BE AHEAD OF THE TIMES STAY HUNGRY FOR THE UNKNOWN AND WRITE YOUR OWN HISTORY. THAT’S WHAT WE DO.

Great people | Great instruments

BE AHEAD OF THE TIMES STAY HUNGRY FOR THE UNKNOWN AND WRITE YOUR OWN HISTORY. THAT’S WHAT WE DO.

Great people | Great instruments

A world where people with cancer live better and longer lives. That’s Pfizer’s vision. We are accelerating breakthrough cancer medicines that bring new hope to patients everywhere.

Pfizer is tackling one of the most challenging health crises of our time. Nothing is more urgent, or more personal, than our goal to outpace, outsmart, and outmaneuver cancer at every turn.

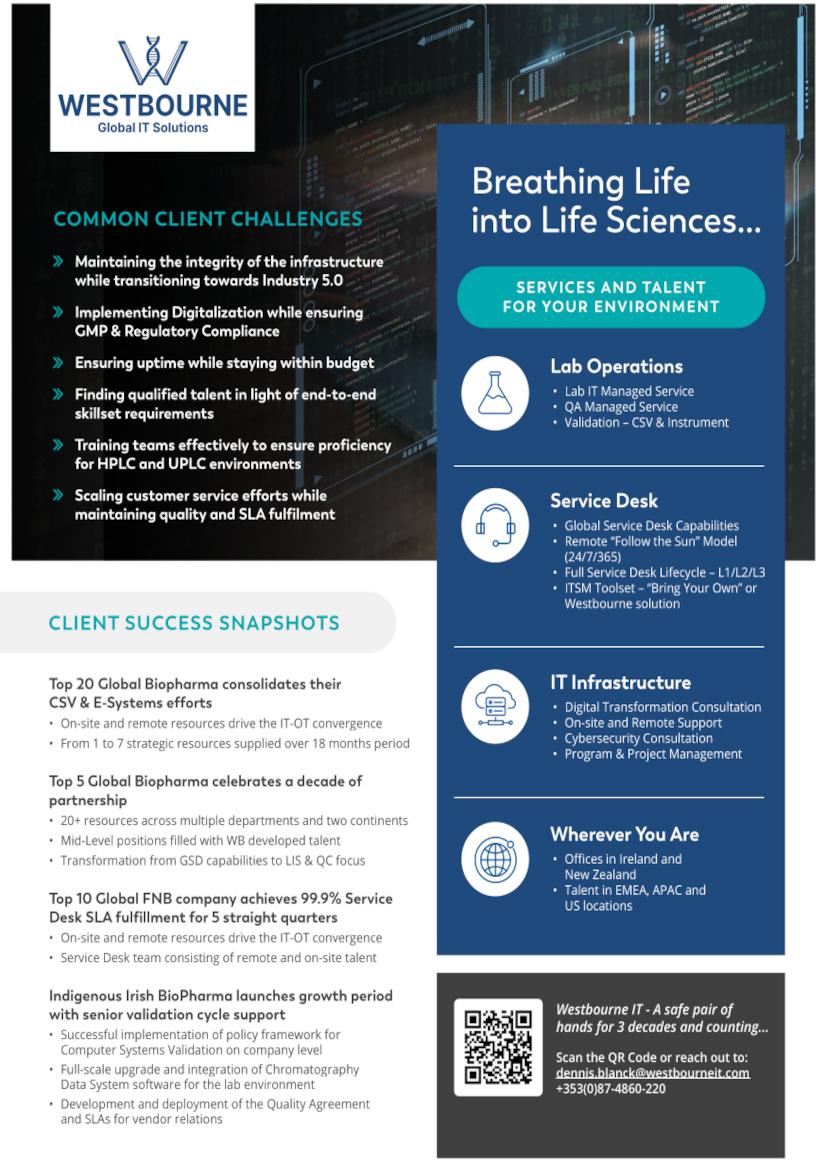

4 MINISTER’S FOREWORD

Minister Peter Burke underlines the Government’s commitment to enhancing competitiveness and discusses the development of Ireland’s National Life Sciences Strategy.

6 SECTORAL OVERVIEW

Sinead Keogh, Director, BioPharmaChem Ireland, reflects on a tumultuous year for Ireland’s BioPharmaChem sector, which displayed tremendous resilience in the face of global challenges.

12 NATIONAL LIFE SCIENCES STRATEGY

30 BIODIVERSITY

How the Lower Harbour Biodiversity Forum is creating a shared vision for Cork Harbour and restoring nature across Cork’s pharma cluster, by Michael Kilkelly, Senior Executive, EHS, BioPharmaChem Ireland.

33 BIOPHARMACHEM SKILLNET

2025 was a very successful year for BioPharmaChem Skillnet, including new programmes, exciting collaborations and respected award wins.

36 NIBRT

Lisa Goodman, Senior Public Affairs Executive, BioPharmaChem Ireland, provides the backdrop to the development of Ireland’s first-ever National Life Sciences Strategy and argues that to deliver targeted outcomes, the Strategy must be governed by a dedicated national Office of Life Sciences.

14 DIGITAL HEALTH

Ireland is in a unique position globally to lead the development of Digital Health, explains Sinéad Keogh, Director, BioPharmaChem Ireland and Head of Sectors, Ibec.

16 SUSTAINABILITY

The transition to Green Chemistry presents a business opportunity for Ireland’s API sector, writes Michael Kilkelly, Senior Executive, EHS, BioPharmaChem Ireland.

20 SUPPLY CHAIN

Karina Cassidy, Senior Executive, Regulatory Affairs, BioPharmaChem Ireland, stresses the importance of ensuring an agile supply chain for Ireland’s Pharmaceutical industry, in the face of a volatile trade environment.

22 BIOPHARMACHEM IMPACT 2026

BioPharmaChem Impact 2026 is a much-attend event for senior leaders in the industry. Sinéad Keogh, Director of BPCI, provides a sneak preview of what to expect.

24 MANUFACTURING

Sharon Higgins, Executive Director, Membership and Sectors, Ibec, reflects on Ibec’s fifth Annual Manufacturing Report, which presents a mandate for Ireland’s manufacturing future based on securing competitiveness by controlling costs and mastering AI.

27 ARTIFICIAL INTELLIGENCE

Adopting Generative AI is huge challenge, but one Ireland’s Life Sciences sector must embrace if it is to continue its international success, argues Sinead Keogh, Director BioPharmaChem Ireland and Ibec Head of Sectors. 4 33 24 6

Navigating disruption: opportunities and challenges in a year of transition, by Killian O’Driscoll, Chief Commercial Officer, NIBRT.

42 EDUCATION

A partnership between a Waterford school and BioPharma company Sanofi points the way to how we can advance education for sustainable development through school/industry partnerships.

44 PHARMACEUTICAL MANUFACTURING TECHNOLOGY CENTRE

PMTC brings together multinationals, SMEs, and academic institutions to tackle realworld challenges in Pharmaceutical and BioPharmaceutical manufacturing.

46 SSPC

SSPC’s recent impact report highlights the centre’s incredible economic contribution to Ireland since 2008.

47 LEAP COMPLIANCE

Leap Compliance work with Pharmaceutical and medical device manufacturers to build skills, strengthen capability, and create high performing teams.

48 ASTELLAS

Astellas recently announced a multi-site investment of €129 million over the next three years.

50 IDA IRELAND

Rory Mullen, Global Head of BioPharma, IDA Ireland, reflects on a buoyant year in 2025, despite challenging global headwinds and geopolitical conditions.

52 BIOLOGICS TESTING & MICROBIAL QC SOLUTIONS

Charles River provide world class biologics testing, alongside regulatory guidance and consultative expertise, helping their clients towards regulatory approval.

56 CHEMICAL SOLUTIONS: CSG

CSG, including Clemifloc and GI Chemicals, provide reliable chemical solutions for Ireland’s Life Sciences and utilities sectors.

58 LEADERSHIP IN LIFE SCIENCES

The upcoming National Life Sciences Strategy is a huge opportunity for Ireland to cement its competitive advantage in global Life Sciences, write Niall Best and Conor Cunningham, McCann FitzGerald’s Life Sciences Group.

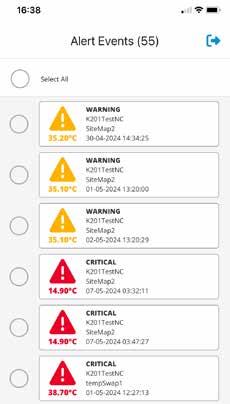

60 KELSIUS

CoolCheck by Kelsius is an automated, wireless monitoring system that delivers efficiency without compromising compliance.

