IMPOSSIBLE POSSIBLE MAKING THE

Works on a busy throughfare have highlighted the potential of alternative road construction methods

Engineered excellence

A story of rising up the ranks in a male dominated industry

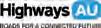

Transport’s hot topic What’s required from the transport sector to cater for the inevitable use of autonomous vehicles

The Most Innovative Paver Technology!

VÖGELE SUPER 1700-3(i) / SUPER 1703-3(i)

VÖGELE SUPER 2000-3(i) / SUPER 2003-3(i)

The number one paver manufacturer on the global market presents innovative “Dash 3” pavers and screeds for Australia. Equipped with state-of-the-art Cummins engines available in either Tier 3 or Tier 4 Final / Euro Stage V emission standards, are the perfect choice for any application in the Universal (2.5m) and Highway (3.0m) paver classes. Thanks to the easy-tounderstand ErgoPlus 3 operating system which is common across all VÖGELE products both paver and screed operators can handle all VÖGELE pavers simply and safely. These machines are also available with vibrating screeds or high compaction tamping & vibrating screeds for those critical jobs. In combination with advanced optional features, such as VÖGELE EcoPlus, AutoSet Plus and Navitronic Plus 3D, these models are the stars of any road construction site.

www.wirtgen-group.com/australia

COVER STORY

14 Making the impossible possible

An industry collaboration has delivered works – that should’ve taken months – in just one week, for a busy thoroughfare in Melbourne’s Hobsons Bay area.

DIVERSITY

18 Engineered excellence

Major Road Projects Victoria (MRPV) Senior Project Engineer Deborah Mallari has shared her story of a life well-lived in engineering and what it takes to rise up the ranks.

ROADS REVIEW

20 This month, we asked the industry’s decision-makers, ‘What can the infrastructure sector do better to narrow the existing skills gap?’

INNOVATION

22 Keeping the nation moving Geoquest Australia is supporting freight movement and essential rail links across the country by offering a full suite of civil, structural, and geosynthetic solutions.

25 More than just ticking the box FODS composite rumble grids have impressed transport authorities around the world, satisfying compliance and local regulations, regardless of the jurisdiction.

RESEARCH

28 Transport’s hot topic

Results from a survey conducted in part by the University of South Australia has detailed the role that augmented reality could play in Australia’s transport future.

MACHINERY AND EQUIPMENT

31 Fuel efficiency a guarantee Caterpillar continues to make great gains in fuel efficiency and advances in product technology.

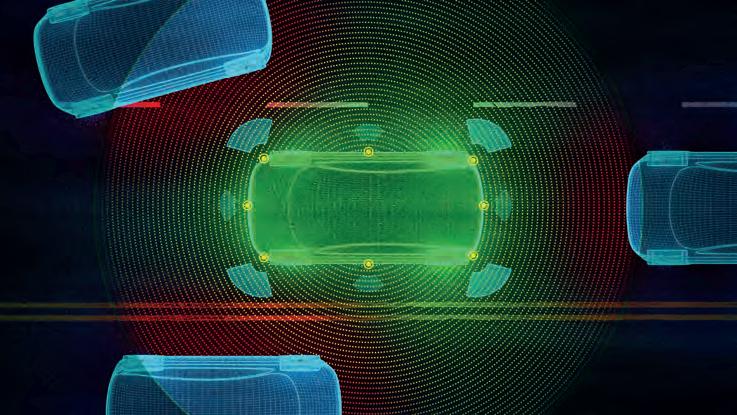

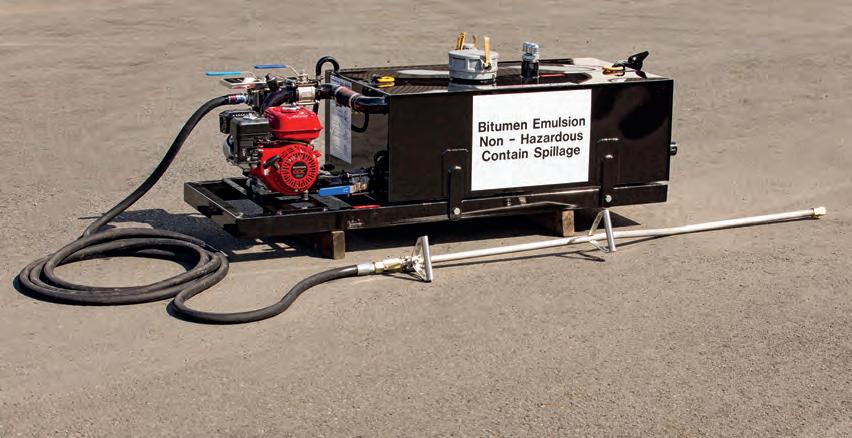

32 Specialised, for a reason Specialised Roading Equipment is answering the growing call for emulsion equipment in Australia, with a constantly improving and expanding range.

34 The best possible foundation Crusher Screen Sales & Hire’s PM1200-20TB pugmill is providing quarry and material suppliers with extreme precision, right down to the gram.

36 Making safety stick for tomorrow’s workforce Safety is at the forefront of Komatsu’s concerns as a company. A key reason why its dedicated Safety Week program is leading to better outcomes.

38 All under control Quality Fabrication & Engineering is on a mission to improve safety, durability, versatility, and innovation within its iconic offering.

40 Look on the light side

BOMAG’s articulated tandem rollers under five tonnes are an ideal range of machinery for everyday use.

