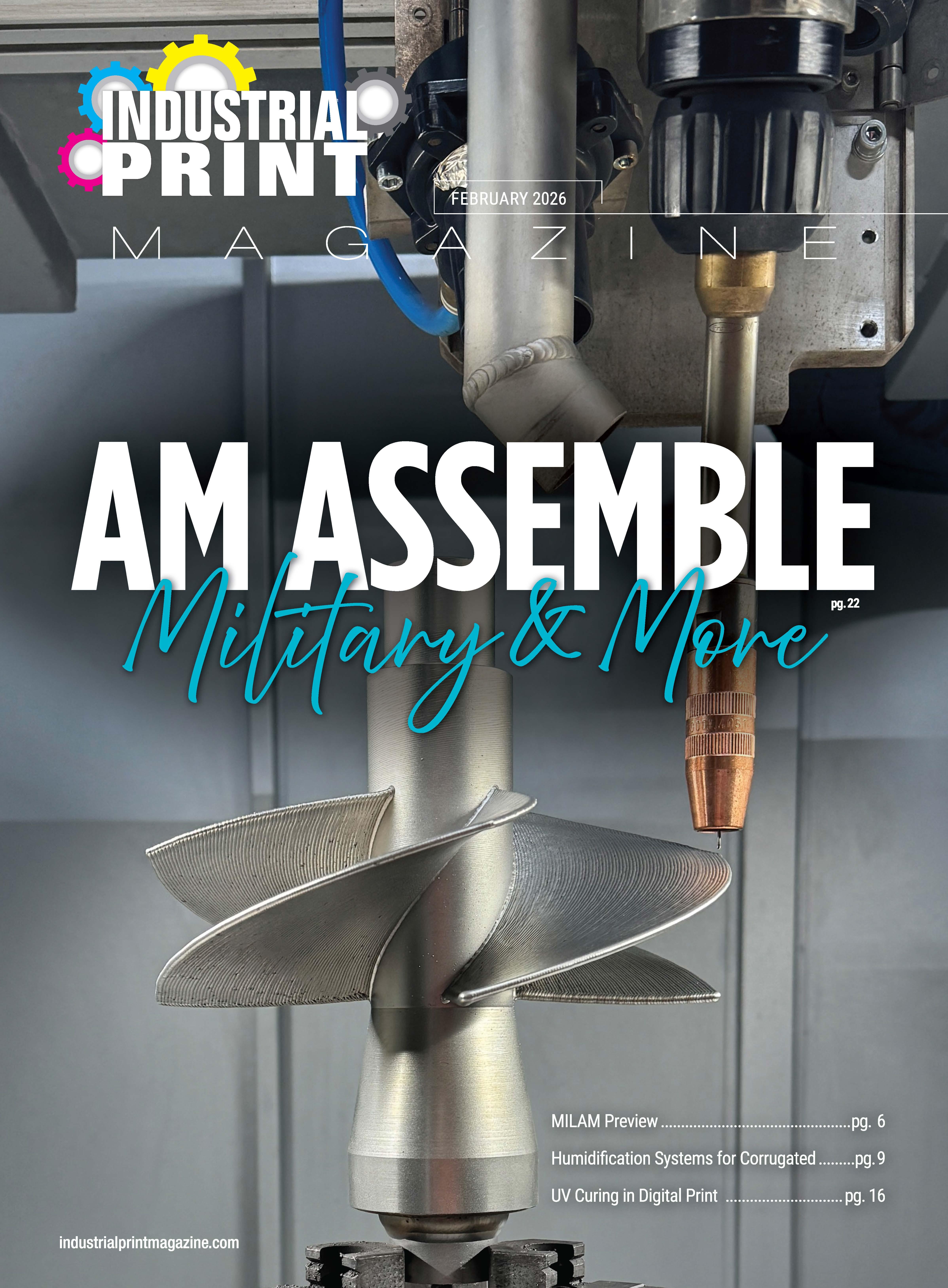

The tenth annual Military Additive Manufacturing (MILAM) summit and technology showcase takes place February 3 to 5, 2026 in Tampa, FL at the Tampa Convention Center. Hosted by the Defense Strategies Institute (DSI), it is billed as the largest military, aerospace, defense, and warfighting three-dimensional (3D) printing event in North America.

At MILAM, attendees have the opportunity to network with key decision makers in the military and government as well as AM industry experts. Speakers guide discussions on accelerating the integration of AM into military vehicles like ships and aircrafts, utilizing 3D printers to rapidly scale production of items such as drones, and driving joint force readiness through AM integration in the logistics enterprise.

Beyond educational opportunities, the event hosts an exhibit floor with over 150 vendors ready to share the latest technologies in action.