62 HUB PACKAGING

Hub Packaging can be your trusted partner in industrial packaging, with a broad range of packaging solutions available.

64 MICRO-BIO

Ireland’s only Chlor-alkali manufacturer, Cork’s Micro-Bio are pioneers in Membrane Cell electrolysis.

65 HOVIONE

Hovione are a science-based, integrated CDMO, with over 60 years of experience in Pharmaceutical development and manufacturing operations.

66 PHARMACEUTICAL TESTING

Anton Paar’s series of FTIR spectrometers and software solutions are ideal for the Pharmaceutical industry, where they are used to confirm the identity of raw materials, verify the composition of intermediates, and assess the quality of finished products.

70 RENEWABLE ENERGY: GREENVOLT NEXT

Greenvolt Next have developed a 4 MW solar PV plant for global BioPharmaceutical company Sanofi in Waterford.

72 EDUCATION: ATLANTIC TECHNOLOGICAL UNIVERSITY

Atlantic Technological University’s new School of Life Sciences offers an innovative range of programmes and research for the Pharma, BioPharma and wider Life Sciences industries.

74 GE HEALTHCARE

GE HealthCare announced a massive $138 million investment in their Cork campus in 2025, with work progressing well on-site.

76 BIO PHARMA TECHNICAL CONSULTING

Chemistry, Manufacturing and Controls (CME) should be the backbone of any drug development programme and Bio Pharma Technical Consulting can help you to accelerate success.

78 ENDRESS+HAUSER

Endress+Hauser’s dedicated Flow Calibration Lab in Cork has achieved ISO 17025 accreditation, providing superior service for customers.

80 NATIONAL CHEMICAL COMPANY

Alan Looney, Managing Director of NCC, explores how the company’s strategic approach delivers a competitive advantage in chemical sourcing.

82 HEALTHCARE LOGISTICS: KUEHNE+NAGEL

Seamus Keane, VP Pharma and Healthcare Europe, Kuehne+Nagel, advises on optimising your Pharma and BioPharma logistics network.

84 MASON TECHNOLOGY

Mason Technology have built a reputation as a trusted partner to Ireland’s Pharmaceutical, BioPharmaceutical, and Medical Device industries.

85 AUTOMATION: BONNER

Bonner’s automation specialists work together with clients to review existing systems, create tailored upgrade strategies, and deliver solutions with minimal disruption.

86 ANALYTICAL SOLUTIONS: ALMAC

With more than 55 years of experience across five global locations, Almac can add real value to drug development and commercialisation programmes.

88 WASTE SOLUTIONS: INOPSYS

InOpSys are committed to providing circular waste or side stream solutions for the chemical and Pharmaceutical industry.

90 SOLTEC

Soltec enjoyed a great 2025, and were recently rewarded with two major sustainability awards.

Managing Director: Patrick Aylward

Editor:

Advertising

Currently it is a time of many challenges for procurement professionals. Reliably sourcing and securing supply of vital chemicals. It seems there’s ever greater pressure, fewer certainties, more hurdles.

But some of the world’s best-known companies have a hidden advantage. They don’t spend too much time problem solving If they need something, it’s sourced and supplied. Quietly and efficiently. They don’t need the headaches of multiple vendors and different standards, it’s streamlined. Compliance, paperwork, it’s taken care of. They have an advantage.

They have Camida.

Minister Peter Burke , underlines the Government’s commitment to enhancing competitiveness and discusses the development of Ireland’s National Life Sciences Strategy.

As Minister for Enterprise, Tourism and Employment, I am honoured to contribute to this year’s Irish PharmaChem Yearbook. I had the opportunity this summer to contribute to the summer edition of the Yearbook and I set out the strengths of this sector in Ireland, its agility and its resilience in the face of increasing uncertainties.

The current Programme for Government called for the preparation of an Action Plan on Competitiveness and Productivity which was published in September. Our commitment to the Life Sciences is underpinned in each theme of the Action Plan.

• Under Productivity, we’re embracing research, innovation and skills, particularly through R&D, talent development, and collaboration between academia and industry.

• We are Internationally Focused, we are aiming to boosting FDI and exports by using Ireland’s role as a global hub for Pharma/Medtech with strong EU-US trade links.

• We’re creating and scaling more SMEs, leaning into partnerships between multinationals and SMEs, and creating opportunities for indigenous enterprises.

• On Competitiveness, we’re regulating for growth and controlling costs so Ireland can uphold its reputation as a pro-enterprise nation and remain a destination of choice for global BioPharma investment.

• Increasing the State’s capacity to deliver Infrastructure is key to our ability to attract investment and enable regional development.

• And the Action Plan’s final theme, Sustainability, is about growing sustainable Irish businesses and boosting regional development, with an emphasis on decarbonisation, renewable energy integration and green innovation.

The Action Plan highlights the importance of the development of a National Life Sciences Strategy. Engagement with stakeholders will be key in developing an ambitious strategy, clearly aligned with the needs of the industry.

The public consultation on the development of the National Life Sciences Strategy was opened late last year to seek your views on key themes including scope, objectives, areas for opportunities and alignment with the European Life Sciences Strategy. With the input of key stakeholders like you, we can develop an ambitious, coherent strategy that will deliver real-world impact.

I am confident that in 2026 the Life Sciences sector will continue to be a cornerstone of Ireland’s economic success, and the development of the strategy will further harness this.

I wish the Irish PharmaChem Yearbook, and everyone involved, every success in 2026.

Peter Burke TD, Minister for Enterprise, Tourism and Employment

Sinéad Keogh, Director, BioPharmaChem Ireland, reflects on a tumultuous year for Ireland’s BioPharmaChem sector, which displayed tremendous resilience in the face of global challenges.

The past year has been defined by complexity, challenge, and, most importantly, strategic resilience and tangible delivery. The BioPharmaChem sector in Ireland, a sector that directly and indirectly employs over 80,000 people, has achieved unprecedented success despite headwinds.

As an industry, we have navigated shifting global supply chains, absorbed fundamental international tax reforms, and managed the acute pressures of talent acquisition, all while continuing to drive record exports and therapeutic innovation. Crucially, this period has been profoundly marked by geopolitical risk and the chilling effect of trade uncertainties. The sector has faced mounting risks from factors like the introduction of US tariffs and increasing global competition, which has directly impacted forward-looking sentiment and investment decisions across our membership.

It is precisely within this dynamic and pressurised environment that BioPharmaChem Ireland (BPCI) has reinforced its role as the essential strategic partner for our members and for the Government. The period under review marks a pivotal moment where the collective advocacy and strategic influence of our organisation translated directly into quantifiable, pro-investment policy outcomes, securing the sector’s competitive edge for the decade ahead.

Our focus has been uncompromising: to ensure Ireland remains the globally recognised centre of excellence for the sustainable manufacture and supply of pharmaceuticals, biopharmaceuticals, and chemicals.

This success is measured against our core framework, the Five Strategic Pillars which guide our advocacy, resource allocation, and value proposition to every member company: Quarterly Trends and Risk Analysis, Talent

& Workforce Development, Sustainability & Responsible Care, Digitalisation & AI, and Ecosystem Development.

Pillar 1. The Strategic Imperative: Quarterly Trends, Opportunities, and Risk Analysis

The first and most foundational strategic pillar is ensuring our organisations have the foresight and analysis necessary to navigate a volatile global environment.

The BioPharmaChem sector, contributing approximately €116 billion in annual exports, operates at the sharp end of the knowledge economy, and its stability is a national economic priority.

The new theme: uncertainty and cost pressures

Our internal analysis, powerfully reflected in our BioPharmaChem Manufacturing Report,

December 2025, identifies a pervasive theme: Uncertainty. The assessment of the wider manufacturing environment is significantly less positive than this time last year.

This sentiment is directly tied to mounting cost pressures and geopolitical risks. The findings register higher expectations of increased costs for wages (86%), and for both raw materials and energy (71%) in the months ahead. This cost inflation, coupled with market uncertainty, is dampening forward-looking metrics, with reduced numbers expecting profitability to increase (down from 33% to just 14%), and lower levels of expected increased capital investment (54% to 39%).

The most prominent challenge is explicitly external: trade uncertainties (68%), a figure that has tripled since 2024 (21%). Moreover, three-quarters of participating businesses expect to be impacted by US tariffs, with the majority anticipating a negative effect. This pervasive risk is even leading to concerns over Ireland’s fundamental appeal, as the nation's reputation as a manufacturing hub poses a major or minor challenge to half of Pharma firms (54%).