EVENTS

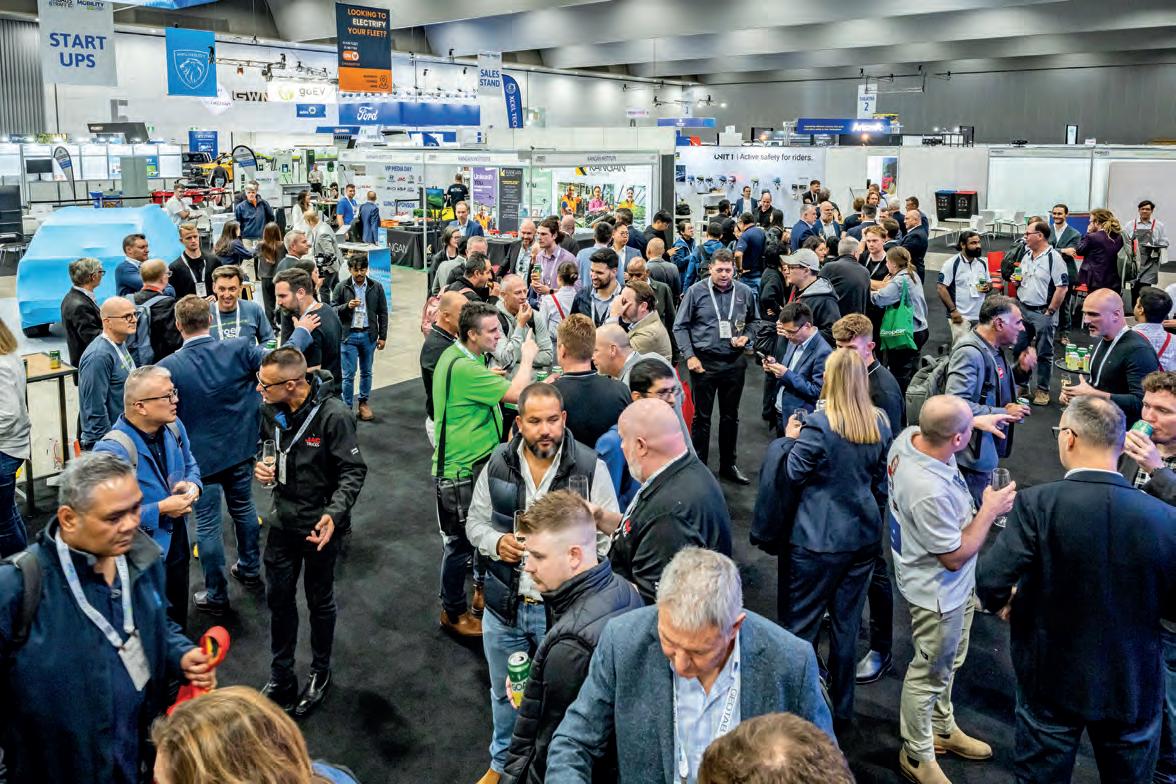

42 Building smarter and more sustainable roads

Australia’s road networks are under increasing strain. Luckily, Highways AU is here to showcase the solutions that could transform the sector of tomorrow.

44 Social scene on sale

Tickets for No-Dig Down Under’s vibrant social events are on sale and ready for purchase.

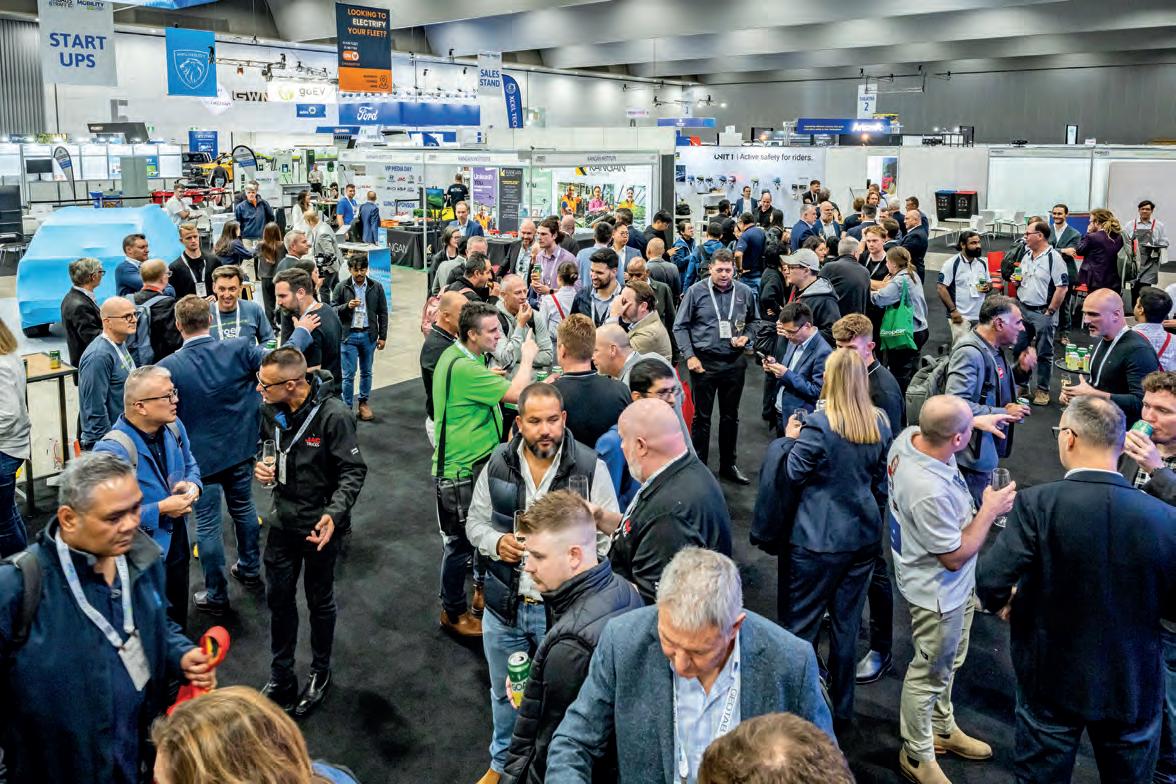

46 Breaking ground and barriers

A long and successful career in civil engineering has recently been recognised with an esteemed honour at the 2025 Women in Industry Awards.

Above: Diversity and big projects are a primary focus for the sector, as well as this edition of Roads & Infrastructure magazine. Image: MRPV

48 Converge: Industry’s platform for collaboration

A premier voice on sustainability in the built environment outlines the opportunities to come from the highly anticipated Converge 2025 construction expo.

50 The next level

The CONEXPO-CON/AGG Next Level Awards, coming up next year, have added two brand-new categories.

ASSOCIATION SECTION

52 Diversity in the Pavement Industry

The Australian Flexible Pavement Association writes on the importance of attracting, training and retaining skilled individuals in the pavements space.

54 Webinar informing all

An upcoming webinar is set to provide essential information around the future of temporary traffic management.

56 Closing the Knowledge Gap

How precast training is stepping up to ensure that the sector can cater for future infrastructure demand.

CONTRACTS AND TENDERS

58 Roads & Infrastructure provides an update on some of the contracts and tenders recently awarded or put to market.

CEO Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey

ART DIRECTOR

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Loren Katie Logan lorenkatie.logan@primecreative.com.au

CLIENT SUCCESS MANAGER

Sabrina Zor sabrina.zor@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia

p: +61 3 9690 8766 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COVER IMAGE

SAMI Bitumen Technologies

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

KEEPING PACE IN 2025

AS SCARY AS IT MAY SEEM, we’re already at the pointy end of 2025. For many –me especially – it’s hard to understand just where the year’s gone.

It’s already been three months since Western Australia’s Thornlie-Cockburn line opened, and roughly the same amount of time since the opening of Tasmania’s new $786 million Bridgewater Bridge, the largest transport infrastructure project in the state’s history.

“Blink and you’ll miss it’,” seems to be the common theme from the past nine months.

The September edition of Roads & Infrastructure magazine is your go-to resource to catch up on what’s been happening from right across the industry – featuring the latest machinery, technology, industry events and personnel profiles.

A highlight this month was sitting down with UniSA (University of South Australia) researcher Dr James Walsh. Walsh and a group of researchers have explored the human-centred aspects of emerging technologies in vehicles, particularly focusing on mixed reality, augmented reality, and autonomous vehicles. This essential research is taking a look at what can be done to better accommodate and implement autonomous vehicles into the current transport network, as well as the potential impacts on drivers and the general public.

