You can now receive your industry news in a range of formats: Newscast, Website, Social Media, and a magazine. So whatever your preference is for catching up with the latest innovations and news in the industry, there is a Window News format to suit everyone.

We aim to keep readers up-to-date with the latest industry news, trends, technical innovations and suppliers. Our web format means that we can be in the right place at the right time – wherever that may be.

The contents of Window News are provided for general use only and do not constitute general advice and should not be relied upon.

Views/opinions, replies and specific advice expressed by external persons are not necessarily those of Window News and are not subscribed to by Window News. To see the full terms and conditions please visit: http://www.windownews.co.uk/window-news-disclaimer/ Privacy Policy: http://www.windownews.co.uk/window-news-privacy-policy/

Publisher Gerald Batt Tel: 01255 850245

E-mail: gerald@windownews.co.uk

Editorial E-mail: edit@windownews.co.uk

Production E-mail: production@windownews.co.uk

Copyright © 2026 PO Box 13225. Frinton-on-Sea, CO13 3BT www.windownews.co.uk

Residence 9 windows installed as part of Grade II listed farmhouse renovation in Leicestershire’ promotion read more on page 98

BM Group, the UK fenestration industry’s leading software, data and web specialist, best known for products like Evolution, Evonet and Logikal, will operate under the Forterro name going forward and present all its digital software solutions within a unified brand identity. Having become part of the international software provider Forterro at the start of 2025, this step makes the BM Group’s affiliation with Forterro clearly

visible and underlines the shared strategic direction.

The BM Group switch aligns with that of Orgadata, the Germanybased developer of Logikal, which was also acquired by Forterro last year. Both the BM Group and Orgadata product portfolios are being brought together under the Forterro brand to create clarity and consolidate the company’s strengths for the

benefit of customers and partners. Established solutions such as Logikal, Evolution and Evonet, together with additional Forterro offerings, now form an integrated portfolio that supports companies digitally across their entire value chain – from planning and costing through to production and process integration.

Dean Hodges, sales director at Forterro, commented: “The new brand identity sends a clear message: we are no longer operating as a standalone company, but as part of a unified organisation with shared resources and a clear vision.”

Bernd Hillbrands, founder of Orgadata and head of the windows and doors business unit within Forterro added: “For all our customers, this means combining our deep industry expertise with Forterro’s international strength. This allows us to accelerate investment in cloud technologies, expand support structures and develop solutions that simplify processes, grow alongside the business and ensure long-term

competitiveness.”

The business unit’s strategic direction aligns with Forterro’s goal of providing comprehensive software support to small and medium-sized companies in manufacturing and skilled trades. With the successful acquisitions of both BM Group and Orgadata, Forterro has significantly strengthened its position in the windows, doors and facades segment. Under the Forterro umbrella, innovation is set to progress more rapidly, synergies will be leveraged and customers across different markets will be supported in a more targeted way.

The transition to the new branding applies to BM Group’s entire product portfolio. All existing customer relationships and support structures remain in place. In this context, the Forterro brand stands for continuity and reliability, as well as a clear commitment to supporting companies in advancing their digital processes in a successful and self-directed way.

https://bit.ly/3Zae4eh

Framexpress has announced its aluminium range has exceeded £1 million in sales in its first full year of operation, marking a significant milestone in the company’s longterm investment in ‘Ali by Framexpress’.

Launched in 2024, the aluminium range has grown rapidly as more installers look to diversify their portfolios and offer higher specification products to homeowners, commercial clients and developers. The business attributes the early momentum to a combination of reliable fabrication, a higher spec as standard across the range and consistent On-Time, In-Full delivery.

Jonny Green, principal product manager at Framexpress, explains: “Reaching the £1 million mark so quickly confirms what we are seeing across the industry. Installers are ready to do more with aluminium when the offer feels straightforward, well supported and built around how they work day-to-day. The response to the range has been incredibly positive, and we are now focused on strengthening it

even further for 2026.”

The Ali by Framexpress Club of products includes aluminium casement and flush windows, heritage windows and doors, entrance doors, patio doors, bifold doors, rooflights, roof lanterns and commercial doors. The past year has also seen several additions and refinements rolled out across the range, including built-in trickle vents, heritage door options and the introduction of a triple track patio system.

Jonny added, “Installers want aluminium that arrives ready to fit, performs exactly as expected and helps them stand out on every project. That is what has driven the early success of the range. We’re seeing more existing uPVC customers introduce aluminium for the first time, and others using it to grow their share of higher-value work.”

The business says demand for aluminium is expected to rise further in 2026, driven by homeowner appetite for slimmer sightlines, long-term durability and higher specification upgrades.

Framexpress says it will continue expanding the aluminium collection in the year ahead, alongside additional installer support and enhanced product resources designed to make quoting, ordering and installation even more straightforward.

www.framexpress.co.uk

SRS8, the parent company of hardware distributor Window Ware, has announced a significant expansion to its portfolio with the acquisition of specialist ironmongery distributor, BJ Waller.

This strategic investment marks a pivotal moment for both companies, forging a new partnership in the UK’s fenestration supply sector. The move strengthens SRS8’s commitment to expand its service capability ensuring greater stability, choice, and dedicated support for customers across the entire fenestration landscape – from UPVC and aluminum to the rapidly expanding timber joinery market.

This acquisition is said to be a carefully considered investment that provides BJ Waller with the infrastructure, scale and strategic backing of a larger group, while maintaining the specialist expertise

customers rely on. Crucially, BJ Waller’s commercial operations team will remain in place, guaranteeing consistency and in-depth knowledge for the joinery sector.

Sam Nuckey, a shareholder of SRS8 and managing director of Window Ware, commented on the deal: “This investment by SRS8 is a clear signal of our belief in the long-term strength of fenestration and the value that BJ Waller brings to the growing timber joinery sector. It’s about joining forces with specialist talent and invaluable market sector insight. This move allows us to further strengthen our infrastructure and provide a level of service and scale that will benefit customers and brand partners of both businesses, by significantly enhancing our collective market position and raising the standard of excellence and reliability across the whole industry.”

Silka is forecasting a major shift in installer sales strategies in 2026, with premium, technology-led entrance doors set to become the hero product of the home improvement journey. Installers are now increasingly leading with highspecification entrance doors to anchor conversations around security, design and wholehome upgrades, reflecting changing expectations and project priorities in the UK and Ireland.

Silka says installers are entering 2026 with a renewed focus on higher-value entrance doors, in response to homeowner

demand for better security, smart-home compatibility and stronger visual impact. The trend has accelerated throughout 2025, with Silka’s premium Kärben collection often used by trade partners to open customer conversations and frame the direction of the full project.

High-end features – such as the fingerprint entry, keypad unlocking, smartphone integration and embedded LED approach lighting that come with Kärben – are now shaping project briefs much earlier in the buying journey. Installers report stronger early engagement and greater homeowner confidence

when cutting-edge technology is introduced upfront, rather than treated as optional addons further down the track.

This change aligns with wider market behaviour. The Residential Doors Market Report UK 2025–2029 confirms that while approximately 10.6 million residential doors were sold in 2024, market value has been sustained by a shift towards higher-specification products, supported by growing interest in smart technology integration, energy efficiency and design customisation. Silka says this is translating into practical changes on the showroom floor, where premium entrance doors are increasingly becoming the foundation for broader renovation plans.

“As installers map out their plans and strategies for 2026, we’re seeing premium doors move to the centrepiece of the sales process,” says Asa McGillian, managing director at Silka. “Homeowners are making bigger decisions earlier, and products like Kärben set the tone for the entire project – premium materials, smart functionality and a finish that lasts. Installers need hero products that demonstrate value instantly, and that’s exactly where the market is heading.”

Silka expects this momentum to continue rising in 2026, driven by the demand for entrance doors that last longer, secure better and integrate with smarthome set-ups. Kärben has continually evolved to embody the change, bringing together a carbon fibre-reinforced Thermafill core, bonded Italian porcelain ceramic panels and smart-enabled features in a premium hybrid aluminium entrance door system built for the next generation of home upgrades.

https://bit.ly/49m6oM1

Fabframes has brought forward the next phase of its aluminium strategy after experiencing “exceptional” trade demand for its Stellar slimline bifold doors. Originally focused on bifold manufacture, the Devon-based fabricator is now moving into full production of the complete Stellar Aluminium window and door range.

The decision has been driven by ongoing installer feedback praising the bifold door for its slimline aesthetics and installation efficiency, with many of Fabframes customers calling it ‘the best bifold they have ever fitted’.

Mike Taylor, managing director at

Fabframes, said: “We always listen closely to our customers and the response to Stellar bifolds has been superb. Installers appreciate the ease of installation and the quality of the finished result. When your customers are that enthusiastic about a product, you know you’re onto the right thing.”

To support the expansion into inhouse aluminium fabrication, Fabframes has continued its investment in additional manufacturing space and equipment dedicated to aluminium production, ensuring capacity is in place to meet growing order volumes.

Mike added: “Our customers

rely on us for quality, reliability and service they can trust. Stellar enables us to deliver all of that while maintaining the fast turnarounds the market expects. Bringing the full Stellar range into production now makes perfect commercial sense.”

Jon Foulds, key account manager at Stellar Aluminium, said: “Fabframes only began fabricating Stellar in August 2025 and their progress has been exceptional. The speed at which they have expanded to the full system shows just how well the products are performing for them and their customers. We’re proud to be supporting their growth and to see Stellar playing such a key role in it”

Fabframes will now manufacture the entire Stellar Aluminium portfolio, including windows, residential doors, sliding doors, heritage windows and its popular bifold system, ensuring installers across the South-West have faster access to a complete suite of premium aluminium products. www.stellaraluminium.co.uk

Sternfenster has released a brandnew Quote Follow Up Tool within its EasyAdmin+ platform, designed to help installers win more work by increasing conversion rates.

Developed as part of its ongoing investment in digital support for its trade customers, the new tool delivers professional, automated follow-up emails that help installers stay front of mind with homeowners – without adding to their workload.

Early results from Sternfenster’s own retail operation show the tool can improve conversion rates by up to 36%, demonstrating the tangible impact structured followup can have on sales performance.

“In a competitive market, winning the job isn’t just about producing a good quote – it’s about what happens next,” said Nathan Court, chief sales officer at Sternfenster. “Too often, quotes go cold simply because installers don’t have the time to chase them properly. This tool takes that pressure away and helps customers convert more opportunities into orders.”

