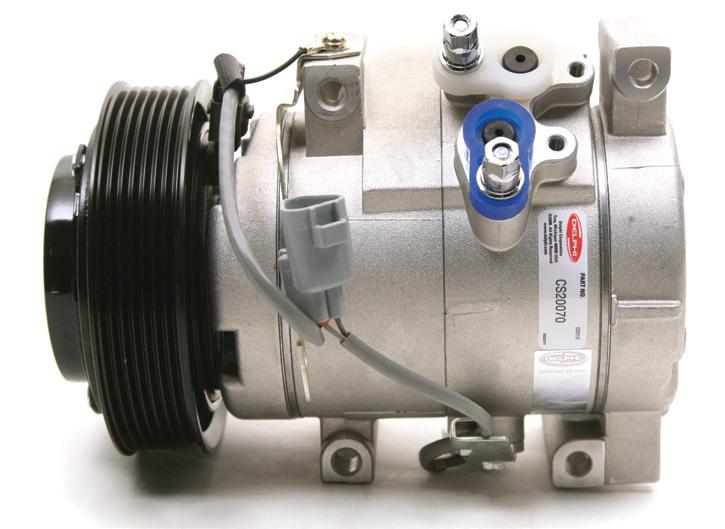

LOOKING AFTER YOUR CUSTOMERS’ AIR CONDITIONING NEEDS

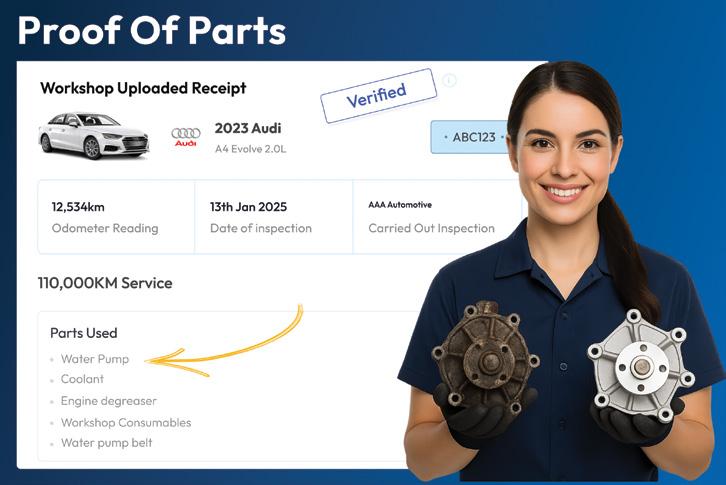

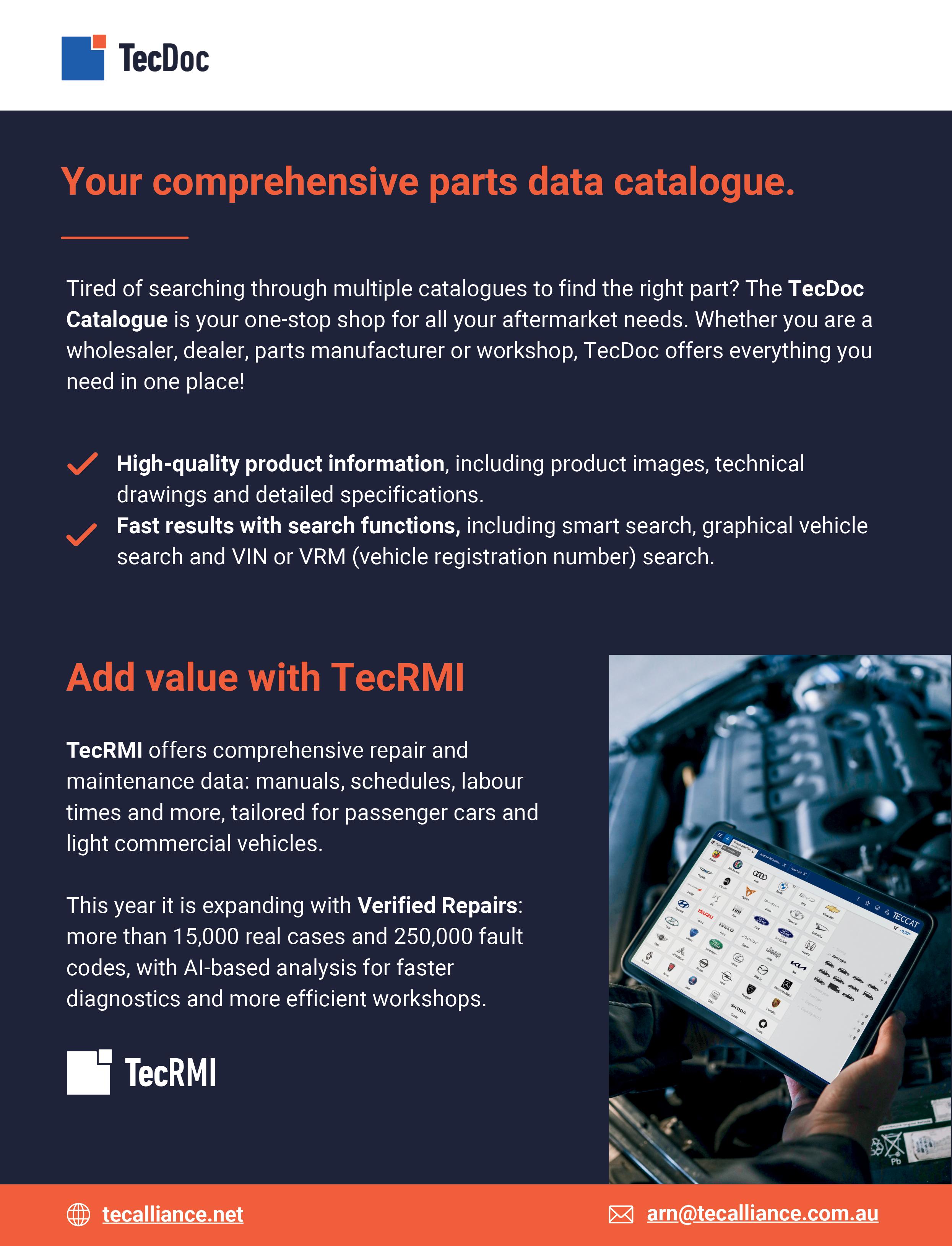

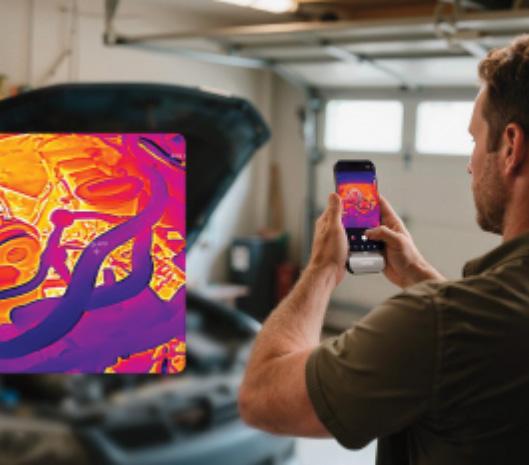

THE FUTURE OF CAR MANAGEMENT

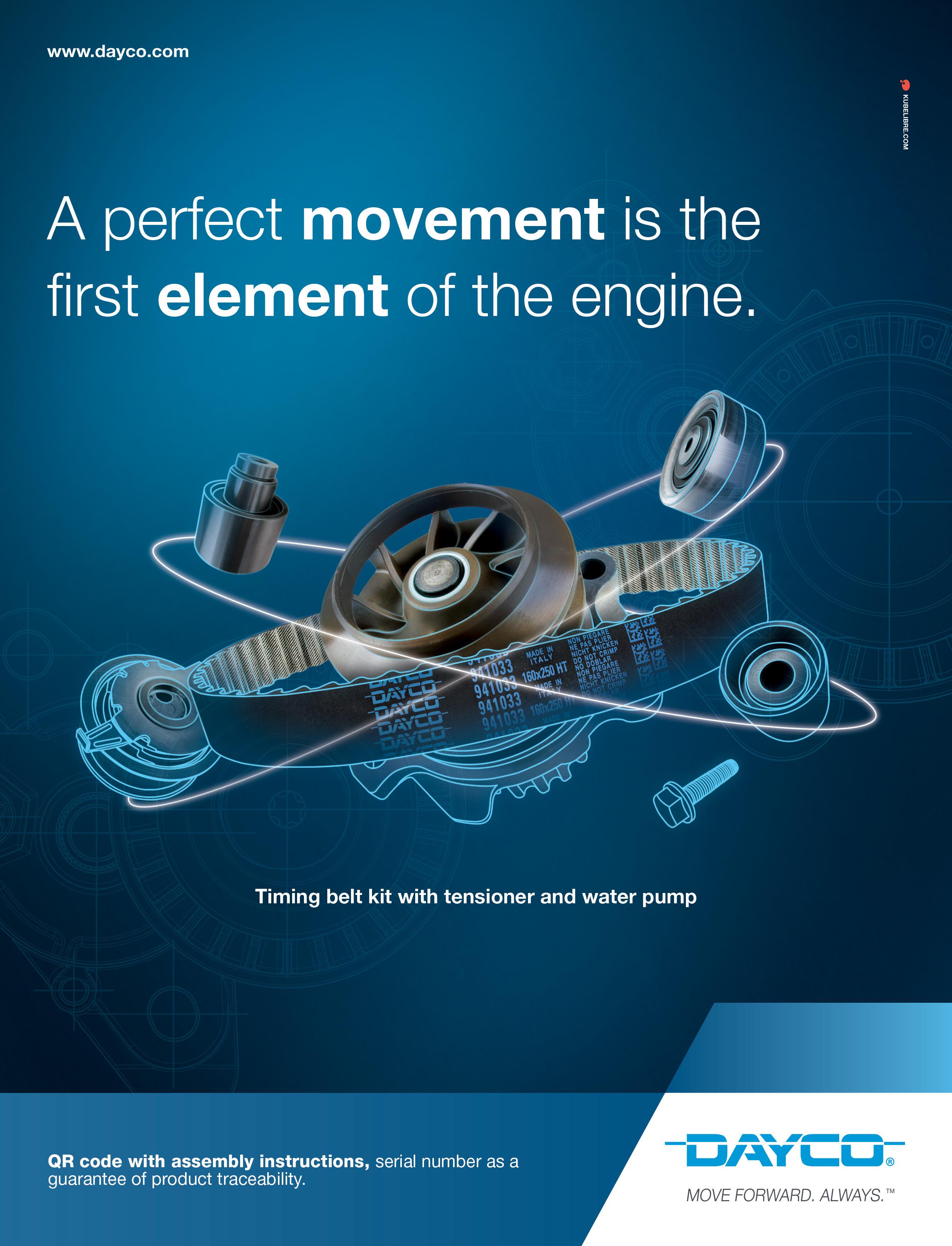

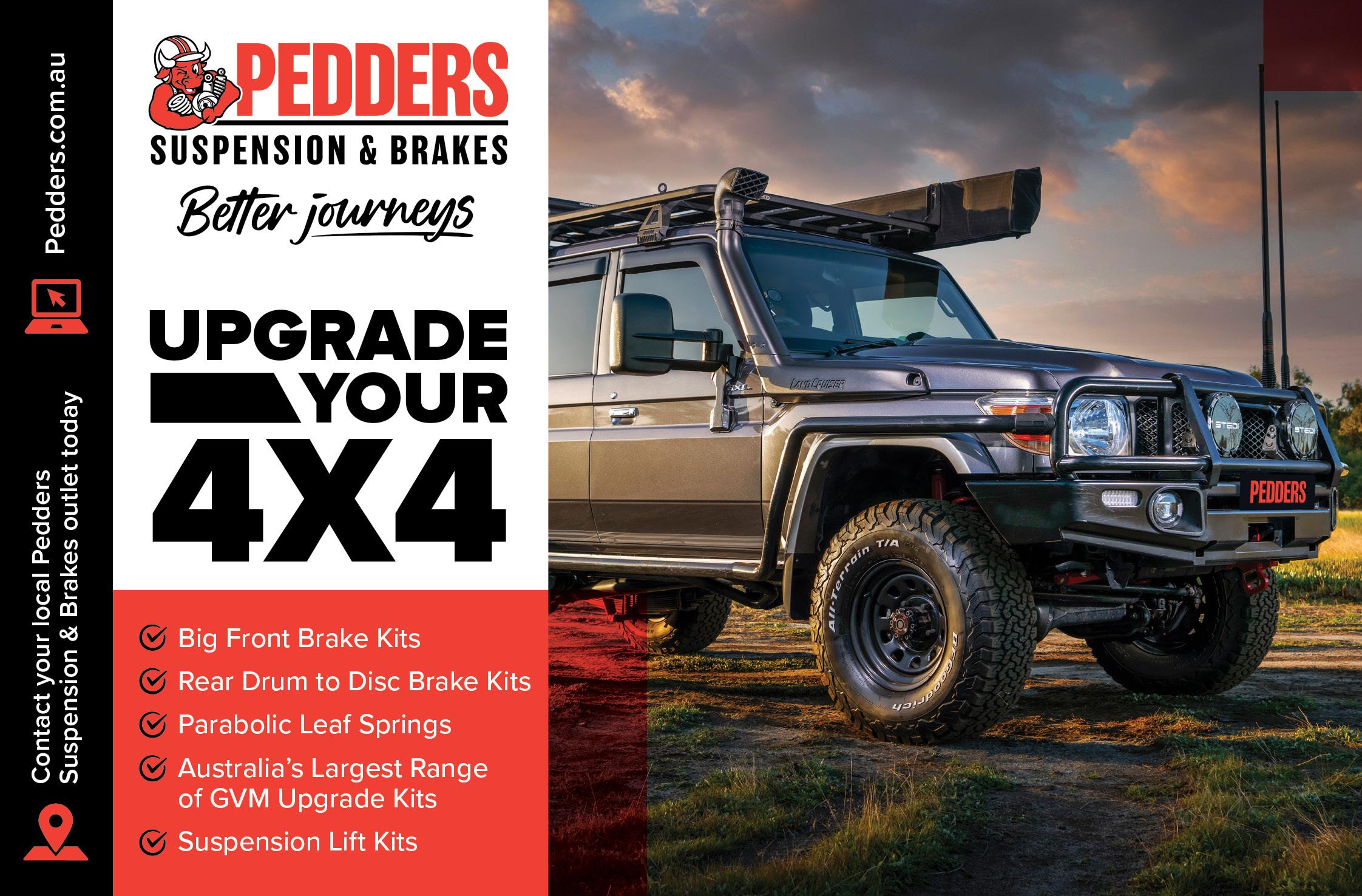

