INDUSTRY SPEAKS

ELEVATING FIRE SAFETY IN FAÇADE DESIGN

Experts' views & thoughts to safeguard building envelopes from fire

Experts' views & thoughts to safeguard building envelopes from fire

Dear Readers,

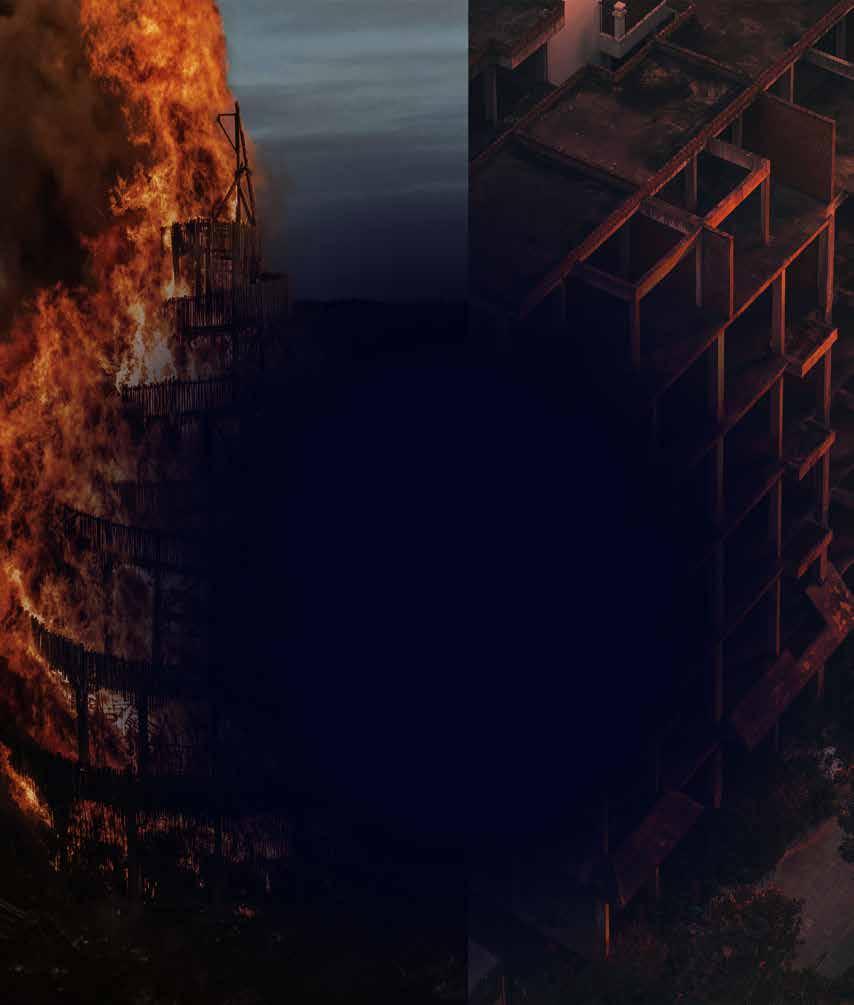

When disaster strikes a high-rise, the lessons learned should transcend borders. The sight of rapidly spreading flames climbing a building’s exterior has become a terrifyingly familiar image in global news cycles, from London and Dubai to Melbourne and beyond. These façade fires, often fueled by combustible external wall materials, are not a local anomaly; they represent a systemic, worldwide failure in how we design, regulate, and construct our urban environments.

The problem is fundamentally international. As cities worldwide reach skyward, the pressure to use lightweight, cost-effective, and often flammable materials has created a ‘vertical tinderbox’ epidemic. The focus, historically, has been on structural integrity and internal fire suppression, often overlooking the devastating potential of the exterior skin to act as a chimney for fire spread. When a façade material allows fire to jump floors, bypassing internal safety measures, even the best sprinklers become insufficient.

What is desperately needed is a unified, global shift in regulatory thinking. Safety standards cannot remain siloed, fragmented by national borders and susceptible to local lobbying. We need international building codes to adopt a rigorous, universal baseline: mandatory use of demonstrably non-combustible materials for all external wall systems on multi-occupancy buildings, regardless of height.

Furthermore, accountability must be enforced globally. Designers, material manufacturers, and building inspectors must be held to strict, harmonised standards. No corner of the world should become a dumping ground for materials deemed too dangerous elsewhere.

We would love to hear from you! Your feedback and suggestions mean a lot to us. Write to us a line at editorial@wfmmedia.com to share your thoughts or ideas for future topics. We will do our best to bring you articles that truly matter.

07

Fenestration: The Key to Unlocking Sustainable Design

David-Isaac Arinze, Project Officer (Affordable Warmth & Sustainability), Glasgow City Council

Buildings That Breathe: The Era of Kinetic Façades is Here!

Edd Wilson, Divisional Director (Projects & Façades), Jesmonite

Early Supply Chain Engagement: The Case for Involving Façade Contractors in Schematic Design

Mohammed Abu El Kheir, General Manager, Al Maghrabi Factory for Metal Products

Modern Challenges in Façade Glazing: Balancing Innovation and Cost in Today’s Competitive Market

Praveen Kumar Hariram, Operations Manager, Bestway Façade Co. – Dubai, United Arab Emirates

24

How Circularity will Change the Façade Industry

Hans Jansen, Research and Development Leader, Permasteelisa Group

Harnessing Efficiency: Double Glass Panels and the Path to Green Building Sustainability

Alaa Alhabash, External Finishing Manager, Egis

The Rise of Sustainable Homes in Dubai: Embracing Green Living Options

Karthik Dube, COO, Gold Coast Group of Companies

Elevating Fire Safety in Façade Design

Interview with Magdy Eladl, Co-Founder & CEO, Smart Window

Industry Speaks

Interview with Magdy Eladl, Co-Founder & CEO, Smart Window

Face to Face

Interview with Michele Pasca Di Magliano, Director, Zaha Hadid Architects

19

David-Isaac Arinze Project Officer (Affordable Warmth & Sustainability), Glasgow City Council

David-Isaac Arinze is a purpose-driven innovator, passionate about transforming the built environment through data, design, and technology. He is currently leading the development of a groundbreaking sustainable housing proptech platform, enabling individuals to rent, buy, invest, and retrofit for a net-zero future. At Glasgow City Council, he has supported the Affordable Warmth Programme by developing a no-code Power BI retrofit analysis dashboard that streamlines decision-making and enhances service delivery for fuel-poor households across the city. He is building bridges between climate goals and real-world housing outcomes, empowering both public and private sectors to reimagine housing as a force for good.

Fenestrations are often overlooked as mere functional necessities, meaning windows, doors, skylights, and other architectural openings. However, when strategically designed, they hold enormous potential to optimise a building’s energy efficiency, indoor comfort, and connection to the natural environment. Let’s explore cutting-edge considerations for sustainability-focused fenestration design:

The Bullitt Center in Seattle, dubbed “the greenest commercial building in the world,” is a testament to

fenestration’s transformative power. Triple-glazed, operable windows with dynamic exterior shades create unparalleled energy performance. The design team carefully balanced daylight optimisation against minimising solar heat gain to achieve maximum occupant comfort with minimal reliance on mechanical systems.

• Orientation Matters: Northfacing fenestrations provide soft, even daylight, while those facing south need careful shading design to prevent overheating. Global location and a building’s specific context are critical factors that require analysis and simulation.

• Glazing Revolution: Highperformance glazing materials with multiple layers and Low-E coatings dramatically reduce heat transfer. Architects can choose options that balance thermal insulation needs with the desired levels of visible light transmittance and solar heat gain.