Another excellent industry story in this edition is a discussion with Major Road Projects Victoria (MRPV) Senior Project Engineer Deborah Mallari. Mallari shares her story of determination and discovery in what is a male-dominated profession, and details why female and non-binary professionals should be looking to work in the infrastructure space. Looking to learn what it takes to work on some of the nation’s largest projects? Then this is the piece for you.

The events season is also heating up. If you’re looking to get out amongst industry, make sure to check out our dedicated events section. There you’ll find more about the highly anticipated Converge expo, the only Australian-owned major event showcasing the latest tools and technology in the municipal works, civil and commercial construction sectors. Maybe you want to learn more about what’s happening in the transport space? If so, then Highways AU may be the event for you. Highways AU will unite industry experts and leading solutions for the betterment of the sector, taking place later this year in Sydney. Conversely, if it’s construction you’re looking for, why not learn more about one of the world’s largest construction trade shows, in CONEXPO?

Look out for this and so much more in the latest edition of Roads & Infrastructure magazine.

Happy reading!

Tom O’Keane

TOM O’KEANE – EDITOR

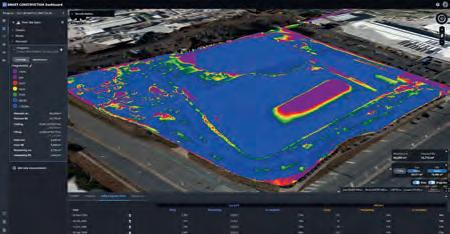

Stay ahead of the curve with Komatsu’s smart technology, tailored for the modern job site. Future-proof your projects with innovative features that empower you to deliver better results, faster.

Scan the QR code below to find out more.

NEXT STAGE AHEAD FOR CLYDE ROAD UPGRADE

The next major task on the Clyde Road Upgrade will begin soon, with Victorian Government crews demolishing the existing barriers and footpaths on the bridge over the Princes Freeway.

Crews will use high pressure water jets, known as hydro-demolition, to remove the concrete barriers.

This allows the concrete to be removed without damaging the steel reinforcements underneath, ensuring the bridge retains its structural integrity.

Cranes will also be used to remove the barriers and footpaths to create additional space for the new 10-lane bridge.

The expanded 10-lane bridge will be supported by a 5.6-metre-tall wall, currently being constructed within the centre median of the Princes Freeway.

The 570-tonne structure – comprising 230 cubic metres of concrete – will help support the weight of the new bridge, including 14 new bridge beams, each weighing 74 tonnes.

The new-look bridge will expand from six lanes to 10 lanes, which includes new turning lanes on and off the freeway and improved bus access.

Upgrading Clyde Road in Berwick aims to relieve bottlenecks, improve traffic flow, and make journeys safer and more reliable. Image: stock.adobe.com/Angelov

The Clyde Road upgrade between Enterprise Avenue and Bemersyde Drive will also involve upgrading the intersections at Clyde Road and Kangan Drive, and Clyde Road and the Princes Freeway as well as installing new street lighting, road signage, drainage and landscaping.

CONSTRUCTION UNDERWAY ON $400M WIND FARM INFRASTRUCTURE

The upgrade will improve traffic flow and access to local facilities and streets. It also aims to improve safety and reduce the risk of crashes with upgraded intersections and additional lanes, while making it easier and safer to walk and cycle along Clyde Road.

Works have begun on a $400 million expansion of the Warradarge Wind Farm near Eneabba, in Western Australia.

An additional 30 wind turbines will be built during the second stage of the expansion. This will add to the existing 51 turbines that have been in operation since 2020. When completed, the expanded wind farm will provide

The Warradarge Wind Farm is located near the towns of Warradarge and Eneabba in the Mid West region of Western Australia. Image: stock.adobe.com/Golen House Images

up to 283 megawatts (MW) of power for the South West Interconnected System, making it the biggest wind farm in WA. It will also be the largest by energy generated, able to power about 164,000 households a year.

The 30 new wind turbines will be capable of providing 103 MW of wind energy. They will be the same

size as the existing turbines, with a tip height of 152 metres and blades 67 metres long.

Warradarge Wind Farm is owned by Bright Energy Investments (BEI), a joint venture between Government-owned Synergy and Potentia Energy.

The expansion is due to be completed in 2027.

OPENING DATE REVEALED FOR METRONET BYFORD RAIL EXTENSION

Residents in Byford and the wider Serpentine-Jarrahdale area will connect to the Perth CBD on a 46-minute train journey once the Byford Rail Extension is complete. Image:stock.adobe.com/Andrea Izzotti

The Western Australian and Federal governments have announced that the METRONET Byford Rail Extension will

open for services on Monday October 13.

The project will deliver an eightkilometre extension of the Armadale

line, which will take place between Armadale Station and Byford. The project scope includes a brand-new station in Byford, as well as a new elevated station built in the centre of Armadale.

The removal of seven level crossings, two new road-over-rail bridges, eight hectares of new public space and eight kilometres of new shared paths for pedestrians and cyclists will also be delivered as part of the project.

Works on the delivery of eight kilometres of new dual-rail track have included 22,000 sleepers and 40,000 tonnes of crushed rock.

The federal and state jointlyfunded project is now entering a critical phase, which includes testing and commissioning, as well as driver training.

LUKE BOWEN BRIDGE OPENS IN COFFS HARBOUR

A new pedestrian and cyclist bridge honouring the memory of local student Luke Bowen has officially opened in Coffs Harbour, marking a major milestone in the

The pedestrian bridge replaces the older and shorter bridge of the same name, and now provides a safer, more accessible connection across the highway,

of remembrance for Luke. The Coffs Harbour Bypass is a $2.2 billion project jointly funded by the Federal and New South Wales governments.

The bridge replaces the older and shorter bridge of the same name. Image: stock. adobe.com/SATSUKI

GEORGIOU DELIVERS MAJOR FLOOD RECOVERY WORKS FOR QLD COUNCIL

Georgiou has delivered a $95 million Flood Recovery Project (North) for the Toowoomba Regional Council (TRC) in Queensland.

The North Package is part of TRC’s wider $300 million Flood Recovery Program, established in response to three significant flood events that devastated the Darling Downs region in late 2021 and early 2022.

The floods caused widespread damage across a vast 13,000 square kilometre area, directly impacting over 23,000 stakeholders and requiring repairs across more than 7000 individual sites.

The works included drainage, slope rehabilitation and bituminous works, desilting and repair of drainage structures, road formation grading, extensive rectification works to approximately 550 kilometres of flood-affected unsealed roads and 80 kilometres of sealed roads and minor bridge construction works.

The project was delivered under TRC’s collaborative delivery model,

NORTH EAST LINK’S FIRST PERMANENT ROAD SECTION NOW OPEN

The first permanent section of road to be delivered as part of works on the North East Link project in Victoria is now open.

A section of the Bulleen Road Interchange is open and will enable traffic to keep moving as crews continue to work on the entrance to the North East Link tunnel.

The new connection will also keep traffic moving as crews continue progress on the interchange that will connect the Eastern Freeway to the 6.5-kilometre tunnels.

