Combining cutting-edge design with superior performance.

– Aligned sashes for a perfectly symmetrical view

– Minimal aesthetic (7 cm central post with NP Ultra handle)

– Load capacity up to 400 kg

– Concealable frame with low threshold

– New generation rollers

– Fully anodized diverters with stainless steel guide

– High performance with central gasket and perimeter closure

– Micro-ventilation available

– Anti-burglar hardware compatible

GIESSE SMART CHIC

The brand new concealed motorised tilt-and-turn system.

I prefer facade materials that deliver a premium

I prefer facade materials that deliver a premium look without demanding constant upkeep. Greenlam Clads stands out with its superior finish, UV-resistant performance, and long-lasting quality. It works exceptionally well for high-end residences and commercial projects, ensuring the building continues to look refined over time.

LIGHT FASTNESS PROPERTY (UV RESISTANT)

WITHSTANDS EXTREME TEMPERATURE -60°C TO 80°C

NO.: 1800 833 0004 To explore visit: www.greenlamclads.com *Mail us the photograph of your project at: designlab@greenlamclads.com or contact our sales representative.

More than 60 years of innovation, development & production of premium hardware for aluminum windows and doors.

Stretto is a high-performance, clampable three-part door hinge engineered for Euronut profiles (14/18 mm and 10/14). Its compact design with a slim knuckle delivers exceptional stability, a wide effective adjustment range, and reduced losses thanks to the knuckle’s optimized position close to the profile. Designed for all open-in and open-out doors, Stretto installs quickly with no profile preparation, requires only one height adjustment per door, and can be mounted using just two tools. Suitable for doors and balcony windows, it combines robust aluminium construction with refined aesthetics, offering extensive finish options to match any project.

Stretto: efficient installation, precise adjustment, and a clean, modern look—engineered to perform.

Sobinco, your reliable partner for high-end, architectural hardware.

in touch: abhishek.kale@sobinco.com - 3rd Floor, Shivana building, Right Bhusari Colony, Chandani Chowk, Pune 411038

GEALAN doesn’t just give windows a frame with our profiles, we’re genuinely trend-setting in uPVC window systems. And on top of that, we develop innovative solutions that offer all our partners and customers real added value.

We form the framework for the world of windows.

GEALAN doesn’t just give windows a frame with our profiles, we’re genuinely trend-setting in uPVC window systems. And on top of that, we develop innovative solutions that offer all our partners and customers real added value.

We form the framework for the world of windows.

Hardware

Head Office cum Application Centre: 28/01/8, Site IV, Sahibabad Industrial Area, Ghaziabad (UP) - 201005

Delhi Office: 4899 Hauz Qazi, Delhi-110006

Coimbatore Office: 2/227 D Erangathu Thottam, Rasipalayam Sulur, Coimbatore-641402

Website: www.pego.in

For Sales: West: 8929070625/9311600436

North: 8929070621/9999697732

East: 9319623434

Karnataka: 9999697660

Tamil Nadu & Kerela: 8929070623

Andhra & Secunderabad: 8929070624

Customer Care: 8929701016

Volume 12 | Issue 1

18

21

Façade – An Architectural Interface to a City’s Culture and Identity

Ar. Vivek V. Shankar, Principal Architect, Vivek Shankar Architects

Façade Performance and Building Energy Optimisation in Tropical Climates

Sneha Murthy, Sustainability Associate, McD BERL

24 The Future of Airport Terminal’s Façades & Fenestration

29

media@wfmmedia.com

+91 98701 44425

Ar. Sapan Gupta, Head of Design, GMR Group

Designing the Future of Façades: Smart Glass, Use of AI, and the Path to Sustainable Architecture

Sandeep Singh, Managing Director, Brawn Globus Turnkey Solutions Pvt Ltd

32 The Role of Sustainability in Façade & Fenestration: Building a Greener Future

Sanjay Chitnis, Retired Senior Vice President – Technical Services, JK Lakshmi Cement Ltd

36 Beyond the Entrance: The Silent Power of the Mall Façade

Rajan Vernekar, M.DES., IDC, IIT BOM., Founder, Rave Design

39 Turn Your Balconies, Façade, and Canopies into a Powerhouse

Rajeev Kumar, Independent Consultant and Advisor

42 Design Efficiency in Façades and Fenestrations: Material Synergy Approach

Ar. Sumit Dhawan, Founder & Principal Architect, Cityspace 82 Architects

46 Modern Window Trends Shaping Today’s Homes

Dinesh Chandra Pandey, Founder, Shankar Fenestrations & Glasses India Pvt. Ltd.

51 One-Part Dry-Fit Stone Wool Lamella Firestops for Practical and Robust Perimeter Void Fire Protection in Curtain Walls

Donel Dippi, Head of Technical & Compliance, Siderise Group

54 Beyond Functionality: Observing How People Shape Hardware Design

Paaul Sandip, Product Designer, Paul Studio

58 The Expert’s Edge

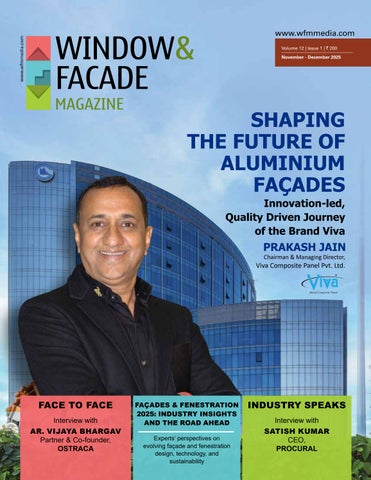

Interview with Prakash Jain, Chairman & Managing Director, Viva Composite Panel Pvt. Ltd.

66 Cover Story

Façades & Fenestration 2025: Industry Insights and the Road Ahead

95 Industry Speaks

Interview with Satish Kumar, CEO, PROCURAL

98 Face to Face

Interview with Ar. Vijaya Bhargav, Partner & Co-founder, OSTRACA

106 Case Study

CGST Bhawan, Ghaziabad: Shaping an Aesthetic and High-Performance Façade Through Fenestration Optimisation – Project by Studio Next

116 Project Watch

A Sustainable Sales Office Built from Shipping Containers - Project by SAGI Architects

118 Project Watch

AVIARA Residence: A Poetic Dialogue of Light, Nature and Timeless DesignProject by WMA

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications. Printed at Thomson Press India Limited, 18/35, Delhi-Mathura Road, Faridabad - 121007, Haryana, Name of the Editor-Ms. Renu Rajaram”

As we turn the page on 2025 and step confidently into a new year, it is a fitting moment to pause, reflect, and look ahead. The past year has been one of remarkable momentum for India’s built environment. With the Indian real estate and construction industry valued at over USD 300 billion and projected to reach nearly USD 1 trillion by 2030, the scale and ambition of development across housing, commercial, infrastructure, and urban regeneration have been unprecedented. Rapid urbanisation, policy reforms, infrastructure investments, and an increasing focus on sustainability have collectively reshaped how we design, build, and inhabit our cities.

At the heart of this transformation lies a renewed understanding of buildings as living systems—responsive, efficient, and deeply human-centric. This is most evident in the evolution of the façade and fenestration industry, which forms the focus of our cover story. In 2025, façades have decisively moved beyond visual novelty. No longer mere stylistic skins, they have become intelligent interfaces that mediate between climate, comfort, performance, and longevity. Architects today are designing envelopes that respond to orientation, manage heat and daylight, integrate adaptive shading, photovoltaics, and advanced materials such as terracotta, low-carbon concrete, and high-performance glazing. Digital tools, including predictive modelling, AI, and digital twins, are enabling façades that are not only resilient but also restorative—enhancing energy efficiency while improving occupant well-being. Importantly, the industry is witnessing a shift from transactional vendor–client relationships to deep technical partnerships between architects, consultants, and manufacturers. This collaborative approach is essential as façades and fenestration become critical contributors to sustainability goals and ease of living.

