Do You Have Tariff Concerns?

Metalworking fluids formulated to meet aerospace demands.

• Improve process stability on heat-resistant Super Alloys

• Easier robotic handling with cleaner parts

• Reduce costly maintenance interruptions

• Approved for Alloys of Aluminum, Titanium, Nickel, Chrome, and Steel

• Maximize gains from high pressure systems

• Enhance filtration system performance

Editors Corner

Dear Readers, Customers, and Friends,

After 20 years of publishing our A2Z Manufacturing Magazines, Kim Carpenter and I want to share some news. The time has come to pass the torch. Beginning with the next issue, Charlie and Alexandra Hushek will take the helm of A2Z Manufacturing, bringing fresh energy, vision, and a deep respect for the manufacturing community that has made this magazine thrive.

When I purchased the magazine two decades ago, it was called Arizona Metalworker. Our mission was simple: to celebrate the incredible companies, people, and technologies that make American manufacturing vital. Over the years, with the help of Kim, we evolved the publication to refect the full spectrum of precision manufacturing, renaming it A2Z Manufacturing and expanding with two regional editions — one for the West Coast and another serving the Rocky Mountain region. Looking back, buying this magazine was the best business decision of my life, and I have gained such respect for the shop owners and employees who build intricate, often mission-critical parts for many Fortune 500 clients.. Along the way, we have met countless shop owners, leaders, and innovators who embody grit, ingenuity, and perseverance. Your stories have flled our pages, your insights have shaped our content, and your support has fueled our work. We are deeply grateful to every advertiser, subscriber, and contributor who believed in us and helped shape the magazine into what it is today.

The timing for this transition feels right. Across the nation, we’re seeing what many call the “Silver Tsunami” — a generational wave of business owners and leaders preparing to retire and hand over their life’s work to the next generation. This moment of transition is not an end but a renewal, ensuring that the knowledge, traditions, and values we’ve built are carried forward with new vision and vitality.

Charlie Hushek, president of Phoenix Heat Treat, knows this better than most. As the third-generation leader of a family-owned business, Charlie understands the responsibility and opportunity that comes with stewardship. He and his wife Alexandra (Alex) are committed to continuing A2Z Manufacturing’s mission of spotlighting the best in American manufacturing while bringing fresh ideas to help the publication grow. Both Alex and Charlie bring a superior grasp of technology and social media, tools that are increasingly essential for connecting with readers and advertisers alike. Because of this, you may notice some exciting changes going forward — new ways to engage with the magazine, expanded digital reach, and even more timely coverage of the industry we all care about.

Kim and I could not imagine better hands to guide this magazine forward.Thank you for welcoming A2Z Manufacturing into your shops and offces for the past two decades. Thank you for trusting us to tell your stories, for sharing your triumphs and challenges, and for being part of a community that provesthat manufacturing is not just alive in America — it is thriving, innovative, and essential to our economy and our future.

Here’s to the next chapter, and I encourage you to contact Charlie and Alex to share your advertising plans. You can expect to see Kim and me around, as we are supporting the Hushek’s efforts over the foreseeable future. As always, God bless our troops.

Linda Daly, Former Publisher

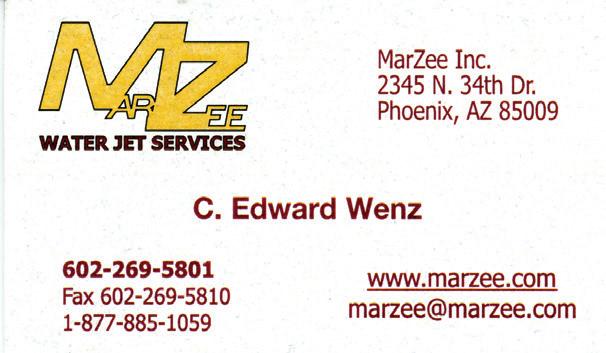

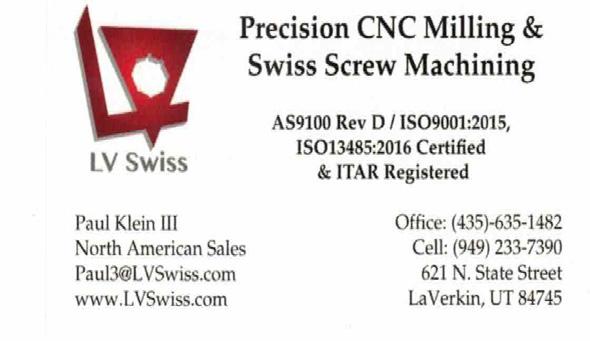

Do You Have Tariff Concerns. LV Swiss, 100% Made in La Verkin, Utah.

This Month’s Feature Article.

Linda Daly

Mail Address: 24 W Camelback Rd. #A-408, Phoenix, AZ 85013

Telephone: (602) 565-8268

Website: www.a2zMfg.com

E-mail:

Connect@a2zmanufacturing.com

Carpenter

P ublished bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z Manufacturing has compiled and maintains a master list of approximately 6500 people in the Rocky Mountain states actively engaged in the Precision Manufacturing Industry. It has an estimated pass on readership of more than 18,000 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to www.azManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Nothing is sweeter than the sound of a spindle making chips, especially when it’s the high-performance spindle found on one of our NHP Series of Compact Horizontal Machining Centers. These workhorses can handle whatever you throw at them, and are always asking for more.

That’s where our Linear Pallet System (LPS) comes in. It feeds the NHP around the clock, which leaves nothing but pallets upon pallets of precise, ready-to-ship parts. And if foor space is a concern, the Rotary Pallet System (RPS) will ft right in.

ISO/AS9100

Full Consulting To Prepare You For Certification

BMSC LLC, A Woman Owned Business • Contact Bretta Kelly Today!

You Have 3 Very Good Reasons To Call BMSC:

√ Are you certified and ready to simplify your ISO 9001, AS9100, AS9110 or AS9120 System?

√ Do you need Quality Management System Software? Bretta Kelly also President of CIS WWSG, is now offering $3,500 Templates FREE with purchase of CIS Software!

√ Need Help Maintaining Your Internal Audits or Management Reviews?

Visit www.businessmsc.com today and review the more than 220 company referrals!

BMSC is now offering packages to come in and conduct Internal Process Audits and Facilitate Management Reviews to ensure you are effectively maintaining your ISO 9001 and/or AS9100 System.

We Can Help! We Have Helped Over 200 Manufacturing and Service Companies. Call to Learn About our Templates - From $3500. CIS Software visit www.cissoftware.com.

Announcements & Releases

Small Business Administration unveils loan program for small manufacturers

Eligible borrowers will be able to access revolving credit of up to $5 million for working capital needs, effective Oct. 1, and use the funds in tandem with other SBA and commercial loans.

The agency is launching a loan program that allows manufacturers to borrow up to $5 million for working capital needs.

• The U.S. Small Business Administration has launched what it calls its frst-ever loan program designed to support small manufacturers across the country by providing additional credit for working capital needs.

• Effective Oct. 1, the Manufacturer’s Access to Revolving Credit (MARC) Loan Program will provide a maximum amount of $5 million to borrowers engaged in manufacturing, according to SBA documents. The money must be used for working capital needs, such as inventory purchases or new projects.

• MARC loans can be used in combination with other SBA and conventional commercial loans, providing added fexibility to manufacturers and lenders looking for a new line of credit.

The new loan program is part of a larger, ongoing effort to

strengthen domestic manufacturing. In March, the SBA pledged to cut $100 billion in regulation, promote workforce development and expand fnancing for manufacturing to spur U.S. industrial activity.

“With 98% of American manufacturers classifed as small businesses, the new MARC Loans represent a powerful source of targeted capital for those who are growing our nation’s production,” SBA Administrator Kelly Loeffer said in a statement.

MARC capital can be structured as a term loan for up to 10 years or a revolving line of credit for up to 20 years. It cannot be used for non-working capital purposes, such as ownership changes and foor plan fnancing, according to SBA documents. If borrowers default on their MARC loans, the SBA will provide lenders a maximum guarantee of 85% for loans of $150,000 or less and 75% for loans over $150,000.

In May, lawmakers introduced a bill that would double the individual limit for 7(a) and 504 small business manufacturing loans to $10 million. Neither the House nor the Senate have voted on the bill. The SBA also launched a Make Onshoring Great Again Portal that connects small businesses with more than 1 million domestic suppliers and producers.