REPLACEMENT PARTS FOR YOUR CUSTOMERS’ VEHICLES

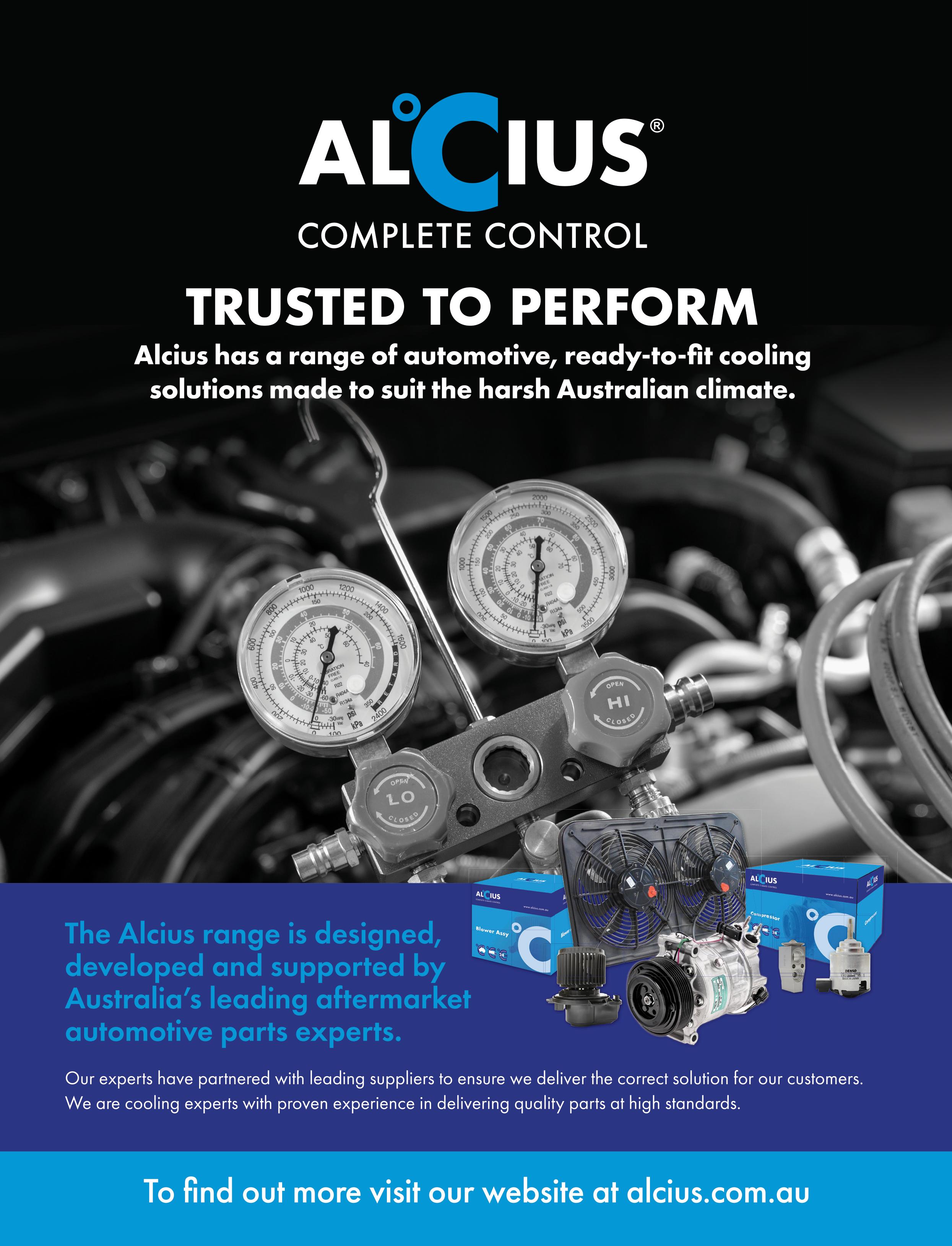

LOOKING AFTER YOUR CUSTOMERS’ AIR CONDITIONING NEEDS

THE FUTURE OF CAR MANAGEMENT

REPLACEMENT PARTS FOR YOUR CUSTOMERS’ VEHICLES

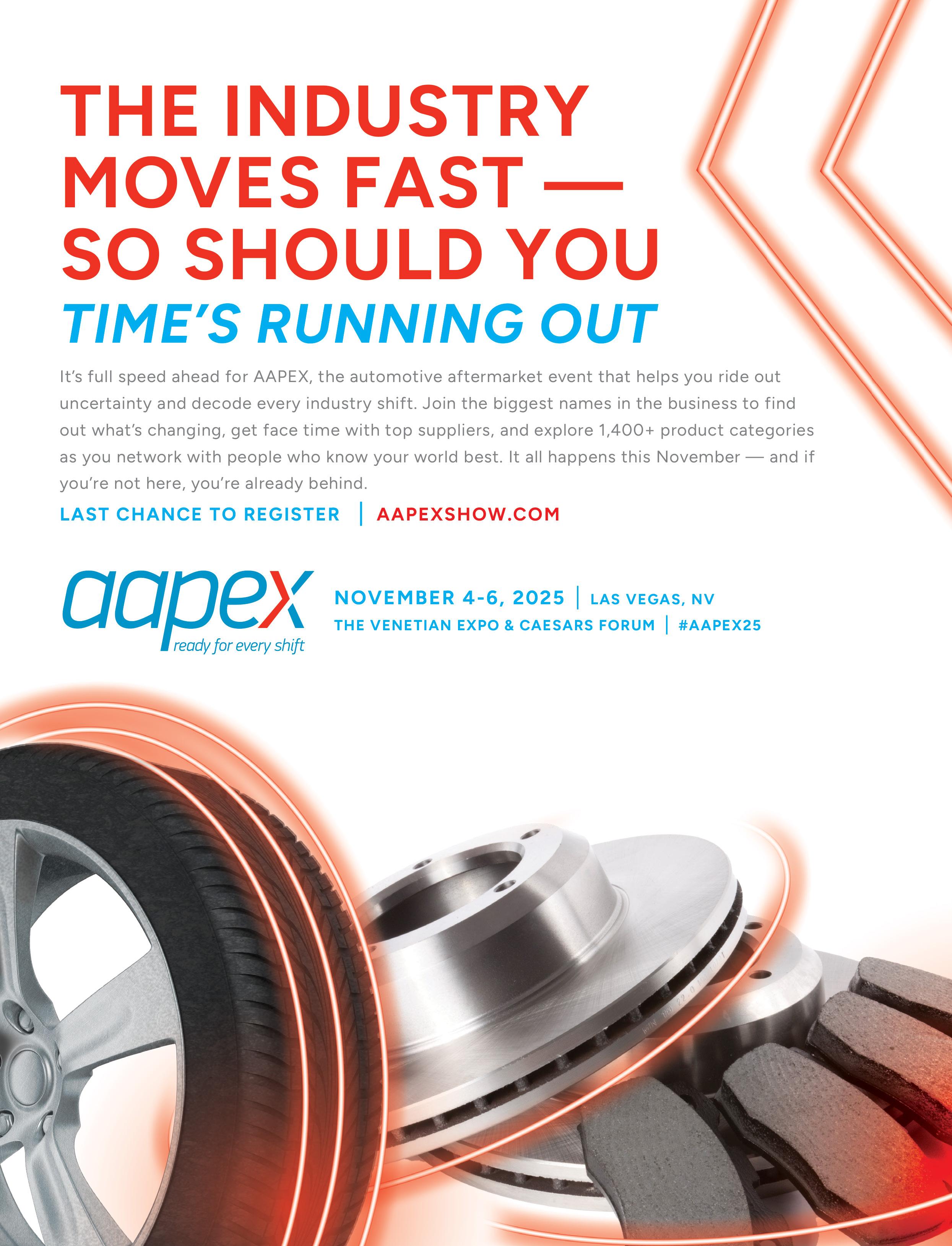

AAPEX 2025

The Venetian Expo & Caesars Forum Las Vegas 4 – 6 November 2025 www.aapexshow.com

