it becomes evident that their driving force is a deep-seated commitment to doing what is right. This sense of loyal

stewardship stems from their unwavering commitment to the community. With a steadfast focus on physiological and psychological health and safety, as well as proven sustainable practices, Metafor elevates these concepts as a cornerstone of their design philosophy.

In keeping with the concept of evolution, Metafor has this month undergone a purposeful rebrand that involves not only a change of name but a new identity, message, and mantra. This rebrand reflects the studio’s desire to better define its core values, vision, and niche.

With this impressive legacy and brand equity, Metafor was determined to build upon its momentum under new leadership and capitalize on untapped business potential. Thus, the studio embarked on a rebirth to honour its past, while embracing a brighter future.

Metafor has always been known for its visionary approach, but with the rebrand it now has a clear direction for the challenges ahead. With a renewed focus on socially and sustainably-focused projects, the company is poised to lead the way towards a better future. The leadership team’s unwavering commitment to these values is evident in their ambitious goal to collaborate on such projects by 2029 – a timeline that aligns perfectly with the broader 2030 goals set by the Canadian government and private development firms. By building on its past successes and taking bold steps towards a sustainable future, Metafor is demonstrating its leadership in both the business world and society at large.

“As architects we have the opportunity to affect actual change within our community and society as a whole, by listening to our clients’ needs, being collaborators, and understanding the challenges they face as they fulfil important mandates within the communities in which we live, work, and play in. We realized that Metafor is more than architecture – we believe in being collaborators, truly integrating design, sustainability, and building science to achieve superior results. Social change and sustainability are here to stay, and we are embracing the new thinking required and how we can make tomorrow better than today,” explains managing principal Claudia Schaaf.

Metafor’s commitment to creating a socially just, culturally rich, and ecologically restorative world is more than just words. Due to their collective success in establishing mutual trust among themselves, their clients, and the communities they serve, Metafor has been designated a Just 2.0 Organization by the International Living Future Institute – a transparency platform for organizations to disclose their operations, including how they treat their employees and where they make financial and community investments.

“Pursuing the Just 2.0 Label allows us the foundation to pursue all aspects of our work with a more defined sense of purpose,” says principal Jeff Lyness. “Sir David Adjaye’s statement ‘made by the people waiting for it’ embodies our belief that design team members are a community of professionals designing for a community of people. We care about who we work with, and for, and are a making a commitment to engage in an open and transparent process of collaboration and education. Sharing knowledge openly is key to success for us.”

The company’s unwavering dedication to sustainable design, community place-making, and adaptive building is reflected in its impressive portfolio of projects. Two notable examples are The Performing Arts Theatre of Hinton (PATH) and the ROAM Transit Operations and Training Facility.

The former is a great example of adaptive re-use in a community. Despite initial uncertainty about its fate, Metafor principal Mike Woodland’s innovative approach to reducing waste and carbon footprint proved that the building could be transformed into a multi-use Performing Arts Theatre, as well as FCSS offices and Guild Art Society. The result is a testament to the power of sustainable design and how overlooked opportunities can be leveraged to bring new life to old buildings, while providing essential amenities that attract and retain residents in the town.

“The profession of architecture is evolving and requiring us to be stronger stewards of the environment, think about equity of design in our communities and accessibility to all, while also making sure we are providing a high level of value to our clients by helping them understand that meeting ESG goals is good for their business, good for the community, and good for the environment,” says Woodland.

While very different in nature, ROAM in Banff is another great example of a Metafor community-driven project. The project was designed to house an expanding transit service with a high degree of sustainability that would meet the town’s greenhouse gas (GHG) reduction policy goals. The design-build project

incorporates innovative features, such as an electric bus fleet with charging stations powered by a large rooftop PV array, and a low-carbon district heating plant that uses waste biomass from Parks Canada as fuel. The design is simple yet stunning, seamlessly blending with the surrounding natural environment while meeting the town and Parks Canada’s design guidelines and mountain theme.

The outcome is an inspiring showcase of renewable energy solutions that respect the pristine mountain environment, while demonstrating the community’s commitment to reducing GHG emissions. In recognition of its climate leadership and optimal building performance, the project won the 2022 CaGBC Zero Carbon Design Award.

This deep sense of community and sustainability lies at the heart of each and every Metafor project. For example, Bridlewood Affordable Housing prioritizes the environment and the needs of the community; Clifton House is stand-out in that it has been designed in a collection of small neighbourhoods that promote flexibility and connection; and the stunning three-storey wood frame Lookout Ridge has been designed to blend seamlessly with its surroundings, while offering residents a private amenity landscape and lookout feature with breathtaking views of Stewart Creek in Canmore, Alberta.

And while the team already has an impressive track record, Metafor is poised to take on even greater challenges and breathe new life into communities with their upcoming projects. “We’re excited to take on the challenges coming our way and explore new opportunities where our expertise can be both valued at the same time as being challenged for growth,” says David Leonard, principal at Metafor. Those opportunities include projects such as Deer Lodge in Lake Louise, Cascade visitor accommodation, CRPS Land Use and ARP, and the purpose-built rental 900 Railway Avenue.

While Metafor has been a trusted industry leader for many years, their recent rebranding marks an exciting new chapter in their journey, empowering them to continue to push the boundaries of what’s possible. “We’re asking ourselves questions that perhaps haven’t been asked before and then asking, ‘what’s the worst that can happen if we try?’ And, ‘what is the worst that can happen if we don’t, and can we live with that?’ The new brand gives us a platform where our values can be rooted but the brand will evolve with our firm over time into the future,” says marketing and communications lead, Monica Silenzi.

As we look to the future, we can expect a multitude of even more remarkable accomplishments from Metafor and its community. Chris Sparrow, Metafor principal, concludes, saying: “I’m excited about the way architecture can contribute to the experience and sense of place of a community, and have a positive impact on the users, inhabitants, and visitors of those places. As the communities and municipalities we work in evolve, the buildings we design and the fabric of the communities they form part of change. We take great pride and responsibility for the role our firm takes in creating and defining the experiences of these places for future generations. Simply put, let’s make tomorrow better than today.” A

Clifton House, Calgary, AB

Bridlewood Affordable Housing, Calgary, AB

The Performing Arts Theatre of Hinton, Hinton, AB

Total Precast Concrete Key Attributes to Passive House Development are:

· Manufactured in local precast facilities under controlled conditions

· The whole building envelope in one composite panel; air barrier, moisture control, insulation and the structure

· Hollowcore floor slabs allow for a much lower depth to span ratio

· Hollowcore provides the lowest GWP per m2 of concrete floor area

· Precast concrete dramatically reduces the construction schedule, site congestion, noise and environmental impacts

For more information and educational presentations check out Learn on Demand, a 24/7/365 Educational Platform. Visit: cpci-learnondemand.com/

For more information on Passive House Total Precast Concrete, visit www.cpci.ca/publications to download your free copies of the Structural Solutions Guide and the Putman Family YWCA Total Precast Concrete Case Study.

Project: The Putman Family YWCA, Hamilton, ON Architect: Kearns Mancini Architects Inc., Toronto, ON

THE BUILDING BLOCKS OF CONSTRUCTION

Precast concrete industry advances sustainability with innovative techniques and partnerships

by ROBIN BRUNET

With sustainability in the construction sector continuing to be a vaguely defined value at best, it’s no surprise that the precast concrete sector is singled out by some as a major contributor to carbon emissions. Fortunately, many people in the sector are fighting back, and their arguments for the use of precast as a sustainable building material are compelling.

John Carson, executive director at AltusGroup, says, “There’s lots of discussions about cement being a high carbon material, but concrete buildings last an awfully long time, several hundred years or more if constructed properly.”

Carson offers practical advice to carbon-conscious designers. “The best way to reduce the embedded carbon in a precast concrete wall panel is to reduce the amount of cement used. CarbonCast panels with carbon fibre grid reinforcing and integrated insulation can reduce concrete use by 30 percent or more compared to solid panels. Also, the thermal efficiency of the panels results in higher R-values than other technologies, which reduces operational carbon.”

