America Knits, Swainsboro, Ga., is a modern cut-and-sew facility with a mission to revive “Made in America,” while working differently to attract a younger workforce.

Co-owner Steve Hawkins and his wife Alejandra, pictured operating the company’s automated pocket setting machine, regularly work in the plant where employees are treated like family.

Carter discusses the company’s part in developing the U.S. hemp ecosystem — growing, processing and building partnerships.

Knits: Sparking Big Change In A Small Town

America Knits is a modern cut-and-sew operation in rural Georgia built with a mission to revive “Made in America.”

with FTC regulations is essential to avoid enforcement actions,

AAs 2025 draws to close and the turmoil of the past year lessens with signs of a new footing taking hold, many view the 2025 blitz on the long-held framework of U.S.international trade policy as a dream come true.

A new fair-trade focus establishing America’s self-interests as a cornerstone of policy broke with the long-held commitment to an open,“free”trade policy,fraught with barriers to U.S. manufacturing competitiveness.

In a split second,an extremely contentious divide opened in the status quo of not only trade policy, but global relationships,alliances and longstanding assumptions concerning the goals of U.S.trade policy.

Even at the time of this writing,with the U.S.Supreme Court yet to rule on President Trump’s authority to enact such a tariff regime,the president’s proponents espouse other avenues the president will, could,or should pursue if the court rules against him.

Investment has been stymied by the tariff effect on imported machinery, a weak U.S.dollar and the benefit of new full depreciation tax policy not really hitting home.

Throw in a government shutdown — which affects numerous government business relationships,health insurance uncertainty and lack of consensuses on the future of the very existence of humanity — and it is a murky stew. Will cooler heads prevail in 2026? One would think so,but there are many challenges ahead.

If President Trump’s history as a negotiator is considered,it is a by-his-book approach to stake an extreme position,

well beyond the goals of the negotiation, and then settle back to a more moderate position.It has happened over and repeatedly,but few take notice and settle quickly. It is painful to watch and well outside the nature of statesman-like behavior but,in many cases,can be extremely effective.

In 2016,similar concerns for the future took hold after his election — before he was even sworn into office.Back then,the economy really sprang to life as business and consumers felt reassured that the world wasn’t going to end.Political battles raged in President Trump’s first term within his own party and in opposition.The internal hostility seems to have moderated this time,with steep political and social hostility very much in place.

U.S.textiles has always survived,and even thrived,by doing a good job of “reading the room.”The National Council of Textile Organization (NCTO) has had an effective run at getting the voice of the industry heard in Washington.Though not spoken of everyday,the end of the de minimis loophole for low-value commercial shipments is a major achievement and step forward towards fairer trade.

What will happen with the USMCA agreement that links the United States, Canada and Mexico into a trading block; or the CAFTA partners — some of which are not admired by the president; or even the Berry Amendment? Who knows?

That said,may 2026 be a healthy and prosperous new year!

James M. Borneman jborneman@TextileWorld.com

EDITOR IN CHIEF James M. Borneman

EXECUTIVE EDITOR Rachael S. Davis

TECHNICAL EDITORS Dr. Lisa Parillo Chapman

Dr. Peter J. Hauser

Dr. Trevor J. Little

Dr. William Oxenham

Dr. Behnam Pourdeyhimi

Dr. Abdel-Fattah Seyam

Dr. Andre West

CONTRIBUTING EDITORS Jim Kaufmann

INTERNET CONTENT EDITOR Rachael S. Davis

CIRCULATION MANAGER Julie K. Brown-Davis

ADVERTISING BUSINESS MANAGER Denise Buchalter

ART & PRODUCTION MANAGER Julie K. Brown-Davis

OWNER/PUBLISHER James M. Borneman

PO Box 683155, Marietta, Georgia 30068, USA Telephone +678-483-6102

www. T e x t i l e W o r l d .com

ADVERTISING REPRESENTATIVES

UNITED STATES/CANADA Turner Marketing & Media, LLC +864-594-0921 • sturner@textileworld.com

MEXICO, CENTRAL & SOUTH AMERICA Virgilio L. González + 58-412-622-2648 • vlgonzalezp@gmail.com

EUROPE (except ITALY) Sabine Dussey +49-171-5473990 • sabine.dussey@dussey.de

ITALY Ferruccio & Filippo Silvera +39-022-846716 • info@silvera.it

ASIA James M. Borneman +678-483-6102 • jborneman@textileworld.com

INTERNET & CLASSIFIEDS OPPORTUNITIES Julie Davis +678-522-0404 • jdavis@textileworld.com

Spartanburg,S.C.-based Milliken & Company has acquired the assets of Highland Industries Inc. in Cheraw,S.C.,in a move that bolsters Milliken’s technical textiles capabilities and strengthens its U.S.operations.Milliken said the Highland site will serve as a regional hub for technical textile weaving and knitting.

“We remain committed to the U.S.textile industry and grounded in our belief that precision manufacturing of innovative,high-performance materials is crucial for industrial resilience,”said Halsey Cook,president and CEO of Milliken.

“In addition to reinforcing current operations, acquiring Highland adds new offerings to the technicaltextiles portfolio,”said Allen Jacoby,executive vice president,and president of Milliken’s technical textiles business.“Highland provides important assets to help us better serve our customers and opens the door to new growth opportunities.”

In other Milliken news, the company was recognized with a 2025 EcoVadis Gold Rating for the fourth consecutive year.The award puts Milliken in the top 5 percent of the more than 150,000 global organizations that are considered for the recognition each year.

“This recognition reflects the dedication of

our teams around the world and our continued focus on fostering transparency and driving innovation across our businesses,”Cook noted.

Champion Thread Co. (CTC),Gastonia,N.C.,has established the Poovey Family Scholarship in honor of its late founder,Robert “Bob”Lee Poovey III.The need-based undergraduate scholarship will support students pursuing degrees at the Wilson College of Textiles at NC State,Raleigh, N.C.The Poovey family has multiple NC State alumni across three generations, and the scholarship is funded through a permanent endowment created during the Wilson College’s 125th anniversary year.

CTC CEO Matt Poovey said: “This scholarship is more than a recognition — it’s a reflection of my father’s lifelong devotion to the textile industry and his unwavering pride in the Wolfpack.He believed deeply in the transformative power of education, excellence,and service. His passion for textiles was matched by a quiet generosity — he had a gift for recognizing when someone just needed a helping hand and he offered it freely,without fanfare.… This scholarship carries that spirit forward, empowering future students to pursue their goals with

Pakistan-based Artistic Milliners has acquired a majority stake in Cone Denim from Elevate Textiles,Greensboro,N.C. The resulting multinational company will operate under the Cone Denim name,and Artistic Milliners’ Pakistan operations will continue independently. The transaction is expected to close in early 2026.The combined entity will include Cone Denim’s mills in Mexico and China, as well as Artistic Milliners’ garment facility in Parras, Mexico,and its Star Fades International laundry and development center in Los

courage,diligence,and the values that shaped his life and legacy.”

Bob Poovey worked in textiles for more than 50 years and founded CTC in 1979.

Italy-based Itema recently began construction on a new manufacturing site in Ponte Nossa,Italy. The company acquired the unused site in 2022 that previously housed Cotonificio Cantoni,and is moving forward with a multi-step redevelopment plan intended to modernize operations and expand its presence in the Seriana Valley.Step one,now underway and scheduled for completion in 2027, includes a world-class production hub to support

Angeles.Cone will operate as a standalone portfolio company led by President Steve Maggard.

“We are committed to bringing the full breadth of our expertise to help unlock Cone’s competitive strengths,”said Artistic Milliners’Murtaza Ahmed and Omer Ahmed in a joint statement.“Cone Denim will preserve its unique identity while continuing to drive its own business strategy.Our goal is to collaborate closely with the Cone Denim team,building on the legacy and achievements of more than 130 years.”

Itema’s weaving machinery production.The project later will include development plans for Lamiflex S.p.A.

“In 2022 we took the decision to begin a journey that would lead Itema Group to have a position adapted to the turbulent changes taking place and at the same time strengthen our brand,which is recognized throughout the textile world as an ambassador of‘Made in Italy’,”said Ugo Ghilardi, Itema Group CEO.“One step of this journey involves both process and production,and product assets,which find a home in this new manufacturing site in Ponte Nossa.”