SEMA Show 2025

Las Vegas Convention Center 4 – 7 November 2025 www.semashow.com

Automechanika Shanghai

National Exhibition and Convention Center (Shanghai)

26 – 29 November 2025 www.automechanika.messefrankfurt.com

Automechanika Dubai

Dubai World Trade Centre 9 – 11 December 2025 www.automechanika.messefrankfurt.com

PRI Show 2025

Indianapolis, Indiana, USA 11 – 13 December 2025 www.performanceracing.com/tradeshow

Australian Auto Aftermarket Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.autoaftermarketexpo.com.au

Collision Repair Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.collisionrepair.com.au

AAA Mechancial

132/7 Hoyle Avenue CASTLE HILL NSW 2154 Ph: 02 9899 3079 E: rjrm@aaamechanical.com.au

AMA Group Ltd

Level 5, 484 St Kilda Road PRAHRAN VIC 3004 Ph: 03 7066 5022 E: ray.smith-roberts@amagroupltd.com

Antest Pty Ltd

PO BOX 4007 DANDENONG SOUTH VIC 3170 Ph: 03 9056 9050 E:info@antest.com.au

ASPIRE DIESEL

16 Capricorn Street GRACEMERE QLD 4702 Ph: 0408186 470 E: perrin@aspirediesel.com

AUTOMARK

38 Winton Road JOONDALUP WA 6027 Ph: 08 9300 2886 E: mark@automark.com.au

Autopro Muswellbrook

11 Maitland Street MUSWELLBROOK NSW 2333 Ph: 02 6543 3333 E: sales@muswellbrook.autopro.com.au

Banana Coast Batteries

44 Marcia Street COFFS HARBOUR NSW 2450 Ph: 0411426 827 E: mitch@bcbcoffs.com.au

Bosch Car Service Dandenong (SBK Automotive Pty Ltd)

41 Plunkett Road DANDENONG VIC 3175

Ph: 03 9705 0245 E: sbkautoaus@gmail.com

Bosch Car Service Oakleigh (Real Automotive)

47 John Street OAKLEIGH VIC 3166 Ph: 03 9939 7141 E: alphacarcc@gmail.com

Fully Equipped

75 Kabi Circuit DECEPTION BAY QLD 4508 Ph: 07 3203 2212 E: kayne@fullyequipped.co.nz

IAA Australia

1/57 Burnside Road YATALA QLD 4207 Ph: 1800 243 422 E: elizabeth.owen@iaai.com

Interstate Batteries

3642 Word Street DALLAS TX 75204 USA Ph: 2057399814 E: luke.rabun@ibsa.com

Macey’s Auto Electrical

11 Walsh Court LEONGATHA VIC 3953 Ph: 0417 949 432 E: maceysautoelec@gmail.com

Prestige Auto Works

25 Cosgrove Road South STRATHFIELD NSW 2136

Ph: 0426 234 827 E: paw.sydney.nsw@gmail.com

Ramp Auto Group

unit 2/27 Ledgar Road BALCATTA WA 6021

Ph: 08 9249 9515

E: regan@rampautogroup.com.au

Repco Authorised Service Arndell Park (Zarate Mechanics)

7/1 Holbeche Road ARNDELL PARK NSW 2148 Ph: 02 9622 6565 E: zaratemechanics@gmail.com

Repco Authorised Service Blacktown (IP AUTO CARE) 56 Sunnyholt Road BLACKTOWN NSW 2148

Ph: 0433 031 256 E: ipautocare@outlook.com

Repco Authorised Service Currumbin (GT Tyre & Mechanical)

1 Leonard Parade CURRUMBIN WATERS QLD 4223 Ph: 07 5525 7522 E: gttyre@bigpond.com

Repco Authorised Service Derrimut (Toledo K Solution Group)

7/1 Calarco Drive DERRIMUT VIC 3026

Ph: 0406 225 774

E: toledoksolutiongroup@gmail.com

Repco Authorised Service Hornsby (Gurkhas Auto Repairs Pty Ltd) 2/124 George Street HORNSBY NSW 2077 Ph: 0457 272 573 E: gurkhasautos@outlook.com

Repco Authorised Service St Peters (Universal Motor Repairs) 344 Princes Highway SAINT PETERS NSW 2044 Ph: 02 9519 7010 E: info@universalmotorrepairs.com.au

TVS SCS

2 Northern Avenue MOORABBIN AIRPORT VIC 3194 Ph: 03 8558 8338 E: karen.dawson@tvsscs.com

Ultra Tune Bentleigh 276-280 Poath Road EAST BENTLEIGH VIC 3165 Ph: 9570 1944 E: eastbentleigh@ultratune.com.au

Waverider Nominees Pty Ltd

T/As Walkers Diesel Services PO Box 52 WONGAN HILLS WA 6603

Ph: 0457 218 564 E: office@walkersdiesel.com

Save the date – the Auto Aftermarket Expo and Collision Repair Expo are coming!

Planning is well underway for the 2026 Australian Auto Aftermarket Expo, co-located with the Collision Repair Expo, set for Melbourne from 14–16 May 2026.

Delivering an event of this scale is a major undertaking for our Association – and one we are proud to host. It requires months of preparation, careful consultation, and a clear focus on what our industry needs most.

The Expo is not just another date on the calendar – it is the flagship event for Australia’s automotive aftermarket, a sector that contributes over $58 billion to the Australian economy every year. It is where the industry comes together to connect, to learn, to showcase innovation, and to prepare for what’s next.

Our industry is evolving at an unprecedented pace. Advanced Driver Assistance Systems (ADAS) are now standard on new vehicles, electric vehicle uptake continues to rise, and workshops across the country are adapting to new technologies. With access to manufacturer data now available through the Motor Vehicle Information Scheme (MVIS), workshops are embracing a game-changing shift in how they diagnose, service and repair vehicles, all while responding to rapidly changing customer expectations.

As the national association for the aftermarket, it’s vital that we don’t just keep pace with these changes – we help lead our members through them. That’s why our Expo continues to evolve. We are working closely with the Australian Repairers Council of Australia (ARCA), our Collision Repair subcommittee, and engaging with stakeholders across the supply chain to ensure the 2026 event tackles the issues that matter most.

Over recent times, we’ve hosted multiple industry meetings, roundtables and feedback sessions. This collaborative process ensures the program reflects the real-world challenges and opportunities facing

workshops, repairers, manufacturers and suppliers. The message has been clear: our industry wants training that is practical, technology that is hands-on, and opportunities to connect with the best brands and brightest minds.

The 2024 Expo was our biggest success yet –the largest in the event’s history. Thousands of professionals filled the halls, connected with more than 400 exhibitors, and joined technical training, business development sessions and live demonstrations. The energy, ideas and sense of industry pride were impossible to miss.

We are determined to build on that momentum. The 2026 Expo will feature new ideas, new formats, and expanded opportunities for learning and networking. We’re taking everything that worked so well in 2024 and raising the bar again.

What

When you walk into the Melbourne Exhibition Centre in May 2026, you’ll experience the very best our industry has to offer. The Expo floor will showcase the biggest brands, the latest products, and world-leading technology.

Our training program will feature world-class presenters delivering sessions across both technical and business management streams. Whether you’re looking to upskill in EV servicing, understand the latest ADAS calibration requirements, attract new staff, or learn strategies to grow and futureproof your business, you will find it here.

Live demonstrations will showcase the latest innovations, giving you the chance to see, touch and experience new products and equipment in action. The Collision Repair Expo will continue to grow as a dedicated hub for body repair professionals, with a focus on advanced materials, repair methods and refinishing technologies.

And of course, the Expo is the best networking opportunity of the year. It’s where suppliers and

workshop owners, managers and apprentices, innovators and decision-makers all come together. Conversations that start at the Expo often lead to partnerships, ideas and opportunities that shape the next chapter of our industry.

If you are serious about being part of the automotive aftermarket, this is the event you cannot afford to miss. It is the one place where the entire industry is represented, from local independent workshops to the world’s biggest brands.

This is where we celebrate our industry, face its challenges, and embrace its opportunities. It’s where we show that the Australian aftermarket is strong, innovative, and ready for what’s next.

If you are a business wanting to be involved, please hurry, as exhibition spaces are nearly fully booked –please contact partnerships@aaaa.com.au

We are excited to welcome you to another worldclass Expo – an event designed by the industry, for the industry, and sharing in what promises to be the most important automotive aftermarket event in 2026.

Tickets will open shortly via www.autoaftermarketexpo.com.au and www.collisionrepair.com.au

Stuart Charity Chief Executive Officer

It has been an exciting time for Capricorn of late, says Group CEO, Brad Gannon

It has been a fantastic few months announcing the first ever Capricorn Rising Stars Region Winners and celebrating the incredible apprentices making their mark in workshops across Australia and New Zealand. With over 350 nominations received, it is clear the automotive community are passionate about recognising emerging talent, and so is Capricorn.

So far, we’ve announced winners from New Zealand, New South Wales/Australian Capital Territory, Victoria/Tasmania, Queensland and Western Australia, with more to come.

You can meet the winners on our website and social media channels. There have been some great surprise reactions to share.

A huge thank you to everyone who nominated an apprentice and to our sponsors. Your support helps build a stronger, more vibrant industry, and we can’t wait to announce the Overall Winner later this year.

In September we shared our 2025 State of the Nation Australia report, offering a deep dive into how our Members are feeling about the automotive industry.

To amplify the findings, we launched a strategic media campaign that has had great traction.

The report’s release in Brisbane led to an article in the Courier Mail, an interview on Sky News Weekend, and additional coverage on 2CC and 4BC Radio. These efforts are helping bring visibility to the challenges and opportunities facing the sector, and are part of our broader mission to reshape perceptions of the industry, attract new talent, and build a stronger future.

This month we also launched our New Zealand State of the Nation Report sharing insights from our friends from across the ditch.

Whether it is celebrating apprentices or driving industry recognition, Capricorn is proud to support the people who keep Australia moving.

For more on Capricorn Society membership, visit www.capricorn.coop

Matthew Douglass has been appointed to the role

Repairify Australia has announced the appointment of Matthew Douglass as General Manager, effective 1 September 2025.

Matthew will lead Repairify’s continued growth across Australia and New Zealand, driving sales momentum, strengthening partnerships, and expanding the company’s world-leading remote diagnostic and calibration services.

Matthew brings more than 30 years of experience in automotive diagnostics and engineering across the UK and Australia.

His career began in the early 1990s as an apprentice technician, where he quickly developed expertise in emerging vehicle technologies and diagnostics.

He went on to hold technical and engineering roles with vehicle manufacturers, covering everything from production line support to customer aftersales and quality engineering problem-solving.

In the aftermarket sector, Matthew has built a strong track record in technical sales, customer support, and product development.

Most recently, he was Head of Tools and Equipment at CoolDrive Auto Parts, where he developed a strategic approach to enhance their diagnostic tools and capital equipment offering. His deep technical expertise, combined with strong commercial leadership, positions him to accelerate Repairify’s market presence.

“General repair shops, auto electricians and collision repairers require diagnostic tools with broad vehicle coverage – particularly in Australia and New Zealand where the number of brands on the road is greater than in many other countries,” Repairify Australia General Manager, Matthew Douglass, said.

“The Repairify solution is unique: a single diagnostic platform supported by remote services to handle functions a workshop cannot complete alone.

“Coupled with our highly trained technicians who provide hands-on support, it’s like having an expert team on call in your own workshop. That’s a winning solution.”