Carson adds, “While continuing to come under attack from wood enthusiasts and environmentalists for its carbon dioxide [CO2] footprint, the concrete products industry has made significant strides in CO2 reduction. Today, CarbonCast precast concrete enclosures using composite design remain one of the most effective ways to create long-lasting fire safe structures, and we have been doing so for nearly 20 years.”

As for the state of the precast market in 2023 overall, Carson says, “The North American market remains robust, and some precast producers are booked into 2024. Novel architectural facade aesthetics, unique structures, and mixed-used projects including retail, housing, and parking are drivers. Data centres and distribution continue to lead precast growth in select metro regions.”

However, he adds that while few projects have cancelled as a result of rising interest rates, “it remains an industry concern. Inflation and rising material costs, increased labour cost, and material supply chain are still key concerns. Global cement supply and type is a primary concern to precasters currently.”

Lafarge Canada has made a huge commitment to achieving sustainability across its production facilities and with its products. Its latest initiative is an agreement with TransAlta Corporation (which owns, operates, and develops a diverse fleet of electrical power generation assets in Canada, the U.S., and Australia) to advance low-carbon concrete projects in Alberta.

The new project will repurpose landfilled fly ash, a waste product from TransAlta’s Canadian

coal-fired electricity operations west of Edmonton, which ended in 2021. The ash will be used to replace cement in concrete manufacturing.

Landfilled fly ash must first go through a beneficiation process in order to be used in concrete; this project will utilize the Ash-TEK Ponded Ash

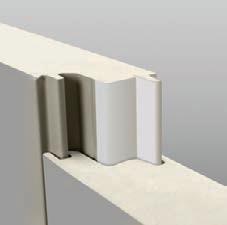

Monolith concrete insulated panel tilt-up system.

CarbonCast High Performance Insulated Wall Panels.

Transformation that’s more than skin deep.

Lehigh Hanson becomes Heidelberg Materials

We at Lehigh Hanson are pleased to join our global parent company in transitioning to Heidelberg Materials. Our entire North American family of brands is united under this new banner while remaining focused on what we do best: heavy building materials.

While this rebrand is an outward change, it represents a deeper transformation in our company. An evolution that has both responded to — and shaped — our industry.

It reflects a much broader and innovative approach to serving you, our customers, as we lead the industry in sustainability and digital solutions. Material

Beneficiation System (PABS) technology, which consistently produced high quality ash during trials and is said have a low carbon footprint and an economical operating cost. Lafarge will deploy this unique approach to the process, removing moisture from the ash, milling it, and removing excess carbon in order to ensure it meets regulatory standards as well as market expectations.

Brad Kohl, president and CEO, LafargeHolcim, Western Canada, says, “We recognize that seizing opportunities to optimize cement is a key part of our CO2 reduction strategy … there is great potential in repurposing materials across the construction value chain; transforming landfilled material such as fly ash into a usable product for construction is a winwin solution for all of us.”

Heidelberg Materials’ contribution to the cause of sustainability most recently took the form of announcing the successful completion of a memorandum of understanding with the Government of Canada. The partnership will support Heidelberg developing a full-scale Carbon Capture Utilization and Storage (CCUS) facility at the company’s Edmonton location.

The new facility is expected to be operational by late 2026 and will capture more than one-million tonnes of CO2 annually from its Edmonton cement production facility. “Our Edmonton CCUS project, as the world’s first carbon neutral plant, is another milestone in Heidelberg Materials’ ambitious drive to lead the industry to net zero, and we’re excited to begin realizing this as soon as possible,” said Chris Ward, president and CEO of Heidelberg Materials

North America. “We are fortunate to partner with the Government of Canada in this endeavor and we look forward to continued collaboration as we move forward with this exciting project.”

One of the biggest advocates of the concrete sector is Brian Hall, managing director at the Canadian Precast Prestressed Concrete Institute. When asked to assess industry activity in 2023 to date, he replies, “Sustainable and resilient architecture and construction are now more critical than ever before, and as the frequency and severity of climate-related disasters increase, the economic and human cost to respond to and recover from those disasters is increasing.

“We know we can’t change the weather, but we can change how we build. By adding resilience to the tender progress, we can build structures that can withstand disasters or, at the very least, recover from those disasters quicker and with less economic impact.”

Hall notes that prefabricated construction is growing rapidly due to the lack of skilled and unskilled workers. “Modular, or prefabricated precast construction presents many benefits, including quick and more resilient construction, while maintaining aesthetic versatility. The precast industry recognizes the importance of decarbonisation and the importance of resilient architecture and construction; as such, we’re developing our 2030-50 Roadmap in consultation with industry and regulators.”

Some companies in the precast realm are rebranding in 2023 to attract more sustainability-based business. NZ Builders, a custom home building company based in Victoria, B.C., recently

Resilient precast architectural panels.

CarbonCast ® enclosures with C-GRID ® carbon fiber grid shear connectors offer a combination of benefits unmatched by any other insulated precast wall system:

n Full composite action for load-bearing performance and a thinner interior wythe for weight reduction

n Continuous insulation (c.i.) to meet the National Energy Code of Canada for Buildings

n Your choice of EPS, GPS, XPS, polyiso or phenolic insulation depending on your preference or R-value needs From thermal efficiency to remarkable aesthetic versatility, the choice is clear: CarbonCast.

Available from our Canadian AltusGroup members altusprecast.com 866-GO-ALTUS

unveiled a new logo and look, while retaining its commitment to quality craftsmanship and service.

The rebranding was done to attract a niche clientele interested in building sustainable, architecturally stunning homes that last and look incredible, as well as attract architects who are interested in pushing the boundaries of building science. Conversely, NZ has stated that it will no longer take on jobs that do not fit its design/construction niche.

The rebrand reflects a shift to focus solely on durable, high-performance custom homes and upgrades that consider future climate and energy costs. NZ founder’s Damon Gray notes that more homeowners and builders will need to factor in these considerations as the BC Building Code’s Step

Code 5 requirements come closer to taking effect in 2032. “We can still build architecturally stunning homes that push the envelope of building science, while creating something sustainable,” he says, “It’s far easier to upgrade your kitchen or finishings later when you have the extra budget, but if the foundational structure of your home is deteriorating, that’s a much bigger and more costly fix.”

Gray is known in the concrete realm for coming to Canada from his native New Zealand and realizing, after performing dozens of costly renovations on young homes that had deteriorated due to rot and mould, that B.C.’s climate required more than traditional building techniques. This led directly to the development of a concrete insulated

panel (CIP) tilt-up system called Monolith for residential construction, with Gray’s own home being the test project and subsequently receiving accolades for being the first net zero-ready residence on Vancouver Island.

Since then, Monolith Systems (an NZ sister company) provides concrete insulated panels for homes built using tilt-up wall systems and helps connect architects, designers, builders, and homeowners looking to build unique and elegant homes they can enjoy for generations.

Gray says, “Everybody deserves to live in a healthy, comfortable home, and we feel it’s our responsibility to educate our clients about how the decisions they make in the initial stages of building will help protect the health of their family and their investment long term.”

Jason Stubbe, managing director at Stubbe’s Precast, reports that because high interest rates have negatively affected Ontario’s residential condominium market (which represents his company’s traditional work), operations have pivoted to take advantage of the province’s robust warehouse market.

This continues to be an ideal venue for Stubbe’s structural wall panels, double tees, columns, and beams. “Clients are looking for rapid construction, especially in 2023 with costs being the way they are,” he says. “With our products and expertise, we’re able to get the job done twice as fast, with a variety of finishes for all-weather installation.”

However, Stubbe predicts the residential market will heat up again soon. “We’re doing a ton of quoting, and the demand for new housing is intense,” he says.

Applying the final touches to a precast concrete panel installation.