The North East Link tunnels will connect the upgraded Eastern Freeway to the completed M80 Ring Road – cutting travel times by 35 minutes, skipping 18 sets of traffic lights and taking 15,000 trucks off local roads daily.

which brought together TRC, Georgiou Group, Golding Contractors, and five local consultancies: Aurecon, Titus Consulting, HIG Infrastructure Group, Tell Advisory, and Stantec.

In addition to rebuilding vital

infrastructure, the program delivered significant economic benefits to the region, with over 71 per cent of construction spend directed to local businesses, exceeding TRC’s 60 per cent local spend procurement target.

Work is ramping up on the major upgrade to the Eastern Freeway, which includes new express lanes, managed motorway technology and Melbourne’s first dedicated busway.

In the coming months, crews will also replace two key pedestrian bridges over the Eastern Freeway at Estelle Street (Balwyn) and Heyington Avenue

(Doncaster), to improve connections, and provide a link to the Koonung Creek Trail.

To safely replace the existing bridges, sections of the Eastern Freeway were closed at times overnight from late July to September.

This project is jointly funded by the Australian and Victorian governments, and will be complete in 2028.

As part of Victoria’s Big Build, The Victorian Government is delivering three major road projects, including the North East Link tunnels. Image: stock. adobe.com/Adam Calaitzis

This was the first collaboration between Georgiou and the Toowoomba Regional Council. Image: stock.adobe.com/Iryna

• Reinforced backfill applications

• Soil-structure interaction

• Precast concrete solutions

• Geosynthetics

• Environmental hazard protection

www.geoquest-group.com.au

BW100, BW120, BW138

Powerful combination of crusher and screen

Built for contractors who can’t afford downtime, the BW100, BW120, and BW138 rollers deliver consistent results, smart tech, and rugged reliability.

At Tutt Bryant Equipment, we’re proud to bring you the latest in BOMAG innovation, the light tandem rollers. Built for precision, durability, and comfort, these rollers redefine compaction for roads and infrastructure projects across Australia. From footpaths to road repairs, these machines thrive where precision matters and space is tight.With features like maintenance-free articulation joints, ECONOMIZER compaction intelligence, and the industry’s most comfortable operator platforms, every detail is designed to save you time, money, and fatigue.

SUNSHINE STATION WORKS UNDERWAY IN PREPARATION FOR MELBOURNE AIRPORT RAIL

Geotechnical investigations are underway at Sunshine Station to prepare for improvements to the rail network in Melbourne’s west.

Works have included the testing of soil and locating underground utilities, which will inform the design and construction of the project.

These investigations are a critical part of preparing for the construction of two new platforms at Sunshine Station.

Planning consultation is also underway, with locals asked to have their say as part of the planning process.

Procurement for the project is progressing with construction industry representatives attending a recent online briefing to learn more about opportunities to deliver the works. A new construction alliance will be established to deliver the

project’s package of regional line works, which includes the new platforms at Sunshine Station.

The remaining works packages on the project will be delivered by the existing Level Crossing Removal Project delivery alliances.

The Sunshine redevelopment is the first stage of the Melbourne Airport Rail and is

Sunshine Station is set to become a superhub as part of the Melbourne Airport Rail project.. Image: stock.adobe.com/Jackie Davies

required to be completed before tracks can go to the airport.

The new station will have the capacity to support more than 40 train services per hour, creating capacity for additional services for the growing west and to the airport.

Design and planning is now underway, with works expected to start in early 2026 and be complete in 2030.

SYDNEY METRO’S BANKSTOWN STATION NEARS COMPLETION

The Sydney Metro conversion of Bankstown Station has reached 80 per cent completion, bringing Southwest Sydney’s first major transport interchange one step closer to opening.

More than 100 workers are on-site daily delivering upgrades to transform the centuryold station.

The Sydney Metro station entrance building at the eastern end of the site has reached its final construction stage, with paving of the concourse area underway as well as the installation of 19 new Opal gates.

On the 170-metre-long metro platforms lined with platform screen doors, work is ongoing to complete the platform tiling, and glazed balustrades.

In the Sydney Metro station building, interior fit-out works are progressing for the ceilings and back of house rooms.

The new Sydney Trains entrance building, located directly opposite the new metro entrance, is also nearing completion with the ceiling being installed and gate line preparation works to commence soon.

Work at the site will next shift focus to the delivery of a new 90-metre-long, tree-lined pedestrian plaza. First up, earthworks will take place to level out the corridor area for

the new plant life. The cross-corridor plaza, featuring dining and retail options, will be on the doorstep of the new station entrances and will connect the north and south of Bankstown to pedestrians for the first time.

Across all 10 southwest stations, site works are progressing, with equipment being energised to support the testing and commissioning of key communication subsystems, including PA and CCTV systems.

Train testing is also continuing, with the critical ‘kinematic envelope test’ underway. This test confirms the train has sufficient clearance from surrounding infrastructure, including station platforms.

To date, more than 700 kilometres of testing has taken place across different parts

of the Southwest line, at speeds between five kilometres per hour and 25 kilometres per hour.

The next critical phase of testing is underway, with a focus on the advanced smart signalling system that will enable fully driverless metro services.

Next year, when the final section of the M1 Line opens, Sydney will have a 66-kilometre fast and reliable metro network and Sydney’s southwest will have fast metro journey times.

Below: The T3 Bankstown Line is being converted to metro standards between Sydenham and Bankstown with all stations to be fully accessible with lifts and level access. Image: stock.adobe.com/den-belitsky

MAKING THE IMPOSSIBLE POSSIBLE

A COLLABORATION BETWEEN RMIT, SAMI, RABS AND ALEX FRASER HAS DELIVERED WORKS – THAT SHOULD’VE TAKEN MONTHS – IN JUST ONE WEEK. ROADS & INFRASTRUCTURE FINDS OUT HOW THE USE OF SAMIBIOPRIME AND SAMIFALT I-BRID MADE THIS OUTCOME POSSIBLE.

When Hobsons Bay City Council recognised the need to upgrade Toll Drive in Altona North, Melbourne, multiple challenges quickly came to the fore.

Toll Drive is situated in the heart of Altona North’s busy industrial precinct, frequented by a high volume of vehicles, especially freight and heavy movers.

To shut down such a road for works would cause significant disruptions, not only to local businesses, but also to what is an essential route for the transport of goods and services throughout the region. As such, long-term shutdowns were out of the picture.

It’s here that Hobsons Bay City Council began to think outside of the box. As

Aten Kumar, Coordinator, Civil Design and Projects, Capital Works – Hobsons Bay City Council explains, SAMIBioPrime and SAMIfalt I-Brid were two products that stood out.

“Every opportunity we get, we look for innovative products that not only support good project outcomes, but are also beneficial for the environment, and beneficial for the community,” he says. For projects such as these, Hobsons Bay City Council can utilise its vast network of industry relations. RMIT is one such partner the council has been working with increasingly over the past few years.