Repairify Australia says it continues to deliver a complete product and service offering for the market, including the All-In-One device, ADAS calibration equipment, and remote services.

Under Matthew’s leadership, the team of factorytrained technicians will support workshops in keeping complex jobs in-house, completing repairs efficiently and to OE standards.

“We are delighted to welcome Matt to Repairify,” Repairify Inc Managing Director (International), Philip Peace, said.

“As one of Australia’s leading diagnostics professionals, Matt brings a balance of technical expertise and commercial acumen, and we are confident he will build on the strong foundations already established in Australia.

“His focus will be on strengthening our thought leadership position and supporting growth by working closely with customers across collision, glass, and mechanical workshops.

“Matt will ensure our proposition is clearly understood and that it remains straightforward and effective for customers to work with us.

“With Repairify’s patented technology driving the expansion of our remote services, Matt will play a key role in facilitating further growth in the Australian market.”

Repairify thanked outgoing General Manager, Tristan Sender, for his leadership and the pivotal role he has played in establishing and building the business in Australia.

“Whilst I am moving on to a new opportunity, I am also sad to be leaving Repairify,” Tristan said.

“We’ve built a fantastic team and a unique product offering in Australia, and I’m incredibly proud of everything we’ve accomplished together.

“I’m confident Matthew will continue to lead the business to new heights, and I look forward to following the Repairify team’s ongoing success.”

Matthew is an active contributor to the industry and participates in technical working groups including the AAAA/ARCA ADAS Technical Working Group and AUSMASA (Australian Mining and Automotive Skills Alliance).

For more from Repairify, visit www.repairify.com.au

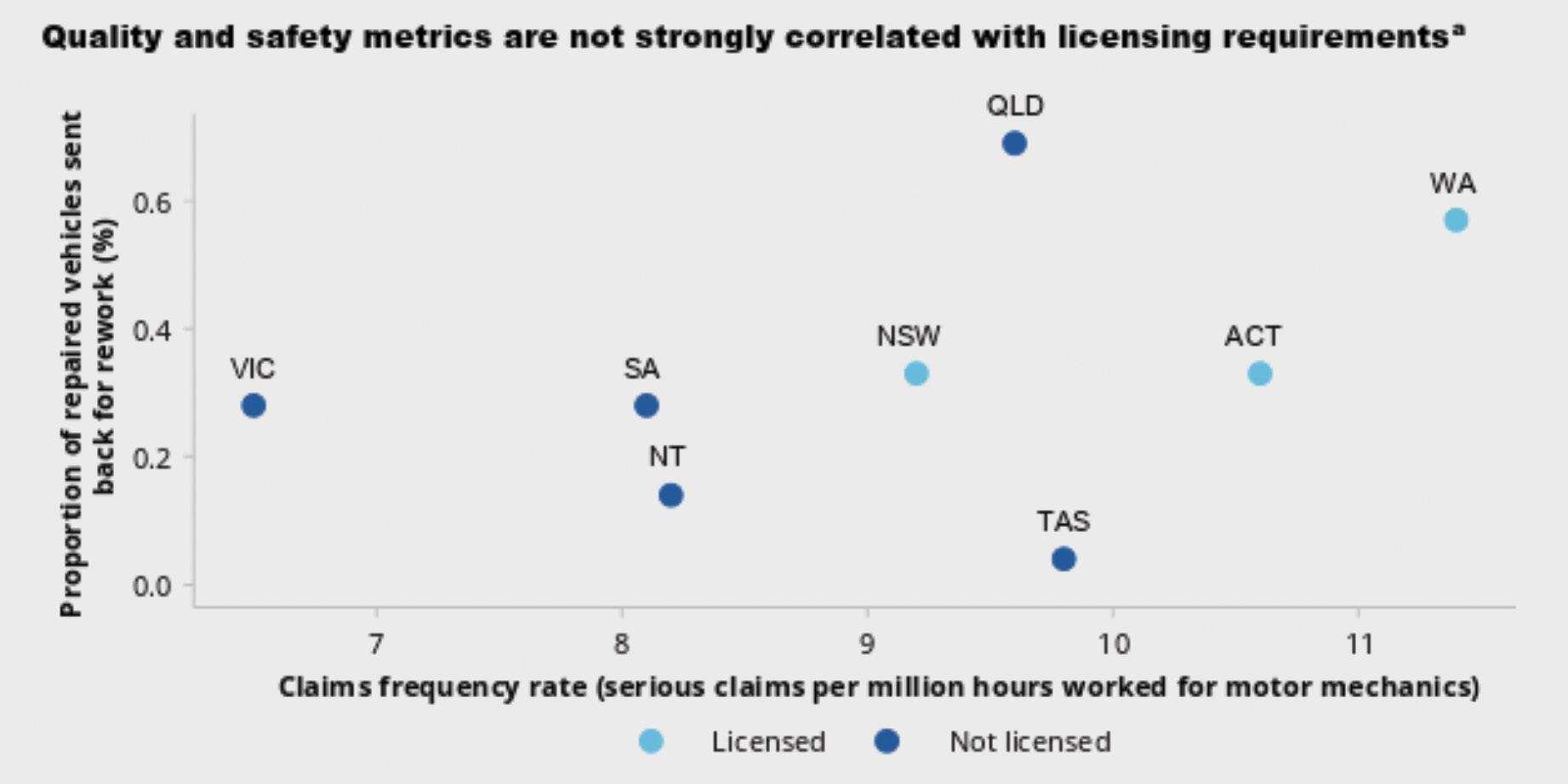

What the data really says about licensing, and how industry and regulators can make it work

It compares the safety and quality outcomes of each state and territory against their licensing regimes for automotive repairers. The conclusion? Licensing has no clear link to better outcomes.

In plain terms: whether or not a state requires a licence to repair cars, the data shows little difference in actual safety or quality.

The theory versus the reality

On paper, licensing sounds appealing. Many in our industry support the idea in principle. It creates a “hurdle rate” – a sense that you have to prove your competence before calling yourself a qualified technician.

For workshop owners who have invested in training and equipment, licensing offers recognition and protection against backyard operators. But in practice, licensing systems often fail to deliver. Governments tend to focus their compliance activity on licensed operators, after all, they’re the ones whose names and addresses are on file.

Meanwhile, the very people licensing is supposed to keep out of the industry – the unlicensed and unqualified – carry on with little interference.

The result? Legitimate businesses are bogged down in red tape, and fined for minor paperwork breaches, while unlicensed operators keep trading unchecked.

The NSW EV licensing push

We saw this play out in New South Wales when the government proposed a mandatory licence for working on electric vehicles. AAAA opposed the measure because it risked doing more harm than good.

It threatened national consistency, added duplication for compliant workshops, and ignored the real issue; unqualified operators flying under the radar.

The irony? The Productivity Commission’s own data suggests licensing does not automatically improve safety outcomes.

Following the money

There’s another layer to this debate; one the Commission itself acknowledges. When training providers help design the very rules that create a market for their courses, the risk of regulatory capture is real.

In the NSW EV debate, some of the loudest supporters of mandatory Skill Set 64 were also delivering the course.

That doesn’t mean their safety concerns weren’t genuine, but it does raise questions about whether commercial interest was shaping regulatory policy. Consumers and businesses deserve better than regulation that doubles as a revenue stream.

Towards smarter regulation

The Productivity Commission is right to warn against excessive occupational entry requirements. But equally, AAAA believes the solution isn’t to discard licensing altogether. Our members want recognition for their professionalism, and consumers deserve protection from unsafe operators.

Smarter, nationally consistent regulation should be guided by four principles:

• Enforcement focused on unlicensed operators

• Entry requirements that reflect genuine safety risks

• Independence from vested interests

• A system that rewards compliance while punishing negligence

A wake-up call

The Commission’s evidence shows what our industry has long suspected: licensing, in its current form, is a poor proxy for safety.

Lesley Yates, AAAA Director of Government Relations and Advocacy info@aaaa.com.au

If governments are serious about protecting consumers, they must move beyond symbolic regulation and focus on stamping out unqualified operators.

Anything less is window-dressing – and another burden on the businesses already doing the right thing.

A national conversation

This is a national conversation our industry needs to have.

If we don’t form a clear, unified view about accreditation, licensing, recognition of skills, and how best to elevate respect for our trade, we leave regulators free to design clumsy, ineffective rules on our behalf.

The Commission’s report is a reminder that the stakes are too high for silence.

It is time for us, as an industry, to decide what good regulation looks like – before government does it for us.

If you would like to offer your thoughts on this subject, please email advocacy@aaaa.com.au

This investment creates a new strategic alliance focused on hydrogen

Brembo and SIAD have announced their investment in Hydrospark, a start-up supported and launched by Petroceramics, which is specialised in the development of advanced technology for hydrogen energy production and storage.

The agreement foresees an equal investment up to €1 million from each company.

For Brembo – a global leader in braking systems, investing through its venture capital unit, Brembo Ventures – and SIAD – an international group active in Industrial Gases, Engineering, LPG, Natural Gas and Healthcare sectors – this investment underlines the technological and industrial value of Hydrospark.

Hydrospark reportedly brings a major innovation into the sector: a modular, scalable platform built on proprietary ceramic materials and optimised manufacturing processes, enabling the production of Solid Oxide Cells with higher energy density and reduced manufacturing costs.

Solid Oxide Cells, developed by Hydrospark, are said to produce electricity and heat from hydrogen with high efficiency and zero emissions. They can also convert renewable energy into hydrogen, providing an advanced solution for sustainable energy storage.

Brembo and SIAD state this technology is

considered one of the most promising for decarbonisation of the industry and mobility and represents a fundamental step into the construction of an efficient and sustainable hydrogen supply chain.

“Hydrospark exemplifies the kind of technologydriven innovation that has the potential to create meaningful impact,” Brembo Group Executive Chairman, Matteo Tiraboschi, said.

“Our investment reflects a commitment to fostering the growth of dynamic entrepreneurial talent and advancing solutions, including those, like Hydrospark’s, that can contribute to a more sustainable future.”

“Our investment in Hydrospark is fully aligned with SIAD’s long-term vision: driving the energy transition through innovative technologies,” The SIAD Group Chairman and Chief Executive Officer, Bernardo Sestini, said.

“Hydrogen is a key enabler for a decarbonised future, and Hydrospark brings together industrial expertise and technological vision in a truly pioneering project.

“At the SIAD Group, we believe that collaboration among Italian centers of excellence can create lasting value for the industry and for future generations.”

Hydrospark has already achieved significant industrial milestones and established collaborations with international partners. By its second year of operations, it aims to breakeven and achieve an annual production capacity of one million cells.

“Welcoming two highly prestigious private companies into our shareholder base represents a key strategic step,” Hydrospark Chief Executive Officer, Fabrizio Gualandris, said.

“This investment will allow us to validate our technology in an actual production facility, while seizing the opportunity to grow and position ourselves as a leading player in the hydrogen market.”

For more from Brembo, visit www.brembogroup.com

From music to mechanics, one apprentice’s story highlights why more women should consider a career in the workshop

Research by the Victorian Automotive Chamber of Commerce shows that more than 600 vacancies were advertised in 2024, yet fewer than 250 roles were filled, resulting in a placement rate of just 37 percent.

According to the Mining and Automotive Skills Alliance’s Industry Workforce Plan, one major challenge in filling these positions is the low participation of women in the sector.

Only 14 percent of the workforce is female, and just six percent of current students are women. One training provider helping to buck that trend is Box Hill Institute (BHI).

