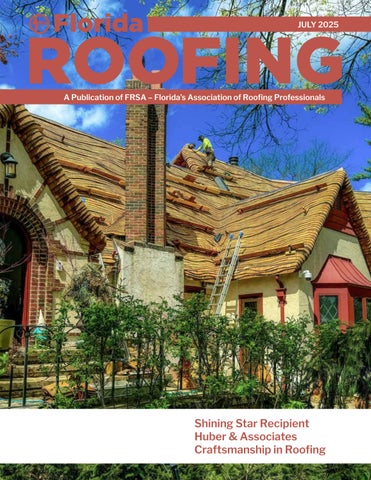

A Publication of FRSA – Florida’s Association of Roofing Professionals

Shining Star Recipient

Huber & Associates

Craftsmanship in Roofing

Shining Star Recipient

Huber & Associates

Craftsmanship in Roofing

MFM introduces IB-3™ StormStopper Plus, designed specifically for the Florida roofing market. Stop storm damage in its tracks and offer your customers a qualified FORTIFIED PROGRAM product for years of worry-free service. This 50-mil, self-adhering roofing underlayment features a granulated surface and a non-removable selvedge edge for a secure seal on overlaps for whole roof protection.

IB-3 StormStopper Plus meets ASTM D 1970 and Florida Building Code FL# 41919.1.

FRSA-Florida Roofing Magazine Contacts:

For advertising inquiries, contact: Skip Heymann at: skip@floridaroof.com (800) 767-3772 ext. 127

All feedback and reprint permission requests (please include your full name and address) contact: Lisa Pate, Editor, at: lisapate@floridaroof.com (800) 767-3772 ext. 157

Florida Roofing Magazine PO Box 4850 Winter Park, FL 32793-4850

View media kit at: www.floridaroof.com/ florida-roofing-magazine/ #FRSA #roofingprotects

FRSA President Tibor Torok, Bob Hilson & Co. Inc.

The commotion from FRSA’s Convention and Expo has settled down and we are back to the daily grind hoping for a slow hurricane season. FRSA had another banner year with the Convention and Expo. Between the Convention Committee, Lisa and the FRSA staff, the dedication and hard work paid off for the entire FRSA membership. They are truly professionals at what they do – we all owe them a bit of gratitude for the sacrifices made on the Association’s behalf. I believe their dedication and hard work is, in part, a reflection of the dedication, hard work and professionalism of the membership. Without you, there would be no need for them.

Speaking of dedication and professionalism, I can think of no other organization that has influenced roofing and the building code in Florida more than FRSA. Through the efforts of the Board of Directors, Codes Committee, lobbying, legal and you, the membership, we have strengthened the building code requirements for consumers and provided safer homes, businesses and public structures for every person in the state. You all deserve a hearty pat on the back.

Professional roofing contractors – thanks in large part to FRSA, our lobbyist and the efforts of our Governmental Affairs Committee – can now do hurricane mitigation work for roof-to-wall connections, which eliminates the need for a GC and possibly an engineer, saving the public money.

Our professional Technical Director, Mike Silvers, CPRC, has been working successfully with the professional personnel in the HVHZ to ensure that portion of the code stays strong regarding underlayment uplift and tile installation.

Roofing has changed more in the last 25 years than the entire 100 years prior and we as roofing professionals have been a guiding force. Not just to Florida but to entities influencing building code changes nationwide. You should all be proud of your joint accomplishments.

These are just a very few of the accomplishments that we as roofing professionals, through FRSA, bring to the table.

Does it seem like I have overused the word professional? When I look at the members of the FRSA, I think not. Oxford’s Learner Dictionary defines a professional contractor as:

“A professional contractor is one with skill, experience, expertise and resources to carry out and complete work of a similar nature to the work

under the contract. Professionalism involves adhering to ethical stan dards, maintaining a positive and respectful demeanor and demon strating responsibility in one’s work.”

FRSA is not just a mem bership of contractors but each member is a roofing professional across the entire spectrum of roof ing. We all help ensure the comfort and safety of all Floridians and visitors through our efforts to provide the best roofing solu tions and installations for each situation and structure. You are the gold standard of Our theme this year is "Roofing Excellence Through Professionalism and Education." Education not just of ourselves but of the public too. I salute every one of you and am extremely proud and excited to serve as the 104th President of FRSA.

Kind regards,

Tibor Torok FRSA President slrcbhc@msn.com

P.S. – We asked Tibor what the initials in his email stand for. His reply? "State Licensed Roofing Contractor Bob Hilson & Company," another proud roofing professional

Tammy Hall Named Vice President of Marketing & Government Relations

Partners, LLC

Daryl Hendricks, CEO of Reroof Partners, LLC, is pleased to announce that Tammy Hall has been appointed Vice President of Marketing & Government Relations at Reroof Partners, LLC., the Southeast’s leading commercial roofing company. Broadwing Capital, based in Dallas, Texas, facilitated the acquisitions and subsequent combination of Campany Roofing Company, CFS Roofing and RPI Roofing to form Reroof Partners. Hendricks stated, “Tammy has been a leader in the roofing industry and a power in business and government in the Gulf Coast for many successful years. I am more than pleased to have her as part of our team.”

supports our teams across the country,” said Kurt Schwahn, Chief Revenue and Operations Officer. “We’re proud to welcome Brian Spence and to recognize the well-earned promotions of Phillip McCullum and Robert McCalman, both of whom were part of the Elite Roofing Supply team. We’re equally excited about the new branch managers joining our family – each bringing the experience, energy and values that help make Gulfeagle the distributor of choice.”

Brian Spence joins Gulfeagle as District Manager for the Northeast, bringing over 38 years of experience across commercial construction, retail and wholesale building materials. He studied Business at Buffalo State College and has served as a volunteer fireman for more than 22 years.

“My first impression of Gulfeagle Supply is that this is a company that shares both my values and professional drive. I am very excited about the opportunity to work with and learn from the Gulfeagle Supply Team,” said Spence.

With over 25 years of marketing and public advocacy experience, including 12 years dedicated to advancing the roofing sector, Tammy brings exceptional industry knowledge and leadership. During her tenure at CFS Roofing Services, she established and led a successful Service & Maintenance Division for 10 years while developing impactful branding campaigns that strengthened the company’s Southwest Florida presence. Her industry influence is demonstrated through her leadership on NRCA and FRSA Board of Directors and committees, advocating at both national and state levels, active participation in Southwest Florida Roofing Contractors Association and regular contributions as a respected commentator for RoofersCoffeeShop. Tammy’s expertise in business development, industry advocacy and roofing operations position her perfectly to drive continued growth and excellence in the specialized roofing industry.

Gulfeagle Supply, one of the nation’s leading roofing and building material distributors, is proud to announce the addition and promotion of several key leaders across its growing national footprint. These updates reflect the company’s ongoing commitment to local service, operational excellence and a strong, people-first culture.

“As Gulfeagle continues to grow, we remain focused on investing in leadership that shares our values and

Phillip McCullum has been promoted to District Manager of Southern California. With nine years of industry experience, McCullum has developed a strong foundation in operations, customer relationships and team leadership. He earned a bachelor’s degree in Entrepreneurship from Cal Poly San Luis Obispo.

“I’m truly grateful for the opportunity to take on this new role,” said McCullum. “I’m looking forward to continuing to grow with this team, building strong relationships and contributing in a way that helps all of us succeed together.”

Robert McCalman has been promoted to District Manager, overseeing branches in Louisiana, Mississippi and Beaumont, Texas. McCalman brings 21 years of experience in roofing distribution and is well-respected for his leadership and dedication to customer service.

“I’m excited for this new opportunity and the chance to work even more closely with the incredible team,” McCalman shared. “I look forward to building on our momentum, supporting our branches and continuing to grow together.”

Gulfeagle is also pleased to announce several new branch managers, each bringing deep industry experience and a strong commitment to customer success:

■ Matt Kaiser, Branch Manager – Billings, Mont.

■ Joe Lundy, Branch Manager – Tampa, Fla.

■ Rikk McCown, Branch Manager – Belgrade, Mont.

■ Peter Wrenn, Branch Manager – Joliet, Ill.

These appointments further demonstrate Gulfeagle’s investment in experienced local leadership to serve the unique needs of contractors and communities across the country.

VELUX, the global leader in skylights and daylighting solutions, is proud to announce the expansion of its Pro Partner Academy with new state-of-the-art training centers and mobile installation training in Rockville, Md. and Orlando, Fla. The academies reflect VELUX’s ongoing commitment to being the best partner to pro customers, helping them grow their businesses through free expert training, hands-on experience and strategic business resources.

“VELUX is here to upskill roofing and remodeling contractors, ensuring they have everything they need to succeed with skylights,” said Paul Johnson, Director of Installer Engagement, VELUX North America. “We’re making it easier than ever to access expert guidance that directly translates into boosting their sales and profits.”

The Rockville center, now open and serving the DMV and Baltimore areas, offers a full suite of free training courses, including installation training in both English and Spanish. The academy program is designed to help roofers and remodelers integrate VELUX Skylight Systems into their projects, bringing the potential for increased profit margins.

The Orlando center, serving Central Florida, is set to open this month. This location is connected to VELUX’s new 34,741 square foot Florida Distribution Center, enabling faster delivery and expanded product availability across the state and enhanced customer service with same-day local pick-up and on-the-ground support. Both locations feature custom-equipped mobile training vans that bring onsite product demonstrations and training to surrounding areas.

Central States Inc., a leader in metal building components, roofing and building packages, announces Doug Watts has joined the 100 percent employee-owned business as Central States Manufacturing President. Watts comes to his new post with more than two decades of manufacturing and leadership experience and will oversee operations, sales, logistics and customer service for Central States Manufacturing.

“First and foremost, Doug was a strategic fit for us from a culture and customer-first perspective,” said Jim Sliker, Central States Inc. CEO. “Doug’s experience in the building products industry is only surpassed by his character, leadership and dedication to excellence. He will be instrumental as we guide the company toward continued success and innovation.”

With more than 25 years of experience in the building materials and glazing systems industries, Watts brings a wealth of leadership and operational expertise to his new role as President of Central States Manufacturing. His background includes deep experience in delivering full building envelope solutions, ranging from aluminum storefronts and curtain walls to windows and glass, supported by robust estimating, engineering and project management services. Watts holds a Master’s degree in Business Management from West Texas A&M University. His proven track record of driving growth, operational excellence and customer-focused innovation positions him well to lead Central States into its next chapter.

“I’m honored to step into the role of President at Central States Manufacturing,” Watts said. “This company’s culture of integrity, innovation and employee-ownership is truly special. I’m excited to serve alongside our incredible team of employeeowners as we continue building on our legacy of excellence. I also want to thank Tim Ruger for his outstanding leadership over the last decade. Tim’s contributions have positioned us for continued success and I look forward to building on that foundation.”

Tim Ruger joined Central States in 2013 after a long career of leadership positions in automotive manufacturing. Under his leadership, Central States Manufacturing has experienced significant expansion, averaging more than 25 percent growth year over year, bringing new products and services to the market and opening five new manufacturing facilities with two more scheduled to open this summer. Ruger continues his work with Central States in the role of Chief Strategy Officer, helping to focus Central States on new ventures.

As part of its ongoing commitment to fostering innovation, improving operational efficiencies and delivering greater value to its contractor network, Duro-Last announced the promotions of several longtime leaders across its operations and technology teams.

“These leaders have been instrumental in driving the manufacturing excellence that ensures our products meet the highest standards of quality, performance and reliability,” said Mitch Gilbert, Vice

President of Technology. “Their expanded roles will allow us to further streamline operations, enhance efficiencies and continue innovating the products that our contractors know and trust.”

Bill Clark has been promoted to Director of Quality Control, where he will continue to lead product excellence and quality control initiatives. Since joining Duro-Last in 1997, Clark has shaped the company’s robust quality control program and upheld its stringent product standards.

Mary Koutras has been promoted to Director of Research & Development, where she will continue leading product testing and innovation efforts to meet the evolving needs of the commercial roofing industry. Koutras, who joined Duro-Last in 2012, has spearheaded pivotal research, formulation development and testing programs.

Scott Rosebrock has been promoted to Director of Maintenance, where he will oversee maintenance initiatives across all Duro-Last facilities. Rosebrock, who joined the company in 1986, has led numerous maintenance and capital improvement projects.

Scott Craven has been promoted to Senior Plant Manager, overseeing EXCEPTIONAL Metals and Duro-Last’s Michigan manufacturing operations. Craven joined Duro-Last in 2019 and has successfully led manufacturing operations at sister brand Plastatech with a focus on quality and productivity.

John Glasscock has been promoted to Senior Plant Manager, overseeing manufacturing operations at Duro-Last’s Oregon and Iowa facilities. Glasscock, who joined Duro-Last in 2024, has led production operations in Oregon with an emphasis on process improvements and plant performance.

Florida

Print Circulation

5,000 Industry Professionals

1,332,902 Industry-focused 12-Month Digital Impressions

Contact skip@floridaroof.com for advertising info

James Shoquist has been promoted to Senior Plant Manager, overseeing manufacturing operations at Duro-Last’s Texas, Mississippi and North Carolina facilities. Shoquist, who joined Duro-Last in 2019, has driven operational excellence and process efficiencies in Texas.

David Wade has been promoted to Senior Plant Manager, overseeing Anvil Paints & Coatings as well as Duro-Last’s Florida and Massachusetts manufacturing operations. Since joining Duro-Last in 2010, Wade has led Florida operations with a focus on efficiency and production excellence.

“These promotions reflect Duro-Last’s deep bench of talented leaders who are committed to driving innovation and delivering the highest-quality solutions to our contractor partners,” Chris Warner said. “We look forward to their continued leadership as we advance our strategic goals.”

The Roofing Alliance proudly announces their Board of Trustees for 2025-2026. Greg Hudson of GeorgiaPacific Gypsum will serve as President and Sherri Miles of Miles Roofing Inc. will serve as Vice President.

The Roofing Alliance is a diverse, thoughtful and dedicated forum of roofing contractors, manufacturers, distributors, service providers and industry professionals united to shape, improve and advance the roofing industry. This group of committed leaders has attracted some of the industry’s best and brightest roofing professionals.

The Roofing Alliance thanks the following officers and trustees for their commitment to the roofing industry:

■ Jason Dark, Duro-Last

■ Reed Gooding, GSM Roofing

■ John Campbell, Eagle Roofing Products

■ Piers Dormeyer, EagleView

■ Paige Harvill, Nations Roof

■ Scott Keith, Jobba Trade Technologies

■ John Kiesel, Division 7 Roofing

■ Michael Kruger, L.E. Schwartz & Son Inc.

■ Daryl Maronic, Dataforma, Inc.

■ Bob Morgan, Upstate Roofing and Painting, Inc.

■ Bob Pringle, Evans Roofing Company, Inc.

■ Craig Rainey, Supreme Roofing

■ Natalia Rizzatti, All Weather Insulated Panels

■ Jason Stanley, IB Roof Systems

Trent Cotney, Attorney & Partner, Adams & Reese

When you re-roof a home, Murphy’s Law is always lurking. A stray tear-off nail punctures a tire or a sudden storm finds a partially covered sheathing panel and leaves a watermark on the living-room ceiling. Your contract may feature iron-clad limitation of liability language but cutting a small check or offering a credit without first securing a written release can give the homeowner an open runway to sue again later. Below is a guide for Florida roofing contractors on why a release is different from and just as important as a good damage’s waiver clause, what the courts say about each and how to build a good paper trail the next time a jobsite mishap turns into a customer claim. Your contract may limit types of damages but not the right to sue. Here is a typical damages limitation provision:

To the fullest extent permitted by law, Contractor’s total aggregate liability to Owner under or arising out of this Agreement shall not exceed the Contract Price actually paid. In no event shall Contractor be liable for any consequential, incidental, indirect, special, exemplary, or punitive damages, including but not limited to loss of use, lost profits, lost rental income, diminution in property value, or alleged emotional distress, whether claimed in contract, tort, statute, or otherwise.

Portions of this provision are similar to AIA A201-2017 § 15.1.7, which has been enforced repeatedly by courts so long as it is clear and unambiguous. Florida appellate decisions likewise uphold clauses that expressly list the barred categories of damages and make the intent unmistakable.

But a waiver of damages only says which buckets of money the owner cannot pursue and not that the owner won’t pursue any claim at all or repackage the same facts into a different theory such as negligence, deceptive trade practices, express or implied warranty claims or lien offset. Absent a separate settlement document that releases the underlying claim, nothing stops the owner from handing your $1,500 check to a lawyer and seeking more six months later.

Generally speaking, Florida’s Uniform Commercial Code, § 673.3111, does create the ability to extinguish a disputed claim by tendering a check that bears a conspicuous statement such as “paid in full settlement of all claims arising from job at 123 Palm Avenue.”

If the owner endorses and deposits that check, there is a good argument that the claim is discharged. Two practical problems make sole reliance on this statute risky:

■ Ambiguity invites litigation. Courts will not find accord and satisfaction unless the pay-in-full notation is crystal clear and the dispute truly bona fide. Roofing defect cases often involve evolving scopes and multiple suspected causes, leaving plenty of room for argument.

■ Electronic transfers and app payments (ACH, Zelle, Venmo) do not accommodate restrictive endorsements, undercutting the statutory mechanism altogether.

A short, lawyer-drafted Release and Settlement Agreement avoids those pitfalls, eliminates doubt about mutual intent and can bundle in extra protections such as confidentiality, non-disparagement and even an indemnity from the owner if a future buyer resurrects the claim.

■ Identification of the parties and project – Tie the release explicitly to the street address and contract number.

■ Recitation of consideration – Spell out the payment amount or describe non-monetary consideration (“Contractor will patch and seal the south-driveway crack no later than August 5, 2025”).

■ Scope of released claims – Use broad words: “all claims, demands, causes of action, damages (direct or consequential), liens, costs or attorneys’

fees of every kind, known or unknown, which the Owner ever had, now has or may have…”

■ No admission of liability – Preserve your reputation and insurance standing.

■ Signature formalities – Date, witness or notarize and have all titled owners sign (including spouses who are on the deed but not the contract).

Courts routinely enforce such releases so long as they are supported by consideration and not procured by fraud or duress.

■ Front-load your contract. Enumerate barred damages (consequential, incidental, indirect, special, punitive).

■ Train PMs and sales staff never to hand over cash or sign a change order labeled “credit” without simultaneously obtaining a homeowner release.

■ Use conspicuous language on checks if you absolutely must mail payment before a formal release can be signed and follow up to get the document anyway.

■ Log every settlement in your CRM with amount, date and PDF of the executed release.

■ Review releases annually with counsel to ensure they dovetail with evolving lien, consumerprotection and contract-waiver statutes.

A crisp limitation-of-liability clause keeps catastrophic damage theories at bay but it is not a substitute for

a signed release when you pay to make a customer whole. Spending an extra 15 minutes to memorialize the settlement can spare you months of litigation, protect your deductible and keep your online reputation intact. Put the release template in every superintendent’s glovebox and make it policy that no check leaves the office without one. In the long run, the cheapest patch you install might be the ink on that one-page release.

The information contained in this article is for general educational information only. This information does not constitute legal advice, is not intended to constitute legal advice, nor should it be relied upon as legal advice for your specific factual pattern or situation.

Trent Cotney is a partner and Construction Team Leader at the law firm of Adams & Reese and FRSA General Counsel. You can reach him at trent.cotney@arlaw.com or 866-303-5868.

Adams & Reese is a full-service law firm dedicated to serving the roofing industry. FRSA members can contact Trent Cotney to discuss and identify legal issues and to ask general questions through access to specialized counsel. They offer free advice (up to 15 minutes) for members. If additional legal work is required, members will receive discounted rates. This is a pro bono benefit provided to FRSA members only. Contact Trent at 866-303-5868.

Chris Dawson, Attorney & Lobbyist, GrayRobinson

On May 19, 2025, Governor Ron DeSantis signed House Bill 715 (HB 715) into law, enacting significant updates to Florida’s roofing regulations. Effective immediately, the law introduces key changes for roofing contractors and residential homeowners, particularly regarding contracts executed during a declared state of emergency.

The following outlines the most notable changes introduced by the “Roofing Services” bill, highlighting new consumer protections for homeowners and tighter compliance requirements for roofing contractors – especially in the context of declared emergency situations.

What is the “Roofing Services” Bill / HB 715? HB 715 reflects Florida’s ongoing commitment to hurricane preparedness and consumer protection by:

■ Allowing roofing contractors to perform critical roof-to-wall strengthening work,

■ Clarifying and tightening homeowners’ cancellation rights following emergencies and

■ Mandating clear insurance coverage notices in all residential roofing contracts.

In response to these changes, contractors should update their contract templates to include the new insurance notice and adjust cancellation language as required by HB 715 and also train their teams on the expanded scope of roofing work and updated compliance standards. Homeowners are encouraged to familiarize

themselves with their cancellation rights and verify insurance coverage and policy terms with their providers before signing any roofing contract.

Historically, licensed roofing contractors in Florida were not authorized to evaluate or improve roof-towall connections, commonly called “hurricane straps,” which are critical structural components that help protect buildings during high-wind events. HB 715 changes that by expanding the definition of “roofing contractor” to include the evaluation and enhancement of roof-to-wall connections for structures with wood roof decking, as specified in Section 706 of the Florida Building Code. These enhancements must:

■ Be performed in conjunction with a roof covering replacement or repair and

■ Be installed and inspected according to the Florida Building Code, the Office of Insurance Regulation’s (OIR) uniform mitigation verification inspection form or project-specific engineering standards that exceed these requirements.

This revision provides greater flexibility for homeowners seeking to strengthen their homes against future storms and creates new business opportunities for licensed roofing contractors.

Under previous law, homeowners who signed roofing contracts after a declared state of emergency could cancel the contracts within 10 days of signing or before work began. HB 715 keeps this 10-day cancellation right but clarifies the roofing contract must be signed within 180 days of the event that caused the emergency. This change aims to protect homeowners from rushed or opportunistic contracts after disasters while providing clearer rules around cancellation rights.

To increase homeowner awareness, all residential roofing contracts must now include the following advisory in bold, 14-point font:

“If the proposed work is related to an insurance claim, you, the residential property owner, should contact your insurance company to verify coverage for the proposed roofing work, including any claims, deductibles, and policy terms, before signing this contract. By signing this contract, you acknowledge that you have been advised to contact your insurance provider regarding coverage and reimbursement of the proposed work.”

This new notice requirement aims to improve homeowners’ understanding of their insurance coverage, helping to prevent disputes and reduce the likelihood of denied claims.

Previously, roofing contracts signed during a state of emergency had to include a cancellation notice in 18-point bold font. HB 715 lowers this to 14-point bold font, matching the size of the new insurance notice. This subtle change helps streamline contract formatting while maintaining the prominence of required disclosures.

HB 715 introduces important updates to Florida’s roofing laws, enhancing consumer protections and tightening contractor requirements. By expanding roofing contractors’ scope of work, clarifying homeowners’ cancellation rights and requiring clearer insurance notices, the law better supports both homeowners and contractors, especially during declared states of emergency. Contractors and homeowners alike should understand these changes to ensure compliance and promote stronger, safer roofing practices throughout Florida.

FRM

Chris Dawson is an Attorney and professional Lobbyist for GrayRobinson’s Orlando office and is licensed to practice law in both Florida and Alabama. He primarily focuses on lobbying and government relations for public and private sector clients at the executive and legislative levels of state government. He is credentialed as a Designated Professional Lobbyist by the Florida Association of Professional Lobbyists. Chris also holds two degrees in Civil Engineering and has experience in construction litigation and design professional malpractice defense.

John Kenney, CPRC, CEO, Cotney Consulting Group

In the roofing industry, leadership isn’t confined to the office or boardroom – it lives and breathes on the jobsite. For every high-performing roofing company, the differentiator often isn’t just pricing, branding or equipment, it’s the strength of the field leadership team. Foremen, superintendents and project leads are the boots-on-the-ground forces that translate plans into performance, ensuring safety, productivity and quality from start to finish.

Yet, too often, field leadership is an afterthought. Talented tradespeople are promoted based on skill, not leadership readiness. The result? Projects suffer from poor communication, low morale, missed deadlines and margin fade. In today’s competitive market, roofing contractors can no longer afford to leave field leadership to chance.

Developing the next generation of field leaders isn’t just smart, it’s essential. This article explores what modern roofing field leadership requires, the consequences of getting it wrong and how to implement a system that builds capable, accountable leaders from the ground up.

For decades, the typical path from crew member to foreman was informal: prove yourself in the field, show up consistently, work hard and eventually, get a truck, a title and a crew to manage. However, as roofing projects have grown more complex and client expectations have risen, the traditional model is no longer enough.

Today’s field leaders are expected to do much more than supervise installation. They coordinate with multiple trades, interpret drawings and specifications, manage production rates, document work for closeout packages, enforce safety standards and communicate between the office and the jobsite. It’s a multifaceted role that requires planning, accountability and leadership maturity.

The best forepersons and superintendents are calm under pressure, clear in their expectations and consistent in their communication. They know how to motivate without micromanaging and correct without causing conflict. These qualities don’t develop independently – they must be identified, nurtured and supported over time.

To build strong field leadership, roofing contractors must clearly define what success looks like in the role. Here are key competencies that every high-performing field leader should possess:

■ Planning and scheduling: They must know how to review job documents, plan daily activities and sequence tasks to avoid delays.

■ Productivity management: Leaders must track crew output and adjust on the fly to meet goals without sacrificing quality.

■ Safety enforcement: They are responsible for upholding jobsite safety standards and building a culture of safety-first thinking.

■ Communication: Effective leaders maintain clear, respectful communication with crews, subcontractors, vendors and office staff.

■ Adaptability: Field conditions change rapidly. Leaders must know how to handle material delays, scope adjustments and unforeseen jobsite conditions.

■ Delegation: Leaders must balance direct supervision with crew empowerment, developing others while staying accountable.

Few field leaders arrive with all these traits. That’s why investing in their development is not a luxury, it’s a necessity.

The absence of strong field leadership can erode profitability, client trust and employee morale. Projects without adequate oversight often suffer from the following:

■ Labor inefficiency: Crews stand idle, waiting for direction, materials or clarification on scope.

■ Rework and callbacks: Quality lapses go unchecked, increasing punch list time and cost.

■ Safety incidents: Without strong leadership, safety standards are inconsistently enforced, increasing risk.

■ Schedule slippage: Delays stack up due to poor planning or failure to coordinate with other trades.

■ Frustrated clients and poor reviews: Jobsite disorganization or communication gaps reflect poorly on the company.

Each issue chips away at profit margins and reputation, often in ways that office-level leadership may not immediately detect. Strong field leadership prevents minor problems from snowballing into costly mistakes.

One of the most effective ways to improve field leadership is to treat it like any other critical business function: with structure, training and a pathway for growth. Here’s how to begin building a development track:

■ Identify future leaders early: Look for crew members with initiative, reliability and good communication. Leadership potential often reveals itself through small behaviors.

■ Create shadowing opportunities: Pair emerging leaders with experienced forepersons and superintendents to learn firsthand expectations, planning and crew dynamics.

■ Offer leadership training: Covers communication, time management, conflict resolution and even the basics of job costing. Understanding the business side helps align field performance with company goals.

■ Define roles and responsibilities: Don’t assume new leaders understand what’s expected. Provide written job descriptions, checklists and performance metrics.

■ Mentor through mistakes: Leadership development requires patience. Create a culture where mistakes are viewed as learning opportunities, not grounds for dismissal.

Structured development strengthens your leadership pipeline and increases loyalty and job satisfaction by showing field employees a path to grow within the company.

Strong leaders need the right tools to execute their responsibilities effectively. Roofing contractors should equip field leaders with resources that enhance planning, communication and accountability, such as:

■ Daily planning sheets or digital tools for tracking tasks, material usage and crew assignments.

■ Photo documentation systems to support quality control and project closeouts.

■ Field-accessible job costing dashboards that show daily progress against budget and labor targets.

■ Standardized jobsite communication templates for safety talks, crew huddles and issue escalation. Tools that are easy to use and tied to performance expectations empower field leaders rather than overwhelm them.

Clear expectations and follow-through are essential to effective leadership. Roofing companies should implement systems that support both:

■ Regular progress check-ins: Weekly meetings between field leaders, PMs or operations managers help surface issues early and align expectations.

■ Job closeout reviews: Analyze what went right and wrong on each project and use that feedback to coach leaders for future improvement.

■ Performance evaluations: Use defined metrics –on-time delivery, labor efficiency, quality and crew retention – to measure leadership effectiveness.

■ Corrective pathways: Address performance gaps early and constructively. Document expectations, provide support and set clear improvement goals.

Leadership thrives in environments where success is measured, recognized and continuously improved.

Leadership should be visible and valued on every crew, not just those in titled positions. Field leaders set the tone but every team member should understand they have a role in upholding standards. Encourage crews to lead by example: cleaning up after themselves, showing up on time and double-checking their work. Celebrate leadership behaviors. Recognize forepersons who consistently run organized, productive jobs. Thank crew members who step up to solve problems or train others. Public praise reinforces the company’s values and motivates others to raise their game. When field leadership becomes part of the culture, it doesn’t just improve job outcomes – it elevates the entire company.

Ultimately, your clients, suppliers and competitors judge your business not by your mission statement but by what happens on your jobsites. Your field leaders control that narrative every day.

Continued on page 20

Mike Silvers, CPRC, Owner, Silvers Systems Inc. and FRSA Technical Director

The definition of a “roofing contractor” was added to the Florida Statutes Chapter 489 in 1975. This established the services or scope of work that a roofing contractor could perform. Only once prior to May 19, 2025, has there been a major expansion in the services that roofing contractors can offer and perform. In 2008, the following was added to the definition of a roofing contractor in the statutes:

"The scope of work of a roofing contractor also includes required roof-deck attachments and any repair or replacement of wood roof sheathing or fascia as needed during roof repair or replacement."

Before that expansion, in many jurisdictions you had to be a Division I contractor to do any sheathing work because it was considered structural. For context, I’m paraphrasing FS 489.113:

"Contractors are subdivided into two divisions, Division I, Residential, Building and General

contractors as defined in paragraphs (a)-(c), and Division II, consisting of those contractors defined in paragraphs (d)-(q): which includes (e) Roofing contractor."

This 2008 expansion wasn’t passed to make roofing contractors’ jobs easier, although it did, it was done to accommodate the desire to add fasteners to roof sheathing on homes permitted for construction prior to the implementation of the Florida Building Code (FBC). This was a part of the code’s extensive hurricane mitigation requirements. That change, however, made it clear to all jurisdictions in Florida that roofing contractors could do that work. This effort to address enhanced sheathing attachment has clearly worked with most of the applicable structures, having been addressed.

Now, for the first time in 17 years, another major change has once again expanded our scope of work. With the passage of HB 715 (an act relating to roofing services) along with the Governor’s signature on

May 19, the following was added to the definition of a roofing contractor:

"and the evaluation and enhancement of roof-towall connections for structures with wood roof decking as described in Section 706 of the Florida Building Code-Existing Building, provided that any enhancement, which was properly installed and inspected in accordance with the Office of Insurance Regulation uniform mitigation verification inspection form, the Florida Building Code, or project specific engineering that exceeds these requirements, is done in conjunction with a roof covering replacement or repair."

Yes, there is a lot there but, rest assured, it will benefit our trade in both obvious and not so obvious ways.

A roof replacement permit triggers the requirement to address many of the FBC’s hurricane mitigation sections. Yet many jurisdictions would not allow roofing contractors to evaluate, enhance or even provide estimates that addressed roof-to-wall (RTW) connections. This, when a roofing contractor is typically the only contractor who can perform roof replacement. Those days should now be behind us as the options to evaluate, provide pricing and enhance are all now available. The bill became effective when it was signed by the Governor. Make no mistake, this has real world implications for those who perform roof replacements.

On the not so obvious side, please note that the combined vote of both the House and Senate that allowed the bill to pass was 149 to 1. Yes, you read that right. Just a few years ago, when “roofers’” reputations were being trashed, linking us to fraudulent insurance scams, I’m not sure the vote might not have been the other way around. FRSA and the roofing industry have worked diligently to claw back much of our reputation that could have been permanently lost. The passage of this law now clearly states that a roofing contractor can address these RTW connections. For many contractors, the question should be, are we prepared and knowledgeable enough to jump into this complex work? If the work is not done right, our reputation will again be under attack and we could easily lose the ground we’ve gained.

A special note to all those involved in the preparation, planning, lobbying and, at times, even arm twisting that was provided by our Legislative Counsel, Chris Dawson and the whole FRSA team – my sincere thanks for making this happen.

FRM

Mike Silvers, CPRC, is Owner of Silvers Systems Inc. and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient and brings over 50 years of industry knowledge and experience to FRSA’s team.

CHAPTER 489

489.105 Definitions. — As used in this part: (3) (e) “Roofing contractor” means a contractor whose services are unlimited in the roofing trade and who has the experience, knowledge, and skill to install, maintain, repair, alter, extend, or design, if not prohibited by law, and use materials and items used in the installation, maintenance, extension, and alteration of all kinds of roofing, waterproofing, and coating, except when coating is not represented to protect, repair, waterproof, stop leaks, or extend the life of the roof. The scope of work of a roofing contractor also includes all of the following and any related work: skylights, required roof-deck attachments, and any repair or replacement of wood roof sheathing or fascia as needed during roof repair or replacement and the evaluation and enhancement of roof-to-wall connections for structures with wood roof decking as described in Section 706 of the Florida Building Code-Existing Building, provided that any enhancement, which was properly installed and inspected in accordance with the Office of Insurance Regulation uniform mitigation verification inspection form, the Florida Building Code, or project specific engineering that exceeds these requirements, is done in conjunction with a roof covering replacement or repair.

Congratulations to FRSA Immediate Past President Manny Oyola Jr. who was recently appointed to the Florida Building Commission's Roofing Technical Advisory Committee (TAC). Manny attended his first meeting as a TAC member in June.

Gary A. Cohen, Executive Vice President, Certified Contractors Network (CCN)

Artificial Intelligence (AI) has long been the buzz of tech circles but it’s no longer reserved for Silicon Valley. Today, it has found a home in the roofing industry and here at Certified Contractors Network (CCN), we have embraced AI with open arms. From automating inspections and optimizing scheduling to boosting marketing performance and predicting customer needs, AI is giving roofing contractors an edge in a rapidly changing market.

This is excellent news, as the roofing industry is more competitive than ever. We are experiencing rising material costs, labor shortages and shifting customer expectations. This puts pressure on roofing contractors to work smarter and more efficiently. Roofing companies that have adopted AI in their business are seeing improvements in their sales performance, operating efficiencies and in customer satisfaction. Frankly, if you are not utilizing AI in your business today, you are at risk of falling behind.

At Certified Contractors Network, we are putting a strong emphasis on leveraging AI in what we call, the 6 Pillars of Success for Roofing Contractors –Marketing, Sales, Sales Management, Production, Business Operations and Managing by the Numbers (data-driven decision making). We have built strong partnerships with top companies leveraging AI in every area of a roofing business, enabling roofing contractors to seamlessly integrate AI into every area of their businesses. Let’s break down how roofing companies across the country are successfully using AI today and how you can too.

AI is revolutionizing how roofers find and convert leads. Traditional marketing efforts – direct mail, canvassing or relying on storms are fine but they can be unpredictable. Many AI-powered marketing platforms now utilize predictive algorithms to identify homeowners who will most likely need roofing repair or replacement. This is based on data that includes a home’s age, weather history in that geographic area and more.

This is a great tool for tweaking your advertising campaigns across your chosen digital and social media platforms to maximize your return on ad spend and your cost per lead. AI can do this for you in real time, optimizing marketing efficiency.

Some systems even use machine learning to write ad copy or landing pages that outperform what humans might create, freeing up contractors to focus on closing deals instead of guessing what message will resonate.

Bottom line: Contractors using AI marketing tools are reducing cost per lead, increasing conversion rates and gaining a competitive edge in crowded markets.

Sales

Sales is still a people business but even the best roofing sales reps can benefit from AI-enhanced tools that make estimating faster and more accurate. Modern roofing CRMs now integrate AI to help with:

■ Predicting close rates for each lead.

■ Recommending ideal pricing based on past jobs, materials and market trends.

■ Surfacing upsell opportunities that will increase average job size.

■ Analyzing sales rep performance and suggesting coaching opportunities.

AI doesn’t just make estimates faster, it makes them smarter. That means fewer surprises during production, fewer change orders and more jobs sold at or above target margins.

Bonus tip: AI-powered proposal software can also automatically generate polished digital presentations, helping sales reps close deals faster and look more professional in front of the homeowner.

In many roofing businesses, job scheduling and production planning are still managed through spreadsheets or whiteboards. But with labor shortages and tight project timelines, inefficient scheduling can cost contractors thousands each month. AI-powered project management tools now help companies:

We’ve evolved from roofing-only to a trusted partner for trades of all kinds. And now, we’re stepping into the future as BrightFund with the same values, stronger tools, and an even bigger vision.

Why Licensed Contractors Choose BrightFund:

• Dividends paid back to members

• In-house safety experts

• Responsive claims support

• Subcontractor compliance help

• Easy COI requests

• Personalized services

■ Schedule jobs based on crew availability, location proximity and real-time weather forecasts.

■ Predict supply delays and suggest backup vendors.

■ Optimize routing to reduce fuel costs and time between jobs.

Some software platforms have added features that will automatically adjust schedules if the weather changes or if delivery issues arise. This will maximize the productivity of your crews, meaning you should see better crew utilization, fewer delays and happier customers.

AI also enhances how roofing companies interact with their customers. There are numerous virtual assistants and chatbots available that can handle incoming inquiries, qualify leads, schedule appointments and even answer FAQs. In 2025, homeowners expect fast, digital-first communication and AI will deliver that without overwhelming your team.

There are AI tools that will analyze customer feedback, detect issues in call transcripts and alert managers to potential issues before they escalate further. This enables a proactive approach to follow-up and service recovery. This is a game changer for your reputation management.

Result: Creating a smoother, more satisfying customer journey and this leads to more five-star reviews and referrals.

One of the latest applications of AI in roofing is predictive service planning. AI can analyze data on a roof’s age, the roofing materials that were used, any prior roofing repair data and historical local weather information to forecast when a roof is likely to need repair or replacement.

Now you will have the tools to contact your past customers with timely service reminders, inspections or maintenance plans. This will help build loyalty and trust and should increase your repeat and referral business.

Think beyond your installation: AI will help you stay in touch with past clients and extend lifetime customer value.

AI might sound intimidating but you don’t need to hire a data scientist to get started. Many of the industry’s top tools already come with AI baked in. The key is to:

■ Identify your biggest bottlenecks. Is it lead quality? Job costing? Customer response time?

■ Explore tools that solve that problem. Many CRMs, drone platforms and marketing tools now offer built-in AI features.

■ Train your team. Even the best AI system is useless if your team doesn’t know how to use it.

■ Track performance. Monitor ROI, track KPIs and refine as needed.

The goal isn’t to replace people. It’s to empower your people with smarter tools that help them win more often and work more efficiently.

Final Thoughts: Don’t Get Left Behind

Artificial Intelligence is no longer a luxury; it’s a strategic advantage. Roofing contractors that embrace AI today will be the ones dominating their markets tomorrow. Whether you’re trying to generate more leads, improve estimating, streamline production or deliver a better homeowner experience, AI is ready to help.

As the saying goes, work smarter, not harder. With AI in your toolbox, you can do both and build a more scalable, more profitable and more future-ready roofing company.

FRM

Gary A. Cohen is Executive Vice President of Certified Contractors Network (CCN), North America’s leading training, coaching and networking organization for home improvement contractors. With over 30 years of industry experience and a background in business education, Gary specializes in helping contractors achieve scalable growth through proven systems and processes. He can be reached at gary@contractors.net.

Field Leadership, continued from page 15

Developing the next generation of roofing leadership requires more than just promotions – it’s a plan. By investing in your forepersons and superintendents, equipping them with the tools and training they need and holding them to clear expectations, you build more than just jobs – you make a resilient, reputable roofing company. The future of your company isn’t just on the horizon. It’s already on the roof.

FRM

John Kenney, CPRC, has over 50 years of experience in the roofing industry. He started his career by working as a roofing apprentice at a family business in the Northeast and worked his way up to operating multiple Top 100 Roofing Contractors. As CEO, John is intimately familiar with all aspects of roofing production, estimating and operations. If you would like further information on this or another subject, you can contact John at jkenney@cotneyconsulting.com.

Heidi J. Ellsworth, Owner, RoofersCoffeeShop and HJE Consulting

At the 2025 International Roofing Expo (IRE), an all-women team from the University of North Florida proudly competed in the Roofing Alliance’s 2025 Construction Management Student Competition and took home a Best Presenter award. The excitement surrounding this first-ever team of all women was contagious, filling the event with energy and pride. Each year, the Student Competition showcases the talent,

The Eagle Talon 5000 automatic hot air welder is designed to weld all types of thermoplastic membranes (TPO, PVC, CSPE). This machine is an extremely “user friendly” easy to use tool.

creativity and professional ism of the next generation of roofing industry leaders and 2025 was no exception.

Now in its eleventh year, the Roofing Alliance’s Annual Construction Management Student Competition continues to build momentum and inspire future industry professionals. Held in conjunction with IRE, the 2025 competition took place in San Antonio, Texas and introduced students to roofing as a dynamic and rewarding career path. It also provided valuable networking opportunities with peers, faculty and Roofing Alliance members.

This year’s competition project, provided by Beldon Roofing Company of San Antonio, challenged teams to develop a comprehensive bid proposal for the reroofing of the Embassy Suites by Hilton San Antonio Airport Hotel. Working closely with contractor mentors, students prepared detailed bid packages that demonstrated project management, estimating and safety skills. Finalists were invited to IRE to present their proposals live to a panel of industry judges. They also attended the Roofing Alliance’s Welcome Reception, toured the project site and participated in NRCA’s Industry Awards Ceremony where winning teams were recognized on stage.

The University of North Florida’s team included team captain Cheyenne Campbell along with Elma Mesic, Fallon Harris, Vanja Muzdeka and Michaela Colton. Although they did not win in 2025 as a team, they were proud to have Cheyenne Campbell receive the Best Presenter award.

All members of the team are construction management majors who brought unique perspectives and motivation to the competition. For many, this was their first deep dive into the roofing industry. In an interview with the team, we found that the experience was game changing for their college careers.

Michaela, whose mother owns a roofing company, shared how her upbringing influenced her interest in roofing, noting that attending as a student competitor provided a fresh and valuable experience compared to her previous visits to roofing expos.

Vanja, a sophomore and the youngest member of the team, joined to gain early exposure to the construction industry. She embraced the learning curve, eager to build her experience and industry knowledge. Fallon and Cheyenne, both second-year competitors, spoke about the perseverance it took to balance classwork, late-night project sessions and managing team dynamics to succeed at the national level.

Throughout their journey a common thread emerged – a deep sense of accomplishment and community. The students emphasized how the competition expanded their technical understanding of roofing, introduced them to real-world innovations and forged lasting friendships. Elma noted that the experience was not just about technical skills but also about building relationships that could last a lifetime.

When asked what advice they would give to companies looking to recruit top student talent, Cheyenne stressed the importance of authentic engagement. She encouraged employers to attend career fairs, sponsor events and support competitions like the Roofing Alliance Student Competition. She explained that in-person interactions allow students to experience a company’s culture and values in a way that cannot be replicated online.

These remarkable young women represent the evolving face of the roofing industry, one that is more diverse, inclusive and innovative than ever before. As

they move closer to graduation and prepare to launch their professional careers, companies would be wise to connect with them early and support the educational programs that shape future industry leaders. The future of roofing is bright and it is being built by students like these. For more information about the Student Competition and the Roofing Alliance, visit www.roofingalliance.net.

FRM

Heidi J. Ellsworth has worked in the roofing industry since 1993 and has held positions with Malarkey Roofing, Carlisle Construction Materials and EagleView Technologies. She is currently a partner and President of RoofersCoffeeShop and owner of HJE Consulting. Heidi is also one of the founders of National Women in Roofing (NWIR). She served as Chairperson for the first two years and in 2020 was awarded the WORLD Award.

Working with both RoofersCoffeeShop and HJE Consulting, Heidi currently focuses on supporting overall marketing strategies, sales success and content development for companies and associations within the roofing and metal construction industries. With a passion for networking and win-win-win scenarios, Heidi continues to provide consulting and progressive digital advertising opportunities for companies and associations, building strong collaborations for business profitability and success.

Kevin Lindley, Safety Rep, FRSA Self Insurers Fund

As the temperature climbs during the summer months, so do the risks on construction sites and other outdoor activities. While summer brings longer days and increased productivity potential, it also includes hazards such as increased risk of heat-related illnesses, dehydration, storms and equipment-related injuries. Prioritizing summertime jobsite safety is essential for protecting workers’ health and maintaining operational efficiency.

Heat stress, heat exhaustion and heat stroke are serious conditions that can affect anyone working in elevated temperatures. Symptoms include dizziness, nausea, headache, excessive sweating, blurred vision, muscle cramps, brain fog and confusion. Heat stroke, the most severe of these, can be fatal if not treated immediately.

■ Attempt to schedule the most physically demanding tasks for early morning or late afternoon.

■ Encourage frequent rest breaks in shaded or air conditioned areas.

■ Provide ample water – about one gallon of water per person, per day and encourage hydration every 15–20 minutes.

■ Train workers to recognize and respond to symptoms of heat-related illnesses.

Dehydration can set in quickly under the sun, impairing judgment, reducing endurance and increasing the likelihood of accidents. Alongside proper hydration, balanced meals that include electrolytes and energy-boosting nutrients can support stamina and focus.

■ Set up shaded hydration stations onsite near or in close proximity to the work area.

■ Avoid caffeinated, alcohol and sugary beverages that can accelerate dehydration.

■ Encourage workers to eat small, frequent meals rich in fruits, vegetables and proteins.

Prolonged sun exposure can lead to sunburn, heat rash and increased long-term skin cancer risk. Protective measures are essential. Recommendations include:

■ Equip outside workers with long-sleeved, waterwicking company logo shirts.

■ Require the use of sunscreen with SPF 30 or higher, reapplied every two hours.

■ Provide wide-brimmed hats or hard hat attachment sunshades, UV-protective clothing and outdoor tinted safety glasses.

■ Provide temporary tents with base securement weights to provide shade during breaks.

Metal tools and machinery can become extremely hot under direct sunlight, posing burn risks. Additionally, heat can impact the performance of some materials and equipment. Precautions include:

■ Store tools in shaded or covered areas when not in use.

■ Use gloves and other PPE to handle hot surfaces safely.

■ Conduct daily inspections of equipment for heat-related wear or damage.

While PPE is essential for safety, it can also trap heat and reduce ventilation, increasing the risk of heat stress. Choosing the right gear for summer is critical. Summer PPE considerations include:

■ Use lightweight, breathable materials when possible.

■ Rotate workers more frequently to reduce heat load from heavy PPE.

■ Integrate cooling towels or vests when feasible.

Heat can dull reflexes, reduce reaction time and cloud decision-making. Promoting mental sharpness and a culture of communication helps prevent incidents before they happen. Encourage these helpful practices:

■ Implement a buddy system so workers monitor each other for signs of distress.

Continued on page 35

John Hellein, Director, FRSA Educational Foundation

From FG Building Product's Kooler Kart to KARNAK Corp’s coatings; from the Jimmy-Buffet-flying-boat inspired travel trunk package – complete with a parrot – to a basket of premium rum and rare cigars, this year’s Foundation Auction offered many special items along with great bargains on industry products and services donated by associate members and

1905 Family Restaurants

4C's Spray Equipment Rental

Abita Brewing Company

Abuelo's Mexican Restaurant

AJC Tools

Aliante Casino Hotel & Spa

All Point Tile & Slate

American Eagle Outfitters

Atlantic Equipment

Atlas Roofing Corporation

Basin Park & Crescent Hotels

Boston Crawling Pub Tour

Brauner Safety Services

Bravoz Jump Arena

BrightFund

Butterfly World

Celebration Golf Club

Cellucrete

CentiMark Corporation

CertainTeed LLC

Chicago Cubs

Commercial Roofing Specialties

CompanyCam

Continental Materials, Inc.

Crayola Experience

Crown Roof Tiles

Drexel Metals

DubsDread Golf Course

Duro-Last

Eagle Roofing Products

Ecostar

Estimating Edge

Fabral

FG Building Products

Florida Everblades

Florida Roofing Magazine

Foxtail Coffee

FRSA Ladies' Committee

Gaco

GAF

Gaylord Palms Resort

Geocel

Gorjana

Gulf Coast Nail

Gulfeagle Supply

Holiday World & Splashing Safari

IR Analyzers

ITEL

Jack Hellein Photography

Jacksonville Icemen

John Mansville

Julian Davis

KARNAK Corporation

Kendra Scott

Kennedy Skylights and

Solar Ventilation

Kennedy Space Center

Visitor Complex

exhibitors. Thanks to the item donors and the attendees who bid on those items, the FRSA Educational and Research Foundation raised over $30,000 in support of scholarships.

For more information about this year’s scholarship recipients, see page 36. Thank you to the following people and companies who made it possible.

Landry's Inc.

Leap

Lion Country Safari

Luke's Kitchen & Bar

Manny Oyola Jr.

Merlin Entertainments

METALCON

Mike Silvers, CPRC

Millennium Metals Inc.

Mission Resort & Club

Museum of Discovery & Science

National Corvette Museum

NRCA

O'Hagin LLC

Ocean Breezes Design

OMG Roofing Products

Orlando City Soccer Club

Orlando Family Stage

Orlando Philharmonic Orchestra

Orlando Science Center

Orlando Shakes

Orlando Solar Bears

Owens Corning

Petersen | PAC-CLAD

Pittsburgh Steelers

Poseidon Roofing

Quirk Richmond Hotel

Rock & Roll Hall of Fame

RoofersCoffeeShop

Ruby Falls Caves

Salty Sam’s Pirate Cruise

Sawgrass Recreation

Park Airboats

Seattle Aquarium

Sherwin Williams

Side Splitters Comedy Club

SOPREMA

St. Augustine Alligator Farm

St. James Hotel

Suncoast Roofers Supply

TAMKO Building Products

Tampa Bay Buccaneers

Tarco

The Huntington Botanical Gardens

The North Carolina Arboretum

TopGolf

Toronto Blue Jays

Trent Cotney

TruFast

Verea Clay Tile

Victory Casino Cruise

Walt Disney World Golf

Wheeling-Nippon Steel

WonderWorks

FRM

This year's Shining Star – the "Best of the Best" among S.T.A.R. Award recipients – was awarded to Huber & Associates for its Minnesota Cottage Reroof project. Barry Huber is the project's roofing contractor.

The S.T.A.R. Awards – Spotlight Trophy for the Advancement of Roofing – is an awards program designed by the Florida Roofing and Sheet Metal Contractors Association to recognize members' unique and outstanding projects. A panel of judges evaluates the entries for outstanding performance in each category. The panel also selects one project from all submissions to receive the “Shining Star” Award and recognition as the best roofing project of the year. This year, there are 11 S.T.A.R. Award recipients in four categories including:

Low Slope – Modified Bitumen/Single Ply (TPO, PVC, EPDM)/BUR-Tar and Gravel/Metal; any variation of the above types of low-sloped roofing systems.

Steep Slope – All shingle, tile, metal, slate, wood shake/shingle or composite material applied as a roof system to a 2:12 or greater roof slope.

Craftsmanship in Roofing – A roof system installation where a superior level of workmanship is evident and made the completed project unique in fit, finish or use. Open to any size or type of roof system.

Community Service – Any non-profit roof installation that can be documented as a whole or partial donation (minimum 50 percent free material or labor).

The S.T.A.R. Awards program is open to all members, regardless of company size. If you have a unique or difficult roofing project, we encourage you to take multiple high resolution photos of before, in-progress and finished projects substantially completed in 2025. Drone shots are welcome, however closeup photos –especially in-progress details – help the judges better understand and evaluate a project. The following pages feature this year's S.T.A.R. Award recipients.

First Place

Huber & Associates

Type of Roof Application:

Custom Shingles 16-inch

Western Red Cedar Shingles

Roof Size: 6,800 Square Feet

Roof Height: Two Stories

Contractor: Barry Huber

Project MVP: Carlos and Crew

Estimator: Albert Gonzales

Project Manager: David Piper

Superintendent: Micah Cady

Foreman: Carlos Palma

Manufacturers: Custom Shingles, GAF

Quality Roofing Inc.

Type of Roof Application:

ATAS International 24GA 316

Stainless Steel 1.5-inch Field LOK and Custom Flat Lock Valley

Roof Size: 4,300 Square Feet

Roof Height: 18 feet

Contractor: Richard C. Jenkins

Project MVP: Julio “Junior” Romero

Third Place

Precision Exteriors, LLC

Type of Roof Application: Santafé Clay Tile

Roof Size: 2,488 Square Feet

Roof Height: One Story

Contractor: Caleb Laughlin

Project MVP: Michael Tatum

Estimator: Caleb Laughlin

Project Manager: Caleb Laughlin

Superintendent: Caleb Laughlin

Foreman: Caleb Laughlin

Manufacturers: Santafé Tile Corp., Westlake Royal Roofing Solutions, DuPont Tile Bond

Distributor: ABC Supply, John Tatum

This 1930s cottage exudes charm with intricate brick and stucco designs, flowering gardens and a sweeping fauxthatch roof. At the end of 2023, however, the home was hit by a terrible hailstorm that damaged almost the entire roof. The crew, dedicated to replicating the previous style, paid immense attention to detail, carefully working their way up the roof, constantly referencing photos to match the style and wave-coursing as closely as possible. The wave-coursing averaged a mere 2-1/2-inch exposure, which meant using twice as much material as a typical install.

Tampa Quality Roofing, Inc. completed a highly specialized roofing project at the University of Tampa, where the building is a national historic preservation site. Due to the building’s unique status, every aspect of the project had to be customfabricated. While some components were precisely created using a laser on a tripod, other elements had to be custom fabricated directly in the field. The Quality Roofing team is extremely proud of their work on this project, which required a high level of craftsmanship and attention to detail to meet the historic preservation standards.

This historic home in Jacksonville’s San Marco neighborhood was last reroofed in the 1970s. The owners chose Santafé Spanish “S” tile. Precision Exteriors worked with Santafé’s sales department to create a custom blend of four colors. The entire roof was mortared in place but once the tear-off started, the team from Precision Exteriors saw that some areas were actually concrete, up to 1-1/2 inches thick. The tear-off was slow, back breaking work. A rotary hammer was used to break up the concrete in places. Once the project was completed, the team from Precision Exteriors knew it had been worth the effort.

First Place – Register Roofing & Sheet Metal, Inc.

Type of Roof Application: Two-Ply Modified Bitumen, Perforated Panels, Pavers

Roof Size: 35,000 Square Feet

Roof Height: 50 Feet

Contractor: Lincoln Register

Project MVP: Alex Yost

Estimator: Lincoln Register

Project Manager: Alex Yost

Superintendent: Jay Combs

Foreman: Arturo Castellanos

Manufacturers: Siplast, Hanover Architectural Products, Petersen | PAC-CLAD

Distributor: Commercial Roofing Specialties Inc., Mike Howard

Quality Roofing Inc.

Type of Roof Application: LWIC, Modified Bitumen, Terrace Waterproofing, Pavers and Vegetative Garden Planters

Roof Size: 43,000 Square Feet

Roof Height: 80 Feet

Contractor: Richard C. Jenkins

Project MVP: Francisco Cruz

Estimator: Richard C. Jenkins

Project Manager: John Garrison

Superintendent: Francisco Cruz

Foreman: Jaichmark Gomez

Manufacturers: Siplast, Hanover

Architectural Products

General Contractor: The Beck Group Architect: Baker Barrios Architects Inc.

Florida Quality Roofing, Inc.

Type of Roof Application: MuleHide

Three-Ply APP Modified Bitumen, Tapered ISO Insulation

Roof Size: 46,500 Square Feet

Roof Height: 90 Feet

Contractor: German Duarte

Project MVP: Vincent Zeledon

Estimators: German Duarte, Vincent Zeledon

Project Manager: Vincent Zeledon

General Contractor:

Florida Quality Roofing Inc.

Manufacturer: MuleHide

Distributor: ABC Supply, Robert Chapman

The KLS Martin expansion was a highly intricate yet rewarding endeavor, exemplifying Register Roofing’s capabilities as a diversified and skilled roofing contractor. By successfully implementing five distinct roofing systems and managing multiple specialized crews, they demonstrated their expertise in executing large-scale, multi-faceted installations with precision and efficiency. Register Roofing’s partnership with Siplast enabled the integration of a comprehensive range of roofing solutions, ensuring optimal durability and long-term performance. The final result was a superior-quality roofing system that met the client’s expectations and contributed to the successful realization of their flagship expansion.

Quality Roofing Inc. was selected by The Beck Group for several roofing sections of this University of Tampa building, including the Skypark, which consisted of Siplast lightweight insulating concrete roof, a waterproofing system with Hanover pedestal paver system and vegetative garden planters. The building stands 11 stories. The most challenging part of the project was transporting heavy materials, particularly the pavers, through the elevator system in the middle of the building.

The Cosmopolitan Residence is a luxury condominium with 223 units. The roof spans 44,500 square feet, covering two buildings: one four stories and the other six stories. A threeply APP modified bitumen system was installed, providing the Cosmopolitan with a new 20-year roofing system. A tapered ISO system using a modified bitumen torch and tapered insulation system with a cover board was installed directly to the concrete deck to provide adequate drainage and eliminate ponding water. The project’s success was derived largely from good communication with the condo board that allowed it to be completed without disruption to the residents.

Type of Roof Application: Petersen Snap-Clad Standing Seam and Polyglass MTS Underlayment

Roof Size: 27,500 Square Feet

Roof Height: 90 Feet

Contractor: Richard C. Jenkins

Project MVP: Jairo Diaz

Estimator: Richard C. Jenkins

Project Manager: Nathan Cole

Superintendent: David Placensio

Foreman: Jairo Diaz

Manufacturers: Peterson Aluminum, Polyglass USA Inc.

Distributor: ABC Supply, Joe Bosio

Type of Roof Application: Brava

Composite Spanish Roof Tile

Roof Size: 800 Squares

Roof Height: Eight Stories

Contractor: Cody Bates

Project MVP: Dennys Ochoa

Estimator: Jonathan Fountain

Project Manager: Cody Bates

Field Manager: Dennys Ochoa

Superintendent: Gustavo Musa

Foreman: Gustavo Musa

Manufacturer: Brava Roof Tile

Distributor: FLS Roofing Supply

Type of Roof Application: Ludowici Roof Tile

Roof Size: 7,600 Square Feet

Roof Height: 25 Feet

Contractor: Thierry Devove

Project MVP: Eva Eddy

Estimator: Thierry Devove

Project Manager: Thierry Devove

Superintendent: Thierry Devove

Foreman: Thierry Devove

Manufacturer: Ludowici Roof Tile

Distributor: ABC Supply

General Contractor: Thierry Devove

The roofing project on Harbour Island in Tampa involved the installation of a steep-slope metal roof on two seven-story buildings. It featured Polyglass MTS underlayment and Petersen Snap-Clad standing seam panels. Due to the challenging height and steep pitch, the crew had to come up with unconventional methods of fall protection to ensure safety. Scaffolding was placed in each corner of the buildings, providing support for the crew while carrying 10 to 12-foot panels during the project. Despite the difficulties, Quality Roofing, Inc. successfully completed the project.

Following extensive hurricane damage, two Grand Isles Towers underwent a complete roofing replacement to restore durability and aesthetics across the community. The project involved installing 365 squares of Brava composite slate and Spanish tile on multiple structures. Executing a high-rise roofing project of this nature required rigorous safety measures, expert coordination and technical precision. By utilizing Brava’s premium composite materials and industry-leading steep-slope roofing techniques, FL Specialty Roofing delivered a storm-resistant, architecturally stunning roof system that enhances the Grand Isles community’s resilience and aesthetic appeal.

The owner of this new construction project requested a custom blend of blue tile from Ludowici to complement the aesthetic of the house. To create a seamless look, he requested the same color for the mortar. The project also included the installation of several dormers. Together, the uniqueness of the tile color and matching mortar on a large custom home made this installation stand out.

Tampa, Inc.

Type of Roof Application: TAMKO Asphalt Shingles

Roof Size: 405 Squares

Roof Height: One Story

Contractor: Karen Ruel

Project MVP: Zachary Johnson

Estimator: Zachary Johnson

Project Manager: Steven Burley

Superintendent: Daniel Romero

Manufacturers: TAMKO Building Products, GAF

Distributor: Gulfeagle Supply

General Contractor: CSI of Tampa

Type of Roof Application: Tri County Metals 5V Galvalume

Roof Size: 45 Squares

Roof Height: One Story

Contractor: Larry Neese

Project MVP: Larry Neese

Estimator: Joshua Neese

Project Manager: Derrick Neese

Superintendent: Ramon Cruz

Foreman: Jeremiah Neese

Manufacturer: Tri County Metals

A Kid’s Place is dedicated to providing a safe haven for children entering into the foster care system. When Tanner of Jenkins Roofing learned the nonprofit was raising funds for the renovation of their facilities, he knew Jenkins Roofing had to step up to the plate. The safety and stability of the children’s living conditions being paramount, reroofing the main building and the five adjacent homes was identified as the key priority. Thanks to the generosity of numerous businesses, including Gulfeagle Supply, Jenkins Roofing was able to complete the renovations at a fraction of the cost.

A local 47-year-old business, Al’s Family Farm was devastated by an EF3 tornado in the aftermath of Hurricane Milton in October of 2024. That’s when the local community came together. Neese Roofing, one of Tri County Metals’ customers, agreed to cover the roofing and wall labor and looped in Tri County Metals, who agreed to provide a 5V metal roof, accessories and materials free of cost. The materials needed included 26g 5V galvanized roof and wall panels. Tri County Metals was pleased to play a role in helping this local community family-favorite and business icon.

Heat Safety, continued from page 24

■ Conduct daily safety briefings with weather updates and reminders.

■ Empower workers to report unsafe conditions without fear of reprimand.

Summer storms can roll in fast, bringing high winds, heavy rain and lightning. Lightning is especially dangerous on jobsites with metal tools, elevated work location and open areas without lightning protection systems connected. Stay storm-ready:

■ Monitor weather forecasts throughout the workday.

■ Suspend outdoor work if lightning is within 10 miles from the work location, before and after the storm.

■ Avoid sheltering under trees or near tall equipment.

■ Resume work only after 30 minutes without thunder.

Summer brings unique challenges to the jobsite but with proactive planning and vigilant safety measures, risks can be minimized. By focusing on hydration, heat illness prevention, sun protection, storm readiness and proper use of PPE, employers can create a safer, more productive work environment that ensures everyone goes home healthy at the end of the day.

FRM

John Hellein, FRSA Educational Foundation Director