And when that happens, Stubbe’s Precast will offer even more efficiencies to clients. The company’s new fast track modular precast service speeds up the process of development and construction of residential mid-rises by predesigning modules using a BIM driven process. The outcome of this is standardized units that have been fully designed with input from all stakeholders and trade specific drawings.

Also, Stubbe’s Precast now offers a unique box shaft solution. Following the tradition of precast products, this is the company’s answer to cast-inplace stairwells and elevator shafts, designed so they can be fully installed in the early stages of a wood or steel building construction. They also boast the accuracy, strength, and quality that Stubbe’s is famous for.

Peikko, which supplies a large selection of concrete connections and composite beams for both precast and cast-in-situ solutions in a wide variety of applications, continues to enjoy high demand of its Deltabeam Slim Floor Structure. This composite beam is a great alternative to post-tension flat slabs and enables slim floors for multi-storey buildings of any type, whether low-rise or high-rise.

The composite action between steel and concrete allows Deltabeam to easily span over 30 feet between columns. And since Deltabeam is often utilized to support pre-stessed hollowcore slabs, the spans

perpendicular to the beam can even go beyond 40 feet. The long spans in both directions mean that less columns are needed on the floor plate, and a floor layout with less columns allows for floor plans to easily be altered to suit the varying needs of tenants.

Mark Johanson, business development, Peikko, says, “Deltabeam is typically being combined with precast structures and even mass timber buildings, and currently Ontario and Manitoba are especially busy with a host of projects. Examples include affordable and long-term care housing, and a high-rise in St. Catherine with deep steel decks. In Winnipeg we recently completed a 43-storey building, and many more projects are coming down the turnpike.”

Not only does Deltabeam’s shallow design decrease a building’s floor-to-floor height, while eliminating conflicts with HVAC systems, Underwriter Laboratories (UL) fi re tests have proven it also has excellent fire resistance without any additional protection. A

Precast box shaft installation.

Installation of a long-span Deltabeam Slim Floor Structure.

Dare to Accelerate Change

BUILDEX

Aim High

Roofing and cladding trends for 2023 and beyond

by ROBIN BRUNET

Given that the look of a roof can make or break any property’s curb appeal, the goal for developers should be to aim high: that’s the message of BP Canada (Building Products of Canada) in announcing roofing directions for 2023 and beyond.

Topping the list of on-trend roofing colours is grey, but not the standard grey; instead, nuanced grey-beige or “greige,” infused with a mix of nature-inspired tones. “Black roofing shingles have always been seen as a safe choice for consumers, but now people are starting to realize that softer neutral shades like grey can actually add more wow-factor to a home’s exterior,” says BP Canada’s marketing director Nathalie Lambert.

Although black is still the company’s top-selling shingle, grey shingle sales have increased in popularity over the last year, especially in Western Canada, and Lambert attributes this to the end of the pandemic. “Consumers tastes are changing as they look for finishes that exude a sense of calm and security. They want the best of both worlds: a balance of traditional and contemporary, soothing and invigorating, sober and bold, and a style that asserts individual personality.”

In response to changing market preferences, BP Canada has launched a multi-toned pale grey shingle called Morning Mist. Part of the brand’s Mystique Collection, Morning Mist is the first shingle colour of its kind, consisting of grey, white, and brown, and providing consumers with an alternative to traditional solid grey options.

Lambert cites other aesthetic trends in the roofing market, including the pairing of shingles in shades of black, brown, and grey with white vertical siding and dark accents to achieve a contrasting effect (increasingly popular in new construction). “Conversely, blending dark siding with pale finishes creates an equally harmonious contrast.”

Lambert predicts that trends for the next few years will shift toward richer, deeper shingle colours. Also, she encourages developers to select highperformance products that provide maximum resistance and protection against high winds and wind-driven rain, ice build-up, and hail. “No matter what style you prefer, it’s important to choose a roof that’s made to stand the test of time,” she says, noting that today’s high-performance shingles are made to withstand hail the size of golf or billiard balls, as well as category four hurricane winds.

Morning Mist shingles from BP Canada’s Mystique Collection.

Jeff Ker, senior technical advisor at Engineered Assemblies, points out that the goals of beauty and visual appeal in the roofing sector should apply to cladding as well. And with Engineered Assemblies being the Canadian distributor of Frontek, the cladding market – especially in the commercial sector – has an uncommonly resilient panel that is also startlingly beautiful.

That’s because Frontek is made of extruded porcelain, which has many benefits in its own right, plus it’s augmented with a 19-millimetre (mm) thickness and is ported (hollowcore). Ker says, “The combination of all those elements makes for a truly special panel. Its thickness is the solution to other panels that are typically six to eight mm or even thinner, and provide little to no impact resistance. The hollowcore adds to the structural integrity, and it also hides the attachment clips that are truly unique to Frontek.”

This is a fully mechanical hanging system, absolutely no adhesives are required, and this means two things: extreme ease of installation, plus unlike cladding systems requiring adhesives it can be installed in adverse weather conditions, which is a huge benefit to developers. While porcelain cladding has been making inroads in the Canadian market over the past 10 years, all of them use adhesive, so this is a game changer.

“Additionally, Frontek is graffiti resistant, the colours won’t fade, and it complies with rainscreen design. It is available in one-by-three metre sheets, which is an important consideration for the architectural community.”

Frontek originates from Spain-based Greco Gres Internacional, a conglomerate of companies with a longstanding ceramic tradition dating back to 1940. The Frontek Inside and Outside System offers a dynamic multi-layer surface on any façade, without the requirement to modify the substrate. With inner and outer pieces in two different layers, this solution adds a volumetric and sculptural effect to the façade. Also, the use of porcelain panels reduces air conditioning and heating consumption by up to 35 percent and also act as insulation against sound and solar radiation.

Frontek has been used in numerous projects across Canada of late. “We’re just finishing projects in the Maritimes and other climate aggressive regions, for commercial facilities where minimal maintenance is required over the long haul,” Ker says. “In general, I think Canada is embracing the fact that you have

Frontek extruded porcelain panel with its fully mechanical hanging system from Engineered Assemblies.

Manoir – Vienna

to invest in high quality products in order to avoid unnecessary maintenance and repair. It sounds obvious, but it’s easier said than done.”

Vicwest, the metal roofing and cladding specialist, is deeply committed to sustainability, making the most of the fact that most steel products contain upwards of 80 percent recycled content and are infinitely recyclable at the end of their life. The company has reduced the amount of waste they produce that goes to landfill to 60 percent, with the remaining 40 percent being recycled. All of its scrap or defective steel is being recycled and reused, and it has taken other initiatives such as installing rainwater harvesting capabilities at its facilities and redesigning its transport crates to use less lumber (which has also proven to be a benefit for fuel efficiency as it lightens the weight of transport trucks).

Almost inevitably, products from major manufacturers that are released in the U.S. eventually are introduced into the Canadian market, which is why a new release from Carlisle SynTec Systems is worth keeping an eye on.

Carlisle has been the leader in the commercial single-ply roofing industry for more than 50 years. It transformed the commercial roofing industry with the introduction of its Sure-Seal EPDM single-ply membrane, and today its product offerings in addition to Sure-Seal include Sure-Weld TPO, Sure-Flex PVC, and FleeceBACK membranes.

In the U.S., Carlisle’s introduction of the industry’s first-ever 16-foot-wide TPO sheet brings labour savings and enables crews to get more done in less time. With fewer rolls to load onto the roof, less time spent positioning and kicking out rolls, and fewer seams to weld, 16-foot wide TPO is the fastest way to install adhered and induction welded TPO roofs.

Sure-Seal EPDM single-ply membrane.

Completed Sure-Seal EPDM roofing project, Centreville School, Centreville, ON.

Installation of Sure-Seal EPDM.

Loading and staging a job often requires significant crane time and co-ordination. Regardless of a roll’s size, it must be moved into position, kicked out, and aligned before it can be adhered or secured in place. But every time a 16-foot roll is kicked out and positioned it covers 60 percent more roof area versus a 10-inch by 100-inch roll. Also, the bigger rolls cut down the number of seams, saving significant welding time, installing T-joint patches, and inspecting and probing at the completion of the job. Plus, fewer rolls on the job means less packaging and core waste to dispose of compared to smaller sheets.