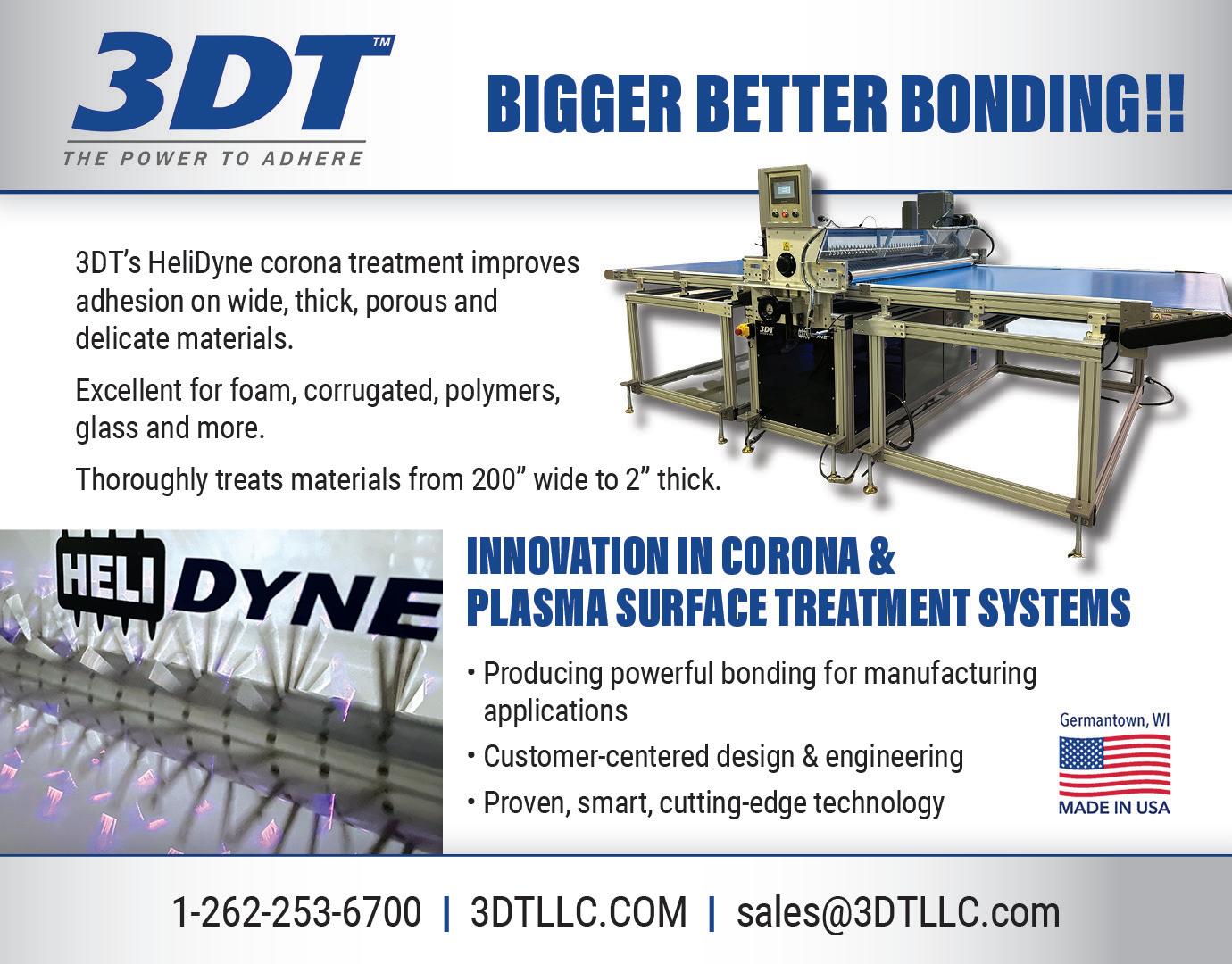

3D Systems, booth 619, offers a broad portfolio of hardware, software, materials, and service solutions spanning from plastics to metals, and is backed by industry-specific engineering expertise in its Application Innovation Group. The company takes a consultative, application-focused approach to solving customers’ most difficult design and production challenges. The combination of its solutions, expertise, and innovation helps customers eliminate conventional manufacturing limitations and maximize the value of AM to their organizations. INFO# 170

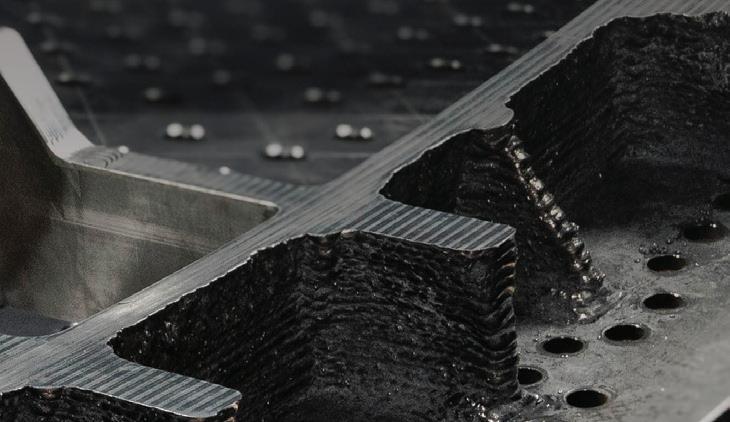

Caracol, booth 109, spotlights its Vipra AM, Caracol’s metal AM process engineered for large, complex, and structural components and Heron AM, the company’s robotic composite platform for producing large, high-performance parts. Particular emphasis is placed on Caracol’s metal AM capabilities, highlighting process efficiency and the ability to deliver high-strength parts,

functional prototypes, and tooling aligned with the strict requirements of aerospace and defense programs. Caracol presents its extensive track record in delivering industrialized parts and solutions in transportation fields, including shipbuilding, rail, and automotive, showing how these capabilities translate into scalable, performance-driven solutions for aerospace and defense supply chains. INFO# 171

Conflux, booth 606, features its latest range of AM heat exchangers engineered for aerospace and land-based defense systems. The portfolio spans liquid–liquid, gas–liquid, gas–gas, cold plate, and two-phase architectures, demonstrating Conflux’s capability to manage any two-domain or multi-domain thermal system. By leveraging AM, each design optimizes flow distribution, enhances heat transfer efficiency, and reduces pressure drop, enabling compact, lightweight solutions that integrate easily within dense system envelopes. Component geometries are tuned for specific operating envelopes, ensuring stable performance under

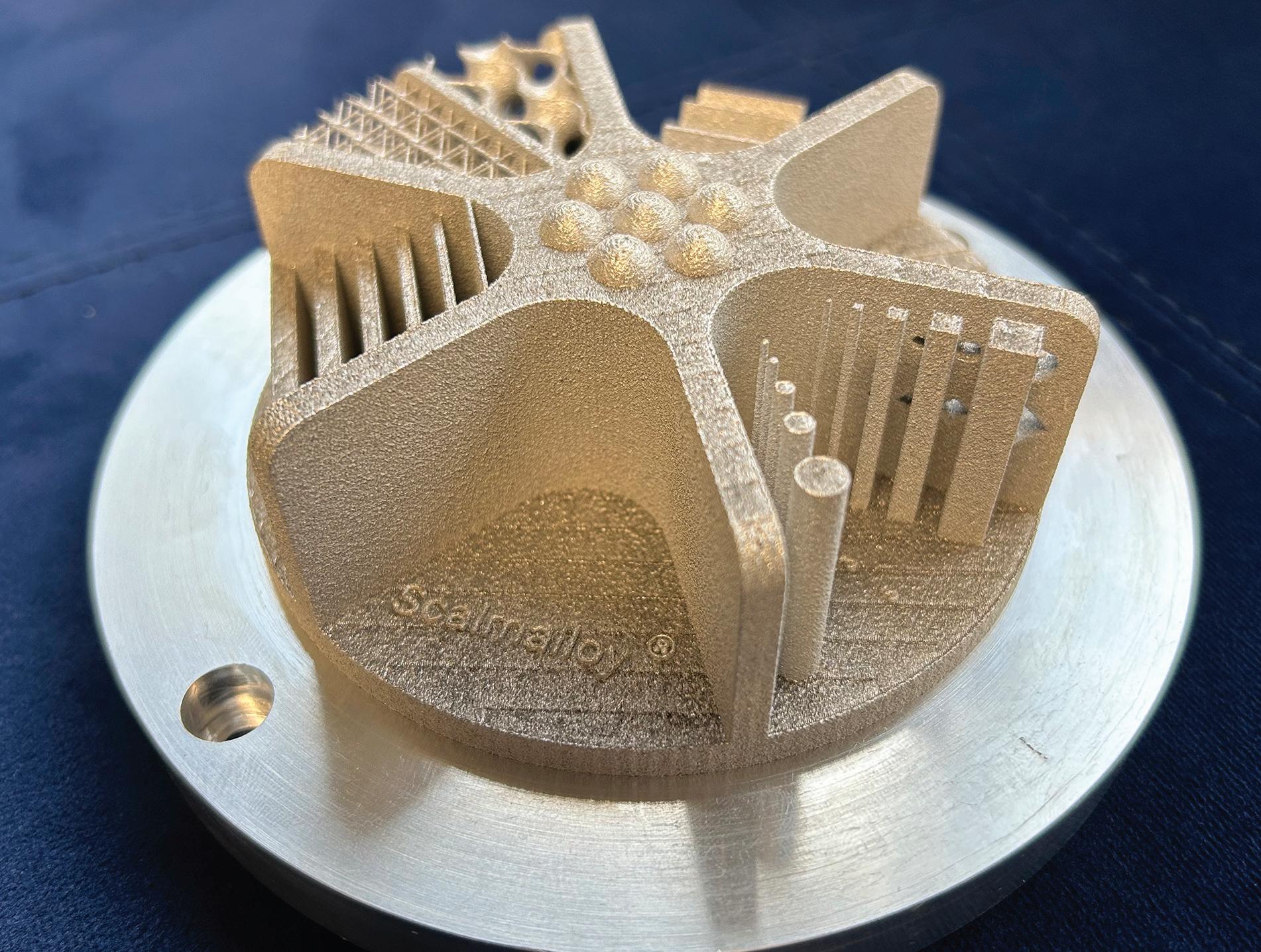

1. Equispheres, booth 318, showcases new advancements in specialized alloys, including its collaboration with APWORKS on the development of North American production of Scalmalloy, an aluminum-magnesium-scandium alloy.