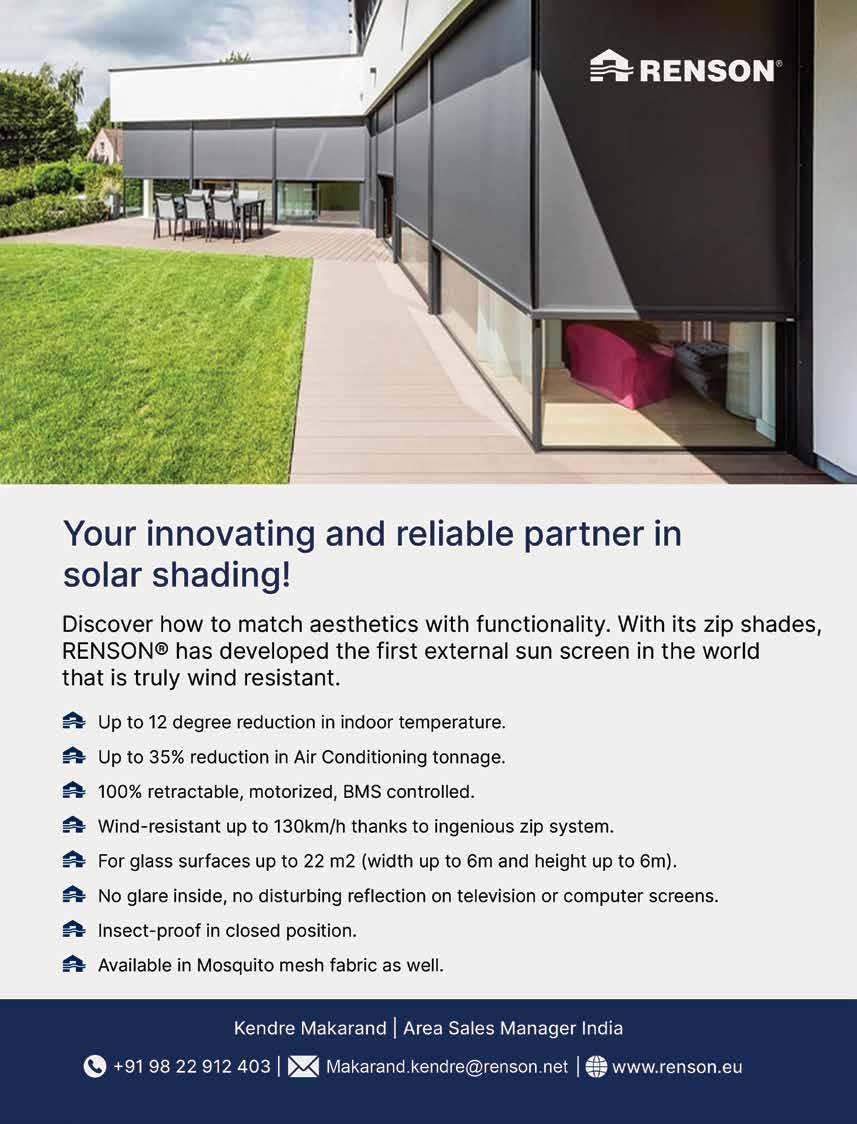

• Shading Strategies: Welldesigned external shades, both fixed and dynamic, can mitigate heat and glare while allowing views and ventilation. Interior blinds and screens offer further flexibility for occupants. Integrating shading systems with automated control can further optimise performance.

• Beyond Energy: Biophilic Design: Research proves that views of nature and access to daylight boost well-being and productivity. Fenestrations should be designed to maximise those benefits and create a healthy indoor environment.

Italy’s “vertical forest” demonstrates that fenestrations can seamlessly

integrate with green design. Expansive windows and balconies allow lush vegetation on each floor, which provides natural shading, air filtration, and a remarkable connection to the outdoors at a high density.

Striking a balance between performance and aesthetics can take time and effort. Architects at the forefront of the field are embracing several strategies:

• Whole-Building Approach: Fenestration design is not standalone. It must integrate with a building’s massing, insulation, and mechanical systems.

• Customisation: Local climate data and occupant needs should

drive specific fenestration systems.

• Client Education: Demonstrating the long-term cost savings and occupant benefits of welldesigned fenestrations is key to getting client buy-in.

Advances in material science, smart controls, and simulation tools are opening new dimensions in sustainable fenestration design. Architects and designers who prioritise this element hold the keys to creating spaces that are not only energy-efficient but also enhance human experience and connect us more deeply with our environment.

Edd Wilson Divisional Director (Projects & Façades), Jesmonite

Edd Wilson is a highly experienced Sales, Marketing, Commercial and Business Development Manager/Director, with a demonstrated history of working at managerial and board levels in the construction, sales, product development, and manufacturing industries. He adopts a pragmatic approach to problem-solving, solution-finding, and innovation. He specialises in refining operations and processes while maximising sales and maintaining the growth of key accounts. He implements both short- and long-term business strategies with proven results, supplemented by the ability to actively problem-solve and create market-driven sales and marketing campaigns with measurable impact.

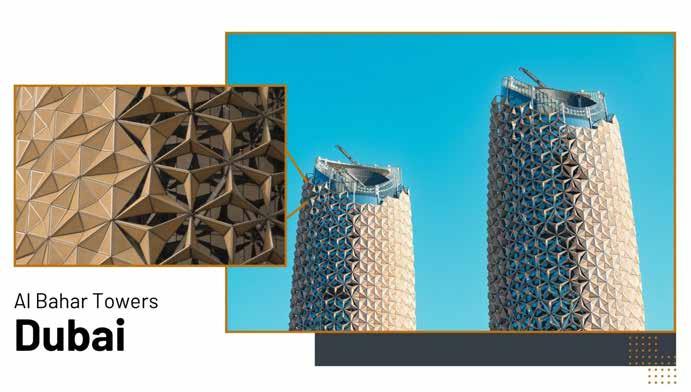

These twin towers feature a responsive façade that directly addresses the harsh climate

Let’s look at something truly awe-inspiring – something that is transforming our cities from static concrete jungles into living, breathing entities. This time it’s not biophilic design, but kinetic façades.

For too long, building exteriors have been, well, just that: exterior walls. Beautiful, often iconic, but fundamentally static. Now imagine a building that can respond to its environment – one that can adjust to the intensity of the sun, shield itself from the wind, or even interact with the people around it. This is the thrilling reality of kinetic façades, and it’s rapidly becoming an integral part of modern architectural design.

These dynamic building skins are designed with movable elements

that respond in real time to external stimuli such as sunlight, temperature, and wind. It’s a profound leap from traditional design, merging incredible functionality with groundbreaking aesthetics. The secret sauce? Advances in technology – including sophisticated sensors, automation, parametric design, and digital fabrication – now allow us to create responsive building envelopes that move mechanically or even through smart materials.

This shift is crucial because kinetic façades not only look good, but they do real work. They offer a multitude of benefits that are redefining how we think about sustainable construction and occupant comfort.

Energy Efficiency: By dynamically adjusting to solar gain and ventilation needs, they dramatically reduce

reliance on artificial lighting and air conditioning, leading to significant energy savings.

• Adaptability: They are inherently flexible, able to adjust to diverse climates and changing environmental conditions, optimising interior comfort no matter what the day throws at them.

• Aesthetic Innovation: This is where the artistry truly shines. Moving elements create ever-evolving visual patterns, transforming buildings into dynamic sculptures that bring urban landscapes to life.

• User Interaction: In some cases, occupants can even directly control aspects of the façade, personalising their environment and fostering a deeper connection with their building.

Let’s look at some incredible examples where this concept has moved from the drawing board to dazzling reality.

Take the Al Bahar Towers in Abu Dhabi. In a city known for its intense sun, these twin towers feature a responsive façade that directly addresses the harsh climate. Inspired by the traditional Islamic mashrabiya (a screen for privacy and shade), their exterior is cloaked in over 2,000 umbrella-shaped panels that open and close throughout the day in response to the sun’s movement. This ingenious system effectively reduces solar gain by over 50%, significantly cutting cooling energy consumption and dramatically enhancing comfort for those inside. It’s a brilliant fusion of ancient wisdom and cutting-edge technology.

panels that can be electronically controlled. The façade responds to external conditions to optimise the internal climate, but here’s the truly innovative part: users can also personalise their own spaces by dictating how much sun or shade they want. It’s a fantastic example of putting control directly into the hands of the occupants, blending

macro-level responsiveness with micro-level personalisation.

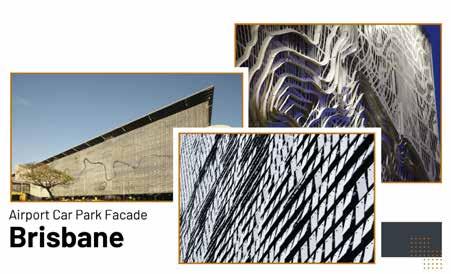

Another compelling example, though subtle in its kinetics, is the Brisbane Airport car park façade. Its 118,000 suspended aluminium panels ripple fluidly with the wind, creating a stunning visual effect that responds directly to natural forces. It is a dynamic and engaging welcome to the city, demonstrating that kinetic elements can be both functional and mesmerising.

These examples are just the tip of the iceberg. As urban environments increasingly demand structures that are not only sustainable but also adaptive and visually striking, kinetic façades are rapidly transitioning from experimental ideas to mainstream architectural solutions. They represent a significant leap forward in understanding buildings not as static objects but as active participants in our environment, constantly optimising and evolving.

Then there’s the Kiefer Technic Showroom in Austria. This building showcases a kinetic façade made of individual aluminium

Mohammed Abu El Kheir General Manager, Al Maghrabi Factory for Metal Products

Mohammed Abu El Kheir oversees the Aluminium Façade Division, driving operational excellence and project success. He has over 20 years of experience in the aluminium façades industry. His tenure has been marked by a robust handle on vendor sourcing, which has been pivotal in streamlining the supply chain and enhancing product quality. His skills in vendor relations and façades fabrication have been honed through hands-on management of complex projects. He has led the team in implementing continuous improvement programs that have substantially elevated the company’s production and installation processes.

Modern construction projects face increasing complexity, requiring a shift from traditional linear workflows to more collaborative models. The conventional separation between designers and contractors often leads to execution gaps, costly changes, and delays. This paper advocates engaging façade contractors during the conceptual design phase to ensure constructability and achieve more efficient outcomes.

Façade systems are among the most technically demanding and costintensive elements of a building. Their performance affects:

• Thermal and acoustic comfort

• Structural integration and tolerances

• Daylighting and energy modelling

• Fire safety and wind resistance

• Visual identity and branding

When façade contractors are involved early, they contribute:

• Buildability insight: Ensuring design details are executable within budget and site constraints

• System selection guidance: Balancing performance, aesthetics, and cost

• Interface coordination: Resolving clashes with structure, MEP, and envelope transitions

• Material intelligence: Advising on availability, lead times, and fabrication methods

• Risk forecasting: Identifying technical and logistical risks before tender

Early involvement is not about handing control to contractors—it is about collaborative intelligence. The benefits include:

• Design optimisation: Contractors help refine concepts into practical, high-performance solutions

• Cost certainty: Realistic pricing and value engineering reduce budget volatility

• Schedule efficiency: Fewer RFIs, change orders, and redesign loops

• Innovation access: Time to explore prefabrication, kinetic façades, or smart materials

• Sustainability alignment: Early input supports LEED, WELL, and energy targets

Clients may hesitate to involve contractors early due to concerns about cost control, design freedom, or procurement protocols. These concerns are understandable—but often misplaced.