Finally, what lies ahead for the roofing sector in terms of technological evolution? That was something Soprema recently discussed with the Canadian Roofing Contractors Association, Flynn, Rogers, and other professionals, given that Soprema – which specializes in waterproofing, insulation, soundproofing, and vegetated solutions for the roofing, building envelope, and civil engineering sectors – wants to continue to actively contribute to the development of the construction industry by investing in research and development as well as in education in order to transform the roofing industry.

Soprema states, “One of the most important changes today is undoubtedly the interest in flameless products. These solutions, in addition to being highperformance products, are also safer for workers and the environment.

“Through discussions with several key industry players, we want to help change and improve industry practices to reduce the risks associated with works on commercial roofs. We believe that by driving discussions around flameless technologies, we will be able to demystify and encourage their use,” Soprema states on its website.

Soprema has designed a range of low-temperature products, including highperformance waterproofing membranes that can be installed during all seasons and without the use of propane-powered tools. SBS-modified roofing systems are the popular choice for low-slope commercial, industrial, and institutional buildings, while the SopraSmart family of laminated boards, high-performance membranes such as Colply Base 410 and adhesives such as Colply EF all fall under this category, for projects where the use of a flame is not permitted or desired such as hospitals or schools. A

Soprema’s low-temperature flameless products, including SBS-modified roofing systems, Colply Base 410 membranes, and Colply EF adhesives.

The True GAME CHANGER in

the Siding Industry

We design, engineer, manufacture and install Wood100®DLT, a 100% wood, no glue DLT

> A truly healthy, sustainable and energy efficient building product.

> Collaborating with architects on detail solutions across the design process.

AgainstThe Grain

The rise of engineered wood products following an unpredictable market

by NATALIE BRUCKNER

Despite facing market uncertainty, misconceptions, and supply chain challenges over the past few years, the engineered wood industry has emerged stronger than ever before.

B.C. has established itself as a leader in mass timber construction, having constructed several notable buildings using this sustainable material. In fact, in 2022, the province built more mass-timber wooden buildings than almost the entire U.S. combined.

Several B.C. companies, including StructureCraft in Abbotsford, Kalesnikoff in Nelson, and Structurlam in Penticton, have been gaining attention for their production of mass timber. These companies primarily source their wood from second-growth forests in the Interior. As demand for sustainable materials continues to increase, particularly in the education sector, the cross-laminated timber (CLT) market is expected to experience significant growth. Shawn Keyes, executive director at Wood WORKS! BC Canadian Wood Council, says the advent of Encapsulated Mass Timber (EMTC)

construction type in the building code, which allows buildings up to 12 storeys, is one reason for this growth. However, he adds that despite the potential of this new typology, “some challenges to adoption still exist.”

Keyes explains: “Beyond the learning curve associated with any new construction approach, one of the primary obstacles is zoning. As it stands, very few structures in B.C. fall within the sevento 12-storey height range, which currently limits the potential of this new category of building. The financial incentive is typically to construct as tall as possible on a given site to maximize returns, particularly in the Lower Mainland. We can continue to push towards taller buildings via alternate solutions and new code provisions, however, these approaches will take time. For an immediate impact, municipalities must consider zoning for the missing middle six- to 12-storey heights allowable by code so that greater density can be achieved while building with wood.”

There are number of exciting projects happening in B.C. of late, including the BCIT Tall Timber Student Housing project that is currently under construction and the 837 Beatty Street Rehabilitation project, which involves adding a four-storey mass timber office building to an existing heritage structure constructed in 1911. “This project takes advantage of wood’s light weight and offers a sensitive approach to preserving, adapting, and expanding a local heritage building, while avoiding the carbon emissions that would result from demolition. It is a useful case study for developers and engineers interested in reducing the costs of upgrading existing buildings to accommodate additional storeys, particularly heritage buildings requiring rehabilitation. As our infrastructure continues to age, solutions for reusing building components and avoiding material waste will be essential,” says Keyes.

As for the future, Keyes is excited about the potential that engineered wood buildings offer in addressing some of the most pressing societal challenges. “The rising cost of living and inflation has made it increasingly challenging for individuals to reside in our province. However, engineered wood products present a prefabricated form of construction that can provide a viable solution by rapidly delivering the housing that our province so desperately needs,” Keyes says.

Kinsol Timber Systems is also thriving in the North American market, with contracted revenue at an all-time high. To meet the growing demand, the company is building a new factory on Vancouver Island that will manufacture Nail Laminated Timber and add capacity to the market. The factory is expected to be operational by April 2024.

Mass timber is already well-known as an innovative building material, but new applications for it continue to emerge. For example, Kinsol is using mass timber for vertical applications like sheer walls, stair cores, and elevator cores.

Kinsol’s work on The Malahat SkyWalk project demonstrates the versatility of mass timber. It features a single-storey Visitor Center, a 600-metrelong elevated Boardwalk, and a 30-metre-high mass timber Viewing Tower. The Tower’s structural elements consist of Douglas Fir glulam columns and beams with steel connections and lateral bracing. CEO Mike Marshall, says the project is “a grade A example of how timber can be used for durability.”

WHAT’S YOUR Colour Narrative?

Urban or Rustic?

Neutral or Colourful?

Modern or Classic?

Find your Colour Narrative in our fullspectrum palette that captures more of the widely specified paint colours from across Canada, determined by our Customers and Colour Experts.

Kinsol is currently working on YouTube’s Headquarters in San Bruno, California. “The project uses glulam posts and beams and CLT panels for the floors and roof. It is phase 1 of 5 phases and adds to the growing body of work that Kinsol is doing in Silicon Valley and within the tech sector in Northern California,” says Marshall. “It’s the biggest project we’ve ever had with around 30,000 carpentry hours and $11 million in labour.”

Despite ongoing challenges with recruitment and supply, Kinsol’s COO Steve Stevenson is optimistic. “We know of multiple fronts where more suppliers are looking to open up facilities north and south of the border.” Additionally, Kinsol has a sideline product called KinsolPlay, a natural playground design-build company that is experiencing extraordinary demand. It’s fair to say, when it comes to wood, Kinsol has established its roots.

Western Archrib, a leader in the design, manufacture, and custom fabrication of glulam is yet another company that has been extremely busy of late, and according to Andre Lema, manager of business development, there are several factors contributing to this trend.

One of the main drivers is the growing recognition of wood’s carbon sequestration capabilities, which has caught the attention of government officials. “It’s just better understood now, and government is very alert to its capabilities. Also, the speed and ease of construction of mass timber buildings have become more widely understood by developers, making them an attractive option for projects. We have seen a shift where we are moving

mass timber beyond concept and trials into a more mainstream structural building product,” says Lema.

In the past, the fire durability of mass timber buildings was also a major concern for many. However, recent research has shown that they are not only safe and strong, but also resistant to fires.

Lema cites a recent testing program conducted by the Canadian Wood Council, which partnered with federal and provincial governments to conduct a series of five separate fire research burns (one being on a full-scale mass timber structure in Ottawa). The results of these tests showed that the fire performance of the mass timber structure was comparable to that of non-combustible construction in a similar fire scenario.

The primary goal of this project was to support the market acceptance of tall and large mass timber buildings in Canada and promote the adoption of the 2020 National Building Code, which includes provisions for 12-storey mass timber buildings. The fire tests had multiple objectives, including advancing building codes to permit taller and larger wood buildings.

The full-scale research fire test results showed that mass timber structures have fire performance similar to non-combustible construction, and they can withstand rare fire scenarios where the sprinkler system fails and the fire department cannot respond. During the four-hour test, the mass timber structure largely burned out within the first hour and demonstrated a quick and controlled burnout after the building’s furnishings

Bremer Bank, Minot, ND

were consumed. The structure was equipped with 400 thermocouples and radiation sensors to monitor the fire development, which helped researchers gain more insight into the nuances of fire safety in mass timber construction.