Equally significant in 2025 has been the emphasis on architectural honesty and simplicity— designs that age gracefully, are rooted in context, and balance aesthetics with measurable performance. As climate pressures intensify, lifecycle thinking, early integration, rigorous testing, and certification are no longer optional but fundamental to responsible design.

In this spirit of shared learning and dialogue, WFM Media continues to strengthen its knowledge-sharing initiatives through the WFM Podcasts. WFM Studio—our infotainment platform dedicated to the Architecture, Engineering, and Construction fraternity, as well as informed end users, through conversations with experts, case studies, brings insights on innovative materials, emerging technologies, best practices, safety, and certification. We aim to build awareness and foster informed decision-making across the industry through this platform.

As we welcome the New Year, we extend our warmest wishes to our readers, partners, and contributors. May 2026 bring thoughtful design, meaningful collaboration, and buildings that protect both people and the planet. A very happy and inspiring New Year to you all.

Acity’s growth is primarily measured by its economic condition and the opportunities it offers for living. The urban identity of a city is defined by its culture, climate, and social makeup, enabling evolution and sustainable transformation over time.

As we travel across a city, the perception formed stems from both the open and built environment, their interplay, or, in some cases, the segregated model of urban planning. Most Indian cities with rapid growth potential—and those already highly developed—offer a spectacle of building façades that may or may not appropriately relate to their surroundings or internal functions.

This article examines what the façade entails, along with the direct and indirect consequences of its impact.

From an architectural perspective, the façade embodies three intertwined aspirations: Functionality, Aesthetics & Visual Experience, and Social Responsibility.

A high-performance façade serves as a climatic interface. Thermal comfort depends on insulation, glazing ratios, shading devices, and orientation. Poorly calibrated façades can drive indoor temperatures outside the 20–26°C comfort range, increasing reliance on HVAC systems and energy use.

Visual comfort is equally vital. Daylight penetration, glare control, and solar shading influence circadian rhythms, visual fatigue, and productivity.

Acoustic insulation—achieved through double-skin façades, high-performance cladding, or porous materials—ensures that urban noise does not penetrate interiors, while operable elements and natural ventilation strategies maintain indoor air quality, crucial for occupant health. Cognitive–sensory design in façades refers to the light, insulation, and noise infiltration that affect inhabitants on a day-to-day basis.

Adequate daylight has been shown to improve alertness, reaction time, working memory, and overall cognitive performance. A façade is a cognitive and sensory stimulus; careful modulation of rhythm, proportion, and depth is essential for comfort and perception.

Workers in naturally lit offices show 18% higher cognitive performance and up

to a 25% improvement in short-term memory. A 2017 study in Sleep Health demonstrated that employees exposed to greater natural light obtained 46 minutes more sleep per night, enhancing daytime alertness and executive function.

Poorly insulated façades allow heat fluctuations that elevate physiological stress, triggering the hypothalamic–pituitary–adrenal (HPA) axis, subsequently impairing concentration and decisionmaking.

Noise infiltration is governed largely by façade quality. Inadequate acoustic insulation exposes occupants to environmental noise from traffic, aircraft, and urban activity—stimuli known to impair cognitive function. World Health Organization data shows that noise above 50 dB can disrupt attention, concentration, and memory. In educational settings, students near noisy façades have demonstrated up to 20% lower reading comprehension, highlighting the cognitive system’s sensitivity to auditory disturbance. Highperformance façades with proper sound attenuation are therefore essential to maintaining cognitive resilience in noisy urban environments.

Façades are not merely functional— they are psychological instruments.

People respond intuitively to humanscaled modules, proportional openings, materiality, texture, and articulation. Operable shading devices and windows allow personal control, improving satisfaction and productivity.

Empirical studies show that workers with access to outdoor views experience lower stress, higher creativity, and reduced mental fatigue compared to those in windowless spaces. Even small window apertures can reduce stress biomarkers such as cortisol levels and heart rate.

Façades have always been more than architectural boundaries—they are

symbolic carriers of culture, climateresponsive devices, and interfaces shaping human experience. In India, a land of climatic diversity, layered history, and rich material traditions, façades hold particularly deep cultural and environmental significance. Their evolution—from temple exteriors and Mughal jalis to contemporary glass towers—illustrates how architecture communicates values, identity, and a relationship with nature.

Today, as cities expand rapidly and climate pressures intensify, façade design is central not only to aesthetics but also to sustainability, well-being, and cultural continuity.

Rapid “glass-box” architecture risks erasing regional identity and increasing energy consumption. There is a growing need to:

• Reintegrate traditional elements such as jalis, courtyards, verandahs, and chajjas;

• Use local materials and crafts

• Reflect cultural aesthetics that resonate with Indian communities

Façade design becomes a medium to honour cultural memory while addressing contemporary needs. It responds to the site, the urban fabric, and its contextual narrative.

Dynamic façades, such as the Fosun Foundation Theatre in Shanghai, demonstrate how architecture can be

performative, contextual, and culturally resonant. In our cities, façades must do more than perform—they must activate streets, respond to climate, and convey identity. They are instruments of civic responsibility as much as architectural expression.

Examples such as Hawa Mahal (Jaipur), Chettinad mansions (Tamil Nadu), and Kerala’s timber dwellings illustrate traditional façade systems integrating vegetation, natural light, and airflow. These typologies show that biophilic façade design is not a recent import but an extension of indigenous architectural logic.

In our ongoing commercial project for a corporation, we explored a façade strategy balancing performance, sustainability, and human experience. Rather than relying solely on DGU glass to address heat gain, we designed vertical fins optimised through thermal simulations, offering shading while preserving daylight quality. White cement board panels serve both as aesthetic articulation and passive solar control.

An internal street connects indoor and outdoor zones, enhancing crossventilation and promoting informal interaction as a spatial bridge between two building volumes. This façade

demonstrates functional elegance, environmental sensitivity, and humancentred design.

The evidence is unambiguous: façades are active, performative elements shaping human experience, energy use, and urban life. They are visual instruments, climatic regulators, and psychological tools all at once. As cities grow denser and more complex, architects must create façades that go beyond enclosure—those that mediate the environment, respond to climate, enhance well-being, and express cultural identity.

A well-conceived façade is a quiet yet powerful agent of transformation. It can calm or stimulate, invite or repel, engage or exhaust. It is both a building’s voice and its body language. Designing façades with intention involves creating spaces that prioritize human experience, climate responsibility, and urban empathy.

Architecture is not merely shelter; it is a vessel shaping how we feel, move, and exist. And the façade is its most eloquent expression.

The future of architecture lies not in spectacle but in façades that heal, connect, and restore. Shaped with intelligence and empathy, they can become the quiet engines of a more humane urban world.

Principal Architect, Vivek Shankar Architects

Vivek Shankar Architects was established in 2002 by Ar. Vivek V. Shankar, following his return from London, where he completed his M.Arch (Design Research Lab) at the prestigious AA School of Architecture and subsequently worked at the Office of Zaha Hadid. He firmly believes that the intertwined combination of design innovation and software technology creates a profound impact on the approach to an architectural project, in which the process comprises methodologies derived from advanced 3D modelling and computational design. He has consistently pushed the boundaries of innovation by adopting animated graphics and 3D analysis of the site and the land available for the built mass in order to create a new user experience. The firm’s very first project, a commercial building, was nominated for the Aga Khan Award for Architecture in 2004.

Buildings in tropical regions encounter highly demanding environmental conditions, including intense solar radiation and elevated outdoor temperatures. These climatic factors place substantial stress on mechanical cooling systems, which often account for 40–60% of total energy consumption in such buildings. As the primary interface between the external environment and conditioned interior spaces, the façade—especially its glazing and window systems—plays a decisive role in determining heat transfer, daylight penetration, and ventilation behaviour. High-performance façades can substantially reduce cooling loads, improve visual comfort, and enhance indoor environmental quality while maintaining architectural flexibility and without necessarily incurring excessive construction costs.