The policy wins of the past year were designed precisely to combat these headwinds and preserve Ireland's competitive edge:

• R&D Tax Credit Increase: Our most significant policy victory, working with Ibec, was securing a major enhancement to the national R&D Tax Credit, increasing the rate from the previous 30% to a globally competitive 35%. This is an immediate, quantifiable benefit that directly lowers the effective unit cost of innovation, targeting capital investment and acting as a crucial defence against international competitive pressures. Our influence is built on direct, strategic engagement with Government leaders; the BPCI Board met with then Finance Minister Paschal Donohoe TD to discuss core priorities, including incentives for innovation.

• National Life Sciences Strategy Commitment: Following years of sustained lobbying, we successfully secured a formal Government

commitment to develop a National Life Sciences Strategy for Ireland. Our influence in this process means the strategy is being designed by industry, for industry, creating a predictable, competitive landscape for the decade ahead. We hosted a roundtable meeting with Irish Medtech and subsequently submitted a cross-sectoral White Paper to the Government, and the public consultation phase is now officially underway.

In line with this global focus, BPCI actively engaged with EU and international partners throughout the year:

• Brussels Delegation and EU Policy Influence: In March, BPCI led a delegation to Ibec's Annual St Patrick’s Day event at the European Parliament, engaging with key figures including Commissioner Michael McGrath, Séan Kelly MEP, Billy Kelleher MEP, Nina Carberry MEP, and Cynthia Ní Mhurchú MEP. This advocacy work directly influences the debates on key policy files, such as the EU Biotech Act, which

BPCI responded to the EU Commission consultation in collaboration with members, as well as the General Pharmaceutical Legislation, the Critical Medicines Act, and the Urban Waste Water Treatment Directive. We also met with Minister of State for European Affairs and Defence, Thomas Byrne TD, in October to discuss priorities for the upcoming Irish Presidency of the Council of the EU.

• Presence at BIO International: BPCI maintained a vital presence on the global stage, with our attendance at the annual BIO International Convention in Boston in May. This included attending the annual ICBA meeting and engaging with EU Health Commissioner Olivér Várhelyi. This engagement is critical for maintaining dialogue with international counterparts and shaping global trade and regulatory environments. The ICBA continues to meet monthly.

The engine of the BioPharmaChem industry is its talent. Our association’s focus is on securing and continuously upgrading the skills pipeline for roles across the entire value chain.

With Ibec, our lobbying efforts for increased public sector research funding resulted in a major success: the substantial €4.55 billion investment into the Department of Further and Higher Education, Research, Innovation and Science (DFHERIS) under the National Development Plan. We advocated for this investment to close the funding gap in the higher education system and ensure a pipeline of high-calibre researchers.

A key highlight of our strategic influence this year was the dedicated member roundtable with James Lawless TD, Minister for Further and Higher Education, Research, Innovation and Science, in July and a meeting with Secretary General (DFHERIS) Colm O‘Reardon in June. This direct engagement allowed BPCI to shape the Government's focus on innovation, talent, and skills, ensuring our specific needs are recognised at state level.

To champion the critical role of these research centres, we produced essential thought leadership, including impactful podcasts with the SSPC (Solid State Pharmaceutical Cluster) – the SFI Research Ireland Centre for Pharmaceuticals - and the National Institute for Bioprocessing Research and Training (NIBRT).

We are deeply involved in governance and strategy: BPCI continues to work closely with the Expert Group on Future Skills Needs (EGFSN) Biopharma Skills Implementation

Group, and we secured a commitment to take on the sectoral lead role for this group from February 2026 to November 2027; the group held its inaugural Skills Forum in Cork on November 6, 2025.

Driving industry/school engagement and skills development

We recognise the necessity of engaging early to build the pipeline: in November, BPCI, in collaboration with the Department of Education, unveiled the Inspiring Futures: Mapping Industry-School Engagement in Ireland Report 2025. We engaged directly with Education Minister Helen McEntee TD in October to discuss the findings.

Furthermore, our practical work ensures the sector offers diverse and compelling career pathways, achieving a 20% increase in the numbers on the Lab Apprenticeships programme, and launching a new Bio Process/Chemical Process Technician Apprenticeship, along with extensive training and development run through our award winning BioPharmaChem Skillnet.

These focused initiatives provide a crucial, immediate supply line for skilled technicians and combat the acute pressures of talent acquisition. This is supported by specific working groups, including the HR Forum and the inaugural Learning and Development (L&D) Forum, ensuring continuous, peerled professional development across our member companies.

The industry’s commitment to responsible growth is articulated through our work on Sustainability and Responsible Care. This commitment is a strategic necessity, ensuring both environmental stewardship and operational licence.

A key highlight was the publication of the BPCI Sustainability Strategy and Responsible Care Report 2025 in March, tracking industry progress in energy, emissions, data management, and culture. The knowledge and data gathered here have helped members benchmark themselves against other companies in the sector. Our commitment to this pillar includes the oversight of the BPCI Sustainability Steering Group and the launch of the BPCI Biodiversity Network in lower Cork Harbour, with ambitions to establish a second network soon.

As a testament to the impact of this collective work, BPCI was honoured to receive the highly prestigious National Association Prize at Cefic’s annual Responsible Care Awards in Brussels in December, recognising the measurable impact we are making across this strategic theme.

Beyond policy, we focused on practical engagement and best practice sharing across the industry. This included hosting the Water Stewardship Workshop in Waterford in May, directly addressing the critical issue of

resource management, and the BPCI Energy Forum in October, which included a site tour at Takeda, Grange Castle, focusing on achieving energy efficiency and stability in the face of rising costs. These best practice guides derived from these key regional sites are immediately transferable to operations nationwide, providing a national blueprint for compliance and efficiency.

We are proactively shaping environmental policy: we secured the establishment of an Interdepartmental Group on Urban Waste Water Treatment Directive (UWWTD) through extensive lobbying with other partners, including the Irish Pharmaceutical Healthcare Association (IPHA) and Medicines For Ireland (MFI), which is crucial for industry input on national policy implementation. We maintain continued bi-annual formal engagement with the EPA, OEE, ECHA, and HSA on crucial issues such as EPA licencing and auditing, ensuring we support members with compliance through multi-annual engagements.

The rapid integration of technology is foundational to the future competitiveness of our sector, making Digitalisation and AI a core strategic pillar. Our BioPharma Report validates this focus, showing an uplift in those planning AI initiatives in the next one to two years from 75% to 86%, with the primary objective being to improve efficiencies. Digitalisation remains the second most widely mentioned business priority (43%).

A major output was the joint release of the Generative AI for Life Sciences Playbook

2025 in September, with Connected Health Skillnet and lead authors Brightbeam. This Playbook serves as a strategic, GxPcompliant roadmap for adoption and scaling of GenAI. The playbook identified 100+ use cases across five value streams in manufacturing, and was developed over the course of 10 months. The playbook was launched at our GenAI Forum in September and we’ve established a new Digitalisation & AI Steering Group (Board-led) in 2025 to provide strategic oversight.

Furthermore, we continue to collaborate

with ISPE on the joint Lab 5.0 objective, hosting ‘Smarter Labs, Stronger Science' in November to share best practice on the digitalisation transformation in the QC Lab. These forums are crucial for embedding new technologies.

Collaborating on cross-sector digital health strategy

Our work in this area is intrinsically collaborative, exemplified by the crosssectoral campaign 'Where Digital Health Thrives', which we drive alongside the Irish Medtech Association and Technology Ireland. The Digital Health Report, co-launched in July, provided critical research underpinning our national vision.

This pillar is dedicated to building the depth, resilience, and diversity of the entire BioPharmaChem ecosystem in Ireland. We launched the first-ever BioPharma Business Services (BBS) Strategy 2025 in May. This positions Ireland as the global location of choice for BioPharma Business Services, a segment that represents approximately 20% of total employment in the sector.

An interesting facet is the resilience and growth of the API (Small Molecule) sector; contrary to some previous predictions, it is currently growing in Ireland, with over 140 APIs being manufactured here and increasing. This is work we will continue into 2026.

Furthermore, work has commenced on a BioPharma Indigenous Strategy. This strategy, launching in Q2 2026, is being designed specifically to address the scaling needs of

our indigenous members, focusing on access to capital, supplier networks, and peer-topeer technical support. To date, we have already mapped 130 indigenous companies across the ecosystem.

Community, events, and member value

Our success is amplified by the platform we provide for networking, learning, and collaboration. Our flagship events are essential for senior-level connection: The BioPharmaChem Impact Conference and Awards in May was an outstanding success, bringing together over 300 delegates, and this was complemented by the crucial Annual BPCI Leaders Forum and Dinner for site leaders in October.