high heat flux and dynamic flow conditions. Through this integrated design and manufacturing approach, Conflux delivers compact, high-reliability thermal solutions that meet the rigorous performance and environmental demands of contemporary aerospace and defense platforms. INFO# 172

EDM Network, booth 100, in addition to offering the largest selection of fast (moly) wire EDMs, now offers both vertical, as well as horizontal, fast wire EDMs that are made in Taiwan. It provides three models of four-axis vertical fast wire EDMs, with 450x300x450, 650x500x650, and 800x600x800 millimeter (mm) cutting capacities. For the compact horizontal FC models that cut inverted build plates submerged in water, it offers build plate sizes of 250x250, 400x400, and 625x625 mm.

All of its EDMs include free, on-site training at the customer’s lab. INFO# 173 Equispheres, booth 318, develops technologies for the production and deployment of advanced metal powders in AM. The Equispheres portfolio of aluminum and copper powders enables the serial production of lightweight, complex components for aerospace and defense applications. Engineered for performance and reliability, Equispheres powders support faster, more economical laser powder bed fusion (L-PBF) processing while delivering consistent mechanical properties across builds. This year, the Equispheres booth showcases new advancements in specialized alloys, including its collaboration with APWORKS on the development of the North American production of Scalmalloy, an aluminum-magnesium-scandium

alloy with excellent corrosion resistance, strength, and ductility—ideal for structural parts from lightweight brackets to satellite components. Attendees also learn about Equispheres’ oxygen-free copper powder, featuring high sphericity, ultra-thin oxide layer, and tightly controlled PSD—ensuring efficient L-PBF processing and high conductivity in finished parts. INFO# 174

Impossible Objects, booth 727, revolutionizes military manufacturing with its composite-based AM (CBAM) technology. The CBAM-25 industrial 3D printer produces mission-critical parts 15 times faster than traditional methods, delivering unparalleled strength and lightweight performance using advanced materials like carbon fiber and PEEK. Trusted for its precision and reliability, Impossible Objects enables the production of durable

components for drones, aerospace, and defense applications. INFO# 175

JEOL USA, booth 520, promotes its electron beam powder bed fusion technology that leverages over 70 years of electron optics expertise, which enables the JAM-5200EBM printer to produce high-quality, reproducible parts for series production in a variety of applications, with numerous advantages for metal 3D printing. INFO# 176

Materialise,booth715,showcaseshow Materialise CO-AM-an open and secure software ecosystem-enables the supply base to achieve mission-critical goals in AM. With built-in encrypted file delivery, CO-AM safeguards data transmission directly to the machine, ensuring last-mile security even in the most challenging environments. From in-theater, distributed manufacturing to secure spare parts IP for on demand sustainment, Materialise CO-AM software ecosystem gives defenseteamsadecisiveoperationaladvantage. INFO# 177

NIDEC Machine Tool America, booth 107, is a leading global provider of precision machine tools and manufacturing solutions. The LAMDA series of laser powder direct energy deposition AM systems offers accurate, large-scale 3D printing capabilities.

2. Materialise, booth715,showcaseshowMaterialise CO-AM-anopenandsecuresoftwareecosystem-enablesthesupplybasetoachievemission-criticalgoals inAM.

Utilizing a sophisticated local shield system, it prints reactive materials without the need for an environmental chamber. NIDEC's advanced monitoring and feedback system, coupled with AI-driven anomaly detection, ensures a stable and precise printing process. By collaborating with NIDEC OKK, PAMA, and TAKISAWA, the companydelivers high-quality, efficient machine tools that serve diverse industries worldwide. INFO# 178

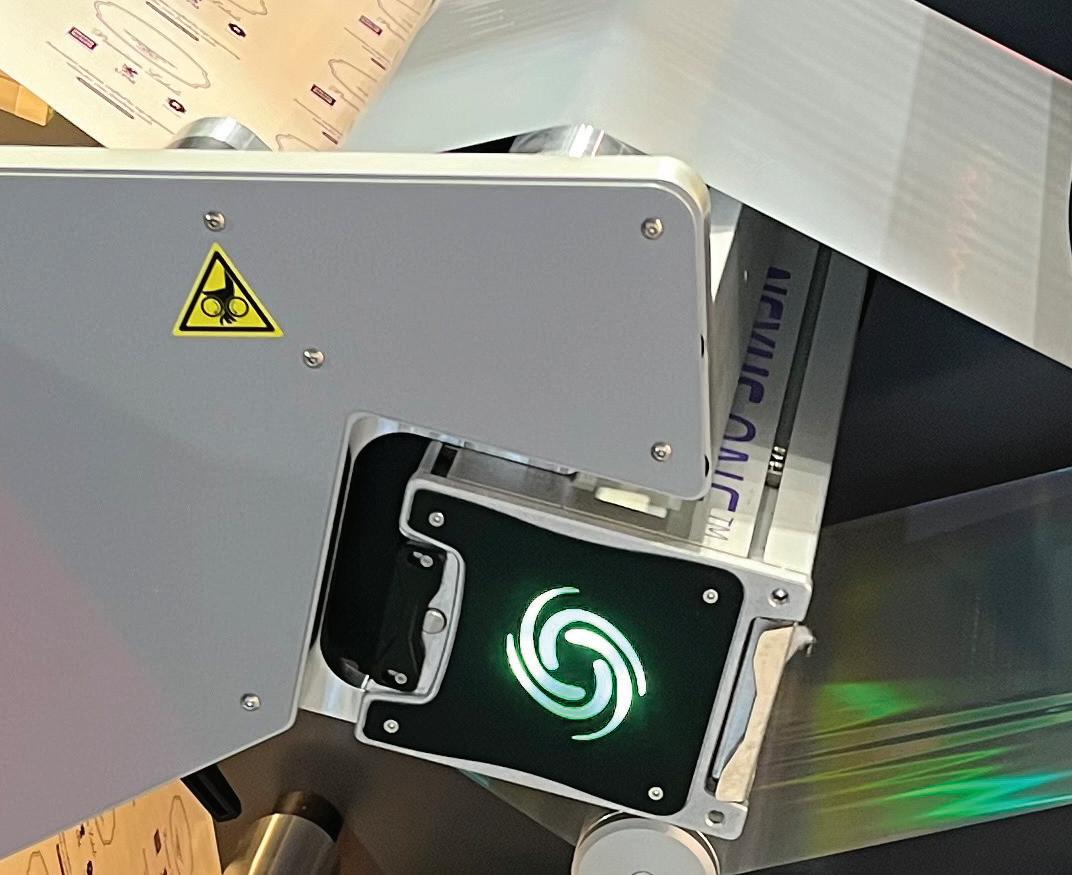

Nikon SLM Solutions, booth 201, is a globalproviderofintegratedmetalAMsolutions. It is home to some of the world's fastest metal AM machines boasting up to 12 lasers. With a portfolio of systems to suit everycustomer's needs, along with its team of experts closelycollaborating at everystageoftheprocess, NikonSLMSolutions leads the way on return on investment with maximum efficiency, productivity, andprofitability.