Early engagement does not compromise creativity; it enables it. By surfacing constraints early, the design team can make informed choices, avoid late-stage compromises, and deliver a more coherent, integrated solution.

Case studies consistently show that projects with early façade input achieve better outcomes in aesthetics, performance, and delivery.

Procurement is often seen as a downstream function—but in ESCE, it becomes a strategic enabler.

• Contract structuring: Facilitates Pre-Contract Service Agreements (PCSA) or Design-Assist models

• Timeline alignment: Synchronises procurement milestones with design development

• Vendor prequalification: Selects façade partners based on collaboration capacity, not just price

• Bid packaging: Includes early workshops, mock-up reviews, and performance consultations

• Risk management: Ensures contractual clarity and phased commitments

Traditional procurement models may resist early involvement due to pricing uncertainty or perceived risk. To overcome this:

• Adopt progressive procurement frameworks, allowing phased engagement

• Train procurement teams in collaborative delivery models

• Align procurement, design, and project management under shared goals

• Empower procurement to innovate beyond lowest-cost selection

In the Soundstage Studios development, our team adopted the Early Supply Chain Engagement strategy by involving the façade contractor and procurement

department during the schematic design phase. This proactive collaboration yielded measurable benefits across multiple dimensions:

• Design precision: The façade contractor helped refine the architectural concept into a buildable system tailored for acoustic performance and visual impact—critical for a soundstage environment.

• Cost efficiency: Early pricing input enabled the selection of a modular façade system that reduced material waste and saved approximately 18% compared with initial estimates.

• Schedule optimisation: By aligning bid packages and lead times early with procurement, we avoided delays in sourcing specialised acoustic panels and glazing systems.

• Technical integration: The contractor’s early involvement ensured seamless coordination between façade elements and structural tolerances, minimising RFIs and eliminating late-stage redesigns.

• Innovation enablement: The team was able to explore advanced façade finishes and

integrated lighting features that would have been unfeasible under a traditional late engagement model.

• Procurement agility: the procurement department structured a phased engagement model, allowing technical input before final pricing, which improved vendor responsiveness and reduced negotiation cycles.

This project demonstrated that early façade and procurement involvement is not just a theoretical best practice—it is a proven accelerator of quality, efficiency, and innovation.

To institutionalise early façade engagement, stakeholders should:

• Include Early Contractor Involvement (ECI) clauses in consultant and contractor agreements

• Allocate budgets for preconstruction services and technical workshops

• Promote Integrated Project Delivery (IPD) or Design-Assist models

• Encourage public and private clients to embed ESCE in procurement criteria

• Foster a culture of collaboration over fragmentation

Engaging façade contractors during the conceptual design phase represents a strategic shift in project delivery. The benefits extend beyond financial savings to include innovation, quality, and risk mitigation. This paper encourages industry stakeholders to adopt this model for future projects, particularly those aiming for engineering excellence and sustainability.

Praveen Kumar Hariram

Operations Manager, Bestway

Façade Co. – Dubai, United Arab Emirates

Praveen Kumar Hariram has over 12 years of extensive experience in the aluminium façade industry across Oman and Dubai. He specialises in operations management, covering the full spectrum from estimation to project management. He has successfully managed and delivered complex façade projects by cultivating strong, long-term relationships with clients, contractors, and suppliers. Skilled in negotiation, value engineering, and technical solutions, he ensures cost-effective execution while maximising project profitability without compromising quality. Currently leading Estimation, Procurement, and Project divisions, he actively pursues market opportunities and optimises supply chains to boost business growth. His diverse portfolio includes high-profile developments and largescale commercial and residential projects, where he drives timely completion through strategic planning, effective communication, and innovative façade solutions.

In today’s fast-changing architectural landscape, façade glazing has become a defining feature, merging form with function. Beyond aesthetics, glazed façades boost energy efficiency, occupant comfort, and overall building performance.

With sustainable practices, innovative materials, and smart technologies on the rise, expectations for façade systems are higher than ever. Yet developers and contractors face tighter budgets, rising costs, and fasttrack schedules—forcing cuttingedge design to coexist with financial discipline.

This article explores the balancing act between innovation and cost in façade glazing, showing how value engineering, technology adoption, and smarter collaboration can deliver high-performance, visually striking

façades—without compromising budget or buildability.

As buildings become more complex and performance-driven, the demand for innovation in façade glazing has intensified. Today’s building envelopes must deliver far more than aesthetic appeal—they are expected to meet stringent thermal insulation, acoustic performance, and structural resilience standards, along with sustainability benchmarks such as LEED and Estidama certifications.

Architects and clients are pushing design boundaries with complex geometries, free-form surfaces, and expansive transparent façades that blur the divide between indoors and outdoors. These striking concepts require advanced engineering solutions and precise fabrication—

often under tight deadlines and budget constraints.

To meet these demands, the industry is embracing innovative systems and advanced technologies for their adaptability to environmental changes. While often costlier, correct specification and optimal use of these solutions are crucial to achieving both high performance and cost efficiency.

While innovation in façade glazing continues to advance, financial constraints remain a constant challenge. The construction industry is grappling with steadily rising costs driven by a combination of factors—surging raw material prices, increased transportation and logistics expenses, and a shortage of skilled labour, particularly in

specialised trades such as glazing and cladding.

Simultaneously, developers and contractors face mounting pressure to deliver projects faster, more efficiently, and within increasingly tight budgets. With accelerated timelines becoming the norm, there is little room for delays or cost overruns, placing significant strain on the design, procurement, and installation phases.

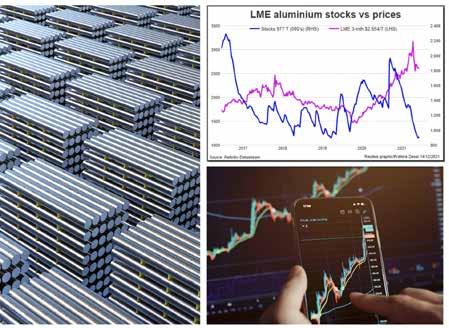

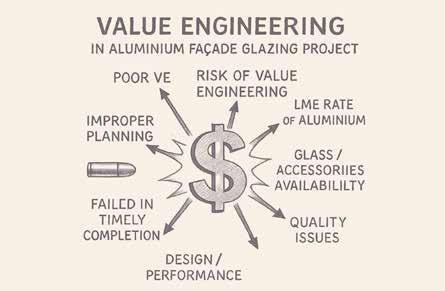

Global inflationary pressures have further exacerbated façade pricing and availability. The unpredictable London Metal Exchange (LME) rates for aluminium profiles, along with fluctuating costs and inconsistent availability of accessories, often result in spikes in project budgets and extended lead times. This volatility forces project teams to adapt quickly or seek alternative solutions.

In this context, achieving design intent while maintaining budget discipline becomes a constant balancing act. Façade engineers

and fabricators must look beyond traditional methods to identify smarter, more flexible approaches that deliver high-performance systems without compromising cost-effectiveness or project timelines.

In the face of rising costs and tighter project margins, value engineering (VE) has become a crucial strategy in façade glazing. However, it is often misunderstood as a mere costcutting exercise. In reality, true value engineering is about optimising performance, constructability, and aesthetics—while maintaining budgetary control.

Effective VE starts with a deep understanding of the project’s design intent and performance goals. It involves evaluating alternative materials, glazing systems, and fabrication methods that deliver equal or better outcomes at lower costs or improved efficiency. For

example, replacing custom profile systems with standardised extrusions, or substituting laminated glass with performance-coated monolithic glass where possible, can result in significant savings without compromising safety or visual quality.

Early collaboration between architects, façade consultants, contractors, and fabricators is critical to successful value engineering. It allows teams to identify smart trade-offs, reduce material waste, and avoid rework or redesign later in the process. The goal is not to reduce quality but to ensure that every element of the façade delivers maximum value.

When done thoughtfully, VE becomes a tool for innovation, enabling the delivery of elegant, high-performance façades that meet both design vision and financial reality.

Effective cost optimisation in façade works starts with understanding the complete project scope and technical requirements. By analysing the specifications in detail, fabricators can propose practical, compliant alternatives without compromising performance or aesthetics.

Key strategies include:

• Aluminium Profiles: Propose the correct profile size and thickness through proper structural analysis, avoiding unnecessary material overuse.

• Labour Efficiency: Streamline fabrication through effective internal planning, proper labour allocation, and strong engineering to minimise waste and time delays.

• Glass Performance: Reduce the performance grade of highspec glass if the project location does not require extremely low U-values.

• Glass Thickness: Perform structural calculations to determine the actual thickness needed. Reducing oversized glass panels or divisions can cut costs.

While cost optimisation brings clear benefits, implementing it in façade projects often uncovers real-world challenges:

• Stakeholder Misalignment: Architects focus on design, contractors on time and cost— without alignment, quality and performance suffer.

• Poorly Managed Value Engineering: Unreviewed changes to glass or profiles can harm structural integrity and thermal performance.

• Material Availability: Specified high-performance materials may be hard to source, causing delays or costly substitutions.

• Skilled Labour Shortage: Even the best designs fail without experienced façade installers.

Overcoming the challenges requires early coordination, realistic planning, and transparent communication

• Site & Installation Constraints: High-rise access, tight logistics, and trade coordination can add unexpected time and cost.

Overcoming these challenges requires early coordination, realistic planning, and transparent communication—ensuring that cost-saving strategies are both technically sound and practically executable.

The future of façade glazing lies in smarter, integrated approaches that balance innovation with costefficiency. In today’s environment, seamless collaboration between architects, engineers, fabricators, and system suppliers is essential—not optional—to deliver high-performing façades that are both inspiring and economically viable.

Avoid comparisons with low-cost, substandard fabricators; true cost control comes from intelligent engineering and quality-driven decisions, ensuring lasting value for both clients and contractors

Leading trends include the adoption of slimline aluminium profiles from established system suppliers, paired with cost-effective glazing solutions, and precision-engineered accessories that further support cost-effective yet high-quality façade construction.

These advancements not only reduce initial costs but also improve ease of installation, durability, and long-term performance. The focus is increasingly shifting from upfront expenditure to total lifecycle value— considering energy efficiency, thermal performance, maintenance needs, and environmental impact.

Clients now prioritise solutions that offer long-term returns, both financial and ecological. As a result, digital tools, BIM integration, and

data-driven design are becoming standard practices in value-focused façade execution.

To succeed in this evolving landscape, the façade industry must continue to push boundaries while staying grounded in real-world constraints—by embracing lean thinking, early coordination, and sustainable engineering.

The evolving demands of architecture require façades that are visually striking, high-performing, cost-effective, and sustainable throughout their lifecycle. Striking the right balance between innovation and affordability is essential. Effective cost optimisation relies on practical strategies such

as precise material specification, structural accuracy, consideration of material availability, and upfront design focused on cost control— without compromising quality. Realworld challenges must be addressed through transparent communication and realistic planning.

By embracing value-driven engineering, advanced technologies, and lifecycle performance, the façade industry can deliver smarter, leaner, and more resilient building envelopes.

Avoid comparisons with low-cost, substandard fabricators; true cost control comes from intelligent engineering and quality-driven decisions, ensuring lasting value for both clients and contractors.

Hans

Jansen

Research and Development Leader,

Permasteelisa

Group

About the Author

Hans Jansen has been working for Permasteelisa Group, Scheldebouw, initially as a cladding designer and is now the Lead Concept Designer for cladding. He has delivered design solutions for numerous buildings, including The Shard, London Bridge Place, 150 Cheapside in London, Project Twenty One in Stockholm, the AstraZeneca Campus in Cambridge, 425 Park Avenue in New York, and more recently, the International Quarter London and Shard Place in London.

Circularity, adaptability, R-strategies, avoided carbon and many more terms are used frequently nowadays — but what makes sense and what does not? Is tearing down a 20-year-old metal façade and replacing it with a brand-new façade the right thing to do? Should we preserve it, or upgrade it? Can we save carbon emissions during the remaining lifespan of the building to justify that this is the right choice? And what if we recycle the old glass — does that help? Does it even matter what engineers calculate if the building owner is determined to give the building a new look in order to make the office space relevant?

Let’s start at the beginning. The built environment is full of metal

façades constructed in the ’80s, ’90s and ’00s and, quite frankly, to me it is unclear how they imagined refurbishment scenarios after 25 or 30 years of service. We can find lifetime expectancy schedules in the O&Ms, but some materials or systems are underestimated and others overestimated. The biggest issue is that they do not align. This means that some façades may be considered at the end of life after 30 years because one component is no longer meeting requirements — forcing other materials to be scrapped as a consequence. It breaks my façade heart to see 25-yearold aluminium extrusions being discarded, when we know they can have a lifespan more than twice that. How to avoid scrapping buildings or façades prematurely is another

topic that should be discussed separately among building owners and architects.

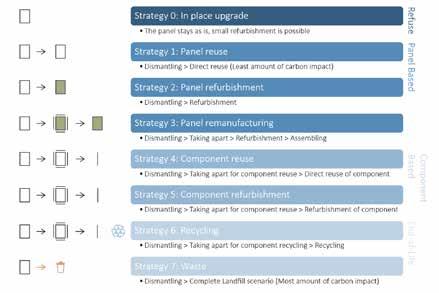

How can we be more environmentally friendly and sustainable when refurbishing the built environment? How can we enhance circular principles and reduce carbon emissions when refurbishing older buildings? This question-initiated research into circularity, which we first began with Rianne Teeuwen, a Master’s student at TU Delft Civil Engineering and Geosciences. She investigated the options available when replacing a façade and analysed the potential carbon impact of different strategies. In this case, we assumed a 25-yearold unitised façade made of aluminium and double-glass. The

seven strategies mentioned below were analysed and ranked, with Strategy 0 added as a benchmark.

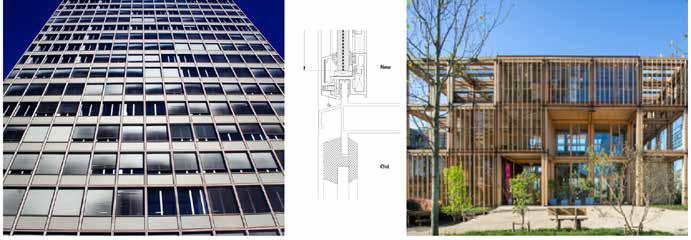

A literature study highlighted several notable examples across industries of different R-strategies. The most impressive, to me, was Caterpillar’s remanufacturing process for heavy equipment, in which they take back old machines, strip them down to the smallest component, clean and repair them, and subsequently rebuild the machine.

In the façade industry, there are numerous commendable initiatives,

such as recycling glass and other materials, as well as componentbased strategies like stone re-use or refurbishment.

When we examine the Permasteelisa Group’s experience, three examples particularly stand out. The first is Project Koningskade in The Hague, a 60-year-old façade respirante designed by Jean Prouvé. The façade remained in place, but the gaskets holding the single outer glass were replaced with a new system, and the single glass was replaced with laminated glass. The original single glass was re-used at

the Floriade, in The Natural Pavilion. This demonstrates that aluminium façade systems and glass can last longer than 60 years if designed and maintained well.

Secondly, the project One Triton Square in London involved the temporary removal of the external double skin, followed by cleaning, replacement of the gaskets, and reinstallation of the panels. This demonstrated that unitised curtain wall panels can be dismantled from a building without damage and subsequently reinstated.

A final example that was analysed was the Commerzbank in Düsseldorf, where old façade units were dismantled from the building, fire-hazardous materials were removed, insulation was added, and the aluminium sheets were cleaned before the panels were reinstalled. This demonstrated not only that the units could be removed and replaced, but also that they could be remanufactured to improve performance.

Let’s return to our 25-year-old façade, which we initially assumed would be replaced, and examine what was actually happening at the time, as well as how to increase

circularity and reduce carbon emissions. We identified seven strategies and have observed examples of each. As a façade contracting company, we focus on assembling façade panels and adding value in the process.

At the end-of-life stage for a building façade, when replacement becomes necessary for any reason, we can have the greatest impact by considering R-strategies based on panels rather than components or recycling. When it comes to recycling or re-using individual materials or components, the relevant industries are far better equipped and achieve greater efficiency by handling larger volumes; therefore, we did not focus on these in our research. Take the glazing industry, for instance, which is making significant improvements in the re-use and recycling of insulated glass.

We also excluded the direct re-use scenario—similar to a second-hand marketplace—where we do not add value to re-used façades. Instead, we focused on refurbishment and remanufacturing scenarios. The potential savings in embodied carbon that we, as façade contractors, can achieve by refurbishing and remanufacturing old façades are substantial compared to waste and recycling scenarios, making it our moral duty to investigate further.

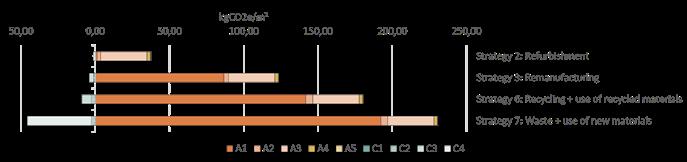

The amount of embodied carbon that can be saved through refurbishing or remanufacturing façades can be expressed as what we call avoided embodied carbon. In this example, we state that we can avoid embodied carbon when comparing a baseline scenario, in which a façade reaches the end of its life, is discarded, and a new façade is built from scratch. Carbon emissions can be avoided if we do not discard

the façade but re-use it. The effort required for re-use varies depending on the R-strategy.

It requires more carbon emissions to dismantle a façade panel, recycle the materials, and build a new façade than it does to refurbish it. The graph below illustrates the potential carbon savings at the different stages. To the left of zero, we show the carbon emissions for the C stage of the old panel, and to the right, the A1–A5 stages.

Now, the service life needs to be considered, and B-stages for existing façades also need to be taken into account. We will elaborate on this complexity another time. The concept of avoided carbon, as shown above, clearly demonstrates that discarding façades that are not at the end of their life after 25 years is a missed opportunity to save carbon. This is because the main components—such as aluminium framing, steel sheets, stainless steel, single glass, laminated glass, internal gaskets, brackets, and insulation— are not at the end of their life after 25 years, but rather after 60 years. Yes, the insulated glass might be at its theoretical end-of-life, like the exposed gaskets, but we still need to reconsider the value of the remaining service life of a used

façade. This is why our research into the remaining service life of materials is so important: it proves how long materials can still be used.

This brings us to the core of the avoided carbon method: assessing the possibilities when a façade is regarded as redundant or underperforming in a building. Can we upgrade it in situ? What is required to achieve energy performance class A+++, and is that even possible? Should we replace it partially or fully, and if we replace it, what can be done with the old façade? Can it be re-used or remanufactured for another building?

Through this approach, we can assist building owners, architects, and engineers with our knowledge of façades. Our method, or Circular Flow Chart, starts with the analysis of the existing façade and the desired façade. The desired façade could be on the same building, for example, in an in-situ refurbishment, but it could also be a re-used façade on a receiving building. In both cases, the analysis will quickly indicate whether R-strategies are worth investigating. If they are, these should be compared to determine which provides the best value for the client—not only in monetary terms but holistically.

Comparing avoided embodied carbon, as shown above, is one parameter, but not the only one. Other parameters should be agreed

upon and include, but are not limited to, aesthetics, operational carbon improvements, service life, warranty, cost plan, and programme.

So, finally, imagine that we have redundant windows that are not at the end of their life, and we have five potential projects to which these windows could be allocated. We could assess the best possible scenario to determine the destination for these

windows—where the most carbon could be avoided. Or imagine that we could convince a client to upgrade their façade, rather than discarding it and purchasing a new one. That, in my humble opinion, is something worth striving for. This is how I believe circularity, R-strategies, or simply common sense—whichever term you prefer—will transform the façade industry. Because, ultimately, it is the right thing to do.

Alaa Alhabash External Finishing Manager, Egis

the Author

Alaa Alhabash has over 16 years of experience in façade engineering and building envelope systems. He specialises in delivering high-performance solutions across complex architectural projects. His focus lies in design coordination, façade performance evaluation, and sustainabilitydriven system optimisation. He has worked across Saudi Arabia, Qatar, and the UAE on projects exceeding 500,000 m² of façade scope. He currently provides technical advisory support for façade design reviews, constructability assessments, and code compliance guidance, including LEED, SBC, IBC, and ASTM.

In the pursuit of sustainable and energy-efficient building design, architects and builders are constantly seeking innovative solutions to reduce carbon emissions and enhance environmental performance. Among these solutions, the use of double glass panels has emerged as a gamechanger. This article explores the efficiency of double glass panels within the context of green building and energy sustainability, shedding light on their role in mitigating carbon emissions and promoting a more environmentally conscious future.

Double glass panels, also known as insulated glazing units (IGUs), consist of two layers of glass separated by an air- or gas-filled space. This

configuration provides superior thermal insulation compared with single-pane windows, reducing heat transfer between the interior and exterior of a building. The trapped air or gas acts as an insulating barrier, minimising thermal bridging and enhancing energy efficiency.

By incorporating double glass panels into building design, architects can significantly reduce reliance on mechanical heating and cooling systems. The improved insulation properties of IGUs help maintain a stable indoor temperature, minimising the need for excessive heating during cold seasons and reducing demand for air conditioning in warmer climates. This reduced reliance on HVAC systems directly translates into energy savings and a notable decrease in carbon emissions.

Beyond thermal insulation, double glass panels also contribute to the optimisation of daylighting strategies within buildings. The use of IGUs allows for larger window areas while maintaining energy efficiency. The increased glazing area permits abundant natural light to penetrate the interior, reducing dependence on artificial lighting during the day. By harnessing natural light, buildings can minimise energy consumption and create visually stimulating, comfortable environments for occupants.

Moreover, double glass panels offer the advantage of improved acoustic insulation. The dual layers of glass help dampen external noise, creating a quieter

and more tranquil indoor setting. This contributes to the overall comfort and well-being of building occupants, enhancing their productivity and satisfaction.

The adoption of double glass panels aligns with the goals of green building sustainability and energy conservation. By reducing reliance on artificial lighting and HVAC systems, buildings equipped with IGUs can significantly lower energy consumption, resulting in reduced carbon emissions and a lighter environmental footprint. This not only benefits the immediate occupants but also contributes to the wider goal of combating climate

change and achieving a more sustainable future.

Furthermore, the use of double glass panels can qualify for various green building certifications and rating systems, such as LEED (Leadership in Energy and Environmental Design), which recognise and promote energy-efficient building practices. This not only enhances the marketability and value of the building but also demonstrates a commitment to environmental stewardship.

Double glass panels have revolutionised the way we approach building design in the realm of green building and energy

sustainability. Their superior thermal insulation properties, ability to optimise daylighting, and role in reducing energy consumption make them a powerful tool in mitigating carbon emissions and promoting a more environmentally conscious future. By incorporating double glass panels into building envelopes, architects and builders can create energy-efficient structures that prioritise occupant comfort, reduce operational costs, and contribute to a sustainable and resilient built environment. As the drive for green building practices gains momentum, the efficiency of double-glazed panels stands as a testament to the industry’s commitment to a greener and more sustainable future.

doesn’t just give windows a frame with our profiles, we’re genuinely trend-setting in uPVC window systems. And on top of that, we develop innovative solutions that offer all our partners and customers real added value.

top of that, we develop innovative solutions that offer all our partners and customers real added value.

We form the framework for the world of windows.

We form the framework for the world of windows.

Karthik Dube COO, Gold Coast Group of Companies

About the Author

Karthik Dube is a dedicated real estate agent with over two years of experience. He is committed to exceptional service and ethical standards, helping clients achieve their property goals. He is the Co-Founder of Gold Coast Real Estate India and COO at Gold Coast Real Estate Dubai.

In recent years, Dubai has emerged as a global leader in architecture, luxury living, and innovation for sustainable homes in Dubai.

But beyond the glitz and glamour, another trend is taking hold – the rise of sustainable homes. As the world wakes up to the urgent need to live eco-friendly, Dubai is responding with a dramatic shift towards more sustainable housing options.

This article examines the growing popularity of sustainable homes in Dubai, highlighting the benefits, initiatives, and growing popularity of green living options.

EMBRACING ECO-FRIENDLY LIVING: DUBAI’S SUSTAINABLE HOUSING LANDSCAPE

In a city known for its skyscrapers and luxury living, the way homes are designed, built, and maintained is undergoing a quiet transformation.

Sustainable housing is the mainstay of Dubai’s urban development programmes to focus on. From energy-efficient buildings to ecofriendly features, these homes are designed to reduce carbon emissions while offering modern comforts.

Energy efficiency is at the forefront of sustainable buildings in Dubai. Designers and architects are incorporating new methods such as solar panels, improved

Sustainable homes are a smart investment. Lower energy and water consumption translates into lower utility costs, resulting in long-term savings for homeowners.

Also, by integrating energy-efficient technologies, homeowners may qualify for government incentives and tax breaks.

Green homes prioritise natural light, fresh air, and indoor air quality. This focus on the well-being of residents enhances the overall experience of life, promoting physical health and mental well-being.

The government of Dubai has taken active steps to promote sustainable living, creating an enabling environment for the development of sustainable homes.

insulation, and energy-efficient appliances to reduce energy consumption.

It is not only that these products help things environmentally, but they also provide significant cost savings for homeowners.

Using sustainable materials is the cornerstone of building green homes. Recycled materials, lowVOC paint, and responsibly sourced wood are becoming popular with manufacturers.

Additionally, sustainable practices such as rainwater harvesting and greywater recycling have been

integrated to conserve valuable resources in this arid region.

The shift towards sustainable buildings in Dubai is not just about environmental responsibility; it also brings many benefits that improve the quality of life for residents and the city as a whole.

Sustainable homes significantly reduce carbon footprints, greenhouse gas emissions, and help improve both air and water quality.

As Dubai addresses environmental challenges, adopting sustainable building practices is an important step towards a more sustainable future.

At the heart of Dubai’s commitment to sustainable development is the Clean Energy Strategy 2050. The strategy aims to make Dubai a global hub for clean energy and the green economy. As part of this strategy, they are investing heavily in renewable energy, which is well aligned with sustainable building goals.

Dubai Municipality implements strict building codes that require all new buildings to meet minimum development standards.

These regulations cover areas such as energy efficiency, water conservation, sustainable homes in Dubai, and the indoor environment, to encourage the development of sustainable homes.

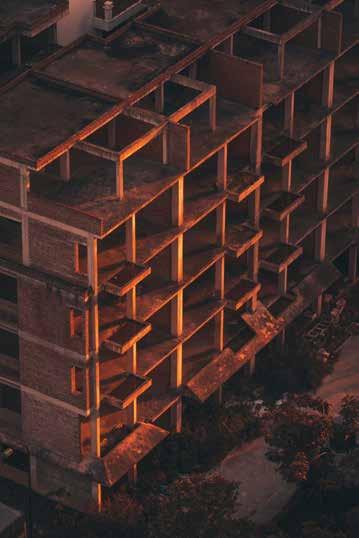

One of the most vulnerable aspects of building design is the façade. Because the majority of the populace is unaware of the material’s performance, they frequently misunderstand the importance of façade design, particularly in limiting or spreading fire spread. Fire safety has traditionally been overlooked in favour of beauty, energy efficiency, cost, and other factors. However, in light of current market trends, this has progressed beyond only the aesthetic aspect and now plays a larger role in light conveyance, acoustical execution, and efficacy.

It is about the universal understanding of the reality that any possible fire threats can only be mitigated when façade systems, materials, and testing are given the attention they deserve. The emphasis should be on a comprehensive approach to examining the performance of façade materials, components of façade design for fire safety, fire testing of façade materials, compartmentalization, and much more.

The opinions and ideas of subject-matter experts are featured in this cover story. We sought to collect their thoughts on things like façade fire safety, laws and regulations, appropriate materials, the best approach to build a fire-safe façade, and so on.

Façades are more than just a building's skin; they are a critical line of defence against fire. Yet, as our skylines grow, so does the risk of overlooking their vital role in fire safety. The journey to safer, more resilient structures is fraught with common fire safety mistakes, from poor material choices to simple gaps in workmanship, which can turn a small error into a catastrophe. Consequently, stricter building codes are pushing the industry to evolve, demanding not just compliance but a fundamental shift towards accountability and innovation in material selection and design strategy.

This drive for safety requires us to scrutinise whether new façade materials are truly safe, looking past glossy

marketing to focus on rigorous, system-level performance data. Ultimately, creating genuinely safe buildings relies on early collaboration between architects, engineers, and safety experts, ensuring safety is designed in from day one. By adopting smart façade design strategies for high-rises and learning the hard-won lessons from global fire incidents, we can pave the way for a future where innovations are driven by safety first. Crucially, even the best regulations fall short without a genuine need for awareness and training among every professional involved.

To explore these vital topics, we have interviewed the industry experts and their thoughts have been provided in the story.

FAIMEEN SHAH Managing Director, Vortex Fire

FERNANDO MORANTE

Technical Design Director Specialism, Egis

SYED HAMMAD RIZVI Principal Fire Consultant, Egis

VINAY V. DESHPANDE Founder & Managing Director, Vitruvius Fire Safety Consulting Fz-LLC

to engage competent, qualified, and licensed fire safety engineers at the design and installation stages.

One of the most common mistakes is treating façades as purely architectural features, without giving equal importance to their fire performance, Syed Hammad Rizvi, Principal Fire Consultant, Egis, points out. He adds that material selection often overlooks combustibility and the overall behaviour of the entire assembly in a real fire scenario. Another critical gap, he highlights, is the lack of early involvement of façade firestopping material suppliers, leading to compromises. He also mentions not following the listed or tested systems and poor detailing at slab edges as issues that can severely undermine safety.

Fire safety in façades is often overlooked, leading to serious risks. From poor material selection to gaps in compliance, even small errors can escalate quickly. Addressing these issues early ensures safer, more resilient buildings.

One of the most concerning issues is the tendency to ignore combustible façades on existing buildings, Faimeen Shah, Managing Director, Vortex Fire, notes, adding that stakeholders often would rather avoid discovering a potential fire life safety risk than undertake a comprehensive evaluation. Other mistakes he observes include relying on unapproved systems and the use of unskilled and untrained labour during installation. Above all, he says, there is a recurring failure

The most common mistake, Vinay V. Deshpande, Founder & Managing Director, Vitruvius Fire Safety Consulting Fz-LLC , comments, is treating façades purely as aesthetic skins rather than integral parts of a building's fire safety strategy. This leads to combustible cladding choices, poorly executed edgeof-slab details, a lack of continuous fire stopping, and inconsistent workmanship. Deshpande warns that even small discontinuities—like gaps around service penetrations—can act as 'hidden highways' for flames and smoke to spread unchecked.

Fernando Morante, Technical Design Director Specialism, Egis, simply says that often engineering details are not followed during construction, citing poor workmanship or poor-quality assurance/quality control (QAQC) as the cause.

Building codes are evolving with greater stringency, pushing the industry to rethink how façades are designed and the materials selected. These changes are not just about compliance but about creating safer, more resilient, and future-ready buildings.

Shah notes that the codes themselves are not necessarily becoming stricter, as many requirements have been in place for some time. What has improved significantly, he says, is the understanding and enforcement of these codes by authorities. Shah believes this has elevated the responsibility of façade designers, who must now look beyond aesthetics to ensure compliance and take ownership of selecting systems that balance design ambition with fire life safety.

Rizvi confirms that stricter building codes are directly changing the way façades are designed, requiring design teams to start with fire performance. He points out that codes now mandate the use of non-combustible or limited-combustible materials. He notes that testing standards have become tougher, pushing for full wall assembly tests (such as NFPA 285 or BS 8414), which forces the early integration of tested systems and closer collaboration across disciplines.

The evolution of building codes, particularly in the UAE and across the GCC, has transformed façade design, Deshpande comments. He highlights that the requirement for full-scale system tests, non-combustible cladding, and compliance documentation has moved the industry towards better practices. Deshpande says that designers

now consider fire safety earlier in the design cycle, concluding that stricter codes are not barriers, but catalysts for innovation and accountability.

Morante simply states the influence is “in a very good way,” making things more and more safe for the end user.

With the rapid emergence of innovative materials and technologies, distinguishing genuine safety from clever marketing has never been more crucial. Understanding the real risks behind façade choices ensures buildings are both secure and future-ready.

The first step is to look past marketing claims and focus on objective technical evidence, Shah says. He insists that a thorough review of fire test reports, classifications, and technical specifications is essential, as promotional jargon is no substitute for rigorous fire performance data. Shah then compares the results against the prescriptive requirements of the relevant codes, considering the practical risks and the way the material will be applied on site.

Rizvi’s first step is also to look for evidence, which means compliance with internationally recognised tests such as ASTM E136, NFPA 285, or BS 8414, supported by accredited lab certificates. He says a product showing only surface flame spread data is not enough, as it must be tested under real fire exposure. Rizvi evaluates how the material performs within a system, not in isolation, and says he prefers materials already approved by the local Civil Defence or Authority Having Jurisdiction.

The evaluation process must go beyond marketing, Deshpande notes. He looks for full-scale test reports from accredited labs, not just small-scale material certificates, and alignment with international codes. Deshpande stresses the need for System-level compliance rather than component-level compliance, warning that even noncombustible panels can fail if combined with combustible adhesives or insulation.

Morante says he first requests all needed tests as per different standards and Civil Defence requirements, and then uses the materials in possible studies or tries to visit sites where the material has already been used.

In complex construction projects, seamless collaboration from the outset is essential. When architects, façade consultants, and fire safety experts align their expertise early, it minimises costly revisions, ensures safety, and delivers a building that performs efficiently and aesthetically.

Shah stresses that true collaboration begins by ensuring no façade materials are procured or installations commenced before the fire safety evaluation and approval process is complete. He notes that procurement often gets ahead of design approvals. Shah argues that experts must engage as a team from the early concept stage, ensuring compliance is built into the design rather than retrofitted.

Rizvi agrees that collaboration from day one is essential to avoid costly and unsafe compromises. He says the most effective approach is to establish a multidisciplinary team at the concept stage to choose tested

and listed systems early. Rizvi adds that collaboration must continue into construction and site supervision to ensure installation follows the tested configuration, as failures often occur because site execution deviates from approved details.

Deshpande views façade fire safety as "inherently multidisciplinary," requiring alignment right from concept design. He warns that when collaboration is late, fire safety often becomes a "value engineering" casualty. Deshpande recommends integrated design workshops early in the project, where fire safety goals are defined and agreed upon as non-negotiable.

Morante simply agrees that the façade consultant and safety expert should be involved in the concept stage, and the architect should listen to specialists in the field.

High-rise buildings face unique fire safety challenges, as flames can travel swiftly along façades. Thoughtful design, careful material selection, and precise detailing play a crucial role in slowing or halting this spread, safeguarding both occupants and the structure itself.

Shah states that the most effective measure is ensuring the correct façade materials and assemblies are specified and installed in the first place. Beyond this, detailing strategies such as horizontal spandrels or balconies can act as effective barriers against vertical fire propagation. Shah mentions that for existing buildings, retrofitted solutions like external sprinklers may provide interim protection, but recladding remains the more reliable solution.

Rizvi notes that the key is to use certified materials and ensure the project matches the tested assembly. For cladding, he recommends using non-combustible materials and installing properly detailed cavity barriers. For curtain wall systems, Rizvi highlights that voids between the floor slab and curtain wall should be sealed with an approved perimeter fire containment system, and spandrels also act as a shield.

Deshpande lists effective strategies, including compartmentation at floor slabs using fire-rated spandrel panels and robust perimeter fire stopping, as well as cavity barriers (both horizontal and vertical). Deshpande concludes that a façade's safety depends not only on

the product specification but in how it is detailed and installed on site.

Morante’s strategy is to use proper materials, install all fire protections as requested by specialists, provide a certified installer, and run a proper QAQC system.

While designs may promise performance on paper, reallife fire accidents reveal the true resilience of façades. Each incident brings invaluable lessons, prompting the industry to re-examine materials, codes, and practices with greater urgency and responsibility.

Shah calls the number of existing buildings that continue to carry combustible façades the "most sobering lesson". While loss of life has often been limited, Shah points out that the property and business continuity losses have been severe. He argues the industry must prioritise regular fire audits and ensure that active and passive systems are functioning, adding that routine emergency drills are vital.

Rizvi states that the biggest lesson is that compartmentation must extend to the exterior façade. The use of combustible cladding materials was shown to pose an unacceptable risk, which drove the global shift toward non-combustible alternatives. Rizvi reiterates that reliance on individual component test data is insufficient, which led to the adoption of largescale system tests. He notes that failures also exposed gaps in accountability, leading to stricter requirements for third-party inspections.

Deshpande says that events like the Grenfell Tower fire exposed systemic failures: combustible façades, inadequate regulatory oversight, and weak maintenance regimes. The key lessons, he notes, are that fire safety must be addressed at the system level, retrofitting unsafe façades is urgent, and maintenance and inspections cannot be neglected.

Morante observes that most fires occurred in buildings constructed under "previous rules and standards," and current standards should avoid this type of incident. However, he suggests new rules should be created to regulate all work and changes happening on a façade after the handing over, arguing that a façade does not burn by itself, but due to uncontrolled post-handover changes.

As buildings grow taller and designs become more ambitious, the role of façades in fire safety is gaining critical importance. Looking ahead, innovative systems and materials promise to reshape how we protect lives while achieving architectural excellence.

Shah views new developments more as new challenges on the horizon. He cites Building-Integrated Photovoltaics (BIPV) as an example, noting that many such systems have yet to undergo adequate fire testing. While firefighting technologies are evolving, Shah firmly believes the emphasis should remain on prevention: selecting and installing compliant, non-combustible façade systems in the first place.

Rizvi is excited about the growing use of non-combustible cladding materials, such as mineral-based panels and advanced ceramics. He also sees modular façade construction as a key innovation, as prefabricated units reduce installation errors. Rizvi notes the huge potential of AI tools for façade design to help engineers make safer choices.

Deshpande lists promising innovations, including noncombustible composite cladding systems and fire-rated

glass façades. He also highlights advanced insulations like aerogel and smart façades with embedded sensors to detect hotspots.

Morante expresses interest in composite materials and the evolution of UHPC Terracotta, noting that terracotta is a product fired at high temperature and is very good for protecting against fire propagation.

While building codes are becoming increasingly stringent, the question remains whether regulations alone are enough. Raising awareness and providing dedicated training for professionals could ensure that façade fire safety goes beyond compliance, fostering a culture of responsibility and prevention.

Shah notes that awareness and training certainly play a role, but it is equally important that professionals should only practice within their specific areas of expertise. Those without the necessary background, he says, should seek peer support from qualified and licensed experts. Shah concludes that while codes provide the framework, ongoing professional development,

awareness campaigns, and knowledge-sharing are essential.

Rizvi states that codes provide the foundation, but are not enough, as many fire incidents show that failures occurred because people did not fully understand how to apply them in practice. He says awareness campaigns and regular training are essential to bridge this gap, as professionals need a deeper understanding of how façades behave in fire. Rizvi concludes that expanding such initiatives would create a stronger safety culture.

Deshpande agrees, saying that codes and standards alone cannot guarantee fire safety because the human factor remains the weakest link. He urges the need for continuous training for architects, engineers, contractors, and inspectors. Deshpande stresses that contractors and facility managers must understand the importance of details and maintenance.

Morante strongly recommends that the training be extended to the people installing the façades on site,

with very clear explanations on the consequences of bad workmanship. He notes that safety is for all parties, not just designers and engineers.

Ultimately, the journey to safer façades is not just about meeting minimum legal requirements; it’s about fostering a culture of uncompromising responsibility. The insights from our industry experts underscore a crucial truth: failures often stem from simple oversights—be it poor material choices, inadequate detailing, or a lack of early collaboration.

While stricter codes and innovative materials provide the framework for safer buildings, they are only as effective as the human expertise behind them. By learning the sobering lessons from global fire incidents and committing to continuous awareness and training, the industry can ensure that fire safety is treated as an integrated design priority, not an afterthought. Moving forward, the goal must be to build structures that are not only architecturally stunning but are fundamentally and reliably safe for all who live and work within them.

About the Author

MAGDY ELADL Co-Founder & CEO, Smart Window

Magdy Eladl is the Co-Founder and CEO of Smart Window, a leading façade company established in 2002 that bridges the gap between architectural vision and engineering practicality to meet the façade industry’s evolving requirements. Under his leadership, Smart Window has grown to a team of over 700 professionals and has delivered landmark projects across the Middle East. He is also the sole Founder of International Façade Consultant (IFC), a global academy and consultancy dedicated to advancing façade engineering knowledge and practice. IFC provides training and advisory services in both Arabic and English, serving professionals worldwide. Magdy holds an MBA (Master of Business Administration) and studied for a Master’s in Façade Engineering in England, combining business acumen with deep technical expertise.

Infinity Towers, Saudi Arabia

• Every successful company has an interesting beginning. How did Smart Window come into being, and what was the vision that drove you to start this journey?

Smart Window was founded in 2002 with the mission of bridging the gap to fulfil the façade industry’s evolving

requirements. We wanted to connect architectural creativity with engineering practicality, ensuring that façades meet new demands in performance, sustainability, and aesthetics.

Later, I founded International Façade Consultant (IFC) as a separate initiative. IFC is not just an academy—it is also a specialised consultancy firm. It started with a focus on the Arabic-speaking market, offering façade training and advisory services in Arabic. Within two months, IFC will expand to operate in both Arabic and English, making it accessible globally. Our vision is for IFC to serve not only the Arab world but the entire international façade community with both education and consultancy.

• Today, Smart Window has a team of more than 700 people. How do you keep such a large team motivated while ensuring that innovation and craftsmanship remain consistent across projects?

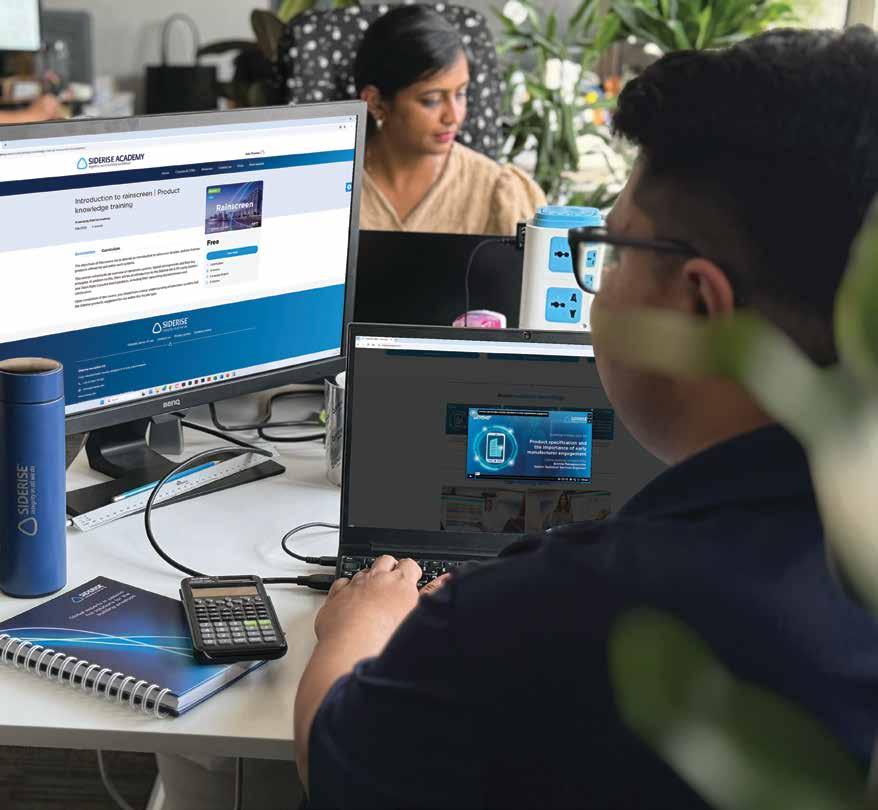

Smart Window today has a team of over 700 professionals, motivated through training, performance systems, and a culture of innovation. IFC complements this by providing

structured courses, knowledge-sharing, and consultancy services that go beyond our company. Through IFC, we aim to elevate the industry as a whole—training individuals, supporting companies, and consulting on complex façade challenges worldwide.

• Sustainability is no longer just a buzzword in construction. What concrete steps has Smart Window taken to make its products and processes more eco-friendly?

Smart Window integrates eco-friendly solutions such as low-E glass, high-performance insulation, and double-skin façades into projects. IFC extends this mission globally by educating engineers and advising companies on sustainable façade practices, ensuring that the knowledge and consultancy we provide impact not just projects but the wider industry mindset.

• You work closely with global names like Schuco, Technal, Gutmann, and Alumil. How do these partnerships influence the kind of projects you deliver?

Smart Window’s collaborations with Schüco, Technal, Gutmann, and Alumil bring advanced systems into our

projects. IFC complements this by transforming these innovations into knowledge and consultancy. We don’t just implement technologies—we share insights and offer strategic guidance so others can adopt global best practices across different markets.

• The façade industry is constantly evolving, with new technologies, materials, and design trends. How does Smart Window keep pace with these changes?

The façade industry evolves rapidly with new technologies and materials. At Smart Window, we adopt automation, robotics, and digital tools such as BIM. IFC works in parallel by teaching, consulting, and guiding stakeholders about these technologies. Our dual model ensures we stay at the cutting edge of execution (Smart Window) and knowledge (IFC).

• Leading a company is very different from just building one. As a co-founder, how would you describe your leadership style and the values you try to instill in the organisation?

As co-founder of Smart Window and sole founder of IFC, my leadership style blends business leadership with industry

mentorship. At Smart Window, it is about motivating a large team to deliver excellence. At IFC, it is about educating, consulting, and building a global knowledge platform. Across both organisations, I emphasise values such as innovation, trust, quality, and sustainability.

• Looking ahead, what’s your long-term vision for Smart Window? Where do you see the company in the next 10 years, especially in terms of sustainability and technology?

Over the next decade, my vision is twofold:

• Smart Window will grow into one of the top five façade companies in the Middle East, with international expansion across the GCC, Africa, and Europe, while leading in sustainable and smart façade solutions.

• IFC will become a global façade consultancy and academy, serving both Arabic and English markets. IFC will not only educate but also consult on projects worldwide, bridging knowledge gaps and raising professional standards across the industry.

Together, Smart Window and IFC represent the two sides of impact: delivering landmark projects and delivering global knowledge and consultancy.

Michele Pasca Di Magliano Director, Zaha Hadid Architects

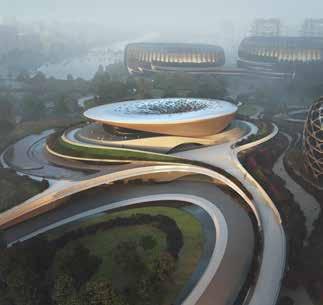

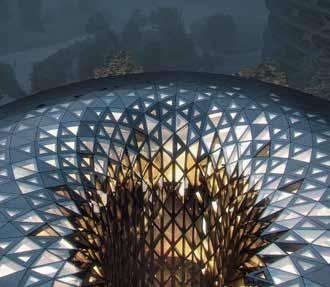

Science Centre in Singapore

Waterfront view of the new Science Centre

Note: The image is an artist’s impression, and the final design may be subject to changes

Image courtesy: Render by Negativ

About the Author

Michele Pasca Di Magliano joined ZHA in 2004 and is now a director, specialising in high-rise developments. He is currently working on a variety of exhibition schemes, as well as selected furniture and interior products. He studied architecture at the University of Naples (2001) and holds a master’s degree from the Architectural Association in London (2004). He is currently directing several major ongoing projects throughout Australia and eastern Asia, including the Singapore New Science Centre, which won in competition, and the Sleuk Rith Memorial Institute in Phnom Penh. He also served as project director on the Morpheus Hotel & Resort at City of Dreams in Macau, a leading integrated resort comprising a casino, two theatres, a shopping district, 20 restaurants and four hotels. He has built a strong relationship with China through his work with leading developer SOHO China, resulting in major projects such as Wangjing SOHO and Galaxy SOHO.

• What drew you to join Zaha Hadid Architects, and how has your role as Director evolved?

When I studied Architecture, I could not even dream of joining ZHA. I completed my Diploma in Italy, which has a very good technical foundation but is dominated

by a traditional approach to design. I was fortunate to have a thesis tutor who directed me to some heroes of English architecture, such as James Stirling and Richard Rogers, which widened my horizon. It was not until I moved to Rotterdam that I seriously considered the key impact of creativity in urban planning and decided to move to the UK. Zaha Hadid Architects was simply the best place in the world to pursue cutting-edge design and advance the construction industry, and it still is today.

As a Director, I look for new clients and help them deliver a vision that will elevate their project; at the same time, I manage and empower my colleagues to help them build a stronger practice. Architecture is a team effort.

• ZHA works across such a wide range of projects. Which types of projects do you find most rewarding to be involved in?

We have a design-driven approach, which affords us a great typological variety and flexibility. Our approach creates a very interesting and challenging design process, where we must describe our complex geometries in simple, buildable elements. My drive is towards the future: exploring new regions and

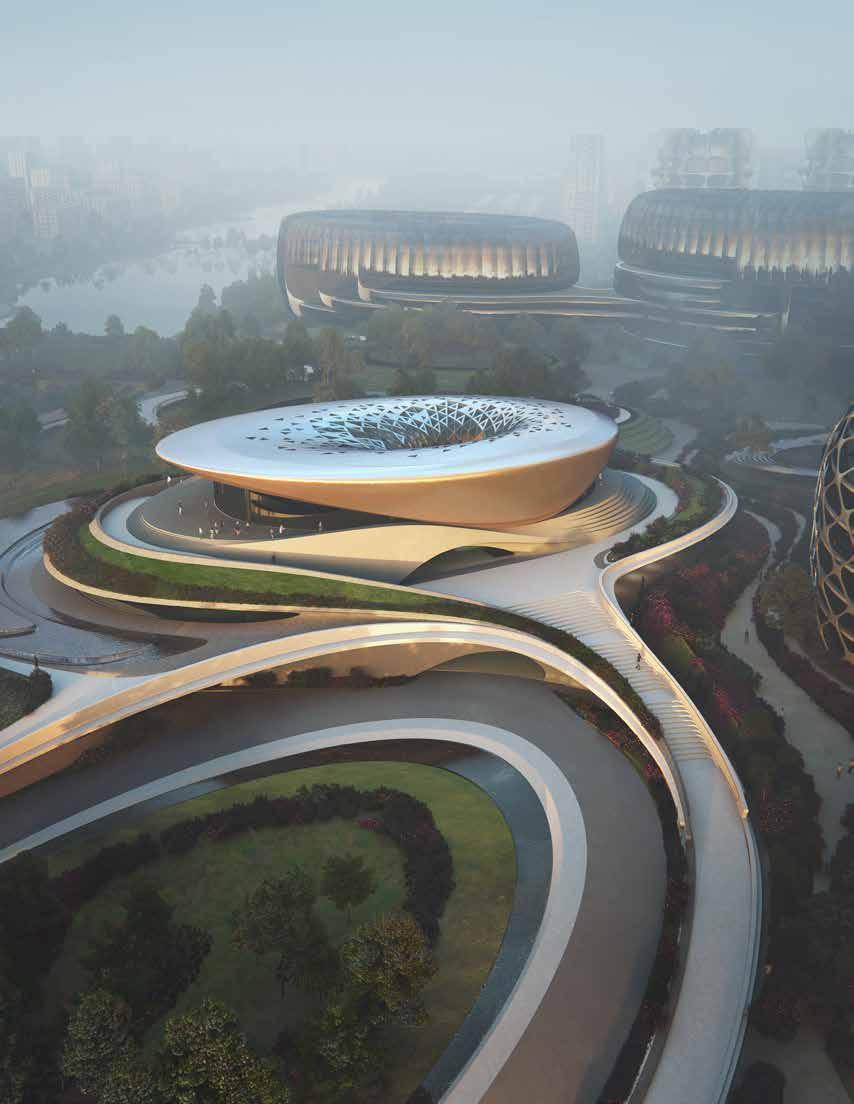

typologies. In terms of built and ongoing projects, significant public commissions are always a great challenge, such as Unicorn Island, which is our largest to date—1 million square metres with over 30 highly complex buildings designed by us—and the Science Centre in Singapore, which will have a great impact on the future of STEM education and development in the region.

• Façades are often the most recognisable element of ZHA’s designs. How do you approach their development to strike a balance between performance and visual impact?

We are unapologetically design-driven, yet our design is founded on a strong mathematical and scientific approach. We look at views, thermal performance, fire resistance, weight, assembly, buildability, modularity and repetition, alongside input from clients and consultants, to develop a highly performing envelope. The façade is the “promise” of the building’s performance. In essence, it creates an envelope that contains and protects from the elements, but it also signifies its performance to the surrounding city.

• With today’s push for sustainable design, how do you see façades contributing to energy efficiency and climate responsiveness in ZHA projects?

We have built on our in-house knowledge to help us engage in dialogue with sustainability consultants and standards, which tend to vary slightly from region to region. We have a great passion for passive systems, where the orientation and shape of the building can help to self-shade and minimise solar gains. This is something which enters our design process very early, already from the initial massing stage, when we look at the best orientation and reduce large areas

exposed to solar gain. Ultimately, advancements in glass performance and smart systems can help improve the outcome.

• Many of ZHA’s façades rely on advanced geometry. What role does technology play in making these complex designs feasible?

Absolutely. We have seen great advancements in the construction industry, and I am very proud to have witnessed digital systems achieve what was unthinkable a few years ago. For the Morpheus in Macau, we were able to design, detail and document a highly complex geometry and high-performing façade thanks to scripting our software. The same building would have been impossible to draw by hand. What is important to me is that complex geometry is always driven by a clear design intent and performance, and never purely decorative. In this way, technological advancement is the outcome of a rigorous process and not a display of technology for its own sake.

• How do you balance the creative ambitions of the practice with the day-to-day realities of delivery?

Each new project has its own story and trajectory, yet somehow it finds its way into our portfolio. When we design a new project, we carry our previous experience and focus on what has the greatest impact and efficiency. The ambition is to continue pushing ourselves to create more ambitious projects—larger, with higher complexity and a greater number of stakeholders. It is rewarding to see that we are recognised in the industry as experts in so many fields, and to have the honour of collaborating with the greatest engineering offices, both London-based and abroad.

• Could you share a project you’ve worked on at ZHA that has been particularly meaningful to you?

The work on Morpheus was incredible. I mentioned its complexity earlier, but having a global design and

delivery team was truly a unique opportunity. It all starts with a very committed client who drove the project in a streamlined way. We had London- and Hong Kongbased engineers, a French contractor, and most of the construction happening in China, to deliver a project in Macau. The clients had a fixed budget and we had to work hard to stay within their delivery timeline, with typical floors being built on a three- to five-day

cycle and a highly innovative exoskeleton structural system. We had to figure out how to orient mullions, how to maximise flat glass, and how to combine it with cylindrical and freeform façades. We had a limited range of flexibility in the aluminium cladding and even less for the curvature of the structural system—all to deliver a luxury hotel to the highest standards of hospitality.

The project was such a feat that we flew the whole office out to Macau for a celebratory opening party. My biggest reward was the congratulations from my colleagues, both senior and junior, as well as from the hotel and restaurant staff, who take great pride in working there.

• Many of ZHA’s projects have become cultural landmarks. What is it like to see people engage with buildings you’ve been deeply involved in?