This article examines the principal components of façade performance in tropical climates, strategies for energy optimisation, the analytical tools that support design decisions, and case studies demonstrating measurable impacts on building performance.

In tropical settings, thermal performance is dominated by the need to limit unwanted heat gain. Achieving this requires careful specification of glazing assemblies, which are often the most significant pathways for heat transfer. Low U-value glazing reduces conductive heat gains, while spectrally selective coatings minimise the admission of infrared radiation without compromising visible light. The

selection of an appropriate window-towall ratio—typically between 30% and 45% for tropical commercial buildings— helps balance daylight availability and thermal performance. Thermal breaks in curtain wall systems further reduce heat bridging, and high-performance insulation in opaque façade elements contributes to a more stable indoor environment. Even marginal reductions in the solar heat gain coefficient (SHGC) can translate into meaningful reductions in cooling demand because glazing typically accounts for the majority of external heat ingress.

Solar control is equally critical in the tropics, where direct solar exposure can create severe overheating. External shading devices, such as vertical fins along east–west façades or horizontal overhangs on north–south orientations,

block sunlight before it strikes the glazing, preventing solar radiation from entering the building envelope. Dynamic shading systems, including automated blinds and electrochromic glazing, respond to real-time variations in sun position and intensity. Architectural solutions such as brise-soleil and vegetated façades also help diffuse or filter harsh sunlight. External shading strategies are generally two to five times more effective than internal shading because they prevent thermal energy from reaching the façade surface. Given that glazing surfaces are among the most thermally vulnerable elements of the building envelope, solar control devices significantly enhance occupant comfort and reduce HVAC energy use.

Daylighting performance is another central aspect of façade design. Although tropical sunlight is intense, well-designed façades can harvest diffuse daylight while preventing glare and excessive heat gain. Light shelves redirect daylight deeper into interior zones, reducing reliance on artificial lighting. Glazing with high visible transmittance but low SHGC improves daylight penetration while maintaining thermal comfort. Reducing east–west exposure through massing and orientation decisions further supports effective daylighting, and the integration of daylight-responsive lighting control systems can achieve lighting energy reductions of 20–40%. Because windows directly mediate the quality and distribution of daylight, their optical and thermal characteristics fundamentally shape both visual comfort and energy consumption.

High-performance glazing is one of the most effective means of reducing cooling energy consumption in tropical commercial buildings. Low-E double glazing designed for humid climates reduces conductive and radiant heat transfer, while spectrally selective glazing allows visible light to enter while filtering out infrared wavelengths. Electrochromic glass introduces additional flexibility

by adjusting tint levels in response to solar exposure, improving both thermal performance and visual comfort. Because window systems represent a critical control point for heat gain and daylighting, improvements in glazing technology often yield disproportionately large energy savings.

Adaptive and responsive façades incorporate sensors, automation, and predictive algorithms to adjust shading, ventilation, and glazing tint based on environmental conditions. Automated louvres and shading screens track the sun and regulate heat gain, while photo-responsive and occupancyresponsive systems optimise daylight availability. More advanced AI-driven controls integrate façade performance with building management systems, predicting solar loads and adjusting cooling strategies accordingly. Such adaptive façades typically reduce cooling energy consumption by 10–20% relative to fixed-shading designs.

Passive design strategies continue to provide some of the most cost-effective means of reducing façade-related heat gain. Orienting the building to minimise direct sunlight, recessing windows, incorporating deep overhangs, and specifying light-coloured façade materials

all reduce the amount of solar radiation absorbed by the building envelope. These strategies underscore the importance of integrating façade considerations early in the design process.

Finally, façade performance must be integrated with broader building systems. HVAC systems must be sized according to realistic façade heat loads, avoiding inefficiencies associated with oversizing. Lighting systems should respond dynamically to the availability of daylight, and building automation systems should monitor shading devices, operable windows, and façade-integrated renewable systems. Building-integrated photovoltaics (BIPV), whether integrated into opaque façades or glazing systems, can further reduce operational energy use and contribute to long-term sustainability objectives.

Advanced simulation tools support rigorous analysis of façade performance in tropical climates. Whole-building energy modelling, daylighting simulations, and parametric modelling enable designers to test numerous façade configurations rapidly and evaluate glazing and shading combinations with respect to energy and daylighting performance.

Across the Indian tropical context, some of our projects demonstrate the significant impact of façade-driven environmental optimisation. At the Maharashtra National Law University in Nagpur, the campus implemented a second-skin façade that completely shielded the primary building envelope from direct solar exposure. Combined with the use of light shelves, the subdivision of windows into dedicated daylight and vision panels, and the precise calibration of shading elements, this strategy produced fully daylit interiors and achieved indoor temperatures up to 12°C lower than outdoor conditions.

In Bangalore, the Umiya Velociti development adopted a façade system integrating low-E glazing with angular vertical fins and horizontal overhangs positioned to block solar heat ingress while preserving daylight availability. Likewise, the Infosys campus in Nagpur employed a climate-responsive façade incorporating deep overhangs, vertical fins, and internal light shelves, resulting in improved daylight distribution and almost 51% overall energy savings.

Collectively, these examples highlight how integrated façade strategies— focused on glazing performance, shading geometry, and daylight management—

can markedly enhance thermal comfort and reduce cooling loads in tropical environments.

Looking ahead, developments in biomimetic façade systems and prefabricated modular façades promise to enhance performance and streamline construction. The increasing adoption of net-zero energy standards across tropical regions will further accelerate the integration of façades with renewable energy generation and advanced control systems.

Façade design, and particularly the performance of glazing and window systems, is one of the most influential factors affecting energy efficiency, comfort, and sustainability in buildings located in tropical climates. With high cooling demands and extended operating hours, these buildings benefit substantially from strategies that reduce solar heat gain, optimise daylighting, and integrate façade performance with mechanical and electrical systems. Through integrated design approaches and advances in façade technology, next-generation tropical buildings will be better equipped to meet energy targets, reduce operational costs, and provide healthier and more comfortable indoor environments.

Sustainability Associate, McD BERL

Sneha Murthy is an architect and sustainability leader with over 16 years of experience in the construction industry and academia. As Sustainability Associate at McD BERL, a pioneering MEP consultancy in Bangalore, she has advanced regenerative design through Net Positive Campuses and highperformance, climate-responsive buildings. She also employs an iterative design approach to develop building façades optimised for superior energy performance. Her work blends indigenous design principles with modern engineering to achieve energy efficiency, water self-sufficiency, and carbon neutrality. With several publications and innovations, her current focus on Sustainable Urban Scale Cooling explores microclimate revival to enhance urban thermal comfort. At industry forums, she offers evidence-based insights that bridge architectural innovation with measurable sustainability.

Airport terminals have evolved far beyond their original role as transit spaces. Today, they function as cultural landmarks, sustainable ecosystems, and high-performance engineering marvels—places that leave lasting impressions on millions of passengers each year. As global air travel accelerates and expectations rise, the spotlight is turning towards one critical element: the façade and fenestration systems that shape how terminals look, feel, and perform.

From climate-responsive skins to intelligent glazing, the next generation of airport building envelopes is redefining aviation architecture. Here is a deep dive into the innovations driving this global evolution.

In modern terminal design, façades serve as the face of a nation. They communicate identity, welcome passengers, and mediate climate.

Architectural Expression & Branding: Airports increasingly reflect regional culture through:

• Sculpted, flowing forms inspired by local topography

• Perforated metal screens echoing traditional motifs

• Iconic glass façades creating distinctive silhouettes

• Composite cladding materials enabling bold, expressive geometry These elements transform terminals into unique cultural ambassadors.