Through discussions with Professor Filippo Giustozzi, Civil and Infrastructure Engineering Discipline Leader, Materials and Structures – RMIT, Kumar and the Hobsons Bay City Council team were made aware of two revolutionary products that could cater for the unique challenges of the Toll Road project.

SAMIBioPrime and SAMIfalt I-Brid were together presented as a more durable and sustainable solution to upgrade the existing – and ageing – Toll Drive surface and sub-surface.

SAMI Bitumen Technologies’ is well known for its technical excellence and expertise in delivering innovative road surfacing products and additives.

PRIME

AND I-BRID

The SAMIBioPrime and SAMIfalt I-Brid solutions represent yet another advancement in solutions available to industry.

SAMIBioPrime is an environmentallyfriendly, petroleum solvent-free bitumen emulsion, capable of penetrating all bound and unbound compacted base courses. The SAMIfalt I-Brid is a highperformance hybrid modified binder that excels in resisting rutting and fatigue, making it ideal for areas with heavy truck traffic.

SAMIBioPrime surpasses other primers, saving time and increasing efficiency by allowing the subsequent layers of spray seal or asphalt to be applied within one

The shorter time required for curing helped to ensure that the project could be completed in a matter of days, rather than months.

cause inconvenience, we learned that we could do it in five nights and have an equal or better outcome,” he says.

SAMIBioPrime and SAMIfalt I-Brid continue a long history of innovative material science developments for road construction.

hour, compared to the standard 24 hours or three days required by other emulsions or cutbacks.

It’s one of the key reasons SAMI’s solutions stood out, Kumar says.

“Rather than using conventional methods, that could’ve taken months and

The product not only ensure a fastpenetrating prime coat but also promote a greener approach to construction by being nearly carbon-neutral and containing no volatile organic compounds.

Professor Filippo Giustozzi, who was involved in the initial research and testing of both products, says they represent significant improvements in the performance and sustainability capabilities of bitumen additives. Adding that these products optimise what’s possible under Australia’s strict material innovation regulations in transport.

“The challenge was that in Victoria, the

This project represents a collaboration between RMIT, SAMI, RABS, Alex Fraser and Hobsons Bay City Council.

climate can range from very cold winters to very hot summers. There wasn’t a single product that can tackle both the performance at low temperature and high temperature,” he says. “The idea of the hybrid is to combine the best of these two worlds and create a single product that can offer what the elastomers do, and can at the same time offer the performance properties provided by plastomers.”

SAMIBioPrime is also a petroleum solvent-free bitumen emulsion which offers a safer user experience and eliminates the risk of explosion associated with other cutbacks.

Creating a universally compatible solution was a significant challenge. But as Giustozzi explains, these products were developed using existing knowledge and trials around elastomer and plastomer performance.

“You can guarantee the maximum resistance to cracking when it’s very cold, but at the same time, the product doesn’t soften when it’s very hot. That’s the essence of a hybrid,” he says.

Created and developed locally, both products have been designed and curated to cater for the unique challenges of Australian projects, while also supporting local industry and innovation.

ACHIEVING KEY OBJECTIVES

With SAMI providing both the SAMIBioPrime and SAMIfalt I-Brid, and Alex Fraser producing the asphalt, the next step was locking in an experienced asphalt laying service provider.

RABS Group, one of the leading asphalt laying and road profiling companies in the industry was selected, based on its strong

Images: SAMI

The works at Toll Drive had to be completed at night in order to minimise disruptions for motorists and local businesses.

track record in delivering complex projects and works for Hobsons Bay City Council.

Braeden Cairney, Operations Manager – RABS Group says the company was quickly impressed with the performance capabilities of both SAMIBioPrime and SAMIfalt I-Brid.

“We were in touch with Filippo [Giustozzi], who got us in touch with Brad Richards from SAMI. That was when we got the lowdown on the hybrid solutions and what they could provide,” he says.

Brad Richards, State Manager Southern Region – SAMI Bitumen Technologies says that while the benefits are obvious, aligning product use with the right application can be a challenge.

That is, with products that aren’t as versatile as SAMIBioPrime and SAMIfalt I-Brid.

“It’s rare to have exceptional rut resistance and at the same time very good crack resistance,” he says. “Never before have the two been as good, in the same binder.

“SAMI prides itself on its innovation and new technologies, and it’s these aspects that solidify SAMI’s place in the market as one of the leaders in the industry,” Richards adds.

For Cairney and the RABS team, the biggest box ticked was the time required for curing.

“A standard prime can take anywhere from 24 to 48 hours to cure up,” he says. “It’s a far cry to have something that can break down as quickly as 20 minutes, to an hour and a half, depending on the temperatures.

“They were products that we were really excited to give a go, because we’re always

pushing for the use of new products that the industry could benefit from.”

It wasn’t long after initial trial runs that the entirety of the RABS team was onboard with the use of both additives, reflecting the ease of placement required for the SAMIfalt I-Brid asphalt – a common theme among many of SAMI’s PMB (polymer modified bitumen) binder asphalt products.

“Crews are always hesitant to trial a new mix, but as soon as we got that first load down, they said, ‘This is fantastic’. There was no smell difference. There was no layability difference. It just felt like a normal mix to them, which is exactly what you want,” Cairney says.

“We know performance is better after the fact, but for them to think it’s the same as a conventional mix while they’re laying, that’s super critical.”

PROJECT OUTCOMES

Works on the project concluded in February 2024. The following months have acted as additional endorsement for the application of SAMIBioPrime and SAMIfalt I-Brid.

Importantly, the project also delivered several long-term benefits for the community. Not only in reducing potential disruptions during delivery, but also in laying the groundwork for more sustainable, local projects in the region.

These works have also highlighted the potential for high quality outcomes that can arise from collaboration between industry innovators.

Cairney says that without participation from all four project stakeholders, the works would have been significantly more difficult.

“It was a high-pressure job, but for it to go as well as it did, I credit everyone who was involved. From Hobsons Bay, to SAMI, to Alex Fraser and our business,” he says. “Everyone just worked cohesively and well together, and I’m super proud of the result.”

The project has been such a success that it’s won the 2025 AfPA (Australian Flexible Pavement Association) Industry Award, for ‘Outstanding Project Less Than $10 Million’.

R ichards says its recognition like this that will cement the achievements reached on the project for years to come.

“It’s been a great recognition of all the hard work and teamwork that’s been put in, because this has been a massive collaboration,” he says.

“It’s clear that our clients and partners value quality, and that they’re looking for something outside of the box and sustainable. [They’re looking] for additives like these, that not only constitute the sustainable components in the product itself, but also support more durable –and therefore sustainable roads.”

Speaking to future collaboration, Richards says SAMI is excited to continue working with Hobsons Bay City Council to deliver favourable project outcomes. He adds that this extends to the other project partners, many of whom SAMI shares a long history with.

“Due to the success of this project and the road looking so good more than a year on, we’ve done another project using the same product in a different area for Hobsons Bay City Council. It just goes to show the confidence that they have in this technology,” he says.