INFO#179

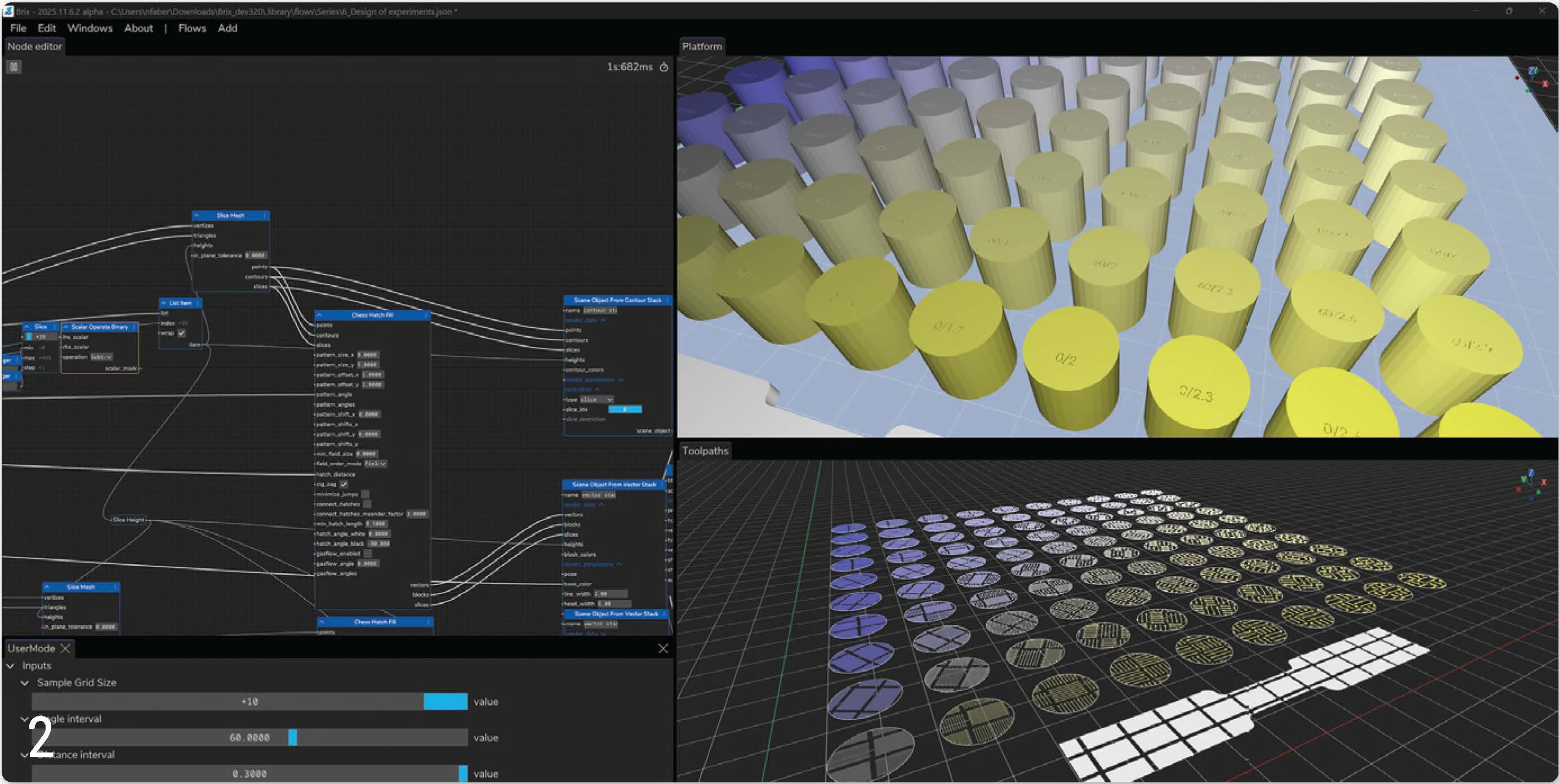

Senvol, booth 307, promotes Senvol ML, a data-driven machine learning software for AM that is used to accelerate material and process development. The software helps optimize AM process parameters, qualify AM machines and materials, predict material properties, gain insights from in-situ monitoring data, leverage preexisting data, and minimize data generation costs. INFO# 180

Stratasys, booth 301, returns as the lead sponsor for MILAM for the second consecutive year, reinforcing its commitment to advancing defense manufacturing.

It showcases technologies addressing Department of Defense requirements for manufacturing, including MRO and spares, low-cost drone production, and industrial shipbuilding using fused deposition modeling (FDM), selective absorption fusion (SAF), and programmable photopolymerization (P3) platforms. On displayis the F3300 (FDM), H350 (SAF), and Origin Two (P3), demonstrating production-ready solutions for missioncritical applications. Attendees can see enhancements to GrabCAD Print Pro, including FixtureMate, which automates fixturedesignwithoutCADexpertise, and new silicone material for P3, expanding capabilities for defense and aerospace. Stratasys continues to lead innovation that empowers readiness and operational efficiency. INFO# 181

Thermwood, booth 210, showcases advanced large format manufacturing capabilities, including a pair of precisionmachined drone molds and examples of cut layer additive parts.Attendees explore howThermwood'sinnovativelargeformat additive solutions from its large-scale AM line support efficient production of industrial tooling, fixtures, patterns, molds, and other large composite structures. The booth also highlights Thermwood's three- and five-axis CNC router technology, engineeredfordemandingaerospace, composite, and advanced manufacturing applications. Thermwood representatives are available throughout the event to discusssystem capabilities, material options, workflowadvantages, andhowthesetechnologies help manufacturers streamline production, reduce costs, and accelerate time to market. INFO#182

DSI is designed to advance the mission criticalgoalsoftheU.S.militaryandgovernment through high-level educational training summits and symposiums like MILAM. The February event kicks off a year-long collection of learning opportunities./PM

by Cassandra Balentine

Integrated technologies are increasingly adopted to support humidification in digital corrugated printing environments.

“In the past, humidity readings were displayed on a unit- or wall-mounted display, and operators would check them periodically. Today, facilities take a more integrated approach—collecting humidity data across the production floor, linking it to print quality and performance metrics, and using that information to maintain tighter control of the environment,” suggests Dave Schwaller, senior application engineer, DriSteem.

Advancements in humidification, including better integration opportunities, offer benefits like purposeful data, more sensors, better visibility, and automatic control.

“By integrating humidity and temperature data with production performance metrics, operators can directly correlate environmental conditions with print quality issues. This allows teams to fine-tune humidity settings based on actual results, improving consistency and minimizing waste, especially where precise moisture addition is critical to print quality and board stability,” explains Schwaller.

This approach is especially valuable when using adiabatic humidification systems, which Schwaller says are commonly selected in print facilities not only for their natural cooling effect, but also for their ability to humidify different zones independently—allowing the feeder, print deck, drying section, and stacking area to each receive the required conditions.