Climate-Responsive Form Finding: With airports located in extreme climates— from deserts to Arctic zones—façades are evolving into intelligent, climate-

adaptive envelopes. Key strategies include:

• External shading louvers and glazing tuned to solar exposure

• Optimised building orientation

• High-performance insulated panels

The result is architecture that works with the environment, not against it.

FENESTRATION: WHERE LIGHT, TRANSPARENCY & PASSENGER EXPERIENCE CONVERGE

Natural light is central to airport design. Fenestration systems regulate daylight, frame views, and influence psychological comfort.

Large-Span Glazing & Curtain Walls: Advances in structural glass now make it possible to design soaring transparent façades that enhance:

• Daylight penetration

• Passenger well-being

• Airside visibility

• A sense of scale and openness

Cable-net systems, steel–glass hybrids, and silicone-sealed façades enable this without compromising safety.

Skylights, Clerestories & Light Wells: Modern terminals are celebrated for their luminous interiors, achieved through:

• Continuous skylight ribbons

• Geometric or domed skylights

• Atrium-based light wells

These systems create dynamic light patterns that evolve throughout the day.

Acoustic & Thermal Comfort: Advanced multi-layer glazing balances transparency with performance, offering:

• Superior aircraft noise reduction

• Controlled solar heat gain

• Enhanced thermal insulation

• Reduced condensation

Comfort is now a fundamental design requirement—not a luxury.

HIGH-PERFORMANCE MATERIALS REINVENTING TERMINAL FAÇADES

Material science is playing a pivotal role in reimagining airport envelopes.

Next-Generation Glazing Technologies: Key innovations include:

• Low-E and selective coatings

• Electrochromic smart glass

• Vacuum-insulated glazing (VIG)

• Bird-safe fritted patterns

Smart glass, in particular, is transforming terminal energy efficiency and interior ambience.

Composite & Engineered Cladding Panels: Airports demand lightweight yet durable materials. Popular choices include:

• Aluminium Composite Panels (ACP)

• Fibre-Reinforced Polymer (FRP)

• High-Pressure Laminates (HPL)

• Perforated metal screens

These materials support rapid construction, lighter structures, and longterm durability.

ETFE & Tensile Membrane Systems:

ETFE is becoming a preferred choice for modern roofs and façades due to its:

• High translucency

• Feather-light weight

• Self-cleaning properties

• Longevity and UV resistance

ETFE cushions create bright, thermally efficient spaces with minimal structural demand.

DIGITAL & INTELLIGENT FAÇADES: USHERING IN SMART AIRPORTS

Digitalisation is transforming building envelopes from static surfaces into intelligent systems.

Sensor-Driven Adaptive Façades: Today’s smart façades integrate:

• Temperature and daylight sensors with automated louvers

• AI-based climate control and predictive maintenance analytics

• IoT-linked façade panels

These systems respond in real time to environmental changes.

Parametric Design & BIM Engineering: Advanced KPIs allow architects to simulate:

• Sun paths and glare

• Material performance

• Wind pressure and energy consumption

Digital Twins for Lifecycle Management: Airports increasingly deploy digital

twins to monitor façade health, analyse performance, and plan maintenance, reducing operational downtime and costs.

SUSTAINABILITY: THE NEW IMPERATIVE FOR TERMINAL ENVELOPES

As aviation moves towards decarbonisation, façades play a central role in sustainability strategies.

Passive Design Approaches: Passive solutions can significantly reduce HVAC loads, including:

• Double-skin ventilated façades

• Thermally broken framing systems and fixed shading devices

• High-insulation opaque panels

Renewable Energy Integration: Façades are evolving into energy generators through:

• Building-integrated photovoltaics (BIPV)

• Solar-active shading fins

• Photovoltaic glazing, reducing

the terminal’s operational carbon footprint

Material & Water Sustainability:

Contemporary façade systems also prioritise:

• Recyclable materials and lowembodied-carbon products

• Rainwater collection surfaces

• Longer-life coatings and laminates

Sustainability is now mainstream, not optional.

SAFETY, SECURITY & RESILIENCE: NONNEGOTIABLES IN AIRPORT DESIGN

Airport façades must comply with stringent safety standards and withstand extreme conditions. Key requirements include:

• Blast-resistant glazing

• Non-combustible, fire-rated cladding

• Systems designed to withstand cyclones, snow loads and seismic events

These measures ensure round-the-clock operational continuity.

THE FUTURE: ADAPTIVE, AUTONOMOUS & CLIMATE-RESPONSIVE FAÇADES

The coming decade will witness transformative developments, including:

• Kinetic façades that adapt to climatic conditions

• Aerogel-based super-insulation for ultra-thin envelopes

• Autonomous drones and robotic BMUs for cleaning and maintenance

• Carbon-absorbing façade materials supporting carbon-neutral ambitions

These innovations promise terminals that are not only efficient but regenerative.

Airport terminal façades and fenestration systems are undergoing a profound transformation. What was once a protective shell is now an intelligent interface—one that adapts, performs, expresses identity, and enhances passenger well-being. The future of terminal design lies at the intersection of technology, sustainability, culture, and human-centric innovation.

As the aviation industry evolves, the façades of tomorrow will not only meet functional demands but elevate airport environments into inspiring, resilient gateways that celebrate both place and progress.

SAPAN GUPTA Head of Design, GMR Group

Sapan Gupta is an accomplished Architect and Urban Planner with over 1.5 decades of experience shaping sustainable, future -ready urban and aviation environments. A specialist in airport design-planning, terminal design, master planning, and integrated urban strategies, he delivers innovative, high-performance solutions for complex urban and aviation ecosystems. His experience spans passenger terminals, cargo and MRO facilities, SEZs, land-use planning, transport systems, and urban renewal, ensuring seamless integration of functionality, sustainability, safety, and aesthetics. He has led major national and international projects, including Hyderabad, Delhi, Goa, Vizag, and Nagpur airports, Dubai, The Netherlands, etc., as well as Smart City initiatives and large-scale city master plans. With strong expertise in development strategy, business growth, annual operating plans, capital expenditure planning, and concept of operations, he drives projects from vision to successful execution. Passionate about sustainable design and resilient urbanism, he brings a strategic, future -mobility-aligned approach to planning and design.

In the evolving narrative of modern architecture, building façades have transformed from mere aesthetic envelopes into highly functional, performance-driven systems. Today, façades are no longer just about how a structure looks; they are about how it breathes, adapts, conserves energy, and interacts with its environment. As urbanisation intensifies and sustainability becomes non-negotiable, the efficient use of glass and advanced fenestration systems has emerged as a defining element of contemporary building design. The building materials and façade technologies have transformed tremendously over the past few decades. The innovations we see today—whether in energy-efficient glass, AI-assisted design tools, or integrated automation— are redefining what buildings can achieve in terms of performance, comfort, and environmental responsibility.

Glass has long symbolised openness and progress in architectural language. From

skyscrapers to institutional campuses, glass façades form the face of modern urban landscapes. Yet, their efficient use is critical. A poorly designed glass façade can contribute to heat gain, glare, and increased energy consumption. On the other hand, advanced glass technologies—such as lowemissivity (Low-E) coatings, double glazing, and spectrally selective coatings—enable architects to strike a balance between aesthetics and thermal comfort, as well as energy efficiency. What we see now is a growing awareness that the “transparency” of glass must come with responsibility. A

façade should invite natural light while filtering excess heat, contributing to occupant well-being without placing an undue burden on HVAC systems. This balance is achievable only when designers embrace performance-driven glass specifications from the conceptual stage.

Traditionally, façade design involved extensive simulations, trial-and-error modelling, and manual interventions. Today, AI-powered tools and advanced parametric design software have fundamentally changed this process. AI algorithms can analyse multiple variables—orientation, climate, wind patterns, and solar angles—within seconds to recommend the most efficient façade and fenestration designs. For example, AI can simulate how a façade will perform over an entire year in terms of daylighting, heat gain, and shading. Designers can use this data to refine glass types, shading devices, and fenestration layouts for optimal efficiency. This is not merely theoretical; it is already in practice. Across the globe, projects are increasingly being designed with AI-led façade optimisation, helping architects minimise energy costs, maximise comfort, and improve sustainability ratings.