EXCELLENCE ENGINEERED

MAJOR ROAD PROJECTS VICTORIA

(MRPV) SENIOR PROJECT

ENGINEER DEBORAH MALLARI HAS SHARED HER STORY OF A LIFE WELL-LIVED IN ENGINEERING AND WHAT IT TAKES TO RISE UP THE RANKS IN THIS BOOMING INDUSTRY.

From growing up in the Philippines, to learning her field in Singapore and eventually moving to Australia, Deborah Mallari, Senior Project Engineer for Major Road Projects Victoria’s (MRPV) journey has been one of discovery and growth.

A 10-year veteran of the Victorian construction industry, she has been part of some of the state’s biggest projects including the Princes Highway Upgrade in Sale and the Monash Freeway Stage Two Upgrade.

It all started with a little encouragement from her family, which planted the seed that blossomed into a burgeoning career in engineering.

“When I was younger, my parents told me that I was good at maths compared to other subjects, so they encouraged me, as I had the potential to become a good engineer. As I got older, that became my aspiration,” Mallari says.

Her parents’ encouragement, as well

as her skills in maths were not the only factors that pointed to a career in engineering. Mallari also knew that her leadership skills made her well suited to potentially lead a team of people.

“From a young age I was already thinking about how I could work in a managerial role when I grew up,” she says.

“My options were going into the health field and becoming a doctor or going into business and law, which didn’t interest me. Or I could use my maths skills and become an engineer.

“Those other careers didn’t interest me, so I was beyond happy to pursue a career in engineering.”

At first, Mallari wasn’t sure which field of engineering she wanted to pursue.

With multiple options in mechanical, electrical and civil pathways, it took her some time to figure out the right path.

“When it came time to enrol, civil engineering felt like the right fit for me,” she says.

“I had never been as drawn to electrical or mechanical engineering, and civil just aligned more closely with my interests.”

It’s not just the building of impressive structures and roadways that interest her though – the importance of working with stakeholders and planning all aspects of the project have been an unexpected joy in her time as an engineer.

“I think one of the things that has stood out to me is the importance of proper planning in the project,” Mallari says.

“This includes engaging with all the relevant stakeholders and working with them through the planning and construction processes.

“One of the unique and interesting things that I did as part of VicRoads/ MRPV is when I worked with the archaeologists in Traralgon where we did some salvaging works on Aboriginal artefacts.”

Mallari says she found it important to be a part of compliance with the planning

Major Road Projects Victoria Senior Project Engineer Deborah Mallari.

and environmental requirements prior to commencing works.

“I enjoyed partaking in the respectful act of how we value the culture and history of the people who lived there before,” she says.

“This is what I love in my job, because I’m getting the opportunity to work on different aspects of the project, as well as knowing other people in the design and construction fields.”

She’s risen in the ranks during her time at VicRoads and MRPV, becoming a Senior Project Engineer. She is now working on the Thompson Road and Berwick Cranbourne Road Intersection Upgrade.

“Being a Senior Project Engineer has helped me understand how to manage projects as a whole,” she says.

“It has also given me the opportunity to build connections in the construction industry, as well as influence other people, for the success and best outcome of the project.

“One of my big highlights working on major road projects is when we reached the completion of the project and fully opened up the road to the public.

“This gives me the feeling of joy and a sense of fulfilment in serving the community.”

Although she has found success in her career, starting off wasn’t easy.

“My time breaking into the industry was difficult, especially because engineering was, and still is, a heavily male-dominated industry,” she says.

“Although my journey wasn’t simple, I managed to overcome the challenges and enjoy every experience that I had through it, which made me want to become an engineer.”

Mallari says she has learnt that if you are clear about your goals you will succeed.

“I’ve learnt that if you know what you’re doing and understand your career path, you’ll be fine,” she says.

“It can be challenging at times, but if you have a genuine passion for what you do, it will carry you through.

“When you truly love your job, you’re better equipped to handle the challenges and difficult circumstances that come your way.”

For those who are anxious about breaking into the industry, Mallari says don’t be.

“You don’t have to do it all alone,” she says.

“Engineering is built on collaboration, and most projects are driven by teamwork. Don’t be afraid to lean on that.

“I’ve been fortunate to work with the MRPV team, who’ve supported me every step of the way. They’ve helped shape the person and professional that I am today, building my confidence and encouraging me to keep growing. Their belief in me has made all the difference.”

Mallari says she hopes to build a stronger engineering industry that’s more inviting for women. She’s also hoping to further decrease risk on site.

“One of my hopes in engineering is to encourage more women to join this field,” she says.

“I hope the construction industry will cooperate and adapt to the culture and initiatives within MRPV, which supports women and treats them fairly and with respect.

“Given that the construction industry is a high-risk environment, I also hope that there will be more safety innovations that will be introduced with the help of our evolving technology, that can significantly reduce any incidents during delivery on our projects.”

Images: Victorian Government

One of Mallari’s projects, the Hall Road Upgrade, has eased congestion in the Carrum Downs/Cranbourne areas.

Mallari is currently working on the Thompsons – Berwick Cranbourne Road Intersection Upgrade, which recently began works.

ROADS REVIEW

THIS MONTH, WE ASKED THE INDUSTRY’S DECISION-MAKERS, WHAT CAN THE INFRASTRUCTURE SECTOR DO BETTER TO NARROW THE EXISTING SKILLS GAP?

MATTHEW BERENI, CHIEF EXECUTIVE OFFICER – TRAFFIC MANAGEMENT ASSOCIATION OF AUSTRALIA

To close the skills gap in the infrastructure sector, we must ensure skills at all levels are properly recognised on the Skills Occupation List, allowing us to fill critical roles with the right overseas talent. Nationally standardising training and qualifications – without increasing costs – will help skilled workers move where they’re needed most. We also need to promote diversity and inclusion, especially among women, First Nations people, and young Australians. Finally, we should clearly outline career paths so prospective job seekers fully understand the range of opportunities available within our industry.

Image: Traffic Management Association of Australia

CRAIG MOSS, DIRECTOR CAPABILITY AND DEVELOPMENT – AUSTRALIAN FLEXIBLE PAVEMENT ASSOCIATION

To address the skills gap, the sector must prioritise industry-led learning and development programs specifically designed to meet the needs of the workforce, especially in regional areas and for local governments. Practical, hands-on training developed and delivered by industry experts ensures that the skills taught are relevant, builds capacity, and supports long-term workforce retention. Additionally, incentivising procurement practices to support capability development and adopting new technologies will help attract new talent. Collaboration among government, industry, and education providers is essential; however, leadership should primarily come from the industry.

Image: Australian Flexible Pavement Association

SARAH BACHMANN, EXECUTIVE ADVISOR – NATIONAL PRECAST CONCRETE ASSOCIATION AUSTRALIA

Educational resources dedicated to precast concrete are finally here to help close a critical knowledge gap in our construction workforce. With the National Precast Micro-Credentials – supported and funded by the Queensland Government - workers can now access the first online, industry-built training, dedicated entirely to precast concrete. Covering topics such as safety, quality, environmental requirements, industry-specific plans and documentation, reinforcement and mould assembly, finishing and curing, as well as lifting and transportation, they give anyone working with or in precast essential knowledge. Free in Queensland and available for a small fee elsewhere, they arrive just as Victoria’s Big Build, major New South Wales civil projects, hospitals and the T2D (Torrens to Darlington) project in Adelaide, plus the 2032 Queensland Olympics drive unprecedented demand. With many projects already mandating training, replacing generic courses with targeted learning is the logical choice.