This year, the Victorian TAFE has 14 female preapprentices and apprentices studying automotive courses, representing nine percent of all automotive students.

Apprentice Rebekka Walker, 25, is taking a Certificate III in Light Automotive. After high school, she completed a music degree at university but soon realised it wasn’t her ideal career. With a keen interest in vintage cars and curiosity to

learn more, she enrolled in a pre-apprenticeship at BHI to try her hand.

“I decided to do a pre-apprenticeship to see if it suited me. It only took me 10 weeks, and I loved it,” Rebekka said.

Ready to take the next step, Rebekka secured an apprenticeship at the Blackburn Kia dealership. Initially, some team members were sceptical that a woman would have the strength for the more physical aspects of the job.

However, the dealership’s Workshop Controller, Carlo Di Campli, says their concerns were quickly allayed.

“Rebekka has blown us away with her work ethic and ability to learn. She’s running rings around some of the other apprentices,” Carlo said.

While Carlo spotted Rebekka’s potential and welcomed her to the team, he believes more needs to be done to attract women to the industry.

“Being a mechanic these days is less about heavy lifting and more about problem solving,” Carlo said.

“There are a lot of clever women out there who can do it well.”

BHI’s Head of Trades, Stuart Hoxley, agrees.

“The automotive industry is evolving rapidly. Women represent a largely untapped source of skills for the sector, and they easily meet the needs of employers. They have the capability and drive to shape the future of the automotive industry,” Stuart said.

For more from Box Hill Institute, visit www.boxhill.edu.au

AAAA welcomes what it describes as a constructive outcome

The Australian Automotive Aftermarket Association (AAAA) has welcomed the South Australian Government’s decision not to proceed with its own stand-alone licensing scheme for professional engineers, instead supporting further national consideration through the Productivity Commission’s inquiry into occupational licensing reform.

AAAA Director of Government Relations and Advocacy, Lesley Yates, said the announcement reflects the value of open, evidence-based dialogue between government and industry.

“This is exactly the type of grown-up conversation we need to have about licensing reform,” Lesley said.

“Too often, licensing is assumed to be synonymous with worker safety or consumer outcomes. The evidence shows that the link is far from automatic.”

AAAA made formal submissions to the South Australian Government, cautioning against duplicating the failings of the Victorian licensing model, which has included automotive engineers as part of its program.

The Association argued that regulation should only be introduced where there is a clear risk and benefit analysis, and where evidence demonstrates that new rules will meaningfully improve outcomes.

Importantly, AAAA emphasised that the debate must remain anchored in the realities of the automotive sector.

The original policy push for engineer licensing arose from concerns in the construction industry about sole operators working without oversight.

Extending that model to the automotive and manufacturing sectors, where engineers are typically employed in teams, subject to governance and existing legislation, and accountable within corporate structures, has no clear justification.

“Our manufacturing base is one of Australia’s most important assets,” Lesley said.

“We should be supporting it, not layering on new costs and red tape based on misplaced assumptions.

“Engineers in automotive manufacturing already operate under strict governance and safety frameworks.

“Extra licensing in this context is confusing, unnecessary, and risks undermining competitiveness.”

AAAA stressed that it is not opposed to minimum standards and supports regulation where it demonstrably improves public safety or consumer outcomes. However, licensing for its own sake adds burden without benefit.

“We have seen the damage broad licensing scopes have done to businesses in Victoria,” Lesley said.

“Any national licensing must not follow in the footsteps of Victoria’s system and double up on already stringent governance and safety systems in place for automotive engineers.

“Licensing requirements should only be introduced for sectors that have a demonstrated market failure.

“What we want is a system that sets the right standards at the right level. That means supporting training, supporting innovation, and ensuring regulation is risk proportionate.

“The South Australian Government’s willingness to engage in this discussion is a welcome step.” For more from AAAA, visit www.aaaa.com.au

The Australian Government has stopped the unlawful export of 10 shipping containers of illegal tyre waste from Sydney to Malaysia.

The Australian Border Force (ABF) detected the 280-tonne shipment, the equivalent of 175 passenger cars, during ongoing border monitoring.

Compliance and enforcement officers from the Department of Climate Change, Energy, the Environment and Water (DCCEEW) inspected the contents of the 10 containers and found a mixture of non-compliant baled waste tyres and bags of shredded waste tyre pieces in contravention of the Recycling and Waste Reduction (RAWR) Act 2020 and the Recycling and Waste Reduction (Export— Waste Tyres) Rules 2021.

Following the inspection, the Melbourne based tyre-exporter was issued with a compulsory direction to deal with non-compliance and was required to collect the containers from the facility at his own cost.

The exporter is liable to pay container detention, inspection and transport costs – in this case believed to exceed $30,000 – and may be

responsible for additional costs to process the tyres to the legal standard.

Anyone found to be illegally exporting tyres can face up to five years’ imprisonment and fines of up to $198,000 for an individual or $990,000 for a company.

Since the implementation of the RAWR Act Tyre Rules , DCCEEW has worked closely with the ABF to intercept 61 shipping containers of noncompliant waste tyres over 14 separate export consignments by licence and non-licence holders. This equates to stopping around 1,700 tonnes of waste tyres from leaving Australia unlawfully. This waste may have been sent overseas and caused harm to human health and the environment.

“Exporters who send their illegal waste overseas seek to take advantage of markets that don’t apply the same recycling standards as Australia and are driven by higher profits at the expense of the environment,” said a spokesperson for the Department of Climate Change, Energy, the Environment and Water.

“Tyre exporters need to be vigilant and source

end of life tyres that are processed correctly and always ensure they comply with licence conditions and Australia’s waste export legislation.

“Through the work of our compliance team and our collaboration with the ABF we are catching illegal waste exporters in the act.

“You can be part of efforts to combat waste crime.

“The public can report a breach of national environment law through the department’s webpage.”

To report a breach, visit www.dcceew.gov.au/about/ contact/report-environmental-incident

Ironman 4x4 recently took action to enforce design rights

Ironman 4x4 has achieved a successful outcome in proceedings before the Federal Court of Australia, following action taken to protect its Australian design rights against Zeus 4x4 Accessories Pty Ltd and Mr Hassan Nazari.

On 17 July 2025, Ironman 4x4 commenced proceedings in the Federal Court, asserting Zeus and Hassan had infringed six of Ironman 4x4’s certified Australian design registrations, which protect the company’s proprietary Premium, Deluxe and Raid bull bar and Raid canopy designs.

Following those proceedings, Zeus and Hassan gave formal undertakings to the Federal Court of Australia, confirmed by the Court as binding, requiring them to cease the manufacture, importation, and sale of the specified bull bar and canopy products sold under the Zeus 4x4 brand for the duration of Ironman 4x4’s design registrations; and destroy (by recycling) all Zeus 4x4 canopy products that were the subject of the Federal Court proceeding, and provide a certificate of destruction confirming completion of that process.

“Ironman 4x4’s primary objective – to stop the sale of the bull bar and canopy products that it asserted infringed its design rights and to ensure those products were destroyed – has been fully achieved. Consequently, the proceedings have now been discontinued,” Ironman 4x4 Managing Director, Tom Jacob, said.

“This outcome reinforces Ironman 4x4’s commitment to protecting the integrity of its designs and the innovation behind our products.

“We invest significant resources in the research, development, and engineering of premium 4x4 accessories, and we will not hesitate to take legal action where others attempt to infringe our intellectual property rights.”

For more information, visit www.ironman4x4.com

The company says it is proud to report that its partnership with Recycle Mate is making battery disposal easier

Century Yuasa Batteries (CYB) recently announced a new partnership with Recycle Mate.

The announcement comes as the leading battery manufacturer continues forward in its mission to build a circular battery economy amidst its commitment to make lead-acid battery recycling simpler, safer, and smarter.

Thanks to CYB’s national network of recycling centres points now being integrated into the Recycle Mate app and website, real-time, locationspecific recycling guidance is provided across the country.

The move marks a major step forward in addressing one of Australia’s most urgent waste management challenges: the safe disposal of hazardous battery waste.

When incorrectly placed in kerbside bins, lead-acid batteries pose contamination risks – yet awareness of proper disposal methods remains low.

Century Yuasa Batteries General Manager –Automotive, Shaun O’Brien, said the initiative builds on the company’s commitment to drive sustainable change across the industry.

“Battery recycling shouldn’t be hard – but the reality is, too many Australians still don’t know where to start,” Shaun said.

“We’ve been leading the charge on battery recycling for years, and now we’re putting that expertise directly into the hands of everyday Australians with a tool that makes doing the right thing easier than ever.

“This initiative is part of our broader commitment to building a more sustainable and circular battery economy.

“We’re taking real, practical steps to close the loop on battery use – supporting responsible and safe lead-acid battery recycling and helping drive industry-wide change.”

The Recycle Mate platform uses geolocation to remove recycling guesswork, drawing on data from over 530 council areas and more than 40,000 drop-off points.

All CYB recycling locations are now discoverable in the Recycle Mate app and website, complete with branded presence and educational content.

Recycle Mate Program Lead, Lara Barclay, said the collaboration is about removing confusion and making it as easy as possible for people to direct waste to the best possible recovery option.

“People want to do the right thing when it comes to recycling, but confusion and lack of awareness

about local disposal options are some of the biggest barriers,” Lara said.

“That’s why we created Recycle Mate – to give every Australian clear, localised answers in seconds.

“By integrating Century Yuasa’s recycling network, we’ve turbocharged that capability.

“We’re not just advising people what to do – we’re showing them where to go, right now, based on where they live. This collaboration is exactly what’s needed to solve Australia’s battery waste problem at scale.”

Recycle Mate is backed by the Australian Council of Recycling (ACOR) and supported by government and industry. Its AI-powered tools deliver tailored, product-specific disposal advice based on users’ locations.

Australian Council of Recycling Chief Executive Officer, Suzanne Toumbourou, said the initiative demonstrates the power of industry collaboration in tackling hard-to-solve waste challenges.

“Lead-acid batteries pose serious health and environmental risks if not handled properly. At the same time, they can be successfully recycled – but only if they’re taken to a proper collection point,” Suzanne said.

“That’s why partnerships like this one are so important.

“By combining digital innovation with a trusted national recycling network, Century Yuasa and Recycle Mate are helping Australians take safer, smarter action – and delivering real progress toward a more circular economy.”

The ongoing initiative includes national promotion of CYB’s recycling program, educational tools on lead-acid battery recycling, and a branded presence across Recycle Mate’s digital ecosystem.

CYB says its leadership in battery recycling is longstanding. From local manufacturing to national product stewardship, the company has continually invested in circular solutions, with the latest collaboration a natural extension of its ambition to lead the industry toward a truly sustainable battery future.

To learn more about how your business can benefit from the Century Yuasa Battery Recycling program speak to your Century Yuasa Representative on 1300 362 287.

For more on Century Yuasa’s battery recycling initiatives, visit www.recyclemybattery.com.au

The Australia Collision Industry Alliance (ACIA) has welcomed three new board members to strengthen the skills and experience of those leading the not-for-profit organisation, which promotes careers in the collision industry.

These appointments are on a casual basis pending endorsement by a member vote at the next AGM.

Anne McClure of McClure Refinishing in Northern Queensland; Tracey Richards of Geoff Richards Panel Beating in Dubbo, New South Wales; and Paul McMartin of Sydney Automotive Paint and Equipment have recently been appointed to the board.