The next frontier in façade technology lies in automation. With the integration of IoT and smart sensors, building façades can now adapt in real time to external conditions. Automated shading systems, electrochromic glass (which changes its tint based on sunlight intensity), and responsive ventilation panels are revolutionising building performance. Imagine a façade that automatically darkens its glass panels during peak afternoon sun to reduce cooling loads, then reverts to clear transparency by evening to maximise natural light. Or

louvers that adjust their angle based on wind speed to reduce structural stress. Such intelligent systems not only save energy but also extend the lifespan of the façade itself. For India, where climatic diversity ranges from scorching summers to heavy monsoons, adopting smart façades can be transformative. It can help cities reduce their carbon footprint while enhancing the quality of life for millions of urban residents.

Globally, sustainability goals are driving façade innovation. Green building certifications such as LEED and GRIHA place strong emphasis on energy-efficient fenestration. Governments are also tightening regulations around building energy codes, making it imperative for developers to adopt smarter façade solutions. In India, with its ambitious netzero targets, the building sector will play a critical role. Glass and façade systems are central to this shift, as they determine how much energy a building consumes or conserves. By combining efficient glass, AI-led design, and automation, we can create buildings that are not only visually striking but also environmentally responsible.

By combining efficient glass, AI-led design, and automation, we can create buildings that are not only visually striking but also environmentally responsible

While technology drives innovation, the ultimate goal of any façade system should be human comfort. Studies show that access to natural daylight improves productivity, reduces stress, and enhances overall health. Smart fenestration systems that optimise daylight while minimising glare are essential for creating healthier work and living environments. In this sense, glass façades are not merely about efficiency; they are about empathy. They connect occupants to the outside world while protecting them from its extremes, offering transparency without vulnerability.

The façade industry stands at an inflection point. With climate change pushing us towards sustainable practices, and with AI and automation unlocking unprecedented possibilities, the future of façades lies in integration— where aesthetics, performance, and sustainability coexist seamlessly. The next decade will belong to adaptive, intelligent, and environmentally responsive façades. Glass, as a material, will continue to dominate, but its role will evolve beyond appearance into active performance. The challenge for architects, engineers, and developers is to embrace these innovations early, not as add-ons but as integral elements of design philosophy. By doing so, we can create future-ready buildings— structures that are not only symbols of progress but also stewards of sustainability. In the end, façades are the face we present to the world. It is time we ensure that this face reflects not only beauty but also intelligence, responsibility, and resilience.

Managing Director,

Sandeep Singh is the Managing Director at Brawn Globus Turnkey Solutions Pvt Ltd. He is a seasoned entrepreneur, civil engineer, and business transformation leader with more than 25 years of experience in real estate, construction management, and corporate fitouts. For the past two decades, he has been at the helm of Brawn Globus Turnkey Solutions Pvt Ltd., a 20-year-old design-and-build company headquartered in Noida, where he has played a pivotal role in establishing the firm as a trusted name in India’s corporate interior and infrastructure sector. A hallmark of Brawn Globus under his leadership is the trust and loyalty of its clients. A graduate civil engineer with a master’s in construction management from NICMAR, he continues to pair strategic foresight with meticulous execution, shaping Brawn Globus into a benchmark for quality, reliability, and innovation in India’s evolving workplace landscape.

architectural landscape with strength, safety, and style.

For over 21 years, Alstone has stood as the backbone of modern facades — from airports and metros to high-rises and institutions our legacy is written on skylines across the nation.

THE ROLE OF SUSTAINABILITY IN FAÇADE & FENESTRATION: BUILDING A GREENER FUTURE

As the world confronts the realities of climate change, resource depletion, and

rapid urbanisation, sustainable building design has become a global imperative. Among the many components that shape a building’s environmental performance, the façade and

Façade vs. Fenestration: A Comparative Overview

Feature

Definition The entire exterior face or "skin" of a building, which can be opaque (walls) or transparent (glazing).

Components Includes all structural elements, cladding materials (e.g., composite panels, masonry), insulation, and the fenestration systems themselves.

Primary Role Provides the main barrier against external elements (wind, rain, UV radiation), contributes to structural stability, and defines the building's aesthetic identity.

Performance Assessed for overall thermal efficiency, air/water tightness, fire resistance, and structural load resistance.

Design Focuses on the holistic design of the building envelope, integrating all materials and openings to create a cohesive appearance and meet energy codes.

fenestration system stand out as one of the most influential. These systems not only define a building’s visual identity but also determine how efficiently it consumes energy, manages natural resources, and enhances occupant wellbeing.

The façade is the external envelope or “skin” of a building, comprising opaque and transparent elements that protect the structure from environmental forces. Fenestration refers specifically to the openings within this envelope—windows, doors, skylights, and curtain walls—that enable natural light, ventilation, and visual connectivity.

Together, they form the building envelope, a critical interface between indoor comfort and outdoor climate.

Refers to all transparent or semi-transparent openings within the façade, including their design, construction, and arrangement.

Primarily consists of windows, doors, curtain walls, skylights, and the associated hardware and glazing.

Manages the interaction between interior and exterior spaces, controlling natural light, ventilation, and views, while also impacting thermal performance and acoustics.

Performance is measured by specific metrics like U-factor (heat transfer), solar heat gain coefficient (SHGC), and visible light transmittance (VT), often certified by bodies like the National Fenestration Rating Council (NFRC).

Focuses on specific design choices for the openings themselves, such as the type of glazing (double or triple-glazed), framing materials (thermally broken frames), and shading strategies.

The Asia Pacific region leads the global façade market, accounting for nearly 38% of worldwide demand. The global façade market is projected to reach USD 325 billion by 2025, driven by:

• Rapid urban development

• Government incentives for green buildings

• Growing awareness of energy efficiency

China, India, the United States, Germany, and the UAE are among the top contributors in innovation, volume, and sustainability-focused façade solutions.

A thoughtfully designed façade and fenestration system can dramatically improve a building’s environmental footprint. Key sustainability benefits include

• Enhanced Energy Efficiency: High-performance materials reduce heat gain, heat loss, and air leakage: insulated panels, low-conductivity materials, and advanced glazing systems significantly lower energy consumption.

• Optimised Natural Light & Ventilation: Strategic fenestration design reduces reliance on artificial lighting and mechanical ventilation, improving both energy savings and occupant comfort.

• Water Conservation: Modern façade systems can integrate rainwater harvesting, greywater reuse, and surface runoff management.

• Sustainable Material Choices: Utilising recycled glass, FSC-certified timber, low-VOC coatings, and eco-friendly composites reduces environmental impact throughout the building’s lifecycle.

• Improved Indoor Air Quality: Better ventilation, reduced infiltration of pollutants, and noise control contribute to healthier indoor environments.

The industry is witnessing rapid advancements that blend performance, aesthetics, and sustainability:

• Double Skin Façades: Two layers of glazing create a thermal buffer, improving insulation and reducing HVAC loads.

• Green Roofs & Living Walls: Vegetated surfaces enhance insulation, mitigate heat island effects, and improve air quality.

• Smart Glass Technologies: Electrochromic and thermochromic glass adjust transparency based on environmental conditions, reducing glare and cooling loads.

• Solar and Energy Generating Windows: Photovoltaic glazing enables buildings to produce clean energy without compromising daylight.

• Bio-Based Materials: Innovations include plant-based composites, biopolymers, and mycelium-reinforced panels.

Indian Standards:

• National Building Code of India 2016 (NBC 2016) provides guidelines for

façade and fenestration design, including requirements for energy efficiency, fire safety, and structural integrity.

