The Australian Forest Contractors Association is entering a new chapter, with a refreshed Board, a stronger focus on members and several practical adjustments to how the organisation operates.

As part of these changes, the Board confirmed the termination of employment of former CEO Tim Lester, and that the Board intends to introduce a new Operational Engagement Manager role in the near future — one designed to bring AFCA closer to members and the issues they face every day.

AFCA’s new Chair, Lloyd Martin, says the transition offers an ideal moment to pause and listen.

“AFCA exists for its members,” Mr Martin said. “Before making decisions about our operational structure or long-term direction, we want to hear directly from the people we represent. It just makes sense.”

The structural changes coincide with the retirement of several longserving directors—Adan Taylor, Steven Bell, Mark Blackberry, Lauren Carter, Ricky Leeson, Ian Reid and Wayne Shaw-Johnston— whose leadership has shaped AFCA over many years.

The refreshed Board now comprises Mr Martin (Leesons Logging & Cartage, Victoria), Francis Richardson (Orana Enterprises, Tasmania), and returning directors Mark Brown

(University of the Sunshine Coast) and Meeghan Price

processes,” he said. “The Board wants to understand

(TP Bennett & Sons, Tasmania).

Given that only two directors from the previous Board have continued, Mr Martin said it was important for the new Board to gain a clear view of AFCA’s current operations, priorities and challenges.

“The board has plans for a face-to-face strategy meeting in December to formalise some of our thought

what’s working well, where improvements could be made, and how AFCA can better support forest service businesses in such a demanding and everchanging industry.”

Over the coming weeks, Board members will reach out directly to AFCA members and ask them to identify their top three issues— the pressures affecting their businesses, the chal-

lenges unique to their regions, and the areas where AFCA can make the most meaningful contribution.

“Every state, every forest service business, every operation faces different realities,” Mr Martin said.

“We don’t want to assume anything. We want to hear it straight from members, respond, and report back transparently—whether the results are good or bad.”

Mr Martin also highlighted the strength that comes from having a Board with varied experience across the country.

“Different operating conditions bring different insights,” he said. “It’s valuable to have that spread around the table, and we’re fortunate that former directors and other industry colleagues are still willing to lend their expertise when needed.”

The Board is taking a measured approach to filling the new Operational Engagement Manager role.

“We want this position to be genuinely useful to members,” Mr Martin said.

“Right now, our focus is on stabilising current projects, understanding what’s underway, and ensuring we build the right role for the long term.”

In the meantime, AFCA will continue relying on the collective experience of the Board and the broader industry network while it works through the transition.

The NSW State Government has finalised a comprehensive Worker Support Package for employees at the six timber mills on the North Coast directly impacted by the recent moratorium on timber harvesting within the proposed boundaries of the Great Koala National Park (GKNP).

The Worker Support Package was developed in consultation with trade unions, industry, and workers to ensure it delivers meaningful, practical assistance to those directly affected.

It also extends to harvesting operators contracted by the NSW Forestry Corporation whose supply has been restricted by the moratorium.

The Timber, Furnishing and Textiles Union (TFTU), Australia’s only timber union, has welcomed the package as a hard-won outcome for workers.

“It is never a good day when members face losing their jobs. However, given the circumstances these workers face in small towns with limited re-employment possibilities, we are pleased to have helped them achieve justice and the respect of a decent support package.

Continued on page 21...

Established 1991

News 3-17

Green Triangle Timber Awards 8-9

Forestry Austraila Conference 10-12

Fire season 18-19

Silviculture 24-25

Haulage 26-27

Mill profile 28-29

Front Cover:Front Cover: Victoria's fighting capability has been crippled according to the Nationals with the entire G-Wagon and Unimog fleet pulled off the road indefinitely amid serious safety concerns just weeks before fire season with Forest Fire Management Victoria reportedly seeking to borrow up to 40 units from authorities interstate.

Story Page 18

Publisher and Chief Executive: Hartley Higgins

General Manager: Robyn Haworth

Editor: Bruce Mitchell

b.mitchell@ryanmediapl.com.au

Adelaide Office: (08) 8369 9521

Advertising:

Jamie Richardson

j.richardson@winetitles.com.au

Adelaide Office: (08) 8369 9514

Creative Services:

Robyn Haworth

Trader classifieds:

Jamie Richardson

Adelaide Office: (08) 8369 9514

Subscriptions: subs@forestsandtimber.com.au

Adelaide Office: (08) 8369 9500

Subcription rates

One-year (6 editions) $44.65

Two-years (12 editions) $77.65

Accounts:

ar@winetitles.com.au

Adelaide Office: (08) 8369 9500

Postal Address: 630 Regency Road, Broadview South Australia 5083

Phone: (08) 8369 9500

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122

Phone: (03) 9810 3262

Website www.timberbiz.com.au

Printed by Lane Print, Adelaide, SA

Conditions The opinions expressed in Australian Forests & Timber News are not necessarily the opinions of or endorsed by the editor or publisher unless otherwise stated. All articles submitted

The Timber, Furnishing & Textiles Union has condemned the NSW Government’s handling of the Great Koala National Park decision, saying workers are being offered redundancy support packages five times worse than their Victorian counterparts.

TFTU NSW Secretary Alison Rudman said the contrast showed just how little value the NSW Government placed on regional workers.

The NSW State Government has finalised a comprehensive Worker Support Package for employees at the six timber mills on the North Coast directly impacted by the recent moratorium on timber harvesting within the proposed boundaries of the Great Koala National Park.

The Worker Support Package was developed in consultation with trade unions, industry, and workers to ensure it delivers meaningful, practical assistance to those directly affected.

It also extends to harvesting operators contracted by the NSW Forestry Corporation whose supply has been restricted by the moratorium.

Under the Worker Support Package, the workers will receive:

• Top-up redundancy payments ensuring affected workers receive four weeks base pay (inclusive of employer redundancy payment) for each year of

employment with an impacted timber mill or harvesting operator, capped at $150,000.

• Additional support for employees over 45 years of age - a further three weeks of pay for every year of service after the age of 45 (up to a cap of $50,000), to be calculated separately from the top-up redundancy payment.

• Education and training payments ofup to $9,000 for retraining and upskilling with a registered training organisation, as well as any associated travel costs.

• Relocation payments of up to $45,000 for affected workers who move more than 50 kilometres for new employment including property prchase, tenancy termination fees, removal-

ist services and other expenses.

• Free access to mental health support and financial and legal guidance through TELUS Health via phone, video, app or faceto-face.

Eligible employees are those employed on the North Coast of NSW on a full-time, part-time or casual basis who were employed on 7 September 2025 (date of the moratorium announcement) and made redundant within 18 months of that date, being 7 March 2027, as a result of this decision.

Redundancy payments and entitlements will be provided to workers by their employer in accordance with their employment contracts or enterprise areements.

The Government’s redundancy top-up payment will also be provided to the workers via the employer. Parttime and casual employees will be eligible for the redundancy payments at a prorata value.

“Victoria showed how displaced timber workers should be treated: with dignity and proper support.

In NSW, workers are being thrown scraps. This is Labor abandoning its own people in regional communities who have stood by the party for generations,” Ms Rudman said.

The union said the NSW Government has also been dragging its heels on giving

workers’ answers.

“We’ve asked again and again for information about how their scheme for unemployed workers will actually operate. Instead, the Government hides behind Press releases and spin while workers face unemployment.

“That is not a fair go and it’s not what people voted for when they elected Labor,” Ms Rudman said.

Workers across the mid north coast are already reporting deep anxiety and uncertainty, with many forced to explain to their families that their jobs may be gone.

In towns like Heron’s Creek, 85 mill jobs represent one-third of the town’s workforce, a blow that would hollow out the entire community.

“When you kill the timber industry, you kill the towns, schools, health services and small businesses all suffer. The so-called replacement jobs in tourism don’t exist. That’s the reality this Government is ignoring,” Ms Rudman said.

The TFTU is calling on the Government to reverse its decision and commit to a fair deal for timber workers and the communities they sustain.

Page 15: NSW study confirms koalas ‘not harmed by harvesting’

TWhile

he past year has been one of transition, pressure, and strategic recalibration for Australia’s forestry sector. Against a backdrop of climate variability, shifting market dynamics, and evolving policy settings, the industry has continued to navigate challenges while building toward greater resilience and long-term sustainability. One of the most significant themes has been

the ongoing adjustment following the closure of native forest harvesting in several states, most notably Victoria and Western Australia.

Mills and processors faced tight log availability, prompting renewed calls for national investment in expanding the plantation

estate and protecting existing resources from land-use competition.

It's a theme about to be repeated in New South Wales as a result of the creation of the Great Koala Park.

Bushfire risk again looms large, with hotter, drier conditions across the country raising concerns about plantation vulnerability and the long-term impacts of previous fire seasons.

And so to the many con-

tributors and industry organisations who are integral to this publication, plus the advertisers who have supported us to bring it to our readers, we thank you. Our sales, editorial production and support team remain passionate about the industry and we look forward to serving our customers and readers next year. Best wishes to all for a Merry and Safe Christmas followed by a Prosperous New Year.

The Hyne Group has welcomed the release of the Queensland Future Timber Plan which recognises Queensland’s timber as one of the state’s most valued, renewable resources.

The Hyne Group CEO, Jim Bindon was one of several industry leaders who were consulted as part of the plan’s co-design,

“Our industry and its products are not only essential for building family homes and much needed infrastructure, but also for their by-products used in the manufacture of pallets, particle board, packaging, commercial scale potting mix to grow fresh food – to name a few.

“The Government is acutely aware, that as the population increases, demand for these products is only increasing, as is the need to provide employment

amidst thriving, regional communities such as the Wide Bay.

“The need for secure, plantation pine volumes goes hand-in-hand to meet this demand which needs to be planned for now. As stated in the report, ‘The decisions we make today will shape timber supply well beyond 2050’.

“On behalf of the Hyne Group, we congratulate the Queensland Government

and its collaborative approach in developing and delivering the Queensland Future Timber Plan.”

The Hyne Group is Queensland’s largest manufacturer and re-processor of locally, sustainably grown plantation pine. It was established in 1882 in Maryborough and today, continues to employ over 300 people in the region and over 800 nationally.

Products include timber framing, glue laminated timber and cross laminated timber used for housing construction and the recently constructed Queensland Government social housing development in Inala, the National Throws Centre of Excellence in Brisbane, the Queensland Train Manufacturing Program’s new train manufacturing facility and the Queensland Fire and Emergency Services North Coast Region

Headquarters and Maryborough Fire and Rescue Station.

This latter project was only last week, awarded the International public infrastructure award at the Built by Nature Summit held in London in recognition as a world leader in design and construction for the future.

The Built by Nature award follows a rigorous shortlisting and judging process by international experts including Kevin McCloud, Architect and Grand Designs host.

As the winning building, it will be further showcased as part of COP30 being held in Brazil in November including the launch of a short documentary featuring Sir David Attenborough.

Just 12 months ago, His Majesty King Charles III visited a Hyne Group supplied social housing complex under construction in Glebe,

Sydney, in recognition of the sustainability credentials of mass timber, as specified by the King’s Trust Australia.

Mr Bindon said the company was well placed to scale up and deliver for the future demands of Queenslander’s and beyond,

“We are here to work with the Government and grow our industry including our historic commitment and significant investment in research and development and product innovation.

“Our products are internationally recognised, celebrated and awarded for quality while sequestering carbon and significantly reducing emissions in the construction sector.

“With genuine recognition and support, the industry can thrive into the future including delivering for the 2032 Olympics.”

For more information, visit www.hynegroup.com.au

Timber Queensland, the peak body for the forest and timber industry, has welcomed the release of the landmark Queensland Future Timber Plan, describing it as a balanced and forward-looking strategy that provides longoverdue certainty for the sector and regional communities.

“This plan is a major step forward for Queensland’s forest and timber industry,” said Timber Queensland Acting CEO, Clarissa Brandt.

“For the first time in decades we have a long-term strategy that recognises the essential role our industry plays in housing, construction, regional jobs and environmental outcomes, setting a clear direction for growth and sustainability.”

The plan outlines a whole-

of-supply-chain approach, developed in collaboration with industry, First Nations, forest science and building sector representatives and through extensive public consultation.

Mrs Brandt said the plan aligns with the broader Primary Industries Prosper 2050 blueprint which recognises the importance of Queensland’s food, fibre and timber industries in

driving a sustainable and resilient economy.

“The Queensland Future Timber Plan is structured around five-year action plans that will evolve with emerging needs, driven by key challenges such as housing shortages, market access, and the demand for lower-carbon materials,” said Mrs Brandt.

“We are pleased to see the Plan’s five core focus areas of supply, supply chain and market, workforce, regulatory framework, and research, development and extension reflect many of the priorities we raised during consultation,” Mrs Brandt said.

Timber Queensland emphasised that delivery would depend on appropriate co-government and industry funding and implementation, particularly

in the first five year action plan.

“We take pride in managing healthy forests that deliver lasting economic, social, and cultural value to Queensland communities. Looking ahead, we’re enthusiastic about a future shaped through strong collaboration and shared investment between government and industry,” Mrs Brandt said.

“Priority actions that we hope to see in the first five year plan include a targeted planting program to expand plantation resources and support downstream processing, long-term crown resource contracts for native hardwood beyond 2026, and a worldclass, industry-led forestry extension service that partners with private landholders and First Nations communities.”

“We also call for investment to lift the international competitiveness of local supply chains through infrastructure, resource recovery and value-added technologies; measures to stabilise market cycles via long-term public procurement and major projects like the Brisbane Olympics; and reforms to reduce sovereign risk and remove policy and financial barriers to plantation and farm forestry investment, including those within the Land Restoration Fund.”

“This Queensland Future Timber Plan is a strong foundation. With the right investment and collaboration, we can ensure Queensland’s most renewable resource continues to deliver for future generations,” Mrs Brandt said.

From a single ute and a few big ideas, to managing 30% of Australia’s plantation carbon projects — Tasmanian-based SFM is celebrating 21 years of innovation, impact, and integrity in forestry.

Founded in 2004 by Tasmanian-born Andrew Morgan and David Wise, SFM has grown from humble beginnings into a national leader in sustainable forestry and carbon development. The company now operates across four states, manages plantation assets on behalf of institutional investors, and leads the country in plantation-based carbon project development.

The pair first met as students at the University of Tasmania — fittingly, over a beer at the UniBar — bonding over their shared love of the environment, business, and a healthy debate.

Morgan and Wise credit much of SFM’s success to their partnership.

“If Dave’s the accelerator in this partnership,” Morgan quipped, “then I’m probably the steering wheel — making sure we’re still pointed in roughly the right direction when he hits the gas.”

Reflecting on the early days of environmental consulting, Managing Director Andrew Morgan said the pair were agile and hungry.

“There was no big strategy at the time,” recalls Morgan. “Just a ute, a laptop that made strange noises, a few half-decent ideas, and people who believed forestry could be done differently — with integrity, long-term thinking, and a bit of grit.”

SFM was born out of that conviction and has never looked back. Over two decades, the company has built a reputation for forwardthinking forestry — from managing carbon assets at scale, to launching one of the world’s only underwater timber recovery operations, Hydrowood.

“Starting SFM wasn’t about following the rules,” said Managing Director of Strategy, Risk and Trading,

David Wise. “It was about creating something we believed in — a company that could bring people together around forestry, innovation and impact. The work we do now with our brilliant team is practical, tangible and grounded in the real world, and that’s something we’re incredibly proud of.”

hat ethos evolved into what the company calls Future Focused Forestry — a mindset that continues to guide the business.

“At SFM, we talk a lot about looking ahead; identifying opportunities, moving early, and taking a strategic leap while others are still deciding whether to jump,” said Morgan. “This mindset is part of our core DNA.”

The business has faced its fair share of challenges, including navigating the Global Financial Crisis, when many others were scaling back. In a bold move, SFM purchased the historic Battery Point property it had been leasing: a two-storey gothic residence in one of Hobart’s most iconic heritage precincts. It became the company’s headquarters — and the site of forestry’s most infamous Christmas parties.

Innovation with substance

Over the past 21 years, SFM has repeatedly stayed ahead of the curve:

• Among the first in private forestry to achieve FSC certification (2011)

• Created Hydrowood, salvaging high value, coveted Tasmanian timber from submerged forests

• Pioneered remote fire detection and digital for-

estry technologies

• Made early investments in carbon project development

• Developed innovative landholder models to integrate forestry into farming systems

• Expanded across regions and diversified its client base

“The thing that’s made SFM different is our willingness to look beyond convention,” said Wise. “We’re not just managing forests, we’re creating new models that work for farmers, investors and the environment.”

Their leadership has been recognised across the industry nationally.

“A lot of people in natural resources have just stuck to their knitting,” said New Forests founder David Brand. “But with SFM, there’s been a willingness to explore different investment models and economic models — to take forestry into the 21st century and position it as a real source of solutions.”

What’s next: scaling what works

Today, SFM is scaling up

its impact across partnerships, landscapes, and regions.

“If the first 21 years were about proving what’s possible,” said Morgan, “the next 21 are about scaling it; scaling partnerships with farmers, investors and clients; scaling landscapes through replanting and restoration; and scaling environmental, economic and social impact through projects that show how forestry and natural capital can work hand in hand.”

“And we’ll keep doing it the way we always have —

grounded, practical, and quietly ambitious,” he said. “Because the future of climate and nature-based solutions won’t be built by the biggest names or the boldest headlines — it’ll be built by people who stay the course and do the work properly.”

Wise agrees: “We’ve quietly built two businesses that are unique in their fields. Both SFM and Hydrowood prove that with the right people, values and perseverance, we can punch well above our weight.”

Onet r ak

Forest & Wood Products

Australia has launched the first stage of a new centralised research archive to provide the forestry and wood products industry with streamlined access to decades of research outputs.

The first stage of the project consolidates over 40 research reports from the National Institute for Forest Products Innovation (NIFPI), bringing together critical findings into a single, searchable database. The archive can be accessed at https://fwpa.com.au/resourceshub/nifpi-reports/

Term completed

Forest & Wood Products Australia’s deputy chairman Professor Tony Arnel will complete his final term this month after serving on the FWPA Board since October 2016.

For more than nine years, Tony has brought deep expertise in sustainable construction, policy, and industry transformation.

As both a leader and a guide, his governance and insight have helped steer FWPA’s work to strengthen codes and standards, advance Australia’s mass-timber capability, and improve public understanding of timber’s climate credentials.

ForestrySA chairman

Former CEO of Forest Wood Products Australia Ric Sinclair has been appointed Chair of ForestrySA. He replaces June Roache who has held the position since 2018.

Mr Sinclair has been a non-executive director since 2023 and was previously chair of the board’s audit and risk committee. He brings a wealth of expertise in forestry, communications and strategy, and has a history of encouraging innovation in the industry. He was CEO of Forest Wood Products Australia from 2008 to 2021.

Hub appointment

Lara Kroeger has been appointed workforce development manager with the Green Triangle Forest Industries Hub.

Ms Kroeger brings valuable international and regional experience in project management, stakeholder engagement, and strategic communication, together with direct experience in timber and fibre processing through her previous role with Polytec (Borg).

More than 520 guests from across the Green Triangle timber industry came together for the 2025 Green Triangle Timber Industry Awards — the largest celebration of the industry’s people, businesses, and achievements since the awards began.

Hosted by Australian comedian and television personality Peter Helliar, the evening began with laughter and ended in applause as stories of innovation, resilience, and community pride were shared from across every corner of the sector.

Each award winner spoke with heartfelt gratitude — thanking mentors, employers, and peers who have supported their careers and contributed to the success of an industry that remains one of the Green Triangle’s most important economic and social foundations.

The highlight of the evening was the presentation of the Timber Legend Awards, marking the first time in GTTIA history that two recipients were honoured in the same year.

Through short films and personal reflections, guests were given a glimpse into the careers of Mr Laurie Hein and Mr Stephen Van Schaik, two leaders whose contributions, leadership, and integrity have shaped the industry for decades.

GTTIA Chair Adrian Flowers said both legends represent the best of what the industry stands for.

“Laurie and Stephen come from very different parts of the timber supply chain, ut what they share is a lifetime of dedication and a genuine passion for people. They’ve each played an important role in shaping the professionalism and

unity our industry is known for today,” he said.

Mr Flowers said this year’s event reflected the continued growth and strength of the timber sector.

“The 2025 GTTIA has been our most successful event to date. We received the highest number of nominations in the history of the awards, saw a strong increase in female repre-

sentation, and welcomed a record number of guests.

It’s a clear sign of the pride people have in the work they do and the value of recognising that publicly.”

He also acknowledged the vital role of sponsors in making the celebration possible.

“Our sponsors make this event what it is. Their support allows us to celebrate

the achievements of our people and create an evening that our industry genuinely looks forward to each year.”

From harvesting and haulage to sawmilling, training, safety, and sustainability — the awards recognised excellence across all areas of the timber supply chain.

The Victorian Government is offering to help landowners grow more trees on farms and extract greater value from their existing plantations through a new program starting in the north east.

The Trees on Farms Utilisation (ToFU) Program is a $4.5 million initiative that will help farm forestry plantation owners make the most of their existing plantations.

Through the program eligible landowners can access a free professional assessment of their plantations, providing tailored insights into timber quality, market opportunities, and next steps – all with no cost or obligation.

If an assessment identifies a commercial opportunity, landowners may be eligible for funding for management activities in later stages of the program, such as thinning, to improve their plantation for enhanced timber quality and market access.

The launch includes local government areas of Moira Shire Council, Indigo Shire Council, City of Wodonga, Towong Shire Council, Greater Shepparton City Council, Benalla Rural City Council, Rural City of Wangaratta, Strathbogie Shire Council, Mitchell Shire Council, Murrindindi Shire Council and Mansfield Shire Council.

To be eligible under the program, plantings must be between 3 and 30 hectares, planted before 2020 specifically for wood production, and not already allocated or committed for sale.

Launching initially in the state’s north east, the program will be extended to the rest of the state early next year.

This initiative supplements the suite of programs available through the Trees on Farms program which helps farmers plant more trees.

Applications for the program in the north east will close on 19 December 2025. For more information on the programs or to apply today visit agriculture.vic.gov. au/trees-on-farms.

Australia could soon see a wave of prefabricated timber housing factories, with the Federal Government backing a new research project aimed at fast-tracking timber-led modern methods of construction to ease the national housing shortfall.

Announced by Minister for Agriculture, Fisheries and Forestry Julie Collins at the Forestry Australia conference in Adelaide, the project is one of 14 funded under the latest round of the Australian Forest and Wood Innovations (AFWI) program.

“Together [the new projects] represent an investment of $30 million, with more than $10 million from AFWI and over $20 million contributed by industry and partners,” Minister Collins said.

“Collectively this research is strengthening Australia’s forestry future – growing the next generation of researchers whilst delivering innovative solutions to boost productivity, sustainability and climate resilience across the sector.”

The projects span a wide

range of priorities, including biosecurity, Indigenous-led timber recovery, and advanced manufacturing.

“They range from developing a national biosecurity program for giant pine scale, to an Indigenous-led cultural timber recovery project in the Northern Rivers, through to an advanced manufacturing precinct strategy to accelerate prefabricated timber housing,” Ms Collins said.

The advanced manufacturing precinct strategy is expected to accelerate timber-based MMC at scale, positioning timber as a key solution to Australia’s housing crisis.

