Finding solutions for real world challenges

With a focus on efficiency, scalability, and precision, designing state-of-the-art environments that optimize workflow, enhance safety, and drive technological breakthroughs.

Since 1935, we’ve believed that design has the power to make the world a better, more beautiful place.

That’s why clients and communities on nearly every continent partner with us to design healthy, happy places in which to live, learn, work, play, and heal. We’re committed to Living Design, an approach that integrates environmental, social, and design considerations to advance ecological health and well-being. Our partners include Schmidt Hammer Lassen Architects; Portland; Nelson\Nygaard; and Pierre-Yves Rochon (PYR).

Planet Positive Firm of the Year

Metropolis Magazine, 2023 Firm of the Year

Texas Society of Architects, 2024

Brand That Matters Fast Company, 2021

We have designed more than 50 million square feet of science and technology facilities in the past ten years, working in every type of industry including private, federal agency, and academic institution. Our projects range from a 1,000 square foot interior laboratory fitout to a multi-million square foot science city. We believe in cross-disciplinary advancement in design. Our firmwide expertise is part of our toolkit of design resources. Words we live by are conducting practiceinformed research for research-informed practice.

Adaptability is key. Our designs embrace flexibility, scalability, and resilience—anticipating future technologies, workflows, and challenges yet to emerge to ensure today’s facilities are ready for the discoveries of tomorrow.

By integrating flexible work areas, shared innovation hubs, and accessible design, we create environments that foster diverse perspectives and teamwork. Thoughtfully designed spaces break down barriers, encourage knowledge exchange, and empower everyone to contribute—driving progress through inclusivity and shared creativity.

“The devil is in the details. All great science buildings are designed from the inside out.”