Mayer & Cie.,a Germany-based manufacturer

of circular knitting and braiding machines,has filed for insolvency under self-administration.The company,which employs about 280 people,cited a significant decline in global demand.Wage and salary payments are secured for three months through insolvency benefits.

Mayer & Cie.reported that geopolitical tensions, including the U.S.-China trade conflict and the war in Ukraine,have discouraged investment,while high inflation in Turkey and price pressure from subsi-

percent drop in sales last year.

In the self-administration process,management will oversee restructuring with support from specialist Attorney Martin Mucha of Grub Brugger,who joins as general representative.

“On Thursday,together with the management,I informed the workforce about the insolvency application,”Mucha said.“At the same time,the necessary steps were taken to maintain business operations. We intend to continue business operations as

on maintaining the company’s core competencies.”

Germany-based KARL MAYER will discontinue its flat knitting machine business under the STOLL brand as part of a strategic shift toward warp knitting, warp preparation and technical textiles.Manufacturing at the STOLL production site in Reutlingen,Germany,has already ceased, and production in China will cease by the end of the

“STOLL stands for a long tradition,”said Oliver Mathews,president of the STOLL Business Unit.

“That is precisely why we deeply regret that we were unable to lead the business into the future successfully. It was not possible to find an investor to continue production at the main site in Reutlingen with its 280 employees.”

KARL MAYER will continue servicing the installed base,with spare parts to be supplied from warehouses in Obertshausen,Germany, and China.Software license keys will remain available. TW

APR 21–24, 2026 FRANKFURT, GERMANY

trend agency with more than five decades of experience. According to organizers, the showcase will introduce “the season’s key color stories, material innovations and creative directions — translating future trends into tangible inspiration for designers and sourcing professionals alike.”

Offers New Features, Unified Innovation Hub

Offers New Features, Unified Innovation Hub

Texworld NYC taps Peclers Paris for trend direction while introducing fresh programming, and a reimagined Innovation Hub for sourcing professionals and designers.

TW Special Report

JJanuary 20-22, 2026, the textile and garment industry will gather in New York City at the Javits Center for Texworld NYC. The biennial trade event will collocate with Apparel Sourcing NYC and Printsource for the Winter 2026 Edition to create a hub for fabric sourcing and solutions for the textile and garment industry.

Texworld, organized by Atlantabased Messe Frankfurt Inc., is a showcase of fabrics in on trend-color palettes comprising basics up to those containing unique fiber blends and innovative structures.

Apparel Sourcing NYC is a joint venture between Messe Frankfurt and China-based Sub-Council of Textile Industry, China Council for the Promotion of International Trade (CCPIT-Tex). Exhibitors specialize in finished apparel, contract manufacturing and private label development. Apparel and accessories will be displayed including ready-to-wear collections for men, women and children.

Printsource highlights hundreds of design collections from surface designers and textile design studios all over the world. Applications include apparel, bed and bath, kitchen and tabletop, wall coverings and window fashions, among other applications.

Organizers are combining the Next-Gen Materials, Technology Lab and Solutions Studio into a single destination — the Innovation Hub. Within the hub, visitors can learn about biobased, circular and low impact textiles, digital tools and artificial intelligence systems including blockchain and 3D design, as well as services offering transparency and accountability options for the global supply chain.

As always, trend forecasts form the heart of Texworld NYC. This edition’s Texworld Trend Showcase is curated by trend partner Peclers Paris, a creative consultancy and

“We believe every story in fashion begins with the fabric,” noted Yvonne de Bruyn, Trend & Type director for Consultancies, Peclers Paris. “It is the foundation of creativity, the vessel of emotion, and the touchpoint of connection. Fabric shapes not only garments, but also the narratives they carry and the feelings they evoke. That is why we are proud to partner with Texworld New York, bringing our trend-driven vision to the fashion capital of the United States.”

The Chicago Pattern Maker Founder and President Xochil Herrera Scheer will host a new hands-on tech pack workshop for attendees. “Your Fashion Design Blueprint” aims to demystify the tech pack, which is an essential blueprint for bringing garments to life. Seats are limited and tickets can be purchased during online registration.

Other returning event features include the Exhibitor Pitch stage presented by Texpertise, which will present new products and innovations; Textile Talks where experts will discuss a variety of issues pertinent to the fashion and textile industries; and the Deadstock Sourcing area that will provide buyers access to surplus materials as sustainable sourcing alternatives.

The shows are open 10 a.m. to 5 p.m. on Tuesday and Wednesday, January 20-21; and from 10 a.m. to 4 p.m. on Thursday, January 22. TW

For more information about the shows and to register, visit texworld-usa. us.messefrankfurt.com and printsource newyork.com.

RISE® 2025 —which honored Keel Labs with the RISE Innovation Award (far right) for its Kelsun® seaweed-based fiber —allowed for networking and learning while spotlighting the technologies that are redefining what’s possible in engineered fabrics.

TThe Cary, N.C.-based Association of the Nonwoven & Fabrics Industry (INDA) recently hosted its 15th RISE ® conference, cohosted by The Nonwovens Institute (NWI). The two-day RISE — Research, Innovation & Science for Engineered Fabrics — event focused on emerging technologies and ideas with the aim of connecting innovations with real-world applications for professionals in the nonwoven/engineered fabrics industry. The event this year was held at the McKimmon Center on the NC State campus in Raleigh, N.C.

Topics focused on sustainability and innovation. Carbon-smart materials and fiber science featured heavily on the agenda, and green chemistry and nonwoven processing technologies also were included in the presentations. INDA’s Director of Government Relations, Wes Fisher, concluded the conference with his presentation on “Nonwovens in a Shifting Landscape: Navigating Tariff and Policy Risks in a Second Trump Administration.”

Each year, INDA searches for commercializable technical products and technologies to honor with the RISE Innovation Award. The top three nominees for the award in 2025 — EsterCycle LLC, Rockline Industries and Keel Labs — presented their technologies at the end of the

15th annual RISE designed to explore collaboration and creativity for a more sustainable future in the nonwovens and engineered fabrics industry.

first day of conference proceedings, and then RISE attendees voted for their favorite innovation. Once those results were tallied with votes cast by INDA’s Technical Advisory Board and the affiliated Conference Committee, Keel Labs, Morrisville, N.C., was announced as the winner of the 2025 RISE Innovation Award for its Kelsun ® fiber. The seaweed-based fiber is a sustainable, biodegradable alternative to petroleum-based fibers. Kelsun also is soft, inherently flame resistant and antimicrobial.

The day before the conference, those interested in golf participated in a charity golf tournament at the Lonny Pool Golf Course on the NC State campus. Money raised by the tournament supports graduate students with travel costs to attend INDA events.

During the conference, attendees had the opportunity to learn about research taking place at a variety of universities via the graduate research

posters that were on display. It’s a great opportunity for the students to share their work with industry experts and potential investors. Tabletop exhibits from participating companies also were positioned around the posters in the exhibit area offering additional learning opportunities.

At the close of the conference, attendees were given the chance to tour NWI. This “Open Innovation” resource on the Centennial Campus of NC State comprises a consortium of stakeholders spanning the breadth of the nonwovens value chain. The collaboration between academia, industry and government works to develop nonwoven solutions and is the first accredited academic program for engineered fabrics. NWI houses more than $65 million in pilot lines and analytical labs for trials and development work.

“RISE continues to spotlight the technologies that are redefining what’s possible in engineered fabrics,” said Dr. Matt O’Sickey, INDA’s director of Education & Technical Affairs. “From renewable carbon and green chemistry to next-generation fibers and recycling innovations, this year’s conference showcased the kind of collaboration and creativity that will shape a more sustainable future for our industry.”

INDA has announced the date for RISE 2026, which will return to the McKimmon Center August 2526, 2026. TW

Meredith Boyd, executive vice president, chief product officer, UNIFI® and SYFA president

Exploring recent developments in fiber innovation, trade and the economy, the Synthetic Yarn and Fabric Association delivered at its recent fall conference.

TW Special Report

TThe Charlotte N.C.-based Synthetic Yarn and Fabric Association (SYFA) recently held its annual fall conference at the Sheraton Charlotte Airport Hotel in Charlotte, N.C.

SYFA President Meredith Boyd opened the conference stating: “Our theme this conference, ‘From Fiber Forward: Technology, Trade, and Transformation,’ captures what this moment means for our industry. Today, we’re no longer just a manufacturing sector, we’re a strategic industry that anchors national security, environmental progress, and economic competitiveness. We are the quiet enablers behind nearly every major innovation shaping modern life, and it all starts with chemistry, engineering, and ingenuity.”