• IS 875 (Part 3) - Code of practice for design loads (other than earthquake) for buildings and structures, Part 3: Wind loads.

• IS 2553 - Safety glass - specification (Part 1).

• IS 2835 - Specification for flat transparent sheet glass.

• IS 3548 - Figured, rolled and wired glass - specification.

International Standards:

• ISO 15099 - Thermal performance of windows, doors, and shading devices - Detailed calculations.

• ISO 10077-2 - Thermal performance of windows, doors and shading devices - Calculation of thermal transmittance - Part 2: Frames.

• ISO 6612 - Windows and door height windows - Wind resistance tests.

• ASTM E2270 - Standard Practice for Periodic Inspection of Building Façades for Unsafe Conditions.

• ASTM E2128 - Standard Guide for Evaluating Water Leakage of Building Walls.

• ASTM E1186 - Standard Practices for Air Leakage Site Detection in Building Envelopes and Air Barrier Systems.

• EN 12153 - Curtain walling - Air permeability - Test method.

• EN 12155 - Curtain walling - Water tightness - Laboratory test under static pressure.

• EN 12179 - Curtain walling - Resistance to wind load - Test method ¹ ² ³.

These standards provide guidelines for the design, testing, and installation of façade and fenestration systems, ensuring safety, energy efficiency, and durability.

The National Building Code (NBC) 2025 draft is expected to bring significant changes to India’s building construction landscape, focusing on fire safety, sustainability, and accessibility.

Strategic fenestration design reduces reliance on artificial lighting and mechanical ventilation, improving both energy savings and occupant comfort

Sustainable Materials

• Recyclable Materials: Aluminium composite materials (ACM) and Metal Composite Materials (MCM) are popular for their durability and ecofriendliness.

• Bio-based Materials: Mycelium-based composites, bamboo-reinforced panels, and upcycled metal façades are gaining traction.

• Energy-Efficient Materials: Highperformance insulated panels with phase-change materials (PCMs) and aerogels are being used for superior thermal insulation. e.g.

1. Triple-Glazed Windows: Reduce heat loss, minimise noise, and lower energy bills.

2. Low-E Glass: Reflects infrared radiation, keeping homes cool in summer and warm in winter.

3. Thermally Broken Frames: Reduce heat transfer and energy loss

• Electrochromic Glass: Glass that changes tint with electrical voltage, reducing glare and heat gain

• Thermochromic Glass: Glass that adjusts opacity based on temperature changes

• Kinetic Façades: Movable shading elements that optimise shading and ventilation

• Automated Windows: Controlled remotely, these windows optimise energy efficiency and convenience.

• BIM and AI: Building Information Modelling and Artificial Intelligence enable precise designs and efficient project execution.

• 3D Printing: Customised façade elements and complex geometries are possible with 3D printing.

• Dynamic Finishes: Advanced finishes that mimic natural materials like wood or stone.

• Living Façades: Green façades incorporating plants and vegetation for thermal insulation and improved air quality.

• Bold Colours and Textures: Add a pop of colour to your home’s exterior with vibrant door and window finishes.

• Minimalist Frames: Sleek, slim frames maximise glass area and natural light.

• Floor-to-Ceiling Windows: Create a seamless transition between indoors and outdoors

• Multi-Point Locking Systems: Enhance security and peace of mind.

• Impact-Resistant Glass: Withstands extreme weather conditions and break-in attempts.

• Smart Locks: Integrate with home automation systems for seamless control

Sustainable façade and fenestration design is no longer optional—it is central to the future of responsible construction. By embracing innovative materials, smart technologies, and performance-driven design, the industry can create buildings that are energy efficient, environmentally responsible, and deeply comfortable for occupants. As global climate challenges intensify, the façade and fenestration sector will continue to play a pivotal role in shaping greener, healthier, and more resilient built environments.

• Energy-Harvesting Windows: Generate electricity while allowing natural light to enter Disclaimer: The views and information presented in this article are intended solely for general awareness and knowledge enhancement. Certain creative liberties have been taken to simplify complex concepts and present them in an accessible manner. Readers are encouraged to refer to official codes, standards, and professional guidance for project-specific decisions.

Retired Senior Vice President –Technical Services, JK Lakshmi Cement Ltd

Sanjay Chitnis is a retired Senior Vice President – Technical Services at JK Lakshmi Cement Ltd, Delhi, bringing over four decades of rich experience and hands-on expertise across industrial construction, master planning for employee townships, and multidisciplinary project execution. His career spans diverse sectors, including cement and concrete, automobiles, chemicals, and sugar industries, where he has led complex projects with a strong focus on quality, safety, and long-term value creation. He has been closely associated with new product development and R&D initiatives, contributing to innovation and technical advancement within the industry. Known for his practical, field-tested insights, Sandy remains an active and influential voice on LinkedIn. He publishes a technical article every Sunday, sharing real-world learnings and best practices with the professional community. To date, he has authored 146 articles, each reflecting his commitment to knowledge sharing and industry development.

BEYOND THE ENTRANCE: THE SILENT POWER OF THE MALL FAÇADE

Before you step inside, before you smell the cookies or smell the bespoke perfumes, or hear the distant hum of commerce, the mall has already spoken to you. Its first and most powerful

statement is its façade. Far more than just a wall or an entrance, the mall façade is a complex piece of architecture, marketing, and urban storytelling. It is the carefully crafted mask that sets the stage for the experience within, a silent salesman working tirelessly to draw you in.

THE FORTRESS OF PLENTY: THE BIRTH OF THE INWARD-GAZING GIANT (INDIA DID NOT HAVE ANY MALLS YET)

In the post-war boom of the 1950s and 60s, the first-generation enclosed shopping malls arose as sprawling indoor centres which were, in a literal sense, cathedrals of consumption. Their façades, much like medieval fortresses, were designed not to invite scrutiny from the outside but to protect and contain the paradise within. Architects like Victor Gruen, the father of the modern American mall, envisioned these structures as self-contained utopias, insulated from the chaos of the city and the unpredictability of the weather. The exterior was frequently a monotonous expanse of blank concrete or brick, punctuated only by signage and utilitarian entrances. The message was

simple: the magic is inside; the outside is just the protective shell.

The façade of this era was often an exercise in brutalist or modernist minimalism. Vast, unadorned expanses of concrete, brick, or pre-cast stone dominated the exterior. Entrances were functional but not necessarily grand; the real spectacle was reserved for the interior. The message was clear: the outside world is irrelevant. All that matters is the climate-controlled, curated consumer wonderland on the other side of this wall.

As competition intensified, the mute fortress façade was no longer sufficient. The 1980s and 90s ushered in an era of theatricality, where the exterior became a stage set designed to dazzle and attract. This was the age of the “retail theme park”, and the façade was its marquee.

Gone were the blank concrete walls, replaced by soaring glass atriums, neonlit arches, and grandiose entrances. Water features, from fountains to waterfalls, became common, adding a sense of luxury and dynamism. Architects began borrowing historical and cultural references, creating façades that could evoke a vague sense of European grandeur or futuristic fantasy. The mall’s name, often in a custom, flamboyant font, was illuminated in lights, visible from the highway like a Broadway sign.

This shift reflected a new understanding of shopping as entertainment. The façade was no longer a barrier but a preview, a trailer for the sensory experience inside. It promised not just goods but an event. It was loud, confident, and unapologetically commercial, mirroring the exuberant consumerism of the era. The mall was selling a dream, and the façade was its most allusive and extravagant advertisement.

Today, that approach has been radically reimagined. The modern mall façade is the cornerstone of its brand identity. It tells a story about what shoppers can expect.

• The Palace of Luxury: For highend centres, the façade is about opulence. Think imported marble, gleaming glass curtain walls, polished metal accents, and grand, sweeping canopies. The architecture is minimalist yet imposing, communicating exclusivity, quality, and calm. The message is clear: this is a destination for discerning shoppers.