Conclusion and acknowledgements

The past year has been a period of highimpact delivery and unprecedented collaboration. While the challenging sentiment in our new BioPharma Report

signals caution, it underscores the strategic importance of BPCI's core mandate: to secure a competitive, predictable, and de-risked operating environment for every member.

This work is possible only through the dedication of our leadership and the commitment of our network. I offer my sincere gratitude to our Chair, Joyce Fitzharris, President, Small Molecule, SK Pharmteco, and our outgoing Vice Chair, Vice President, Dana Danescharavi, Johnson & Johnson Innovative Medicine, for their extraordinary guidance and tireless commitment over the past year. We also warmly welcome our incoming Vice Chair, Tim Shanahan, Vice President, Ipsen.

A profound thank you is due to the entire BioPharmaChem Ireland Board for their strategic foresight. We extend our sincere appreciation to all our Working Group Chairs and every participant who contributes their knowledge and time. Their voluntary time is a strategic asset. This peer-led engagement prevents costly regulatory missteps, de-risks new technology

adoption, and identifies operational efficiencies. Your operational insights are the engine of BPCI's best practice development.

Finally, we thank the many external stakeholders and partners who collaborated with us throughout 2025. This includes government departments and agencies such as the HSA, EPA, Skillnet, SOLAS, Enterprise Ireland, IDA Ireland, DFHERIS, D. Health, D. Enviro, Uisce Éireann, CRU, HPRA, SEAI, and the Department of Education, alongside our European and global partners, including EuropaBio, Cefic, and BIO. Your willingness to engage with the BPCI voice is fundamental to shaping a fit-for-purpose regulatory and legislative environment.

By maintaining our unified focus across the Five Strategic Pillars, we ensure that the Irish BioPharmaChem sector is wellpositioned, well-supported, and ready to meet the global opportunities that lie ahead, securing our status as a global centre of excellence for decades to come.

We are driven by a mission to change what it means to live with a rare disease. Built on a legacy of turning pioneering science into trans formative treatment s , we lis ten to and par tner with the rare disease ecos ys tem to help improve outcomes for more people impac ted by rare diseases across the globe. alexion.com

Lisa Goodman , Senior Public Affairs Executive, BioPharmaChem Ireland, provides the backdrop to the development of Ireland’s first-ever National Life Sciences Strategy and argues that to deliver targeted outcomes, the Strategy must be governed by a dedicated National Office of Life Sciences.

The close of 2025 marks a year defined by profound progress and pivotal change for Irish BioPharma. Our sector, a vital pillar of the Irish economy and fundamental to providing patients worldwide with essential medicines, has leveraged our ecosystem strengths to remain a resilient, globally competitive hub. Yet, we stand at a critical juncture. The rapidly shifting global landscape is now defined by intensifying global competition for investment, geopolitical uncertainty and disruptive technological leaps. In this new era, standing still is not an option.

This backdrop is what makes one of the key achievements of 2025 so monumental. After years of sustained, strategic advocacy by BioPharmaChem Ireland (BPCI) and Irish Medtech, we have successfully secured a landmark commitment from Government: the development of Ireland’s first-ever National Life Sciences Strategy (NLSS), under the Department of Enterprise, Tourism and Employment.

This is more than just a policy win; it is a game-changer. For the first time, our nation will have a single, cohesive roadmap to guide the next phase of growth for our interconnected ecosystem.

Securing this commitment was a multiyear endeavour, the culmination of BPCI’s persistent calls in our manifestos, from

‘Electing for Business’ to ‘BPCI - Global Impact’, and our annual budget submissions. Securing Government’s commitment to developing the strategy in the Programme for Government in January 2025 was the critical first victory. But this victory immediately presented a new, more profound challenge: ensuring the strategy is not just a theoretical blueprint, but a living charter designed to drive tangible action, create accountability and delivery measurable change for the next decade.

With the commitment for National Life Sciences Strategy secured, we faced a critical question: what strategic priorities must be included and how can they be effectively delivered? BPCI's leadership in 2025 was defined by our work to answer that very question, not in isolation, but by working with our colleagues in Irish Medtech and stakeholders from across the ecosystem.

Convening the ecosystem: building a unified voice

The true strength of Ireland’s Life Sciences sector is its unique convergence of BioPharma, Medtech and digital health. Therefore, our first and most crucial task was to bring these powerful, interconnected voices to the same table.

We began developing an understanding of the necessary scope and deliverables for

the NLSS in consultation and collaboration with our members since we first identified the need for such a strategy four years ago. In 2025, as part of our ongoing advocacy on the NLLS, BPCI and our partners at Irish Medtech jointly hosted the ‘Shaping our Future’ workshop. We gathered 40 cross-disciplinary and cross-sectoral leaders from across our member companies and the wider ecosystem for a single purpose: to identify and prioritise the core considerations that must underpin the National Life Sciences Strategy, ultimately ensuring the strategy addresses industry needs and incorporates strategic imperatives required for future global competitiveness.

This was not a time for incremental thinking. The clear consensus was that in the face of global challenges, the NLSS must be ambitious and must set a bold, long-term vision for Ireland.

Our industry's vision, forged in this workshop and subsequent member validation, was then detailed in a White Paper for Government, to set the context for a strategy that delivers clear, transformative outcomes. We have called for a prioritised set of actions designed to leverage and enhance Ireland's unique and collective capabilities, ultimately positioning Ireland as a globally recognised leader in innovation and healthcare excellence.

BioPharmaChem Ireland and Irish Medtech jointly hosted the ‘Shaping our Future’ workshop to identify and prioritise the core considerations that must underpin the National Life Sciences Strategy.

Sinéad Keogh (standing, centre), Director, BioPharmaChem Ireland, and Eoghan Ó Faoláin, Director, Irish Medtech, at the ‘Shaping our Future’ workshop.

This means the strategy must rapidly address barriers, establish Ireland as a global R&D leader, and future-proof our national talent pipeline. Crucially, it must align the efforts of government departments and agencies to ensure a cohesive, whole-ofgovernment approach.

The headline ask: a new engine for execution

Our White Paper contains many critical recommendations, but it is built upon one central, non-negotiable pillar: governance.

The challenges facing our sector, from developing a future-proof talent pipeline to enhancing our R&D infrastructure and ensuring regulatory agility, are complex. They transcend the remit of any single department. A siloed approach, where different parts of government work without coordination, will lead to a siloed and ineffective strategy.

Therefore, BPCI's headline recommendation is the establishment of a dedicated, empowered and well-resourced National Office of Life Sciences.

This Office would not be another layer of bureaucracy. It would be the ‘engine room’ of the NLSS, responsible for its implementation, oversight, and adaptation. To be effective, this cross-departmental and cross-agency

body must have real authority and be comprised of senior officials from all critical departments, including the Departments of the Taoiseach, Health and Further and Higher Education, Research, Innovation and Science.

Furthermore, it must embed all key implementing agencies, from IDA Ireland and Enterprise Ireland to the HPRA, HSA and EPA, to ensure policy is grounded in operational reality.

Most importantly, our submission insists that industry must have a formal seat at the table. We have called for national industry associations, research centres and patient representatives to be embedded in this governance structure. This is the only way to ensure the strategy is practical and remains agile enough to respond to the real-world needs of the sector. A strong governance structure is the fundamental prerequisite for the strategy's long-term success.

The establishment of this Office is the how, but the why is even more compelling.

The NLSS is our vehicle to secure Ireland's competitiveness for the next decade.

This strategy must be a lever to move up the value chain. Ireland is already a global leader in BioPharma manufacturing. The NLSS

A dedicated, empowered and well-resourced national Office of Life Sciences would be the ‘engine room’ of the NLSS, responsible for its implementation, oversight, and adaptation.

is our chance to build on that excellence and become a world leader in high-value innovation and R&D. It must create the conditions for more investment in clinical trials, advanced therapeutics and nextgeneration drug discovery.

It must also be the catalyst for building our indigenous ecosystem. The strategy must provide targeted funding and growth supports for indigenous start-ups and scale-ups, fostering the next generation of Irish-owned Life Science champions that can compete on the global stage.

We have an opportunity that is truly unique to Ireland. Our unprecedented levels of interconnectedness between globally leading BioPharma, Medtech and technology companies create a convergence that other nations can only dream of. The NLSS must be the plan to harness this unique advantage, fostering collaboration and enabling new entrants to reinvent traditional operating models.

The work of 2025 centred around building the blueprint for success. The mandate for 2026 and beyond will be to ensure Government’s development and execution of the NLSS is robustly ambitious, fully resourced, and effectively delivered.

We have a rare window of opportunity to deliver something truly transformative. But in the face of rife global competition for investment, this is more than an opportunity; it is an imperative. The National Life Sciences Strategy is not a ‘nice to have’. It is the ‘musthave roadmap’ that will secure our sector’s success, drive innovation, and cement Ireland’s position as a global Life Sciences leader for the next decade. BPCI is proud to have led the charge to this point, and we are ready to partner with Government to make this vision a reality.

Ireland is in a unique position globally to lead the development of Digital Health, explains Sinéad Keogh, Director, BioPharmaChem Ireland and Head of Sectors, Ibec.

The transformation of healthcare is no longer a distant vision; it is a present and accelerating reality. Digital Health, broadly defined as the intersection of healthcare and technology, involves the innovative use of software, hardware, and data. Its goal is to deliver better, more efficient patient care, empower individuals in their own self-management, and provide clinicians with powerful tools to support decision-making.

The scale of this global shift is immense. The Digital Health market is projected to reach over $946 billion by 2030, expanding at a compound annual growth rate of over 22% (Grand View Research, 2025).

Here in Ireland, we are in a globally unique and enviable position to lead this convergence. This is a cross-sectoral

endeavour, driven by the powerful collaboration of Ibec's Irish Medtech, BioPharmaChem Ireland, and Technology Ireland associations. This ‘triple helix’ of expertise has built a global powerhouse ecosystem, with over 700 Life Sciences and health technology companies employing 90,000 people directly. The presence in Ireland of nine of the top 10 global medtech firms, all 10 of the top 10 Pharma companies, which includes over 200 Digital Health businesses, makes Ireland the place ‘Where Digital Health Thrives’.

Core business imperative

This is not just a theory; it is a core business imperative. A recent Ibec Digital Health Sector Report, launched at a dedicated Digital

Health Forum in Ibec's Dublin head office in July 2025, confirmed this momentum. An overwhelming 83% of Digital Health business leaders identified digitalisation as ‘very important’ to their operations, with 82% actively planning to invest in Digital Health activities. These are not abstract concepts; they are tangible solutions, with 48% of companies already engaged in connected medical devices and remote patient monitoring, and others focused on personalised healthcare (30%) and digital therapeutics (26%).

This planned investment is sharply focused. The top priorities for Irish operations are Artificial Intelligence (65%) and Cybersecurity (61%). This reflects a mature understanding that to deliver connected

The

Ibec’s ‘Where Digital Health Thrives’ is a crosssectoral campaign with BioPharmaChem Ireland, the Irish Medtech Association and Technology Ireland, to enable Ireland to become a recognised global hub for Digital Health.

top priorities for Irish operations are Artificial Intelligence (65%) and Cybersecurity (61%). This reflects a mature understanding that to deliver connected devices and personalised therapeutics, the systems must be intelligent, predictive, and secure.

devices and personalised therapeutics, the systems must be intelligent, predictive, and secure. This investment is about building the fundamental infrastructure for the next generation of healthcare.

This push for innovation is happening within a complex new regulatory landscape. The Ibec report highlights that industry is preparing for significant impacts from new European frameworks, with 61% of leaders expecting the EU AI Act and the European Health Data Space (EHDS) to affect their business.

This new reality is creating an urgent need for new capabilities. Business leaders identified significant gaps in access to essential skills. Looking to the future, the top skills needs are in Data Science and AI (identified by 70% of leaders) and, critically, in Regulation (61%), a direct response to the new compliance demands of the AI Act and EHDS. The report reveals companies are planning a dual strategy to fill these roles, balancing external recruitment with upskilling existing staff.

This clear focus on skills, combined with the defined investment priorities, demonstrates a sector that is moving in unison. The data is unequivocal: Irish industry is not just investing in Digital Health, it is defining what it means in

practice and strategically building the expert talent pool required to deliver its future.

For more information visit about Ibec’s ‘Where Digital Health Thrives’ campaign, visit: www.ibec.ie/digitalhealth

Ibec’s ‘Where Digital Health Thrives’ is a crosssectoral campaign with BioPharmaChem Ireland, the Irish Medtech Association and Technology Ireland, to enable Ireland to become a recognised global hub for Digital Health.

The transition to Green Chemistry presents a business opportunity for Ireland’s API sector, writes Michael Kilkelly, Senior Executive, EHS, BioPharmaChem Ireland.

The goals of Irelands Climate Action Plan 2024 1 and the EU’s Chemical Strategy for Sustainability 2 are key drivers of sustainability and environmental policy in Ireland. They share an ambition to protect public and environmental health, and they both align on strategies to do so: setting 2050 as the target year for net zero 3 climate neutrality and supporting innovation in the production and use of safe, sustainable chemicals.

In terms of net zero targets 3, the biggest challenge for the BioPharmaChem industry is decarbonisation in the supply chain. Typically, Scope 3 emissions ⁴ account for about 80% of greenhouse gas GHG emissions for the sector. Bundled under the category of Purchased Goods and Services, the largest share of Scope 3 emissions (60%) comes from the procurement of ingredients, chemicals, solvents and packaging. Chemical processes are a major part of this category, as the manufacture of active pharmaceutical ingredients (API’s) and intermediates involve energy-intensive chemical synthesis and raw material extraction.

The big challenge is that for many of the

current first-generation API processes, change is restricted by competing regulatory pressures. Changes to processes for API’s require costly development of new chemistries, rigorous application of change control, multiple risk-assessments, extensive validation activities, increased inspections and regulatory approval across multiple jurisdictions to fulfil strict GMP and EHS requirements. To employ these secondgeneration processes takes years to complete and requires significant investment and risk.

However, the medium-term sustainability challenges of API production and substitution of restricted chemicals could present long term business opportunities.

The estimated cumulative investment required for the global transition to sustainable chemical feedstocks is between US$440 billion and US$1.5 trillion by 2040 and potentially reaching between US$1.5 trillion and US$3.3 trillion by 2050 ⁵. This represents a huge potential for Europe to revitalise its chemical industry through innovative technologies such as carbon capture, green hydrogen, biomass utilisation, etc.

Even though Ireland’s role in chemical manufacture is limited, there is great

potential to position itself as a leader in green chemistry for API’s in small molecules. The global API market itself is projected to be worth US$330 billion by 2034 ⁶.

However, most API manufacturing sites in Ireland are not directly involved in the development of first-generation API processes. These processes generally come from discovery chemists based outside Ireland.

Discovery chemists use lab grade, lab-scale reagents, catalysts, synthetic pathways that

2050 is the target year for net zero climate neutrality and supporting innovation in the production and use of safe, sustainable chemicals.

provide small amounts of pure materials for pre-clinical trials. Focus is on high throughput screening.

In the past, little if any consideration was given to the environmental impact of the synthetic routes. Once successful in clinical trials, the synthesis is often locked in. It is almost always the case that efficiency and environmental impacts are considered only post-approval. Manufacturing plants and reactor configurations are then built around these resource-heavy processes, essentially scaling up these inefficiencies. Then validation locks this in for years.

A second-generation process (focusing on efficiency, cost, lower environmental impact) needs to go through a lengthy and expensive approval process from a quality point of view. The time gap from first generation synthesis scale-up to validation of an efficient second-generation process represents lost opportunity.

The question for the Irish small molecule API sector is this: do we focus our decarbonisation efforts on second generation process development and leverage on the existing process development experience and skills in the sector?

In the shorter term, this makes sense, given that most, if not all, of the firstgeneration discovery chemistry is carried out elsewhere. However, the more strategic option would be for Ireland to start focusing more on drug discovery and to develop an end-to-end life cycle approach from discovery to market. This presents an opportunity to develop the indigenous industry and to embed Sustainability by

Design (SbD) at the earliest stage.

An end-to-end approach would also facilitate the overlay of a single data source from discovery to market using AI to collate and analyse all aspects of the life cycle and remove data silos. Localising discovery chemistry coupled with green chemistry principles would reduce dependence on volatile supply chains.

How do we, as the broader Irish BioPharmaChem sector, influence and embed green chemistry principles as early as possible in small molecule drug development trajectory? The first step is to align it with a broader strategy in developing the Life Science Sector in Ireland through policy.

An aligned approach through a dedicated Life Science Office would help co-ordinate a National Life Sciences Strategy ⁷. A significant part of this is to aggressively develop and support indigenous drug discovery in Ireland. The recent increase of the R&D tax credit from 30 to 35% and expansion of its remit are positive developments but we need to go further. Successful drug discovery can then be the starting point of embedding green chemistry across the drug life cycle.

BPCI will launch its Indigenous strategy at BioPharmaChem Impact 2026, which will focus on supporting the ecosystem around this strategic growth area. BPCI is also working on mapping the broader small molecule API sector in Ireland, which will be published early in 2026. It is significant to note that there are over 140 small molecule API’s currently manufactured in Ireland and so the opportunity to deploy green chemistry is immense.