Image: National Precast Concrete Association Australia

RAQUEL RUBALCABA, DEPUTY SECRETARY, INFRASTRUCTURE PROJECTS AND ENGINEERING –TRANSPORT FOR NSW

We must be honest about the challenges and work together – as government and industry – to solve them. We need policies and targets but these are not the ‘silver bullet’. This is why Transport is working with industry on practical actions such as pre-apprenticeship programs and work placements – and seeing dividends. An ongoing call to action for our projects is the prioritisation of the physical and mental health of every worker so that once they are in the industry, they stay in the industry. But unless we can change the culture, we will continue to face significant productivity and labour challenges.

Image: Transport for NSW

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2025, please get in touch with Editor, Tom O’Keane: tom.okeane@primecreative.com.au

KEEPING THE NATION MOVING

GEOQUEST AUSTRALIA IS SUPPORTING FREIGHT MOVEMENT AND ESSENTIAL TRANSPORT LINKS ACROSS THE COUNTRY BY OFFERING A FULL SUITE OF CIVIL, STRUCTURAL, AND GEOSYNTHETIC SOLUTIONS, EACH DESIGNED SPECIFICALLY FOR THE RAIL SECTOR.

This year’s Federal Budget outlined a whopping $17.1 billion over the next decade for both road and rail projects. State by state, spending on transport projects – rail in particular –has created new-found confidence in the national project pipeline.

It’s why many in the industry are gearing their solutions towards rail, identifying what will continue to be a growing space filled with opportunity.

Geoquest Australia is one such company that has positioned itself as a one-stop shop for rail and infrastructure projects, offering a comprehensive suite of solutions that span civil, structural, and geosynthetic disciplines.

As Riccardo Musella, Managing Director – Geoquest Australia explains, major investment nationally has coincided with an expansion of the company’s offerings in rail.

“There’s been massive and historic investment in rail in the past few years. But for us, rail has been a strong focus for some time,” Musella says. “Rail has long been a core and very important aspect of the company’s offering.”

From structurally efficient MSE (Mechanically Stabilised Earth) walls and precast retaining systems to custom tunnels, rail platforms, and drainage options, Geoquest Australia’s solutions are designed to answer the call throughout the entirety of the project cycle.

Take the company’s precast elements for example. Whether it’s safety barriers,

noise walls, rail platforms, or bridge abutments, Geoquest Australia provides a suite of options designed for modular installation with minimal disruption – offsite manufacturing allows for improved site safety and efficiency.

The company also provides geosynthetic and drainage solutions, including high-performance drainage layers under ballast, erosion control systems and other geosynthetic materials that provide enhanced rail longevity, stability, and water management.

And this is just a small snippet of what the company does in the rail space.

In the past 12-24 months alone, Geoquest Australia has supplied products and project expertise to some of the largest and most nationally significant rail projects.

This includes the Byford Rail Extension, part of the major METRONET infrastructure program in

Western Australia. Geoquest Australia supplied retaining walls, with towering precast panels and other precast components, such as railway platforms and barriers, to help support new station and track alignments as part of the program.

Another is the Bell to Preston Level Crossing Removals, one of several works that the company is contributing to as part of the Victorian Level Crossing Removal Project.

Each project presents its own unique set of challenges. But Musella says Geoquest Australia is yet to encounter one that it can’t handle.

“One of the common characteristics with rail work is that they’ve got very specific and non-flexible timelines,” Musella says. “Line shutdowns can cause major disruptions to the community, so it’s essential that we’re able to hit those demanding timelines. Our vertical integration as a company plays a big hand in that.”

Geoquest Australia’s internal structure allows the company to customise designs, manufacture in-house, and provide a range of proprietary systems

Above: Geoquest Australia is constantly expanding its range of solutions, designed for rail applications.

tailored to each project’s needs.

“Our internal structure is very flexible. Because we provide fully customised designs, we can foresee potential issues and design in a way that overcomes those potential challenges when encountered,” Musella says.

“We are very vertically integrated because we also manufacture internally. We can adjust the design and production in a way that best suits the project, compared to a company that does the design, but doesn’t have the manufacturing capabilities.”

Being a vertically integrated business also reduces the need for multiple subcontractors, streamlining project management for the client.

“The other good thing is that many of these products are complementary. So, on one specific job, you don’t have to go looking for different options and companies, you can just rely on us,” Musella says. “From a contractual point of view, it’s a simple conversation with a single company, rather than several touchpoints. This is a big help, as coordination can get very complicated, especially on large-scale projects.”

TAKING THE NEXT STEP

With the company now offering a much wider variety of products and services for rail projects, Geoquest Australia is continuing to evaluate successful applications and products overseas, with future ambitions to expand the company’s range.

“We have a more comprehensive range of products than ever before,” Musella says. “One area of interest for us is the solutions that are yet to be heavily implemented in Australia. There are a number of precast designs, for example, that have been produced by our sister companies, such as TechWall and T-Wall.

“These are just some of the products that we see as ideal alternatives that could benefit the Australian market.”

Geoquest Australia is also expanding its focus geographically, with new projects and tenders on the east coast of Australia, including the Inland Rail and Sunshine Coast projects.

Backed by five decades of experience and a constantly adapting, evolving and improving product range, Geoquest Australia’s innovation in the rail sector is

here to stay, says Musella.

“No longer can – and do – we provide just the precast panels, or the steel straps. Rarely are we not combining multiple services and products as part of a single package. That’s how we’re growing the rail market,” he says.

Images:

Geoquest Australia

Rail has historically been a strong part of Geoquest Australia’s project pipeline.

Some of Geoquest Australia’s products have been used as part of major rail works, like the Level Crossing Removal Project in Victoria.

TICKING THE BOX MORE THAN JUST

FODS COMPOSITE RUMBLE GRIDS HAVE IMPRESSED TRANSPORT AUTHORITIES AROUND THE WORLD, SATISFYING COMPLIANCE AND LOCAL REGULATIONS, REGARDLESS OF THE JURISDICTION. BUT HOW DO THEY FARE AGAINST AUSTRALIAN SPECIFICATIONS? ROADS & INFRASTRUCTURE FINDS OUT.

Satisfying department of transport officials, project stakeholders and environmental regulators, among others, to land a product on an approved list can be a significant challenge.

It can often take substantial time to conduct this process in just one state, let alone nationally.

It’s a journey that FODS composite rumble grids have undertaken in recent times.

Designed to prevent mud, sediment, and dust from being tracked off construction sites onto public roads, FODS mats help contractors comply with stormwater protection regulations, reduce environmental impact, and improve site safety by preventing debris from being carried onto public streets.