• The Beacon of Entertainment: For family-oriented or entertainmentfocused malls, the façade is dynamic and playful. Large, colourful digital screens, bold geometric shapes, vibrant lighting schemes, and visible attractions like Ferris wheels or climbing walls turn the exterior into a billboard of excitement. It promises an experience that goes beyond shopping.

• The Integrated Community Hub: In newer lifestyle centres, the façade aims to blend with the community. The mall eschews the monolithic look for a streetscape feel, with multiple storefronts, outdoor seating, green walls, and pedestrian-friendly walkways. The materials are often warmer — wood, stone, and textured panels — to feel less commercial and more like a natural part of the town centre.

A successful façade is not just beautiful; it’s highly functional. It is a masterclass in wayfinding, guiding visitors intuitively to the main entrances, basement parking, and valet points. Strategic use of lighting is crucial. By day, the façade must work with natural light, using shadows and reflections to create visual interest. By night, it transforms entirely. Carefully orchestrated LED lighting can highlight architectural features, create moods, and make the mall a landmark visible from miles away.

Materials, too, play a dual role. Beyond aesthetics, they are chosen for durability, energy efficiency, and sustainability. Green façades with living plants can improve insulation and air quality, while smart glass can adjust tinting to control solar heat gain, reducing energy costs.

Ultimately, the power of the mall façade lies in its role as a psychological threshold. Its design directly influences our mood and expectations. The heavy, imposing façade of the past commanded a sense of awe and anticipation for the wonders within. The transparent façade of the present lowers the barrier to entry, reducing anxiety and making the space feel more accessible and less intimidating. It invites casual visitation, not just dedicated shopping trips.

The materials, colours, scale, and lighting all work in concert to tell a story. Warm materials like wood and stone suggest authenticity and quality. Cool, sleek metals and glass imply modernity and luxury. Ample natural light pouring through glass fronts creates a positive, energising environment, while the artificial, controlled lighting of the old malls created a timeless, captive bubble.

It says, “We are not a sealed-off vault of merchandise; we are a part of your town, a place where life happens.” This design also aligns with the “see now, buy now” impulse, allowing the curated interior world to tempt the potential customer from the pavement through its large

digital screens. The fortress walls have been replaced by a friendly, inviting face, acknowledging that to survive, the physical mall must integrate into the urban and social fabric.

VERNEKAR , M.DES., IDC, IIT

Founder, Rave Design

The evolution of the mall façade is moving towards a complete dissolution of the barrier between inside and outside. The rise of open-air, mixed-use developments means the façade is no longer a single wall but a series of interconnected experiences. Furthermore, technology is integrating directly into the architecture. Interactive digital displays, augmented reality features that can be accessed via smartphone, and façades that change appearance based on the time of day or façades that dance to the whims of the wind are becoming the new frontier.

In an era where online shopping offers unparalleled convenience, the physical mall must offer an experience that cannot be replicated through a screen. The façade is the first, and perhaps most critical, part of that experience. It is the handshake, the smile, the promise of something more. It is not just a wall; it is the welcome mat to a world of curated experiences, and its power lies in its ability to make you want to cross the threshold of online shopping and discover the magical experiences of a real mall.

Sounds ironic, but yes, today’s façade is that magical portal which teleports you from the VIRTUAL to the PHYSICAL world of shopping.

Rajan Vernekar is the Founder of Rave Design, TEDx speaker, Ex Design Head, Kshitij Malls, Ex Design Director, Sq.Ft Consulting, India Operations, and an industry veteran with 32 years of work experience. He has experience working with top management in Indian real estate at Strategy and Leadership levels, Design Management, Product Innovation, and Design. He has launched some of the largest worldclass mixed-use developments in India. He is a pioneer in the shopping centre industry in India. He brings a unique blend of international experience in the best design and development processes, combined with a deep understanding of the Indian mindset and the Indian market. He has Middle East work experience and has collaborated with international architects. He has set up and led large teams of architects and designers with Director-level responsibilities in the real estate industry. He has written for trade magazines and has been a panellist at real estate and retail sector conferences. He is associated with IDC, IIT Bombay as an External Jury member for Master-level thesis projects and has been invited to deliver a series of talks at various platforms and design schools.

Gone are the days when rooftops were the only spaces available for installing solar power systems. With the advent of Building-Integrated Photovoltaics (BIPV), architects and engineers now have access to innovative, customised solutions for harnessing clean and sustainable solar energy. Structural glazing has emerged as an attractive façade option, especially for architects seeking a sleek, contemporary aesthetic for modern buildings.

By integrating solar technology into building elements such as façades, balconies, railings, and canopies, BIPV offers immense potential to blend functionality with design. When combined with thoughtful architectural planning, these systems not only generate renewable energy but also enhance the utility and visual harmony of the overall structure.

As global energy demands escalate and environmental challenges grow

more urgent, the pursuit of sustainable energy solutions has become vital to modern design and engineering. BIPV stands at the forefront of this shift— merging architectural elegance with advanced solar technology. Unlike conventional solar panels added as external components, BIPV systems are seamlessly built into the structure itself, serving a dual purpose as both energy generators and integral building materials.

BIPV refers to photovoltaic materials that are directly integrated into the building structure—replacing conventional materials like glass, tiles, or metal sheets—while simultaneously producing electricity

Size: Solar panels for Building-Integrated Photovoltaics (BIPV) are available in a wide range of standard dimensions—

from 300 × 300 mm to 2400 × 1200 mm—to meet diverse architectural needs. Additionally, they can be customised to suit specific design or structural requirements, offering maximum flexibility in application.

Colour and Patterns: BIPV panels come in an extensive colour palette spanning red, yellow, green, blue, grey, black, and white, allowing them to seamlessly blend with any architectural style. To enhance visual appeal, panels can also be designed with textures and finishes resembling mosaic, marble, granite, brick, tile, or wood grains, adding both elegance and character to building exteriors.

Installation: When used as cladding, BIPV panels are typically installed using a rainscreen system, where the photovoltaic panels form the outermost layer fixed to a metal framework, ensuring proper ventilation and moisture management behind the façade. In balcony applications, they can function as parapets or railing systems, serving a dual role as protective barriers and energygenerating surfaces. When integrated into outdoor spaces like sidewalks, plazas, flooring, or terrace designs, the panels are frame-mounted, making them walkable while supporting green spaces or elevated garden structures through intelligent architectural integration. The use of covering material in Pergola, Canopy, Gazebo, Skylights and Atrium can be profiled to suit the shape and geometry of the structure.

• PV Modules: Solar cells embedded into building materials (glass, laminates, etc.)

• Inverters: Convert DC power generated into AC for building use

• Energy Storage Systems (optional): Batteries to store excess energy

• Power Management Systems: Control, monitor, and optimise energy flow.

• Perovskite-based BIPV Glass: Enhances transparency and efficiency.

• Flexible Thin-Film Modules: Enable curved and lightweight architectural designs.

• Smart BIPV Systems: Combine energy generation with sensors, automation, and smart shading control.

Unlike bulky rooftop panels, BIPVs integrate seamlessly into building design and render aesthetic appeal to the structure. It reduces material and labour costs since it replaces conventional cladding or glazing, enabling cost efficiency in the life cycle cost. It is expected to recover additional capex cost within 6-10 years. On-site renewable energy generation also

contributes to Energy Independence. This system provides thermal insulation, thus reducing cooling and heating demands. It contributes to net-zero energy building goals, a standard feature of modern architecture, offering a reduced carbon footprint. Future innovations in transparent solar cells, building energy modelling, and AI-based optimisation will drive even greater uses and benefits. With the rise of smart cities and sustainable design mandates, BIPV is set to become integrated and efficient.

Building-Integrated Photovoltaics mark a paradigm shift in how we think about solar energy. They transform buildings from passive energy consumers into active producers, aligning perfectly with global goals for net-zero carbon emissions. As technology matures and costs decline, BIPV will redefine urban skylines — turning every building into a power plant of the future.