We need to build upon the current skills and talent in chemistry and engineering to focus on green chemistry. Curricula need to be updated to include not just green chemistry technologies but also life cycle analysis (LCA).

Embedding green chemistry principles as early as possible into the chemistry, pharmacy and chemical engineering programmess is essential. Sustainability by Design is as much of a mindset as it is a technical challenge.

A great initiative in this area is the partnership of Research Ireland with My Green Lab to promote certification of laboratories in third level institutions.

BioPharmaChem Ireland are also working with My Green Lab to promote the uptake of this same standard with the BioPharmaChem sector in Ireland. The aim here is to make this accreditation a standard across industry and education. We also need to develop expertise in hard technologies.

‘ Hard’ technologies

There are several technologies that can be deployed in reducing the environmental burden of API processes.

Bio-catalysis:

Several companies now employ enzymes such as lipases to effect very selective chemical transformations and the possibilities are expanded beyond nature's transformations through advances in protein engineering and enzyme immobilisation techniques. This removes toxic, precious metal catalysts from API synthesis.

Solvent free processes:

Small molecule API manufacture often uses large amounts of solvents, which present a significant scale of hazard. Complete removal of solvents through mechano-chemical processes or flow chemistry is an area worth exploring. Where solvents can’t be removed, then it is worth considering replacing toxic solvents with natural or biodegradable solvents and also looking at renewable raw materials, shifting from petroleum-based substances to bio-based feedstocks.

Catalyst technology:

Heavy metal catalysts such as palladium, platinum, and rhodium are widely used as catalysts due to their efficiency, but they pose challenges including supply volatility, high cost and the need for rigorous removal to meet regulatory limits on metal impurities in drugs and the environment. In the medium term, we can look at Closed Loop (advanced recovery and recycling). In the longer term, replacing heavy metals with different modalities such as nanoparticle catalysts may be the way forward.

Photochemistry:

Light-driven reactions often occur at room temperature and avoid the need for high thermal energy. Photochemical processes can offer direct access to target molecules, avoiding lengthy multi-step procedures and improving atom economy.

Electrochemistry:

This can often replace traditional oxidation or reduction methods that involve hazardous chemicals and is starting to be used more broadly

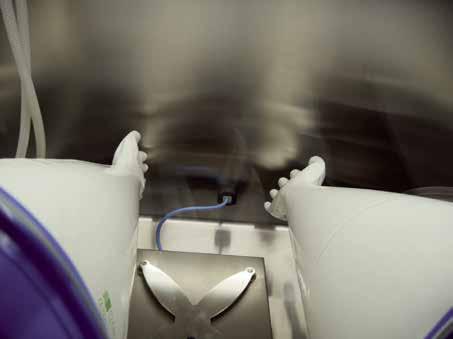

Continuous processing:

Continuous processing and in particular the use of flow chemistry provides techniques to perform energetic chemistry at scale, to reduce solvent and energy use, to have higher yields and more selective chemistries, and overall can be safer and more environmentally friendly. It does require a unique blend of chemistry, engineering and process control to design and scale-out. Several manufacturing sites in Ireland have already implemented flow chemistry and interesting process research in this area is carried out by SSPC, APC and Pfizer’s Process Development Centre in Cork. There is an opportunity to build in modules on continuous processing into courses and leverage the current experience in industry to help deliver these modules.

In silico methods:

Drug design using AI is a powerful screening tool that can be used for selecting drug candidates and is often cited as a game changer. In addition, design of experiments (DoE), when properly employed, can significantly reduce the number of experiments in process development, thus reducing environmental impact. Computational techniques such as Dynochem pioneered by Dr Joe Hannon in Ireland have helped development chemists use modelling to optimise and scale up processes faster, thus saving significant resources.

How do we, as the broader Irish BioPharmaChem sector, influence and embed green chemistry principles as early as possible in small molecule drug development trajectory? The first step is to align it with a broader strategy in developing the Life Science Sector in Ireland through policy.

Future advances will leverage precision automation and advanced process analytical techniques (PAT) with CMC teams to accelerate smarter more efficient processes. The recent partnership between Metler-Toledo International and indigenous company APC is a great example of these partnerships. These types of combinations will be further enhanced by deploying edge LLM’s to analyse field data in real time.

Summary

There is a significant opportunity for the BioPharmaChem sector in Ireland to become a world leader in green chemistry. This is not just a business opportunity but also a way to de-risk our exposure to complex supply chains and significantly reduce our carbon footprint. We have the technology; we have the talent; we have the ideas. What we now need is the funding and the policy to bring all the disparate groups together to build the infrastructure. The future is bright and the future is green.

Sources

1. https://www.gov.ie/en/department-of-climate-energyand-the-environment/publications/climate-actionplan-2025/

2. https://echa.europa.eu/el/hot-topics/chemicals-strategyfor-sustainability

3. https://www.climatecouncil.ie/media/CBWG%20 Report%20TIMES-Ireland%20Model.pdf

4. https://ghgprotocol.org/corporate-value-chain-scope-3standard

5. https://www.futuremarketsinc.com/the-globalmarket-for-sustainable-chemical-feedstocks-20252035/#:~:text=The%20transition%20to%20sustainable%20 chemical%20feedstocks%20represents,US$1.5%20 trillion%20to%20US$3.3%20trillion%20by%202050.

6. https://www.biospace.com/press-releases/smallmolecule-api-market-size-to-reach-usd-331-56-bn-by-2034

7. https://enterprise.gov.ie/en/consultations/publicconsultation-on-national-life-science-strategy.html

DELIVERING COMPLIANT, HIGH-PERFORMANCE

FACILITY SERVICES THROUGH ENGINEERING AND TECHNICAL EXPERTISE

35+ years supporting world-leading pharmaceutical manufact urers.

Expertise in commissioning, calibration, and o perations & maintenance.

Co-d esign partnersh ip mod el ensuring compliance, relia bility, and e fficiency.

Operations across EMEA and the USA.

Karina Cassidy, Senior Executive, Regulatory Affairs, BioPharmaChem Ireland, writes on the importance of ensuring an agile supply chain for Ireland’s Pharmaceutical industry, in the face of a volatile trade environment.

In today’s complex and dynamic global environment, supply chain agility is no longer a competitive advantage for Ireland's Pharmaceutical industry; it is a business necessity. The mission to reliably deliver essential medicines to patients worldwide is challenged by persistent volatility, regulatory complexity, and global disruptions.

As a key global manufacturing hub, Ireland’s Pharmaceutical sector is deeply integrated into global supply networks. This brings great strength but also inherent vulnerability. Key challenges for our members include significant global disruptions; a heavy reliance on Active Pharmaceutical Ingredients (APIs) from third countries, for example, exposes the sector to geopolitical tensions and international trade disruptions, such as the recent US tariff measures. This is not just a global trend; BPCI’s Manufacturing Report 2025 found that 'trade uncertainties' were the single greatest major challenge cited by members (68%).

Additionally, members face notoriously unpredictable demand volatility, which is influenced by factors from patent expirations to epidemics. With forecast errors averaging up to 40% and lengthy manufacturing lead times that can vary from two to 12 months, flexibility is constrained. Finally, there is the resource-intensive challenge of regulatory and handling complexity. Adhering to stringent global standards like Good Manufacturing Practices (GMP) and Good Distribution Practices (GDP) is demanding, and the growth of biologics and specialty drugs requires sophisticated, temperature-controlled cold chain and specialised handling capabilities to maintain product integrity.

Collaboration and insight through BPCI BPCI plays a key role in addressing these challenges by strengthening the entire value chain. This work is a direct expression of our 2025 strategic theme, 'Ecosystem development'. The BPCI Supply Chain

Working Group is the primary way we bring this strategy to life. It acts as the central hub, connecting our members with each other and with expert solution providers to build a more resilient and collaborative sector. This group provides the vital platform for members to share best practices and navigate this complex landscape together.

The value for members is generated through this group's dual focus. First, it drives strategy by focusing on members' highest priorities. This focus is a direct response to member feedback, as our 2025 research highlighted 'managing supply chains/ suppliers' and 'introducing digitalisation/ advanced manufacturing initiatives' as top business priorities.

The group's work on risk mitigation, transparency, and sustainability directly addresses these stated needs. Future work is already targeted at supplier diversification, emerging risks, and compliance to ensure the continuity of supply and protect patient outcomes.

Second, this strategy is brought to life by fostering direct, peer-to-peer collaboration through sessions where members share best practices and develop actionable solutions. Recent forums, such as those hosted by members Camida and McArdle Skeath, have proven invaluable for this essential, practical engagement.