AFWI, established last year with a $100 million

federal commitment comatched by industry, is a cornerstone of the government’s plan to grow the $28 billion forest and wood products sector.

Hosted by the University of Tasmania, AFWI works with more than 20 research partners including the University of Melbourne and University of the Sunshine Coast.

“From house frames, to farm gates, to furniture in homes and offices, to the cardboard products we use every day, it’s clear that the forestry sector is at the heart of everything that we do,” Ms Collins said.

“The Albanese government is interested in growing plantations, modernising infrastructure, investing in research and development, tackling illegal timber at the port and upskilling the workforce.”

AFWI Executive Director Dr Joseph Lawrence said the new investments reflect national priorities and realworld impact.

“These projects bring together Australia’s leading researchers, industry partners and collaborators

to solve real-world challenges – from forest health and biosecurity to housing, bioenergy and advanced manufacturing,” he said.

“They demonstrate how AFWI is building national capability across the full forest-to-housing value chain, in partnership with government, universities, and industry.”

Among the funded projects are:

AFWI Research Centres Projects

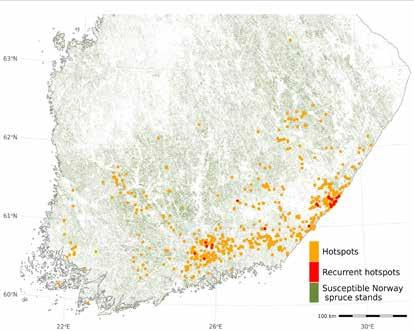

• Risk models for pine pests under future climates using empirical data

• Productive and climateresilient eucalypt germplasm for Indigenous forestry in Northern Australia

• Fibre to fuels: linking sustainable forestry and renewable energy

• Bio-based construction systems for small-footprint dwellings

• Mapping silvopastoral supply chains in Australia

• SilvaNaut: robotic weed control for forest machinery

• Sustainable management

of plantation forest pests under changing climates

AFWI National Open Call (Round 2) Projects

• Bundjalung Cultural Timber Project

• Innovative bio-processing for treated timber waste

• Automated design for prefabrication in timber construction

• Genomic infrastructure for forest tree breeding

• Advanced manufacturing strategy for prefab dwelling adoption

• Valorisation pathways for hardwood forest waste

• Long-term management program for giant pine scale

The announcement was made before an audience of more than 400 forestry professionals, scientists, land managers and policymakers, reinforcing the government’s commitment to innovation and sustainability in the forest sector.

Shona Heading has been named as the recipient of the 2025 Richard Stanton Memorial Leadership Award in recognition of her leadership in sustainable forest management and promotion of certified Australian timber.

The Richard Stanton Memorial Leadership Award, established in 2015 to honour the late Richard Stanton — a pioneer in sustainable forestry in Australia and internationally — recognises individuals who have demonstrated exceptional commitment to Forest Management or Chain of Custody Certification under the Responsible Wood Certification Scheme.

Presented at the Forestry Australia conference in Adelaide by Responsible Wood CEO Simon Dorries and Chair Dr Tony Bartlett, the award acknowledges

Heading’s leadership, innovation and dedication to advancing certified timber markets.

“Shona exemplifies outstanding leadership in sustainable forestry,” said Mr Dorries. “Her dedication to promoting certified Australian timber, her innovative approach with the Australian Araucaria™ campaign, and her ongoing commitment to industry collaboration perfectly reflect the values Richard Stanton championed. We are thrilled to recognise her achievements with this award.”

The nomination highlighted Heading’s leadership of the Australian Araucaria campaign, a national initiative designed to raise the profile of Araucaria cunninghamii (Hoop Pine) — a plantation species grown exclusively in

Queensland under Responsible Wood certification.

Under her guidance the campaign established a distinct brand identity, emphasised sustainability and biodiversity, and promoted the responsible use of certified timber.

Beyond her role at HQPlantations, Heading is co-owner of Hall Homes, a residential building company that actively champions the use of certified Australian timber. She also contributes to national industry initiatives as a Steering Committee member for the Timber Market Index and the Timber Market Survey, and as an advisor to Responsible Wood’s branding and marketing activities.

About the trophy

The Richard Stanton Memorial Leadership Award honours Stanton’s legacy

by recognising individuals who demonstrate exceptional commitment to sustainable forest management and the principles of Responsible Wood certification. “Richard Stanton was a passionate advocate for sustainable forestry, and this award continues his mission by celebrating those who contribute significantly to the health and sustainability of our forest industry, ensuring they remain a vital resource for generations to come,” Mr Dorries said.

This year’s Richard Stanton trophy is made from a mix of timbers certified under the Responsible Wood scheme and was designed and manufactured by George Harris, a member of Wood Connect, a Responsible Wood certified group scheme.

Forestry Australia’s three-day Conference in Adelaide celebrated the remarkable contributions of Bob Gordon, Dr Peter Stanson PSM, and Dr Tom Fairman, who were honoured with the 2025 N.W. Jolly Medal and Prince of Wales Award respectively.

Held from 20 to 23 October, the conference brought together 400 attendees under the theme Restoring forests and landscapes and securing Australia’s future, marking the 150th anniversary of plantation forestry in Australia and the 90-year anniversary of The Institute of Foresters of Australia, trading as Forestry Australia.

Aligning with the UN Decade of Ecosystem Restoration, the event united experts, researchers, forestry professionals, farmers, rangers, and tree-growing practitioners to advance sustainable forest management and foster the next generation of forestry leaders.

2025 Award Winners

• Robert (Bob) Gordon –N.W. Jolly Medal: Bob Gordon, a nationally respected forestry leader with over 40 years of service, received the N.W. Jolly Medal, Forestry Australia’s highest honour, for his transformative contributions to sustainable forest management, policy reform, and Indigenous inclusion. Beginning his career with the Forestry Commission in Tasmania in 1978, Bob held

leadership roles, including Chief Executive Officer (CEO) of Forestry Tasmania (2006–2013), where he navigated the Tasmanian forest peace negotiations. As National President of Forestry Australia, he spearheaded the merger with Australian Forest Growers, modernised governance, and championed diversity and mentoring. Currently, as inaugural Chair of Australian Forest and Wood Innovations (AFWI), Bob drives national research initiatives. His advocacy for First Nations communities, international market development, and community roles, including Honorary Consul of Finland for Tasmania, have left a lasting legacy in forest governance and professional leadership.

• Dr Peter Stanson PSM – N.W. Jolly Medal (award accepted by his son, Matthew): Dr. James ‘Peter’ Stanton was awarded the N.W. Jolly Medal for his 50+ year career advancing forest conservation, particularly in Queensland’s tropical forests and the Wet Tropics World Heritage area. A professional forester and expert in landscape and fire ecology, Peter’s scientific assessments expanded national parks and protected areas across Queensland and the Kimberley. His work with the Queensland Forestry Department, Queensland National Parks Service, and Australian Wildlife Conservancy shaped con-

servation policy. Recognized with the IUCN Fred M. Packard International Parks Merit Award (1982), the Public Service Medal (1996), and an Honorary Doctor of Science from James Cook University (2023), Peter’s legacy includes millions of hectares of conserved forests.

• Dr Tom Fairman – Prince of Wales Award: Dr Tom Fairman, a Research Fellow at the University of Melbourne’s FLARE Wildfire Research Centre, received the Prince of Wales Award for his outstanding contributions as a young forest professional. His leadership in recovering alpine ash forests after the 2019/20 Black Summer bushfires, including reseeding over

11,000 hectares and co-developing a $7.7 million seed stock initiative, showcases scientific and operational excellence. Tom’s research, including contributions to the 2025 Alpine Ash Silvicultural Reference Manual, and his roles as Vice President of the Gippsland Forest Dialogue and committee member of the Corner Inlet Landcare Group, reflect his commitment to sustainable forest management. A passionate mentor and science communicator, Tom collaborates with Traditional Owners and has secured over $400,000 in research funding since 2020.