Facilities now place humidity and temperature sensors at key points along the production line, as well as in supply and

return air ducts. Schwaller points out that this strategy of more sensors in more places helps operators capture small climate differences caused by airflow, heat from the equipment, and seasonal changes, which are important for optimizing localized adiabatic mist absorption.

It also offers better visibility into water quality and system health. Performance in high-pressure atomizing systems depends heavily on water quality. “By monitoring factors such as filtration condition, scale potential, and water purity, operators can prevent nozzle wear or clogging, maintain fine droplet quality for fast absorption, and reduce unexpected maintenance,” states Schwaller.

Additionally, modern high-pressure atomizing humidification systems modulate output gradually and precisely and can communicate with building management systems for centralized monitoring and control.

Over time, humidification will become fully integrated with plant building and production management systems…

— Dave Schwaller, senior application engineer, DriSteem

“This prevents sudden

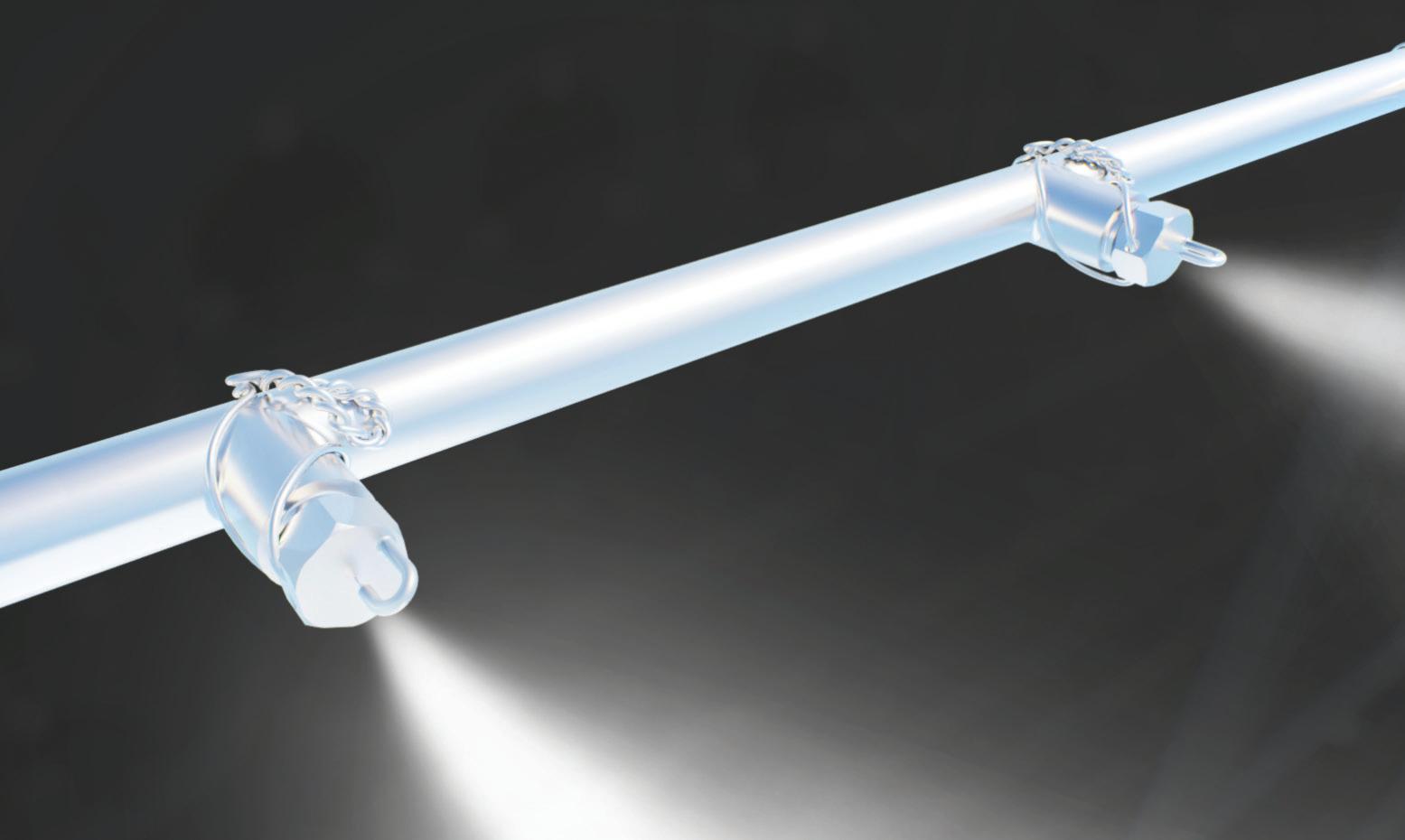

1. The MeeFog system delivers filtered water at 1,000 psi via a ceiling-mounted piping network. Fog nozzles convert water into fine mist for accurate humidity control.

humidity swings that cause issues such as print banding, paper curl, or loss of board strength,” says Schwaller. Beyond sensors, several important challenges are related to digital printing on corrugated paper, including the challenge of maintaining the optimum level of humidity to avoid the potential for board warping and poor ink transfer/adhesion. “As corrugated paper is absorbent, the ink can soak in too deeply, resulting in the dulling of colors and prints that lack vibrance,” notes Thomas Mee III, CEO, Mee Industries Inc.

A key factor in maintaining a constant level of humidity in a printing environment is proper distribution of the humidification system throughout the facility.

Compressed air, electric steam, and ultrasonic humidification systems typically provide humidification control in certain parts of the room. “This causes some areas to be too dry and others to be too humid. MeeFog addresses this problem by evenly spacing humification nozzles throughout the room to deliver uniform humidity,” offers Mee.

The industry is steadily moving toward closed-loop control where the humidification system adjusts based on real conditions at the press, not just a single room average. This helps maintain more

stable board moisture levels, supporting consistent color, reducing warp, and improving stacking performance. “Over time, humidification will become fully integrated with plant building and production management systems, enabling the system to anticipate changes, make proactive adjustments, and signal maintenance needs before issues occur,” predicts Schwaller.

Mee feels that the digital corrugated or hybrid print environment of the future will also take advantage of high-pressure fogging to accurately control humidity levels across the entire room. This is achieved via nozzle distribution tailored to the space and the needs of the printing equipment and through the use of the right kind of nozzles.

“Such a system has a humidity setpoint ideal for that production line and can hold closely to that setpoint regardless of bay doors being left open or other factors that might influence building humidification,” offers Mee.

Humidification systems for corrugate print environments adjust to demands.

Adiabatic humidifiers are an efficient option for digitally printed corrugated environments. “These systems use the heat already in the air to evaporate a fine mist of water. As the droplets absorb and evaporate they add humidity and produce a natural cooling effect. This can reduce the load on mechanical cooling equipment, resulting in energy savings while maintaining stable printing conditions,” shares Schwaller.

DriSteem’s Adiatec high-pressure atomizing system is designed for facilities that need different humidity levels in separate parts of the production area. Each zone—such as the print deck, feeder, or stacking area—can be controlled independently. This targeted approach helps maintain consistent print quality, avoid board warp, and support smooth stacking and handling.

The Adiatec high-pressure atomizing system works with DriSteem’s Vaporlogic controller, which continuously monitors conditions and adjusts the output so the mist is absorbed quickly and effectively. It can also connect to building and production control systems through Modbus, with optional BACnet or LonTalk integration, allowing quick adjustments and centralized supervision. The result is efficient, stable humidity control that supports consistent print quality and reduces cooling energy demand.

Schwaller says water treatment is also key to keeping humidification systems running reliably. Minerals in untreated water can lead to scale buildup, clogged nozzles, and inconsistent performance—issues that are especially problematic in digital printing areas where cleanliness and stability matter.

DriSteem offers integrated water treatment solutions, including reverse osmosis and filtration, to ensure a clean, consistent water supply. This helps protect equipment, reduce maintenance, and prevent mineral residue in the production environment, ultimately supporting both uptime and print quality.

The MeeFog system delivers filtered water at 1,000 psi via a ceiling-mounted piping network. Fog nozzles convert water into fine mist for accurate humidity control. Each MeeFog impaction-pin nozzle is made from high-grade stainless steel.

Mee says the standard nozzle features a 0.006 inch—150 micrometer— diameter orifice that produces billions of ultra-fine droplets per second. Droplet size averages around 20 micrometers, or one tenth the diameter of a single strand of human hair. This system uses one horsepower of energy for every 500 pounds of water dispersed.

“This is roughly eight percent of the energy usage of ultrasonic systems and about five percent of the energy required by compressed air systems. Thus, the nozzles use a tiny fraction of

the water compared to alternative systems,”

Dixie Consumer Products opened a new 6,300 square foot printing facility in Lexington, KY. The company specified that 45 percent relative humidity be maintained at all times to prevent paper distortion and assure that production targets would be met by minimizing rejects.

MeeFog ceiling-mounted nozzle lines were strategically distributed for best

coverage across four plant zones. The result was precise, evenly distributed humidity, improved product quality, and better press consistency and ink transfer. Tight humidity control proved especially important during the colder and drier winter months as this helped the company to maintain board moisture and avoid distortion.

The system consisted of a MeeFog 2500 MFP rack with a pump that outputs up to five gallons per minute, supplying high-pressure fog to four zones

at the facility through independent valves. An onboard variable frequency drive conserves energy by adjusting power output based on active zones, reducing operational costs. Each of the four production zones in the plant can operate independently, allowing precise humidity control tailored to specific processes.

Carel Industries offers a range of steam as well as adiabatic humidifiers. Its adiabatic systems are designed to control humidity and cool the air simultaneously, ensuring minimum energy consumption.

Condair Inc. has a comprehensive range of products to meet printers’ needs. It offers full service expert advice, design, supply, installation, commissioning, maintenance, and spare parts. Products are available as isothermal or adiabatic systems.

DriSteem’s Adiatec high-pressure system is designed to offer both evaporative cooling and humidification for multiple zones. This allows for the customization of humidity levels in different areas, providing precise control and comfort throughout the entire space.

Finestfog produces high-pressure humidification systems as well as reverse osmosis systems.

GoFog, Inc.’s in-house experts can design, engineer, and install one of its

humidification systems, which offer the highest levels of performance.

Humidifirst Inc. manufactures ultrasonic humidifiers like its patented Mist-Free series. They are ideal for humidification needs where visible mist is objectionable, such as laboratories, small hospital equipment rooms, computer rooms, office areas, and low ceiling printing rooms.

Hydrofogger has sold to commercial printers since 2005. It offers affordability, ease in installation, and an overall simple operation, which means a long lifetime of service.

MeeFog systems utilize a network of FogStat humidity sensors to ensure desired humidification levels. According to Mee, a MeeFog system designed for 1,000 pounds per hour output, running 3,500 hours per year, costs around $700 per year to operate, compared to $14,350 for compressed air atomizers and $128,800 for electric steam humidifiers. “That’s up to 180 times less energy use while delivering the same humidity output,” says Mee.

Merlin Technology Inc. offers customized humidification solutions in the print space. All Merlin humidification systems are designed to be integrated into existing climate systems as well as to be implemented as standalone solutions.

Smart Fog’s signature ES100 is touted as an efficient solution for direct space humidification, while the TS100 integrates self-evaporative technology into new constructions and existing duct systems, and the ES100M puts all the benefits of its signature ES100 on wheels.

Integrated humidification systems help print providers maintain a consistent level of humidity based on real-time data. This is essential to ensuring the environment is ideal for corrugated print in digital and hybrid operations. IPM

For the décor sector, brilliant colors, high resistance levels, and customized designs such as digitally structured products in the wood-based materials industry are achievable only with precisely tailored UV technology. “For this reason, we focus not only on UV curing systems themselves but also on developing new UV applications in close collaboration with our partners, creating tangible added value for customers,” shares Davis.

The advantages of UV LED technology are particularly clear in manufacturing environments. This includes switchability, compact system size, and ozone-free operation. “This allows not only paints, inks, and varnishes to be cured inline, but also UV adhesives, all within a minimal footprint,” notes Davis.

Curing technology is evolving from standalone light sources to modular,

networked process units that integrate seamlessly into digital production environments, says Lin. Smart UV systems now leverage process data analytics, predictive maintenance, and real-time adaptive control, transforming curing into an intelligent and connected manufacturing function.

Hoge notices increased automation and the employment of smart machines and smart factories with informed data helping to produce goods more efficiently and productively across the value chain. “By collecting more data from the factory floor and combining that with other operational data, a smart factory can achieve information transparency and better decisions.”

Customers require process control via real-time monitoring of UV LED curing lamps to better support Industry 4.0

manufacturing. “Many of them run ‘dark factories’ that have no lights or no humans during processing, so 24/7 remote performance monitoring is key. Even in facilities with human operators, customers want to be notified about curing issues immediately,” says Hoge.

Lin believes modern UV systems deliver higher output, greater dose intensity, and faster curing cycles, supporting high-speed printing and manufacturing, while compact modular designs allow more flexible installation, shorter setup times, and reduced downtime.

As artificial intelligence advances, it is able to better track ROI, including cost savings, efficiency gains, and environmental impact for printers. “It will also be able to give some guidance on the best technologies to use for printers,” suggests Hoge.

Automation in curing is increasingly driven by the need for repeatability, energy efficiency, and operator ease of use.

Mark VandenBosch, technical sales, IST America, says IST’s SMARTcure system allows operators to save and recall UV settings for recurring jobs, ensuring consistent performance and reduced setup time.

“For LED systems, SMARTcure can detect substrate width and dynamically shut off unneeded modules, reducing power consumption without sacrificing cure quality. This type of intelligent automation aligns with broader industry trends around sustainability, process control, and reducing operator dependency,” adds VandenBosch.

Implementing software helps to integrate prepress, printing, and finishing for seamless operation. In addition to increasing efficiency, Stacy Hoge, marketing manager, Excelitas, sees automation utilized for quality control. “Artificial intelligence (AI) powered inspection systems are being used to detect defects in real time, reducing waste and improving quality.”

It also plays a role in sustainability. “AI will help reduce waste and decrease carbon footprints by detecting predictive maintenance and dynamic scheduling,” foresees Hoge.

Hoenle Americas Inc.’s UV LED systems are already Industry 4.0-compatible. Chris Davis, director of sales, Hoenle Americas, points out that format switching, clocking, and individual intensity control for each LED array open new possibilities when these

Curing requirements change as digital print moves into industrial areas beyond paper-based products.

Also, as digital printing expands into industrial and decorative applications, substrate diversity presents new curing challenges. “Filmic materials, which are widely used in consumer goods and flexible packaging, often require enhanced adhesion and surface hardness. UV inks generally outperform water-based or solvent-based inks in these areas, offering both higher gloss and greater durability,” states VandenBosch.

Higher durability and functional requirements come into play. “Industrial products often require more than surface curing; they demand scratch resistance, chemical resistance, weatherability, or

features are utilized. “Provided that the information is supplied by the customer’s machine, the LED modules could switch individual LED segments on/off and vary the power/intensity of the LED segments depending on the print image. So energy consumption is targeted and the maximum level of efficiency.”

When it comes to after-sales service, Davis says predictive maintenance contributes to running production processes reliably. Collection and evaluation of real-time data from the UV LED system is expected to be used more frequently in the future. Data such as currents and the temperatures of the LED arrays are read out and used to plan maintenance activities on the machine rather than risking downtimes.

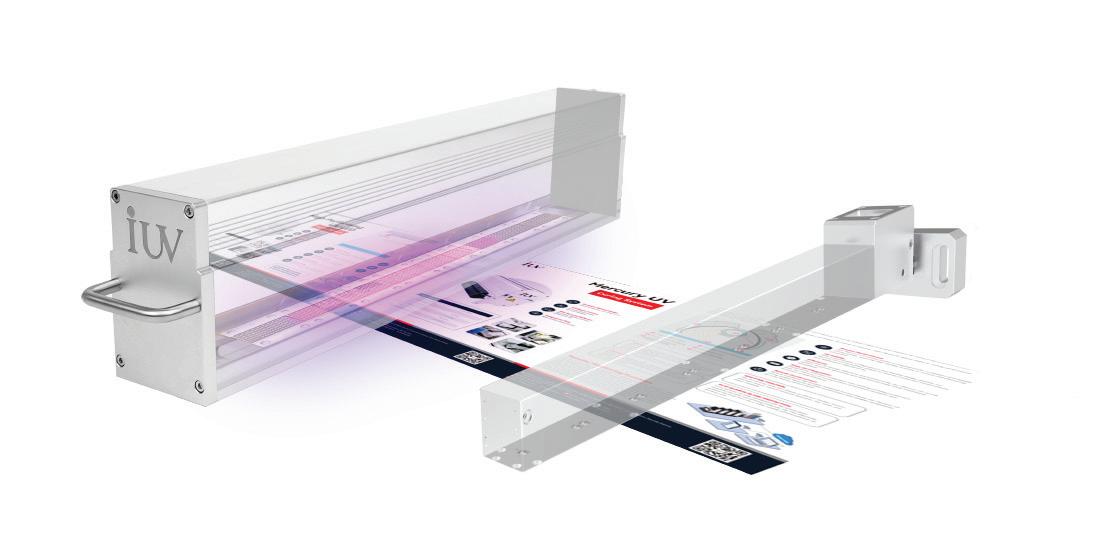

Peter Lin, CEO, IUV, feels that automation technology is rapidly expanding in UV curing and digital printing production systems. Its core objectives are to achieve higher production consistency, reduce manual intervention, and optimize energy efficiency. “In UV curing, automation goes far beyond simply 'replacing human labor,' it is evolving into the central nervous system that enhances the precision, efficiency, and reliability of the entire production process.”

Lin says automatic adjustment of UV source power and exposure time ensures consistent curing and prevents over- or under-curing.

Automation is also used for material recognition and parameter matching, production line integration and synchronized control, equipment status monitoring and maintenance, and energy and quality optimization, concludes Lin.

specific functionalities—conductivity, anti-fouling, and antimicrobial properties. Curing systems must ensure high cross linking, mechanical performance, and chemical stability to meet industrial standards,” offers Lin.

Increased press speeds also require more power from the UV curing light source. “Having enough power is crucial to the curing process. This is where peak irradiance and energy density (dose) come into play. A minimum threshold of irradiance is needed to start the polymerization process, and then a dwell time of dose is needed to finish the curing process. Both high irradiance and energy density are required for a successful cure,” explains Hoge.

Davis says digital printing with UV today relies almost entirely on UV LED

inks, whereas conventional UV inks were previously common. “UV LED technology has now reached sufficiently high peak intensity levels, meaning that further development is focused less on increasing peak intensity and more on achieving a higher overall UV dose. This is accomplished through wider emission windows in UV LED systems, resulting in greater energy input. This trend is particularly evident when printing on closed or non-porous substrates. At the same time, the reactivity of inks and varnishes has generally improved.”

The adoption of digital print encourages advancements in UV and UV LED curing technologies and inks to support more substrates and applications. IPM

crucial advantages in aerospace and defense settings where every millimeter and gram matter,” explains Ben Batagol, commercial lead in North America, Conflux Technology.

Another technology is AM electronic (AME) printers, which Dr. Kenneth Church, CEO, nScrypt, says has the potential to make anything that is 3D printable smart.

“Electrically functional 3D structures will open the door to next-generation electronic packaging. For decades, planar packaging and stacking have been the norm, but AME is introducing shaped electronics that have the potential to impact electronics in much the same way AM transformed nozzles, shoes, hearing aid molds, dental aligners, and even buildings,” continues Church.

The increased adoption of AM in defense and military is influenced by advancements in the technology—hardware, software, and materials. Performance and reliability are non-negotiable and AM delivers.

Shnell points to strides in ease of use, consistency, and material capability as key to the AM technology growing in use in military and defense applications. “Systems that once required deep expertise are now far more automated and reliable, enabling high-quality output with minimal oversight. At the same time, improvements in process stability and advanced materials expand the range of applications AM can realistically support, making it a far more practical tool for real-world industrial and expeditionary environments.”

“AM also enables the production of higher complexity, higher functionality parts that would be impractical or impossible using traditional methods,” notes Poorganji.

With defense and aerospace applications demanding strength, precision, and reliability under extreme conditions, today’s large format AM systems are ideal because they are equipped with advanced thermal management and hightemperature mechanical performance, says Smith.

Suppressors are a prime example of progress in AM. “This application has seen substantial growth in recent years, largely due to the design flexibility, rapid prototyping, and performance optimization afforded by AM,” attests Spragg.

Hoppe says certain technologies help create more autonomy in the defense and military sectors. For example, Meltio’s wire-laser metal 3D solutions provide the opportunity for creating and repairing metal parts. The Meltio Robot Cell can print and repair metal parts in an enclosure solution including a robotic arm integrating with Meltio Engine.

AM materials have expanded and processes have matured, offers Church. “One advantage, a digital input or CAD file can be turned directly into a physical object. Another, the complexity that exists in a CAD file now exists in the printed part. Intricate patterns that dictate electronic performance are modeled and then printed.”

“AM has evolved from a prototyping tool to a practical means of maintaining and extending the life of complex assets. Defense organizations increasingly use it to decentralize production and shorten lead times for replacement parts and maintenance tools. Furthermore, digital part libraries and simulation-driven design are allowing engineers to validate, optimize, and replicate parts globally with complete accuracy,” continues Middleton.