Senior International Trade Manager with the Economic Development Partnership of North Carolina, Jeri Barutis, hosted a discussion with Felicia Pullam, senior director, GeoCommerce, APCO Worldwide, tackling the topic “Trade & Compliance: Challenges & Opportunities in the Textile Industry.” The exchange explored how to navigate trade policy and gave insight into actions small and mid-sized companies may use to deal with compliance issues.

Matt Yakush, Global Market Development leader, Kevlar® EXO™, and Jake Pretko, lead engineer II, R&D

Aramids Product & Process Development, DuPont, presented “Kevlar EXO: Innovating the New Generation of Technical Textiles.” The duo explained the history of Kevlar and the innovations achieved with Kevlar EXO including increased strength, weight savings and flexibility.

Well-known textile trade professional Auggie Tantillo with SRG & Associates presented “A Federal Textile Trade & Tariff Review.” Exploring the chaotic trade landscape, Tantillo gave his take on the good and bad of current trade issues and raised concern regarding the future of the Berry Amendment.

Craig Lindemann, a technical specialist, Product Integration, Reju, presented “Reju: Building a Circular Textile System. He explained Reju as a systems change company that uses selective depolymerization of polyester and a network of feedstock suppliers, brands, and resellers to create a circular textile system.

Roger Tutterow, Henssler Financial Endowed chair, professor of Economics, Kennesaw State University, presented an Economic Review tuned for textile executives. Always entertaining, Tutterow gave context to the current economic situation.

Dr. Ramesh Kesh, senior vice president and Global Business manager - Polartec, and Government & Defense with Milliken & Company, gave an in-depth overview and update on Polartec, titled “Innova-

tion Made to Go Beyond.” Dr. Kesh’s command of the topic of innovation and application was insightful.

Billy McCall, Kintra Fibers’ founder and CEO, discussed “Next Generation Polyester Yarns: Looking Back in Order to Move Forward,” and described his initiative as an interested scientist bringing a fresh approach to fiber challenges while developing a biobased polyester.

Tamsin Ettefagh, chief sustainability officer and vice president of Industry, PureCycle Technologies, presented “Recycled PP for Fiber Applications.” An industry veteran, Ettefagh spoke of her personal journey transforming and reusing postconsumer plastics in meaningful ways.

In concluding the conference, Boyd offered remarks, saying: “Our industry may be centuries old, but it’s also among the most dynamic on earth. We have the rare ability to impact everything, from what people wear and how they work and play, to how they move, heal, and even protect their lives. We’re advancing a shared mission: to make textiles smarter, stronger, and more sustainable for the world we live in.”

SYFA will hold its Spring Conference April 1-2, 2026, at the Sheraton Charlotte Airport Hotel. The SYFA Annual Spring Golf Tournament to raise money for the SYFA Scholarship at Gaston College will be held Tuesday, March 31, 2026, at The Rocky River Golf Club, Concord, N.C. TW

Panda Biotech’s President Dixie Carter discusses the company’s part in developing the U.S. hemp ecosystem — growing, processing and building partnerships with an eye on sustainability.

TW Special Report

IIt was clear early on in this interview that Panda Biotech’s story was about much more than just building a new hemp gin in Wichita Falls.

Panda Biotech’s President Dixie Carter captured the scope of Panda’s approach saying:“By combining regenerative agriculture with clean,efficient technology, we’ve created a model that aligns with the future of sustainable textile manufacturing: local,traceable and circular.The result is not only a lower-impact natural fiber alternative but also a blueprint for how innovation and sustainability can coexist at industrial scale — right here in America.”

And that is the heart of the story,something that’s much bigger than a plant or a company,but is a new industry from farm field through final products.

Carter recently sat down with Textile World to share her take on creating a new industrial hemp ecosystem.

TW : How did the idea of developing a scalable

industrial hemp ecosystem take shape?

Carter: After decades of building clean energy projects,Panda saw industrial hemp as the next frontier in sustainability. The same principles that powered Panda Energy’s success — innovation,efficiency and environmental responsibility — now drive Panda Biotech as we build a fully integrated,zerowaste hemp fiber ecosystem here in America.

TW : How did your previous executive experiences assist you in your role at Panda?

Carter: Throughout my career,I’ve led collaborations with some of the world’s most recognized brands across entertainment,fashion,merchandising and industry.My expertise lies in building brands that connect deeply with people — through storytelling,marketing strategy,global partnerships and capital development.At Panda Biotech, those same principles

apply.We’re building a movement as much as a business — reintroducing American-grown,Americanprocessed hemp fiber to the global textile market.

TW : How does Chairman Bob Carter’s “no excuses”leadership style,influence your management approach?

Carter: Bob’s no excuses leadership sets a tone of accountability and action.He believes every challenge has a solution — and that mindset has become the heartbeat of Panda Biotech’s culture. This mindset reinforces that there’s always a way forward,but it requires discipline,collaboration, and an unwillingness to let obstacles become excuses.

TW : What milestones has Panda Biotech achieved in the development of American Hemp?

Carter: Panda Biotech’s momentum has been built through a series of strategic milestones from purchasing the building,sourcing the

right equipment and building out our facility,raising capital,finding the right seed to grow in our region, partnering with farmers and then working with them to have a successful harvest,commissioning the equipment,working with mills to dial in the right fiber for mass production, and so much more.Panda reinforced each milestone to build credibility,capacity, confidence,and a foundation for a truly American hemp supply chain with global reach and long-term sustainability.

TW : How has Panda’s sustainability focus impacted your choices in designing the Panda hemp gin?

Carter: Sustainability is not a single pillar of Panda’s business — it’s the foundation of everything we do.From the outset, our goal was to demonstrate that industrial hemp can be scaled in a manner that protects both people and the planet.We built the Panda Hemp Gin in

Wichita Falls,Texas,to reflect that commitment in every detail.

Panda’s facility is the most advanced,large-scale industrial hemp processing operation in the Western Hemisphere — engineered for zero waste.Our mechanical cottonization process transforms U.S.grown hemp into a fine, textile-grade fiber,eliminating the use of water or chemicals typically associated with degumming or scouring.Every part of the plant is utilized across multiple value streams.

TW : Building any facility is challenging enough, but what about making

choices — like choosing to pursue mechanical cottonization or using renewable energy?

Carter: From the outset,our goal was to develop a model for large-scale natural fiber processing that could be both environmentally clean and commercially viable — not a pilot project,but a proof of concept for U.S. manufacturing.Our products are OEKO-TEX® STANDARD 100 certified, USDA BioPreferred®,and meet the highest standards for clean fiber production.

Choosing mechanical cottonization was a pivotal decision.We considered bringing degumming in-

house,but the water and chemical requirements ran counter to our sustainability goals.Instead,Panda created a textile-grade fiber using only mechanical cottonization,which had notably fewer short fibers and bundles,and was finer, softer,and longer — similar to degummed and scoured fiber.While this took us longer to achieve, we now have the best and best-priced,mechanically cottonized,textile-grade fiber in the world,at half the price of degummed hemp fiber.This process enables hemp to integrate seamlessly into existing cotton spinning systems, which is crucial for broad textile adoption.

TW : The Wichita Gin is a substantial development. How did you get your arms around the project, and what was the key to managing a team to execute the considerable plan?

Carter: From the outset,we knew that building the Panda Hemp Gin would be unlike any industrial project ever undertaken in this sector — both in scale and

technical complexity.We traveled the world examining equipment and hemp facilities.We assembled an exceptional team of experts in mechanical design, automation,and industrial construction,many with decades of experience in large-scale facilities for the cotton,energy,and agprocessing industries.The state-of-the-art processing line,if measured end-onend,spans 700 yards — or 7 football fields — with three miles of overhead pneumatic ducting,customengineered decortication systems,and a continuous flow design that has never been implemented for hemp at this capacity.

A project of this size demands clarity,collaboration,and commitment. We aligned every engineer and operator around one vision — to build something historic — and that shared purpose made the impossible achievable.

TW : What is your personal connection to Wichita Falls and Seymour,Texas?

Carter: Our family had a ranch in Seymour, Texas,for more than 20 years,so we spent time in the closest big city, Wichita Falls.When we were searching for a building for our first hemp gin,our focus was on very large industrial buildings with high ceilings.When we found a 500,000-square-foot former GM facility on a 97-acre campus that also happened to be in a city where our family had history,we knew we had the perfect place.