The conference also saw nine Forestry Australia members elevated to Fellow status including:

Mark Brown, Euan Ferguson, Blair Freeman, Rod Keenan, Jim O’Hehir. Zoe Ryan, Christine Stone, Suzette Weeding, and Jim Wilson.

The 2025 Conference highlighted Forestry Australia’s commitment to sustainable forestry, First Nations collaboration, and youth engagement. Discussions on innovative forest management, global conservation challenges, and strategies to attract young professionals underscored the sector’s role in delivering ecological, social, and economic benefits for Australia’s future.

Remsoft, a leader in Forest Intelligence solutions, has acquired LOGR, an Australian forestry technology company known for its innovative real-time data capture and operational multi-party analytics platform. The acquisition advances Remsoft’s strategy to build a unified, cloud-based ecosys-

tem that connects every stage of the forest value chain. The announcement was made at Forestry Australia’s conference in Adelaide.

LOGR’s software improves safety and efficiency at busy delivery sites by tracking each transaction in real time and automatically recording product details, optimizing transportation and logis-

tics. By introducing custody tracking earlier in the process, the platform enhances visibility and control across the chain of custody. It integrates seamlessly with enterprise systems, giving forestry stakeholders—including mills, contractors, and landowners—greater traceability and operational insight into areas that were previously

inaccessible. Together, Remsoft and LOGR will deliver a single source of truth for forestry operations, from harvest planning to mill delivery. The combined capabilities will help companies reduce reporting time, minimize manual data entry, and make faster, data-driven decisions that improve profitability,

transparency, and sustainability.

“LOGR brings powerful field-level intelligence into our ecosystem, connecting delivery site operations with strategic planning in real time through its advanced edockets and chain of custody features,” said Kevin Lim, CEO of Remsoft.

● 1/ Tracey Gale from Forestry Australia welcomed delegates at the registration desk.

● 2/ Remsoft’s general manager, Asia Pacific, Carolyn Glasson with Craig Hull, Director and COO of LOGR.

● 3/ Joss Pohl and Greg Nash on the Syngenta stand.

● 4/ SFM's Andrew Morgan, Thiam Seng Cheo from the Raute Corporation, AFWI chairman Bob Gordon and Juha Kuntola from the Raute Corporation.

● 5/ Forestry Australia CEO Jacquie Martin with Blair Freeman from Indufor.

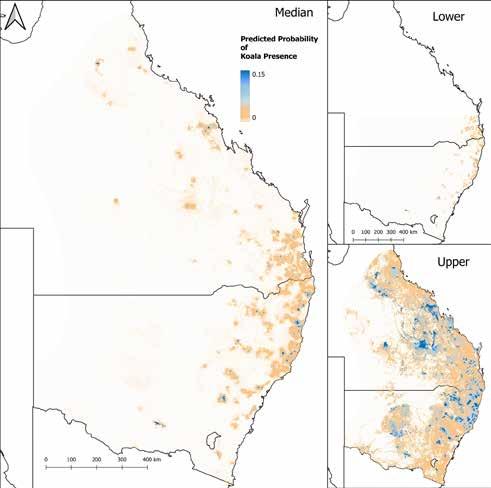

Australia’s koala population — listed as “Endangered” in Queensland, New South Wales, and the ACT since at least 2022 — is now booming across the eastern seaboard, thanks to new data from Australia’s leading science body, the CSIRO.

That is according to CSIRO’s National Koala Monitoring Programme (NKMP), which, since 2023, has used expert data rather than opinion to calculate koala numbers and disturbances, reporting populations at 729,000–918,000 as of May 2025—more than double last year’s estimate of 224,000–524,000.

In effect, current populations are now about twenty times greater than the number forecast by the Australian Koala Foundation – between 32,000 and 58,000 after the Black Summer bushfires, and crucially, more than double the populations estimated in 2012 (forecast to be between 144,000 and 605,000) when Koala populations were first listed as ‘vulnerable’ in New South Wales.

“The latest data-driven estimate for the size of the listed (NSW, ACT, QLD) koala population is between 398,000 and 569,000,” ac-

cording to the CSIRO-managed program.

“This estimate is substantially greater than previous NKMP estimates, arising from the incorporation of additional data from across a wider area and model improvements.” In addition, “the latest population estimate for the unlisted koala population (VIC, SA) is between 303,000 and 381,000 individuals,” it said, adding that the figure is also higher than previous NKMP estimates and varies for the same reasons as the listed population.

According to the CSIRO, “whilst these changes in the population estimates do not necessarily indicate a change in actual koala populations, but rather reflect more data being available and a refinement of the modelling approach from previous NKMP estimates. Like any data-driven model, the estimates themselves and associated confidence bounds will change as more data are added.”

While solely data-driven estimates have challenges— namely, limited and fragmented data—the CSIRO states they “have two distinct advances” over past estimates. First, there was

a concerted effort to collate koala presence, absence, and abundance data from a wide range of sources: individuals, research organisa-

tions, community groups, local governments, and state governments. Second, there is an analytical framework combining all these dispa-

rate sources and data types. Download the CSIRO Koala Population estimate at https://nkmp.org.au/populations.php

An independent, NSW Governmentcommissioned study released in September 2025 has confirmed there is no evidence that selective timber harvesting harms koala populations in NSW’s North Coast forests according to NSW Nationals MP Michael Kemp.

The study, led by scientists from the Department of Primary Industries and Regional Development, found no significant change in koala density three years after harvesting. This is consistent with results recorded immediately after harvesting in 2020.

But Mr Kemp said that despite funding this very research, the State Government had chosen to ignore this high-quality evidence.

The government’s choice

was to shut down the highly regulated forestry operations across the Mid North Coast to make way for the GKNP, which showed poor environmental management based on this research.

“(Environment Minister) Penny Sharpe and (Premier) Chris Minns have got it wrong. They’ve not only shut down an industry that has sustainably managed our forests for generations, but they have also refused to listen to the highest quality scientific evidence we have available,” the Member for Oxley said.

“Politics has been prioritised as they forge ahead with plans to shut down the forests – all to appease a handful of city-based activists for an election promise.”

“Governments commission the experts, spend taxpayer money on a study, they get the evidence, and now the Minns Labor Government is pretending it doesn’t exist because it didn’t fit their political agenda.”

The Natural Resources Commission report analysed six study sites, three in State Forests and three in National Parks, using acoustic monitoring to estimate koala density based on bellowing activity.

Key findings include:

• Significant declines in koala density in National Parks sites were attributed largely to fire, not harvesting.

• No significant change in koala density three years after selective harvesting in State Forests when com-

pared to numbers prior to harvesting.

• Resilience of koalas in managed forestry landscapes improved, where GPS-tracked individuals maintained stable home ranges, bred successfully, and showed no preference for exclusion areas over harvested ones.

“It is well known that koalas prefer multi-stage canopies, which reduces susceptibility to catastrophic fire by managing the understory of growth, providing fresh shoots, and a variety of habitats,” Mr Kemp said.

“How can locking up 176,000 hectares of productive forest, which will undoubtedly increase the fire risk, possibly protect koala numbers? The Government’s own study shows

koalas are not just surviving, but they are thriving in managed forests.

“How can they kill towns, local economies, and significant employment on the Mid North Coast to pretend to save the koala?

“We have high-quality environmental evidence that the Minns Labor Government is ignoring for votes. Managed forests have better-maintained road networks and regulated selective clearing practices, which result in a healthier canopy foliage that koalas love,” he said.

“Hundreds of hardworking families’ livelihoods have been destroyed because this Government cares more about election promises and city votes, than protecting the koala and our environment."

Part of the Trimble Connected Forest® suite, WSX is a tool for efficient log supply chain scheduling. With end-to-end control and data integration capability, electronic docketing, voiceless dispatching, health and safety features, web access, and reporting, WSX seamlessly connects every stage from the forest to the destination.

Afurther $11 million for Australia’s forest industries has been made available under the Federal Government’s Support Plantation Establishment Program (SPEP).