The Quote Follow Up Tool automatically sends professionally written emails to customers at key intervals – 3, 7 and 14 days after a quote is issued – helping installers maintain momentum without manual intervention. The emails are meticulously designed to look polished and clean, reinforcing

professionalism and building confidence with end customers.

To make adoption as easy as possible, the tool is enabled by default for all EasyAdmin+ users. Email templates are pre-filled with proven, high-performing messaging, meaning installers don’t need to set anything up before benefiting from improved follow-up activity.

“For our customers, it’s about working smarter, not harder,” added Nathan. “EasyAdmin+ already helps installers quote faster, reduce errors and manage orders more efficiently. The Quote

Follow Up Tool goes one step further by actively helping them win more business.”

As an added incentive, Sternfenster is offering the Quote Follow Up Tool free of charge to all EasyAdmin+ users until the end of March, after which it will form part of the paid EasyAdmin+ package.

The launch further strengthens EasyAdmin+ as a differentiator for Sternfenster customers, combining manufacturing reliability with digital tools that directly support sales growth.

“This is exactly the kind of added value installers should expect from a modern supply partner,” said Nathan. “It’s yet another reason why more and more businesses are choosing to work with Sternfenster.”

For more information about EasyAdmin+ or the new Quote Follow Up Tool, installers are encouraged to contact their Sternfenster sales representative or the customer service team by emailing sales@sternfenster.co.uk

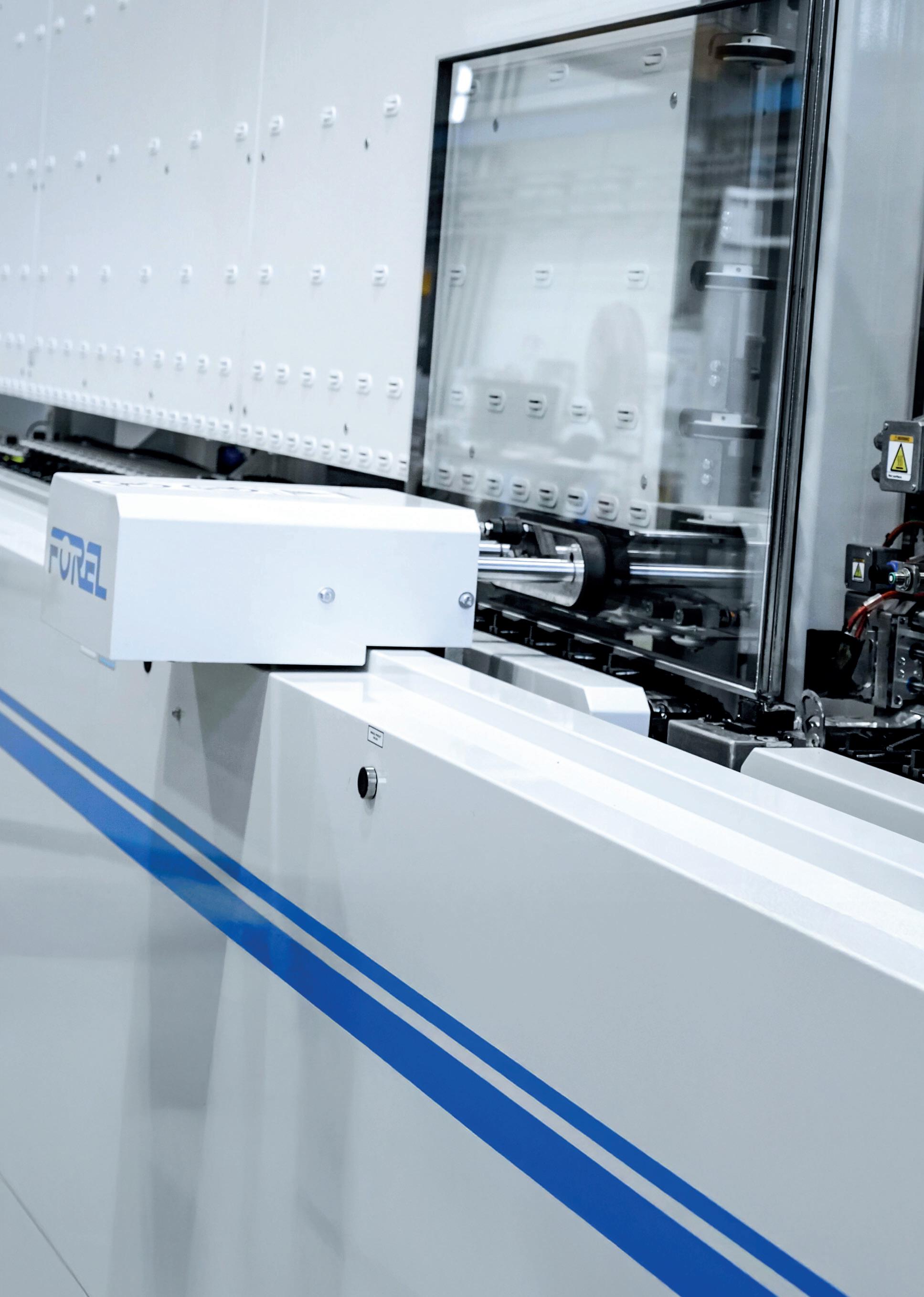

Trade aluminium fabricator DAWS capped off 2025 with a bold statement of intent: a £1.4 million investment in new state-of-the-art machinery and expanded manufacturing space, designed to propel the business into a new era of scale, speed and capability.

At the centre of this investment is the company’s brand-new Schirmer machining centre, signed off in Gutersloh, Germany in November, following months of precision build work to DAWS’ exact specification. The machine — believed by the company to be one of the fastest and most accurate machining centres in the UK — arrived at DAWS’ Knowsley factory in December, where it is in the process of being reassembled, tested, and commissioned ahead of full production in January 2026.

Sales director Phill Cresswell commented: “Having the very latest state-of-the-art machinery on our shopfloor puts us in a place where we can continue to grow our reputation as the trade

aluminium supplier you can rely on. This investment gives us what we believe is the fastest and most accurate machining centre in the country, allowing us to keep delivering the very finest quality products for our customers.”

The substantial investment package also includes additional manufacturing space and wider equipment upgrades, supporting DAWS’ continued expansion as the market shifts further toward residential aluminium products.

With demand for aluminium rising and capacity increasing, DAWS says it is now firmly positioned for a standout year ahead.

“We have great plans for 2026,” added Cresswell. “New products, enhanced marketing support, and exciting technological advancements will help our customers sell more, make more, and do it all with fewer headaches.”

www.daws.co.uk

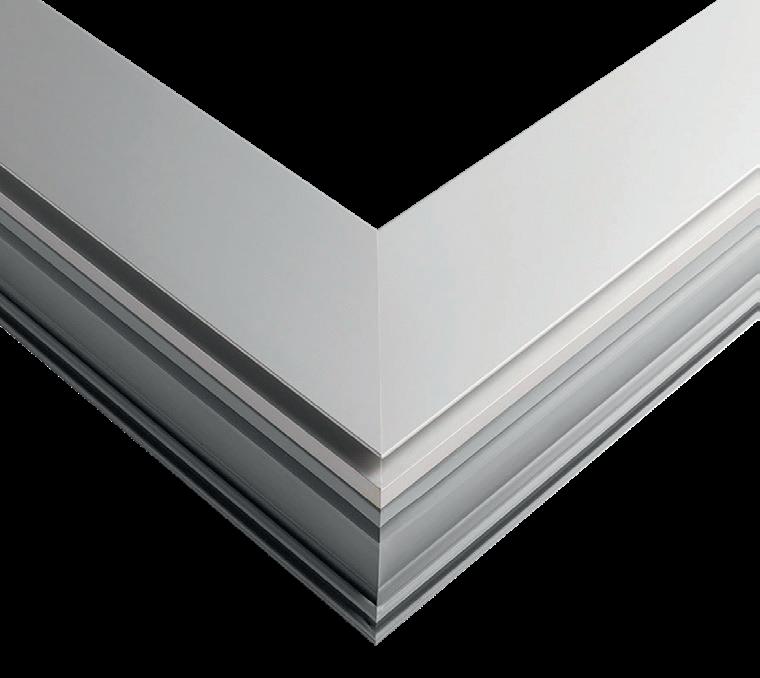

The evolution of an industry leading roofing system - simply better in every

SLIMMER structure

FASTER and SIMPLER to install

Improved THERMAL and SEAL performance

Fully Integrated LED option 10 Year Manufacturers Warranty ISO9001 Quality Manufacture

Design efficiency means LOWER COST PAS24 SECURITY

Vanquish Hardware Protection, a leading manufacturer of precisionengineered intumescent kits for rebated hardware in timber fire door assemblies, has announced significant expansion plans for the first quarter of 2026.

The Salisbury-based business has acquired a new warehouse unit just a few doors from its main headquarters, its third unit on the site, which will provide essential production capacity to support growing demand.

The additional space will allow Vanquish to relocate its warehousing and packing operations, freeing up valuable room within the main facility for a planned fourth extrusion line scheduled for delivery early next year.

This extra capacity is central to enabling Vanquish to introduce several new product lines, all of which are currently undergoing

rigorous testing and certification, which will be unveiled next year and are designed to meet evolving market requirements across a broader range of fire-protection applications.

David Sutcliffe, managing director at Vanquish Hardware Protection, said the investment marks a major milestone in the company’s longterm growth strategy.

“This upgrade directly addresses our current space constraints and gives us the platform we need to support an expanding product range. It’s a clear signal of our continued long-term investment in UK manufacturing and a commitment to the future of the business.”

The newly acquired unit requires a full fit out, before it’s fully operational. Completion of the works is expected by the end of February, at which point the business will begin repositioning

its warehouse ahead of the installation of the new extrusion line.

“While we’ve built a reputation as specialists in hardware protection for fire doors, our manufacturing expertise extends far beyond that,” explained David. “Our proficiency in extrusion technology and deep understanding of intumescent materials allow us to respond to shifting market demands and provide solutions for a broader range of requirements.”

Vanquish’s expanded infrastructure will also support further diversification, allowing the company to develop bespoke solutions. Its service offering continues to include full technical support, from concept to implementation, alongside custom product development, general extrusion capabilities, and specialist cutting facilities for tailored sizing and shapes.

“With more than 30 years of passive fire-protection expertise, this is an exciting new chapter for Vanquish,” added Mike Sutcliffe, sales director at the company. “The expansion will allow us to build new partnerships, enter new markets and enhance our offer to existing customers.”

http://www.vanquish-hp.co.uk/

Driven by Kömmerling innovation and bespoke colour technology, Armstrong Industries, has announced a 10% increase in sales for 2025—a milestone driven by innovation, partnership, and a commitment to helping customers win more business in a competitive market, according to the company.

This growth is closely tied to the company’s continued investment

in the Kömmerling product range, including the chamfered, ovolo, and full flush casement and door systems. These profiles are said to have allowed Armstrong’s trade partners to elevate their product offerings, expand into new design sectors, and deliver the modern aesthetics homeowners increasingly demand.

The full flush casement system,

in particular, has proven to be a stand-out success. Its clean sightlines and premium finish have given installers a high-value product with broad consumer appeal. The company says that combined with the reliability and engineering excellence associated with Kömmerling, Armstrong customers have been able to differentiate themselves from lower-spec competitors and secure additional market share throughout the year.

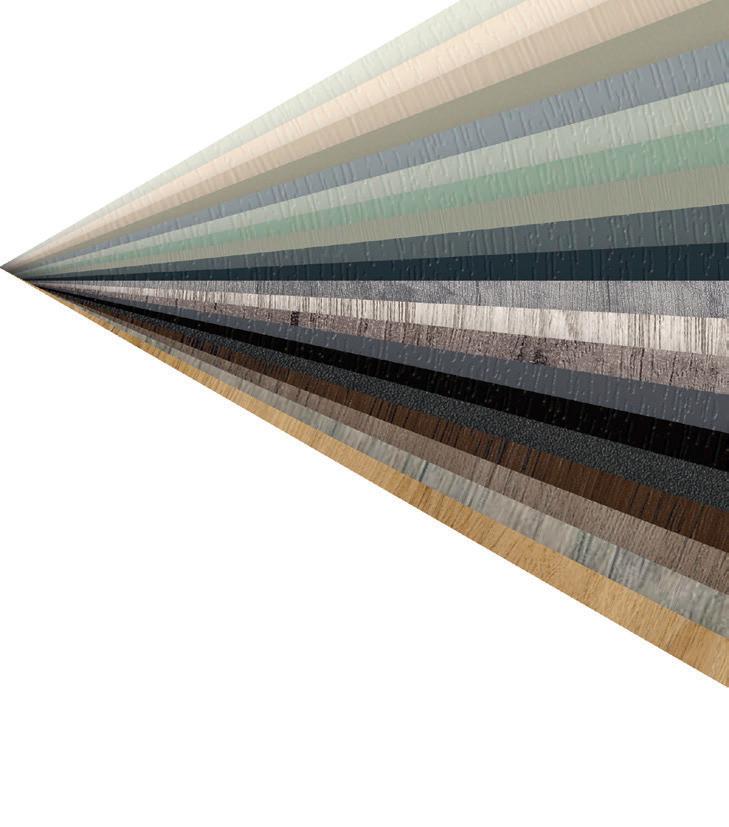

In addition to profile innovation, Armstrong Industries’ inhouse profile paint system has become a decisive advantage for customers looking to offer something unique. Unlike standard foil options, Armstrong’s paint technology allows installers to provide truly bespoke finishes—including contemporary matte tones, heritage shades, and custom architectural colours.

This capability has opened new opportunities for installers who want to position themselves at the premium end of the market. Homeowners increasingly seek individuality and distinctive kerb appeal; Armstrong’s colour system has helped its trade partners meet those expectations with confidence. Many customers are said to have reported winning jobs specifically because they could offer colours and finishes not available elsewhere.

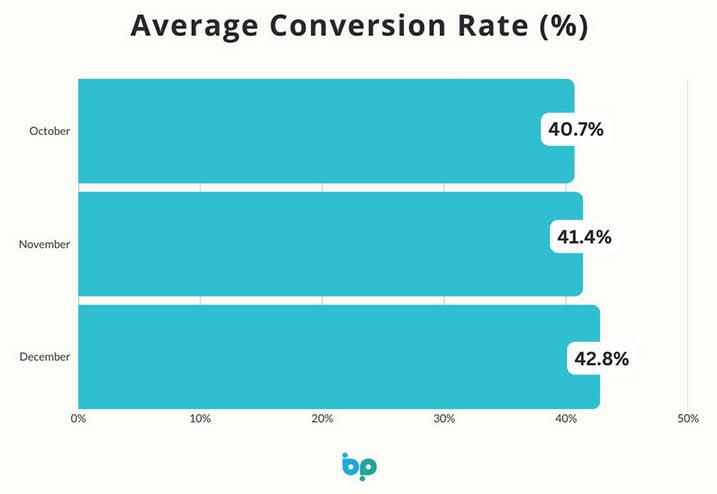

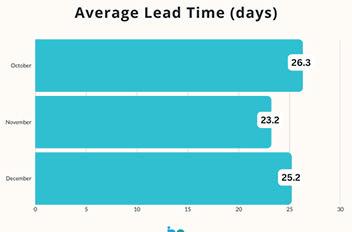

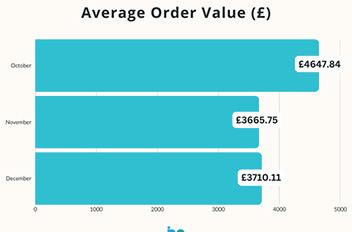

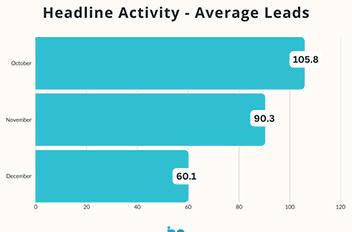

According to Armstrong Industries, the combined strength of Kömmerling profiles and Armstrong’s bespoke colour offering has directly contributed to the company’s year-on-year growth. Installers who adopted the expanded range early in 2025 have seen noticeable uplifts in enquiry volumes, average order values, and conversion rates.

As Armstrong continues to invest in new machinery, streamlined manufacturing, and customer support, the business fully expects further growth into 2026.

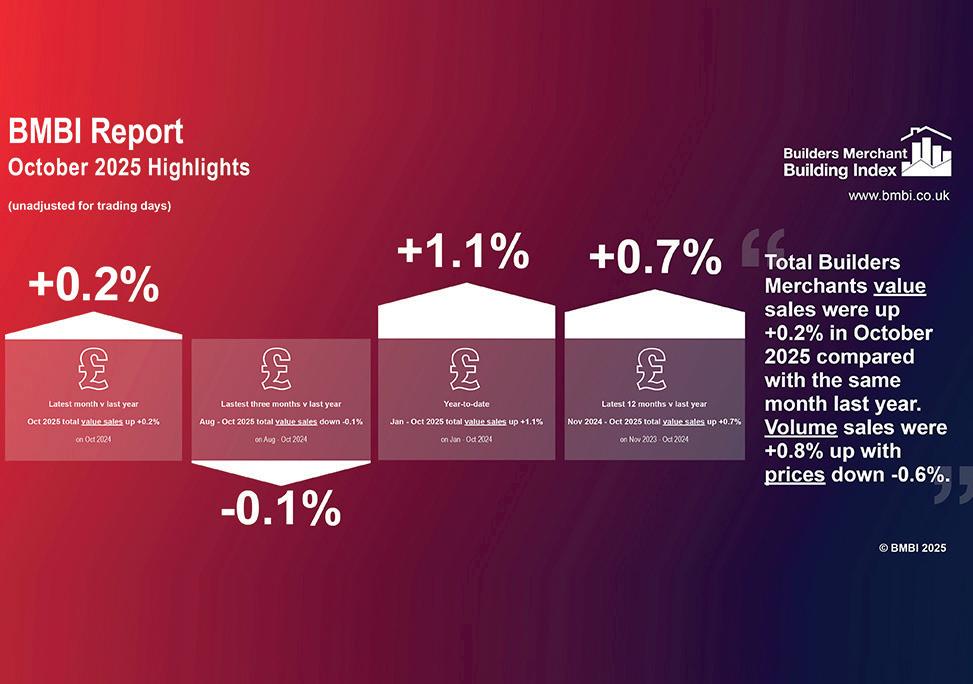

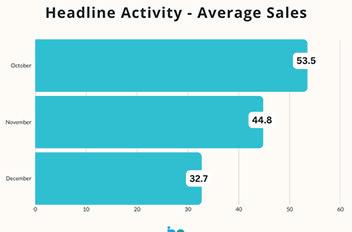

The latest Builders Merchant Building Index (BMBI) report, published in January, shows builders’ merchants’ total value sales in October 2025 were up +0.2% compared to the same month a year before. Year-onyear volumes were up +0.8% but prices were down -0.6%. There was no difference in trading days.

Five of the twelve categories sold more in terms of value compared to October 2024, led

by Miscellaneous (+7.7%) and Landscaping (+6.7%). Of the two largest categories, Timber & Joinery Products was up +1.7%, but Heavy Building Materials was down -1.3%. Renewables & Water Saving was the weakest performing category (-7.6%).

Compared to September, October’s like-for-like value sales (which take trading day differences into account) were down -1.7%. Without the trading day adjustment, total value sales

were +2.8% higher month-onmonth, with total volumes up +1.7%, and prices up +1.0%.

Looking at month-on-month value sales, ten categories sold more with Workwear & Safetywear (+8.3%), Plumbing, Heating & Electrical (+8.2%), Miscellaneous (+7.9%) and Renewables & Water Saving (+7.0%) doing best. The largest category, Heavy Building Materials (+3.3%) performed better than Total Builders Merchants, while the second largest, Timber & Joinery Products (+2.5%) fell marginally behind.

Like-for-like value sales in the 12 months from November 2024 – October 2025 were up +1.1% compared to the previous 12-month period (November 2023 – October 2024). Without the adjustment for the additional trading day in the most recent

12 months, total value sales were +0.7% higher, with total volumes increasing +2.5% and prices falling -1.8%. By value, nine categories sold more with Landscaping (+3.8%), Services (+3.0%) and Miscellaneous (+3.0%) ahead the most. Decorating was weakest (-3.1%).

With an adjustment for one less trading day in 2025, like-forlike value sales for the year-todate (January to October 2025) were +1.6% higher compared to the first ten months of 2024. Without the adjustment, total builders merchant value sales increased +1.1%.

Mike Rigby, managing director of MRA Research which produces the BMBI report says: “Looking at October merchant sales in context – concluding

just weeks before the delayed Autumn budget – they reflect the apprehension felt by businesses and consumers waiting to find out how the budget would impact their finances.

“The IoD’s Economic Confidence Index, measuring business leader optimism in the UK economy hit a record low of -73 in November before the budget. A snap poll post-budget moderated the index to -72, but there was significant impact on revenue expectations, which dropped to the lowest reading since September 2020, and investment intentions, which registered the second lowest reading since May 2020.

“The latest GfK Consumer Confidence index registered a -2 point drop in November to -19 as all metrics took a hit,

Discover service that goes beyond hardware supply. Our team of experts are on hand to advise, source and deliver the hardware you need, when you need it.

particularly the Major Purchase Index, which fell -3 points. The general economic picture was also a cause for concern for consumers, as expectations for the year ahead dropped -2 points to -32, 6 points below November 2024.

“The CPA’s Autumn Forecast was downbeat, with total construction output forecast downgraded from 1.9% growth for 2025 to 1.1%, and the forecast for 2026 being adjusted to 2.8% from 3.7%. The CPA suggests that overall activity has slowed since Spring, and activity in private housing and RMI is subdued with fragile consumer and investor confidence the likely driving factor.”

October’s BMBI report is available to download at www.bmbi.co.uk

Reynaers Aluminium UK, a leading manufacturer of sustainable architectural aluminium systems, has unveiled a new CPD to support confident specification of glazing systems and facades under the Building Safety Act (BSA) framework.

In its latest CPD, titled ‘Mastering the Building Safety Act: Architects, Glazing Systems, Safe Passage, and Holding the Golden Thread’ Reynaers explores how the BSA

affects both the specification and design of glazing and façade systems.

The third CPD in a series written by an architect for architects, the CPD was developed by Vice President of the Manchester Society of Architects Paul Iddon and provides practical insights into the changing role of architects under the BSA.

Since its introduction in 2022, the BSA has ushered in a new era

in building safety and placed a renewed emphasis on competency and accountability across the construction sector. Under the BSA framework, compliance demands traceable performance evidence, verified product data and transparent documentation throughout the lifecycle of the project – with the gateway system ensuring this ‘golden thread’ of information is supplied.

This latest CPD from Reynaers explains how to manage the golden thread and highlights the elevated role of the Principal Designer – whose responsibility has an increased focus on compliance and structural integrity as a result of the BSA.

By using real project testimony, this new seminar demonstrates how early collaboration with manufacturers, a clear specification strategy, and

system-level testing can simplify the Gateway process which has called for many changes, including the need to notify of any alterations to specified systems. In addition, the seminar outlines best practice in supplying full technical submissions so that the Building regulator can make an accurate judgment on Gateway 2 approvals and drive higher standards of performance throughout the built environment.

The CPD also outlines the performance standards of Reynaers products, as well as its commitment to testing and compliance, and looks at the ways in which the company’s expertise is able to support architects in safe, compliant and responsible building design.

Samantha Hill, head of marketing at Reynaers Aluminium UK, said: “At Reynaers Aluminium, we foster a culture of continuous improvement, which includes investment in training, and collaboration with our colleagues

in the industry. We do this not only to ensure projects comply with regulatory change such as the BSA, but to safeguard lives and property, helping to develop a high-quality built environment that stands the test of time.

“This CPD is the third in a series written by an architect to provide a unique perspective on the practical specification of glazing systems under the BSA and connects architectural concepts with our innovative products and services.

“Our CPDs are designed to support the continuous development of high-standards within the industry, and underline our commitment to our customers – and share specialist insights.

“Following the release of ‘The Best of All Possible Worlds’ towards the end of last year, which focuses on curtain walling, and more recently, “Memories of Green’ builds upon the popular use of glazed systems to deepen the connection between architecture and the natural

The latest Insight Data monthly insolvency report shows a widespread decrease in business failures across the glass and glazing, construction, and building product industries.

The analysis shows local builders experienced the sharpest decline, where insolvencies decreased by 38 per cent, falling from 138 in October to 85 in November. Similarly, main contractors, those with a turnover above £5million, experienced a significant dip of 33 per cent, with just four firms going under compared to six in October. The glass and glazing industry

also saw a notable decline with the number of businesses shutting shop dropping by 28 per cent, falling from 124 to 89 in November. Both architects and builders’ merchants maintained relatively stable levels, where insolvencies fell by six and seven per cent respectively.

These improved figures follow a troubling October, which saw insolvencies surge across nearly every sector, and mark a significant, albeit cautious, sign of relief as the year draws to a close.

Alex Tremlett, commercial director at Insight Data, said: “While this reduction in insolvencies shows a

world, this new CPD tackles the practicalities of high-spec systems for facades, windows and doors in tall buildings.

“Content includes looking at practical ways in which architects, as the Principal Designer, can ensure compliance with the BSA and demonstrate best practice in order to navigate the gateway process.”

The CPD is the latest addition to Reynaers’ existing portfolio of RIBA-approved resources, which cover topics including curtain walling, specifying aluminium sliding doors, acoustic glazing solutions, sustainable aluminium systems and more.

Reynaers will present its ‘Mastering the Building Safety Act’ CPD via webinar this December and January. For in-person sessions, onsite or at Reynaers’ UK headquarters in Birmingham, enquire online or contact the Reynaers Consult Team. www.reynaers.co.uk/cpd

positive outcome as the industry heads towards the end of 2025, it doesn’t guarantee recovery. The total number of failures is still incredibly high and I believe these financial pressures will no doubt continue as we enter the new year.

“To stay ahead, I would recommend companies make key decisions based on live market intelligence, rather than instinct or outdated information. From my experience, when working in this competitive and unpredictable environment, the most successful companies are those that are proactive and data driven.”. www.insightdata.co.uk

Steel window and door manufacturer Crittall Windows has announced a significant reduction in its carbon footprint, achieving a 29 per cent decrease in marketbased CO₂ emissions during 2024 compared with the previous year.

The independent assessment, carried out by emissions management company Carbon Footprint Ltd, confirmed total market-based emissions fell from 786.56 tonnes to 529.11 tonnes of CO₂e. Emissions per employee and per £M turnover also dropped by 26 per cent and 28 per cent respectively. As a result, Crittall

has qualified to use the ‘Carbon Footprint Standard’ branding across its communications, demonstrating its ongoing commitment to responsible carbon management.

Crittall MD, Russell Ager

The reductions follow sustained investment and practical improvements across the business. Crittall has introduced a fully electric/hybrid vehicle fleet, installed solar panels at its Witham manufacturing site, upgraded to energy-efficient LED lighting throughout the offices and

fabrication plant, and improved material utilisation to reduce waste.

Working with Carbon Footprint Ltd, the company has set clear targets for continued progress, aiming for a 50 per cent reduction in emissions by 2030 and 90 per cent by 2045.

Russell Ager, managing director of Crittall Windows, said: “This achievement reflects a company-wide effort to operate more sustainably. Reducing our carbon footprint is an ongoing commitment, embedded in the way we design, manufacture and deliver our products.

“Every department, from production to logistics, has contributed to these results, and we will continue to build on this progress as we move towards our 2030 and 2045 goals.”

www.crittall-windows.co.uk

SCALABLE, RELIABLE SUPPLY

SINGLE-SOURCE BUILDING PRODUCT SOLUTIONS

SMARTER FABRICATION, BETTER MARGINS

Premium quality foiled finishes delivered from Liniar’s cutting-edge lamination hall. Our colour options ensure you can stay ahead of design trends and easily satisfy evolving customer demands.

SCAN QR TO FIND A SUPPLIER TODAY! A PARTNER IN YOUR SUCCESS FUTURE-READY PERFORMANCE

Competency is rapidly becoming one of the most significant pressures facing the UK construction supply chain, and soon, it may directly determine whether companies win work, keep work or even get paid.

That was the clear message from Wates Construction’s principal façades manager, Claire Fenton, speaking at the Council for Aluminium in Building’s (CAB) 31st Annual General Meeting.

Addressing members in Stratford-

upon-Avon, Claire offered a candid view of how tier-one contractors are now treating competency under the Building Safety Act: not as an administrative hurdle, but as a measurable requirement that must be evidenced, recorded and maintained.

Competency is no longer optional

Claire reminded attendees that the Building Safety Act now applies to every building, not just high-rise or higher-risk residential projects.

“Competency isn’t about having a certificate on the wall. It’s about knowledge, experience and behaviour,” she said, stressing the shift from one-off qualifications to continuous evidence of capability.

One statistic in particular illustrated the scale of the challenge.

When Wates first reviewed Constructionline Gold members earlier this year, only 56 out of 20,000 had completed the platform’s Building Safety Act requirements. Many companies incorrectly assumed the Act didn’t apply to their work.

Wates, along with other tier-one contractors, is already tightening

its approach. From January, firms that haven’t demonstrated organisational competence may be unable to be onboarded, and, in some cases, may not be paid without director-level approval.

What tier-one contractors now expect

According to Claire, competency must be demonstrated at three levels:

• Organisation-level competence – including Constructionline’s new Building Safety Act requirements.

• Individual competence –covering designers, engineers, surveyors, project managers and anyone exercising technical judgement.

• Installer competence – assessed through national frameworks emerging from the Joint Competency Initiative (JCI).

Claire also warned against relying on informal decision-making on site. Installers adapting design details without the authority or competence to do so are inadvertently taking on design liability, a growing concern under the new regulatory regime.

“What matters now is knowing exactly where your competence begins and ends. If a decision sits outside that boundary, it must be escalated, not improvised.”

Early engagement is becoming essential

One of Claire’s strongest messages was the need for manufacturers and installers to be involved earlier in the design process.

Before 2008, she noted, design meetings typically brought all parties together, contractors, fabricators, installers, designers and engineers. That collaborative model has since eroded, leaving gaps in decision-making and accountability. Under the Building Safety Act, those gaps are no longer acceptable.

Bringing manufacturers into the pre-construction phase, Claire said, helps ensure that details, interfaces and performance requirements are properly understood and correctly specified.

CAB Chief Executive Nigel Headford confirmed that the association is already working with the JCI, CITB and government bodies to support members through the emerging competency landscape.

The aim is to ensure that training delivered by CAB members, including system-specific training, installation courses and technical CPD, can be formally recognised within national competency frameworks.

“Competency is becoming the new currency in construction. CAB is making sure our members can demonstrate it with clarity, consistency and confidence.”

The session highlighted a significant cultural shift: competency is no longer a box to be ticked but a foundation for gaining and retaining work. With tier-one contractors embedding competency audits into procurement and payment processes, the implications will reach every part of the supply chain.

CAB is now encouraging members to:

• Review organisational competence against Constructionline’s Building Safety Act criteria

• Map staff roles against JCI competency frameworks

• Ensure installer training aligns with forthcoming national occupational standards

• Engage earlier with designers and contractors to reduce risk and ensure compliant detailing

• Treat competency as a continuous, documented process, not a one-time assessment

As the industry grapples with new regulations, rising liability and tightening procurement expectations, Claire’s message to CAB members was clear: those who invest in competence now will be future-ready.

The AGM session underscored CAB’s role in helping members make that transition, turning regulatory pressures into a structured, practical process that strengthens both compliance and competitiveness.

www.c-a-b.org.uk

Leicester-based FrameMaker Windows has signed a three-year supply agreement with Stellar Aluminium Systems.

Established in 2002, FrameMaker has grown to become one of Leicester’s leading trade manufacturers. The decision to partner with Stellar represents an important step in the company’s continued expansion into the aluminium market.

After a detailed market review, FrameMaker was particularly impressed by Stellar’s flush aesthetics and installer-friendly design. Guy Kempster, office manager at FrameMaker Windows, said: “The look and style of the Stellar Aluminium system really stood out to us. The slim profiles, excellent sightlines and strong range of stocked colours make it a highly attractive option for our customers.”

FrameMaker has now begun manufacturing the Stellar Casement Window and the Stellar Bifold Door, with customer feedback already exceeding expectations, says the company. Guy added: “One of our biggest customers recently completed a 25-window project using the Stellar Flush Casement system and was absolutely over the moon with the result.”

The onboarding process has been equally positive, with the company praising Stellar’s smooth transition and hands-on support. Guy commented: “The setup process was very straightforward, and Jon Foulds was always on hand to answer any questions. From start to finish, the whole switchover process was extremely efficient.”

Guy added: “The lads on the factory floor love fabricating Stellar. The profiles are well

thought out, fabrication is intuitive and overall we’re very pleased with how the system performs.”

With early demand rising and further product opportunities under review, FrameMaker is confident that Stellar will play a central role in its future growth. Guy said: “We’re already seeing an uplift in enquiries and the system consistently delivers the level of quality our customers expect. It’s a product range we trust and one we’re proud to put our name to.”

Jon Foulds, key account manager at Stellar Aluminium, added: “FrameMaker Windows is a forward-thinking, qualitydriven business and their values align perfectly with the Stellar brand. Their enthusiasm and commitment to the system have been fantastic and we’re delighted to support them as they continue to grow their aluminium offering. We look forward to working closely with the team and building a strong partnership in the years ahead.”

www.stellaraluminium.co.uk

does your business deserve

We don’t just supply integral blinds...

We deliver complete, made-to-order units with best-in-class tech, fastest lead times, and a support team that actually picks up the phone.

When you work with a team who truly knows this industry inside out, the year ahead runs smoother, faster, and with far fewer headaches.

If you need service that works as hard as you do, we’re ready when you are.

Quotes in 60 minutes

Dual sealed units

Manufacturing excellence

Reliable and efficient

Delivered in 10-12 working days*

Free delivery to the UK

Professional after sales service

*Delivery in 10-12 working days when you meet our order cut-off.

SCAN THE QR CODE to find out more

“Build

As the fenestration sector looks ahead to 2026, market conditions continue to be shaped by demand for premium performance, faster lead times and absolute reliability of supply. Against this backdrop, Made for Trade (MFT) is reinforcing its position as a key supply partner to fabricators, trade installers and builders across the UK.

With a reputation built on

engineering excellence, competitive pricing and a consistent focus on service, the year ahead represents a significant milestone for the business. MFT is set to fully launch two flagship Korniche products that are designed to strengthen its offer even further, while ongoing investment in digital ordering continues to support customers looking to operate more efficiently and profitably.

At the centre of this strategy is KwikQuote, MFT’s advanced quoting and ordering platform. Developed to remove complexity from specification and ordering, KwikQuote enables trade partners to generate accurate quotes quickly and place orders with confidence, helping them to win more work and keep projects moving without delay.

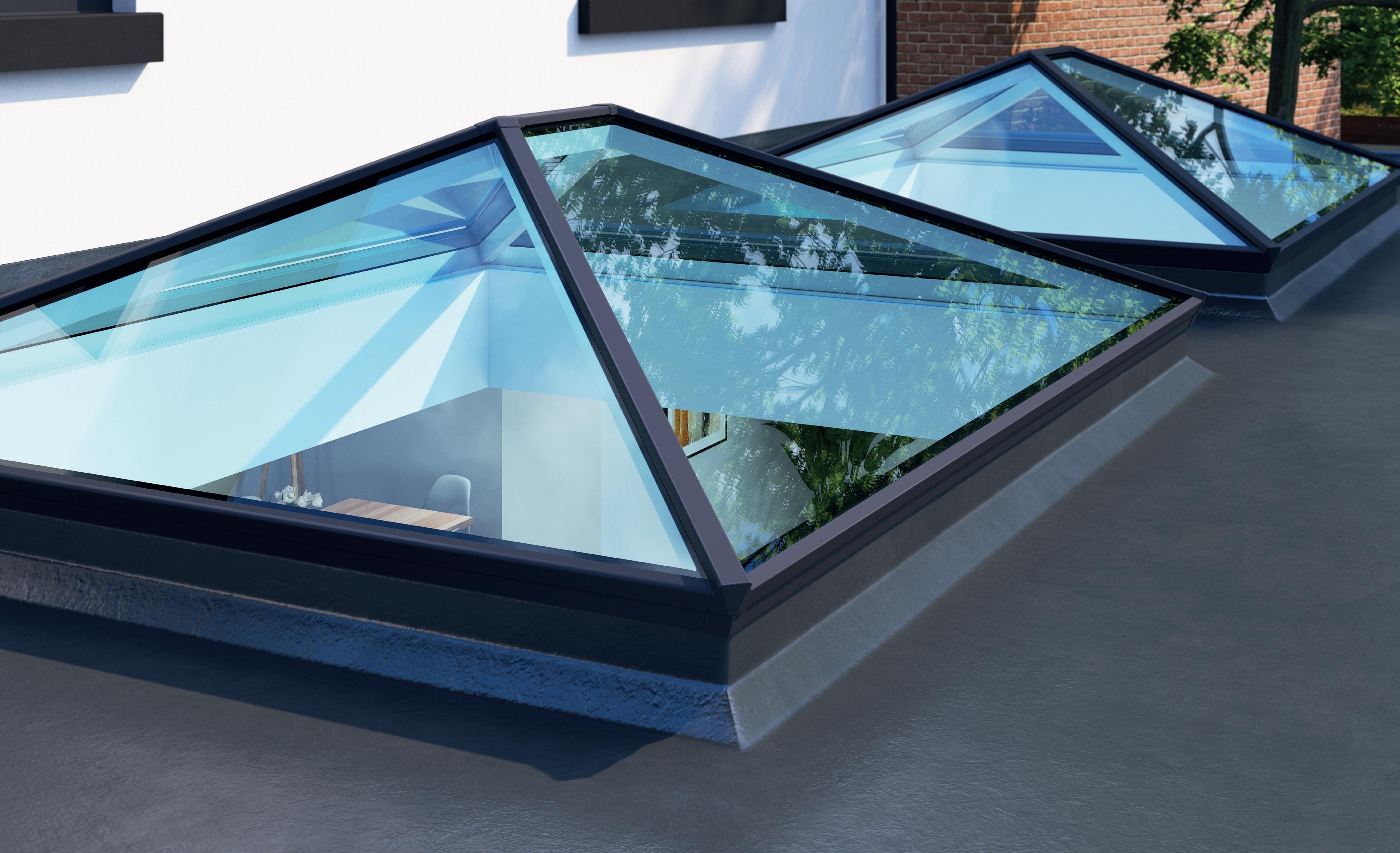

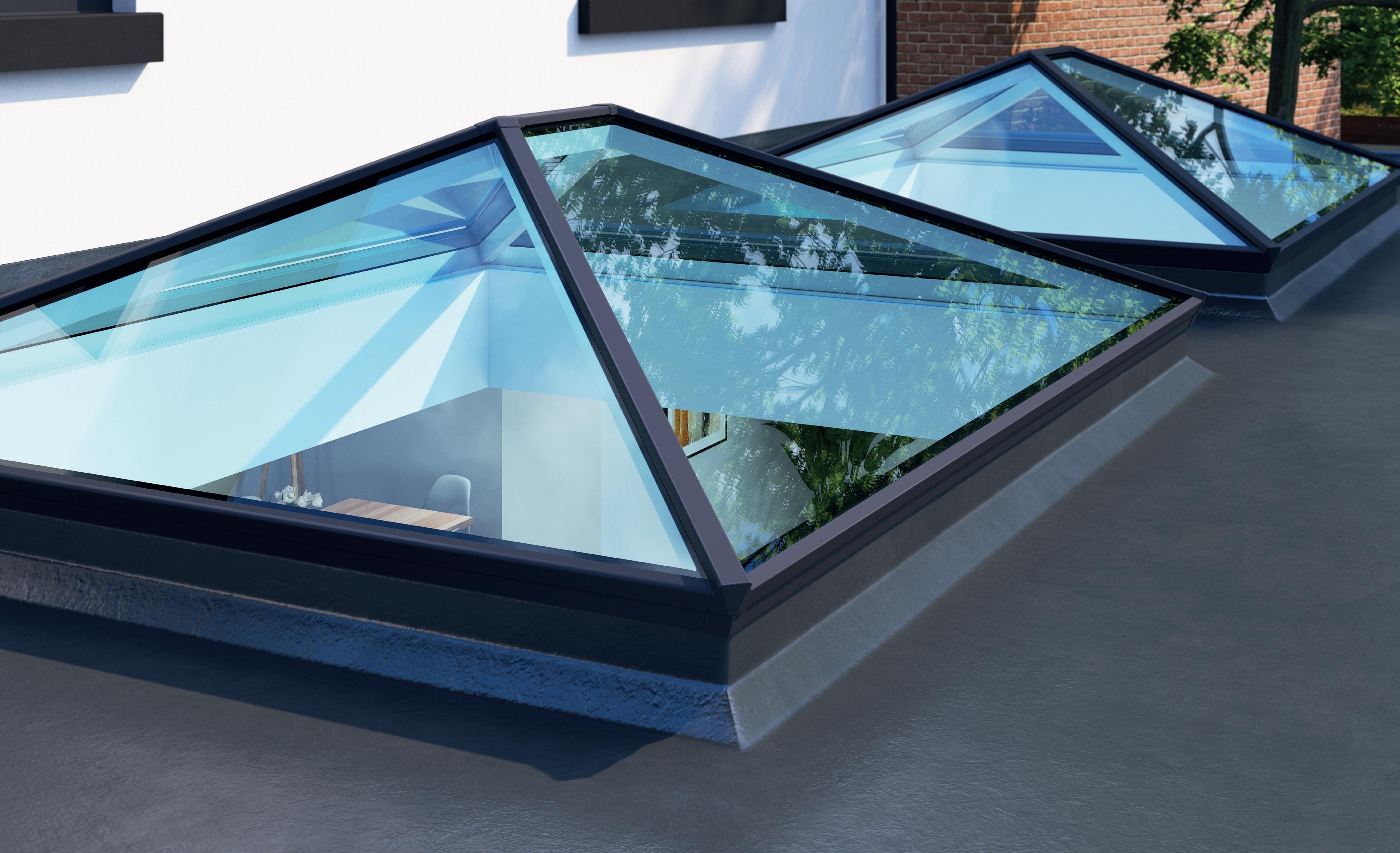

The Korniche Roof Lantern has long been recognised as one of the most installer-friendly and aesthetically refined roof systems available to the trade. Already a multi-award-winning

product, the latest evolution for 2026 raises the bar further in terms of design, performance and ease of installation.

The new lantern features ultra-slim sightlines that maximise natural light while delivering a clean, contemporary appearance. Structural enhancements have been introduced to improve load distribution and overall strength, without compromising the system’s trademark simplicity on site. Security has also been prioritised, with PAS 24 accreditation now provided as standard, alongside high levels of thermal efficiency to support compliance with current and future regulations.

Installers will also benefit from the continued focus on fast-fit installation, allowing time on site to be reduced without sacrificing accuracy or finish. Internally, the lantern delivers a distinctive ‘V’-shaped rafter aesthetic, complemented by a highquality powder-coated finish and precision-manufactured components. Integrated LED lighting is also available, offering a premium enhancement that adds real value for homeowners.

This latest iteration of the Korniche Roof Lantern reinforces why it remains a trusted solution for everything from domestic extensions and kitchen renovations through to highvalue bespoke projects.

Responding to the continued growth in open plan living, home working and internal zoning, MFT is also introducing the Korniche Internal Glass Partition system. The new range brings the engineering principles and design quality associated with the Korniche brand into the interior glazing market.

Featuring slim aluminium profiles with a refined heritage aesthetic, the system has been developed to suit a wide variety of residential and commercial applications. Configurations can

Continued on page 28

Continued from page 27

be tailored to individual projects, including single and double doors as well as multi-panel partitions, allowing installers to meet the demands of modern layouts without compromise.

Precision-engineered components ensure smooth operation and long-term durability, while highspecification glass delivers both acoustic performance and visual clarity. A choice of bespoke hardware, spanning both classic and contemporary styles, completes the system and allows a consistent finish to be achieved throughout the space.

By introducing this product line, MFT says it is giving trade customers access to a premium internal glazing solution without the premium price point, positioning them well to capitalise on the ongoing refurbishment and renovation market throughout 2026 and beyond.

KwikQuote remains a key differentiator for Made for Trade, offering what is described as one of the most intuitive and reliable ordering platforms in the industry. Designed specifically around the needs of the trade, it allows users to configure Korniche products accurately and efficiently, reducing errors and speeding up the entire sales process.

To support new customers in 2026, businesses opening a KwikQuote account before 31st January will benefit from an automatic £200 credit, along with 20 per cent off their second single-item purchase*, subject to terms and conditions. Fast onboarding, instant pricing and clear specification guidance make KwikQuote a valuable tool

for companies looking to scale with confidence. (*Terms and conditions apply)

Commenting on the year ahead, Chris Wann, operations director at Made for Trade, said: “Made for Trade enters 2026 with a sharper focus than ever. Our mission has always been to combine engineering precision with service that genuinely supports the trade. With the launch of the new Korniche Roof Lantern and our Internal Glass Partition system, we are delivering solutions that empower installers to work more efficiently, win more projects and deliver premium results for homeowners. Our continued investment in KwikQuote and the overall customer experience ensures our partners are equipped with the tools they need to grow their businesses throughout the year ahead.”

See Korniche on the Road in 2026

Trade professionals will be able to see the latest Korniche

aluminium glazing solutions in person at the Homebuilding & Renovating Show, where MFT will be exhibiting at all major UK venues. The schedule includes the NEC in March, Glasgow in May, London in September and Harrogate from late October into November, with full details confirmed via the company’s website and social media channels.

A Stronger Partnership for the Year Ahead

With two major product launches, a best-in-class digital ordering platform and a continued commitment to service, Made for Trade is entering 2026 with a clear message to the market. Whether supporting installers on site, providing fabricators with dependable supply, or helping builders deliver smarter, more efficient projects, MFT says it remains focused on building stronger trade partnerships and helping customers build a better business.

For further information, visit www. madefortrade.co.uk

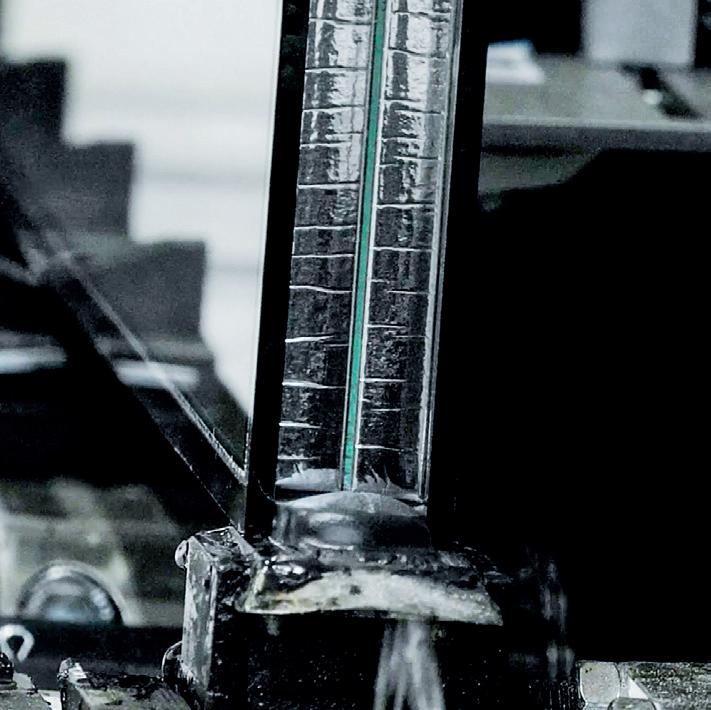

THE WIDTH OF DOUBLE. THE POWER OF TRIPLE.

An ultra-thin centre pane is placed with sub-millimetre accuracy, using our leading flexible warm-edge spacer, allowing for the production of high-performance triple-glazed IGUs that are compatible with 70mm systems and require just one outer seal.

Thin triples, powered by Super

deliver exceptional energy efficiency in a smarter, lighter package

U-VALUES AS LOW AS 0.7-0.9 W/(M 2 K)

DESIGNED TO FIT STANDARD 70MM FRAMES

MORE THAN 40% LIGHTER THAN TYPICAL TRIPLE GLAZING

“We’re fortunate as a business to have a well-established and trusted brand which has been around for 55 years, however, that reputation brings high expectations from customers, which you have to keep working hard to meet.

Hull-based home improvement specialist EYG achieved a 15% surge in sales to domestic clients in its 55thyear in business, according to the company.

The company says, the impressive performance in supplying windows, doors, conservatories, orangeries and garden rooms to homeowners came as the firm also further strengthened its reputation for its work on large scale commercial projects with a string of impressive installations.

Having seen a number of regional and national competitors fall by the wayside in recent years, EYG, which manufactures its products at

its own 75,000ft production facility, says continued investment in new products, equipment and systems has been key to its continuing success.

And managing director Nick Ward says that has ensured it is well placed to repeat the success of the past 12 months in 2026.

“I’m thrilled with how we performed as a business in 2025. We did well across all areas of the business, but to achieve 15% growth in domestic sales over the past year, in what has been an uncertain economic market, has been outstanding and testament to our reputation,” he said.

“To ensure we’ve been able to do that we’ve continued to invest not just in new products, but importantly ones which lead the industry in terms of security and energy performance, whilst never compromising on style and appearance.”

Crucial to the firm’s ambition for further success in 2026 will be the performance of its commercial division, which supplies and installs windows and doors nationally for hotels, care homes, residential developments, new build houses, schools, colleges, and offices.

That part of the business has also outperformed many of its competitors, securing contracts of a value of around £10m over the past year, claims the company.

EYG’s work to glaze the Monocle development in Hull, one of the city’s most recognisable and well-known landmarks due to its curved nature, brought significant acclaim, and stood alongside other significant contracts across Yorkshire in the education sector and new-build housing, working for clients including Beal Homes and Mulgrave Properties.

Also in Hull, large-scale window replacement projects were completed on commercial properties being converted into residential complexes, including at Wilberforce Court, in High Street, and at Criterion House, in George Street.

Added to this, a six-figure investment was made into new CNC Machinery to ensure the business is able to manufacture products which outperform others on the market, and offer them at a competitive price.

At the close of 2025 further investment was made into new automated systems to improve communication with domestic customers throughout their project, with new e-commerce systems also introduced to improve the online sales process, which already accounts for 20% of sales, says the company.

“You’ve got to look after customers and keep modifying your systems and products,” added Mr Ward.

“Online sales are a huge and everincreasing area of sales for us and we are investing to ensure that process, from start to finish, is as smooth as possible for all those who turn to us when looking for home improvements.

“We have the products and we have the credibility. It’s all about continually improving what we do. We’ve never stood still in 55 years, and that has been our strength, and helped us continue to thrive as others fall away.”

Eurocell, specialists in home improvement products, has expanded its nationwide network with the opening of a brand-new trade branch in Chelmsford.

Located at 4 Northumberland Court, Montrose Road, Chelmsford, CM2 6UW, the new branch brings Eurocell’s next-generation format to Essex, designed to give busy tradespeople faster service, better stock availability and easier ways to get what they need, when they need it.

Open from 7:30am to 4:30pm Monday to Friday, and 8:00am to 12:00pm on Saturdays, the Chelmsford branch features a streamlined, walk-through layout that reduces time spent in store. Customers can order at the counter and collect directly from the warehouse, supported by increased stock levels and expanded racking for both offthe-shelf essentials and madeto-order products.

The branch has available a wide selection of PVC-U and aluminium windows and doors, conservatories, composite doors, roofline products, and

outdoor solutions such as fencing and decking.

Designed to give tradespeople even more value, Chelmsford customers can also sign up to Eurocell’s free Power Up loyalty scheme. Created exclusively for Eurocell trade account holders, Power Up is free to join and delivers practical benefits from day one. Members earn points on every purchase, with no limit, making it one of the most rewarding trade-only schemes in the industry. Since launch, customers have redeemed rewards ranging from a weekly Greggs treat to £75 at Asda and even £250 off a holiday.

Stacey Joslin, branch manager at Chelmsford, said: “We’re really excited to bring Eurocell’s new branch format to Chelmsford. Everything here is built around saving tradespeople time, a clear walk-through layout, strong stock availability, and a team who know the products inside out. We’re here to help projects run smoothly and give our customers more value every time they shop with us.”

https://bit.ly/4sMmXsg

Endurance Doors, manufacturer of high-end composite doors, is assuring customers of its commitment to ensuring the continued exclusivity of its products.

To protect the premium quality levels which are a cornerstone of its offer, the business is refusing to adopt an increasingly popular industry model of allowing its doors to be produced by thirdparty fabricators.

Scott Foster, marketing director at the Endurance Group, comments: “On face value, one composite door can seem fairly similar to another, which is why we’ve sought to set our products apart through aspects such as their raw material selection, technical innovation, production methods and performance.

“To safeguard this positioning and the unrivalled consumer perception it has created, we are

understandably protective about how our doors are made.

“Unlike many composite door manufacturers, we don’t sell slabs to fabricators for them to then produce doors which are sold under our name.

“The reason for this is that it can lead to too many variances and result in a degradation in quality, in turn damaging customer satisfaction and our brand.

“We ultimately want installers and homeowners alike to know that if a product carries the Endurance Door’s logo, then it has been manufactured to one harmonised and incredibly high standard, enabling it offer certain assurances as a result.”

This uncompromising commitment to excellence gives Endurance such confidence in the quality of its products that it backs them with an industry-

leading 10-year guarantee, claims the company.

It has also continued to be a core message in Endurance’s consumer-focused marketing activity.

Endurance positions its doors not as a functional necessity, but as an investment aimed at the mid to higher end of the market and catering to the needs of the most discerning homeowner.

In addition, and in keeping with its quality-centric approach, Endurance has also made the conscious decision to not supply online retailers.

According to the company, this prevents its doors from being listed with a ‘supply only’ price and avoids them becoming a commodity product where prospective buyers can shop around on the internet with the aim of finding the cheapest possible price.

As well as helping to maintain the exclusivity of Endurance doors, this protects the margins of the manufacturer’s installer partners.

“At Endurance Doors, we take our responsibility towards our installer partners incredibly seriously. The premise of our offer centres on offering end-to-end quality – from the raw materials we use and how our doors are produced through to the way our doors are installed and handed over to the consumer.

“It would be remiss of us to expect exceptional standards from our installers and then to deviate from that as a manufacturer.

“Ultimately, our uncompromising approach may seem Draconian, but it’s about more than that. It’s about protecting quality levels for the sake of our brand, our business, our installer partners and the homeowner.”

www.endurancedoors.co.uk

Barnsley-based Euroglaze is widely considered as a one-stop shop for PVC-U trade frames, offering what is arguably the widest range of Rehau products of any UK fabricator, alongside Liniar chamfered, sculptured and flush windows and doors.

Now though, the company has gone one step further and added the Liniar Alumina aluminium bifold to its range – and says Euroglaze –giving trade customers even fewer reasons to go anywhere else.

Martin Nettleton, Euroglaze’s managing director, says: “We know trade customers like to buy their PVC-U products from us because we offer a friendly personalised service backed by consistent quality and fast, reliable delivery times. Now we’re giving them the opportunity to buy their aluminium bifolds from us as well and guaranteeing the same level of quality and service.”

The Liniar Alumina bifold suites perfectly with Liniar sculptured

PVC-U frames and stands out in the market because it comes with the option of woodgrain foils as well as powder coated finishes so that buyers can achieve a coherent look throughout their property.

According to Euroglaze, it can span apertures up to 6m wide, with sashes up to 2.5m high so easily matches conventional aluminium bifolds, but feels warmer to the touch because of the foiled finish and achieves impressive U-Values as low as 1.2W/m2K thanks in part to a patented thermal lock system.

Martin Nettleton says it was an obvious addition to the Euroglaze range: “Liniar Alumina is already a proven, popular product. It can be used to fabricate residential and French doors as well as bifolds for replacement, new build and commercial projects, so represents an exciting new business opportunity for Euroglaze as well as our trade customers.”

More details on the full Euroglaze range are at: www.euroglaze.co.uk/

1st January, 2026 marks the centenary of Haffner Germany, the manufacturer of PVC-U and aluminium fabrication technology. Dave Thomas, CEO and founder of Haffner Ltd, said: “Haffner machines have transformed the way windows and doors are manufactured, driving productivity, quality and efficiency for fabricators around the globe. Reaching 100 years is not only a celebration of our heritage, but a reminder of how our machinery continues to set the benchmark for the industry.”

Founded in 1926 in Pforzheim, Germany, by Gotthold Haffner, the company began

by producing precision woodworking hand machines. Over the decades, Haffner has evolved into one of the most influential names in the fenestration sector, known globally for its advanced CNC technology and fully automated fabrication lines.

Today, the company is perhaps best known for its SBA profile machining centres. The latest iteration, the SBA-4 PVC-U profile machining centre, draws on decades of automated expertise and delivers an exceptional balance of cutting and machining performance for PVC-U profiles.

Haffner’s impact on fabrication efficiency is also demonstrated by its welding technology.

The SMR-4 four head welder eliminates corner-weld misalignment by automatically aligning corners and transoms, removing the need for a highly skilled operator and significantly reducing costly remakes. Alongside it, the SMR-5 five head welding machine allows a single operative to weld twice as many frames compared to a standard quad welder, transforming productivity and profitability on the shop floor. Haffner’s KT assembly tables further enhance workflow by bringing multiple assembly processes together in a single, efficient workstation.

Haffner Ltd has been part of the Haffner story for more than 35 of the 100 years, and the company has always continued the track record of excellence set by its German counterparts. It has won

two G Awards for Machinery Supplier of the Year and secured two NFA Awards for Machinery Company of the Year. Dave said: “Our multiple awards reflect our commitment to delivering machinery, technical expertise and long-term partnerships that help fabricators scale with confidence.”

Dave concluded: “As we celebrate this important milestone, we’re not just reflecting on the past, we’re looking firmly ahead. Haffner’s legacy is built on precision machinery design, but its future is about enabling fabricators to compete and grow in an evolving market. Celebrating 100 years is a proud moment for us all and we’re committed to ensuring the next century has just as much impact on the industry as the last.”

www.haffnerltd.com

Composite door manufacturer Entrance Composite Door Solutions has outlined its strategic vision for 2026, emphasising quality and installer partnership over priceled competition as the sector navigates evolving regulatory demands and ongoing market uncertainty, says the company.

Despite fiscal pressures affecting the housing market, the company reports continued strong demand from homeowners investing in highspecification entrance doors that deliver energy efficiency, security and improved kerb appeal.

“The composite door sector remains resilient, but we’re seeing a clear divide emerging between manufacturers committed to genuine value and those chasing volume through price cuts,” says Gregory Kelly, managing director at Entrance CDS. “Our focus is unambiguous – we’re backing quality, compliance and the installer partners who depend on us to deliver consistently excellent products.”

With the Future Homes

Standard driving stricter building regulations, Gregory emphasises that Part L and Part Q compliance has moved from competitive advantage to essential baseline. “These aren’t selling points anymore –they’re minimum standards,” he says. “Manufacturers who’ve been treating them seriously for years will naturally separate from competitors still positioning compliance as a premium feature.”

Entrance CDS’s 2026 strategy centres on controlled expansion of its product portfolio while maintaining the manufacturing standards that have built installer confidence across its network, according to the company. The company is continuing investment in design tooling, operational infrastructure and workforce development.

“Uncertain markets reward businesses that demonstrate stability and genuine partner support,” Gregory adds. “Our installer network needs to know we’ll be there with quality products, technical backing and operational consistency – not just marketing promises. That’s what builds lasting relationships and sustainable growth.

“We’re not interested in shortterm gains at the expense of long-term reputation. Quality manufacturing, regulatory rigour and absolute reliability for our partners – that’s our commitment for 2026 and beyond.”

Ken Rhodes

While many installation companies continue to prioritise digital channels, Upminster-based installer Ken Rhodes is making the case for the continued power of the high street—especially as homeowners grow more cautious in the current economic climate.

The business, founded in 1985 by Scottish carpenter Ken Rhodes Snr, remains rooted in its original high street location. Now run by his son and namesake, the company has gradually evolved its product range and marketing approach to reflect shifting customer expectations. Despite the modest frontage, the firm operates with the same entrepreneurial drive that has long

defined the UK’s independent window and door sector.

A key part of that evolution has been the introduction of the Gerda steel and aluminium entrance door range—installed as a full working sample in the showroom. According to Ken Rhodes, the decision was driven by growing demand for demonstrable security and premium build quality:

“When Pioneer introduced the Gerda door to us, we knew it was something a bit special,” he said. “Security remains a real concern for many of our customers, so it’s reassuring to have a product that can demonstrate high levels of secure locking that the more

premium householder is seeking.”

The timing is significant. Ken reports that leads are currently down by around 30%, and the typical sales cycle has extended from 28 days to 35. Homeowners, he argues, are increasingly selective: “The typical customer today is less keen to take on any significant debt and is increasingly stringent in choosing quality when making a significant purchase.”

In response, the business has adopted a more proactive marketing strategy. This includes data reactivation work, such as a recent SMS trial on 500 existing customers that generated seven appointments—a modest but welcome return at a time when every lead counts.

Ken adds that brand recognition remains a valuable driver, praising Pioneer’s support and the upcoming TV campaign for Gerda.

He also believes the wider industry has lost some of the visibility once generated by national players: “The loss of some of the larger multinationals has probably affected the public perception of products as a whole—the millions that were once pumped into nationwide advertising is no longer there. The onus on us being more proactive has definitely increased.”

Alongside retail installations, the company continues to service local commercial work, recently completing four Gerda door installations on a new-build development that required nonstandard widths.

“Gerda fits that bill of being something a bit alternative, without compromising on aesthetics, nor whacking up the price,” Ken said. “It’s the perfect door brand to help us through the tougher months.”

https://gerdadoors.co.uk/

As its name suggests, Yorkshire-based Sternfenster installer, The Window Doctor, is an expert in window repairs. But thanks to a strong supplier partnership, patching up existing fenestration products is not the only string to its bow.