TW : Panda’s Gin is just part of the story.Can you address Panda’s concentration on the hemp ecosystem — from the farm to merchantable product — like the “Pay-to-Grow”program?

Carter: The Panda Hemp Gin is the centerpiece of a much larger vision — building a truly scalable and sustainable hemp fiber ecosystem here in the United States.From the outset,we recognized that processing capacity alone wouldn’t be sufficient.To make hemp viable at scale,you need to connect every link in the chain,including regenerative farming,worldclass mills,and finished consumer products.

That’s why we’ve invested heavily in programs that support farmers and mitigate risk for participation.Our Payto-Grow program was a cornerstone of that effort for us at the beginning.It ensured growers were compensated for their work while we provided them with genetically proven and consistent seed,agronomic guidance, and a guaranteed market for their harvested stalks. It was a true partnership model that fostered trust and created economic opportunities for American producers.

Beyond the farm,we’ve built relationships with yarn and textile mills, nonwoven manufacturers, and brands that are eager to integrate our U.S.grown hemp fiber into their supply chains.The result is a fully domestic, traceable,and circular model — from seed to

Panda uses only mechanical cottonization, which uses no water and yields fewer short fibers and bundles and at half the price of degummed and scoured hemp fiber.

fiber to finished product — that helps revitalize rural economies while advancing the next generation of sustainable materials.

TW : What is your vision for the future of industrial hemp?

Carter: Hemp is not a fashion trend.It is the future of textiles and fashion.Scientifically proven to absorb more carbon dioxide per acre than any forestry or commercial crop,industrial hemp is the most transformative natural fiber opportunity of our time.It’s renewable,traceable,and circular by design — and it can be grown and processed at scale right here in the United States. Our vision is a global textile industry where hemp stands alongside cotton and synthetic fibers as a core,mainstream fiber — delivering performance, sustainability,and resilience. Early demand is coming from brands and mills that want to decarbonize their supply chains,starting with denim and knits. The long-term potential of hemp touches every sector of textiles.

TW : Are there any significant challenges in developing a vibrant industrial hemp future?

Carter: Any time a new natural fiber enters the global supply chain,the biggest challenge is consistency — mills and brands need to trust that the fiber will perform the same way, every time.Our focus has been on de-risking the transition by producing cottonized hemp fiber that integrates seamlessly into existing spinning systems. We’ve partnered closely with leading mills to conduct extensive spinning trials,optimize blending ratios,and verify quality at scale.By delivering both performance data and a reliable domestic supply chain,we’re helping brands adopt hemp with confidence.

TW : Where does Panda Biotech go from here?

Carter: With the Panda Hemp Gin now fully operational,our focus turns to expanding the ecosystem — deepening partnerships with mills,manufacturers, and brands who are ready to integrate U.S.-grown,

low-impact hemp fiber into their supply chains.

We’re also advancing our bioproducts portfolio,using every part of the plant to create renewable solutions across textiles,nonwovens, and industrial applications. At the same time,we’re working to strengthen our grower network,ensuring that regenerative hemp cultivation continues to create opportunity for U.S.farmers.

In many ways,this is just the beginning.The infrastructure is built,the partnerships are forming, and the demand for sustainable,traceable materials has never been stronger.

The editors of TW appreciate the opportunity to sit down with Panda Biotech’s President Dixie Carter.Her vision is both deep and wide with a bright future for American hemp.As Carter states, “Our mission now is to scale what we’ve proven — to show that sustainability can drive both performance and profitability,and that American innovation can once again lead the world in textile and materials manufacturing.” TW

America Knits founders Steve Hawkins (left) and Dr. David Talton

America Knits is a modern cut-and-sew operation in rural Georgia built with a mission to revive “Made in America” and create a new story.

By Rachael S. Davis, Executive Editor

nyone who has spent time in the textile industry knows its greatest strength has always been the people. And it was these warm, welcoming people who made thoracic heart surgeon Dr. David Talton fall in love with the industry after tagging along with his lifelong best friend — apparel industry veteran Steve Hawkins — to a handful of trade shows and conferences.

In 2018, Talton, looking for a new challenge and enamored with the textile industry, and Hawkins, looking for a lifestyle change, decided to partner creating America Knits — a company dedicated to producing premium, high-quality Made in America apparel in Swainsboro, Ga.

Hawkins has been on a remarkable journey in the cut-and-sew business from the time he graduated college with a degree in finance. From Reelsboro and Ayden, N.C., to

Honduras — requiring his first passport at age 35 — and back to the United States in Swainsboro, Ga.

He didn’t expect to work in the apparel industry. “I thought maybe I’d work in a bank,” Hawkins said. But through his part time job, he met Skip Hudson who owned five cutand-sew plants in and around New Bern, N.C., where Hawkins grew up. “Hudson asked me one day what I was going todo after graduation because he knew I was a senior,” Hawkins recalls. “I really didn’t know, and Hudson asked if I’d like to learn about the sewing business. He said his company was taking a different approach and was looking for someone freshout of college to teach the business. They wanted to find someone that could think outside the box.”

This chance offer set Hawkins on a course that would dictate his career to date. After learning about the cutand-sew business at Hudson’s Reelsboro facility, an investor helped

Hawkins open his own cut-and-sew business in Ayden at the young age of 25. The business thrived staying busy from 1988 until 1994, when the North American Free Trade Agreement (NAFTA) came along. “NAFTA marked the first time since I had opened my plant that we saw a slowdown, and it was the first time I’d ever had to lay anybody off” Hawkins said. He had never owned a passport, so when a colleague in the business asked if he’d ever considered going overseas, Hawkins did not immediately entertain the idea. But when he learned if he set up a plant in Honduras that he could keep it running 52 weeks a year, he was intrigued and decided after somemore research, to take the leap. “That’s where I learned a lot of the full package part of the business,” he said. “I also made many connections with Parkdale, as well as other spinners.”

But in a now well-known twist of events, cut-and-sew work slowly began to move to Asia and work was harder to come by in-between seasons for Hawkins’ Honduras facility. He decided to return to the United States and went to work for a larger, global manufacturer in sales and production management. It was a job he enjoyed, and it allowed him to further his knowledge of the business with another layer of learning. But the extensive traveling required to visit customers and offshore facilities meant he was missing out on homelife with his wife and sons. “I wanted a lifestyle change,” Hawkins said. “I had two young boys that were in first and fifth grade and I was missing everything because I was traveling all the time.”

At that point in his life, industry friends were urging Hawkins to consider opening a plant in the United States again. “That’s where David comes in,” Hawkins relayed. “We had been best friends since kindergarten, and we’d always wanted to be in business together. You’d have to

know David, but I guess saving lives wasn’t exciting enough for him,” Hawkins said with a chuckle. “And that’s what brought us to this little town with a population of 7,000 people in Georgia called Swainsboro.”

Attracted by the potential workforce in Swainsboro, the duo first identified a good building for the plant and then invested in state-ofthe-art equipment from the very beginning. They hoped to differentiate America Knits from other plants in the United States. “We knew the facility had to be something different and spent a good bit of money to outfit it and make it like we wanted it to be,” Hawkins said. “We wanted to avoid the old school thinking of ‘let’s get it as cheap as we can and just get started with used equipment.’ My theory was that we need the plant to look different, it needed to be bright, attractive and a place people would want to come to work.”

Displayed prominently on the plant floor is the company’s slogan, “Together, we are building a new story.”

Hawkins really believes in this idea. “The slogan really applies to the employees on the floor — we can only talk about it,” he said. “The story we are building has to be created by everyone involved in America Knits.

“We also hope that when visitors enter our facility that they see the quality of everything we do, not just the quality of the shirts we make,” he said. “If you have a clean, organized facility, I think that environment naturally promotes quality.”

No sooner had Hawkins and Talton got America Knits up-and-running making basic T-shirts, the Covid pandemic hit. “Just like everybody did at that point in time, we pivoted and figured out how to make personal protective equipment [PPE] like masks and isolation gowns,” Hawkins said. “As a cut-and-sew company in

the United States, we were quite fortunate because there weren’t many companies to turn to for help.”

In 2020, Parkdale Inc. led an effort to build a coalition of companies to respond to the nation’s need for PPE, and America Knits was honored to be included in the group. Hawkins said the collaborative effort generated a lot of free publicity for the fledgling company. “We were the smallest company in the group, but for a period of time, every night our name was mentioned on national television!” he said proudly.

That initial exposure attracted the attention of the State of Georgia and Governor Brian Kemp. In 2021, America Knits was invited to the governor’s State of the State speech where the company was highlighted for its efforts to make PPE during the height of the pandemic and the willingness of its employees to step up and work even though there were so many unknowns. That exposure led to more work for the company producing shirts for the Georgia prison

system at a time when inmates couldn’t work in factories within prisons. “It was definitely hard times, but the exposure built us to where we became a recognized company within the state of Georgia and we have received really friendly treatment from everyone involved, as well as numerous state recognitions,” Hawkins said.

As the supply chain shortages created by the pandemic eased, America Knits refocused on its original business plan. The company currently has the capacity to produce a total of 20,000 pieces a week in an assortment of premium T-shirts, polos and sweatshirts — all made using fabric sourced from U.S.-based manufacturers. A recent expansion investment added screen-printing, embroidery and laundry equipment. Hawkins emphasized fit is something that is very important to consumers and that it is therefore important to him that the shirts sold

With its motto “Together, we are building a new story,” America Knits wants its employees to feel like they are part of the company’s journey. The plant was designed to be modern and pleasant to work in, and employees are encouraged to cross train.

by America Knits are true to size and remain so after home laundering. America Knits’ new washing and enzyme equipment allows the company to precisely control the size of the finished garments.

The company aims to add garment dyeing in the not-too-distant future, and possibly even some spinning capability one day.

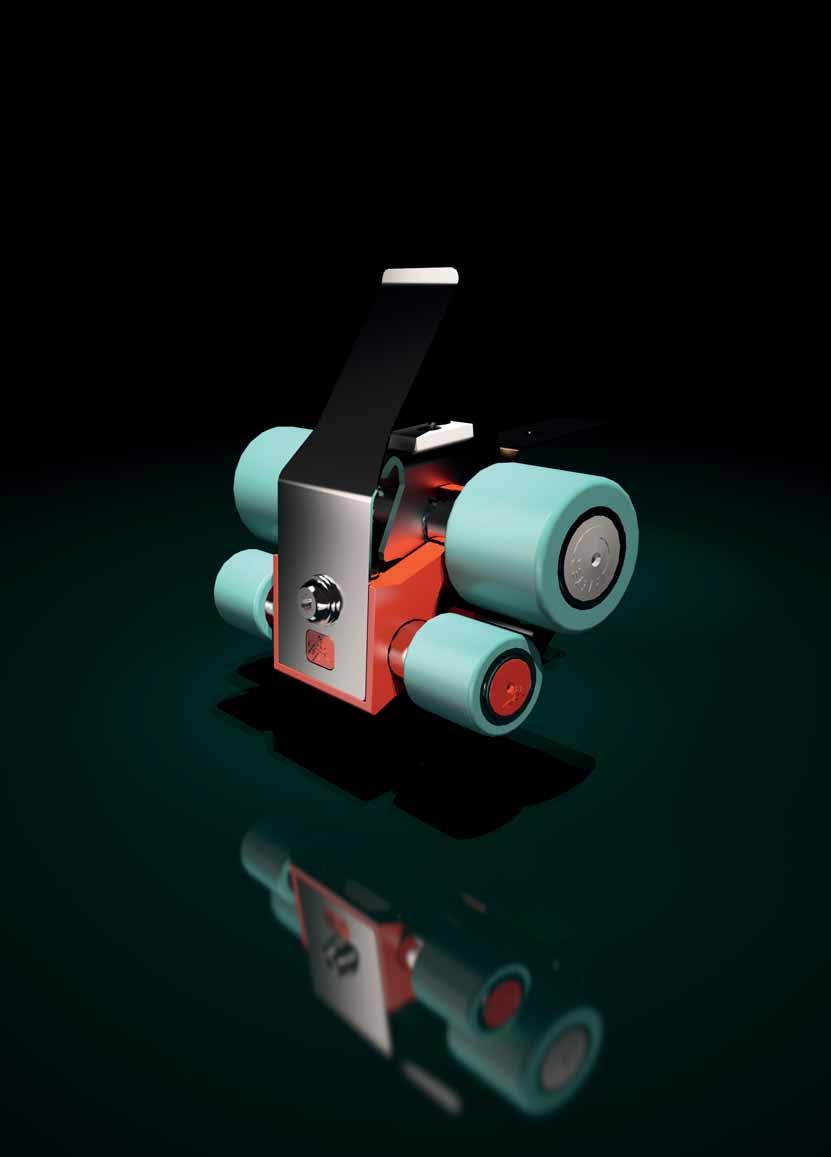

America Knits also is working closely with a Germany-based automation company that is developing robotic technology for T-shirt assembly. “We are sending them cut parts as they need them so they can tweak and experiment making T-shirts using robots,” Hawkins shared. “When they are ready — and they are getting closer — we hope to get a machine in our plant as a beta site.”

As of today, the company employs 53 local people. In many cases, those associates are quite familiar with the sewing business. “We are trying to

rejuvenate a business where for many of our employees, their mothers, fathers and sometimes grandparents worked in sewing plants when they were young,” Hawkins said. “I think engaging employees is important,” he added. “We need to make sure they know what the goals are, and what the vision is for what we are trying to build. We also want them to feel proud of where they are from.”

“Made in Small Town America” is imprinted in every shirt America Knits makes. “That idea means something to me,” Hawkins said. “There isn’t a large enough workforce for us to grow in Swainsboro, but I would like to replicate the business model in other small towns. I think it’s possible because by automating some of the tasks, we’ve made it a nicer place to work.”

Hawkins credits his wife, Alejandra, with suggesting employees be known as VIPs. They also make a point to celebrate birthdays at the plant. They hope such efforts will attract younger people into the business.

Another change America Knits made to the traditional cut-and-sew business model was to eliminate tying wages to production quantities. It was confusing to employees and sometimes meant losing good people because they didn’t fully understand and connect the hourly wage with the incentivized pay. “We took everyone’s average wage from the prior year and made that their guaranteed salary,” Hawkins said. “We still set goals for the teams but find they are more diligent about reaching the goals now than when they made money for production. We still have set costs, but we know the team costs per hour and in the end, we still get what we need. It was a game changer.

“We also encourage employees that the more they cross-train, the more jobs they can do and the more raises they can earn!”

Hawkins understands the value of training and educating the workforce. He never forgot Hudson’s willingness to give him a chance to learn from the ground up when he was a new college graduate.

“We have a really young middle management team at America Knits that is learning this business, and we take on interns and new graduates to learn as well” he shared. “Our goal is to keep layering on new people — hopefully those that have the ambition to eventually start their own plant someday. I believe in character. I hire the people who may not have the knowledge, but they have the character. For someone with the right character, the sky is the limit!”

When it comes to nearshoring the apparel industry in the United States, Hawkins says the solution is obvious, but not easy to implement. “The problem with scaling and ramping up U.S. manufacturing is the lack of middle management,” Hawkins shared. “This industry is valued in small towns, but once an industry has been gone more than 20 years, middle managers are retired or have

moved on to other work. Unfortunately, the middle management aspects of this business are not learned in one month, six months or even a year in most cases. It takes two to three years to become a good mechanic or maintenance guy or shift supervisor. Without those people, it’s hard to make good product.”

He noted that middle management positions pay more and it’s not feasible as a small business to double up on such positions while people are training. In order to expand, experienced people who can hit the ground running are needed so a new plant can generate revenue while also training new people. Hawkins said the ability to bring in trained people from other countries is one way to open facilities faster and with less risk, but as a major political issue, it’s not a popular idea.

While America Knits did not receive any government funding or assistance when it first opened because of its very small size, the company has since been able to take advantage of some incentive programs. “Georgia has a program where they will pay half of a trainee’s salary for up to 12 weeks,” Hawkins said. “We underwent an expansion and did participate in that program, and it went really well.”

In 2020, America Knits joined the Field to Closet initiative — a program designed to increase demand for cotton fiber, reward growers and support communities — to help with a medical scrub project. The group put together a supply chain in the state of Georgia to make scrubs for rural hospitals that were struggling to get the PPE they needed. The cotton was grown and yarn spun in Georgia, fabric was made in the Carolinas, and the all-cotton scrubs were cut and sewn at America Knits. This collaboration led to a second Field to Closet project with Lumberton, N.C.-based Contempora Fabrics Inc. for clothing brand J.Crew.

The J.Crew collaboration allowed America Knits and Contempora Fabrics to become better acquainted, and the companies have since partnered outside of Field to Closet, with Contempora acquiring a stake in America Knits. “Partnering with Contempora is one of the best things that happened to us since we started the company,” Hawkins said. “We now have the credibility of a partner that has more than 50 years in business, and one that shares a philosophy and has similar culture to our own. In addition, together we form a completely vertical factory, and we are not dependent on anyone.” The companies hope that together, they can build a stronger U.S.-based garment supply chain. A new beanie and cap product line was announced this year as part of this partnership.

When brainstorming on future ideas with Field to Closet executives, Hawkins realized the next step for America Knits was to start its own brand. The discussions led to the Seeds II Seams brand, which was developed with focus on sustainability and is 100-percent American made. The brand logo incorporates a crow because as the crow flies, there is only 238 miles between the links in the complete supply chain for the brand’s garments. In comparison, based on a recent independent study, the average T-shirt sold in the United States trav-

els 17,000 miles from fiber to finished product.

While ruminating on his challenging career in the apparel cut-and-sew industry, Hawkins laughed and said: “I always thought it would be fun to be in sports in some way — maybe as a head football or baseball coach. But maybe this is almost the same in a weird way. You have professional people with God-given talents, and you put them together as teams. Then you have to motivate the teams and have to try to get them to pull together in the same direction to hit your numbers.” It’s an analogy that while unexpected, surprisingly works.

Hawkins also spoke of adrenaline and the extremely competitive nature of the business. “It’s competitive in that you are trying to accomplish goals on a daily and a weekly basis, which causes a lot of stress” he said. “But if you’ve been in this business for a long time, you get addicted to the stress and the excitement and ultimately surviving!”

Hawkins has not only survived but thrived in the cut-and-sew industry adapting, rebuilding and learning at every turn. And with its partner, Contempora Fabrics, and an eager workforce, America Knits is poised for whatever comes next — a future Hawkins approaches with the same curiosity, grit and affection for the industry that has carried him through more than 30 years. TW

Arclin,Alpharetta,Ga.,has entered a definitive agreement to acquire DuPont’s Aramids business, including the Kevlar® and Nomex® brands,for approximately $1.8 billion. The deal expands Arclin’s portfolio into aerospace,electrical infrastructure,electric vehicles,defense and personal protection,complementing its existing positions in construction,infrastructure and transportation.About 1,900 employees will transfer with the business. The transaction is expected to close in Q1 2026,pending approvals.

“We are confident that under Arclin’s leadership,these businesses will continue to thrive and expand their impact in new industries and applications,”said Lori Koch,DuPont CEO.

Austria-based ANDRITZ has partnered with biotechnology company Tandem Repeat Technologies Inc., Philadelphia,to commercialize industrial-scale production solutions for Procell™,a biomanufactured proteinbased fiber designed for textiles and nonwovens.The collaboration combines Tandem Repeat’s fiber development expertise with ANDRITZ’s machinery and plant capabilities to provide manufacturing solutions tailored to Procell’s requirements.Procell offers wool-like softness,strength,and durability,positioning it as an alternative to conventional synthetic fibers.

“By partnering with Andritz,we can bring our revolutionary fiber to market on a commercial scale,”said Tandem Repeat Co-founder Dr.Melik Demirel.

FPM Introduces Wetlaid Nonwovens, Sustainability Report; Expands India Site

Germany-based Freudenberg Performance Materials (FPM) has introduced 100-percent biobased polylactic acid (PLA)/wood pulp wetlaid nonwovens made without using chemical binders.The material combines the water absorption and biodegradability of wood pulp with the strength and heat-sealability of PLA,according to FPM.The wetlaid process enables the polymeric and non-polymeric components to be blended,unlike conventional PLA spunlaid nonwoven processes.The new materials are designed for applications in horticulture,packaging, filtration,apparel and healthcare.

FPM also published its first sustainability report,which shows

significant progress,according to the company.This is the first report published separately from the parent company’s group report.

In other company news,Freudenberg Performance Materials Apparel also recently celebrated the opening of an expansion at its Chennai, India,plant.The company added new production lines for 100-percent cotton and 100-percent polyester interlinings in the 20,000-square-feet of additional space.The expansion allows Freudenberg Apparel to introduce new products to the Indian market as well as reduce lead times.

Phifer Inc.,Tuscaloosa,Ala., has acquired all assets of Warsaw, Ind.-based Indiana Coated Fabrics

AMSilk has secured 52 million euros ($60 million) in new financing, including 30 million euros in equity and 22 million euros in convertible bonds.The round was led by ATHOS (AT Newtec) with strong participation from MIG Capital and Novo Holdings.AMSilk’s technology produces biodegradable, microplastic-free biomaterials used in textiles,automotive applications and consumer care.

The funding will support AMSilk’s commercial expansion and industrial scale-up to meet rising demand for its silk-based protein biomaterials. AMSilk has signed several multi-year production agreements and now operates through dedicated facilities at key industrial partners to ensure consistent large-scale output. TW

(ICF),strengthening its position in coated and laminated fabrics while expanding its manufacturing capabilities.ICF will continue operating under its existing name and management team,with customer relationships and operations remaining unchanged.

“ICF has built a strong reputation in the industry for quality and innovation in coated and laminated fabrics,” said Phifer CEO Reese Brooks.“Our teams are working closely to ensure a smooth transition and to maintain the positive,productive experience you have come to rely on.” TW

TThe planet earth is home to a growing population that today stands at approximately 8 billion people, each of whom is estimated to own more than 100 articles of clothing, bed linens, and bathroom linens. Of course, while how many articles of clothing someone owns varies widely depending upon multiple factors including affluence, necessity, and individual preference, clothing still ranks right up there on the essentials list with food, water and shelter.

The global textile and apparel industry — supplying tens of billions of products annually to keep people adequately, comfortably, safely or fashionably clothed — is not only supplying one of life’s essentials but is a major economic engine and employer, contributing nearly 2 percent to global gross domestic product and a much higher percentage in many developing countries. It is an important industry, but with such scale, we must mind our impact on earth and its inhabitants.

As the textile industry has evolved, the understanding of its environmental and social footprint has increased as has the acceptance of responsibility for limiting any negative impact and increasing any positive impact. Over

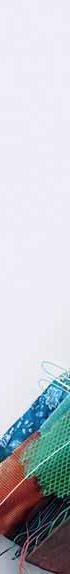

Cotton is a responsible, natural solution to the microplastics issue.

By Hank Reichle

the past 15 to 20 years, much of the textile industry’s focus has been on environmentally sustainable and socially ethical initiatives. Most of these initiatives are about how products are made.

Increasingly, however, the newest initiatives are more intently focused on the products’ environmental impacts during and after use. Of course, a product’s impact during these two phases of its life cycle is greatly influenced by its components. As part of this new and justified focus, the global textile industry, especially brands and retailers, will be looking for better fiber solutions to mitigate challenges like microfiber pollution and end of life disposal.

Cotton, and specifically cotton grown in the United States, offers brands and retailers and their customers a compelling fiber solution because the product is a responsibly produced, natural, renewable,

biodegradable fiber with supply chain transparency that includes traceability and key environmental metrics.

While cotton, and especially U.Sgrown cotton, plausibly has a lesser environmental footprint than synthetic fibers in the production phase, fiber production is not the emphasis of this article. Rather, the focus is on how U.S. cotton is positioned to help the textile and apparel value chain address the huge global microplastics disaster that is unfolding and growing land fill challenge. The microplastics crisis is not a textile-specific issue — 12 percent of all the plastic leakage into the environment from unmanaged or unmanageable waste comes from the polyester value chain, and the textile waste that is managed is estimated to occupy 7 percent of landfill space.

Undoubtedly, plastic has made life easier, and it is difficult to imagine a world that is completely void of plastic, but there are environmental and human health costs to that convenience. Plastic poses significant problems because it is not biodegradable. Rather, it breaks down into microplastics and nanoplastics that taint the earth’s sea, freshwater supply, soil and air.

Consumers are increasingly aware of the issue with plastics, and they are slowly but surely starting to make the connection that polyester is plastic and that their clothing choices can have a huge impact on the environment and human health, including their own. Because clothing, sheets and towels shed the fibers of which they are made when worn and laundered, they are constantly releasing microfibers into the air and water.

Cotton products shed more microfibers than polyester; but when those cellulosic cotton fibers enter the environment, they break down through the process of biodegradation just as nature intended. Conversely, the microfibers of polyester and other synthetics are not targeted by the microbes responsible for biodegradation because they don’t recognize them as natural food sources. Those microfibers contribute to the microplastics crisis facing our environment and human health. Human inhalation or ingestion of microplastics that accumulate over time — including from our food supply; think shrimp and vegetables whose oceans and soil are polluted with microplastics and microfibers — can lead to organ damage, endocrine system disorders with negative reproductive and metabolic repercussions, and may even increase the risk of cancer.

Corporate Strategy & Insights Consumer Survey,” is a public awareness campaign with a goal of educating consumers on the positive contributions they can make to the environment and human health by choosing clothing and home textiles made from natural fibers. The campaign has taglines like: “Plant, Not Plastic,” “What You Wear Matters,” “Choose Cotton — the natural choice to protect your family and y(our) home.”

vincing the European Commission that its preliminary PEF methodology for apparel and footwear has several omissions including microplastic release. Further, the coalition argues plastic waste generation, and the circularity of materials should be accounted for in the PEF.

Cotton wins when it comes to microplastics. It is that simple. Cotton is a naturally occurring plant that grew on earth’s trees, fell onto its soil, and was disposed of by natural biodegradation long before it clothed its inhabitants. In its natural life cycle, carbon dioxide simply moves back and forth from the atmosphere to the plant and then back into the atmosphere.

While consumers have increasingly moved away from checking labels and have shown less interest in fabric content, the highlighted risk posed by choosing synthetic textile goods is likely to cause a significant change in behavior.

Considering the growing number of microplastics studies and major concerns for the global ecosystem, there is renewed interest in natural components. Likewise, natural fibers are highlighting just what it means to be natural. Two such campaigns are the “Plant Not Plastic” — plantnot plastic.org — and “Make the Label Count” — makethelabelcount.org. The “Plant Not Plastic” campaign, launched by the National Cotton Council of America in response to the findings from its “Microplastics

Speaking of labels, the “Make the Label Count” coalition’s work is aimed less at consumers and more at European Commission regulators who are responsible for establishing a standardized life cycle assessment method for measuring and communicating the products and services Product Environmental Footprint (PEF). Under EU regulations, products must be assigned a PEF to enable fair comparisons to be drawn between products when comparing their holistic environmental impacts. The international coalition, made up of natural fiber organizations and environmental groups, has been successful in con-

Some in industry and science want to make the argument that dyed and treated cotton fibers are no longer biodegradable. The dyes and treatments might not be biodegradable, but that’s a small fraction of the fiber’s weight. Comparatively speaking, neither the synthetic microfiber nor the dyes and chemicals in it are biodegradable. But, for cotton to be a viable replacement for brands, retailers, and consumers looking to reduce their microplastic risk, it cannot check only that box, other boxes also matter.

End of product life is another critical factor for our industry to consider. Cotton fiber is already more circular than polyester and has great potential to become even more so thanks to the research and innovations occurring within many public and private organizations including Cotton Incorporated, the Cary, N.C.based not-for-profit research and promotion company for U.S. upland cotton which is funded by U.S. cotton growers and importers. The U.S. cotton industry is incessantly work-

ing on ways to keep the carbon dioxide removed from the atmosphere by the growing cotton plant and stored in its cellulose out of the atmosphere permanently, or at least temporarily, to help lower the textile industry’s carbon footprint.

Examples include compost, biochar, and mechanical and nontoxic chemical recycling and repurposing. Products labeled as “recycled polyester,” are not a polyester-to-polyester product, and it still contributes, perhaps even disproportionately, to the microplastic and land fill problems. If the two fibers are incinerated, cotton simply releases the carbon dioxide it absorbed during photosynthesis while polyester releases multiple toxic gases that are ultimately a source of new, man-made carbon dioxide in the atmosphere.

And, of course, trust in the fiber production system is especially important to brands and retailers. U.S. cotton farmers use advanced, responsible production practices and many are choosing to take the extra step to document what they are doing using practice verification programs like Better Cotton, Regenagri, and the U.S. national sustainability program the U.S. Cotton Trust Protocol (Trust Protocol). These programs are not only thirdparty practice verification programs, but are also a source of transparency, production metrics, and, perhaps most importantly, traceability back to country of origin. Just like cotton farmers, these programs are constantly evolving and increasing the value they offer to the supply chain.

existing infrastructure. The standard Trust Protocol verification process is augmented with advanced satellite imagery analysis to validate regenerative practices.

The Trust Protocol has identified minimum requirements for the Field Partner Program based on regenerative agriculture frameworks from leading organizations. The practices

observed and measured impact soil health, water use, synthetic inputs, water quality and biodiversity. The Field Partner Program is just one example of what the U.S. cotton industry is doing to make sure cotton fiber is a viable, desirable, and safe choice for brands, retailers and consumers.

Cindy Hyde-Smith, would allow entities selling finished products in the U.S. retail market to claim transferable tax credits if they are able to demonstrate proof of the use of U.S. cotton in those products. The tax credit that may be taken depends on the price of cotton as established by the U.S. Treasury, the weight and type of U.S. cotton contained in the finished good — raw cotton, yarn, or fabric — and where the finished product was manufactured. U.S. manufactured yarns and fabrics’ raw cotton weight multipliers of 1.6 and 6.5, respectively, are applied in the case of U.S. cotton value added products. The final tax credit calculated for the product is determined by multiplying by a location factor of 24 percent if the good was made in the United States, or a country with which the United States has a free-trade agreement; otherwise, the location factor is 18 percent. For example, a product made in Pakistan imported for sale in the U.S. retail market that contains a pound of U.S. cotton valued at $0.85 per pound (lb). would be accompanied by a transferable tax credit of $0.15 when the applicable cotton price is $0.85/lb — $0.85 x 1 lb x 0.18 = 0.15. This credit will go a long, long way to increasing U.S. cotton’s competitiveness at U.S. retail compared to other non-U.S. cotton fiber choices.

Once such example of evolving program offerings is the Field Partner Program pilot launched by the Trust Protocol. This program allows merchandiser organizations with proprietary regenerative practices programs to partner with the Trust Protocol to provide brands and retailers with regenerative cotton via the program’s

Increasingly, brands and retailers are going to be looking for natural fiber alternatives as they respond to regulatory and consumer concerns over synthetic fibers. The U.S. cotton industry’s number one legislative priority right now is a federal tax incentive that would provide a financial incentive to make that transition to U.S. cotton easier. The Buying American Cotton Act (BACA), introduced in May 2025 by Mississippi Senator

Given all that is happening with the microplastic crisis in the world and textile waste, it is time for the global textile value chain to revisit its reliance on man-made fibers and move to a responsible natural solution. Sourcing professionals will do well to give U.S. cotton and all it has to offer a closer look. TW

Editor’s Note: Hank Reichle is president and CEO of Staplcotn, the oldest and largest cotton cooperative in the United States headquartered in Greenwood, Miss. He also serves as an officer of the National Cotton Council and as a director for the U.S. Cotton Trust Protocol.

The Woolmark Company represents and promotes the use of Australian Wool.

able and recyclable, making it a perfect fiber for a sustainable eco system.

Beyond luxury fashion, where Woolmark reports wool emerged as a key fiber in recent Spring/Summer collections, wool’s natural properties and seasonal adaptability are motivating sports brands to launch innovative wool apparel.

“As citizens demand more from what they wear — comfort, performance, traceability and responsibility — merino wool is meeting the moment,” said Woolmark Managing Director John Roberts. “With leading influencers and brands alike embracing its story, it’s no surprise demand is rising across luxury fashion, sportswear and lifestyle. It’s the fiber that truly delivers, naturally.”

Innovations from Nuyarn®, Woolx, Ciele, PAKA and Allbirds are proving that natural fibers can deliver technical performance without compromise.

By Rachael S. Davis, Executive Editor

Following is a snapshot of some companies and apparel/footwear brands that are championing the use of wool fiber.

IIn the current era of sustainable textiles, one natural fiber has been quietly staging a come back.

According to The Woolmark Company — a not-for-profit subsidiary of Australian Wool representing the global Australian wool supply chain and promoting the use of wool in premium textile products — merino wool presently is in demand at unprecedented levels.

A recent press release from Woolmark shared that the Australian wool market has experienced its largest price increase in 30 years, in part influenced by “tight inventories, genuine consumer demand and renewed confidence across the supply chain …” Woolmark believes this shift in the market is because of real demand and is not a short-term movement.

According to the press release, the market value for wool is predicted to almost double from $34.9 billion in 2022 to $63.2 billion by 2033.

Once a wardrobe staple along with cotton, wool lost market share with the advent of man-made fibers. Concerns about animal welfare also painted wool as a less than desirable fiber choice. But the natural advantages of wool — including warmth, durability, elasticity, odor resistance, temperature regulation, moisture management, resilience and breathability, among other properties — make it too valuable to exclude from the fiber choice landscape. As a 100percent natural performance fiber, wool also is biodegradable, renew-

According to Andy Wynne, CEO of New Zealand-based Nuyarn®, “The wool industry has undergone a remarkable transformation.” Wynne sees wool escaping its traditional categories of suits, formalwear and sweaters, among other categories, and becoming a “legitimate performance and comfort material across diverse categories including everyday hoodies, footwear uppers, women’s activewear, technical sportswear, loungewear, athleisure, and beyond.”

Technology advancements, such as Nuyarn spinning technology, are helping drive the shift in tradition. Nuyarn’s twist-free spinning technology drafts superfine merino wool with a high-performance nylon filament carrier yarn to produce an ultrafine, two-ply yarn with more volume and aeration than merino yarns made using traditional worsted spun-yarn technologies (See “Nuyarn: Wool A New Way,” T W , January/February 2023). According to the company, the

light weight and softness of the resulting yarns make them perfect candidates for next-to-skin applications in baselayer garments in particular.

Rather than avoiding the conversation, Wynne prefers to tackle historical concerns about wool head on. The company uses transparency, certification and education including full Responsible Wool Standard (RWS) certification, which ensures rigorous animal welfare standards and traceability from farm to finished product. “We’re also bluesign ® , GOTS, and OEKO-TEX certified, demonstrating our commitment across the entire production chain,” Wynne shared.

Nuyarn’s primary customers are active outdoor and lifestyle brands seeking to integrate natural fiber performance garments into their product lines. “Our development process is highly collaborative and tailored to each brand’s specific needs and customer base,” Wynne said. “As a fully vertical business — controlling everything from yarn production to fabric manufacturing to finished garments, we can offer brands a streamlined partnership with a single entity rather than managing multiple suppliers.”

Just some of the apparel brands using Nuyarn include:

• Artilect — A long-time proponent of Nuyarn, Artilect offers baselayer products and accessories made using the yarn including the Flatiron 185 crew and leggings, which are made using a baselayer yarn blend — 91-percent superfine Nuyarn merino wool and 9-percent nylon — knit into a 185 gram per square meter (gsm) fabric that is bluesign certified. Artilect uses hangtags to share the benefits of Nuyarn with consumers under the “More than merino” tagline. The brand also incorporates a TAP wifi-enabled sticker on the hangtags so users can scan using a smartphone to learn more online.

• Ibex — Ibex features Nuyarn in its Woolies Pro Tech Q-Zip and Woolies Pro Tech Bottom baselayers. The fabric, comprised of 85-percent merino wool and 15percent nylon, weighs 125 gsm making it Ibex’s lightest weight base layer ever. While Ibex does not promote Nuyarn specifically on the hangtags, it touts the benefits of merino in a thoughtfully designed hangtag. The company does explain Nuyarn and all of its benefits on its website in the product descriptions.

• Lé Bent — Committed to performance, apparel brand Lé Bent features Nuyarn in its Featherweight Hooded Merino Crew top and Featherweight bottoms. The 125 gsm fabric is made using a Signature Merino Blend that contains 60-percent merino, 25-percent bamboo and 15-percent nylon.

Nuyarn also has established partnerships with Allbirds and HOKA, and the footwear industry currently makes up one of the company’s largest categories.

Additionally, Wynne announced that the Herculan ® technology has allowed the company to transition carpet wool — coarse fibers historically relegated to flooring and upholstery applications only — into high-performance wearable garments. “We’ll be launching a performance wool fleece using this material in fall 2026,” he shared.

“Wool isn’t a fiber of the past, it’s a fiber of the future and I wouldn’t be in this business if I didn’t believe that,” Wynne said. “We’re at an inflection point where consumers are actively seeking alternatives to synthetic materials due to growing awareness of microplastic pollution and climate concerns. Athletes and outdoor enthusiasts are driving demand for natural, sustainable performance options, and technology like Nuyarn makes those choices viable without performance compromise.”

Woolx was founded in 2012 in Endicott, N.Y. as family-run brand focused on merino wool clothing that combines technical performance and everyday comfort. The product line incorporates essentials, pajamas, shapewear and layers, in ultra-heavyweight fabrics, featherlight pieces and everything in between for all seasons.

Traditional wool has an average thickness of 30 microns, while typical merino wool — known for its fineness — has an average thickness of 21 microns. To avoid any itchy, scratchy sensations against the skin,

Woolx uses a super-fine merino wool with an average thickness of only 17 microns in many of its products.

“While wool might make some people think of their grandma’s scratchy sweater, this is not that,” said Nicole Calleo, co-founder and CEO, Woolx. “We’ve taken all the natural benefits of traditional wool — temperature regulation, durability and comfort — and reimagined them in a modern, insanely soft merino that’s as stylish as it is functional.” In addition, all of Woolx’s clothing is ethically sourced and responsibly made. “Every Woolx piece is certified non-mulesed ensuring the highest standards of animal welfare and sustainability, ” Calleo said.

Woolx offers the Stella Leggings and Piper Pocket Leggings. Stella represents one of Woolx’s warmest baselayers for fall and winter, while Piper is a merino wool baselayer with functional side pockets for all-day comfort and performance.

“The idea for Woolx’s merino wool baselayer leggings came from a simple need: clothing that could keep up with active, outdoor lifestyles without compromising comfort,” Calleo said. “The founders wanted something that could move easily, breathe well, and regulate temperature during hikes, runs or even when used in everyday

wear. Merino wool turned out to be the perfect solution — warm when it’s cold, cool when it’s warm, and soft enough to wear all day.”

The company recently extended the use of merino wool to mini Woolx, a new line of kids’ baselayers.

Based in Montreal, Ciele Athletics — focused on headwear and apparel for runners — was founded in 2014 by Jeremy Bresnen and Mike Giles. “We are all very passionate about running, technical garments, responsibility, and doing the best we can as individuals and an organization,” said Dan Marrett, global marketing director, Ciele Athletics.

Ciele works with suppliers to develop technical fabrics and perfor-

“We’ve been exploring natural performance fibers for a while and that exploration led to our Sorino™ fabric line,” reported Ciele’s design team. “Partnering with an industry leader like Woolmark felt like the right move to help us highlight everything that makes merino exceptional. The Woolmark certification gives runners confidence that they’re getting the best quality merino possible. It’s a mark of fiber integrity, performance and traceability — all things that align with how we approach design and manufacturing at Ciele.”

Ciele is reimagining merino as a year-round performance fabric, not just a cold weather choice. “For us, reimagining merino means leaning into what it already does best and redesigning around its strengths to create true, all-season performance,” the company shared.

While sheep’s wool currently is experiencing unprecedented demand, Peru-based PAKA is firmly focused on another fiber in the protein family — alpaca. Founded in 2017 by Kris Cody, the certified B-Corp. business works directly with non-governmental organizations alongside the indigenous people in Peru to create its natural, all-purpose clothing and accessories (See “PAKA: Tri-Blend Fiber Trio,” TW , November/ December 2022) . PAKA’s mission remains one of connecting people to where their clothing comes from and supporting the communities who make the garments.

mance constructions tailored for running and movement. The brand recently partnered with Woolmark to launch its first-ever Woolmark-certified merino wool collection of apparel and headwear for winter. According to Ciele, each piece is independently tested and meets the Woolmark standards for durability, colorfastness and quality. Pieces in the line include beanies, balaclavas and baselayers made using 100-percent wool as well as merino/silk blended yarns.

“At PAKA, we’re continuously exploring how natural performance can evolve across categories,” said Megan Krajco, PAKA Design director. “Our foundation began with alpaca fiber in sweaters, but our vision is to build a complete ecosystem of products that support everyday explorers.”

Most recently, Paka has expanded into the outerwear category with its patented PAKAFILL® alpaca insulation material, which can replace down

or synthetic fiber fill options, providing needed warmth without weight. PAKAFILL is featured in the brand’s Apu parkas and Mayu vests and jackets for men and women.