In this environment, third-party logistic (3PL) providers have evolved from simple vendors into essential strategic partners. They provide the specialised expertise, scalable infrastructure, and advanced technologies necessary to manage the sector's unique demands. These partners are critical in managing the compliance burden of GMP and GDP standards, offering the scalability to manage demand volatility, and providing the sophisticated cold chain logistics vital for biologics.

Crucially, they are also drivers of innovation, increasingly employing digital tools like AI and advanced analytics to improve forecasting, enhance inventory management, and provide the real-time supply chain visibility that is critical for proactive risk mitigation.

As the sector moves toward more complex therapies, 3PLs manage the growing complexity of specialty and biologic drugs, which often require precise handling and direct-to-patient distribution models.

As John Halpin, Senior Manager Business Development, Life Sciences & Healthcare Ireland at DHL Health Logistics, notes: “We are expanding rapidly to meet the increasing demand for best-in-class 3PL services supporting the BioPharma sector across Ireland. Anchored by our state-of-the-art

HPRA approved facilities, Quantum, and Horizon, we offer robust, GxP-compliant solutions that span the full spectrum of cold chain management, including chill and deepfrozen regimes, as well as extensive controlled ambient materials handling.

“Our close collaboration with industry ensures our services are precisely aligned with the evolving needs of the sector, particularly in supporting in-bound logistics to manufacturing and seamless export to global markets. This reinforces our commitment to delivering agile, scalable, and regulatoryready supply chain solutions that enable our customers to thrive in a highly competitive and quality-driven environment.”

Building a resilient ecosystem

The path forward requires integrating supply chain agility into the core of our business strategies. This means fostering deep, transparent collaboration with partners, aligned on quality standards and data-sharing.

As the global landscape continues to revolutionise, Ireland’s industry leaders are redefining supply chain resilience. Through the collaborative platform BPCI provides, our members are building strategic alliances, progressing new levels of agility, and driving resilience. This is the strategic imperative for sustaining our global impact and, most importantly, delivering lifesaving medicines to the patients who need them most.

BioPharmaChem Impact 2026 is a much-attend event for senior leaders in the industry. Sinéad Keogh, Director of BPCI, provides a sneak preview of what to expect.

BioPharmaChem Ireland are proud to announce the return of our flagship event, BioPharmaChem Impact 2026. Set for May 6, 2026, at The InterContinental Hotel in Dublin, this third annual event is the must-attend gathering for senior leaders in our sector. We will once again bring together over 400 of our most influential executives, policymakers, and academic partners for a day of high-level dialogue.

This year's conference comes at a pivotal moment. With Ireland assuming the Presidency of the Council of the European Union in July 2026, we have a unique and powerful opportunity to shape the future of European policy.

Ireland’s leadership role during EU presidency

The day's agenda is structured around 10 dynamic sessions, bookended by two pivotal plenaries. We will open by exploring Ireland’s leadership role during the EU Presidency and its impact on European competitiveness, before closing with a strategic call to action for building our Indigenous BioPharmaChem Ecosystem.

Throughout the day, parallel tracks will offer deep dives into our industry's most critical challenges.

Strategic sessions will cover the future of medicine development, the practical implementation of AI and cybersecurity, and the

2025.

urgent need to close the talent and skills gap.

Our technical tracks will feature C-suite leaders from global CDMOs discussing the future of external manufacturing, expert case studies on green chemistry and sustainability, and essential analysis on future-proofing QA/ RA and compliance. Finally, we will tackle supply chain resilience from every angle, from high-level geopolitical risk to on-the-ground technical logistics.

Of course, the conference is not just about the speakers; it's about the connections. The day is filled with networking opportunities and concludes with our prestigious Annual Awards Dinner. This is our chance to celebrate the outstanding individuals and organisations that make the BioPharmaChem community here a global success.

Last year's attendees called the awards ceremony a "very enjoyable way to celebrate our successes in the industry", and we look forward to building on that tradition.

With 94% of last year's delegates rating the conference either very good or excellent, this is an event that truly delivers.

On behalf of the BPCI team, I look forward to welcoming you on May 6, 2026. This is our moment to connect, share, and lead the future of our industry, together.

To book your place at BioPharmaChem Impact 2026, visit bpcimpact.ie

Sharon Higgins , Executive Director, Membership and Sectors, Ibec, reflects on Ibec’s fifth Annual Manufacturing Report, which presents a mandate for Ireland’s manufacturing future based on securing competitiveness by controlling costs and mastering AI.

Ireland's manufacturing sector is the backbone of our economy. The fifth Annual Manufacturing Report 2025, launched on November 18, 2025, in Ibec's new Galway offices, confirms that this success, though robust, is no longer guaranteed. Our industry, which employs over 240,104 individuals in 2024 and generates over €10 billion in corporation tax, is revealing a deep resilience. However, the report shows this resilience is under intense pressure from global volatility and escalating domestic costs. This analysis provides a critical roadmap for controlling the controllables and securing the future of this essential industry.

The new global backdrop: unpredictability and the margin squeeze

The most significant finding of the 2025 survey is the dramatic escalation of external risk. Trade uncertainties have surged to become the number one challenge for 59% of leaders (up from 30% in 2024). This is not abstract risk; it is a clear and present threat to our export-driven model, validated by the fact that seven in 10 manufacturers are affected by US tariffs. This geopolitical friction, coupled with the expected challenge from Weaker Global Growth (42% challenge), is placing exceptional pressure on investment decisions.

This volatility has forced a shift in mindset: the overall positive outlook ('Very Good' / 'Good' sentiment) has dropped sharply from 69% to 51%. This is not pessimism, but a proactive 'Cautious Resilience’. Our leaders are strategically managing expectations, with the majority of sentiment now concentrated in the 'Average' category (43% concentration).

The cost structure underpinning this caution is noted:

• Wage growth is expected to increase for 81% of respondents.

• Expectations for the cost of energy have doubled to 64%.

• The result is a severe margin squeeze: expected profitability increases dropped sharply to 18% (down from 37% in 2024), with around 30% now expecting a decrease.

This dynamic - increasing costs against flat sales expectations - explains the moderation of general investment, with capital investment dipping to 34% and R&D expenditure dropping to 19%. The need for defensive cost management is paramount. Members should utilise the Ibec Pay and Resourcing Forecast for authoritative benchmarking to manage intense labour cost pressures and prepare strategically for compliance demands.

The AI imperative: the sector's strategic response

The most encouraging data confirms that manufacturers are strategically investing their way out of this uncertainty by controlling the controllables and embracing technology. AI is now a priority for 52% of businesses (up from 39% in 2024), and the motivation is crystal clear: 97% plan AI adoption primarily 'to improve efficiency/ productivity'.

This singular focus confirms that AI is the core resilience investment, immune to the general investment downturn, as our members recognise that mastering AI and digitalisation is the only viable path to defending margins against high labour costs and securing future global competitiveness.

Given that AI adoption is a core competitiveness strategy, members must utilise the Ibec AI Hub for practical guidance on adoption, toolkits for responsible implementation, and EU AI Act compliance. Furthermore, the launch of Ibec's Tariff Hub provides

vital, expert-driven intelligence and tools to assess and navigate the complex risks associated with trade uncertainties and tariffs.

While the sector is proactively investing in AI, structural deficits in the national infrastructure are compounding competitive threats.

The challenges surrounding our talent pipeline and housing remain acute, as the availability of housing for employees remains a major challenge for 48% of leaders. Furthermore, the cost of energy (64% concern) is so acute it is eclipsing the administrative focus on sustainability measures (down to 18% concern), meaning high costs are making long-term green capital investments unaffordable.

Finally, regulatory and planning friction is rising, with Irish planning regulations now a challenge for 25% of leaders, slowing critical infrastructure delivery and undermining our reputation for operational certainty.

Policy mandate: partnership for future growth

Ibec strongly commends the Government’s proactive response in Budget 2026, which delivered on key long-term enablers: the vital increase of the R&D Tax Credit to 35% is a welcome signal to unlock innovation, and the €2 billion commitment to infrastructure is crucial for future capacity.

However, the task now is to build on that momentum and address the immediate operational cost and skills gaps that remain critical threats. Our policy priorities for the next Programme for Government are clear and targeted:

1. Champion an Ambitious EU Trade Policy:

To counter global trade fragmentation, Ibec urges the Government to renew its commitment to openness and advance an ambitious EU trade policy, safeguarding Irish competitiveness in collaboration with key trading partners such as the US and the UK. This includes leveraging the EU mandate to deliver on developing the Single Market.