“As a second-generation business owner, I know how vital it is to prepare the next generation for the future,” Paul said.

“The entire industry needs to get behind ACIA to ensure that future is a successful one.

“Many of our team are former tradespeople, and the same is true across other collision industry suppliers.

“If you haven’t joined ACIA yet, now is the time – if we want a skilled workforce for tomorrow, we need to act today.”

Anne McClure has volunteered at many ACIA careers events helping to spread the word about the opportunities this industry offers.

“As an industry we’ve been slow to position collision repair as a viable career path and that’s left us playing catch up against other industries,”

Anne said.

“We’ve seen trade schools and RTOs in several states remove automotive repair and refinish from their programs, often citing a lack of enrolments.

“Yet when we attend career events under the ACIA banner, it’s clear that students are interested in our trade – they just need to know it exists.

“I joined the ACIA board to help change that. We need to invest in apprentices and ensure this industry is recognised as a rewarding, viable career path that young people can be proud of.”

Tracey Richards was one of the first collision repairers to join ACIA.

“Joining the ACIA Board was a natural step for me because I care deeply about the future of our industry,” Tracey said.

“Our family business in Dubbo has always supported young people – from hosting school work experience to trade visits, which our son Lewis now leads.

“With experienced tradespeople retiring and technology evolving rapidly, we’re at a turning point.

“ACIA is focused on attracting and supporting apprentices, and I’m proud to be part of a group that’s taking real action.

“Even from regional New South Wales, I’m committed to doing my part and encourage other business owners to become members, get involved, and help shape the future of our trade.”

Anne, Tracey, and Paul join Rob Bartlett of SupplySide, Stuart Faid of AMA Collision, Sarah Moynihan of Fortress Collision, and Jason Trewin of I-CAR on the ACIA board.

To find out more about ACIA or to join, please visit www.theacia.com.au

CoolDrive Auto Parts has inducted two new team members into its Hall of Fame, in recognition of their long-standing loyalty, commitment, and contribution to the company.

Announced at CoolDrive’s annual Branch Conference in August, the newest Hall of Fame inductees were named as Sunny Mizzi and Joy Zhang.

Sunny joined CoolDrive in August 1989 as a member of the Box Hill warehouse team when the company was still known as Melbourne Auto Air and operating from a single location.

Working closely with company founder John Blanchard Sr, Sunny quickly became a cornerstone of the company’s operations and is now the Box Hill Distribution Centre Manager, where his knowledge, dedication, and leadership make him a respected and trusted figure across the entire organisation.

The second inductee to the Hall of Fame for this year is Joy Zhang, Purchasing and Shipping Manager who joined the CoolDrive team in 2002.

For more than two decades, Joy has played a vital role in ensuring the smooth flow of products across the business, sourcing from both local and international suppliers, where her professionalism, commitment, and consistency have made her an invaluable member of the CoolDrive team.

“Within the CoolDrive family, there are some people so well-known that you only need to say their first name, and everyone knows exactly who you’re talking about,” CoolDrive Auto Parts Executive Chairman, John Blanchard, said.

“This year, we were proud to acknowledge two such individuals with the company’s highest recognition for their decades of service – Sunny Mizzi and Joy Zhang.

“Sunny and Joy embody everything that CoolDrive stands for – loyalty, dedication, and a genuine passion for what they do.

“Their impact on our business has been profound, and their contribution to our culture immeasurable.

“We are incredibly proud to recognise them as Hall

of Fame inductees and to celebrate the positive influence they continue to have on our company.”

The induction of Sunny and Joy into the CoolDrive Hall of Fame celebrates not only their enduring impact on the business, but also their role in helping shape the company into what it is today.

For further information on CoolDrive Auto Parts, please visit www.cooldrive.com.au

The new partnership supercharges the aftermarket industry leader’s support of the off-road industry’s business and advocacy needs

The Specialty Equipment Market Association (SEMA) has announced the acquisition of the Off-Road Business Association (ORBA), a leading 501(c)(6) organisation dedicated to representing businesses and professionals in the off-road and powersports industries (motorcycles, ATVs, sideby-sides, snowmobiles).

Off-road products and services are the largest and fastest-growing segment of the automotive aftermarket industry.

SEMA says this acquisition enhances its ability to support the advocacy and business needs of the off-road and powersports communities and the innovators who sell their products to millions of enthusiasts nationwide.

“Today is a great day for off-road and powersports enthusiasts and the businesses who cater to them, because it further unifies efforts to advocate in Washington, DC, and statehouses nationwide on their behalf,” SEMA President and Chief Executive Officer, Mike Spagnola, said when making the announcement.

“By acquiring ORBA, SEMA further unifies our shared efforts to preserve motorized access to our nation’s open spaces and secure policies that strike a tenable balance between land use and conservation.

“SEMA has sought ways for our Truck and OffRoad Alliance (TORA) to work more closely with ORBA, out of an immense respect and appreciation

for their work and the individuals whose blood, sweat, and tears over the decades gave a voice to businesses and enthusiasts in the off-road and powersports communities.

“By bringing ORBA under the SEMA banner, we’re scaling up our ability to speak on behalf of the offroad and powersports communities and further extending ORBA’s legacy of service to our industry and enthusiasts.”

The Off-Road Business Association (ORBA) proactively protects recreation access and opportunities by ensuring that America’s families are not arbitrarily denied the right to responsibly recreate.

“ORBA was formed to bring the added resources to support the off-road Industry through business acumen and advocacy, and by directly joining forces with SEMA, this industry will remain at the table on the important issues affecting motorized access to public lands, protecting the right to modify, race, and other important issues to the offroad community,” ORBA Chief Executive Officer, Fred Wiley, said.

“SEMA, since ORBA’s inception, has been a great partner, and I firmly believe our work is in the right hands, with the right partners in the trenches for our great off-road community.

“I’ve always said that the issues facing the off-road industry never truly go away, they just evolve.

“SEMA is uniquely qualified to serve as a steward

for future efforts to protect land access and champion the viewpoints of off-road businesses and enthusiasts.”

Truck and Off Road Alliance (TORA) welcomed the acquisition.

“The Truck and Off Road Alliance (TORA), a SEMA Council, was formed to represent the collective interest of its member companies who manufacture, distribute, sell and/or install accessories for off-road vehicles, light-duty pickup trucks, ATVs, or provide services to this industry,” TORA Chair Dawson Druesedow said.

“We are excited to have the additional firepower of ORBA under the SEMA brand and to expand the advocacy and litigation efforts to not only protect our community but to advance policies that will allow our industry to thrive for generations to come.”

Under the terms of the agreement, SEMA would acquire all ORBA assets. Fred Wiley would remain a senior strategic advisor to SEMA on off-road and powersports issues.

For more information about SEMA, visit www.sema.org

Family Business Day was held on 19 September this year

CoolDrive Auto Parts’ teams across Australia and New Zealand once again came together recently to celebrate the Family Business Association’s National Family Business Day, honouring the contribution of family-owned enterprises to local communities and the wider economy.

This year’s celebrations, held on 19 September, saw CoolDrive branches decorated in green and gold, with team members embracing Aussiethemed attire and sharing morning tea as a way of recognising the values that bind the CoolDrive business together.

With more than 900 staff across 38 branches, warehouses, and offices, the event highlighted the loyalty and teamwork that have defined CoolDrive for nearly five decades.

As part of the occasion, CoolDrive also acknowledged its strong ties to the automotive aftermarket community, paying tribute to the many family-owned workshops it partners with every day.

The business says it remains committed to supporting the industry through supporting apprentices, grassroots motorsport, industry initiatives, and charitable causes.

“National Family Business Day is a chance for us to celebrate not only our own journey, but also the many family businesses we’re proud to work alongside,” CoolDrive Auto Parts Executive Chairman, John Blanchard, said.

“As we approach our fifth decade, we remain focused on innovation and growth while staying true to the values that have guided us since the beginning.

“This day is also an opportunity to honour the people who make CoolDrive what it is — our dedicated team, our loyal customers, and our broader community.

“Together, we look forward with confidence, knowing that family and long-term vision will continue to drive our success.”

With 38 branches across Australia and New Zealand, CoolDrive’s expansive range now numbers over 300,000 parts from categories including air-conditioning, auto electrical, engine management, rotating electrical, tools and equipment, underbody and suspension, engine cooling, lighting, brake and clutch, filtration, lubricants, workshop consumables, and performance and motorsport.

For further information on CoolDrive Auto Parts and its products and services, visit www.cooldrive.com.au

The unveiling of a special livery has kicked off the festivities

Penrite Oil says it was proud to publicly launch its 100-year celebrations at the Bathurst 1000, symbolising a century of trust, Australian manufacturing, and unwavering commitment to quality.

To honour this extraordinary milestone, the Penrite Racing Supercars Team showcased a special livery at the Repco Bathurst 1000 Supercars event across both of its Mustangs.

The striking design featured the Australian flag flowing across the car, complemented by bold gold accents running down the sides – a proud nod to Penrite’s “deep Australian heritage, performance, trust and keeping Australia moving since 1926.”

In a symbolic gesture that captured the spirit of the centenary, Matt Payne’s #26 Mustang –which went on to claim victory at the Great Race – carried the #100 during the week – representing both the company’s journey over the past hundred years and its promise to keep driving forward for the next hundred.

“Reaching 100 years is an extraordinary milestone for our family business,” Penrite Oil Chief Executive Officer, Toby Dymond, said.

“It is a tribute not only to the generations of our family who have poured their heart into Penrite, but also to our loyal customers, partners, and employees who have supported us every step of the way.

“We’re proud to be Australian owned and operated, and this celebration is about honouring the trust placed in us while looking forward to the next century of keeping Australia moving.”

In addition to the on-track celebrations, the livery launch was broadcast live on Sunrise, Australia’s number one breakfast program at 8.00am local time on Channel 7.

This exclusive coverage gave Penrite Racing fans the very first look at the livery as it was revealed, sharing the excitement of this historic milestone with viewers right across the country.

“This is more than just a livery. It is a celebration of everything Penrite has stood for since 1926 –performance, reliability, and a passion for keeping Australians moving,” Penrite Oil Head of Strategy and Engagement, Priscilla Robb, said.

“To see that legacy carried onto the track at Bathurst, one of the most iconic races in the world, was an incredibly proud moment for us.”

Lachlan Madsen has been recognised as a winner in the Capricorn Rising Stars Awards

Lachlan Madsen, an apprentice at Homebush Auto Electrical, has been named the New South Wales/Australian Capital Territory Region Winner in the 2025 Capricorn Rising Stars Awards.

The Rising Stars Awards, now in its eighth year, shine a spotlight on the next generation of automotive talent across Australia and New Zealand.

Backed by industry suppliers Castrol, Repco and The Workshop Whisperer, the program celebrates apprentices who go the extra mile — like Lachlan, whose journey from tinkering in the family garage to solving complex workshop challenges is nothing short of inspiring.

This year marks a new chapter for the awards, with Capricorn recognising Region Winners alongside the Overall Winner, meaning more apprentices are being celebrated than ever before. It’s a timely move, as the industry faces a skills crunch, the rise of EVs and growing competition.

Lachlan’s passion for the trade was sparked early, helping his mechanic dad in the garage.

These days, he’s known for his sharp diagnostic

skills and cool-headed approach to tricky problems, whether it’s tracking down a damaged engine control unit (ECU) wire or uncovering a hidden parasitic drain.