Announcements & Releases

Thompson Machine Celebrates 50 Years of Precision in Albuquerque

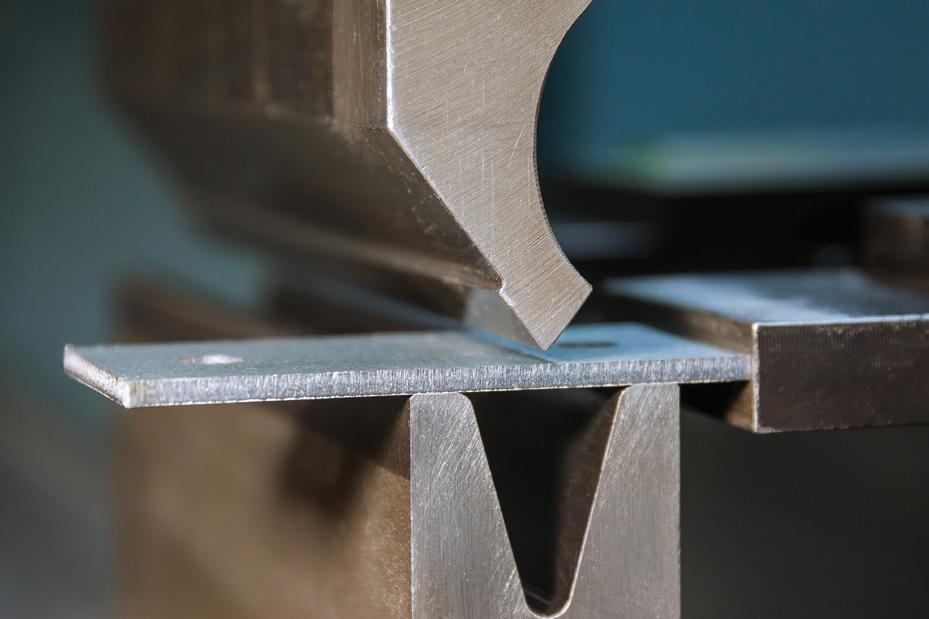

For half a century, Thompson Machine the Tool & Die Group Inc. in Albuquerque has been a trusted partner for customers who rely on highquality tool and die design and manufacturing craftsmanship. Founded in the mid-1970s, the company grew under the leadership of owner Ann Stirling (Thompson) and key employee Tim Bitting, who joined in 1979 and has been instrumental in its success ever since. Known for its expertise in deep draw stamping and precision tooling, Thompson Machine the Tool & Die Group Inc. has thrived by staying committed to its values, investing in equipment, and fostering long-term relationships with both employees and customers.

One of the keys to Thompson Machine’s staying power has been its willingness to evolve with the industry. The

company consistently invests in upgrading their equipment and new technology to expand capabilities. The shop foor is equipped with modern tool and die manufacturing equipment and servo technology stamping presses, the most recent a 170-ton press to support complex jobs. These advancements enable the team to deliver consistent, high-precision results across a wide range of industries.

Behind the machines is a dedicated workforce, many of whom have been with the company for 25 years or more. Thompson Machine is proud of its long-tenured toolmakers and the mentorship opportunities it provides. Today, the company operates as a certifed ISO facility, with a culture grounded in trust, skill, and responsibility. Ann continues to serve as President, with her daughter Leticia “Lettie” Stirling stepping in as COO and succession plan— ensuring Thompson Machine remains a woman-owned business for the future.

Looking ahead, Thompson Machine the Tool & Die Group Inc. plans to continue growing its workforce while preserving the values that have defned it for 50 years. With steady leadership, new equipment, and a commitment to quality, the company is well-positioned for the next chapter. As Lettie puts it, Thompson Machine remains a small business with big capabilities—one that has built its reputation on precision, integrity, and the dedication

SIDEKICK

MEET YOUR NEWEST TEAMMATE

Introducing the new Sidekick!

The newest member of the Methods Night Crew just became easier to use and friendlier to your bottom line. The Sidekick is the team member that will keep your FANUC RoboDrill running without ever clocking out. Faster set up with the Ready-to-Run package to get you in the cut on Day 1.

Announcements & Releases

of a team that truly feels like family.Contact Thompson Machine, the Tool & Die Group Inc. : Thompson Machine, the Tool & Die Group, Inc. 8400 Washington Place NE Albuquerque, NM 87113 Phone: (505) 823-1453

ISM Report: Manufacturing PMI Increases 0.4 Points to 49.1% in September

The ISM (Institute of Supply Management) Manufacturing PMI registered 49.1% last month, making September the seventh consecutive month of contraction. This fgure is 0.4 points higher than August’s fgure of 48.7%.

“Of the five subindexes that directly factor into the Manufacturing PMI, two (production and supplier deliveries) are in expansion territory, the same number as in August,” says Susan Spence, chair of the ISM’s manufacturing business survey committee. Anything lower than 50% represents contraction.

“The consecutive increases in the ISM manufacturing index are a positive sign, but a sustainable push above the 50 threshold is still some way off,” says Oxford Economics Senior Economist Matthew Martin.

The new orders index fell into contraction territory, decreasing 2.5 points for a September reading of 48.9%. The employment index registered 45.3% after gaining 1.5 points, indicating contraction at a slower rate when compared to the previous month.

The production index entered expansion territory after gaining 3.2 points for a September reading of 51.0%.

“In September, U.S. manufacturing activity contracted at a slightly slower rate, with production growth the biggest factor in the 0.4-percentage point gain of the Manufacturing PMI. However, the combined drops in the new orders and inventories indexes (4.2 percentage points) exceeded the increase in the Production Index (3.2), rendering the Manufacturing PMI improvement negligible,” Spence says.

Announcements & Releases

Five manufacturing industries reported growth in September:

Petroleum & coal products

Primary metals

Textile mills

Fabricated metal products

Miscellaneous manufacturing

“Of the six largest manufacturing industries, only one (petroleum & coal products) expanded in September, compared to two in August,” Spence says.

Respondents in the comments of the survey detail the hardships their businesses are facing due to tariffs, infation and geopolitical issues.

“Ongoing macroeconomic conditions highlighted by interestrate management and tariffs continue to impact customer purchasing decisions, resulting in subdued production rates and growing cost concerns on direct material and operations,” writes a respondent in the machinery sector.

Another respondent in the transportation equipment sector explains how these business conditions are impacting employees.“We believe we are in a stagfation period where

prices are up but orders are down due to tariff policy, and again, customers are not willing to pay the higher prices, so they are just not buying. Continuing to fnd ways to reduce overhead, which means letting go of experienced workers.”

Les Humbert is replacing John Beulter after 40 years at the helm of Wrico-AZ.

Les moved to the valley in the fall 1982 from Tucson where he was working for IBM to work for a plastic injection molding company in Tempe / Gilbert where he stays for 20 years in quality roles. He stays in the feld for another 5 years as both Engineering and Quality managers and then moved into machining and welding shops mostly for the aerospace and military industries. Currently has been with Wrico as a compliance quality offcer

and with the retirement of John Beulter, Les is the new general manager as of June 1 2025.

Wrico is a part of the Griffths corporation and have six plus facilities around the country serving many industries including, aerospace, commercial home products, agriculture, transportation, recreational vehicles. Les will maintain a smooth transition of leadership, however; will not be for 40 years.

Bold New Chapter for CheckZero Machine & Manufacturing

We are excited to announce a major milestone in the growth and evolution of CheckZero Machine & Manufacturing—your trusted partner in precision, tighttolerance CNC machining.

From day one, our mission has been clear: to redefne the manufacturing partnership experience through world-class customer service, operational excellence, and forward-thinking solutions. Over the past two years, that vision has come to life as we’ve expanded our client base, taken on increasingly complex projects, and continuously improved our service model based on direct customer feedback.

New Headquarters at The Forge Campus

As part of our ongoing growth, CheckZero has offcially relocated to The Forge Campus in Loveland, Colorado— an ecosystem for advanced manufacturing that hosts nearly 50 cutting-edge technology companies across industries such as Aerospace, Medical, Energy, and Manufacturing. This strategic move places us at the heart of innovation and collaboration, giving us seamless access to a wide range of adjacent services including powder coating, welding, laser engraving, precision sheet metal fabrication, and more—all within walking distance.

For our clients, this means faster turnaround times, improved cost effciency, and access to an expanded suite of services without ever leaving the campus.

Investing in Excellence: Certifcations in Progress

To further strengthen our commitment to quality and security, we are currently in the process of obtaining ISO 9001, AS9100, and ITAR certifcations. These certifcations represent our dedication to robust quality management systems, stringent security protocols, and process transparency—ensuring your projects are delivered with the highest standards of accuracy, reliability, and data protection.