- ED CORDES, SCIENCE & TECHNOLOGY MANAGING PRINCIPAL

Client: Confidential

Size: 400,000 SF

Completion Date: Est. Oct 2025

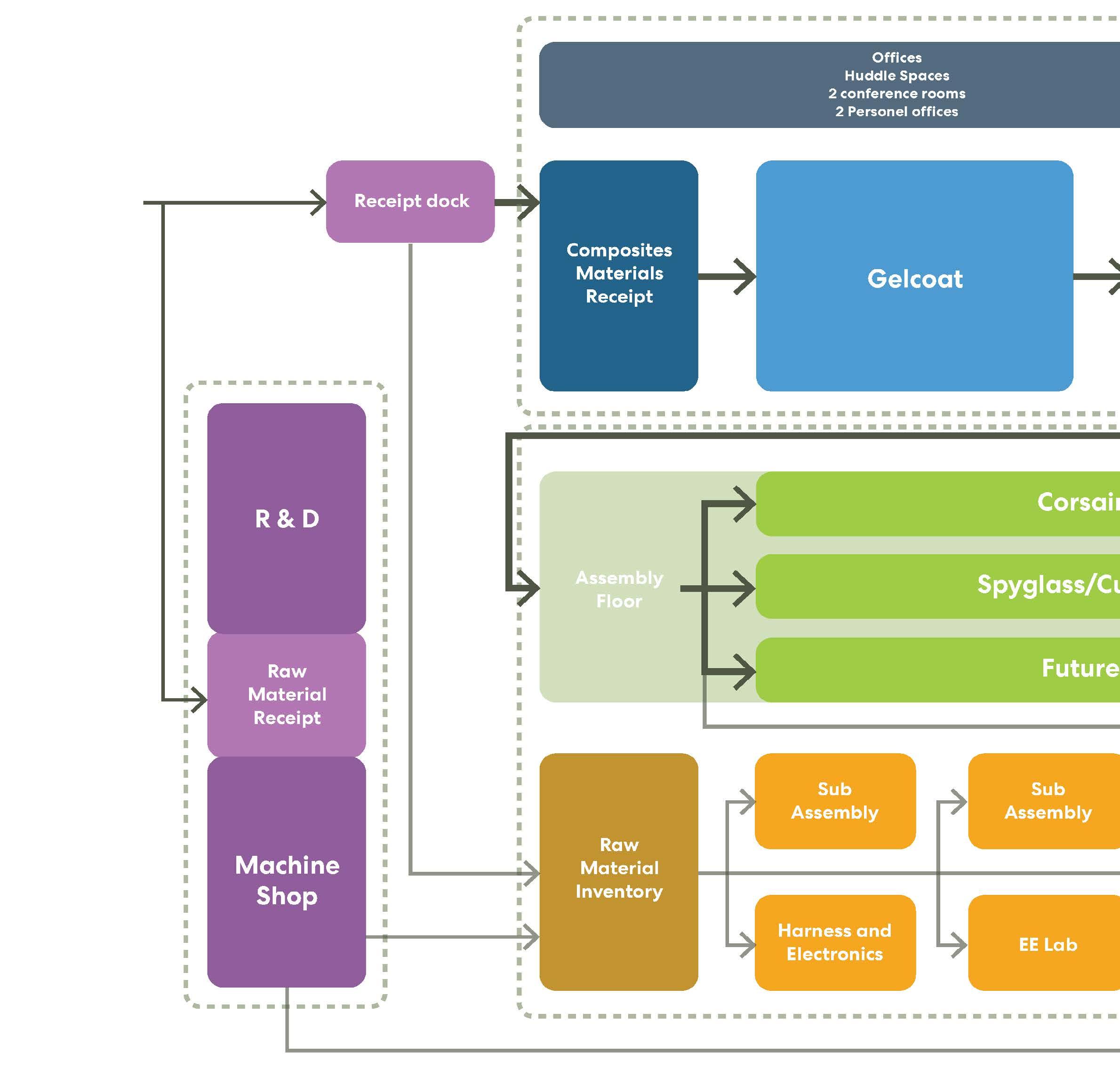

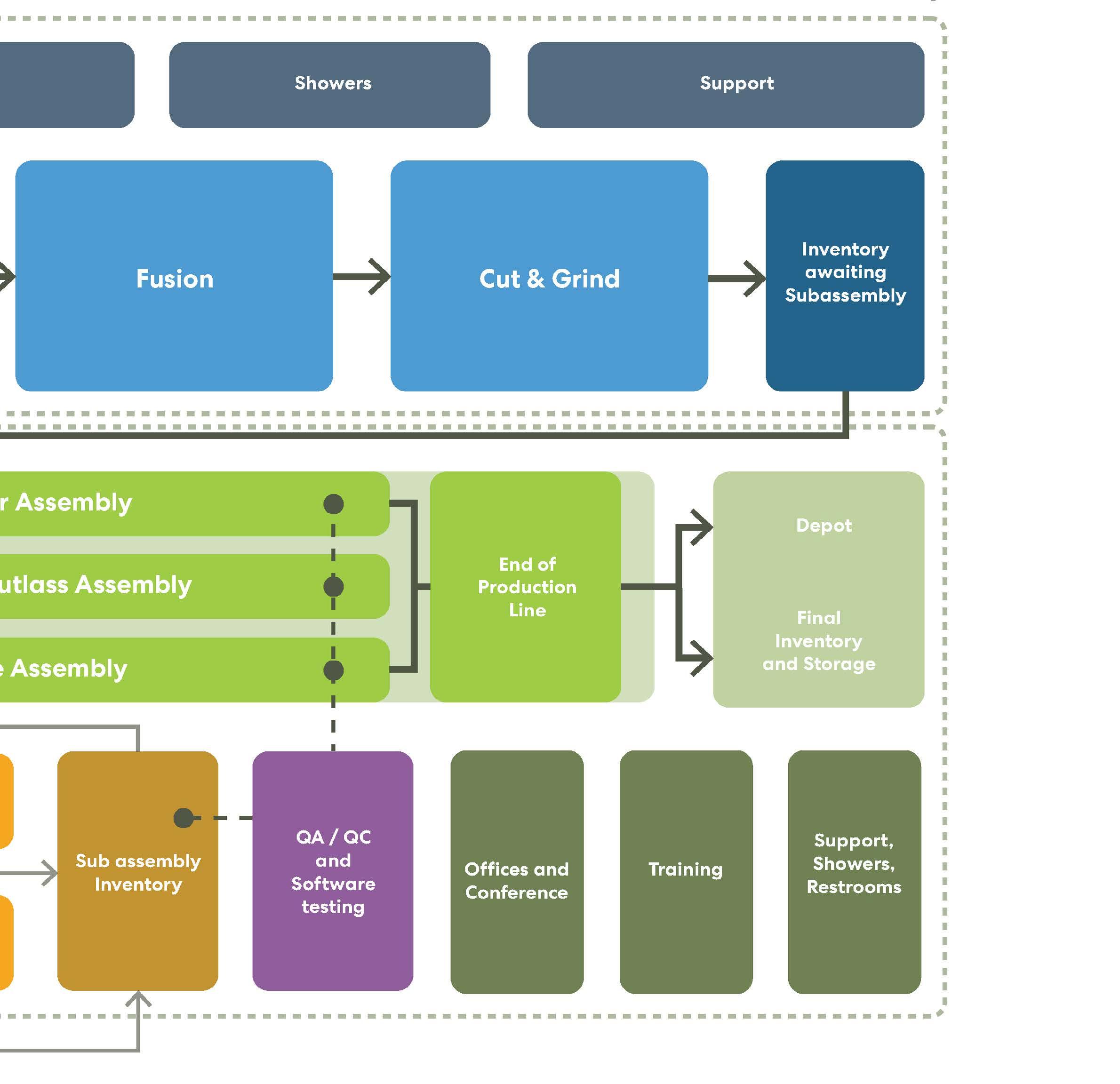

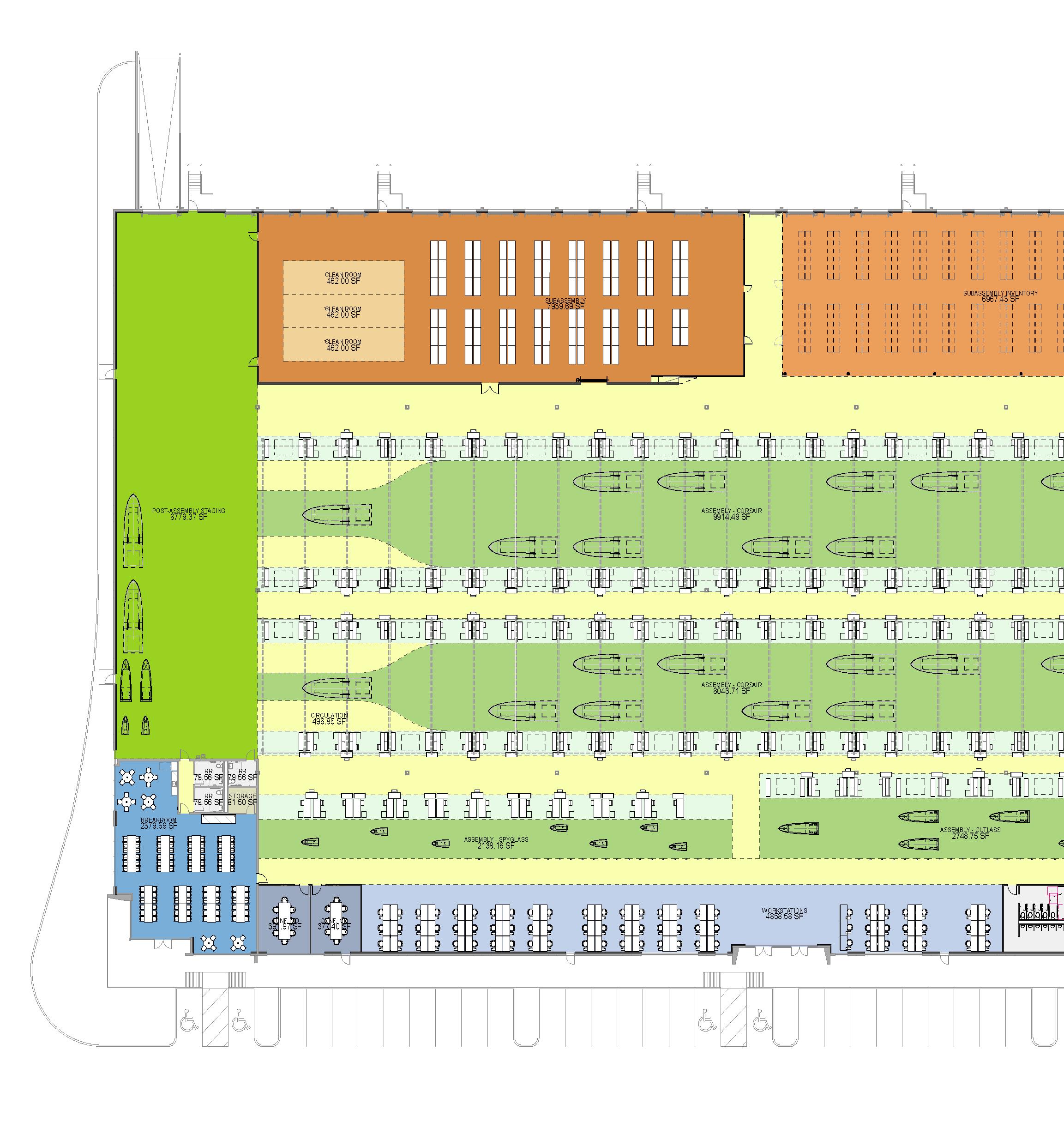

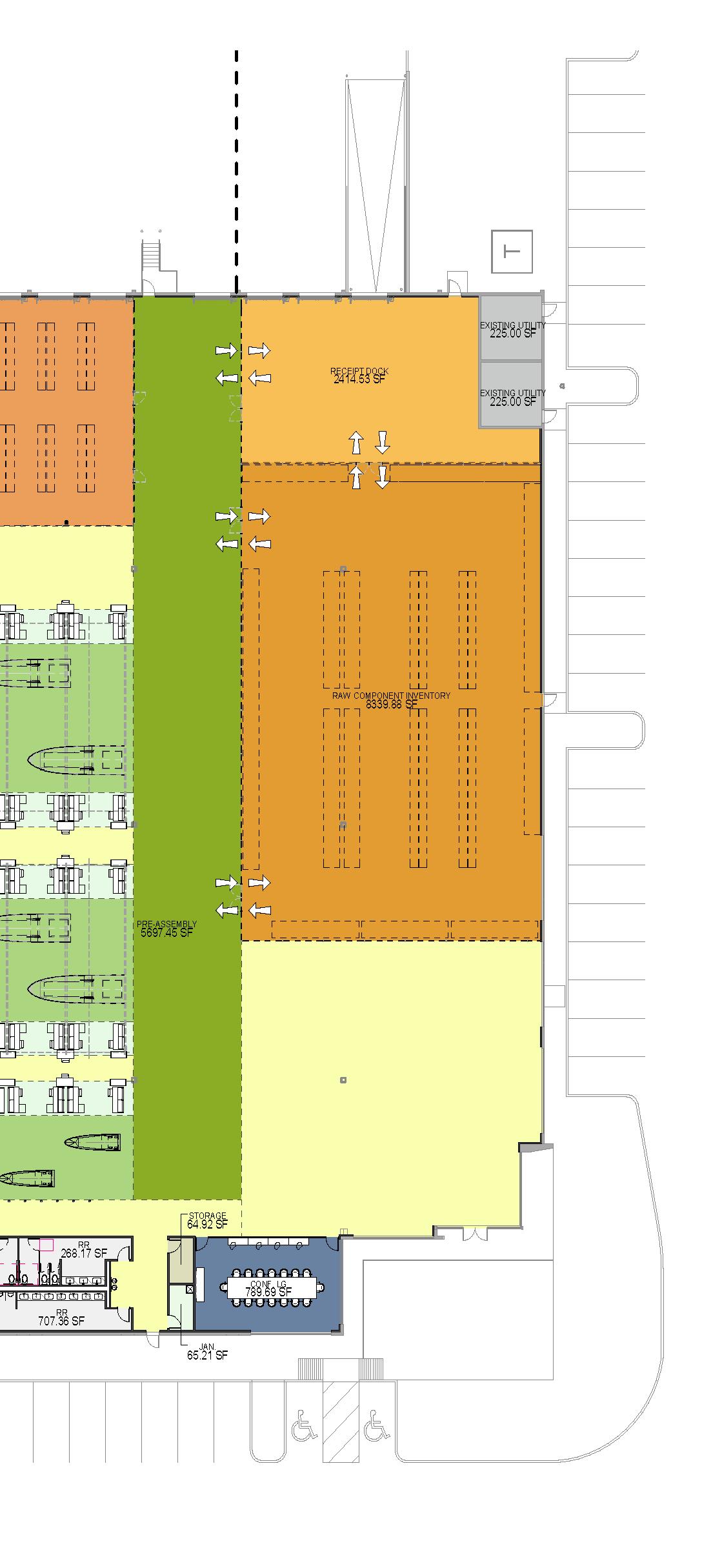

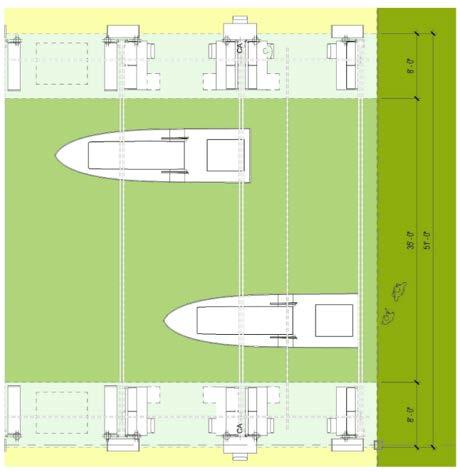

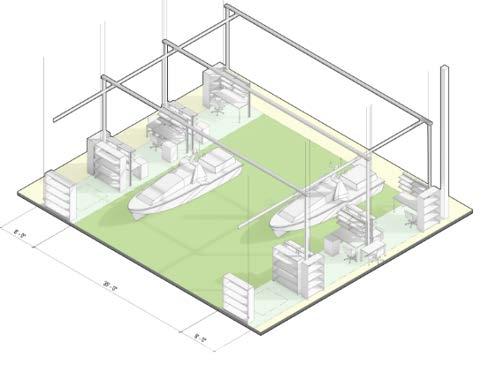

Project Isengard will occupy 7 Flex Industrial Buildings, 391K Sq. Ft. at Eastside Commerce Center, Austin, TX.

Three buildings will house staff made up of software and hardware engineers, satellite / GPS / Surveillance / Communications engineers, ship building vessel manufacturing technicians, SCIF spaces, executive briefing, conference, hospitality, fitness and state of the art client experience center.

Four buildings will house four unique autonomous surface vessel (ASV’s) manufacturing production lines, raw materials storage, composite machining, naval architects, technologists, and naval military experts to complete all production manufacturing and testing of the ASV’s.

Providing for a pressing need of autonomous vehicles, this facility represents the largest real estate deal for R&D and manufacturing in Austin in 2024.

Client: Collin Technical Center

Size: 340,000 square feet

Completion Date: 2020

Awards: Project Achievement Award, CMAA North Texas Chapter, 2021; Best Project Specialty Construction, Award of Merit, ENR Texas & Louisiana, 2021; Honor Award, AIA Dallas, 2021; Design Award, Texas Society of Architects Design Awards, 2022; Design, Community, Planning, Transformation Stars of Distinction, TASA | TASB Exhibit of School Architecture Awards, 2022

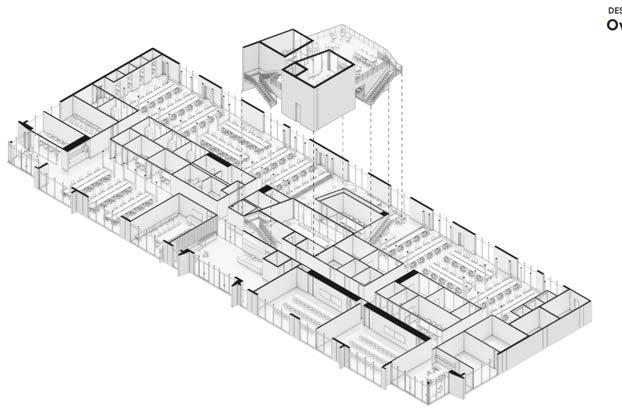

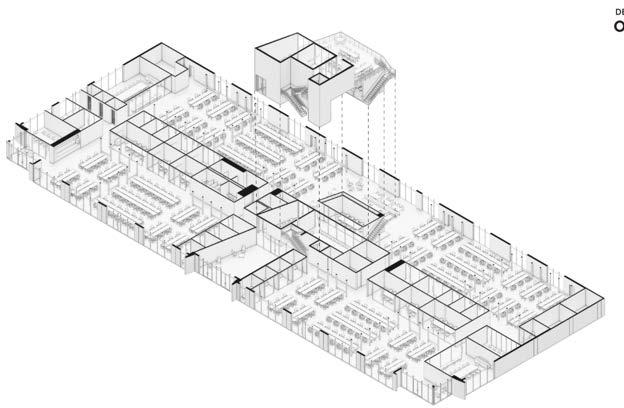

Situated in the fastest growing county in North Texas, Collin College recognized the need to provide strong technical education, trade and workforce training to the community as well as continuing education opportunities for corporate training and workforce partnerships.

To accomplish this mission, Collin College embarked on design and construction of a Collin Technical Campus (CTC) campus in Allen. The building houses classrooms, science labs, early college high school, student services, learning commons, dining, collaboration zones, conference center a wide array of trades and technical spaces including Construction Trades, HVAC, Metals lab, Automotive Repair, Drone technology, Robotics, and Allied Health.

Despite chatter in economic circles suggesting the world is barreling toward a predominantly knowledge- and informationbased economy, we have seen—through projects like Collin College—that the skilled labor force and manufacturing continue to play a critical role in the economy. In Collin County, community leaders and educators believe that strong technical, trade, and workforce training will bring resilience to the local and national economy, particularly as demand for trade workers in the U.S. continues to rise. And for that reason, this community college was willing to invest in great design.

We designed this new technical training center to support a range of programs, from health sciences to automotive repair, while emphasizing well-being through daylighting and a defined sense of place. In addition to technical and trades instruction, the facility offers continuing education opportunities for corporate training and workforce partnerships.

― WHAT IT IS

The new campus is a microcosm of society and is designed to serve people of various ages, skill levels, interests, and backgrounds.

Client: Commonwealth Center for Advanced Manufacturing, University of Virginia Foundation

Size: 63,000 square feet

Completion Date: 2012

Awards:

Award in Architecture, AIA, DC Chapter, 2014

Design Excellence Award, Institutional, AIA, Northern Virginia, 2014

Honor Award, AIA, Potomac Valley, 2013

Best of Best, Global Best Projects Award, Engineering News Record, 2013

Best Manufacturing Project, Engineering News Record, Mid-Atlantic, 2013

CCAM is a research collaboration between the University of Virginia, Virginia Tech, Virginia State University, and manufacturing companies worldwide, including Rolls Royce North America. The 63,000 square foot (5,850 square meter) state-of-the-art facility has been designed for manufacturers to collaborate with faculty and students from Virginia’s top research and teaching institutions to perform advanced research in surface engineering and manufacturing systems.

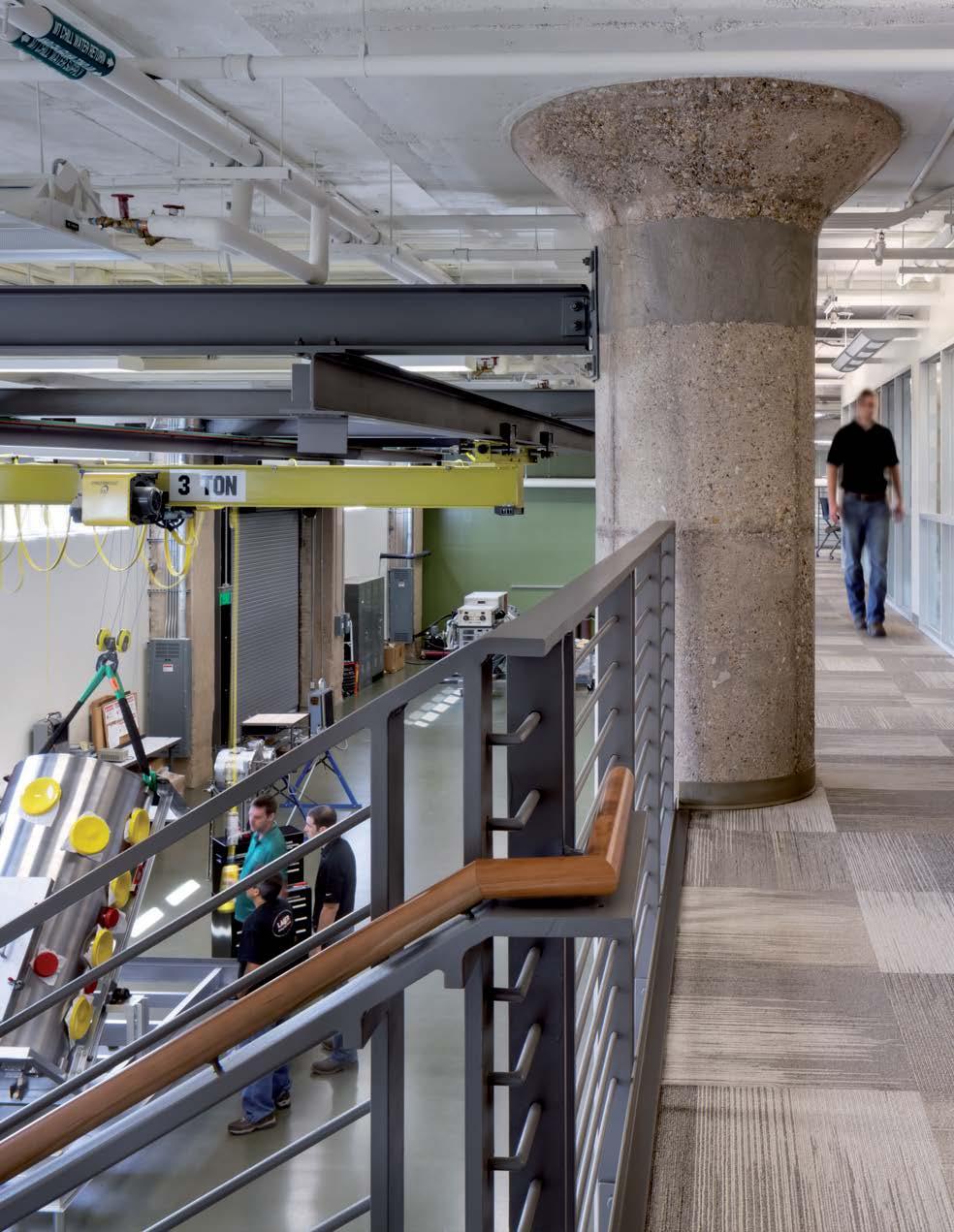

CCAM houses engineering and computational labs, as well as a large high-bay space for prototypical manufacturing processes, including thermal spraying, directed vapor disposition, and multi-axis milling. The facilities also include core laboratories for materials preparation, surface characterization, and computer visualization, as well as conferencing and amenity spaces for CCAM employees and visitors.

― WHAT IT DOES Joins academic research with best-inclass manufacturers for accelerated product innovation.

“The unanimous consensus is that the facility is truly world-class...Researchers will appreciate the efficient layout, the catwalk, the communal areas, and the high bay space...the building is the perfect blend of high tech and industrial, without being soulless.”

Pace Lochte, UVA Director of Regional Business Development

Springfield, Missouri

Client: Ozarks Technical Community College

Size: 122,000 square feet

Completion Date: 2022

The Future is Here

The new 122,000 square foot, two-story Robert W. Plaster Center for Advanced Manufacturing (PMC) serves as Missouri’s regional hub for advanced manufacturing and technology-related education and training. The design for the PMC includes specialized hands-on learning environments, flexible and collaborative classrooms, customizable simulation training centers, long-distance learning space, research and development labs, designated process-improvement space, business incubation test centers, and a large high-bay environment for industryled projects. The PMC offers short- and long-term training opportunities that cover a breadth of industry specializations, and focus on the future of the advanced manufacturing industry, highly technical processes, and employment.

Occupying a key site at the campus edge, the PMC is a signature building that reflects OTC’s critical role in providing skilled talent for Missouri’s advanced manufacturing industries. Fronting one of Springfield’s main thoroughfares, the 500’ long high-bay space offers views into PMC’s main programs including Industrial Systems, Precision Manufacturing, Collaborative Projects, and Industry Partner Space. Alongside the high-bay, a two-story wing accommodates other lab space including Network Technologies, Digital Design, and Rapid Prototyping. To enhance the visitor experience, a choreographed “parade route” helps OTC lead prospective students and industry recruiters through the facility.

Golden, Colorado

Client: Colorado School of Mines Size: 190,000 square feet

Completion Date: Est. 2026 Project Cost: $240 million

Building on a history of successful collaboration, the Colorado School of Mines and the United States Geological Survey seek to revolutionize Earth Science in the 21st Century by partnering in a new interdisciplinary research facility entitled the Subsurface Frontiers Building. This academic and research focused building will serve as the home for both organizations’ mineral exploration, subsurface energy, and mineral economics programs. The relocation and co-location will provide unique national resources fostering collaborative efforts in the application of geoscience to solve real-world problems including the discovery of sustainable sources of energy, an expansion of potential mineral supplies, and strategies to balance energy, water, and climate for a more sustainable future.

Perkins&Will completed an intensive programming/concept design exercise. Preliminary outcomes of the programming process have established a program for a 190,000 GSF building in which lab, office, and common/support spaces are arranged to foster collaboration between agencies and between students, professors, researchers, and practitioners.

Colorado School of Mines, Energy and Minerals Research Facility (EMRF)

Five thematic groups have been established: Geophysics, Mineral Resources, Microanalysis and Sample Characterization, High Performance Computing & Visualization Lab, Isotope and Geochemistry. The building will have a strong general educational component as well, allowing campus visitors to experience the dynamic new frontiers of the research being conducted within.

Client: U.S. Department of Energy Size: 90,000 square feet

Completion Date: 2023

Awards: Special Achievement Award, ACEC Illinois Engineering Excellence Awards,2025, Best Project, Higher Education, ENR Midwest, 2023

The Integrated Engineering Research Center (IERC) is a new laboratory, technical and office building with a focus on collaboration spaces for the Fermilab scientific and engineering community. The IERC is located to the northeast of historic Wilson Hall and connects directly to the Wilson Hall ground floor and atrium.

With the IERC positioned adjacent to Wilson Hall, it collocates engineering and technical staff in the laboratory’s central campus, which is where most of the scientific user community is located. Wilson Hall is highly valued as an architectural icon within Fermilab and the DOE laboratory community as a whole. While the IERC must also be a signature building, its design requires a sensitive and artful approach to its architectural configuration, scale and proportion in response to this proximity to Wilson Hall. This also complements the ongoing and planned renovations of Wilson Hall and establishes the central campus as the anchor point of the site.

― WHAT IT IS New, state-of-theart building with laboratories equipped to deliver on major initiatives in particle physics.

As Fermilab expands to enhance neutrino research, the new Integrated Engineering Research Center brings diverse research teams together under one roof. The center’s design was informed by extensive consultations with users, ensuring future flexibility for ever-evolving scientific needs.

See how this new lab building was future-proofed.

Client: Sany

Size: 400,000 SF (37,161 SM)

Completion Date: 2012

The SANY Office & Assembly Building in Peachtree City serves as the North American Headquarters for a China-based heavy equipment manufacturer. The first phase of a 228-acre site Master Plan, the 360,000 square foot assembly building and integrated 60,000 square foot three-level office consolidates visitor, executive, and employee amenity areas in a single unique hybrid component that limits the land disturbance on site while maximizing future expansion opportunities. The office component is integrated into the northeast corner of the assembly building adjacent to the entry drive.

A three-story, point-supported glass atrium anchors the corner and allows for impressive views in and out of the space. Flowing canopies provide shade to the east-facing atrium and visually weaving the relationship from floor to floor, from east elevation to north and from inside to outside.

―

The wave represents the equipment parts, shipped across the ocean for ultimate assembly here, at the facility.

― Our Expert

We’re creative thinkers with a passion for design and compassion for our communities.