A standout moment came when he mastered the oscilloscope to diagnose a misfire, a skill he says changed how he tackles every job.

“Lachlan’s nomination speaks volumes about his curiosity, persistence and drive to succeed,” Capricorn Group Chief Executive Officer, Brad Gannon, said.

“Recognising apprentices like Lachlan is key to keeping the industry firing on all cylinders.

“Lachlan demonstrates both attitude and determination. He’s not just learning – he is leading, and that mindset will take him far.”

Blending technical know-how with a passion for mentoring the next wave of apprentices and lifting diagnostic standards across the board, Lachlan has a strong future ahead.

“In five years, I see myself stepping into a leadership role, ideally managing or even running a workshop,” Lachlan said.

The launch at Bathurst marked the beginning of a two-year program of 100-year celebrations, which will run through to the end of 2026.

Across this period, Penrite will be honouring its history, employees, customers, and partners, while also looking firmly to the future, with initiatives that celebrate its Australian roots, motorsport achievements, and ongoing commitment to innovation. For more information, visit www.penriteoil.com.au

“I’m passionate about both the technical and business side of the trade, and I want to combine those skills to build a team and deliver high quality services.”

Winning a Rising Stars Award can be a gamechanger — not just for the apprentice, but for the workshop that’s backed their journey.

Lachlan now joins five other Region Winners in the race for the national title, to be announced later this year.

In 2025, Region Winners receive cash and vouchers from sponsors Castrol and Repco. For more information, visit www.capricorn.coop/rising-stars

A landmark Melbourne study has shone the light on non-compliance

A recent study commissioned by the Victorian Automotive Chamber of Commerce (VACC) found widespread non-compliance among commercial delivery E-bikes in inner Melbourne, raising safety, regulatory, and enforcement concerns.

The research was conducted by Monash University, covering eight high-activity sites in May 2025, observed more than 27,000 two-wheeled vehicles, nearly half of which (47 percent) were delivery e-bikes.

The findings revealed that only four percent of delivery E-bikes were observed pedalling –suggesting many are throttle-powered or modified beyond legal specifications.

Speeds up to 54 km/h were recorded, with almost one in five exceeding 25 km/h; at some sites this rose to one in three, with hotspot areas including Swanston Street (Carlton) and Swan Street (Richmond) recording the highest rates of speeding. Further, Elizabeth Street and King Street saw high levels of footpath riding and wrong-way travel.

In contrast, VACC said compliant Zoomo-brand E-bikes were pedalled nearly half the time, travelled at lower average speeds, and recorded no speed-limit breaches.

“Many of these delivery e-bikes are operating as unregistered motorbikes, without the safeguards or enforcement that applies to other vehicles,”

VACC Chief Executive Officer, Peter Jones, said. “We need consistent standards, proper compliance checks, and enforcement in known hotspots to keep all road users safe.”

The VACC is calling on the government to clarify regulatory definitions to match modern delivery e-bike capabilities; enforce existing road rules for non-compliant e-bikes; and close the loopholes that allow illegal e-bikes to be imported. The full report can be downloaded from www.vacc.com.au

Together they are driving a $250K fundraising target for the McGrath Foundation

Following a record first year of fundraising ($217,000), Snap-on Tools has announced the return of its Socket to Breast Cancer initiative.

This year it has Top Fuel Racer Phil Read in the driver’s seat and a bold new goal of raising a quarter of a million dollars.

Combined with last year’s efforts, this will take Snap-on’s total donation to the McGrath Foundation to just under half a million dollars, helping fund specialist McGrath Cancer Care Nurses who provide life-changing support to individuals and families experiencing cancer.

Snap-on’s fundraising initiative will be powered by the sale of limited-edition Pink Tool Sets, sold throughout October during Breast Cancer Awareness month.

In 2024, over 180 Snap-on franchisees across Australia rallied behind the campaign, wrapping trucks in pink, selling pink tool kits, and engaging with local communities, over 11,320 Pink Tools were sold.

This year, Snap-on Tools returns bigger and brighter with the launch of new limited-edition pink Snap-on tools, including tool boxes, a blow gun, hampers, pliers, prybars, and screwdrivers giving mechanics and automotive enthusiasts the chance to equip themselves with premium gear while directly supporting cancer care.

Snap-on ambassador Phil Read, who is a threetime Top Fuel Champion with Jim Read Racing, is standing proudly behind the cause.

“Breast cancer doesn’t just touch individuals, it impacts families, friends, businesses and communities,” Phil said.

“Whether you’re in the pits at the track, in the workshop, or at home, chances are you know someone who has been affected.

“Raising funds for this important cause is deeply personal, a close family friend has undergone treatment for breast cancer and so this year, we’ve proudly wrapped our Top Fuel Dragster pink in support.

“Every pink tool sold is more than gear for the garage, it’s funding for a McGrath Cancer Care Nurse. If buying a pink tool helps even one more family get the support they need, then that’s something I’ll stand behind.”

The Snap-on Pink Tool Set is a symbol of support and a practical way for those in the automotive community to get behind a good cause.

“In racing, you’re always pushing to go faster and achieve more. That’s exactly what we’re doing this year, building on last year’s $217,000 to hit a new target of a quarter of a million dollars,” Phil said.

“It’s a big goal, but I know with the passion of Snapon’s customers and the wider automotive and racing community, we can get there and make a real difference for families facing cancer.”

The Jim Read Top Fuel team debuted the pink and black Socket to Breast Cancer livery for the Dragster at the Spring Nationals at Dragway at the Bend in South Australia across October 3-5. Motorsport enthusiasts were able to donate trackside.

Snap-on Tools ANZ National Sales Manager, Paul Lynch, said the company was humbled by the response in 2024 and motivated to do more, especially given his own family connection to cancer.

“Snap-on franchisees and customers showed us the power of community last year, raising over $217,000,” Paul said.

“We’re proud to be a returning partner to the McGrath Foundation and are committed to reaching a quarter of a million dollars this year to help ensure no one faces cancer alone.”

For many, the campaign isn’t just about tools. Local Snap-on Brisbane Franchisee, Andrew Kent says that for him, “wrapping the truck pink and selling pink tools is about more than fundraising, it was about raising hope in the local Queensland community.”

People can support the Socket to Breast Cancer campaign by purchasing from the limited-edition pink tool range (including hammers, pliers, prybars, screwdriver sets, sheers, ratchets, cutters and more), through Snap-on Franchisees across Australia or donate directly via the website.

For more information and to donate, visit www.pinkisthecolour.com.au/fundraisers/snapon

As the automotive industry undergoes transformation, a new wave of pioneers are emerging

These players will converge at Automechanika Shanghai 2025, showcasing their latest innovations from 26 to 29 November at the National Exhibition and Convention Center (Shanghai).

With more than 7,000 exhibitors expected across 383,000 sqm, the event stands as a premier international platform covering the entire automotive value chain.

This year’s surge in participation from both established automakers and emerging players underscores the show’s critical role as a marketplace for forging strategic partnerships and expanding market presence.

“Automechanika Shanghai showcases the latest technologies and innovations, making it a focal point for the global industry,” Messe Frankfurt (HK) General Manager, Fiona Chiew, said.

“The event has increasingly become a pivotal international platform that consolidates industry resources and, in turn, promotes strategic collaboration from vehicle manufacturing to the aftermarket.

“Simultaneously, innovations are propelling advancements in production, which are generating opportunities across the entire automotive ecosystem, that the event uniquely unites.”

A surge in engagement from carmakers reflects a desire to use Automechanika Shanghai to build awareness, expand global footprints and forge partnerships with an aim to futureproof development alongside transformations across OE, supply chains to after-sales services.

“The automotive industry is advancing rapidly, making supply chain collaboration essential.

Automechanika Shanghai focuses on NEV solutions and supply chain upgrades, connecting distributors and suppliers with innovations, which create excellent opportunities for the application and promotion of these new technologies,” China National Machinery Industry International Co Ltd Chairperson, Li Zhang, said.

“It helps Chinese corporations engage with global markets and drive green initiatives and intelligent transformation in the sector.”

Overall, exhibitors are excelling across multiple sectors, balancing solutions for both fuel-type and new energy vehicles, an interplay that Automechanika Shanghai has expertly fostered over the years.

Moreover, as aftermarket services in China grow, players are diversifying products to meet current vehicle needs.

The country’s burgeoning lower-tier cities and the rapid growth of the independent aftermarket are also significant drivers motivating exhibitors to participate in the exhibition.

The show provides crucial access to these expanding markets, allowing exhibitors to build their reputation, increase brand awareness, and connect directly with their end customers.

Event organisers state that by taking part in Automechanika Shanghai 2025, exhibitors and visitors can experience the transformations shaping the automotive market, gain insights into emerging trends, and build strategic partnerships.

Automechanika Shanghai is organised by Messe Frankfurt (Shanghai) Co Ltd and the China National Machinery Industry International Co Ltd (Sinomachint). For more information, visit www.automechanika-shanghai.com or email auto@hongkong.messefrankfurt.com

It has been recognised as the South Australian Large Training Provider of the Year

MTA Training and Employment has been awarded Large Training Provider of the Year at the 2025 South Australian Training Awards.

It says that this award recognising its unique connection to the automotive industry, and its innovative and industry integrated training model which has reportedly seen a near 30 percent growth in apprentice numbers, cements MTA Training and Employment’s position as South Australia’s best Large Training Provider.

MTA SA/NT Chief Executive Officer Darrell Jacobs dedicated the win to the ongoing support of automotive industry members, customers and apprentices.

“Every day our members provide us with insights and access to the latest trends and technology. Thanks to the support of our industry, the future of automotive is brighter than ever for our apprentices,” Darrell said.

“This approach has delivered results. Apprentice numbers have grown by nearly 30 percent in recent years, with more than 1,100 apprentices currently in training, alongside hundreds of qualified technicians who continue to upskill with us across South Australia.”

MTA Training and Employment’s unique connection to the automotive industry has informed not only its training model, but also innovative and industry leading initiatives such as Australia’s first and currently only automotive dual trade apprenticeships, its pioneering school pathways and its nation leading apprentice mentoring program.

Emphasising the role that industry not-for-profit providers have, Darrell said, “our training is guided by industry, and we reinvest back into industry, delivering the best outcome for apprentices and automotive businesses.”

Darrell said the award reinforced how much there is to celebrate.

“MTA Training and Employment now has more than 100 dual trade apprentices in training. We are leading from the front, with the industry and apprentices alike supporting us,” Darrell said.

“We are in the business of changing the lives of young South Australians. We support an industry worth over $2 billion to our state’s economy through 5,000 businesses who employ 27,000 South Australians.”

Darrell acknowledged the challenging past twelve

months after a fire caused significant disruption to the largest workshop at the MTA Training and Employment Centre in Royal Park.

“The fire could have devastated us, but instead MTA staff banded together and rose to the challenge. To the credit of the MTA team, no apprentice was delayed in their apprenticeship pathway,” Darrell said.

For more information, visit www.mtasant.com.au

It has been a record year of giving back for Capricorn

Capricorn says it is proud to announce a recordbreaking $100 million in Member Returns for FY25, putting profits back into the hands of thousands of small businesses across Australia and New Zealand.

It says this milestone reflects Capricorn’s commitment to supporting its Members, including mechanical workshops, collision repairers, auto electricians, and other small business owners, who are the backbone of the community.

“By returning $100 million to our Members for FY25, we’re helping businesses reinvest in their workshops, reward their teams, or reward themselves and their family,” Capricorn Group Chief Executive Officer, Brad Gannon, said.