2. Mitigate Rising Business Costs:

This is our immediate ask. We would like the Government to introduce a PRSI rebate for exposed companies and accelerate the rollout of low-cost renewable generation to reduce Ireland’s high electricity costs. The Government must also formally assess the impact of all new labour market policy measures on employers using an enhanced SME Test.

The fifth Annual Manufacturing Report 2025 provides a critical roadmap for securing the future of this essential industry and is available to download from www.ibec.ie/manufacturinginireland.

3. Invest in AI Skills Development:

To bridge the critical gap between AI ambition (52% priority) and execution capability, we urge the Government to urgently increase matched funding for Skillnet Business Networks, unlocking private capital for essential AI upskilling through the National Training Fund (NTF).

4. Accelerate Climate Action and Digital Strategy:

The Government must secure a competitive net-zero economy by adopting an interventionist role. This requires implementing an all-of-government masterplan to overcome policy gridlock and accelerating infrastructure delivery by streamlining the permitting process.

5. Optimise the R&D Tax Credit to Unlock Innovation:

Building on the 35% rate, we urge the Government to use the forthcoming R&D Compass to expand the qualifying expenditure definitions and reform outsourcing rules (for connected and unconnected parties) to reward innovation and IP creation, where the value created benefits for Ireland. Clarity is critical for claimant companies.

Ibec in action: inspiring the future

Ibec ensures our members are prepared for these shifts through targeted support initiatives:

• Benchmarking and Compliance: The Ibec Pay and Resourcing Forecast provides indispensable data for managing the intense labour cost pressures (58% challenge) and setting competitive pay rates.

• Talent Pipeline: The launch of Ibec’s National Manufacturing Day Ireland (MDI) saw over 60 manufacturers open their doors, providing firsthand access and immersive experiences to students and jobseekers. This initiative is vital for tackling the long-term talent attraction challenges and showcasing modern manufacturing as a high-tech career path.

• Advocacy Success: We continue to demonstrate Influence at the highest levels, campaigning effectively for the policy changes needed, as demonstrated by the enhanced R&D Tax Credit and our ongoing fight for vital cost mitigation measures.

Manufacturing remains a central pillar of the Irish economy. By addressing these critical cost, talent, and infrastructure barriers, the Government can secure the foundation upon which the sector's inherent resilience and strategic AI investments can deliver the sustained, top-tier growth Ireland relies upon. We look forward to working with all stakeholders to champion these priorities.

Adopting Generative AI is huge challenge, but one Ireland’s Life Sciences sector must embrace if it is to continue its international success, argues Sinead Keogh, Director BioPharmaChem Ireland, and Ibec Head of Sectors.

Generative AI presents a profound challenge for Ireland's €116 billion Life Sciences sector. It is, at once, the greatest opportunity for competitive advantage and a significant new frontier for regulatory compliance. Successfully navigating this landscape is the defining leadership challenge of our time.

The global prize is transformative.

McKinsey estimates GenAI could create $60 billion to $110 billion in annual value for the global Life Science industries. This value will come from radically accelerating R&D, a process that traditionally takes 10-15 years and costs over $1 billion per drug. But for Ireland, AI is also a critical competitiveness shield. Faced with what our 2025 Manufacturing Report calls escalating geopolitical risk and trade uncertainties, adopting AI to drive productivity is not just an option, it is a core defensive strategy to protect our export-led model.

Our members are moving decisively. Our latest BioPharmaChem Manufacturing Report 2025 reveals that AI is now a top priority for 64% of businesses, up from 54% last year. The survey also shows that 86% of businesses are now actively planning AI initiatives, a significant increase from 75% in 2024. The driver is clear: 100% of those investing are doing so to improve efficiency/productivity, with 75% aiming to improve innovation.

The playbook for GXP-scaled AI

Our industry is focused on the specific, highstakes task of GxP-scaled AI. This is why BPCI, with our partners, lead authors Brightbeam and Connected Health Skillnet, developed the 'GenAI in Life Sciences Manufacturing Playbook.' This is not just a report; it is a roadmap for our entire ecosystem to collaborate, build a culture of GenAI adoption with foundational applications, and ultimately scale into the complex, regulated GxP environments that define our sector.

Developed through collaboration with our members over a 10-month work programme, the playbook contains over 100 practical use cases across five value streams, from foundational applications in process development and supply chain management to critical GxP tasks like accelerating deviations management. Our aim is to help the ecosystem collectively build a culture of

AI, with a plan to scale these use cases into more complex GXP environments next year.

As Brian Hanly, CEO of Brightbeam, noted at the launch: "Generative AI is a generational opportunity but many companies are stuck in 'proof-of-concept purgatory'. They are running experiments that don't always scale into real value. This collaborative playbook, on which we were the lead authors, is the antidote. It provides a clear, GxP-compliant roadmap to move from ambition to adoption."

This collaborative model is Ireland's unique advantage. As highlighted in our BioPharma Business Services Strategy 2025, AI will be transformative across the entire business ecosystem, bridging the gap between advanced manufacturing and global services. Today, nearly 9,500 professionals, representing close to 20% of our total employment, drive a dynamic services sector that is transforming from

back-office support into a strategic engine for global corporations. Crucially, AI now presents a new opportunity for these hubs to recapture and secure high-value transactional activity. By leveraging AI to automate and optimise complex, high-volume tasks, Ireland can now be globally competitive in these areas. The EU AI Act positions our GBS hubs as the logical "compliance nerve centre" to deploy trusted, GxP-compliant AI globally.

To win, three critical enablers are required: culture, skills, and regulation.

The critical enablers

First, we must establish the right culture, which starts with leadership. This must be treated as a strategic leadership programme, not an IT project. The greatest challenge in our sector is integrating this technology within stringent GxP-regulated environments. Therefore, the non-negotiable foundation of this culture is a robust "Human-in-theLoop" (HITL) governance model. This ensures a qualified subject matter expert reviews,

approves, and remains accountable for all AIassisted outputs, thereby maintaining patient safety, GxP compliance, and traceability.

Second, we must industrialise our talent pipeline. We cannot scale technology without scaling our talent. Ibec and BPCI are actively lobbying for this increased investment, calling on the Government to scale AI skills development by increasing matched funding for agile, industry-led platforms like Skillnet Business Networks and Springboard+. These are the proven mechanisms to deliver the AI fluency our workforce needs.

Finally, we must implement enabling regulatory frameworks. We must de-risk adoption to accelerate it. We strongly advocate for sectoral AI regulatory sandboxes. This would allow companies to test and validate new AI solutions in a controlled environment, in partnership with regulators

like the HPRA. The recent designation of the HPRA as an AI competent authority and the new National AI Office are welcome steps. We must ensure the BioPharma sector is central to the design of these sandboxes, a key priority for us in the new National Life Sciences Strategy consultation.

EU: The global standard on AI

The European Union is already setting the global standard for ethical, trustworthy AI. By executing on these pillars, we can build on this strong foundation of trust and accountability. This is not about a guaranteed win, but the necessity of mastering GxPscaled AI to ensure Ireland remains a leading global hub. Amidst rife global competition, we must embrace this challenge or risk forfeiting our hard-won leadership.

Our 'GenAI Playbook' identifies over 100 use cases. Here are five examples of AI in action:

AI accelerates GxP compliance and quality oversight. By analysing unstructured text from historical Quality Management System (QMS) reports, the AI can instantly identify patterns to suggest probable root causes, accelerating Root Cause Analysis (RCA). This acts as a "knowledge agent" for the QA team, recommending actions based on past incidents.

Compiling mandatory GxP reports like Annual Product Reviews (APRs) is a manual process that consumes thousands of person-hours. AI solves this by automatically aggregating data from siloed systems (MES, LIMS, QMS), drafting the report, and reducing the risk of human error from manual reconciliation. This frees up expert time, which can be as much as 70% of their focus on certain tasks.

GenAI strengthens supply chain security by analysing global data streams, from geopolitical shifts to weather patterns, to predict disruptions before they happen. It enables rapid 'what-if' scenario planning, allowing teams to proactively adjust sourcing and logistics to protect delivery timelines.

Meeting our climate goals requires precise data. GenAI automates the tracking of Scope 3 emissions by extracting and standardising data from thousands of diverse supplier invoices and reports. This identifies carbon hotspots instantly, moving sustainability from manual reporting to real-time strategic management.

This key low-risk application builds AI culture. AI can summarise complex SOPs and vendor manuals into concise training modules, providing a virtual assistant for operators, and reducing dependency on senior Subject Matter Experts (SMEs). Crucially, it helps retain and transition knowledge of experienced personnel, which is vital for business continuity.