The latest round of plantation grants under the SPEP will see seven new projects receive funding to establish around 5500 hectares of new hardwood and softwood plantations across New South Wales, Western Australia, Tasmania and the Northern Territory.

The announcement brings total funding awarded by the Federal Government under the Support Plantation Establishment Program to more than $57 million.

“We sincerely thank the Government for its ongoing rollout of this program, which we advocated strongly for,” AFPA Chief Executive Officer Diana Hallam said.

“It’s a valuable and highly effective government-industry partnership that’s delivering positive results

and growth for our national forestry sector. It has also been critical in arresting the decline in plantation investment that was occurring prior to the commencement of the program.

“Since its inception, the

innovative program has been a resounding success in stimulating new plantation investment across Australia, strengthening local and regional economies, securing stronger fibre security into the future and advancing the Govern-

ment’s climate and sovereign capability objectives. These new plantations will also underpin the future of the construction sector,”

Ms Hallam said.

“The SPEP has so far supported the establishment of about 25,000 hectares of new timber plantations across multiple states, contributing to long-term timber supply, carbon sequestration, and biodiversity outcomes. Of these, we understand around 23,000 hectares will be registered under the Australian Carbon Credit Unit (ACCU) Scheme.

“Given the SPEP’s demonstrated success, we hope to see an extension of the program and ongoing funding so plantation establishment and expansion can continue without interruption into the future.

“There can be no doubt by extending the SPEP, it will continue delivering tangible economic, environmental and community benefits in communities throughout Australia, from the Tiwi Islands to Tasmania.”

The Minister for Agriculture, Fisheries and Forestry, Julie Collins, said that by investing in Australian timber plantations the Federal Government was supporting key actions from the Timber Fibre Strategy to shore up the industry and the nation’s future.

“The action we are taking now will support a Future Made in Australia, increasing our domestic timber supply and reducing our future dependence on import timber markets,” she said.

“This 5500 hectares of new plantations will assist in growing the timber that is needed for our future, including for more housing.

“This latest announcement brings the total new plantations established to more than 30,000 hectares across Australia.

“These projects will create new opportunities for our forestry sector, unlocking more jobs in our regions and helping to strengthen regional economies,” Ms Collins said.

The Federal Member for Gippsland Darren Chester has challenged the Federal Government to back some of Australia’s leading forest scientists who support the native hardwood timber industry.

Speaking in Federal Parliament, Mr Chester said environmental activists had hijacked the debate with ‘pet scientists’ who had been ‘bought off to promote this religious ideology that all timber harvesting is bad’.

Mr Chester said the bans on native timber harvesting in Victoria, New South Wales and Western Australia meant more imports were needed to meet local demand.

“Labor has demonstrated complete and utter con-

tempt for the forest industry in Australia over the past 20 years. Driven by their desperate need to secure Green preferences in the city they have sold out

blue-collar workers in regional communities, thousands of jobs have been lost, communities have been destroyed and the regions are less safe because we have lost the equipment and the skilled workforce which we’ve always relied on during major bushfire events,” Mr Chester said.

“This is all in the name of political science. This has nothing to do with the environment.

“We have a world-class sustainable native hardwood timber industry in Australia which delivers social, economic, cultural and environmental benefits for our nation, and those timber workers provide invaluable skills and practical support to their communities during times of natural disasters, par-

ticularly bushfires.

“The sustainable native hardwood timber industry is part of the answer to reducing Australia’s carbon emissions, as timber products actually sequester carbon in our floorboards, furniture and other products.”

Mr Chester quoted from scientists who are experienced in the management of native forests to counter the misinformation which has been spread by environmental activists.

“Some of Australia’s leading forest scientists have acknowledged we have the knowledge, the practical skills and the regulatory framework to sustainably manage our native forest, including for timber harvesting in small, carefully targeted areas,” Mr Chester said.

“This is not dodgy science from environmental activists who they buy to get a compliant voice and mouthpiece to trump up their unfounded claims; these are real scientists with peer reviewed papers and years of practical experience.

“Their work has warned against using selective and unbalanced studies, along with rejecting theoretical claims in relation to timber harvesting increasing the intensity of wildfire or reducing water catchment yields.

“People and native animals die because of poorly managed forests, and the Labor-Greens aren’t just killing industry, they are killing regional communities.”

● The Timber Towns Victoria delegation at Australian Sustainable Hardwood’s Heyfield mill.

Timber Towns Victoria still has a vital role to play despite the end of the native timber industry, according to the organisation’s president Karen Stephens.

“We still have a very, very large plantation timber industry, and we have over 18,000 jobs attached to the plantation sector,” Cr Stephens said.

“So, yes, it’s a really important industry for our members.”

Cr Stephens said that even where the phasing out of the native timber had an impact there was still timber manufacturing operations.

“If you look at Australian Sustainable Hardwoods at Hayfield, and you look at Chris McEvoy with Radial Timber, there’s still this manufacturing and value adding to the timber sector,” she said.

“That’s not going to change. There’s still a number of jobs attached to the timber industry within our membership in Eastern Victoria.”

Cr Stephens, who is Glenelg Shire Mayor, was recently re-elected president of Timber Towns Victoria along with Vice President Cr Tim Meyer (West Wimmera Shire), Treasurer Cr Tom Sullivan (Moorabool Shire) and Committee members Mark Coleman (Wellington Shire), Cr Catherine Bannerman (Wellington Shire), Cr Garner Smith (Gannawarra Shire) and Helen Havercroft (Glenelg Shire)

The appointments were made at TTV’s annual meeting as part of a

three-day tour of the Wellington Shire in Victoria’s south-east.

As part of the Wellington Shire tour, the delegation inspected the Australian Sustainable Hardwood’s Heyfield mill with managing director Vince Hurley, before travelling to HVP Plantations — one of the country’s largest private plantation managers, responsible for producing about three million tonnes of pine and 300,000 tonnes of eucalypt — then visited Radial Timbers, Alberton Timbers.

Organised by Mike Coleman, economic development officer, Wellington Shire’s roots run deep: with Heyfield and Yarram home to several mills which sit alongside large plantation estates and specialist timber services.

The region supplies millions of tonnes of fibre each year — including plantation outputs from HVP and feedstock for major processors — and its network of transport links, engineering contractors and secondary manufacturers is a key to growing the state’s forest and manufacturing capacity.

“Timber Towns Victoria continues to be a strong advocate for the community and industry to the State Government on the impact that changes to legalisation have regarding the timber industry and our communities,” Cr Stephens said.

Victoria’s forest firefighting capability has been crippled according to the Nationals with the entire G-Wagon and Unimog fleet pulled off the road indefinitely amid serious safety concerns just weeks before fire season.

Forest Fire Management Victoria has reportedly sent out an appeal to borrow up to 30 tankers from the NSW Rural Fire Service and another eight to 10 from the SA Country Fire Service, to offset the grounding of its G-wagons and Unimogs.

Used by Forest Fire Management Victoria (FFMVic) for rapid response and access to remote terrain, the fleet has been grounded for the second time, despite Premier Allan warning this could be one of the most dangerous fire seasons in years.

Launched in 2017 under Labor’s $32 million “stateof-the-art” upgrade, the vehicles were touted as world-class firefighting assets.

Now, all are parked up due to chassis and subframe faults, forcing CFA volunteers to fill the gap and stretching already overworked brigades.

A NSW RFS spokesman told the Weekly Times that it “was approached by FFMVic to identify any available firefighting vehicles that could be loaned”.

“The RFS has offered a mix of light and medium tankers that are in the process of being decommissioned and are surplus to current operational requirements. FFMVic has not yet indicated whether they intend to accept any of the vehicles offered.

“The proposed support involves vehicles that will not affect the RFS’s preparedness or firefighting capability in NSW.”

Leader of The Nationals and Shadow Minister for

Emergency Services, Danny O’Brien, said it was extraordinary that the same government which boasted about the vehicles’ cuttingedge design has now sidelined the entire fleet.