The findings have raised confidence levels in occupants, owners, and developers, confirming that mass timber can perform well even in rare cases where the sprinkler system fails and the fire department is unable to respond. “As old as the timber industry is, it feels like mass timber has just been invented,” says Lema.

As the interest in mass timber continues to escalate, International Timberframes – a leading timber frame and DLT mass timber manufacturer celebrating 20 years in business – recently announced the building of a new head office and mass timber production facility in Golden, B.C.

With support from the Government Green Construction through Wood Program, the new facility will be the timber framing workshop and production facility of 100 percent wood dowel laminated timber (DLT). DLT panels are being used as roof, floor, ceiling, and wall panels in modern mass timber construction. The production facility will also feature a new DLT press prototype that was manufactured in B.C.

Built to passive design principles and with geothermal and photo voltaic power, the facility will target net-zero carbon and implement a “whole wood” approach. In fact, 80 percent of the construction materials for the new facility will be wood-based, harvested within the Columbia Valley, reducing up-front embodied carbon and transportation related carbon emissions. Commodity lumber will be milled for structural DLT panels, wood fibre board will be used to insulate the building, and wood siding and bark cladding will be the protective outer layer. “We are extremely proud to be championing the production of this innovative sustainable DLT product right here in Golden,” says Sigi Liebmann, founder.

Francisco Villarroel, project and sales manager at Edmonton-based ACQBuilt Inc., says that while the first quarter of 2023 has been slower than usual for his company in Alberta, things are slowly beginning to pick up again.

“The Edmonton construction market really dropped in the first half of the year. There was a reduction of about 40 percent in business compared to last year, however, we saw it coming and there is light at the end of the tunnel. Demand from the rental market is picking up in Edmonton and that is pushing to offsite construction. We are also working on a lot of townhome community projects as well as four and six-storey buildings,” says Villarroel.

ACQBuilt’s innovative building process uses state-of-the-art technology and robotic machines. This construction process eliminates issues associated with outside elements, helps reduce long-term issues, and eliminates any errors before arriving on the jobsite. It also speeds up the process.

However, Villarroel says there is a misconception that less time equals less money. “Everyone wants to do things quicker and quicker, but at what cost? With offsite construction, while it is faster, there are additional costs – it won’t necessarily be cheaper. We build 3.5 houses a day and put a house up in one day, backframe it in one day, and by the third day it’s being shingled – it’s lockup stage; it’s secure and weather-tight.”

CURRENT CHALLENGES

Despite the bid cycle’s continued prolonged duration, Jason Beamish, owner of Beam Craft believes it “is something we learn to live with. The challenge that it presents specifically for the mass timber market is that wood fibre pricing is subject to price changes. This makes bidding on projects with long validity periods particularly risky for all parties including the owner [client], the general contractor, and the supplier. Cost certainty on input fibre for projects that are 12 to 18 months away from production and installation is elusive.”

Moreover, Beamish highlights that Western Canada is facing a limited supply chain for glulam and mass timber panel production, which can deter clients from pursuing building with mass timber due to the difficulties in navigating niche markets with a relatively small number of producers that are in high demand.

Despite these challenges, and in an effort to combat the concerns over lack of certification for mass timber installers in this sector, Beam Craft is currently in the recruiting process as they take on additional mass timber projects in B.C., Alberta, and Saskatchewan. Beam Craft is also in the beginning stages of a mass timber project at Simon Fraser University in Burnaby. The First Peoples Gathering House is a hybrid build incorporating glulam columns and beams, Dowel Laminated Timber (DLT) roof panels, light wood framing, and log poles. “We are thrilled to begin a new relationship with Scott Construction [Burnaby, B.C.] as they are the construction manager for the project,” says Beamish.

SOUND ADVICE

The importance of acoustic comfort in engineered wood buildings is on the rise, and AcoustiTECH has noticed a significant increase in customer awareness of this issue. According to Andre Rioux, co-owner at AcoustiTECH, they receive calls every week from people seeking help to provide more value to their clients and gain a better understanding of acoustics. “This is exciting and motivating. Acoustics is slowly but surely top of mind, as it should be,” says Rioux.

To respond to the increasing demand for acoustic solutions, AcoustiTECH has launched a new line of products designed to address vibration problems in areas such as gymnasiums, indoor pools, mechanical rooms, and elevators. This new line complements the company’s existing range of products that target airborne and impact noise.

“We have also partnered up with a Canadian company [Artopex] to offer two models of a customizable Mutebox for people to use in workspaces and common areas,” explains Rioux. The innovative product offers compact, acoustically optimized booths that can be integrated anywhere in an open area.

To simplify the often confusing world of acoustics in wood buildings, AcousticTECH has introduced a new way for developers, architects, property management companies, condo board members, and consumers to truly experience the sensory difference between ratings and different assemblies. “For the first time, people will have the proper tools to make decisions rather than relying on numbers which can too often be misleading,” explains Rioux.

“Too often professionals and developers assume condo owners or renters are not interested or willing to pay to enjoy a more comfortable acoustic environment. This is not our experience. We often hear people tell us they wish they would be either

offered a choice or would have paid a little more if it meant better acoustic comfort. This means not only being at peace at home but also being able to freely use your own space without being worried of disturbing your neighbours,” says Rioux.

PROTECTION

When it comes to protecting engineered wood products, Sansin wood coatings remains a top choice as it provides UV protection and water repellency for beauty with durability, all in a low VOC formula. One popular product is Sansin ENS, a durable two-coat finish that can be applied to virtually any surface, from windows, doors, and railings to siding and decks – and even to improve the performance of other coatings.

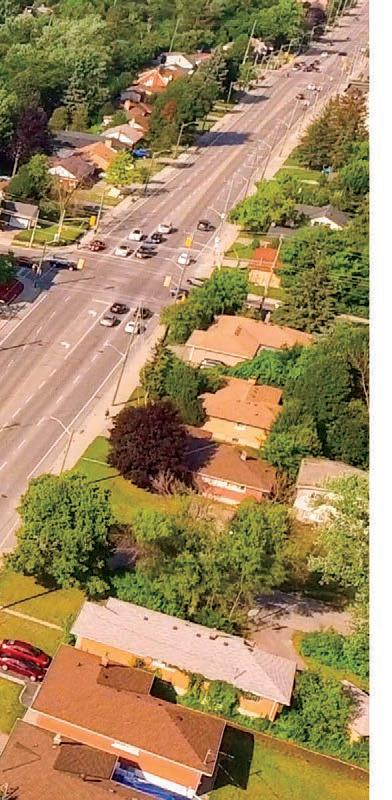

ENS is a tough, flexible finish resistant to wear, doesn’t discolour over time, and provides some of the toughest UV protection available. The exceptional adhesion characteristics of ENS – in natural, semi-transparent, and solid stains and finishes, as well as solid hide paints – raises engineered wood products to a new standard of beauty and durability. One project that utilized this product was the Smart VMC Bus Terminal in Vaughan, Ontario, which features a sustainable, innovative design that uses wood to offer a warm welcome to passengers. All of the structure’s exposed glulam beams and CLT are protected with Sansin’s environmentally friendly wood protection – one coat of KP-12W followed by two coats of Sansin ENS – adding to the project’s sustainable profile. A

Smart VMC Bus Terminal, Vaughan, ON

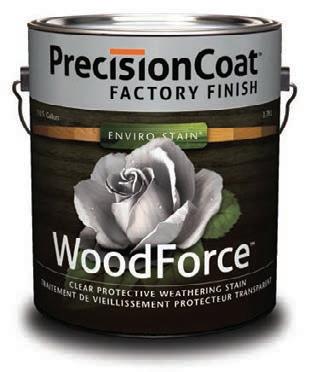

YOUR MASTERPIECE DESERVES THE BEST WOOD PROTECTION

Sansin’s WoodForce offers unparalleled beauty and protection in an environmentally friendly formula –allowing wood to weather gracefully. Contact us about our specification program so we can help you achieve the perfect finish and protection, every time.