“We know just how tough being a small business owner can be, so we are proud to be returning such a substantial amount to our Community.

“Capricorn’s purpose is to support small businesses and help them thrive. This milestone shows just how powerful being a Member of our cooperative can be.”

This year’s Member Returns for FY25 include:

• $20 million in Trade Rebates, paid as additional Capricorn Rewards Points*

• A 7 cent per share dividend for Shareholders (fully franked in Australia and partially franked in New Zealand)

• Millions of Rewards Points earned on everyday purchases

The Capricorn Trade Rebate is a unique benefit that rewards Members for spending through their Trade Account.

A portion of Capricorn’s profits is returned as additional Rewards Points, automatically credited to Members’ accounts, with no forms or applications required.

These points can be used for tools, equipment, travel, or even paying off the Trade Account.

“Capricorn is built on the strength of our Community. When our Members succeed, we succeed, and this record return is proof of that partnership in action,” Brad said.

“Capricorn’s Member Returns are more than just numbers; they’re benefits going back into local

VACC says the decision does not address the financial realities confronting accident towing operators

The Victorian Automotive Chamber of Commerce (VACC) has expressed serious disappointment with the Essential Services Commission’s final decision on accident towing fees, which despite mounting evidence of unsustainable cost pressures facing the industry, has maintained current fee structures.

The ESC’s final report, released in late August after a three-month delay, recommends only minor indexation increases to existing fees, a decision VACC Chief Executive Officer, Peter Jones, said falls well short of addressing the financial realities confronting accident towing operators across metropolitan Melbourne.

“We are deeply concerned that this decision overlooks the genuine cost pressures our members are experiencing and may jeopardise the longterm sustainability of accident towing services in Victoria,” Peter said.

“The ESC appears to have dismissed compelling evidence that demonstrates the current fee structure is no longer adequate to cover basic operational costs.”

The VACC’s comprehensive submission, supported by detailed economic analysis from Deloitte, highlighted significant cost increases since 2021: diesel fuel prices have risen by 34 percent, insurance premiums have increased by 22 percent,

labour costs in the transport industry have grown by 26 percent (double the average wage growth), and industrial land rents in Melbourne have surged by 64 percent.

The organisation recommended adopting the fee structure recently implemented in Western Australia, following their comprehensive cost review.

“We provided the ESC with a practical, evidencebased solution that has already been successfully implemented in another jurisdiction,” Peter said.

“We are disappointed that this recommendation was not given the consideration we believe it warranted, particularly given the thorough consultation process undertaken in Western Australia.”

VACC survey data reveals that 78 percent of accident towing operators indicate current fees are insufficient to cover their operational costs, with many operators subsidising their accident towing operations through other business activities, creating an unsustainable business model that raises questions about the industry’s long-term viability.

“Our primary concern is ensuring Victorian motorists continue to receive timely, professional accident towing services,” Peter said.

businesses that keep vehicles on the road and communities moving.

“Whether it’s upgrading workshop equipment, rewarding staff, or funding a well-earned break, these returns make a tangible difference for our Members.”

Members can earn 1.5 Rewards Points for every $1 spent on eligible purchases throughout the financial year. There is no expiry pressure, as points can be used when it suits the business For more information, visit www.capricorn.coop

“If operators are unable to maintain financially viable businesses, this could result in longer response times, reduced service quality, and ultimately impact road safety and traffic management across Melbourne.”

The VACC says it acknowledges the ESC’s regulatory role but questions whether the current benchmarking approach adequately reflects Melbourne’s unique operating environment and cost structure.

“We believe a comprehensive cost-of-service review would provide a more accurate foundation for setting appropriate fees that balance consumer protection with industry sustainability,” Peter said.

For more from the VACC and to see the full VACC submission, visit www.vacc.com.au

The company says this training is fundamental for those looking to get off the tools

The most successful workshops in today’s market aren’t just fixing cars – they are solving problems that others can’t.

While traditional mechanical repair remains essential, Magic Motorsport Australia says the real money increasingly lies in diagnostic and programming work that separates skilled professionals from the competition.

“If you’re still thinking like a traditional repairer, you’re missing the bigger picture,” Magic Motorsport Australia General Manager and Owner, Anthony Nelson, said.

Modern vehicles present opportunities that didn’t exist five years ago – ECU programming, transmission adaptations, module coding, and advanced diagnostics command premium rates because they require specialised knowledge and equipment.

“More importantly, this work scales differently – instead of billing hourly for labour-intensive repairs, you’re charging for expertise and results,” Anthony said.

“Consider the workshop that handles ECU diagnostics and repairs after flood damage, or performance tuning services.

“These aren’t just additional services – they’re entirely new profit centres. The difference between a $150 diagnostic fee and a $500 programming job isn’t complexity; it is the value you provide to customers with nowhere else to turn.

“This is where investment in yourself pays dividends.”

Anthony said the workshop owner who develops expertise in advanced electronics isn’t just adding another skill – they’re positioning themselves as the go-to expert in their area.

“When other workshops turn away complex jobs, you’re capturing that revenue,” Anthony said.

“Getting off the tools doesn’t happen by accident –it happens by design.

“The most successful operators understand that building systems, training staff, and developing specialised capabilities creates the foundation for real business growth.

“Instead of being under the bonnet daily, you become the person solving problems nobody else can tackle.”

Anthony states the training component is crucial, and states this is why Magic Motorsport Australia now offers both fundamental and advanced learning pathways.

“Tuning Fundamentals one-day course provides essential foundations, while the comprehensive three-day intensive includes dedicated petrol and diesel tuning days using industry-leading Magicmotorsport Flex and Stage X platforms,” Anthony said.

“This hands-on approach with professionalgrade equipment ensures participants leave with immediately applicable skills.

“The workshops thriving in 2025 saw this shift coming. They invested in the right tools, developed the right knowledge, and positioned themselves as problem-solvers rather than parts-changers.

“For those ready to make that transition, Magic Motorsport Australia provides both tools and training foundation.”

For more information, contact Magic Motorsport Australia on 1300 088 726 visit www.magicmotorsport.au

A major milestone in electric vehicle (EV) safety has been reached

EV Fire Protection is pleased to confirm the independent verification of its world-first fixed fire suppression system, EV FirePro. Designed and manufactured in Australia specifically for EV parking bays, the system has been independently tested and validated by world-renowned Applus+ Laboratories in Spain.

EV Fire Protection explains the testing was conducted in 2025 due to the absence of purpose-built EV fire testing facilities in Australia, confirming its effectiveness, safety, and compliance with international standards.

EV FirePro directly addresses the key hazards of lithium-ion battery fires, including thermal runaway, intense heat, and the release of toxic and flammable gases.

By activating at the base of the vehicle, where the battery is located, the system delivers targeted vertical and lateral water spray, suppressing flames, reducing heat spread, and providing safer conditions for emergency responders. During testing, no fire spread to adjacent vehicles. Temperatures around the burning car remained below 60°C, ceiling temperatures were held under 250°C, and heat flux stayed below 2.5 kW/m² – significantly reducing structural risk and preventing ignition of surrounding materials.

The brief temperature spike to 250°C occurred during a deflagration event, caused by the ignition of flammable gases released in the moments immediately before EV FirePro activated.

EV Fire Protection Director, Gareth Morgan, says the system’s value extends beyond emergency response. It offers peace of mind for EV owners, cost mitigation for insurers, and improved fire protection for property developers and managers of high-density structures.

The company is now progressing distribution installations and agreements across Australia, the UK, Europe, Asia, the Middle East, Africa and the Americas.

For more information, visit www.evfirepro.com.au

August 2025 marked a structural turning point in Australia’s automotive market

For the first time, four Chinese brands (BYD, GWM, MG, and Chery) entered the national top 10, collectively selling 16,597 vehicles in a single month (up 69 percent year-on-year).

September’s VFACTS data confirmed the shift is permanent rather than seasonal, with overall Chinese imports up 44,801 units year-to-date versus 2024.

The maths is straightforward: across all brands, approximately 250,000 Chinese-built vehicles have been added to the national fleet over the past 12 months.

Those vehicles will need replacement parts across predictable six-, twelve-, and twenty-four-month service cycles.

The parts-demand curve

Fifth Quadrant modelling projects three distinct demand phases based on standard service intervals. First-quarter 2026 brings six-month services. Oil changes for internal combustion and plug-in hybrid models, air filters, and cabin filters across all powertrains.

With vehicles relatively new and under warranty, this will predominantly be captured by dealer networks, suggesting a limited role for the aftermarket.

The picture changes by third-quarter 2026 as twelve-month service cycles commence. Brake pads, tyres, wiper blades, and lamps represent the first significant independent workshop opportunity. Fast-moving consumables will likely see initial supply pressure as volume builds.

The major replacement cycle then begins in 2027–2028 at the twenty-four-month mark, with brake rotors, suspension components, spark plugs for ICE models, and battery coolant services for EVs. This will coincide with warranty expiry on older models and a level of change of ownership, disconnecting the dealer relationships and delivering a larger aftermarket opportunity.

A critical nuance complicates volume forecasting: not all Chinese vehicles service alike. BYD and MG’s portfolios include significant battery-electric volumes.

The BYD Atto 3 and MG4 eliminate traditional oil and filter change intervals but generate higher tyre wear due to vehicle mass and increased HVAC filter demand.

Plug-in hybrids like the BYD Sealion 6 and Shark 6 blend both service profiles, requiring conventional ICE maintenance plus battery system servicing. GWM’s Cannon ute and Chery’s Tiggo range remain predominantly internal combustion, following conventional service patterns.

Effective parts forecasting must segment by powertrain rather than brand alone.

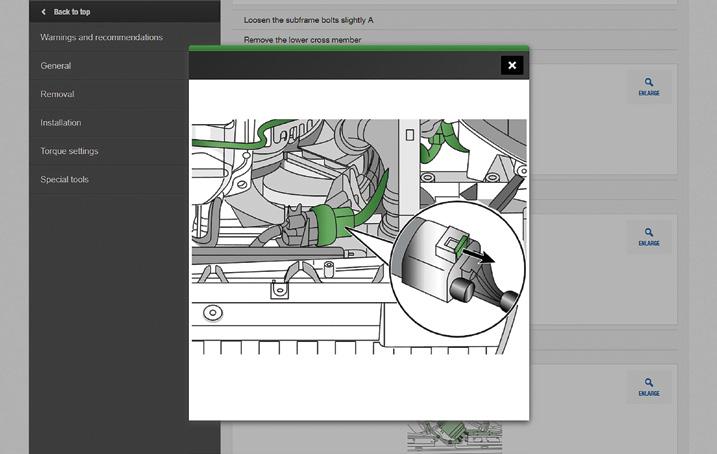

Beyond parts: the ADAS calibration gap

Parts availability is an important consideration, but not the only factor when it comes to considering servicing capability.

Modern Chinese vehicles are equipped with advanced driver-assistance systems: windscreen-mounted forward collision cameras, bumper-mounted radar for adaptive cruise control, and sensor arrays for parking assistance.

Routine services now trigger calibration requirements. Windscreen replacement on cameraequipped screens demands static or dynamic calibration post-installation. Suspension work affects sensor angles when ride height changes. Wheel alignment alters camera geometry. Bumper removal for minor repairs means parking sensor and radar recalibration.

The practical outcome: workshops need both parts inventory, and calibration capability.