Batagol agrees that AM is now reliable in production environments, moving far beyond its roots in rapid prototyping. “It’s now a proven production technology capable of delivering fully qualified hardware that meets demanding industrial standards. The machines themselves are faster and more consistent, which shortens design cycles and accelerates the ability to do testing and iterations. This maturity is one reason the technology is being adopted for defense platforms, where performance and reliability are non-negotiable.”

“Beyond speed, AM allows functional improvements such as integrated cooling channels or mixed-material designs, which enhance performance. The technology also delivers significant material and cost savings, making it both efficient and sustainable,” adds Recke.

AM is currently changing the manufacturing of military-type products and will continue to do so. It not only radically shortens supply chains, but also eliminates storage of parts.

The biggest transformation is the shift toward decentralized manufacturing, according to Recke. “Military units can produce critical components close to the field, dramatically reducing lead times and logistical complexity. This flexibility ensures that urgent demands can be met quickly, while simplifying supply chains and improving operational readiness.”

“AM plays a growing role in new weapon systems, sustainment activities, and on demand production. The ability to print parts at or near the point of need strengthens readiness, reduces logistical dependence, and offers resilience against supply chain disruptions. As a result, AM is becoming an essential capability within next-generation defense manufacturing strategies,” says Poorganji.

It’s an on demand model that eliminates long supply chains. “Instead of waiting on traditional logistics, units can produce certified replacement parts on demand, simplifying support and sustainment. This aligns directly with the Department of Defense’s (DoD’s) growing emphasis on right-to-repair and organic maintenance capability. AM is quickly becoming the primary driver of that shift, giving military units the ability to keep critical systems operational without relying on long, fragile supply lines,” explains Shnell.

“In the near term, this means broader adoption of localized production units, including mobile or deployable setups, that can support maintenance and repair directly in operational contexts. The result is a more adaptive model of manufacturing that strengthens readiness and reduces logistical risks,” points out Middleton.

Mobile AM production cells allow parts to be made closer to where they

are needed, reducing downtime and supply chain risk. “At the same time, AM enables onshoring of key components, giving nations greater control over the production of high-value defense assets. The benefits are tangible—AM allows for faster innovation cycles, where smaller design improvements are made more frequently. That agility is increasingly important for defense programs that need to adapt quickly to evolving operational requirements,” says Batagol.

“The military recognizes the speed at which new concepts can be produced. They also see that old parts can be replaced with identical ones without needing a warehouse full of spares. The concept of storing a CAD file for a part and printing it anywhere in the world is more than intriguing, it is life saving,” states Church.

This principle can be applied to electronic repair. “Repairing or replacing legacy boards from a digital file with an AME printer is impactful in terms of time, cost, and mission readiness. This is the future of military logistics,” adds Church.

AM is also “an effective solution for legacy part reproduction, particularly when original tooling or manufacturing

methods are no longer available or cost effective,” notes Smith.

“The most common advantages of AM include weight reduction and accelerated deployment times. Through innovative design strategies, AM enables the production of lighter components that enhance portability and ease of deployment. Additionally, the ability to manufacture parts rapidly allows critical components to be produced and delivered to operational areas much faster than with conventional manufacturing methods,” adds Spragg.

AM provides “freedom of design to iterate and innovate applications within days instead of months,” argues Homa. However, “for military decision makers, the superior agility of AM production units for on demand, on-site supply of critical spare parts in the field is the real pull for AM into defense.”

And this is specifically where ceramic AM steps in “to redefine how refined and fast ceramic sensors, radomes, ceramic cones, or thermal management applications for the cooling of advanced propulsion systems are created. Even more intricate features needed and only achievable via LCM technology are complex internal channels, functional porosity gradients, and fully optimized cooling structures,” adds Homa.

Despite the advancements and growth in this sector, challenges continue to pop up and must be addressed.

Shnell suggests that the biggest challenges now center on standardization, secure access to parts, and ensuring consistent, repeatable output. “The DoD needs a way to reliably source the right technical data, maintain chain of custody for controlled parts and intellectual property, and trust that printed components will perform the same way every time—regardless of who is operating the printer or where it’s deployed.”

“Manufacturers address this by building secure digital part libraries, embedding traceability and authentication into the workflow, and developing highly automated systems that reduce operator variability. At the same time, there’s a major push toward scalable, repeatable architectures so the military can deploy AM capability across units of all sizes without sacrificing quality or control,” adds Shnell.

Poorganji agrees that process stability and repeatability is an issue, in addition to the qualification of machines, materials, and processes, as well as industry-wide standardization. Scalability, supply chain reliability, and secure vision control are also critical.

“Key challenges include ensuring part performance, managing material quality, and maintaining data security. Every component printed for defense use must meet strict functional and safety requirements,” shares Middleton.

Part of meeting requirements means creating some type of industry-wide standardization, which Batagol says is ongoing. “Defense has traditionally used proprietary testing regimes, but organizations such as ASTM are making progress toward harmonized frameworks for AM parts. Another consideration is building a trusted production ecosystem that meets the defense sector’s evolving needs. AM suppliers, OEMs, and end users are now working more closely to establish transparent processes, from design to inspection, that can be validated under realworld conditions. This collaboration is key to increasing confidence and adoption in mission-critical programs.”

“Bottom line, speaking of reliability, scalability, flexibility, qualification, and supply chain resilience, it all comes down to one prime factor—only by delivering absolute excellence in quality, the AM industry will not only enjoy a short boom period in the military sector but successfully establish sustainable long-term partnerships built on mutual trust,” explains Homa.

Logistics is another challenge. “While AM reduces dependency on traditional supply chains, ensuring the availability of raw materials and maintaining equipment in remote locations requires careful planning,” notes Recke.

While AM from the top level is a mature technology—with consolidation between vendors common practice the last few years—Church sees AM leveling off and moving toward real applications and real impact. AME, however, is

still a new kid on the block and requires more understanding.

“One challenge we face in AME is the lack of maturity and understanding compared to traditional, well-established processes. Material sets are modified and electronic developers are uncomfortable with that. They frankly cannot think in 3D. Their mindset is still 2.5D—stacking. Early adopters can see the potential, but traditional manufacturers struggle. AME can handle smaller parts, more material options, and do what it is naturally made to do—fully use that third dimension. The pressure from electronic demand will drive this. Creativity from early adopters will move the needle,” continues Church.

The military and defense sector also faces the challenge of the shutdown or reduction of traditional casting and manufacturing facilities. The good news, Smith says, “is that AM can serve as both a replacement and an enhancement for casting processes, producing near-net-shape components that require minimal post processing. This not only streamlines the production workflow but also reduces material waste and scrap, improving overall efficiency and sustainability.”

AM is expertly poised to play a large role in manufacturing parts for the military and defense sectors. The technology is growing and changing, influencing how quickly and where items like sensors, thrusters, and casting cores are built.

Printing at point of need is the new reality. Mobile 3D production not only reduces downtime but eliminates risk. When it comes to high-value assets moving through the supply chain, a significantly shorter path of delivery is preferred.

“Military forces think and act in a highly agile way. Shorter lines of reinforcements and lean production are key to enhance dynamics. AM technologies meet this need by enabling faster, more flexible, and more resilient supply chains across air, land, and naval systems,” says Homa. IPM