“Labor promised Victorians a state-of-the-art firefighting fleet – eight years later – Labor has delivered a world-class failure,” Mr O’Brien said.

“When the Premier warns of a dangerous fire season, Victorians deserve answers on how this failure was al-

lowed to happen and what steps will be taken to ensure community safety.”

Mr O’Brien called on Premier Allan to reveal how many vehicles are affected and what contingencies are in place to protect communities.

“Victorians are paying an additional $3 billion through Labor’s new emergency services tax, yet the CFA is relying on ageing vehicles and is now being asked to cover for FFMV, an organisation now being

Forestry Corporation firefighters have prepared for the start to the NSW Bushfire Danger Period with a five-day intensive fire training camp in the Central West.

Staged at Wallerawang near Bathurst, the camp brought together 45 staff members completing nationally recognised qualifications in Fire Fighter, Advanced Fire Fighter and Crew Leader roles.

A fire training camp was also recently held at

Mount Seaview near Wauchope, with further camps planned for Bombala in November and Coffs Harbour in December.

“Fire camps are part of our obligation as a firefighting authority to ensure our firefighters are adequately trained to contain fires and develop strategies to minimise the spread of wildfires,” Forestry Corporation’s Fire Training and Operations Coordinator Nathan Fischer said.

“There are two million hectares of State Forests in NSW, so it’s important our trained firefighters are ready at any moment to respond to fire in the landscape.

“Fire camps help to develop a skilled and capable workforce for the fire season ahead with the training combining classroom learning and practical field exercises, including a live hazard reduction burn in Lidsdale State Forest,” he said.

“During the exercise, firefighters gained hands-on experience in fire behaviour, tactics, leadership, communications and fire tanker and equipment operation and our firefighters are also trained to support other emergency services such as the NSW Rural Fire Service in operations both here and abroad.”

Forestry Corporation currently has around 500 staff members who serve as for-

funded by these additional taxes,” he said.

Shadow Minister for Public Land Management, Melina Bath, slammed the State Government for leaving regional Victoria dangerously exposed ahead of a high-risk fire season.

“Grounding Victoria’s frontline fleet weeks before fire season is an unacceptable failure, given nearly 40 per cent of the state is public land,” she said.

“Labor’s flawed bushfire policy ‘Safer Together’ has delivered just 1.6 per cent of land treated for fuel reduction annually since 2015 and the government routinely fails to meet its own fuel-driven risk targets,” she said.

“Victorians are paying more but getting less protection. Labor’s failure to manage bushfire preparedness is putting lives at risk.

“At a time when we need every piece of equipment and personnel working to reduce risk, it is our CFA volunteers who are asked to carry the load with ageing equipment and limited resources,” Ms Bath said.

“Labor can’t manage money or emergency services while Victorians pay the price.”

est firefighters.

Forestry Corporation also maintains a statewide fleet of fire tankers, light vehicles fitted with firefighting equipment, contracted aircraft and more than 100 drones operated by trained pilots.

Heavy plant machinery such as bulldozers, used in forest operations, is also made available by the broader forest and timber industry to support firefighting efforts across NSW.

Australia’s forestry sector is responsible for more than $100 million of direct annual investment into bushfire prevention, mitigation and response nationally, so it’s important to remember this critical industry contribution as the bushfire season in the southern states commences, according to Australian Forest Products Association Chief Executive Officer Diana Hallam.

“Australia’s forest industry managers make an enormous contribution to bush firefighting, prevention and mitigation efforts alongside government agencies, volunteer groups and other landholders. As the weather warms up and our forests and landscapes dry out, forest industries are well prepared to fight

potential threats to forestry assets, farms, reserves and regional communities,” Ms Hallam said.

“While the bushfire season is underway, fire management is a year-round process, and our forestry companies invest a significant amount of effort and resources into prevention and preparedness activities to ensure our staff are educated and prepared to the best of their ability to protect Australia’s forest estates.”

A new survey of AFPA members shows the contribution the sector makes towards reducing and managing bushfire risk and fighting fires when they start. AFPA members are responsible for:

• Maintaining 137 fire towers, their staff, detection

cameras and other costs, totalling around $8 million.

• Creating firebreaks, roads, undertaking prescribed burning and other maintenance like slashing and pruning, worth almost $65 million.

• More than 1,200 response appliances like tankers, bulk water carrier and command units and more than 1,500 firefighting personnel, worth almost $30 million.

• Insurance and other levies paid worth around $15 million.

“We thank our forestry sector for the contribution and work it does in this critical space, and we remind state governments how important the industry is in

managing risks and fighting bushfires when they happen,” Ms Hallam said.

This year’s outlook suggests an increased risk of bushfire during spring in parts of Western Australia, South Australia and Victoria. The official summer 2025-26 bushfire outlook will be issued in November.

Howitt Society president Peter Flinn told the Weekly Times that fuel reduction burns now amounted to little more than 1 per cent of Victoria’s public land each year, “just one fifth of the minimum recommended per annum by the royal commission into the horrendous 2009 Black Saturday fires, which claimed 173 lives”.

“We are frequently told by FFMV (Forest Fire Management Victoria) they would

like to do more in terms of fuel management, but are constrained by a shortage of funds and/or manpower, objections from some sections of the community, and that climate change is “narrowing the windows” for suitable weather conditions,” he said.

The government has admitted FFMV funding has fallen from $441.3m 202425 to $400.6m this financial year, but stated it was the result of specific project funding for emergency management reforms coming to an end.

However Mr Flinn told the Weekly Times the lack of resources meant fuel reduction burns that FFMVic promised to undertake in the Southern Grampians this spring had not occurred.

Forestry contracting professionals from across Australia gathered in Canberra for a rare and exciting opportunity: a live demonstration of Tigercat’s latest forestry machines, hosted in conjunction with the Australian dealer Onetrak.

With around 80 participants in attendance, the event was a resounding success, bringing together contractors, operators, and industry leaders for a day of innovation, connection, and hands-on experience.

The day began with a short bus ride from Canberra to the first demonstration site, where attendees were greeted by the Onetrak and Tigercat teams after a safety induction from Theresa Lonergan. The atmosphere was one of anticipation and enthusiasm, as participants prepared to witness some of the most advanced forestry equipment in action.

At the heart of the demonstration was the new Tigercat LH822E levelling harvester, operated by Ben Lonergan. This machine, equipped with Tigercat’s own TH573 triangulated processor, showcased the power and precision of fully optimised harvesting technology. Attendees were able to observe the machine in operation and engage directly with product experts, gaining insights into its capabilities and performance in real-world conditions.

Also on display was the Tigercat 1075C forwarder, a 25-tonne heavy-duty workhorse operated by Peter Lonergan. Known for its durability and efficiency, the 1075C impressed attendees with its robust design and smooth functionality. Nearby, the Tigercat L857 levelling feller buncher, fitted with the ST5702-26 disc saw, stood proudly in static display, drawing interest from contractors keen to explore its engineering and application potential.

The opportunity to speak

spent considerable time examining the machine and its performance.

By mid-afternoon, the group returned to Canberra to prepare for the evening’s social event at the QT Lounge. The dinner was a highlight of the day, offering a relaxed and enjoyable setting for participants to unwind, share experiences, and reconnect with colleagues from across the country. It was particularly meaningful to see Australia’s harvesting and site preparation contracting community come together — something that hasn’t occurred on this scale since the conclusion of Austimber.

The success of the event was made possible by the dedication and collaboration of many individuals. A special thank you goes to Tigercat’s International Sales Manager Gary Olsen, who travelled from Canada to attend, and to Kim McLean from Onetrak, whose behind-the-scenes efforts were instrumental in organising the day, despite being unable to attend in person.

directly with Onetrak and Tigercat’s product specialists added immense value to the day. Participants were able to ask questions, discuss machine features, and explore how these technologies could enhance their own operations. Lunch was provided

on-site, allowing for informal networking and further discussion among attendees.

Following the first site visit, the group boarded the bus once again and travelled to a second location, where the new Tigercat 1165 rubber-tire harvester

fitted with Tigercats own TH534 fully optimised processor was hard at work in a pine thinning operation. Operated by Callam and Zoey Lonergan, the 1165 demonstrated its agility and effectiveness in challenging terrain, capturing the attention of many who

Gratitude is also extended to Peter, Theresa, Callam, Ben, and Zoey Lonergan for generously allowing access to their site and machines. Their support and hospitality were key to making the demonstration both informative and enjoyable. Events like this are vital for the forestry industry. They provide a platform for showcasing technological advancements, fostering professional development, and strengthening the sense of community among contractors and operators. The Onetrak and Tigercat demonstration day was a clear reminder of the innovation and camaraderie that define our industry — and a promising sign of what’s to come.

For any further information about what Tigercat products can do for you please contact your nearest Onetrak branch on 1300 727 520.

Continued from page 3...

The announcement was the result of strong and strategic advocacy by union members,” TFTU NSW secretary Alison Rudman told Wood Central.

The Package is part of the Government’s commitment to timber workers and to ensure they receive the support they need as they adjust to these changes. It is in addition to existing redundancy entitlements, providing an added layer of financial security and transition assistance for affected workers.

The package recognises the impact on these employees and provides additional financial compensation, and practical support, to assist with re-employment or career change, and to support workers and their families through a difficult time.

Under the Worker Support Package, the workers will receive:

• Top-up redundancy payments ensuring affected workers receive four weeks base pay (inclusive of employer redundancy payment) for each year of employment with an impacted timber mill or harvesting operator, capped at $150,000.

• Additional support for employees over 45 years of age – a further three weeks of pay for every year of service after the age of 45 (up to a cap of $50,000), to be calculated separately from the top-up redundancy payment.

• Education and training payments of up to $9,000 for retraining and upskilling with a registered training organisation, as well as any associated travel costs.

• Relocation payments

of up to $45,000 for affected workers who move more than 50 kilometres for new employment including property purchase, tenancy termination fees, removalist services and other expenses.

• Free access to mental health support and financial and legal guidance through TELUS Health via phone, video, app or faceto-face.

Eligible employees are those employed on the North Coast of NSW on a full-time, part-time or casual basis who were employed on 7 September 2025 (date of the moratorium announcement) and made redundant within 18 months of that date, being 7 March 2027, as a result of this decision.

Redundancy payments and entitlements will be provided to workers by

their employer in accordance with their employment contracts or enterprise agreements.

The Government’s redundancy top-up payment will also be provided to the workers via the employer.

Part-time and casual employees will be eligible for the redundancy payments at a pro-rata value.

Staff from the NSW Government’s Department of Primary Industry and Regional Development is meeting with affected timber mills and haulage operators and their staff to provide information about the Worker Support Package.

The Government is committed to supporting workers, businesses and industry with a suite of support already announced including:

Business Continuity payments to impacted mills to

support their operations and ensure workers continued to be paid while the Worker Support Program was being finalised.

Grants of up to $100,000 through the $5 million Forestry Industry Supply Chain Support Program to help eligible downstream businesses meet additional business costs.

TELUS Health services providing 24/7 confidential mental health and financial counselling services to affected workers and their immediate family.

The Rural Financial Counselling Service providing free and independent financial counselling to businesses.

Training Services NSW providing advice on training to bridge skills gaps and helping to identify suitable job opportunities.

The delivery of the latest Komatsu 951XC Harvester to Rodwell Logging of Bomballa NSW, last June marked the 40th anniversary of purposebuilt wheel harvesters.

Komatsu’s long-standing history in this field began with its acquisition of the Swedish forest machine manufacturer Partek Forest AB, which originated from the Valmet brand, a pioneer in modern harvester design.

Valmet Logging AB released the first 901 Harvester in Sweden at Elmia Logging Expo in June1985. It was the first single-grip harvester designed with its own specialised chassis, rather than being built on a modified tractor or forwarder chassis.

The first Valmet 901 in Australia was purchased soon after FIME Wood Expo1986 by Rick Korn of Tumbarumba NSW.

Building on the success of the 901, Valmet continued to innovate with larger 6-wheeled machines, the 921 and 941 designed to handle tougher terrain. Valmet’s commitment to purpose-built wheeled harvesters established it as a true trailblazer in forestry machinery innovation.

Komatsu entered the forestry business in 2004 with the acquisition of Partek Forest AB which brought decades of Scandinavian forest machine innovation including the Valmet harvester models under the Komatsu name. Today Komatsu Forest AB, headquartered in Umea, Sweden, oversees production of wheel-based machine production and supports its global distribution network. The company continues to advance the Valmet legacy through innovation and development of larger models, including the introduction of eight wheel versions, with the latest being the Komatsu 951XC.

“We now have a complete range of eight wheeled machines specially designed for demanding conditions,” says Joakim Johansson,

Product Manager Harvesters at Komatsu Forest.

The demand for an eightwheeled harvester for final logging has been strong, and the idea of an eightwheeled 951 has been around for some time. The challenge was to design a machine for harvesting large trees without making it too cumbersome.

“What’s special about the 951XC is that it combines the strength of a 951 with an extremely compact design. It actually has about the same dimensions as a 931XC and so can even be used in denser stands,” Joakim explains.

Thanks to the eight-wheel design, the 951XC delivers lower ground pressure, reducing impact on the forest floor. It is ideally suited for final logging in hilly terrain and on soft ground. Stability is another critical advantage, in addition to Komatsu’s proven stability concept, the XC series features a bogie on the rear frame with dual suspension systems, a swinging rear axle and a bogie providing, completely unique handling characteristics.

The key features of the 951XC Harvester are :

• Komatsu Stability Concept: The innovative swing axle with balancing function enhances stability, comfort, and maneuverability, especially on uneven ground.

• 3-Pump Hydraulic System: The advanced hydraulic setup allows simultaneous operation of multiple crane and head functions at full power, boosting productivity and harvesting cycles.

• Parallel Crane: Since 1999, all Komatsu harvesters have featured a parallel crane, simplifying operation by automatically keeping the head level without separate boom controls.

• XC eight-wheel version: The eight-wheeled XC model provides exceptional traction, stability, and maneuverability for extremes such as steep slopes and soft ground.

The Komatsu 951 remains the largest and best-selling large harvester in the Australian market, with over 30 six-wheel (6WD) models delivered since its launch in late 2015, and four XC versions (8WD) versions added since its debut last year.

In recent years, native forest harvesting has declined while softwood plantation operations have expanded in South-Eastern NSW. This shift prompted contractors like Rodwell Logging to adapt their operations to meet the changing demands of the industry.

Having built a strong reputation in native hardwood logging, particularly in log hauling for Harris-Diashowa, Rodwell Logging made the strategic decision to scale down and restructure its operations. This transition recently opened a new opportunity for a softwood thinning contract in the Bombala region to supply the Visy Mill.

This marked the company’s first venture into thinnings operations and required the adoption of a new harvesting system.

Owners Peter and Mark Rodwell had long relied on Komatsu machinery in his hardwood operations, fostering a close relationship with Komatsu.

This partnership is several decades old and has been further expanded with the

development of their RL21 Firefighting unit, this included the purchase of a Komatsu 895 Forwarder. After exploring their options, Rodwell Logging decided to expand their Komatsu fleet with a Komatsu 951XC Harvester, complemented by another Komatsu 895 Forwarder to support the new thinning contract.

In addition to harvesting, Rodwell Logging’s contract includes hauling processed timber to the Visy Mill at Tumut. Meanwhile, their Komatsu 895 Firefighter also fulfills a spraying contract and remains on standby for fire emergencies in the Bombala region. The new contract began int June, with newly employed operators now producing around 900 stems per day.

“The machines and operators are outperforming our expectations,” said Peter. “And so far, we’re very pleased with KF’s machine maintenance program.

“The local Komatsu Forests agent Hennessey Field Services supported by the Wodonga Branch are both providing professional and highly skilled technicians for all our service requirements.”