RAJEEV KUMAR Independent Consultant and Advisor

Rajeev Kumar has over three decades of expertise in construction and infrastructure management. He has contributed to strategic project planning, contract management and facility operations across defence and institutional sectors. His recent engagements focus on green initiatives, cost control and stakeholder collaboration to achieve timely and sustainable project delivery. As an Independent Consultant and Advisor, he specialises in infrastructure management, client relationship development and the promotion of sustainable practices. His commitment to operational excellence, along with strict adherence to quality and safety standards, drives his efforts to align projects with client objectives and broader community well-being. He is also empanelled as an ‘Independent Director’ with the Ministry of Corporate Affairs (MCA). Community service for a better tomorrow remains a core personal passion.

Architecture today is in the midst of a fascinating evolution that surpasses form and ornamentation to encompass performance, precision, and purpose. This is nowhere more visible than in façade and fenestration design. What was once seen as the decorative “face” of the building, the façade has now been revolutionised into a highperformance system: an intelligent skin mediating between the indoors and the environment.

In a time when sustainability, resilience, and identity dominate architectural discourse, design efficiency has become the new aesthetic. It is not about how a building looks but about how it works — how it breathes, shields, and responds. Within this context, material synergy is key to allowing architects to achieve optimal thermal comfort, daylight

balance, and structural performance while maintaining expressive design freedom.

The façade is the most powerful medium to share stories — the fusing of material science and architectural narrative.

The façade is no longer an afterthought or a decorative layer. It is an engineered system, one that has to perform along several fronts: climatic, structural, acoustic, and aesthetic.

Everywhere, from the humid coastal belts of Bangladesh and the western Indian coastline to the arid interiors, façades continuously battle it out with solar gain, dust accumulation, and fluctuating humidity levels. Such

diversity demands design sensitivity, not only from the aesthetic point of view but also from an analytical approach rooted in performance data.

The design process begins with an understanding of how these different materials behave in concert. Each material offers its unique strength: glass provides transparency and daylight, stone provides thermal mass, metal ensures precision and lightness, while engineered composites allow flexibility and resistance to weather.

A façade that intelligently combines these materials can modulate heat gain and diffuse daylight, reducing the demand for artificial cooling and lighting. For instance, a combination of

The façades of the future will be adaptive systems that respond to climate, occupancy, and data. Emerging technologies in electrochromic glass, kinetic shading panel

ensures that interiors are well-lit yet shielded from harsh glare, thus creating a visual dialogue between indoors and outdoors.

Fenestrations are not designed in isolation but as an extension of the façade system. Every window, every skylight, or every pivot door is contributing to the environmental performance of the building. They are looked at as part of a holistic envelope rather than as independent fixtures.

By integrating these perspectives, the firm can design homes that are visually cohesive and environmentally responsible, where material selection and detailing are driven by measurable performance goals.

Contemporary façade design is inextricably linked with technology. Computational tools, environmental simulation software, and Building Information Modelling (BIM) have changed the way in which architects analyse performance outcomes.

Façades and fenestrations define far more than the mere exterior of a building: they articulate its environmental conscience, workmanship, and cultural relevance

low-emissivity double-glazed glass with perforated aluminium screens allows dynamic control of light and heat: the metal screen functions as a shading device, while the glazing provides thermal insulation to achieve interior comfort with minimal energy load.

In luxury residences, this balance becomes an extraordinary challenge, as the façade frequently plays the role of an identity marker. “The goal is always to make the façade perform without appearing mechanical,” elaborates. “Every joint, mullion, and junction must be designed for a purpose. Efficiency lies in precision detailing — not in adding more systems, but in

making fewer elements perform more functions.”

While façades define a building’s external persona, fenestrations form the tactile interface between the user and the environment. Efficient fenestration design can substantially affect energy performance, acoustic quality, and indoor comfort.

In residential typologies, usually thermally broken aluminium frames, argon-filled glass units, and strategic placement of openings to optimise cross-ventilation are adopted. This

Technology gives the data, but craftsmanship gives the soul. A façade must be engineered to perfection, but it must also feel human. Humanistic, indeed, which in his projects materialises through multi-layered articulation of materials and fine detailing into living surfaces — dynamic, responsive, and expressive.

Design efficiency also extends to the realm of sustainability: façades and fenestrations are some of the most energy-intensive parts of any building, but can minimise energy use significantly with smart material selection and detailing.

The vocabulary also now includes newer materials such as high-performance glass, recycled metal panels, and solarintegrated façades. Dhawan and his team are keen on exploring hybrid assemblies

is an engineered system, one that has to perform along several fronts: climatic, structural, acoustic, and aesthetic

that combine photovoltaic glazing with ventilated cladding systems to achieve energy generation without sacrificing aesthetics.

They have experimented with locally available materials such as sandstone fins and terracotta jaalis to make shading devices in a number of recent projects. They have both cultural resonance and climatic appropriateness. This contextual sustainability is central to the firm’s design philosophy: modern performance rooted in local sensibility.

EXPRESSIVE MINIMALISM: BALANCING IDENTITY AND EFFICIENCY

Designing efficient façades does not have to mean giving up on visual identity. In fact, the performance and aesthetics can coexist in harmony when materials are orchestrated intelligently. The façades often exhibit a restrained elegance — defined by strong geometries, clear alignments, and contrasting textures.

True efficiency lies in clarity. When each material has a purpose, the façade becomes inherently beautiful.

This is manifested, for instance, in the façades of Yuvraj Singh and Gautam Gambhir’s homes, which use layered planes of glass, stone, and metal to articulate depth and dynamism while

maintaining optimal shading and insulation. These projects reflect the firm’s ethos: design as a synthesis of art and engineering, emotion and efficiency.

The façades of the future will be adaptive systems that respond to climate, occupancy, and data. Emerging technologies in electrochromic glass, kinetic shading panels, and AI-driven environmental controls are the pathways to “living façades” that will self-adjust according to changing conditions. However, he says technology must serve design and not vice versa. “We must design façades that are intelligent, not just smart,” he says. “The future is about integrating innovation seamlessly — so that buildings adapt naturally, efficiently, and beautifully.”

In today’s architectural world, façades and fenestrations define far more than the mere exterior of a building: they articulate its environmental conscience, workmanship, and cultural relevance. Design efficiency is not a limitation but a motivating spark.

Every façade tells a story. The architect’s role is to make that story meaningful — where design serves both the eye and the environment.

AR. SUMIT DHAWAN

Founder & Principal Architect, Cityspace’82 Architects

Ar. Sumit Dhawan started a solitary practice directly after completing his B.Arch in the year 2005 and founded Cityspace’82 Architects. His childhood passion for architecture manifested in the perseverance and belief that led Sumit to practice unconditional hard work. Firmly believing in a perfect balance between functionality and form, Sumit ensures to rationalise both the aesthetics and functional regime of every endeavour he outlines. Having experience of almost two decades, Sumit has singlehandedly nurtured this firm and given it the position where it stands today. Ar. Sumit has established his name extensively in the design industry and has found his way to renowned celebrity homes. He has done projects for politicians, bureaucrats, lawyers, the residences of famous cricketers Yuvraj Singh and Gautam Gambhir, and many more. Also, his work is appreciated by developers with whom he has collaborated, including DLF, Ansal Group, Orchid, and MGF, to name a few. His eclectic façade style has made him a favourite amongst numerous practicing architects.

The role of windows in modern housing continues to grow. Windows now serve far more than just the function of providing light and ventilation. They not only enhance aesthetic appeal and comfort but also provide a way to increase a home’s energy efficiency, thereby improving quality of life. Today’s homeowners can choose from a wide variety of styles and materials when selecting the type of window that suits their preferences and requirements. Currently, the following tens of thousands of window styles and designs are among the many ways in which homeowners are taking advantage of the latest modern home design trends: