Caitlan Mitchell Editor-in-Chief caitlan@reviewmags.com

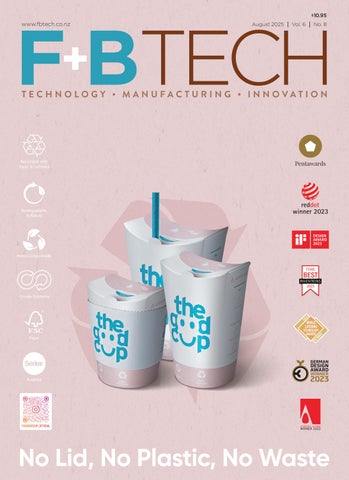

Welcome to this issue of F+B Tech, where our focus is on two stages defining the future of food and beverage. Foodtech Packtech and drinktec are more than dates on a calendar; they are laboratories where ideas become investments. For New Zealand producers, brand owners, and other decision makers, these expos offer a rare chance to see best practice in motion, compare solutions, and return home with decisions that move the needle. The drinktec expo sets the pace for beverage processing, packaging, and digitalisation. Expect cleaner lines, smaller

footprints, and smarter controls, with energy and water stewardship embedded in every upgrade. From high efficiency fillers to closed loop CIP, and from predictive maintenance to inline QA, the step change is practical: lower inputs, higher uptime, clear data. Ingredient suppliers are there in force, showing advances in flavour systems, sugar reduction, and functional additions that keep labels tight while meeting consumer demand. Expect to see robotics and cobots improving end-of-line ergonomics, hygienic design that speeds changeovers, and packaging moves such as rPET, lightweighting, and

returnable systems that deliver real savings. Utilities audits are becoming productised, with metering packs that surface water and energy hotspots in real time.

We are also talking all things beer, from brewhouse to bar. Automation for small and mid-sized breweries is now within reach, with compact lauter designs, low oxygen transfers, and modular canning that scales. Utilities are in focus: heat recovery, CO2 capture, and smart water use to cut costs while improving resilience.

On the raw materials side, hop growers are balancing agronomy with flavour impact.

New Zealand varieties continue to punch above their weight, and global breeding programmes are pushing oils and thiols that open new profiles without heavy hopping rates. The goal is expressiveness with efficiency.

If you are travelling to either expo (or both), plan with purpose: shortlist must-see halls, book meetings early, and leave time to walk and learn.

If you cannot attend, our updates bring the floor to you, with clear takeaways you can act on.

Enjoy the issue.

PUBLISHER Tania Walters

GENERAL MANAGER Kieran Mitchell

BRAND MANAGER Sarah Mitchell

EDITOR-IN-CHIEF Caitlan Mitchell

EDITORIAL ASSOCIATES Jenelle Sequeira, Sam Francks

ADVERTISING SALES caroline@reviewmags.com, daniel@reviewmags.com

SENIOR DESIGNER Raymund Sarmiento

GRAPHIC DESIGNER Raymund Santos

6, Heards Bldg, 2 Ruskin St, Parnell, Auckland.

As consumer expectations and regulatory targets reshape food and beverage packaging, businesses need solutions that deliver sustainability, durability, and strong branding.

For Opal, one of Australasia’s largest paper and packaging companies, this is both a challenge and an opportunity. It designs recyclable cardboard packaging compatible with Australia and New Zealand’s recovery infrastructure.

Through its integrated value chain, from design to manufacturing, collection, and recycling, Opal supports a circular economy. Each year, more than 600,000 tonnes of paper and cardboard are reprocessed at its Botany and Maryvale mills, feeding directly into new packaging products.

Read more here

Green kiwifruit has become the first fresh fruit ever to receive an authorised health claim from the European Commission, marking a breakthrough for kiwifruit marketer Zespri and the wider fresh produce industry.

The European Commission has officially approved the health claim that "consumption of green kiwifruit contributes to normal bowel function by increasing stool frequency", based on a daily intake of two fresh green kiwifruit (Actinidia deliciosa var. Hayward) providing a minimum of 200g of flesh.

This authorisation was among only three health claims approved by the European Commission in the last five years, following a rigorous evaluation process in which only about 1 in 8 claims submitted receive approval.

Read more here

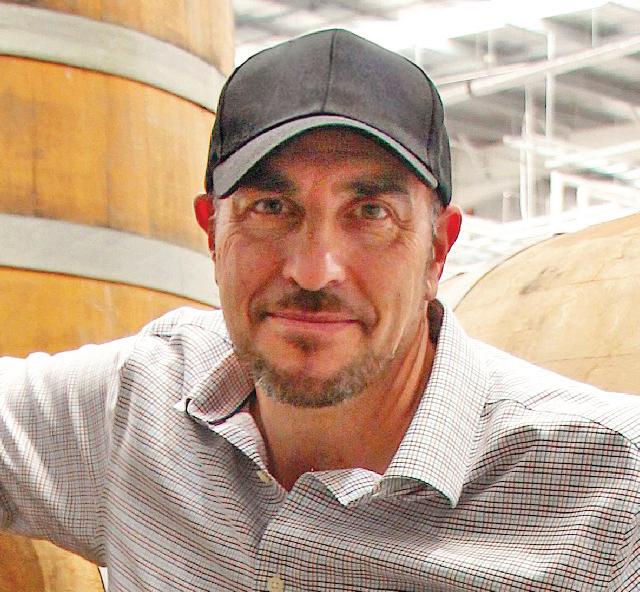

Winemaking technology company, Bucher Vaslin, has launched its Pacific operation to provide local resources to the Australian and New Zealand markets. The new entity will be led by industry expert Paul Baggio, bringing decades of experience and a deep understanding of local winemaking needs.

Bucher Vaslin Pacific stated it now stands as the largest sales and technical support entity dedicated to winemaking equipment in the region. The collective strength of

industry suppliers, including Vitis & Winemakers, SWAT, Wine Energy, Vinvicta and Viniquip powers this capability.

Together, these regional partners aim to ensure onthe-ground support across all key winemaking regions – including New Zealand, Victoria, South Australia, Tasmania, New South Wales, and Western Australia.

At a time when many producers are actively seeking more efficient, resilient, and sustainable wine processing solutions. Read more here

Bitwise Agronomy, the agtech innovator behind the GreenView AI crop analysis platform, has successfully completed a AUD one million capital raise, led by Melbourne Angels, to scale its operations globally.

With product-market fit firmly established, Bitwise Agronomy’s technology is already transforming how medium and large berry operations forecast yields.

After years of meticulous development, the company’s object detection AI has been fine-tuned using berry data from farms worldwide.

GreenView AI “sees” what an agronomist sees, counting fruit across entire farms in minutes rather than days, and combines this with over 200 ripening curves tailored

to 60+ berry varieties, including strawberries, blueberries, raspberries, and blackberries. The result is forecasting accuracy that leaps from around 50 percent to over 90 percent, up to 12 weeks in advance. This precision is helping growers improve harvest planning, labour allocation, and market timing for maximum returns.

“Our mission is to take the guesswork out of growing,” said Fiona Turner, CoFounder and CEO of Bitwise Agronomy.

“This investment is a testament to the hard work of our team and the trust of our customers. We’re excited to scale up and bring our solutions to more berry farms around the world.”

Read more here

In a first for New Zealand’s horticulture sector, the country’s avocado exporters have joined forces to secure a collective FernMark Licence, marking a new chapter in the industry’s global positioning.

The FernMark – the Government awards New Zealand’s official country of origin mark to products that meet strict standards of authenticity, quality, and governance.

While individual avocado exporters have held licences in the past, this new coalition licence represents a unified front, reinforcing the industry’s commitment to collaboration and excellence.

“New Zealand avocado growers and exporters can be proud that their produce is now carrying the official FernMark, demonstrating quality and trust,” said Minister of Trade Todd McClay. Read more here

Amazon Australia celebrated the official opening of its third fulfilment centre (FC) in Victoria.

The new 52,000 square metre facility will create more than 500 local jobs in Cranbourne West and improve delivery outcomes for Melbourne customers, while creating additional opportunities for Victorian small businesses that use Amazon to service customers across the country seamlessly.

This is one of two new, purpose-built sites Amazon has opened in Victoria this month, with the retailer also opening a logistics site in Melbourne’s northwest. Together, these represent an investment of AUD 200 million in Victoria, and the operational sites will boost delivery speeds for customers across Melbourne and create 700 new jobs across the city. The site can store up to four million products sold on Amazon, ranging from electronics, beauty products, furniture and books to everyday essentials. Read more here

Innovative New Zealand winery Invivo announced a strategic investment from Indevin, New Zealand’s largest wine producer, designed to supercharge its global expansion.

The partnership will accelerate Invivo’s growth, powered by its flagship brands, Graham Norton “GN” Wines, Invivo X, SJP, and Invivo Wines, while capitalising on the increasing global demand for premium New Zealand wine.

Indevin’s equity investment, together with a long-term supply chain agreement, will enable Invivo to expand distribution,

scale production, and bolster marketing support for its brands in key export markets.

Invivo remains independently owned and operated, with Indevin joining the Invivo Board. Indevin’s investment has strengthened the Group’s diverse shareholder base, which includes Cofounders Tim Lightbourne and Rob Cameron, long-term collaborators Graham Norton and Sarah Jessica Parker, over 800 Kiwi investors from Invivo’s crowdfunding campaigns, and Invivo employees. Read more here

Fonterra, in partnership with Volvo Trucks New Zealand and EECA, has expanded its electric transport fleet.

The first electric truck to be refrigerated in Fonterra’s fleet will focus on delivering dairy products from Takaanini, Auckland, to customers across metropolitan areas. This truck is the second electric truck in Fonterra’s metro distribution fleet for its Oceania business, meeting the operational needs of the business while also reducing emissions.

Rob Howell, Director of Operations and Supply Chain, Fonterra Oceania, said the new electric truck represented an

important step in Fonterra’s sustainability journey.

"Our objective is to be a leader in sustainability while prioritising our commitment to delivering healthy dairy nutrition to consumers around the country,” said Howell.

“We are working hard to reduce emissions across our supply chain. Working towards an electric fleet is another step in our journey, partnering with Volvo Trucks New Zealand and EECA, providing access to the best technology to allow us to continue to make progress towards our climate ambitions.”

Read more here

From the 15th to the 19th of September 2025, the world of the beverage and liquid food industry will meet again in Munich. Around 1,100 exhibitors will present cutting-edge solutions and future technologies in eleven halls at the Munich Exhibition Centre.

They will once again be dialogue partners for all national and international decision-makers on investment decisions and brand strategy. This exchange will be based on a complete

overview of all raw materials, process technologies, filling and packaging technology, logistics, and IT directly at drinktec, where all projects with the experts can be discussed. With a comprehensive

range of products covering the entire value chain of beverage and liquid food production, visitors to drinktec will gain inspiration for the future orientation of their product portfolios and learn about the latest trends in the industry. With around 70 percent of exhibitors coming from outside Germany, drinktec once again demonstrates its highly international character – a clear indication of the global significance of this platform

within the industry.

The largest groups of exhibitors (after Germany) come from Italy, the USA, and China, countries that have been bringing together the widest range of offerings for the industry at several drinktec editions.

New Liquidrome –Hotspot for knowledge transfer and networking

The new “Liquidrome” format provides additional impetus. Under this

branding, the trade fair team in Hall C4 is presenting a wideranging supporting programme: exhibitor talks, presentations on research projects, and practical insights from the backdrop for strategic decisions in visitors’ own market and brand scenarios.

In this environment, numerous start-ups will also be showcasing new solutions and answering critical questions from the audience during start-up pitches.

All offerings in Liquidrome focus on the key topics of “Circularity & Resource Management,” “Data2Value,” and “Lifestyle & Health.”

“Here on our large Wave Stage, we have a diverse programme that includes macro trends, AI solutions for practical use, and numerous ideas for resource-efficient production,” emphasised Markus Kosak, Executive Director of the drinktec Cluster.

With several offerings on innovation strategies and insights from the start-up scene, the Deep Dive Lounge in the Liquidrome complements the programme and offers ample space for networking.

“We also see strong potential in the functional beverages sector – for example, beverages with health benefits – which is why we have integrated a health bar into the Liquidrome. There, selected partners offer tastings of innovative beverages. This allows them to provide the industry with ideas on how to tap into the segment of beverages with added benefits, potentially.”

The entire offering at Liquidrome is free of charge for visitors and available at the drinktec | Supporting Programme at the Liquidrome.

Online: Exhibitor and product database and Innovation Guide

By purchasing tickets via online registration, visitors benefit from lower ticket prices and are guaranteed quick access to the exhibition halls even after the trade fair opens. All visitors who want to prepare for their visit to the trade fair in advance can already find all exhibitor offers online in the drinktec| Exhibitor & products database.

The information provided in the Official Innovation Guide of drinktec is particularly exciting. Exhibitors with innovative solutions are listed in this overview and can be viewed by trade fair visitors on their mobile phones upon arrival.

The entire drinktec 2025 site can be accessed via the West, Northwest, North, and East entrances, providing optimal connections to both the subway from downtown Munich and the parking garages and outdoor parking areas.

Connections to the airport (arrivals and departures) are available from the North entrance and the East entrance (departures only).

“Market data indicates that positive developments are expected for beverages and liquid foods in many regions,” added Markus Kosak.

“drinktec is the global economic summit and therefore a must-attend event for shaping the future of the industry. Plan your stay now and take advantage of the affordable online booking options. The entire trade fair team at YONTEX looks forward to welcoming all industry players from Germany and abroad to drinktec.”

Automated beer line cleaning system Beer Piper has reminded outlets that they’re here to make beer line cleaning simpler, safer, quicker and cheaper.

Established in 1988, Beer Piper’s concept was simple: to develop a beer line cleaning system that helps to reduce beer wastage and to make line cleaning less time-consuming, less costly and less messy.

For over 30 years, Beer Piper has proven itself as a market leader, successful in thousands of licensed venues in the United Kingdom and expanding globally.

Their latest, next-generation BP5 machine incorporates all the fantastic capabilities of its predecessors as well as a host of new game-changing features. It replicates a traditional manual beer line cleaning sequence: flushing with water, dosing with chemicals, leaving to soak and ending with a final flush of water, while recording and reporting every step to the Beer Piper cloud-based portal. Establishments now need to get themselves ready for summer to capitalise on the imminent upturn in patrons. Carrying out deep cleans on your lines, as well as putting in place

the correct processes, will ensure that you are well-positioned for the upcoming summer rush.

“Summertime signals one of the most important sales periods for pubs, bars and restaurants, so their hygiene standards mustn’t slip during this busy time,” said Linda Adamson, Marketing Manager at Beer Piper.

“Beer Piper takes care of your line cleaning – ensuring that all cleans are quick, easy and consistent.”

At the same time, Jeff Singer, Commercial Director at Beer Piper, added that Beer Piper not only frees time, but it can also save money by reducing waste and eliminating the need for costly gases.

“It’s no secret that times are tough, businesses are worried, and the hospitality industry is no exception. Identifying new moneysaving measures is at the forefront of everyone’s minds, and this is where Beer Piper can help.”

The Beer Piper system is easy to use and can result in significant cost savings for clients by reducing the amount of time staff spend on the task – a clean takes just 8.5 minutes.

Not only does the system improve staff efficiencies, but it also ensures consistent, high-quality cleans are

achieved every time. The sealed system mixes the neat beer line cleaner with fresh water directly into the lines, ensuring the correct dilution rate regardless of flow. The superior quality chemicals used and supplied by Beer Piper ensure lines are immaculate and allow clients to serve the best pints possible.

Another advantage of this is that with time, clients can go longer between cleans. The automated nature of the system also means that there is no need to manually mix these chemicals manually, thus reducing the associated risks to staff. No CO2 is required with the Beer Piper system, so the surging costs of CO2 in the UK need not be a concern.

The system also uses much less water than a manual clean, which also contributes to the cost savings. As does the Beerpush function - unique to the Beer Piper automated line clean, as it allows the beer that would usually be wasted and poured down the drain before a clean to be sold, ensuring even more money is saved.

With this background, Beer Piper has continued to maintain its presence and develop its products, while also providing excellent customer service.

Alpine Hops is a global leader in the sourcing and distribution of premium brewing ingredients and solutions.

Representing some of the most respected hop growers in Slovenia, it takes pride in its long-standing partnerships with leading grower associations in Germany and the Czech Republic. These collaborations allow Alpine Hops to bring an unparalleled selection of Europe’s finest hops to breweries across the world.

Beyond Europe, the company also supplies a curated portfolio of premium American hops, ensuring brewers worldwide have access to the best the global market has to offer.

As part of its vision to serve the brewing industry end-to-end, Alpine Hops has expanded its offering with two new brands: AlpineYeast and AlpineKegs.

AlpineYeast, developed in collaboration with an Italian manufacturing partner, delivers Made in Italy precision and quality. Produced using advanced fermentation and propagation techniques, these

yeast strains offer unmatched purity, consistency, and performance. Brewers can trust AlpineYeast for clean fermentations and authentic, expressive flavours that elevate their craft to the next level.

AlpineKegs are designed and engineered to meet the rigorous demands of today’s brewing operations. Manufactured in Vietnam from the highest quality stainless steel, AlpineKegs are available in a comprehensive range of sizes and configurations. From craft microbreweries to global beverage brands, our kegs deliver durability, reliability, and peace of mind.

Alpine Hops is a trusted partner to brewers around the globe. Its mission is to empower breweries of all sizes with world-class ingredients, innovative solutions, and dependable service. With deep roots in Europe’s brewing heritage and a forward-looking approach to global markets, Alpine Hops stands at the forefront of brewing excellence.

Visit the WMFTS stand to discover how its peristaltic and sinusoidal pumps enable beverage and liquid food producers to increase productivity while reducing energy costs, water use, and waste in their manufacturing processes.

Certa Sine pumps from MasoSine are very easy to clean and perfect for handling viscous products or fluids. Due to its one shaft, one seal design, Certa is considerably more energy efficient than other positive displacement pumps.

Certa pumps have been integrated into beverage systems for carbonated and non-carbonated drinks, or the blending syrup of different viscosities and other beverage ingredients, and are also used by fruit juice producers and breweries.

Certa improves reliability and yield for dairy companies, while also reducing energy costs.

Bredel hose pumps are also being used to transfer viscous fruit concentrate, with reduced energy costs and better hygiene than competitor pumps.

In breweries, the pump and hose solutions optimise efficiencies and increase productivity.

Whether carefully handling yeast, accurately dosing additives, pumping abrasive diatomaceous earth or metering water treatment chemicals, WMFTS can offer a peristaltic and sinusoidal pump solution that ensures your product is transferred or dosed accurately and hygienically without damage.

Aflex FaBLINE hose is a foodgrade flexible hose developed to meet the latest hygiene standards and are used by dairies and breweries in their processes.

Find Watson-Marlow at booth B5-559

Evodia has introduced Yops, an innovative hop aroma created through patented precision fermentation technology.

By using specially selected yeast strains, Yops naturally produce the key aroma compounds found in hops, offering a fresh, vibrant hop character in a stable and easy-to-use format.

Unlike traditional hops, it is unaffected by harvest cycles, weather, or inconsistent quality, making it ideal for both alcoholic and non-alcoholic beverages.

Already making headlines, Yops has helped Danish craft brewery ÅBEN win the title of Best Non-Alcoholic Beer in Denmark 2025 with its awardwinning Y-øl brewed using Yops aroma. The competition, organised by leading industry associations, highlighted how Yops can transform the taste of alcohol-free beer, closing the flavour gap between regular and non-alcoholic options.

For brewers, Yops brings multiple benefits: consistent quality all year round, reduced beer loss during

the hopping process, simplified logistics, and a significantly lower environmental footprint compared to traditional hops. It helps breweries innovate within the fast-growing non-alcoholic segment while maintaining authentic hop flavour and aroma.

Yops also illustrates the broader potential of precision fermentation for the beverage industry, creating reliable, scalable, and sustainable flavour solutions beyond the limitations of agriculture.

Visit Evodia at Drinktec 2025, Hall C, Booth 636, to learn about the science behind Yops and taste howit transforms flavour sustainably.

Our silos are specially designed and manufactured to meet the needs of our customers.

The discharge device attached to the silo is used for controlled, fast and clean loading of the transport vehicle.

Specifications:

Options:

» insulation and heating

» output quantity control, fill leveldependent or time-controlled

» ball collection basket for easy removal of the ball after the pipeline has been cleaned

» silo capacity 5 to 400 m³

» discharge capacity 500 to 1,100 kg/min

» low-maintenance operation

» long service life

Founded in the year 1902 by Wilhelm Ponndorf, Ponndorf Company strives for ever better technical solutions, for perfection and success.

Brewing

We offer a wide range of accessories, long-term supply of spare parts and individual special solutions that meet your needs.

dewatering

• yeast drying plants

» telescopic slides

• wet spent grains conveyors

» screw presses for spent grains dewatering

• conveyors with receiving vessels

» pneumatic conveyors for hops

» non-return valves (stoppers)

» diverters

As a medium-sized family business, Ponndorf has succeeded in preserving its tradition and providing its customers with technical progress in the form of tailor-made supply systems.

• silo plants

• silos with discharging devices

• accessories: stoppers, pipeline shunts, etc.

» stirring devices for installation in the silo cone for overcoming bridging with highly viscous spent grains

Ponndorf Anlagenbau is a specialist in brewing technology. It projects, develops and delivers system solutions according to individual requirements:

• screw presses for spent grains

The product portfolio is specially tailored to the brewery industry and the brewing trade. Whether individual plants or more complex system solutions, your project is in good hands with Ponndorf Anlagenbau.

Visit their booth at DrinkTec 2025, Munich - C2-449

Shandong Tiantai Beer Equipment Co, Ltd, a wellrecognised supplier of beer and beverage equipment industry based in Jinan city of China, provides complete lines and the turnkey service for breweries and beverage projects worldwide.

Wet Spent Grains Conveyors & Receiving Vessels

Wet Spent Grains Conveyors & Receiving Vessels

Silo Plants & Discharging Devices

Silo Plants & Discharging Devices

To provide the turnkey brewing systems, its products mainly include the malt milling line, Brewhouse, Beer Fermenter, Bright Beer Tank, Cooling Units, Control System, Beer Filling Lines, Copper Still, Wine Fermentation Tank, Kombucha Brewing Tank, etc.

Compliant with ISO 9001 management standard, Tiantai Company passes C E PED Certifications for Machinery, Low voltage and pressure Equipment, EAC certifications and has obtained more than 20 patent certifications.

Spent Grains Driers & Yeast Driers

Spent Grains Driers & Yeast Driers

Accessories & Special Solutions

Accessories & Special Solutions

Tiantai company supplies all-round service for breweries, distilleries, and wineries, including customised design, transportation, installation, and training. Its advanced production processing facility and testing equipment cover the Automatic Decoiler, Laser Cutting machine, Automatic Welding Machine, Polishing Machine, CNC Tube Bending Machine, Pressure Detection Bench, RAPrecision Detector, etc.

With continuous efforts and improvements, the company has exported itsbrewery/distillery/ winery equipment to more than 2500 breweries from over 106 countries, including Germany, France, Latvia, Belgium, Austria, Denmark, Finland, Greece, Italy, Netherlands, Romania, Spain, Sweden, Switzerland, South Africa, Singapore, Thailand, Mexico, USA, Canada, South Korea, Japan, Russia, Australia, Argentina etc.

Tiantai company has adhered to the principle of providing quality brewery/ distillery/winery equipment at an affordable price and serving more brewmasters to brew their craft beer to perfection. Tiantai, your honest brewery/distillery/winery equipment builder.

The IFPA Produce Executive Program has proudly delivered over two decades of success in Australia, consistently attracting participants from both Australia and New Zealand.

BELINDA WILSON

IFPA Managing Director ANZ

However, in the post-COVID era, the association observed a noticeable shift in travel behaviours, with reduced cross-Tasman business travel impacting participation in professional development programs.

In response to this evolving landscape, in collaboration with its valued partners at Streamwise Learning, IFPA made a strategic decision to expand the program’s footprint by launching it in New Zealand.

This initiative has been designed to better meet the needs of its New Zealand members and further strengthen leadership and capability development across the fresh produce and floral industries.

Developed through extensive industry consultation and in partnership with an

outstanding lineup of sector leaders, including Michael Franks (CEO, Seeka), Kate Scott (CEO, Horticulture New Zealand), Ryan McMullen (General Manager – Produce, Woolworths NZ) and many more, this tailored offering places a strong emphasis on global trade, recognising New Zealand’s world-class position as a leader in horticultural exports and its reputation for excellence on the international stage.

“There is currently no other program that rivals the depth and impact of the Produce Executive Program,” said IFPA managing director ANZ Belinda Wilson.

“Participants will explore a range of key drivers, including shifting consumer preferences, sustainability demands, retail and food trends, the impact of AI and supply chain dynamics.”

This annual initiative offers a unique six-day immersive experience, bringing together emerging and established leaders from across the industry to build lasting connections, gain meaningful personal and professional insights, and explore a diverse range of leadership styles, strategies, and practical tools to drive team and business success.

According to Wilson, the program equips current and emerging leaders with the tools, mindset, and global perspective needed to navigate change and drive growth.

She said that experiential learning, cross-sector collaboration, and connection are at the heart of the course, fostering strategic thinking and helping participants build a strong, future-focused network that supports continuous innovation and long-term industry sustainability.

Wilson added that the connections forged through this immersive program often lead to unexpected business collaborations, commercial partnerships, and innovative initiatives.

“It’s an environment that fosters meaningful engagement without a set commercial agenda – yet delivers tangible outcomes through the strength of relationships and shared learning,” she said.

“This inaugural 50 percent scholarship opportunity is designed specifically for New Zealand growers who may not have previously considered such a significant investment, but who recognise the value of upskilling future leaders to position their business and the industry for long-term success.”

Time away from work due to injury is rising across many New Zealand industries – and manufacturing is no exception. While the number of workplace injuries each year is coming down, workers in manufacturing are taking longer to return. That creates challenges not just for businesses trying to maintain productivity, but for injured workers, whose physical and mental well-being can be affected by extended time off work.

SELENA ARMSTRONG CEO, ShopCare

We know that returning to work in a supportive environment – or even recovering while still working – leads to better outcomes for everyone involved. But despite the benefits, many workplaces still face practical and systemic barriers that make this difficult to achieve.

ShopCare has just released a new case study that is highly relevant for the manufacturing sector, and I’m pleased to share the highlights with the F+B Tech community.

Working with a large rural manufacturer, the case study highlights how a structured return-to-work approach helped injured workers recover faster and get back on the job.

First, a quick introduction to ShopCare. We are a charitable trust funded by ACC that works to improve health, safety and wellbeing outcomes across the full retail supply chain – from manufacturing, warehousing, transport and logistics, through to the shop floor.

Our work begins at the manufacturer’s or supplier’s worksite and ends when a customer walks away with their purchase. That retail supply chain journey involves approximately 20 percent (492k) of the workforce in New Zealand– and we’re here to help them stay safe, supported, and well.

We do this by partnering with industry leaders and experts to create practical tools, free training resources, real-world case studies, and pilot programmes to test new approaches to long-standing problems.

Our recent case study highlights a successful return-to-work programme developed in partnership with Industry Med – a specialist provider of workplace-based injury support and occupational health services.

Industry Med originated from health centres within large pulp and paper mills in the Bay of Plenty, where businesses had company physicians who worked closely with workers to provide first aid and coordinate return-to-work planning. Building on this model, Industry Med now supports over 2,500 workers across industrial sites in New Zealand, both in person and through telemedicine.

What was it that led to Industry Med’s successes?

One of the most impactful changes Industry Med has introduced is the setup of remote clinics on isolated

industrial sites. Leveraging technology, Industry Med’s virtual clinics are equipped with advanced telehealth technology to enable remote consultations and monitoring. Their video consultation capabilities and virtual monitoring equipment ensure healthcare providers can perform thorough examinations remotely and immediately following injury.

Another factor is that from the initial injury treatment through to rehabilitation, Industry Med manages the entire process, including ACC documentation and specialist referrals.

This case study shows that better return-to-work outcomes don’t require massive investment. It just takes commitment, communication, and a practical plan.

If you’re a manufacturer facing similar challenges, there are three key takeaways:

• Make it easy to report injuries early. The sooner someone is seen, the faster the care can be provided.

• Get everyone on the same page. Collaboration across HR, frontline leaders, kaimahi, and health providers creates stronger recovery plans.

• Stay flexible. Where it’s safe to do so, recovering at work – with adjusted duties – keeps people connected and motivated.

It’s also worth investigating potential partnerships. Industry Med’s onsite support model helped bridge the gap between frontline workers, medical professionals and business leaders. Ultimately, helping someone return to work safely is good for productivity, morale, and long-term retention.

ShopCare is here to support your sector with real-world guidance that helps improve worker outcomes. Thanks to ACC funding, most of our tools and training are free to use. This includes return-to-work resources, data dashboards, case studies, violent and aggressive behaviour training and cultural competency modules.

If you’re in manufacturing and looking to improve the health, safety and wellbeing of your workforce, we would love to help.

Symrise has rooted its approach to natural flavours in a deep understanding of nature itself, combined with cutting-edge science. It has tailored its natural flavour compositions to the specific application and desired sensory profile of the end product.

“While we cannot disclose specific proprietary formulations, we would like to present our code of nature platform, i.e. our holistic approach towards naturalness in taste, nutrition and health,” said Thomas Henriksen, Vice President of Symrise Food & Beverage Oceania and Japan.

“It relies on gentle processes that we have designed to preserve the integrity and efficacy of the natural components. Here, we utilise proprietary technologies and gentle, kitchen-like processes to create

natural signature solutions.”

For flavour compounds in low/ no sugar beverages, Symrise has recognised that reducing sugar has often led to a “taste gap,” where the natural sweetness and overall mouthfeel diminish and undesirable off-notes can emerge. Therefore, it has specifically formulated its tastebalancing solutions to:

Enriching overall taste profiles: Symrise’s focus on enriching and balancing overall taste profiles of sugar-reduced formulations to make these good-for-you products taste great.

Mask off-notes: Symrise solutions effectively mask undesirable notes such as bitterness, astringency, and metallic aftertastes that can arise from sweeteners or the reduction of sugar, salt, and fat. It highlights this core strength in the symlife™ masking and mouthfeel solutions.

Build authentic notes: Symrise can help to create or enrich authentic flavour profiles, such as dairy notes, ensuring a well-rounded and appealing taste experience.

Improve mouthfeel: Symrise’s capabilities extend to improving mouthfeel and adding desirable sensations like juiciness, contributing to a richer sensory experience.

Symrise also offers a modular Taste Balancing Toolbox that addresses aspects like onset, intensity, richness, and finish of the taste sensation. It has combined masking capabilities with taste enrichment tools and top notes to create customised solutions that allow taste retention and deliver a superior sensory experience in lowsugar and sugar-free applications.

Oscar Ramirez, Senior Flavourist at Symrise Oceania, added that carbonation can also influence the release and perception of aromas, and Symrise’s Taste Capabilities include understanding how various factors, including carbonation, affect the aromatic profile and stability of flavours over time.

“We utilise advanced techniques like flavour release monitoring and

specific shelf-life stability testing to ensure our natural flavours deliver a consistent and appealing aromatic experience throughout the product’s shelf life.”

Sensory testing also formed a cornerstone of the development process, with the Consumer and Market Understanding strength, bolstered by a consumer science-led approach, ensuring that Symrise solutions have been rigorously tested.

Symrise also conduct extensive consumer product tests comparing full-sugar versus reducedsugar products, including those incorporating symlife™ solutions. With its proprietary sensory language, symscript®, it can systematically describe sensory gaps and the ideal taste profile.

Examples of such sensory analysis of flavour-based interaction (Drivers of Liking Studies) with symlife™ taste balancing solutions have demonstrated positive sensory effects, such as the balancing of bitterness and astringency in products like soy milk. This was a testament to Symrise’s ability to mask undesirable notes and balance the overall taste profile.

Symrise’s commitment to dedicated long-term research activities, a holistic, global approach to innovation, and deep insights into market and consumer needs has allowed it to act as a partner of choice for manufacturers seeking to create truly great-tasting “better-foryou” products.

Hawkins Watts is the exclusive supplier of Symrise flavours in New Zealand. For more information, contact sales@hawkinswatts.com or +64 9 622 2720 or visit www.hawkinswatts.com.

Foodtech Packtech is one of New Zealand’s largest food manufacturing, packaging, and processing technology trade events.

For more than 40 years, it has been the must-attend showcase for professionals across the food and beverage sector to discover cutting-edge technologies, source practical solutions, and connect with leading suppliers.

Held biennially in Auckland, the

event draws thousands of industry decision-makers, from manufacturers and engineers to product developers and business owners.

Attendees can explore the latest advancements in processing equipment, packaging systems, automation, sustainability, and food safety, all under one roof.

The Australasian Institute of Packaging (AIP) will host the 2025 AIP NZ Packaging Forum on the 2nd of September at Foodtech Packtech New Zealand. The full-day forum is free to attend, open to the entire industry, and offers CPP points plus certificates of attendance.

On the 4th of September, AIP will

also run two globally recognised mini training courses at the Auckland Showgrounds. Each course provides a Certificate of Attendance and 6 CPP points.

Fundamentals of Flexible Packaging will cover the basics of flexible packaging, benefits, material choices, performance, and manufacturing.

Attendees will learn how innovation and technology are making flexible packaging safer, more sustainable, and resource-efficient.

While The Future of Flexible Packaging Design will explore the global and local drivers of change, including food waste, emissions, legislation, labelling, and

recycling challenges, the focus is on sustainability, soft plastics, and the responsibilities of brand owners and suppliers.

Whether you’re looking to innovate, automate, or expand your network, Foodtech Packtech delivers the insights, innovations, and connections.

Dexion’s 75-year presence in New Zealand solidifies their position as the leading storage solutions provider supporting New Zealand’s food industry from farm to fork.

New Zealand’s food and beverage industry operates within strict quality standards and fast turnaround times. From dairy exports to fresh produce, meat, and packaged goods, storage systems must manage large volumes and support reliable distribution. Facilities range from temperature-controlled cold stores to ambient distribution centres, each requiring a storage configuration that matches its operational demands. Storage systems are selected based on product type, turnover rate, and available space. Selective pallet racking is used where immediate access to

each pallet is important. Double deep and push-back racking increase storage density while maintaining reasonable accessibility. Shuttle systems allow high-density storage with efficient pallet movement in and out of lanes, suited to operations handling large quantities of the same product, whilst flow-through racking supports fast picking for high-turnover stock. These solutions are part of Dexion’s design capability, applied according to each customer’s workflow, stock profile, throughput and footprint.

Automated storage and retrieval systems (ASRS) and conveyor systems can be integrated with racking to handle continuous product movement with minimal manual handling. Other facilities may focus on increasing density or improving stock rotation while working within an existing building footprint.

One case in point is Fonterra’s cold store in Hamilton, where the project required an increase in storage capacity, reduced reliance on third-party logistics, and improved control over product movement. The facility was designed to manage high

volumes of butter and cheese while meeting operational and compliance requirements. Dexion’s answer - a shuttle system providing high-density storage seven levels high and 29 pallets deep. The site delivers over 51,000 pallet positions across five temperature zones from -18°C to 13°C, processing more than 2,000 tonnes of dairy products per day.

Seismic performance is another factor for consideration when it comes to designing storage and material handling systems in New Zealand. The country’s location along the Pacific Ring of Fire requires racking to meet local building codes and relevant standards such as European Standard EN15512:2021 and Australian Standard AS4084:2023.

In collaboration with the University of Auckland, more than 950 tests have

been carried out to study the durability and reliability of Dexion’s racking components, like uprights, beams and bracing, under normal conditions and under seismic conditions.

For example, Dexion’s innovative Friction Slipper Baseplate dramatically improves seismic resilience by allowing the rack to ‘rock’ in a controlled manner, dissipating earthquake energy. This not only prevents collapse during a severe earthquake but also ensures no replacement is required postevent, safeguarding your continued operations. This invention has been recognised by both the academic and industrial fields with innovation awards and is protected by a global patent.

Ongoing performance depends on more than initial design. Racking systems require periodic inspection, maintenance, and, where necessary,

repairs or component replacements to maintain safety and compliance. Dexion provides scheduled inspections, damage assessments, and repairs to ensure each installation continues to meet operational needs and regulatory requirements over its lifecycle. This reduces downtime, extends service life, and maintains safety standards over years of operation.

A suitable storage solution must meet operational requirements, comply with safety regulations, and align with a facility’s long-term plans. By combining a range of racking configurations with seismic engineering and ongoing lifecycle support, Dexion delivers systems designed for performance, reliability, and safety in New Zealand.

Contact Dexion, located across New Zealand, for a consultation.

Astrolift, a leader in innovative lifting and material handling solutions, is set to showcase how modern technology can transform food processing and packaging operations.

The company’s display at the upcoming Foodtech Packtech show will highlight industrial lifting systems, automation in material handling, and bespoke engineering solutions.

In today’s fastevolving food and beverage industry, the leaders of tomorrow are those who embrace

smarter, safer, and more sustainable ways of working. Astrolift is at the forefront of this shift, helping with the food industry, meeting standards, and productivity expectations while delivering reliability in high-demand environments.

• Astrolift’s automated systems reduce manual handling, cut workplace injuries, and drive operational efficiency. For highvolume food processors, this means streamlined workflows, faster production times, and less waste.

• No two food facilities are the same. Astrolift’s engineering team develops customised handling systems to solve industry-specific challenges, from raw ingredient movement to final packaging and distribution.

The Business Case for Investment

• Modern handling equipment not only improves safety and compliance but also lowers long-term costs. With reduced maintenance, higher productivity, and greater consistency, the return on investment is significant.

As the sector evolves, automation, efficiency, and sustainability are becoming non-negotiables. Astrolift’s solutions empower food businesses to adapt to changing market demands without compromising on quality or safety.

Formore information, visit www.astrolift.co.nz oremail sales@astrolift.co.nz

DualPakECO is both ovenable and microwavable and can be chilled or frozen and offers secure sealing across a variety of film substrates and machinery. Once used, it can be composted while still containing food residue, or rinsed and recycled.

Certified both commercially and home compostable, DualPakECO is a dual ovenable pressed paperboard food tray. DualPakECO trays are coated with ecovio ® by BASF, a food safe contact, compostable biopolymer coating that provides excellent barrier properties against liquids, aromas and oils.

• Certified to Australian standards AS4736-2006 and AS5810-2010

• Endorsed with the seedling logo and home compostable logo as verified by the Australasian Bioplastics Association

• Certification provides assurance that the trays will completely biodegrade in efficiently run commercial composting systems or home composting

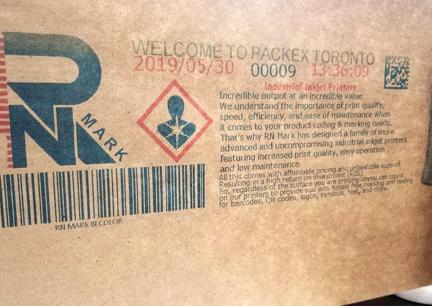

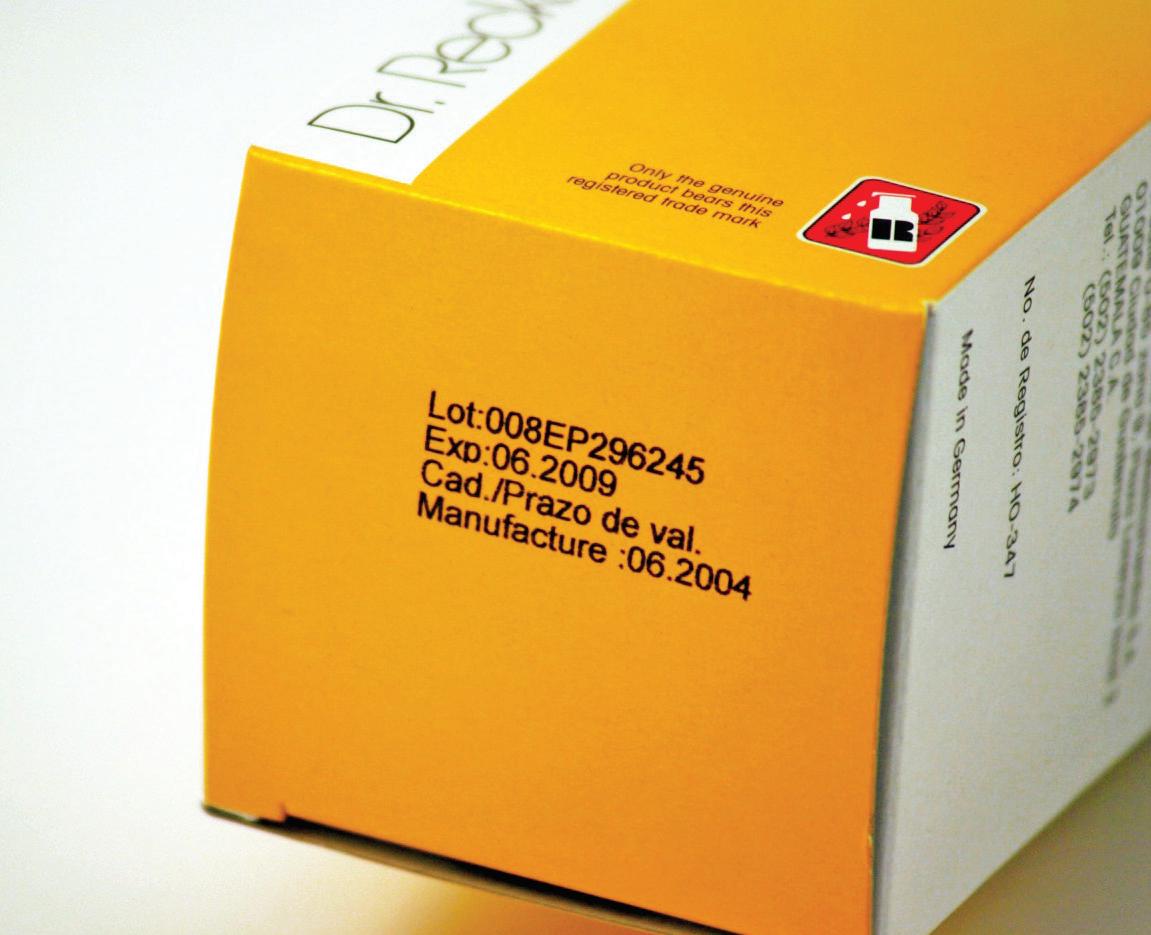

Starting in New Zealand in 2006, GALA Solutions now supports and supplies printers across New Zealand, all states and territories in Australia, Thailand, Malaysia, Singapore and the Philippines.

Its product range consists of all types of packaging printing equipment, with a primary focus on Best Before Date and Barcoding Coding with high-resolution printers with low or no maintenance, suited for all applications and all budgets, with particular focus on costeffective consumables and operational costs with superior customer service and support.

The team has been converting FMCG manufacturing companies across New Zealand and Australia to a more user-friendly printing technology with no servicing costs, saving thousands of dollars per annum on day-to-day operational

manufacturing costs.

Both countries have similar operations, just higher volumes; therefore, the printing costs, service and maintenance of the printing equipment are a higher priority towards the total manufacturing operational costs. When done correctly, it can save the manufacturers thousands of dollars per year.

Over the past two decades, Gavin Carragher, managing director of GALA Solutions NZ and AUS, has observed various changes in coding and labelling within the FMCG and manufacturing sectors.

These included adapting more efficient and cost-effective printing solutions onto all types of applications, substrates and products with a

Protect your brand with inspection solutions that enhance food safety and weight compliance for processing lines.

higher level of printer integration and automation in the manufacturing processes.

With an increase in demand for sustainable labelling and ecofriendly inks or ribbons, Carragher said that it has become essential to supply different technologies and user-friendly consumables that are targeted at reducing waste, carbon footprint and providing more ecofriendly solutions.

LEARN MORE ABOUT OUR EQUIPMENT ONLINE

At the same time, technical support and training are always critical in these applications, something the

GALA Solutions Team pride itself on.

“If the printer stops or fails, this will in turn stop a multi-million dollar manufacturing facility, which could cost thousands every minute it is down or not functioning,” said Carragher.

“GALA’s primary focus is customer support and application efficiency/ costing, and ensuring this is maintained at all times.”

GALA Solutions is always looking to offer a FREE audit to manufacturing companies and assist them with their current date code/barcode printing applications, and explore

options to streamline the current printing systems and processes. It will be showcasing its printers and technologies at the upcoming Foodtech Packtech show this year, allowing visitors to explore smarter, faster and more efficient ways to streamline their operations, minimising packaging printing costs and downtime with equipment that works harder and smarter for FMCG manufacturing companies.

As the manufacturing landscape in New Zealand continues to evolve, the pursuit of efficiency, flexibility, and sustainability has never been more critical.

Traditional, centralised automation systems, once the backbone of industrial progress, are increasingly being replaced by decentralised automation, a smarter, more adaptive approach that puts intelligence where it matters most: right at the field level.

Decentralised automation distributes control functions away from a single, centralised controller and closer to

the actual devices and processes. This shift enables manufacturers to respond faster to changing production requirements, streamline commissioning, and reduce costly downtime. With fewer cables, simpler installations, and modular designs, decentralised systems deliver not only operational agility but also tangible cost savings over the lifecycle of a plant.

For New Zealand’s food and beverage sector, where agility and compliance are paramount, decentralised automation offers a clear path forward. The ability to localise control means processes can be adapted in real time, ensuring consistent product quality and improved traceability. Maintenance teams benefit from easier diagnostics and faster interventions,

while plant operators gain new levels of transparency and control.

Burkert, a leader in fluid control solutions, has long championed this approach. Their decentralised automation platforms empower manufacturers to optimise plant layouts, minimise wiring, and futureproof operations against the demands of tomorrow’s markets. By placing intelligence at the edge, Burkert helps companies unlock new efficiencies and maintain their competitive edge.

As global markets demand more sustainable, responsive, and reliable production, decentralised automation is no longer just an option, it’s a strategic necessity. New Zealand manufacturers ready to embrace this shift will be best positioned to thrive in a world where adaptability and efficiency define success.

Partner with Burkert to discover how decentralised automation can transform your operations and secure your place in the future of manufacturing.

Discover more www.burkert.co.nz

Distributing control functions away from a central controller and closer to the actual devices, now that’s smart.

Partner with us burkert.co.nz

Bredel hose pumps, part of Watson-Marlow Fluid Technology Solutions, have launched the Bredel CIP pump for sanitary and hygienic processes that require optimal efficiency and regular Clean-In-Place (CIP).

Watson-Marlow Fluid Technology Solutions (WMFTS) will showcase its sustainability benefits for users of the new Bredel CIP pump and Certa process pumps at FoodTech PackTech NZ 2025 (Stand R13) at Auckland Showgrounds.

In food and beverage, pharmaceutical and cosmetics production, lengthy downtime for cleaning equipment and batch contamination result in higher costs. However, a pump that supports CIP without bypassing or disassembly minimises production downtime and avoids spoilt product due to contamination. WMFTS has designed the CIP pump with a new rotor to enable companies to achieve the CIP cleaning velocity requirements of > 2m per second.

Automatic retractable shoes for cleaning the pump element inside are specifically designed for CIP processes to allow the pump and the rest of the system downstream to be cleaned at

the correct fluid velocity.

By retracting the shoes during cleaning, hose compressions at high temperatures are eliminated, thereby extending hose life and reducing the costs of replacement hoses. The new CIP pump is available in sizes 20 (600 L/h), 25 (1800 L/h) and 32 (3200 L/h).

Existing customers can easily upgrade their pump rotor to the CIP variant in situ with clear instructions, without removing the pump from the process line and experiencing downtime. Bredel calculates that users of the CIP pump can achieve significant energy savings, leading to lower carbon emissions and a reduced environmental footprint.

For example, a brewery operating 24/7 with four one-hour cleaning cycles a day can now reverse the CIP pump to retract the shoes and turn off the pump during the cleaning process. This saves the brewery four hours of power for a pump that runs during the CIP cycle and therefore reduces energy

consumption by 16 percent or 1,460 hours annually.

Key benefits of the Bredel CIP pump include:

• Reduces maintenance downtime

• Reduces power consumption as there is no need to run the pump during CIP cycles

• Compliance with food-safety standards (FDA, EC1935, and 3A)

• Extended hose life by avoiding hose compressions within the CIP cycle at high temperatures

• Hygienic design – the only point of contact with the fluid is the inside of the hose

• High-accuracy dosing with flow independent of suction or discharge conditions

“The Bredel CIP pump is the perfect choice for reliable, accurate and gentle pumping. It can easily handle delicate ingredients such as yeast, additives and abrasive filtration agents that cause significant wear in other pump technologies. The CIP pump will help increase your uptime and decrease maintenance costs,” said Grace Madden, Bredel Product Manager. Whether it is handling sensitive yeast or abrasive diatomaceous earth, Bredel CIP pumps are an ideal choice for breweries for: Yeast dosing, Yeast transfer, Flavour and colour dosing, Diatomaceous earth dosing for filtration, Polyvinylpolypyrrolidone (PVPP) and silica gel dosing for stabilisation.

In the nutrition space, few windows are as critical as the first 1,000 days of life.

From conception to age two, 80 percent of a child’s brain develops, shaping sensory systems, memory, and learning capacity. The gut and immune system mature rapidly, transitioning from a protected womb environment to one exposed to external challenges. It’s a period where nutrition can influence lifelong health outcomes, including susceptibility to chronic diseases, cognitive performance, and emotional resilience.

Breast milk is the gold standard for infant nutrition: it provides complete nourishment tailored to infant needs, has natural probiotics and prebiotics that help establish a healthy gut microbiome, and provides immune protection and developmental support. However, researchers are now turning their attention to a lesser-known but powerful component within it: Human Milk Probiotics (HMPs).

These naturally occurring strains of Lactobacillus and Bifidobacterium, such as Kerry’s range of LC40® (Lactobacillus fermentum CECT5716) and BfM26® (Bifidobacterium breve CECT7263) HMPs, are emerging as valuable in supporting both infant development and maternal well-being, and are gaining attention among healthcare professionals and formulators alike.

Across the Asia Pacific, the probiotics market is booming, with a retail value of over USD 3.6 billion in 2024 and a projected CAGR of 6.3 percent through 20291. This growth reflects a broader shift toward preventative healthcare and rising interest in supplements and functional nutrition.

Within this evolving space, a new frontier is gaining momentum: specialist probiotics formulated specifically for mothers and infants. According to Kerry’s proprietary consumer research, 53.7 percent of women in Asia are actively seeking alternative solutions to support their pregnancy and breastfeeding journey. Meanwhile, 69.5 percent of parents are looking for products that can enhance their baby’s immune health and reduce the risk of future health issues.

These insights highlight the growing recognition of the microbiome’s role in early life and the demand for targeted, clinically supported solutions that align with modern parenting and wellness priorities.

Establishing a healthy gut microbiome

in infancy is crucial for immunity, digestion, and even cognitive development. Yet not all babies receive the same microbial head start. Infants born via C-section or who are formula-fed often lack exposure to the beneficial bacteria naturally transferred during vaginal birth and breastfeeding. This is where HMPs can make a difference. As strains originally isolated from breast milk, they are well adapted to the infant gut environment and can help close the microbial gap for at-risk populations.

Clinical research on LC40 has shown its ability to reduce gastrointestinal infections by 48 percent and respiratory infections by 27 percent, while supporting a gut microbiome more closely resembling that of breastfed infants. This suggests a reduction of antibiotic use, improvement in infant comfort, and lowering healthcare burdens.

Breastfeeding, while beneficial, is not always easy. Mastitis, a painful inflammatory condition, affects up to 15 percent of breastfeeding mothers, often leading to early discontinuation. LC40 has demonstrated a 51 percent reduction in mastitis incidence in clinical

studies, and mothers who consumed it also reported faster resolution of symptoms and improvements in emotional well.

Beyond physical relief, LC40 also helped alleviate psychological symptoms associated with mastitis. Women reported reductions in anxiety, sadness, and fear around breastfeeding, highlighting the holistic benefits of this probiotic intervention compared to those treated with antibiotics.

The implications are significant for maternal health outcomes and breastfeeding continuation rates, especially in the early postpartum period, where support is most needed.

Colic remains one of the most distressing yet poorly understood conditions in early infancy. B. breve BfM26 has shown positive outcomes in reducing crying time and improving gut comfort, particularly in colicky infants. It does so by modulating the gut microbiota and helping reduce intestinal inflammation—a mode of action increasingly supported by microbiome research.

Beyond colic, BfM26 is also being explored for use in neonatal care. When administered alongside LC40 in preterm infants, the probiotic duo significantly reduced the risk of necrotising enterocolitis (NEC) and lowered mortality rates, making a compelling case for HMPs in clinical settings.

In addition to immediate health outcomes, emerging evidence suggests that HMPs may have longer-term developmental benefits. In one study, formula-fed infants who received LC40 showed improved length gains, with measurable differences persisting up to two years of age. This suggests HMPs may positively influence growth trajectories during a critical window of development.

For manufacturers of infant formula, maternal supplements, or neonatal nutrition solutions, HMPs offer a compelling intersection of natural origin, clinical efficacy, and consumer relevance. As demand grows for science-backed, microbiomesupportive products in the maternal and infant space, these strains represent an evidence-based

approach to formulation. Importantly, their safety profile has been validated across multiple populations, including full-term, preterm, and breastfeeding infants, making them suitable for broad application in early life nutrition.

As the nutrition industry continues to explore microbiome-targeted solutions, Human Milk Probiotics like LC40 and BfM26 are standing out for their unique relevance to early life health. They represent a natural yet science-driven innovation, helping bridge biological gaps in modern birth and feeding practices while supporting better outcomes for both mother and baby. With robust clinical backing and strong consumer interest in preventive, functional health, Human Milk Probiotics (HMPs) can play a defining role in the formulation of next-generation maternal and infant nutrition products.

By Dr. Monica Maria Olivares, RD&A Director, Women & Infant Health, Kerry

Globally, one in three households purchases beer, while one in ten prefer cider, displaying high penetration in the European region. Infrequent beer consumers are high in Latin America, while the same is true for cider consumption in Latin America and Europe. Younger consumers are increasing their consumption for relaxation and taste. Most consumers enjoy alcoholic beverages later in the day, often with friends or family.

The beer market is expected to grow at a five percent CAGR till 2027, with China leading the industry. Other notable countries are the US, Germany, and Brazil. Asia is the fastest-growing region, alongside several African and Middle Eastern countries, showing growth. Europe remains responsible for the highest beer per capita consumption, with the Czech Republic, Romania, and Estonia being the leading countries.

The top three low/no alcohol beer markets are Iran, Japan, and Germany, while the fastest-growing markets are Denmark, Iran, and Japan. The UK is the largest market for cider and perry, followed by Australia, Canada, and the US. The fastest-growing markets in this category include Poland, Singapore, and the Czech Republic.

Top brewers across the globe include AB InBev and Heineken, which together account for five percent of total product launches over the past year. The majority of top innovators are small, speciality producers, indicating the dynamic nature of the beer market. AB InBev leads as a global brewer with operations in 173 breweries.

Their global brands include Budweiser, Corona Extra, Michelob Ultra and Stella Artois, while their local brands feature Cass, Brahma, Aguila and Juliper. They are active in the low/no alcohol beer subcategory with its brands such as Corona Cero, Budweiser Zero and Stella Artois Liberté.

Heineken, another global brewer, manages international, regional, and local beer brands in its portfolio. Their notable strategy for new launches includes limited edition developments with tie-in events such as sports and musical festivals.

Globally, beer launches show signs of slowing down, but the low/no alcohol category launches are expanding at a 7 percent CAGR over the past five years. Western Europe and North America are the leading regions in the low/no alcohol category. However, the best growth comes from North America and Australasia during the same period. Brewers capitalise on collaborations and co-branding opportunities. For example, Heineken collaborates with Netflix to launch a non-alcoholic beer featuring Senna.

Top influential claims remain the same for beer and cider, including traditional, safe, made with real ingredients/natural, and premium. Other notable claims include vegan, cobranding, limited edition, and seasonal. Consumers in different regions prioritise different claims. For example, no alcohol claims are key in Asia, Latin America, North America, the Middle East and Africa. Vegan claims are prominent in Europe, while indulgence and premium claims are important in Asia, Latin America, the Middle East and Africa.

Unflavoured launches remain core in

beer and cider, while fruit flavours lead in flavoured launches. The top three flavour preferences in beer are red raspberry, lemon, and mango. In cider, it is strawberry, lime, and peach. The fastest-growing flavours in beer include desserts and bakery-inspired flavours, while hot, spicy, and floral flavours are popular in cider.

The beer and cider landscape continues to evolve, driven by consumer demand for authenticity, innovation, and sustainability. Brands can adapt to these shifts by exploring novel flavours, emphasising traditional methods, and addressing ethical concerns. Building connections with younger consumers and experimenting with flexible consumption occasions can bring new opportunities in this dynamic market. With growing awareness of health and wellness, brands can introduce beer and cider with functional benefits like probiotics or adaptogens. Brands can position low- and no-alcohol options for broader consumption occasions while appealing to healthconscious consumers. Partnerships between brewers, cider makers, and other industries, such as coffee or dessert brands, can lead to inventive creations. Seasonal and limitededition launches can further enrich their portfolios.

Highlighting locally sourced ingredients, such as regional hops or apples, can resonate with environmentally conscious consumers. Transparent messaging around sustainability initiatives can also strengthen brand loyalty. Beer and cider brands have a lot of new opportunities; by tapping into trends like health-consciousness and sustainability, they can cultivate meaningful connections and expand their reach.

Quad study reveals which craft beer packaging designs attract shoppers.

What makes a beer stand out from the hundreds of others on the shelf? A new study from Quad’s Accelerated Marketing Insights group suggested that packaging plays a critical role in guiding consumer choices in the craft beer category.

The research, conducted at Ray’s Wine & Spirits in Wauwatosa, Wisconsin, used eyetracking glasses to monitor 61 participants as they browsed two full beer walls. In total, the shoppers encountered 474 different craft beer options. After the shopping session, each participant completed a survey to discuss their purchase decisions.

The study aimed to determine which visual and packaging characteristics attracted attention and influenced purchases. Researchers measured visual engagement through three key eye-tracking metrics: total fixation duration, time to first fixation, and fixation count. These metrics revealed not just what shoppers looked at, but how quickly and how often.

According to the findings, 84 percent of shoppers arrived without a specific beer in mind, reinforcing that visual cues play a large role in decision-making. Packaging design ranked just behind flavour and price as the most important factor in purchase decisions. Nearly three-quarters of participants,72 percent, said that the way a beer looked made them more likely to buy it.

Among the standout design trends, illustrations proved to be one of the most consistent attention-getters. The beer that received the longest fixation time was Gus Polinski and the Kenosha Kickers by 903 Brewers, which featured a cartoon of actor John Candy’s face on the label. Researchers have noted that human faces tend to capture visual attention more quickly than abstract or text-heavy designs.

Another trend was the use of descriptive and thematic naming. Products like Hot Dog Lager by Explorium Brewing and Maple Coffee Porter by Lion’s Tail Brewing appealed to participants by directly

referencing flavours or creating a strong sensory association. This approach helped consumers more easily connect with what they were purchasing, the study found.

Label type also played a role. Pressuresensitive labels, which adhere without the need for heat or water, were consistently among the best-performing products. These labels were used by six of the 13 topselling beers in the study, and 80 percent of the top five most visually engaging brands featured them.

While the study did not find that pressure-sensitive labels impacted consumer perceptions of quality, their adaptability and cost-efficiency may explain their popularity among brewers.

Shannon Anderson, Director of Client Research, stated that the findings have implications for seeking optimal packaging in a competitive and crowded market.

“This type of visual data can serve as a leading indicator of purchase intent,” Anderson said.

“When 84 percent of shoppers are coming into the store without a plan, brands that can break through visually have an opportunity to win in that final moment of decision-making.”

The study was conducted in fall 2024 through Quad’s Accelerated Marketing Insights division and is part of the company’s broader marketing experience suite, which includes media, creative, production, and data offerings.

The Tobii 3 eye-tracking glasses used in the research recorded movements at a rate of 50 times per second, providing researchers with a detailed view of how shoppers interact with physical packaging in real-time.

With craft brewers facing rising costs, slower category growth, and general economic uncertainty, standing out on the shelf may be more critical than ever. Quad’s findings suggest that even small changes to visual design could have a measurable impact.

Steve Hewland, founder of Glenorchy Brewing Co., has utilised an electric 550 litre hybrid mash kettle HERMS kind of system, and two unitanks, 3 and 3.5 BBL, for his core range of five beers.

Balancing production with demand has been quite a challenge, as demand is very variable and tied to the tourism numbers.

“I try to keep enough stock, but as it is a dated product, that’s not easy. Especially when juggling cans and kegs production,” said Hewland.

One of his driving sustainable philosophies has been low food miles, using only South Island-grown ingredients and local suppliers wherever possible.

Being mindful of the environment has been ingrained in his DNA, as Glenorchy Brewing Co. has committed to reducing its carbon footprint since the beginning. Initially, the business relied on two LPG burners alone; later, adding a more energy-efficient commercial-grade

califont significantly reduced energy consumption and saved valuable time.

To augment sustainability efforts, Glenorchy Brewing Co. embraced solar power in its new garage brewery.

“We maximise solar energy utilisation by carefully timing the operation of equipment such as the glycol chiller to coincide with peak solar production. Additionally, we enhance energy efficiency by bolstering the insulation of our fermenters with snug blankets and duvets, reducing the demand on heating and cooling during peak winter and summer seasons.”

Recognising the environmental impact of traditional LPG burners, Glenorchy Brewing Co. also custombuilt an electric kettle to eliminate CO2 emissions during the boil. Furthermore, it has prioritised natural fermentation-

derived carbonation in its beermaking process, reducing reliance on manufactured CO2.

Water has also been conserved diligently at the brewery. Rainwater is collected from the roof and stored in a purpose-built underground tank with a capacity of 5000 litres. During dry summer months, when rainfall is scarce, the brewery recycles cooling water, directing it back into the tank.

Moreover, in the summer, it repurposes spent hops, yeast, and diluted liquid waste to nourish the north-facing paddock, benefiting both the land and farm animals. The spent mash also finds purpose in enriching compost and suppressing weeds in the garden during the bountiful summer months.

“We extend our sustainable practices

beyond our property by minimising shipping through bulk ordering and only opting for local South Island ingredient suppliers. By committing to sourcing only New Zealand hops instead of importing from afar, we reduce unnecessary food miles and support local producers.”

Packaging is another area where sustainability is at the forefront of decision-making. Glenorchy Brewing Co. utilise recyclable cans and cardboard, minimising the use of plastic where possible. Additionally, its commitment to a paperless operation is evident through electronic brew recordkeeping.

Looking ahead, Hewland is excited about a collaboration with Altitude Brewing involving his artesian mineral water.

Hub helped launch without the need for upfront investment in equipment.

Baggio added that RTDs have remained one of the fastest-growing categories, particularly those with health, wellness or natural positioning. There was also strong demand for low and no-alcohol drinks, and for more innovative formats such as pouched cocktails and bulk-serve options.

“Quality is a non-negotiable for us. Our facility is SQF-certified, which is one of the highest food safety and quality management standards in the industry.”

He said that many brands were also thinking about sustainability, choosing to work with local or ethical suppliers, using upcycled ingredients and opting for lighter or more recyclable packaging.

“We also hold organic certification, which reflects the growing demand for natural and ethically sourced products. Every product is closely monitored and tested to meet both regulatory and brand-specific requirements. Our production floor is set up to handle a wide range of products without compromising safety or consistency.”

At the same time, the company’s ESG roadmap includes water reclamation through crossflow filtration, CO₂ recapture trials and ongoing work to reduce energy and packaging waste across the board.

Gypsy Hub also helps clients choose more sustainable packaging, offers bulk liquid logistics to cut transport emissions, and supports purpose-driven products that upcycle ingredients or work with local producers.

Startups usually need flexibility. They often require smaller batches, custom packaging options, and more support with compliance or formulation.

“We collaborate with clients at every stage, from developing the initial concept through to trial batches and compliance testing.”

Baggio said that while some clients come with a clear recipe, others start with only an idea. The internal team includes experts in formulation, brewing, distilling and technical compliance, allowing Gypsy Hub to provide guidance on everything from flavour stability to ingredient sourcing.

Baggio added that Gypsy Hub has been regularly challenged by projects that involve complex ingredients or alternative formats. One example is Oh! LemonAid, which uses surplus citrus and has strict sourcing and sustainability requirements.

Another was a range of spirit-based RTDs produced in flexible pouches, which required specialised processing to ensure flavour stability and shelf life.

“Our work with Wonki also pushed us in a good way. They supplied all their own packaging, worked closely with our team and scaled production rapidly to meet national demand. These are the kinds of projects we enjoy most, where creativity, problem-solving and technical precision come together.”

The NZ Brewers Guild has observed strong potential in beer tourism, connecting visitors with unique brewery experiences across the country as well as internationally.

Executive director Melanie Kees said that there was room to grow exports, especially in Southeast Asia, where demand for premium and craft products has risen. Australia has become another key market, being the closest.

Hop growing in New Zealand has also changed, with more hop farmers across the country. New Zealand hops, malt and other local ingredients have become an integral part of the Kiwi beer/brewing story.

“Both malt and hops in beer can help showcase the industry’s connection to the land, and the craftsmanship behind the beer; a story worthy to be shared on the world stage.”

At the same time, rising costs, regulatory pressures, excise taxes, labelling requirements and shifting consumer habits have been tough on small brewers. To stay competitive, many have focused on direct-toconsumer sales and a hyper-local market.

“Strong community engagement, sustainability initiatives, storytelling, and collaboration are key,” said Kees.

“New Zealand breweries follow global trends like automation and energy efficiency. In other cases, I think we are leading the way.”

Kees said that being a country as small and as remote as New Zealand meant industries needed to become more innovative to improve operations. CO2 recapture has grown in popularity, mainly driven by a shortage of CO2, but this has fed nicely into brewing sustainability, a key focus for both brewers and many consumers.

From reusable packaging pilots and regenerative farming to solar power, sustainability is an important consideration. Breweries have been reducing water use, repurposing spent grain, and sourcing local ingredients to lower their environmental footprint.

“This has tied in nicely with the beer tourism angle and telling those great grain-to-glass stories.”

However, training for the next

generation of Kiwi brewers has become limited, with the only brewing-specific NZ-delivered qualification stopping last year.

“We help facilitate education opportunities for our members and support sensory training. The IBD still offers one of the most utilised education programmes in the industry, and in-house training, mentorship and support are always necessary.”

For Kees, the future of an exceptional brewing industry would be resilient, sustainable, and globally recognised.