Precision Coat factory finishes and treatments deliver the colour, transparency and performance that architects, engineers and builders can count on.

Private Residence Mallorca, Spain

DESIGNAWARDS2023 PRAIRIEWOOD

RESIDENTIAL

ThePrairieWoodDesignAwardscelebratesinnova�onandthe individualsthatpushthelimitsofdesigningwithwood.Wood WORKS! AlbertaandtheCanadianWoodCouncil,congratulateall awardrecipientsinthe2022-2023program.

Canmore,Alberta

MountainDeepEnergyRetrofit

Architect: RayniKovacs/HSSDesignBuild

StructuralEngineer: JamieFukushima

GeneralContractor: HSSDesignBuild

PhotoCredit: ThomasWaltonPhotography

INTERIORSHOWCASE

HillsideBeach,Manitoba

GreyBuffaloGrandfatherWellnessLodge

Architect: CibinelArchitectureLtd.

StructuralEngineer: BeachRockeEngineeringLtd

GeneralContractor: ThreeWayBuilders

PhotoCredit: LindsayReidPhotography

COMMERCIAL

SmokeyLake,Alberta

MétisCrossingBoutiqueLodge

Architect: ReimagineArchitectsLtd.

StructuralEngineer: RJCEngineers

GeneralContractor: GenMecACL

RECREATIONAL

PhotoCredit: Cooper&O'HaraPhotography

WatertonLakesNationalParkVisitorCentre

Architect: FWBAArchitects

WatertonLakesNa�onalPark,Alberta

StructuralEngineer: ISLEngineeringandLandServices

GeneralContractor: GrahamConstruc�on

PhotoCredit: AngusMackenziePhotography

Architect: ReimagineArchitectsLtd

NorthernLakesCollegeHighPrairieCampus

StructuralEngineer: RJCEngineers

GeneralContractor: ClarkBuilders

PhotoCredit: Cooper&O'HaraPhotography

Banff,Alberta

Architect: StructureCra�

StructuralEngineer: StructureCra�

GeneralContractor: StructureCra�

PhotoCredit: PaulZizkaPhotography

JURY'SCHOICE

RedCrowCommunityCollege

StandOff,Alberta

StructuralEngineer: ReadJonesChristoffersenLtd

GeneralContractor: ClarkBuilders

PhotoCredit: La�tude

INDUSTRYAWARD

Winnipeg,Manitoba

Architect: VerneReimerArchitectureInc

Architect: KasianArchitectureInteriorDesignandPlanningLtd

TheIntrinsicConnectionBetweenWoodandIndigenousCulture

StructuralEngineer: BeachRockeEngineeringLtd

GeneralContractor: BouchardBros2014Ltd

PhotoCredit: Sco�ZielkePhotography

SOHOCost-effective5StoryStickWoodFrameApartment

We’re finding

energy in unlikely places

Like biogas captured from cow manure to create Renewable Natural Gas1 (RNG). It’s a low-carbon energy2 that can be used in homes and businesses across the province—and we’re adding more to our supply every year.

Our natural gas delivery system can provide RNG to buildings and developments to reduce greenhouse gas emissions. This means buildings can meet strict emissions guidelines without expensive upgrades or retrofits.

Find out more about RNG at fortisbc.com/rngbuild

with us @fortisbc

A Game Changer For The Environment

Emerging topics and groundbreaking studies influencing tomorrow’s sustainable design decisions

by NATALIE BRUCKNER

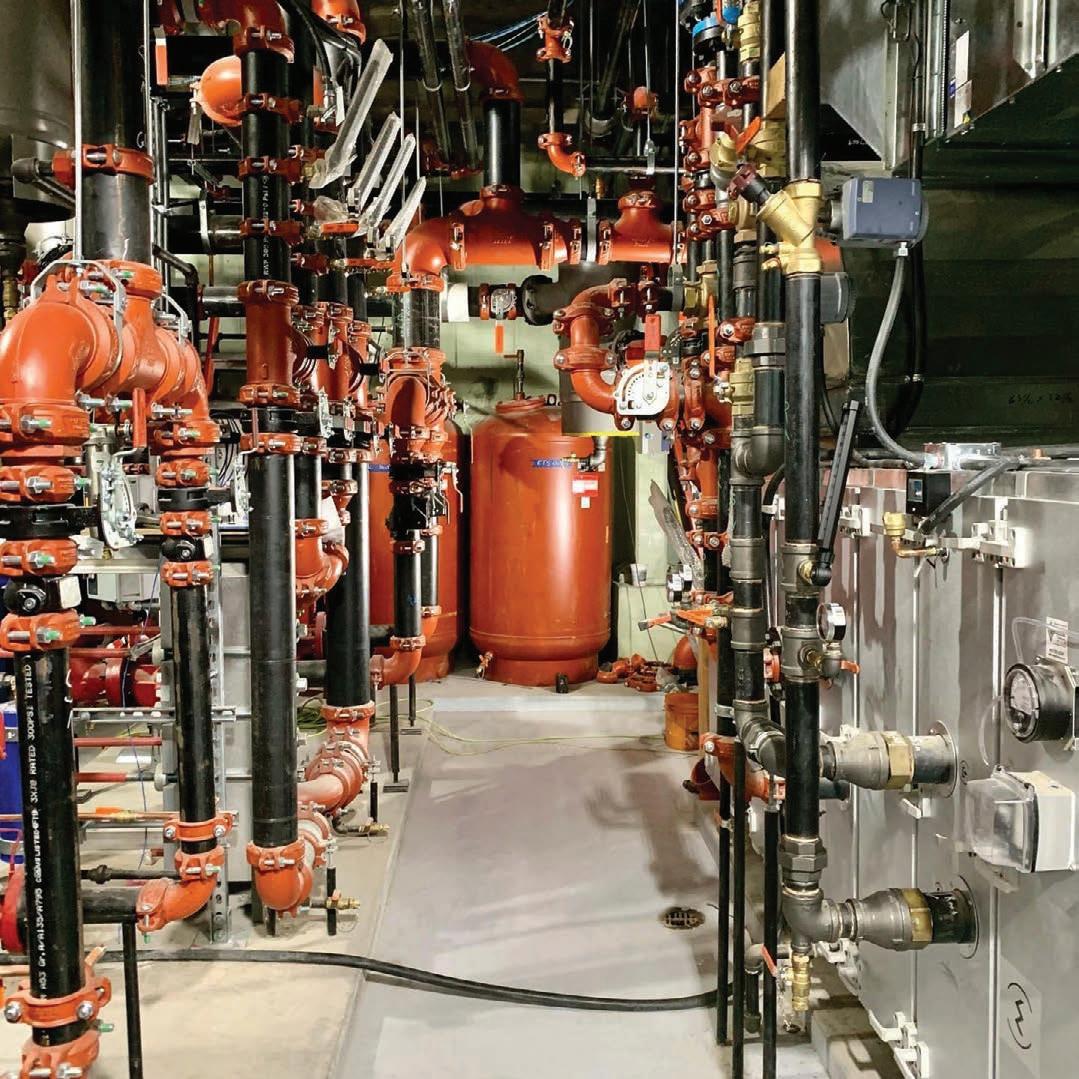

Passive House, living building challenge, sustainable and regenerative buildings these are more than just buzzwords and terms bandied around in board rooms. Today, they demonstrate the many areas being explored to achieve not just net zero energy buildings, but net positive buildings.

The world of sustainable design is one of the fastest growing movements in the industry, and thanks to innovations, new research and data, and regulatory changes, leaders in the field are staying one step ahead and helping build a far brighter future.

Take, for example, the BC Building Code that in May of this year implemented substantive changes that will impact the future of sustainable design. The new changes meant that after May, most new construction submitting for building permit in B.C. had to be 20 percent more energy efficient than base 2018 BC Building Code.