Continued page 14

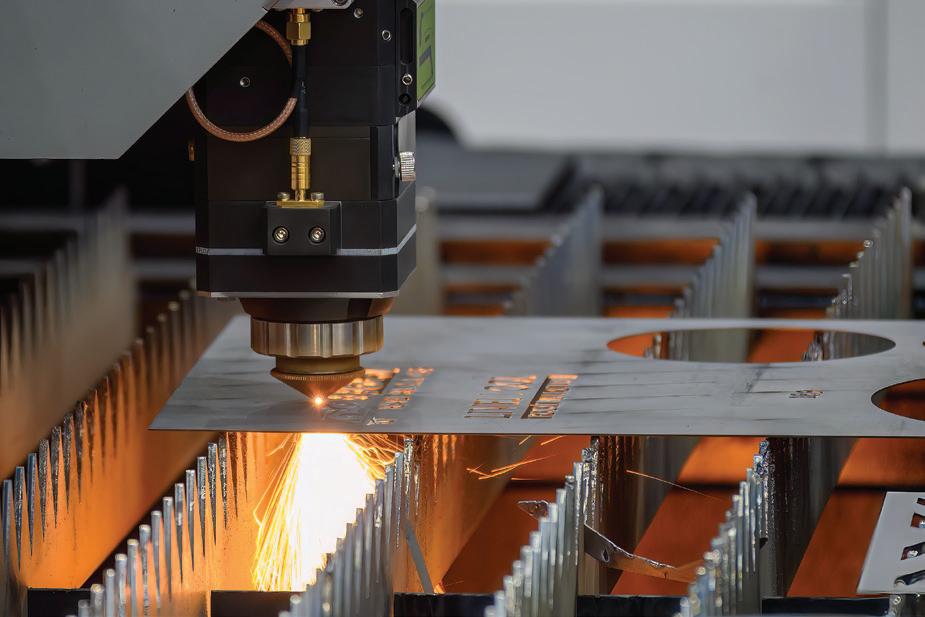

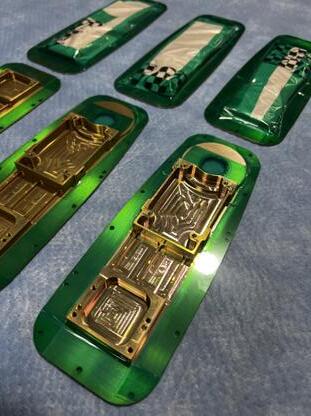

Precision, Partnership, and Peace of Mind: The LV Swiss Story

On a quiet street in La Verkin, Utah, the sound of CNC Swiss machines flls the air. Step inside LV Swiss and you’ll fnd more than just rows of precision equipment — you’ll see a team of craftspeople, engineers, and problem-solvers who treat every part as if it’s bound for a mission-critical application. In many cases, it is. From aerospace components that must withstand extreme temperatures to medical devices that require micron-level accuracy, LV Swiss has built a reputation for producing parts where failure is not an option.

But what makes the story of LV Swiss compelling is not only their mastery of precision machining — it’s the trust they’ve earned by manufacturing 100% in the United States, in an era where tariffs, supply chain disruptions, and uncertainty are the new normal.

A Company Rooted in Precision

Founded with the goal of combining Swiss machining expertise with American innovation, LV Swiss has grown steadily while holding firm to its core values: quality, reliability, and customer partnership. Each machine on the foor represents an investment not just in technology, but in customer confdence. State-ofthe-art CNC Swiss lathes, high-speed milling centers, and CNC lathe stand ready to handle complex geometries and tight tolerances.

Yet LV Swiss doesn’t tell its story through machines alone. The real narrative lies in how customers experience the company: as a dependable partner that delivers what others can’t.

Customers First, Always

Imagine being a purchasing manager at an aerospace OEM, tasked with sourcing parts during a period of rising tariffs on imported goods. Offshore suppliers suddenly tack on new surcharges. Lead

times stretch as parts languish at ports awaiting customs clearance. Budgets shrink, timelines slip, and your production schedule is at risk.

For many customers, LV Swiss has been the antidote to that uncertainty. By manufacturing entirely in the U.S., LV Swiss shields customers from tariffs and unpredictable global supply chain issues. What’s quoted is what’s invoiced. Deliveries arrive when promised, without port delays or international logistics.

As one longtime customer explained, “With LV Swiss, I don’t worry about surprises. I know the parts will be right, and I know they’ll be here on time.”

Precision Manufacturing

The tariff advantage is more than a side beneft — it’s a strategic edge for LV Swiss customers. In industries where margins are tight and timing is critical, avoiding international friction can mean the difference between proft and loss. By sourcing domestically, customers eliminate entire categories of risk: no last-minute duty charges, no currency fuctuations, no cross-border paperwork.

The benefits extend beyond cost. When engineering changes arise — and they always do — working with LV Swiss means changes can be implemented quickly. Design engineers can pick up the phone, speak directly with the LV Swiss team, and see revisions hit production in real time. That speed and clarity is impossible when working across time zones and language barriers.

Precision Without Compromise

Of course, tariff protection and logistics advantages mean little if the parts don’t meet the highest standards. That’s where LV Swiss excels. Certifed to industry-leading quality standards and registered with ITAR for defense-related manufacturing, the company brings accountability and traceability to every part it produces.

Aerospace and defense customers, in particular, rely on LV Swiss for parts that must pass stringent inspections. Medical device companies turn to them for components where a single faw could impact patient safety. Across industries, LV Swiss’s dedication to zero-defect manufacturing translates into confdence that every order will perform as expected.

Effciency Engineered Into Every Step

Much of LV Swiss’s competitive edge comes from the way it has designed its operations for effciency. The company maintains a dedicated tool crib, ensuring that when machinists set up a job, the necessary tools are already delivered to the machine. This saves hours of downtime, eliminates wasted motion, and keeps production fowing smoothly.

Weekly — and as needed — developmental meetings bring the entire team together to allocate responsibility for new jobs. Instead of one person carrying the weight of setup and planning, tasks are distributed across machinists, engineers, and quality staff. That shared accountability dramatically reduces setup time, speeds problem-solving, and ensures that every new part gets off the ground quickly.

A full-time toolmaker and an in-house machine repair specialist ensure that both tooling and equipment stay in peak condition. If a machine needs attention, it’s back up and running quickly, minimizing lost production time. In addition, LV Swiss offers in-house heat treating and passivation, critical processes that many shops must outsource. By keeping these capabilities under one roof, the company reduces lead times and gives customers faster turnaround without compromising quality.

On top of that, LV Swiss maximizes throughput by running its machines 18 hours a day. This blend of human expertise and lights-out machining means customers get their parts faster, without sacrifcing precision or oversight.

A Team You Can Count On

Technology alone doesn’t deliver excellence — people do. LV Swiss is proud of the expertise and tenure of its team, many of whom have decades of experience in precision machining. That accumulated knowledge translates directly into better outcomes for customers: smoother setups, sharper problem-solving, and an instinctive understanding of how to produce diffcult parts consistently.

For clients, the expertise of the LV Swiss team means fewer surprises, faster resolutions, and confdence that even complex or unusual challenges will be met with skill.

Inventory Solutions That Save Customers Time

Another way LV Swiss supports customers is by offering Kanban systems and inventory management for blanket purchase orders. The company will stock fnished components for up to a year, releasing them

on schedule or as needed. This arrangement allows customers to lock in pricing, reduce on-hand inventory, and ensure parts are always available without long lead times. It’s a level of fexibility and foresight that strengthens the supply chain while reducing customer stress.

More Than a Supplier: A Partner

What stands out in customer stories is not just the precision of the parts, but the partnership LV Swiss provides. When a customer faced an unexpected spike in demand, LV Swiss adjusted schedules and added shifts to ensure critical parts were delivered. When another client encountered design challenges, LV Swiss engineers collaborated directly, offering manufacturability insights that saved time and reduced costs.

These aren’t just transactions — they’re relationships built on trust. Customers know that LV Swiss will not only deliver the part, but help ensure the success of the program it belongs to.

Delivering Value Beyond the Part

Customers also find value in the effciency and innovation LV Swiss brings. By leveraging advanced tooling, lean processes, and in-house capabilities, the company reduces scrap, shortens lead times, and provides scalability from prototype through full production.

From an OEM’s perspective, this combination of quality, agility, and cost-effciency means more than just lower risk — it means competitive advantage.

A Future Built on Trust

As global markets remain unpredictable, the value of a trusted U.S.-based partner has never been clearer. Customers choose LV Swiss not only for precision machining, but for the peace of mind that comes with knowing their supplier is stable, dependable, and tariff-proof.

Back in La Verkin, the machines continue to hum, producing parts that will travel across the country and around the world. For LV Swiss, every component tells a story of precision, partnership, and pride in American manufacturing. And for their customers, it means confdence in every delivery, every time.

Contact LV Swiss

Paul Klein, III

621 North State Street La Verkin, Utah 84745

Phone: 435-635-1482

paul3@lvswiss.com lvswiss.com

www.westernstatesmetals.com

solutions tailored to your needs. Our agile service platform is designed to integrate effortlessly with your existing workfows, enabling fast onboarding, real-time visibility, and maximum value from day one.

A Future-Focused Partnership

This announcement marks more than just a change in address—it represents our continued promise to lead with integrity, innovate with purpose, and deliver exceptional results. We invite you to learn more and connect with our team by visiting www.checkzeromm.com and flling out our contact form.

Thank you for your trust and support. With CheckZero Machine & Manufacturing, the future of easy, effcient, and reliable manufacturing is already here.

Tim Johnston Joins Newton Heat Treating

I’m happy to announce I have started a new position at Newton Heat Treating as their Director of New Business and will be working alongside a great team. I’m grateful for

“Retail sales are up, and sectors such as transportation, logistics, warehousing, and construction are performing extremely well,” Arora added. “Right now, business owners are confident in the future of their firms. August is typically a slow month for loan volume, but that wasn’t the case this year.”

my past time at previous companies and I’m eager for the next chapter.

I will be working with the Aerospace, Military, Air, Land & Sea also DOD, including the US Navy programs.

Business loan approval rates rose at regional and community banks as well. Small banks granted 49.8 percent of the funding requests they received in August, up one-tenth from July. It represents the highest figure for small banks since November 2014.

Institutional lenders — pension funds and insurance companies — remained unchanged at an Index record 64.9 percent, up one-tenth of a percent from July’s figure.

Loan approval rates among alternative lenders rose to 56.6 percent, one-tenth of a percent higher than in the previous month.

Our Certification are NADCAP and ISO 9001/AS9100 ITAR, fully accredited. By meeting the rigorous requirements of these standards, you can be assured that your product will be consistently processed to the highest degree of quality while meeting your delivery needs.

Feel free to reach out to me if you have any questions.

Alternative lenders have become a source of quick capital. When small business owners, alternative lenders could approve riskier loans via innovations in fintech, which give them more flexibility than the banks to adjust rates and covenants on the deals. This includes an ability to accept non-conventional sources of collateral, such as real estate and outstanding invoices (h/t Forbes).

Director New Business Development tjohnston@newtonheattreating.com

Star Metal Fluids’ Annual Holiday Special

Credit unions approved 40.2 percent of loan applications in August, a slight drop of one-tenth of a percent from July and a large drop from their all-time high of 57.9 percent in March 2012. By Anthony Noto – Reporter, New York Business Journal

The holiday season has arrived, and with it comes our favorite tradition — giving thanks to you, our valued customers. As a token of our appreciation, Star Metal Fluids is pleased to announce our Annual Holiday Specials, featuring exclusive discounts on all in-stock Qualichem, Lubricants, Castrol, and Hangsterfers products.

Take advantage of these limited-time savings that expire December 31st, 2025. Reach out to your local Star Metal Fluids representative or email us at customerservice@ metalfuids.com.

Thank you for your continued partnership and trust — we look forward to closing out another successful year together!

Star Metal Fluids 800-367-9966

Central States Opens Metal Manufacturing Plant in Utah

The new metal manufacturing plant, boosting production of panels, purlin, trim, and the Alpha Framing System.

Central States, one of the nation’s largest manufacturers of metal building products, has opened its newest

October Rocky Mtn 2018.indd 38

manufacturing facility in Tooele, Utah. The 100,000-sq.-ft plant, the company’s 13th nationwide and westernmost to date, represents a multimillion-dollar investment in the community and is expected to create more than 90 jobs.

“This facility is more than just a building—it’s a symbol of our commitment to growth, innovation, and the power of employee ownership,” said Central States CEO Jim Sliker. This manufacturing expansion supports Central States’ fastgrowing pre-engineered metal building (PEMB) business, as well as its roofng and siding, post-frame, self-storage, living spaces, and metal components operations. The site will manufacture a variety of residential and commercial roof and wall panels in a variety of gauges, a wide selection of accompanying trim, and structural purlin. The new plant will also produce the Alpha Framing System, a proprietary framing system that is faster to install than traditional framing methods and is offered exclusively through Elevate Structures, a Central States company.

The Tooele plant opening marks the frst time in company history that Central States has opened two new manufacturing sites in the same year. In August 2025, the company celebrated the launch of its Springdale, Ark., frame and structural steel plant under its Central States Building Works business.

Denver company closes on $3.5 billion acquisition

Royal Gold Inc. bought all the stock of Canadian frm Sandstorm Gold Ltd. for $3.5

billion and Horizon Copper Corp. for $196 million. According to the company, Royal Gold now has the largest portfolio of mine streaming and royalty assets of any other mining royalties frm, which includes royalties from the world’s fourth-largest copper mine, the company said.

“These acquisitions ft our strategic goal of acquiring high-quality and long-life precious metals assets in mining-friendly jurisdictions, and I believe the addition of the Sandstorm and Horizon interests creates a global portfolio of precious metals interests that is unmatched in terms of diversifcation, development and organic growth potential, and exploration optionality,” Bill Heissenbuttel, president and CEO of Royal Gold said in a release.

“Royal Gold has a 40+ year history of consistently executing a strategy of disciplined growth in gold, and with these transactions, we are frmly positioned as a leading North American precious metal streaming and royalty company with the balance sheet and liquidity to continue to grow and invest in precious metals,” Heissenbuttel said in a

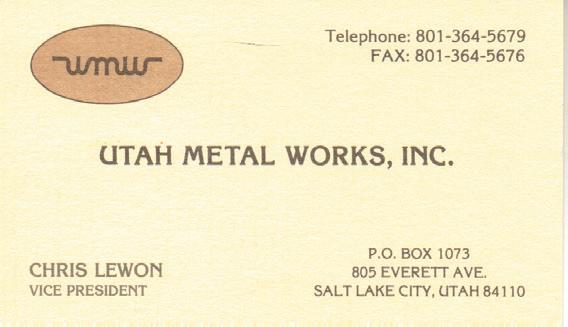

www.umw.com

Tollfree: 866-434-5679

Local: 801-364-5679

property acquired and placed in service after January 19, 2025. This allows manufacturers to expense the entire cost of equipment and certain building improvements in the year those costs are incurred, providing a substantial immediate incentive for reinvestment.

My Metal Worth?

At Utah Metal Works, recycling industrial-related scrap metal is one of the things we do best. You simply won’t fnd more knowledgeable, capable partners for your scrap handling and recycling eforts anywhere. We are known in the industry for our honesty and integrity, and you can be sure you are always getting a competitive return along with superior service. We make it easy for you to cash in on non-ferrous metals from:

Industrial/Manufacturing Scrap

• Punchings

• Solids of any metals

• Turnings and borings

Stainless, titanium, Inconel, Hastelloy, Monel, cupronickel, aluminum;state-of-the-art metal analysis conducted on site; Mixed or contaminated items are accepted and sorted How Much Is

• Skeleton plate

• Machine Shop/Fabricator

• Solids of any size or type

Aircraft/High Temperature Alloy Scrap

New Tax Law: Discover the Many Benefts for Manufacturers

The new tax law known as the One Big Beautiful Bill Act offers some major benefts to manufacturers. Some of the key industry provisions include expanded R&D expensing benefts, greater depreciation opportunities for equipment, and production and manufacturing related tax credits and deductions.

Explore details to learn how your company can take advantage of the new and expanded benefts. For more details on general business and individual benefts, check out our comprehensive analysis of the new tax law.

Key benefts for manufacturers in the new tax law:

Permanent extension of 100% bonus depreciation

The new law permanently reinstates 100% bonus depreciation for qualifying

Expanded research and experimental expensing

Manufacturers can now permanently deduct 100% of domestic research and experimental expenditures paid or incurred for tax years beginning after December 31, 2024. Unamortized research and experimental expenditures from prior years can either be deducted in 2025 or split between 2025 and 2026.

Small business taxpayers (threeyear average gross receipts of $31 million or less) can amend prior-year filings and request refunds for previously paid taxes on capitalized expenditures. However, the R&D tax credit must be reduced on the amended tax returns.

The requirement to capitalize and amortize foreign research and experimental expenditures and amortize over 15 years was retained.

Enhanced Qualifed Production Property deductions

The new law created a deduction for Qualifed Production Property (QPP), which includes nonresidential real property used as an integral part of qualifed production activity. Manufacturers can deduct 100% of the adjusted basis of such property in the year it’s placed into service. The property must be used in qualifed production activity defined as manufacturing, production, or refining of tangible personal property. The original use of

the property must begin with the taxpayer taking the QPP deduction.

This provision excludes properties used for administrative services, lodging, and other nonmanufacturing activities.

Construction must begin after January 19, 2025, and before January 1, 2029, and the property must be placed in service before January 1, 2031. A cost segregation study will be needed to breakout costs and determine the portion of the real estate qualifying as production property.

Advanced Manufacturing Investment Credit increase

The advanced manufacturing investment credit percentage was increased from 25% to 35% for property placed in service after December 31, 2025. This credit is for qualifed investment in advanced manufacturing facilities with a focus on manufacturing semiconductors or semiconductor manufacturing equipment.

Non-industry specifc business benefts in the new tax law

Qualifed business income (QBI) deduction made permanent

The QBI deduction — which allows pass-through entities to beneft from a 20% deduction on qualifed business income — was made permanent.

Interest expense limitation expansion

The interest expense limitation calculation was revised to again include an add back for depreciation, amortization, and depletion. This change is effective for tax years beginning

Phoenix Heat Treating Phoenix Heat Treating

T T

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Established in 1963 Real Time Live Job Tracking

10+ Processes Performed 50+ Furnaces

AOG and Line Down Services Over 10+ Prime Approvals 24/7 Processing

602-258-7751

cs@phxht com

www phoenix-heat-treating com

after December 31, 2024.

If the new adjusted taxable income calculation in 2025 results in excess taxable income, it could create capacity to deduct interest expense disallowed in 2024 and prior years.

Qualifed small business stock (QSBS) exclusion enhancement

QSBS benefts are signifcantly expanded and relax certain requirements:

• Increases gross asset test from $50 million to $75 million (infation adjusted starting 2027)

• Increases lower gain exclusion from $10 million to $15 million (10x basis still available)

• Provides a reduced beneft if stock is held for less than fve years (50% after three years, 75% after four years), while the 100% exclusion after fve years remains in effect.

CJ Precision Machine, Inc. is a leading manufacturer of critical parts for a wide variety of industries, including aerospace, semiconductor, medical, solar, food processing, aviation, automotive, and motorsports.

From our vertical machining centers, to our state-of-the art 5-axis mills and 7-axis lathes, we provide superior customer satisfaction from prototype to production.

CJ provides superior customer satisfaction through exible and dependable service with timely turn-around.

Our precision manufacturing includes working with both plastics and metals in our 9,500 square foot facility in Boise, Idaho. Our machinists have more than 140 years of experience and all manufactured parts are inspected by quality control.

CJ can provide nishing including anodizing, powder-coating, chromate, various types of electro-plating, and many others as required by our customers.

www.cjprecisionmachine.com

ISO 9001 certified

Northrop Grumman Advances Solid Rocket Motor Manufacturing and Technology with Successful Rapid Development Test

Northrop Grumman Corporation successfully conducted its second full-scale static test fre of a new solid rocket motor developed in less than a year, as part of the company’s Solid Motor Annual Rocket Technology Demonstrator (SMART Demo).

The SMART Demo motor demonstrated several innovative technologies and alternate manufacturing materials and processes, including:

• Additive manufacturing was used to produce long-lead tooling components and the motor’s primary nozzle structure

• An improved, cost-effective and versatile solid rocket motor propellant, capable of operating over a wide temperature range to support various launch platforms and applications

• Alternative suppliers and new materials to supplement or replace other long-lead materials and ease supply chain bottlenecks

• New robotic processes during manufacturing to increase reliability while reducing cost and schedule

Jim Kalberer, vice president, propulsion systems, Northrop

Grumman: “Northrop Grumman’s second SMART Demo motor, and the innovations we pursue with the company-funded effort each year, are enabling us to move faster than ever. We’ve successfully demonstrated industry-informed innovations that can accelerate production, strengthen supply chains and reduce solid rocket motor costs.”

Details on SMART Demo:

SMART Demo shows the effective implementation of new solid rocket motor technologies, materials and processes to reduce development time and costs and improve motor performance. The efforts include the design, development, building and testing of a new solid rocket motor, as well as its associated advanced tooling and technologies. These new technologies enable innovative development programs, providing existing production programs learning and implementation opportunities to reduce production time and cost.

Northrop Grumman plans to execute SMART Demo annually as the company continues to invest and advance in solid rocket motor development and propulsion. The technologies and processes demonstrated as part of SMART Demo could support large scale production of solid rocket motors applicable for the Golden Dome for America missile defense project.

SMART Demo expands and strengthens Northrop Grumman’s supplier base by streamlining the test and qualifcation of new materials, processes and alternate suppliers who manufacture critical materials using faster and more effcient processes.

With nearly 100,000 employees and over 30 million square feet of manufacturing space – more than 500 football felds – Northrop Grumman has the capacity, scale, and agility to drive innovation at unprecedented speeds. The company’s manufacturing approach isn’t just about fawless production – it was developed to accelerate and enhance the entire process from design and development to production and testing. The company has invested in U.S. infrastructure, R&D, its workforce, and supply chain to deliver the national security needs of today and for tomorrow.

Northrop Grumman is a leading global aerospace and defense technology company. Our pioneering solutions equip our customers with the capabilities they need to connect and protect the world, and push the boundaries of human exploration across the universe. Driven by a shared purpose to solve our customers’ toughest problems, our employees defne possible every day.

SCRAP PICK-UP SPECIALISTS

We set containers for:

• Machine, welding & fab shops • Manufacturing facilities

• Demolition projects • One-time clean-ups

• Containers: 1 to 60 yards • Flatbed, cargo trailers, rolloffs

• Small boxes on wheels • Locking Lids • Leakproof boxes

Top prices paid for:

• Aluminum • Copper • Brass • Stainless • Steel/Iron

• Alloys • Lead & more

Convenient drive-in recycling:

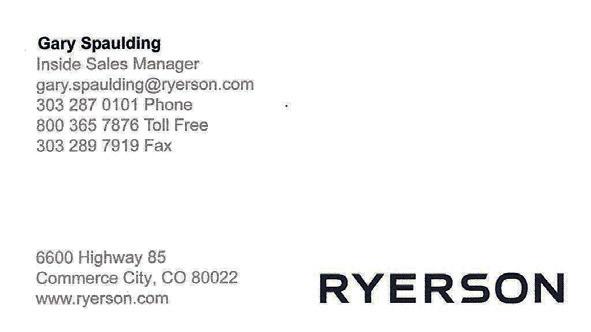

• Easy acces from I-25, I-70 and Commerce City

• Fully paved • Se Habla Espanol ~

Recycling Metals, Conserving Resources,

Manufacturing in Utah ‘really taking off,’ Small Business Administration offcial says

Manufacturing in Utah is “really taking off,” according to the deputy administrator of the U.S. Small Business Administration, touting some of the impacts now being felt by the “big, beautiful bill.”

According to William Briggs, who was confrmed to be the second-in-command of the administration in July, the most common loan application coming from the Beehive State is for manufacturing — in most states or cities, the most popular loans are for hospitality or accommodations, helping restaurant or hotel businesses.

But Utah’s growing focus on manufacturing is “unique,” Briggs told Utah News Dispatch, after touring Beacon Commercial Door and Lock, a nearly 60-year-old company that began manufacturing in-house in 2020 and currently employs 64 people.

Located in South Salt Lake, Beacon credits its success in part to help from the Small Business Administration, or SBA, which helped fnance the company’s expansion. Since 2018, when the company started mulling whether it should manufacture in-house, Beacon says revenue has grown by 28%, its workforce by 22% and its net income by nearly 400%. The company’s president, Chad Riches, said that’s allowed the company to give better benefts, retirement plans and increase wages. “We have more employ-

ees that have higher wages, and they pay more income taxes. Because we have more employees, we pay higher employment taxes. The company makes more and so we pay more in taxes,” Riches said, calling it a “return in investment” for the SBA.

Micron pledges AI education investment to accelerate opportunities for America’s youth

Micron Technology is proud to announce its commitment to the White House’s Pledge to America’s Youth: Investing in AI Education, a national initiative aimed at preparing our youth to lead in an AIpowered future.

Over the next four years, Micron will empower more than 40,000 learners and educators through a comprehensive suite of AI education programs, hands-on learning experiences and employee-led mentorship. This pledge refects Micron’s belief that access to AI education is essential to securing America’s technological leadership. Specifcally, Micron’s commitments include:

• Incorporating AI lessons and activities

in 100% of our signature programs – such as Chip Camps, Going Tech, and Careers in Tech;

• Collaborating with our customers and STEM funders to expand AI education opportunities;

• Launching a volunteer program to mentor over 1,000 students in AI concepts and careers;

• Partnering with national and regional nonprofts to expand access to AI education for our communities;

• Launching free AI activities on Micron’s Educator Hub for teachers to access materials to support their curriculum; and

• Expanding access to technology through ongoing in-kind donations of computers and devices to youthserving nonprofts.

These commitments directly support the White House’s April executive order Advancing Artifcial Intelligence Education for American Youth, and reinforce Micron’s longstanding commitment to strengthening the U.S. STEM pipeline.

Securing America’s future requires winning the AI race. As the only American memory manufacturer and a technology leader, Micron’s innovations – particularly in high bandwidth memory – are key to powering the AI revolution. In partnership with the Trump Adminis-

Precision Manufacturing Demands a Precision ISO Management System

Your Quality Management System should work as precisely as the parts you manufacture – efficient, streamlined, and built to last.

At Cavendish Scott, we’ve spent over 40 years delivering custom ISO systems with measurable results –no bloated paperwork, no wasted motion, no templates.

Why Cavendish Scott

40+ Years in ISO Consulting

100% Certification Guarantee

Simple, Streamlined Systems

IRCA & Exemplar Global Certified Internal Auditing & Training

We guarantee your certification and ensure your system stays lean, effective, and easy to maintain. Get Certified. Stay Certified. Improve. Succeed. Call (303) 480-0111 | www.CavendishScott.com/A2Z

tration, Micron is making the largest domestic semiconductor investment in U.S. history: $200 billion in manufacturing and R&D, which will create an estimated 90,000 American jobs. Micron has long worked to strengthen the domestic STEM pipeline and strongly welcomes public-private partnership to advance AI education in particular.

“I commend President Trump for investing in AI education in schools and communities across the US,” said Micron CEO Sanjay Mehrotra. “AI is unlocking a transformative era, and Micron is committed to meeting this historic moment. This initiative accelerates opportunities for America’s learners in an AI-driven economy.”

Now, impacts from Congress’ budget bill that passed this summer, known as the “big, beautiful bill,” are being felt by small businesses like Beacon. Riches said not taxing overtime and paid or family leave being tax deductible are among the biggest impacts — so is the ability to expense 100% of the manufacturing equipment Beacon bought several years ago to make metal and wooden doors and doorframes at its South Salt Lake factory. “It allows us to put time, effort and money into research and development,” said Riches.

Department of Defense (DoD) Contracts

S&K Electronics Inc.,** Ronan, Montana, has been awarded a maximum $10,000,000 fixed-price, indefinite-delivery/ indefnite-quantity contract for electric air heaters. This was a competitive acquisition with one response received. This is a two-year base contract with three one-year option periods. Allium US Holding LLC, Denver, Colorado, was awarded an $8,729,843 modifcation (P00002) to contract W519TC24-C-0022. Work will be performed in Denver, Colorado, with an estimated completion date of May 28, 2027. . U.S. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity.

Lockheed Martin Space, Littleton, Colorado, is being awarded a $132,599,818 cost-plus-fxed-fee contract modifcation (P00103) under contract N00030-19-C-0025. This effort will support systems engineering and development and testing for Conventional Prompt Strike. Work will be performed in Denver, Colorado (44%); Courtland, Sunnyvale, California (16%); Alabama (12%); Pittsfeld, Massachuestts (7%); Sunnyvale, California (5%); Cambridge, Massachusetts (5%); Huntsville, Alabama (3%); Magna, Utah (2%); Washington, D.C. (1%); Simsbury, Connecticut (1%); Cape Canaveral, Florida (1%); and various other locations (3%). Work under this contract is expected to be completed on Dec. 31, 2025. Fiscal 2025 research, development, test and Evaluation (Navy) funds in the amount of $25,000,000 will be obligated upon award.

No funds will expire at the end of the current fscal year. This contract was awarded as a sole source acquisition pursuant to 10 U.S. Code 3204(a)(1) and was previously synopsized on the System for Award Management (SAM. gov) online portal. Strategic Systems Programs, Wash ington, D.C., is the contracting activity.

Lockheed Martin Corp., Littleton, Colorado, was awarded a $27,859,672 cost-plus-incentive-fee and cost-plus-fxed-fee modifcation (P00121) to a previ ously awarded (FA8823-21-C-0001) for space based infrared system contractor logistics support product support integration contract evolution. The modifcation brings the total cumulative face value of the contract to $1,282,882,509 from $1,255,022,837. Work will be performed on Peterson Space Force Base (SFB), Colorado; Buckley SFB, Colorado; Greeley Air National Guard Station, Colorado; and Boulder, Colorado; and is expected to be completed by Jan. 31, 2026. Fiscal 2025 operation and maintenance funds in the amount of $27,859,672 are being obligated at the time of the award. Space Systems Command, Peterson Space Force Base Colorado, is the contracting activity.

BAE Systems Space & Mission Systems Inc., Boulder, Colorado, has been awarded a $26,394,286 modifcation (P00028) to a previously awarded contract (FA8650-

24/5 Operations & Expedited Processing Available

n o se esting & Anal tics

nd

Northrop Grumman Systems Corp., Clearfeld, Utah, was awarded a ceiling $41,000,000 indefnite-delivery/indefnite-quantity contract for T-38 Sustaining Engineering. This contract provides for sustaining engineering services of T-38 aircraft. Work will be performed at Clearfeld, Utah, and is expected to be complete by Sept. 30, 2035. This award is the result of a sole source acquisition. Fiscal 2025 operations and maintenance funds for three separate orders in the total amount of $3,835,838 are being obligated at the time of award. The Air Force Life Cycle Management Center, Hill Air Force Base, Utah, is the contracting activity).

Rockwell Collins Inc., Cedar Rapids, Iowa; and Colorado Springs, Colorado, was awarded a $17,227,582 contract for Advanced Concept Ejection Seat sequencer update Phase III. This contract provides for fnal development and testing of the Line Replaceable Unit, with additional option testing. Work will be performed at Colorado Springs, Colorado, and expected to be complete by Dec. 31, 2027. This contract is the result of a sole source acquisition. Fiscal 2025 operations and maintenance ammunition funds in the amount of $14,620,932 are being obligated at the time of award. The Air Force Life Cycle Management Center, Hill Air Force Base, Utah, is the contracting activity (FA8213-25-C-0012).

www.AbleElectropolishing.com

22-C-6441) for additional research within scope. The modifcation brings the total value of the contract to $60,164,328 from $33,770,042. Work will be performed in Boulder, Colorado; and Dayton, Ohio, and is expected to be completed by Aug. 4, 2027. Fiscal 2024 6.2 and 6.3 Congressional Interest Item funds in the amount of $752,906 are being obligated at time of award. The Air Force Research Laboratory, Wright-Patterson Air Force Base, Ohio, is the contracting activity.

L3Harris Technologies Inc., Salt Lake City, Utah, is being awarded an indefnite-delivery/indefnite-quantity contract (N00039-25-D-4007) with a maximum potential value of $939,600,000 for the development, production, sustainment, and systems engineering and integration of the Multifunctional Information Distribution System (MIDS) Weapon Data Link Small-Form-Factor Weapons Attritable Radio Multi-Mode Family 2 radio. This total includes fscal 2025 weapons procurement (Navy) funding in the amount of $22,256,315; and fscal 2025 missile procurement (Air Force) funding in the amount of $19,867,599, both of which will be obligated at time of award and will not expire at the end of the current fscal year. T Work will be performed in Salt Lake City, Utah (50%); and Carlsbad, California (50%). The ordering period for this contract is through September 2030. Naval Information Warfare System Command (N00039), San Diego, California, is the contracting authority and awarded the contract on behalf of the MIDS Program Offce (PMA/PMW-101).

Citrine-Olsson JV 2 LLC, Grand Junction, Colorado, was awarded a hybrid contract action with $1,651,745 frmfxed-price and a ceiling of $7,814,178 for High-altitude Electromagnetic Pulse (HEMP) verifcation/re-verifcation testing and test-fx-test services. This contract provides for HEMP hardening assessment and mitigation. Work will be performed at Pituffk Space Base, Greenland, and is expected to be completed by Sept. 30, 2030. This contract was a competitive acquisition and two offers were received. Fiscal 2022 procurement funds in the amount of $9,465,923 are being obligated at time of award. Space Force, Space Operations Command, Space Acquisition and Integration Offce, Peterson Space Force Base, Colorado, is the contracting activity (FA2518-25-F-H001).

Northrop Grumman Systems Corp., Missile Way Roy, Utah, has been awarded a $24,123,880 bi-lateral modifcation (P00029) to a previously awarded contract (FA821421-F-0009) for ICBM operational software sustainment program and contractor logistics support. The contract modifcation enables the Minuteman III System Directorate to provide agile and timely software domain upgrades. The modifcation brings the total cumulative face value of the contract to $507,762,192 from $483,310,620. Work will be performed at West Layton, Utah; Colorado Springs, Colorado; Bellevue, Nebraska; Redondo Beach, California; and Roy, Utah, and work is expected to be completed by Aug. 31, 2028. Fiscal 2025 operations and maintenance funds in the amount of $7,189,683 are being obligated

How Millennials’ Technology Expectations Can Help Save Manufacturing

Colorado industry takes aim at U.S. missile defense as the next big thing in space.

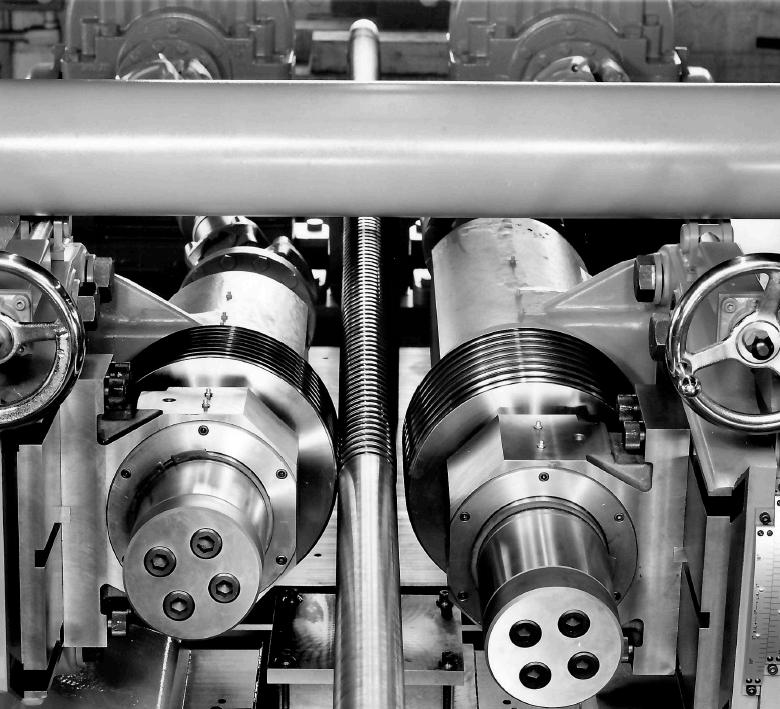

WE OFFER WORLD CLASS THREAD ROLLING CABABILITIES YOU CANNOT FIND ELSEWHERE

&

Tesker Thread Rolling Machine

F

8466 E US Hwy 34

CNC Swiss & CNC Vertical Mill Machining Thread Rolling • Lead Screws OD & Centerless Grinding ISO 9001: 2015 Certi ed MARCO GROB, President

Grinding

Millennials’ technology expectations have been shaped by smartphones, Facebook and digital media – in other words, by easy and ubiquitous connectivity. It’s not surprising, then, that traditional manufacturing systems can seem as retro as waiting for dial-up internet to connect. And that’s bad for the manufacturing sector, because its skills gap is looming large.

ISO 9001: 2008 Certified

Box 1417 Loveland, CO 80539 970-667-5320 Fax: 970-667-5322 Toll Free: 866-667-5320

haroldh@rongrob.com

at the time of award. Air Force Materiel Command, Hill Air Force Base, Utah, is the contracting activity.

Mountain Horse LLC,* Colorado Springs, Colorado, was awarded an $18,306,600 frm-fxed-price contract for the production of M548 metal ammunition containers. Bids were solicited via the internet with three received. Work locations and funding will be determined with each order, with an estimated completion date of Sept. 24, 2030. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity (W519TC-25-D-0043).

Why Contact Faustson Tool?

• We are a leader in 5 Axis Manufacturing Technology, including 5 Axis Milling and 5 Axis EDM.

• We have 30 Years of Experience Servicing Customers.

• Fauston Tool is a Woman Owned Small Business.

• Our customers span the Aerospace, Defense, Medical, Semi-Conductor, Energy and Aeronautic industries.

• Our certifications include: ISO 9001:2000, JPL Flight Certified, Ball Flight Certified, MPC Flight Certified, LASP Flight Certified, ITAR Certified Ball Aerospace: First ever delegated supplier

Sierra Nevada Corp., Englewood, Colorado, is awarded a $14,997,575 cost-plus-fixed-fee contract to provide product-based feld services, to include subject matter experts in support of maintenance and sustainment of the Ukraine Navy Counter-Unmanned Aircraft Systems program. Additionally, this contract provides for reach back support for various systems deployed in Eastern Europe under NATO. Work will be performed in Rzeszow, Poland (52%); Englewood, Colorado (44%); and Fort Walton Beach, Florida (4%), and is expected to be completed in September 2027. Ukraine security assistance initiative (Department of Defense Wide) funds in the amount of 14,997,575 will be obligated at the time of award, all of which will expire at the end of the current fscal year. Naval Air Warfare Center Aircraft Division, Patuxent River, Maryland, is the contracting activity (N0042125C0043).

The state capitol is no longer the only golden dome in Colorado.

The state’s aerospace and defense industry has grown to have a $38 billion impact, economic development offcials estimate, much of it due to government contracts. Now, the Golden Dome, a national program being pushed by President Donald Trump, has put a down payment of $25 billion up for grabs.

A joint study by the Manufacturing Institute and Deloitte Consulting projects a surge of nearly 3.5 million open manufacturing jobs created over the next decade. Some of the empty slots will come by way of retiring baby boomers, while others are related to new positions created as a result of natural business growth, the report found.What the report also predicts: As conditions stand now, 2 million of those jobs will go unfulfilled. In other words, the need for the manufacturing sector to appeal to Millennials – the generation typically defined as those born between 1981 and 1997 – is both critical and a very tall order.

Design specifcs for the Golden Dome, a missile defense system aiming to cover the continental United States, haven’t been fgured out, but this is the general idea:

Indeed, manufacturing still has a negative image among younger generations, experts say. In a 2015 public perception of manufacturing study, also by The Manufacturing Institute and Deloitte, respondents ages 19 to 33 ranked manufacturing as their lowest preference in terms of potential career choices.

A missile aimed at the continental United States screams across the upper atmosphere. A satellite network notices the rocket and triggers the launch of a countermissile to blow it out of the sky before it reaches American soil. Trump has said he wants Golden Dome built by the end of his term, and Colorado’s robust defense industry smells money.

Manufacturing’s image problem is complex and in, some aspects, based on false assumptions. But one real obstacle is that some manufacturing systems can seem antiquated, and it’s an issue that many manufacturers and related organizations are already addressing.

Modern and accessible tech

Congress’ One Big Beautiful Bill Act established a down payment of $25 billion to kickstart Golden Dome. The Congressional Budget Offce estimates that the defense system could ultimately cost between $161 billion and $542 billion over two decades. The White House, alternatively, put a $175 billion price tag on the project.

Colorado, with the largest per-capita aerospace industry in the nation, according to the state’s Offce of Economic Development and International Trade, could see a hefty slice of Golden Dome’s taxpayer-funded pie.

Forward-looking companies and organizations in the manufacturing sector are working to update systems so they better align with the ease and accessibility of user experience so pervasive with personal technology. Traditional manufacturing platforms – for example, manufacturing execution systems and supply chain applications – are being redesigned with new mobile interfaces, cloud capabilities and modern-day dashboards to make what has historically been perceived as arcane into something far more friendly and familiar to a tech-savvy audience.

U.S. Space Force General Michael Guetlein was selected to lead the program. Shortly after his July 17 confrmation, Guetlein said he had been given 60 days to come up with Golden Dome’s architecture. He has not yet released details of what’s being planned.

“As Millennials move into the manufacturing environment, there’s a certain expectation that the technology they are interacting with will work the same as what they grew up with,” said Matt Wells, product general manager for automation software at GE Digital. “The entire generation expects that data will be available to them anytime, anywhere, even outside of the plant. If they need access to information, they don’t want to call someone; they want to pull out their phone and see what’s going on.”

That suggests some elements of Golden Dome will begin to be identifed this fall and lucrative early contracts will be out for defense and aerospace contractors to win in the months and years ahead.

One way to gain traction with Millennials is to provide access to tools they want to use, not simply those required to do their jobs, Wells said. “Millennials want to work in organizations that are reflective of

The dome is expected to involve a system of satellites in orbit, radar systems and other elements connected to defensive weapons — hardware of the sort companies in the Denver area have a history of making for the military.

Virtual Cert™ ISO-9001 certification with American Global Standards can lower operational costs, improve your bottom line, and offer your business a competitive advantage.

American Global Standards (AGS) is an American company and ISO registrar with nearly 30 years of experience assistin g manufacturing and service industries in their quest to remain competitive in the global marketplace, for a competitive annual fee of $1875

• No on-site audit required

• Save top management valuable time

• Save your company thousands annually

• Market your company as ISO-9001 certifed

• Eliminate “non-value added” NCR’s

— Enzo Ferrari

the aesthetics and durability of industry-leading products - from Consumer Products to Space Satellite Technology.

Colorado companies tapped for satellite, battery storage work

OIL MIST AND SMOKE

Two Denver-area companies saw millions in contracts from the U.S. Department of War announced.

Greenwood Village-based City Light and Power Inc. won a $44.5 million contract from the U.S. Navy to build energy-storing batteries in two locations at the Marine Corps Air Ground Combat Center in Twentynine Palms, California, by March 2028. Lockheed Martin’s Jefferson County space division saw its over $4 billion contract with the U.S. Air Force to build GPS satellites upped by $19.2 million as well.

The contract did not specify what part of the project the additional $19.2 million will fund.

Delays in TSMC’s Arizona plant spark supply chain worries

The GPS III contracts cover building and supporting a new generation of global positioning satellites to replace the existing feet as it nears the end of its lifespan. The new satellites broadcast an encrypted signal for the military called M-Code — meant to be more diffcult to crack than existing transmission encryption — and a civilian aviation safety signal called L5.

Taiwan Semiconductor Manufacturing Company (TSMC) has said it is unlikely to equip its new US plant in Arizona with its most advanced chip technology ahead of its Taiwan factories, raising concerns about supply-chain hurdles for tech companies.

Speaking at a university event in Taiwan, TSMC CEO and Chairman C.C. Wei attributed the delays at TSMC’s Arizona factory to a combination of complex compliance requirements, local construction regulations, and extensive permitting processes, according to a Reuters report.

Lockheed Martin Space frst won a GPS III contract in 2008 for the first ten satellites. The company subsequently spent $80 million building a satellite factory at its headquarters in Waterton Canyon near Littleton.

In May, Lockheed Martin won a $509.8 million contract from the U.S. Air Force to build two more GPS III satellites, bringing the total contract value to $4.1 billion.

Wei explained that each stage of construction requires permits, with approval timelines taking at least twice as long as in Taiwan, creating challenges in deploying the company’s most advanced chip technology.

In July, City Light and Power scored a $23.6 million job from the U.S. Army to build power generation and a microgrid — a power supply independent from a centralized grid — in Fort Riley, Kansas. By Jackson Guilfoil – Denver Business Journal

Additional obstacles, Wei said, include supply chain disruptions and a lack of established regulations for chip plant construction in the US, which have further hindered progress.

Breathalyzer maker Lifeloc to merge with tech frm in all-stock deal

Wei also noted that chemical supply costs in the US are substantially higher, citing the need to ship sulfuric acid from Taiwan to Los Angeles and then transport it to Arizona by truck.

Despite these setbacks and increased costs, Wei expressed optimism during the company’s recent earnings call, assuring that the Arizona plant would meet the same quality standards as its facilities in Taiwan and forecasting a smooth production ramp-up.

A publicly traded Wheat Ridgebased company that develops, makes and sells breathalyzers has struck a merger deal to acquire a Washington-based technology company in an all-stock transaction.

The US government has extended robust support to TSMC’s investment, offering a $6.6 billion grant through CHIPS and Science Act to lessen dependence on Asia for semiconductor manufacturing and address geographic vulnerabilities in the global chip supply chain.

Electronic Systems Technology Inc., based in Kennewick, Washington, has agreed to become a subsidiary of Colorado’s Lifeloc Technologies Inc.

Between April and June, the companies started formal discussions regarding an all-stock transaction, according to flings.

TSMC’s challenges in the US Analysts point out that the US regulatory environment is more complex than Taiwan’s, leading to longer timelines and higher costs for TSMC’s Arizona project.

“The Lifeloc Board determined that the proposed merger provides Lifeloc shareholders with the potential for long-term value creation through economies of scale, expanded product offerings, and the opportunity to monetize its investment in ELST by acquiring full ownership in a business with synergistic operations,” Lifeloc’s prospectus said.

“Unlike Taiwan’s streamlined regulations, the US has a sequential, multi-layered approval process, including stringent construction, environmental, and safety codes that necessitate adjustments,” said Manish Rawat, semiconductor analyst at TechInsights. “Supply chain constraints, such as higher material costs and logistical challenges, further increase expenses.”

The SEC flings noted the merger would combine ELST’s customer base with Lifeloc’s manufacturing and distribution capabilities.By Noelle Harff – Denver Business Journal

Taiwan holds over $100 billion in assets and decades of experience in semiconductor manufacturing, while the US is still catching up in terms of resources and governance needed to recreate the infrastructure required to support production, said Hyoun Park, CEO and chief analyst at

Leaders in Aluminum Heat Treating

Leaders in Aluminum Heat Treating

Newton Heat Treating, founded in 1968, has been providing expert services to the Aerospace, Automotive, and Commercial Industries for over 55 years. As a full-service Aluminum Heat Treating specialist, we work to your exact specifcations on every type of aluminum alloy and form. Many customers from other well-known heat treaters have sought our services, discovering that Newton offers higher quality, exceptional service, and faster delivery times at competitive prices.

Leaders in Aluminum Heat Treating

Leaders in Aluminum Heat Treating

Leaders in Aluminum Heat Treating

Newton Heat Treating, founded in 1968, has been providing expert services to the Aerospace, Automotive, and Commercial Industries for over 55 years. As a full-service Aluminum Heat Treating specialist, we work to your exact specifications on every type of aluminum alloy and form. Many customers from other well-known heat treaters have sought our services, discovering that Newton offers higher quality, exceptional service, and faster delivery times at competitive prices.

Real Results

Real Results

Newton Heat Treating leads the way in Cold Stabilization / Uphill Quenching, a process that can provide a real solution to reduce stresses and control movement of all aluminum alloys during machining. Our method has proven to be highly effective compared to methods used by our competitors.

Newton Heat Treating, founded in 1968, has been providing expert services to the Aerospace, Automotive, and Commercial Industries for over 55 years. As a full-service Aluminum Heat Treating specialist, we work to your exact specifcations on every type of aluminum alloy and form. Many customers from other well-known heat treaters have sought our services, discovering that Newton offers higher quality, exceptional service, and faster delivery times at competitive prices.

Real Results

Newton Heat Treating, founded in 1968, has been providing expert services to the Aerospace, Automotive, and Commercial Industries for over 55 years. As a full-service Aluminum Heat Treating specialist, we work to your exact specifcations on every type of aluminum alloy and form. Many customers from other well-known heat treaters have sought our services, discovering that Newton offers higher quality, exceptional service, and faster delivery times at competitive prices.

Newton Heat Treating, founded in 1968, has been providing expert services to the Aerospace, Automotive, and Commercial Industries for over 55 years. As a full-service Aluminum Heat Treating specialist, we work to your exact specifcations on every type of aluminum alloy and form. Many customers from other well-known heat treaters have sought our services, discovering that Newton offers higher quality, exceptional service, and faster delivery times at competitive prices.

Real Results

Real Results

If you have special quenching needs, we have the capability of quenching in various concentrations of polymer glycol solution. We also offer high velocity spray quenching to minimize distortion. You can count on us to achieve the results you need.

Newton Heat Treating leads the way in Cold Stabilization / Uphill Quenching, a process that can provide a real solution to reduce stresses and control movement of all aluminum alloys during machining. Our method has proven to be highly effective compared to methods used by our competitors. If you have special quenching needs, we have the capability of quenching in various concentrations of polymer glycol solution. We also offer high velocity spray quenching to minimize distortion. You can count on us to achieve the results you need.

Newton Heat Treating leads the way in Cold Stabilization / Uphill Quenching, a process that can provide a real solution to reduce stresses and control movement of all aluminum alloys during machining. Our method has proven to be highly effective compared to methods used by our competitors.

Newton Heat Treating leads the way in Cold Stabilization / Uphill Quenching, a process that can provide a real solution to reduce stresses and control movement of all aluminum alloys during machining. Our method has proven to be highly effective compared to methods used by our competitors.

Certifi cations

Newton Heat Treating leads the way in Cold Stabilization / Uphill Quenching, a process that can provide a real solution to reduce stresses and control movement of all aluminum alloys during machining. Our method has proven to be highly effective compared to methods used by our competitors.

Certifcations

If you have special quenching needs, we have the capability of quenching in various concentrations of polymer glycol solution. We also offer high velocity spray quenching to minimize distortion. You can count on us to achieve the results you need.

If you have special quenching needs, we have the capability of quenching in various concentrations of polymer glycol solution. We also offer high velocity spray quenching to minimize distortion. You can count on us to achieve the results you need.

If you have special quenching needs, we have the capability of quenching in various concentrations of polymer glycol solution. We also offer high velocity spray quenching to minimize distortion. You can count on us to achieve the results you need.

We have achieved the highest NADCAP merit for five consecutive audits and are AS9100/ISO 9001 certifi ed. By adhering to these rigorous standards, we ensure that your product is consistently processed to the highest quality while meeting your delivery needs.

Certifcations

We have achieved the highest NADCAP merit for fve consecutive audits and are AS9100/ISO 9001 certifed. By adhering to these rigorous standards, we ensure that your product is consistently processed to the highest quality while meeting your delivery needs.

Certifcations

Certifcations

We have achieved the highest NADCAP merit for fve consecutive audits and are AS9100/ISO 9001 certifed. By adhering to these rigorous standards, we ensure that your product is consistently processed to the highest quality while meeting your delivery needs.

We have achieved the highest NADCAP merit for fve consecutive audits and are AS9100/ISO 9001 certifed. By adhering to these rigorous standards, we ensure that your product is consistently processed to the highest quality while meeting your delivery needs.

We have achieved the highest NADCAP merit for fve consecutive audits and are AS9100/ISO 9001 certifed. By adhering to these rigorous standards, we ensure that your product is consistently processed to the highest quality while meeting your delivery needs.

Phone:(626) 964-6528

newtonheattreating.com • customerservice@newtonheattreating.com 19235 E. Walnut Drive North • City of Industry, CA 91748

(626) 964-6528

Phone (626) 964-6528

OIL MIST AND SMOKE IN YOUR SHOP?

Manufacturer eyes adding 1,700 jobs, moving HQ to Aurora

A longtime Denver manufacturer that specializes in construction services has offcially chosen Aurora for a major expansion that will include the relocation of its corporate headquarters.

RK Industries will expand to a 154,000 square-foot facility that will serve as a headquarters for four of the company’s eight business units, including its corporate headquarters, the company said. Currently, RK’s corporate headquarters is in Denver’s Central Park neighborhood, at 3800 Xanthia St.

In addition to the RK Industries corporate offce, the company plans to house individual headquarters in Aurora for its RK Mechanical, RK Service and RK Electrical, as well as the RK Foundation business units, according to an announcement from the state.

The expansion is expected to add more than 1,700 jobs over the next eight years for roles such as project engineering, fnance, accounting and account management, according to documents from the Colorado Department of Economic Development and International Trade (OEDIT). The added space will amount to doubling of RK Industries’ local operations. The state in August offered RK Industries a job-growth tax incentive package worth $24.4 million to choose Aurora for its expansion over locations in other states. The added jobs are expected to pay an average yearly wage of about $93,000.

RK Industries ultimately chose Colorado because of its strong roots in the state and its robust advanced manufacturing sector, the company said.

“Relocating our headquarters to Aurora isn’t just about expanding our footprint in Colorado, it’s about expanding opportunity,” RK Chief Operating Offcer on Jon Kinning said in a statement.

The company today has close to 1,300 employees, more than 1,000 of whom are located in Colorado and about 700 of whom already reside in Aurora, offcials said.

In addition to its corporate headquarters, RK Industries already has two facilities in Aurora, a fabrication space in Henderson, an offce in Vail and a facility in Colorado Springs, according to its website. The company also has a presence in Arizona, New Mexico and Utah.

RK Industries used to be known as RK Mechanical. The company started as a family-owned business that launched in the 1980s.

The company restructured in 2021 to make RK Industries LLC the umbrella organization for its various business lines, one of which is RK Mission Critical, a modular construction operation that has worked on custom-engineered modular containers with clients in the data center, cryptocurrency and agtech industries.