Starting out as a window repair service almost four decades ago, Sternfenster customer, The Window Doctor, also offers installation services to clients around the country – an aspect

of the business that it’s keen to expand.

“We’re trying to push the installation side of the business at the moment and Sternfenster

have been really helpful with that,” says The Window Doctor’s administration manager, Kirstie Lawrence.

Founded in 1987 by Kirstie’s father, Phil Gledhill, the family business, currently based in Castleford West, Yorkshire, has worked with Sternfenster for almost a decade.

In addition to its repair work, the company fits windows and doors and conservatories, as well as conservatory roof replacements.

“When my dad first set up the business, there weren’t any other repair businesses around. Everybody was selling brand new windows, so we did focus on the repair side back then, but now we do a bit of both,” explains Kirstie.

“As well as domestic work we

do commercial fitting jobs on buildings like hospitals, army bases, schools and colleges. We pretty much cover everything,” she adds.

“With our name, The Window Doctor, not everybody realises that we do installations, so we’re in the process of updating our website to make our full range of services clear. Sternfenster have been assisting us, helping us to demonstrate everything we offer with a virtual showroom to promote that side of business, which has been great.”

Switching to Lincoln-based Deceuninck fabricator, Sternfenster, nine years ago, after experiencing issues with its previous supplier, The Window Doctor team have never looked back.

As well as exceptional products, Sternfenster’s robust customer service offering includes the

unique online customer portal, SF+, and EasyAdmin+, a cloudbased quoting and delivery processing tool. Both have been game changing for The Window Doctor, as Kirstie explains.

“I like the fact that you can do pretty much everything online with Sternfenster. It makes life a lot easier,” she says.

“Once we’ve put the order in and sent it through, everything’s available to see on SF+. With live orders or quotes, we’ve got full visibility of their progress and when things are going to be delivered.

Any questions or issues are flagged it up; it’s just brilliant.

“On the unlikely occasion that a problem does arise, Sternfenster deals with it professionally, straight away. The recent updates to EasyAdmin+ have been fantastic too,” she adds.

When it comes to products, Kirstie struggles to single out a favourite, such is the exceptional quality of the Sternfenster range.

“All of the Sternfenster products are fantastic,” she enthuses. “I’ve used some of them throughout my own home, which I think says a lot!

“Composite doors, French doors, bi-folds, flush casements; they are all high quality, high performing products that look great, manufactured to a very high standard with exceptional colour choice. They’re also easy to fit, and low maintenance, which minimises callbacks.

“Sternfenster keeps you really well informed and the lead times are very good – they’ve reduced significantly which means we don’t have to wait as long, and product delays are very rare.”

With Sternfenster’s strong service offering getting results for its customers, The Window Doctor has also benefited from good account manager relations, and sound advice.

“Sternfenster always try and help us to drive sales whenever they can,” says Kirstie.

“They’ve even given us advice on things like cashflow, which has been really beneficial. With installations, we’d always taken a 50% deposit and then didn’t get the other half until the job was completed. Our account manager suggested taking 50% and then a further 25% prior to order, and that really improved things for us.

“They’re always keen to help us, because if we’re doing well, it means that we keep giving our business to them. It’s a mutually beneficial relationship and we’re glad to be a part of it.”

For more information visit www.sternfenster.com

PVCu systems manufacturer Veka is celebrating its 40th anniversary, marking four decades of growth, practical innovation and longstanding partnerships across the fenestration industry.

Key milestones in the company’s history include the launch of the Matrix system in 1995, the expansion into Fully Reversible and Vertical Sliders and Composite Door systems in 2008, and more recently, the introduction of digital tools WinDoPlan and Vena Edge, which provide customers with specification data, technical content and marketing support.

In 2024, Veka also launched Omnia, the UK’s only a doubleflush, double-rebated system available as a complete suite, while other recent innovations including Feinstruktur and Softline 82 have contributed to Veka’s continued focus on innovation in PVCu systems.

The Old Pickle Factory, Rawtenstall

Veka is using the anniversary to celebrate its long-standing partnerships with fabricators, installers and specifiers, who have supported and championed the development of Veka’s window systems, colour strategy and technical support services. It’s this true partnership and collaboration with its partners that helps ensure Veka’s extensive product range continues to reflect evolving expectations around design and fabrication efficiency, as well as

the required product performance standards, says the company.

The company is also reflecting on its ongoing investment into people and skills, having continually invested into apprenticeships and structured development programmes to support the next generation of fenestration professionals.

Since opening its Burnley site in 1986, Veka is now, and continues to be, a reliable, stable and reputable PVCu systems provider, supported by the global strength of the Veka Group who continue to expand and develop to strengthen their global, expansive portfolio, says the company.

Neil Evans, managing director for Veka, said: “When you look back over Veka’s 40 years in the UK, what stands out isn’t just the milestones – it’s the people and partnerships behind them. From day one, we’ve focused on supporting customers with reliable systems, consistent service and long-term stability, because responsible progress and doing things the right way have always been at the heart of Veka. As the industry continues to evolve, that commitment won’t change. It’s what has brought us here, and it’s what will shape the years ahead.”

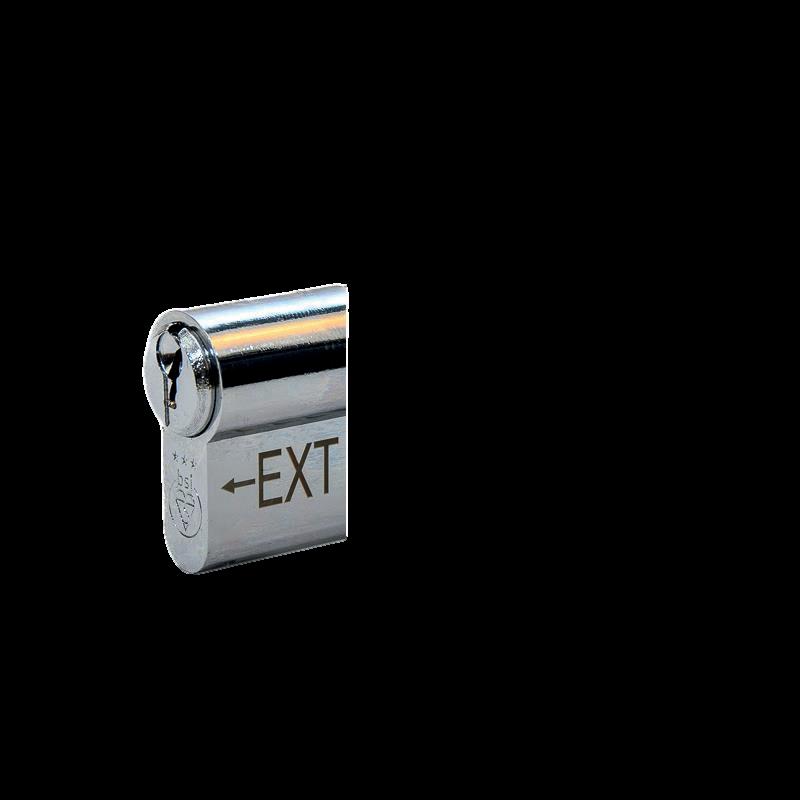

UAP Group Limited (UAP), the Bury-based door hardware specialist, is marking a transformative year defined by strategic growth, product innovation and industry recognition, following its acquisition in August by leading global security products and solutions provider Allegion plc.

The acquisition represents a significant milestone in UAP’s journey. UAP will report into the Allegion International segment, strengthening Allegion’s presence in the region,

complementing Allegion UK’s non-residential portfolio there and expanding solutions offered to the companies’ combined customers.

Alongside this, UAP continued to invest in product innovation throughout 2025, launching several new products, including a door closer range for residential, commercial and public environments, the Bullet Door Chain, and Kinetica Freezeguard 3-star euro cylinder range, the industry’s first to achieve BSI Kitemark

TS007 1:2024 certification and PAS24:2022+A1:2024 and Secured by Design accreditation, according to the company.

UAP’s commitment to innovation, culture and performance was recognised across the industry in 2025, including a double win at the National Fenestration Awards for Best Use of Video and New Product of the Year for Kinetica Freezeguard. The business also picked up a double win at the Locksmith Awards, where the company was named Hardware Company of the Year and marketing director Kamila Kasperowicz received Director of the Year.

Throughout the year, UAP also strengthened its team across the board, with a focus on strengthening its senior leadership, technical functions as well as sales team positions.

David Jennings, CEO of UAP Ltd, said: “2025 has been a defining year for UAP and our people’s dedication and expertise have been central to this success. Joining Allegion gives us the scale to accelerate growth, but our focus remains the same - investing in our people, developing game-changing products and driving progress for our customers and the industry.”

Founded in 1996, UAP holds nearly 200 patents, trademarks and registered designs and continues to invest heavily in research, development and innovation. As part of Allegion, the business enters 2026 with a strengthened platform to continue delivering high-quality door hardware solutions that improve safety, security and performance across the built environment.

Schüco, a global leader in sustainable façade systems, and Mace Construct, a leading construction firm, have announced a carbon partnership to advance decarbonisation in the UK build environment. This collaboration combines Schüco technical expertise and global supply chain with Mace Construct’s proven project delivery capabilities to set new standards for sustainable, high-performance façades. The partnership will:

Drive Net-Zero Goals: Focus on reducing carbon in building envelopes

Deliver Transparency: Provide Environmental Product Declarations (EPDs) and a sustainable product portfolio

Enhance Design & Execution: Offer comprehensive support throughout project phases

Phil Sedge, head of façades at Mace Construct said: “Schüco is a trusted partner for helping decarbonize our portfolio of projects across the UK. Their Value Up and Low Carbon offers in addition to their technical expertise and outstanding supply-chain are key factors for our partnership.”

Dan Gleeson, sales director at Schüco UK said: “Mace Construct is a pioneering and forward-thinking general contractors in the market with very ambitious low-carbon targets. We are proud to team up with Mace Construct to help them accomplish their goals.”

A quiet shift is taking place in the construction materials sector. As the generational profile of customers is changing and more installers and homeowners move their sales online, the traditional approach of collecting materials in branches is beginning to change. A growing number of suppliers are focusing on e-commerce and customer service while relying on fulfilment specialists such as NBP to manage storage and delivery.

Many of these businesses are strong in online marketing and sales generation but do not operate their own warehouses or delivery fleets. Instead, they work with fulfilment partners to facilitate their requirements. High service levels, and strong communication are extremely important in this sector to drive repeat sales and positive reviews from a whole host

of installer types.