The opt-in Zero Carbon Step Code also became available for local governments to reference, starting May 1. “Improved energy performance per the Energy Step Code is now mandatory for all buildings – addressing all municipalities and regional districts – as well as activating the Zero Carbon Step Code [formerly known as the Carbon Pollution Standard], of which some municipalities are adopting this year – Victoria and Saanich being two of the early adopters,” explains Terry Bergen, managing principal at RJC Engineers.

From a standards perspective, and outside of B.C., Bergen says the CaGBC Zero Carbon Building (ZCB) standard is being incorporated into many buildings across the private and public sector and is impacting sustainable design moving forward.

CaGBC’s ZCB standards are among the world’s first zero-carbon building standards and recognize the importance of building emissions in reaching national climate commitments. The standards are considered an important tool in supporting the green building sector’s efforts to decarbonize Canada’s buildings.

“This is putting into action the technologies and approaches discussed the past few years as the design and construction sector strives to do its part in meeting Canada’s carbon reduction goals,” says Bergen.

EMBODIED CARBON

Over the last 12 months, the team at Glotman Simpson has been encouraged by the increased importance of embodied carbon data in design decisions.

Harrison Glotman, project engineer at Glotman Simpson, says that most projects that started in the past 12 months will undergo a whole building lifecycle assessment (wbLCA). “Consultants now have a plethora of programs that can be implemented through various phases of the design cycle, including but certainly not limited to OneClick LCA, Tally, and CARE. These tools, and the increased availability of environmental product declarations [EPDs], have made it much easier to quantify embodied carbon,” Glotman says.

One project of note is 365 Railway with Allied Properties REIT and Perkins + Will. The project consists of four-storeys of mass timber built on top of an existing building dating back to 1949. “Since the building was originally designed to support three additional storeys of concrete, the upgrades required to the existing building were minor. This combination of repurposing space and building in mass timber is ideal from an embodied carbon standpoint,” says Glotman.

In the high-rise arena, Glotman Simpson is excited to work with Westbank and Henriquez Partners Architects on M5 prototype, a hybrid mass timber and steel structure aimed to demonstrate how we can build tall with timber in a sustainable, aesthetic, and cost-effective manner.

As an SE 2050 firm, one of the most impactful changes Glotman Simpson has seen has been through its technical education efforts. “Internally, we’ve introduced an embodied carbon calculator into all of our structural element spreadsheets and held recurring webinars on sustainable technological advancements for our team,” says Rachelle Habchi, project engineer at Glotman Simpson. Externally, Glotman Simpson has been co-ordinating with architects and sustainability consultants early in the design process about embodied carbon implications, presenting to developers about structural solutions to mitigate GWP in structures and publishing monthly studies on how different structural systems can be best optimized for both cost and sustainability.

“Our internal studies show that, more often than not, the more structurally efficient solution ends up being the more sustainably efficient solution – building sustainably does not have to come with a significant green premium,” says Habchi.

A NEW WAY OF THINKING

The team at Williams Engineering agrees with Glotman Simpson’s sentiments and says the decarbonization of buildings continues to trend up. “We’re finding it’s included now in both new build and renovations. The Reframed Initiative that we spoke about last year with Award is a perfect example of where the industry is going. It’s now wrapping up and is transforming how the industry looks at retrofits. Not just the decarbonisation of existing buildings, but also how to eliminate climate pollution and energy waste,” says Liv Ehlert, team lead, building performance and sustainability.

The initiative Ehlert is referring to is a partnership between the BC NonProfit Housing Association, the City of Vancouver, Metro Vancouver Housing Corporation, and the Pembina Institute. It commissioned deep retrofit designs for six multi-unit residential buildings in B.C.’s Lower Mainland, Capital Regional District, and Southern Interior. The results show that the design schemes are set

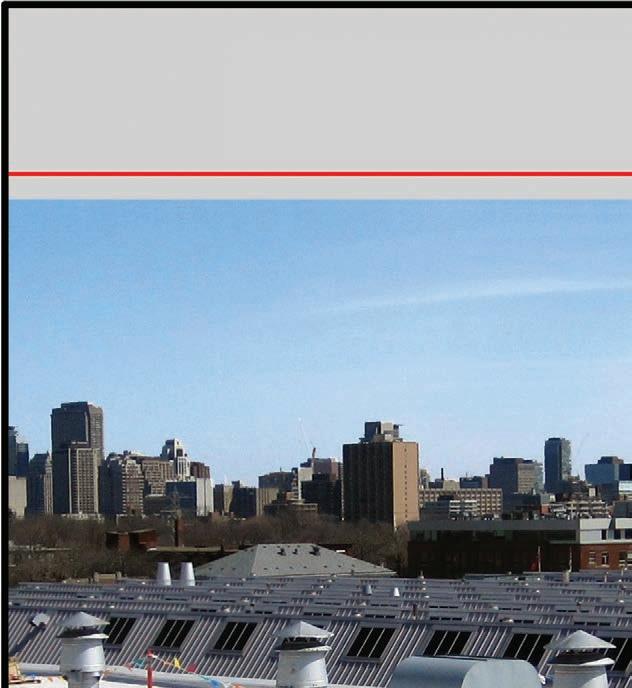

South

Niagara Hospital Project – the first WELL Accredited health-care facility in Canada.

to cut 400 annual tonnes carbon emissions, while minimizing embodied carbon inputs and making the buildings safer, healthier, and better prepared for the coming impacts of climate change.

One topic that is really taking hold this year, and one that Ehlert is excited about, is regenerative design – buildings that have a net-positive impact on the natural environment. “It moves past sustainable design. It looks at bigger system thinking and contributes to a positive change rather than keeping the status quo. The work we did on Crown Manor in New Westminster for the Reframed Initiative very much looked at regenerative design. I think it’s a term you will see being used more and more. What works today, might not work tomorrow, and this kind of thinking will help us stay ahead of the game.”

TALL BUILDINGS

WSP is well-known for its commitment to finding sustainable solutions to future challenges, and as such has once again been recognized in Corporate Knights’ 2022 list of Best Corporate Citizens in Canada – recognizing its social and environmental leadership, for the second consecutive year.

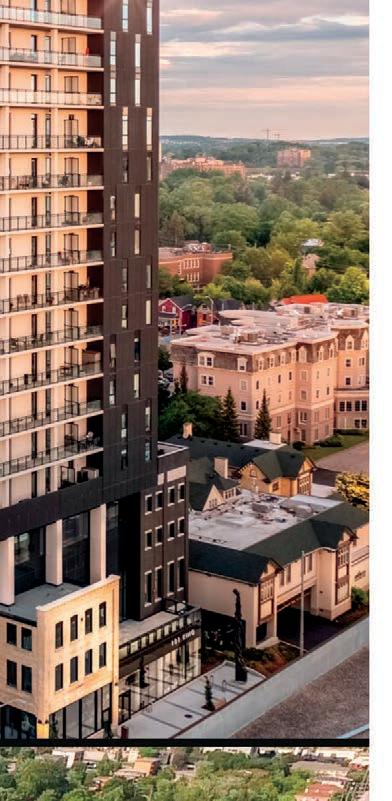

One area of focus for WSP moving forward is finding solutions to design more practical, sustainable, and livable tall buildings, and in turn reducing carbon in tall buildings.

“We must consider how tall buildings in the future can be more sustainable, and perhaps the aim in new construction will be to break new boundaries and achieve great projects that do not simply aim to achieve record-breaking heights but record-breaking results and positive impacts for communities or environment. To be using the vast amount of funds, construction materials, and expertise that large buildings require, it should now be ensured they are constructed with the future in mind, with positive impacts and outcomes secured, and without compromising the vital goal to limit global warming to 1.5 ˚c,” explains WSP.

By assessing different building types and materials, WSP has been able to demonstrate how different design parameters impact the amount of upfront carbon. Among the solutions is a focus on the most efficient methods of new build construction, the use of lower carbon materials like timber and reused steel, and best practice examples of high-rise building refurbishment and retrofit.

“Our buildings experts are constantly striving to achieve the ideal in vertical urbanism. We are committed to making a positive impact, and as such, we want to design buildings that bring so much more than just height to a city. From improving sustainability and operational performance, to nurturing occupants’ well-being and connecting communities, we all need to design and deliver buildings more holistically to create lasting value,” says Tom Smith, global director, property and buildings.

DIGITAL OPPORTUNITIES

The advancement of technology has undoubtedly played a big role in advancing sustainable design. Introba, one of the world’s largest building engineering and consulting firms (formerly Integral Group, Ross & Baruzzini, Elementa Consulting, and Elementa Engineering), is creating Living Systems that are intelligent, resilient built environments that adapt to the needs of the community, while protecting the health of the planet.

“We recognize that business-as-usual engineering will not future-proof against the impact on our planet’s resources or ensure human safety and comfort. Introba has a deep culture of creative engineering aligned with environmental and technological challenges facing their clients, projects, and society,” says Bill Overturf, president.

For Introba, focussing on the digital opportunities provides them an opportunity to create future-flexible systems that elevate the human experience, optimize system performance, and nurture the connection to the environment.

To help meet the increasing demand for sustainable design, Introba established a dedicated group of digital navigators to help clients understand the trends and create customized, adaptive technology plans that guide implementation and operations. From intelligent buildings to AI and mixed reality, digital navigators map client processes to the right technologies and systems to deliver a positive impact now and into the future.

In addition to cutting-edge design and smart technology integration, Introba remains at the vanguard of climate resilience strategy, providing proven strategic direction and engineering solutions to deliver healthy, high-performing spaces where occupants and communities can thrive.

“An integrated approach to buildings and infrastructure is essential for climate action and sustainable development. We must be on a clear path to decarbonize by 2050 and have made significant progress by 2030. Introba has the depth and breadth of expertise and experience to make real changes in our planetary future,” says Richard Palmer, director, global sustainability.

ARCHITECTURAL VIEWPOINT

Sustainable design continues to be front and centre in the health-care industry with increasing focus being placed on biophilic architecture’s benefits for wellbeing and health.

Leading the charge on this is Parkin, who recently took part in the Canadian Healthcare Facilities Decarbonizing Healthcare Research study. Different methods were considered to help reduce the fact that a staggering 5.25 percent of Canada’s total emissions are from health care.

Parkin was also recently awarded the South Niagara Hospital Project – the first WELL Accredited health-care facility in Canada. “This project will focus on promoting well-being and the health of its occupants,” explains Taraah Den Boer, associate at Parkin. “Our team is very excited to be working on this project because it encompasses both the exterior envelope, site design, and interior design of the space, with an increased focus occupant comfort and well-being.”

The government’s commitment to developing a Low Carbon Health System by 2050 has increased the literacy of low carbon initiatives within the healthcare sector, but challenges remain, such as a lack of funding for low carbon strategies, insufficient planning at early phases of design, incompatibility between low carbon initiatives and highly regulated health-care environments, and a hesitation to test innovative new technologies/care delivery models in risk-averse health-care settings.

“Only through meaningful innovation will health-care facilities be able to reach the 2050 targets. Using smaller projects, health-care facilities should be provided with the opportunities to test new technologies and partnerships, with opportunities to revise and respond to lessons learned from the adoption of new technologies, care delivery models,” says Den Boer.

Prairie Architects continues to make progress with its first Passive House project, the Bannerman Green Housing Co-op project – a community-based initiative to create zero-energy housing in Winnipeg’s St. John’s neighbourhood.

In reality, achieving Passive House certification isn’t an easy process in Canada due to the high energy performance requirements as well as the additional expense, as Lindsay Oster, principal architect, explains: “We are still in the very early stages of the Passive House project, but the project is also pursuing the Living Building Challenge through the International Living Future Institute, so there are a lot of moving parts! Building within an existing urban neighbourhood on a tight site in Winnipeg’s extreme climate leaves little flexibility in the project’s ‘energy budget,’ and so the design team is working through the many challenges.”

Once complete, the project will become a replicable prototype of a functional, sustainable housing ecosystem and a beacon of inspiration for the rental market.

Oster says that while the research and science is indeed out there to achieving a sustainable future, in all senses of the word, that “in order to move the dial in a meaningful way, certified systems and materials need to be more widely available and robust financial tools need to be accessible to owners to be able to increase performance of new and existing buildings.”

FINDING THE ENERGY

FortisBC remains committed to taking steps to help builders and developers achieve higher levels of the Energy Step Code with their new construction programs. Most recently, FortisBC completed a number of case studies with B.C. home builders to understand the tactics needed to reduce total energy requirements in new homes.

For example, Tyee Homes, a home builder in Kimberley B.C., worked alongside a FortisBC energy advisor to improve the energy efficiency in their homes. One of the homes, which was located within a seven-unit duplex development, achieved Step 5, the highest level of the B.C. Energy Step Code, by incorporating passive solar design, a high level of airtightness, and a high-efficiency gas combination space and water heating system.

The Wilden Living Lab is another excellent illustration of how FortisBC is collaborating with the building industry to create more energy-efficient homes. The combined use of Renewable Natural Gas (RNG) and electricity in the Wilden Living Lab demonstrates how both energy sources play a key role in B.C.’s GHG emissions reduction strategy.

FortisBC’s new construction rebates, such as the New Home Program that began in 2011, are helping encourage builders to create more sustainable homes with improved building envelopes and high-efficiency equipment and appliances.

In an effort to continue its goal to help reach B.C.’s climate targets, FortisBC filed an application with the British Columbia Utilities Commission in 2021 to ensure that every newly constructed home connecting to the gas system would automatically receive 100 percent Renewable Natural Gas (RNG) for the lifespan of the building. If approved, this initiative would give all British Columbians a choice for reducing greenhouse gas (GHG) emissions in their new homes. A

WEST COAST CONTEMPORARY LINE

A custom home build is quite often the single largest investment in one’s life. This is a tremendous responsibility to entrust to the construction community.

Understanding this concept and exceeding customers’ expectations are what Westeck strives for and is at the core of the Westeck culture.

BIG PRODUCTS FOR ALL SIZES EMBRACE THE PATIO EXPERIENCE INDOOR/ OUTDOOR LIVING VANCOUVER 1480 Kootenay St, 1‑877‑606‑1166 CHILLIWACK 8104 Evans Rd 1‑877‑606‑1166

westeckwindows.com sales@westeckwindows.com

Opportunity Knocks

by STACEY MCLACHLAN

For the ever-evolving door and hardware industries, opportunity is knocking once again. After a few tough years struggling through supply chain issues and rapidly changing energy codes, 2023 offers producers a chance to push the limits of entry design in exciting new directions.

Driven by technological advancements, changing consumer preferences, and environmental concerns, the latest products on the market are at once high-performance and high-impact. From smart doors to sustainable materials, from residential front doors to specialty commercial garage doors, we’re taking a closer look at the exciting innovations that are transforming the door industry – and what they mean for the future of architecture and design.

GORGEOUS GLASS

Whether for front doors, back patios, or even commercial garage-style doors, you can’t beat a glass door in 2023. “Full glass to give optimal views is the trend,” says Jon Gustad, sales director for HydAway Hydraulic Walls, which offers walls and doors for all architectural applications, with sizes available up to 36’x12’.

The door industry continues to evolve and shape building design

Don Welsh, general manager for Tormax, agrees. “We are seeing an increase in demand for all-glass automatic doors in executive style homes,” pointing to garage and pool or workout area separations, or to block off wine coolers or hosting areas.

One example of a company delivering on-trend glass door designs is Duxton Windows and Doors. Duxton offers FiberWall swinging doors and sliding doors that allow beautiful views and access to natural light. While the glass panes are transparent, the frames that hold them are a chance for designers and architects to get creative, thanks to a wide selection of colour finishes and styles. Even sage green and midnight blue are options for these premium door designs.