But how?

“WE’VE HAD THE MATS THIRD-PARTY TESTED IN A VARIETY OF CONDITIONS AND DIFFERENT SOIL TYPES. THIS INCLUDES DIFFERENT TRAFFIC TYPES DRIVING OVER THE MATS, ALL IN DIFFERENT ENVIRONMENTS, AND THEY CONTINUE TO PERFORM.”

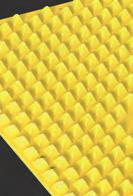

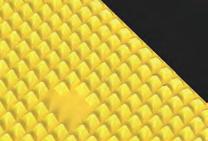

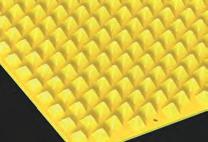

FODS vastly improves on conventional rock entrances to infrastructure sites by providing specialised mats with pyramidlike structures that capture and contain dirt and debris from vehicle tyres as they exit construction areas.

FODS requires minimal maintenance, such as occasional sweeping or shovelling, compared to rock entrances that need constant replenishment and levelling as the effectiveness of stone rapidly declines. Rock entrances can also create road hazards, with vehicles entering on-site potentially kicking up stones that can cause accidents.

The system works across various environments, from urban sites to dry

landscapes, and can handle different vehicle types and weights, from small cars to heavy mining equipment.

To categorically validate these claims before compliance satisfaction could be sought, FODS engaged experts in the industry. As Sales Manager, Chloe Moretz explains.

“Road and transport authorities want to see that an alternative can at least meet the same standards as other methods. In the case of FODS, it had to be as effective as rock,” she says.

“We have always had confidence in the product, because we know how much more efficient and effective it is. To back that up, we’ve had the mats third-

party tested in a variety of conditions and different soil types. This includes different traffic types driving over the mats, all in different environments, and they continue to perform.”

This validation has also been developed to cater for the specific needs and differing perspectives of project stakeholders.

“The standard you have to achieve is a little bit different, depending on who you’re talking to,” Moretz says.

“For engineers, effectiveness is key, and they’re often thinking about the safety perspective. The contractor’s top features are reusability over time and cost effectiveness. Whereas regulators really like that they can tell exactly when the mats need to be cleaned or refreshed. They can go out with a tape measure and say, ‘All right, time to clean them off’ – whereas with rock, that’s not very quantifiable.”

Images: FODS

FODS composite rumble grids continue to satisfy local rules and regulations across the globe.

KEY MILESTONE

Over the past few years, FODS’ had received approval from dozens of regulatory bodies around the world but FODS’ testing efforts focused on seeking approval from CALTRANS, the California Department of Transportation.

Considered the leading authority in best management practices for erosion and sediment control standards, CALTRANS is identified nationally as a trendsetter in the space.

Its strict environmental compliance requirements, rigorous evaluations of alternative solutions and emphasis on environmental protection in infrastructure projects (supported by agency CASQA – California Stormwater Quality Association) can present challenges for product approvals before use.

Satisfying CALTRANS requirements was a major milestone for FODS, with many international erosion and sediment control handbooks also referencing California as a benchmark.

“A lot of states and even countries refer to California as a gold standard,” Moretz says. “CALTRANS has been using our mats for several years already. Getting that official approval does really signify to others that FODS is an approved and verified alternative.”

With CALTRANS’ and many other state-specific DOT approvals within its arsenal, FODS has quickly expanded worldwide. Differing requirements and specifications between each jurisdiction have presented some challenges due to the lengthiness of the process and each

agency having their own methodology, Moretz admits. But still, FODS has been able to hold its own under scrutiny.

“I have seen a lot of countries become more congruent across the board over the past few years,” she says. “In the late 2010s and then early 2020s, there was some massive overhauling of the handbooks and specifications.”

Now with a foothold in the United States and Canada – as well as continuing expansions into Europe and the Middle East – the FODS system is rapidly in demand in a growing Australian market.

“We’re really excited, because the regulatory piece is there. Australia is pretty strict, and is becoming stricter around environmental compliance,”

Moretz says. “It does seem like the contractors have a big emphasis on the environmental aspect as well.

“There’s a lot of population and construction growth in the metro areas. Some projects of that have already seen FODS applied.”

Just some of these projects include the West Gate Tunnel and Metro Tunnel in Victoria and Queensland’s Captain Cook Highway project. A number of initial trials have also already taken place.

This is thanks in part to FODS’ growing distribution channels, with Shore Hire and JWA already providing stock nationally.

Moretz says FODS views this is as just the first steps for the system in Australia.

“Now that we’re building out our distribution network and have a rental option available, I expect things to only continue to grow,” she says.

Also on FODS’ radar is further expansion into Canada.

“We are used across Canada on a variety of high-profile jobs. We are also included in the British Columbia sediment and erosion control handbook,” Moretz says.

“They have a section for a synthetic mat, stabilised entrance, and it’s literally a photo of FODS.”

With growing markets across the world, FODS – as well as it’s contributions to major infrastructure projects – is showing no signs of slowing down.

Satisfying California Transport requirements was a major milestone in compliance for the FODS system.

FODS is eyeing further growth globally, especially in Australia.

TRANSPORT’S

HOT TOPIC

RESULTS FROM A SURVEY CONDUCTED IN PART BY THE UNIVERSITY OF SOUTH AUSTRALIA HAVE DETAILED THE IMPORTANT ROLE THAT AUGMENTED REALITY AND AUTONOMOUS VEHICLES COULD PLAY IN AUSTRALIA’S TRANSPORT FUTURE.

Augmented reality (AR). Autonomous vehicles. Transport algorithms. They’re words that are often floated and associated with the transport and infrastructure sectors. But some are unaware how quickly technology – that seemed a distant future – is already impacting our everyday lives, globally.

Autonomous vehicles and ‘robotaxi’ services are already in operation in Los Angeles, San Francisco and several other locations in the United States, as well as China, thanks to the popular use of services such as Waymo and Cruise.

The increased use of autonomous vehicles is inevitable. But how much is known about the potential physical and psychological impacts, not only on the general public, but also the transport network itself?

A new study, led by UniSA (University of South Australia) and (French university) IMT

Atlantique PhD candidate Thi Thanh Hoa Tran, aimed to explore the human-centred aspects of emerging technologies in vehicles, particularly focusing on mixed reality, AR, and autonomous vehicles.

Tran, alongside fellow researchers from IMT Atlantique, as well as co-author and UniSA researcher Dr James Walsh, wanted to understand how these technologies could and would impact user trust, confidence, and the overall experience, both for drivers and for others sharing the road with autonomous vehicles.

“It’s one thing to have these systems out there, but there’s also this huge trust element in terms of, ‘well if I don’t trust it, if my parents don’t trust it, if my grandparents don’t trust it’, people will be less likely to use it,” Walsh says.

“We know it’s just a matter of time before these technologies are rolled out, so looking at the potential ways that we can improve trust is really important. As is asking ourselves ‘how do we, and can we, improve the experience right now’.”

To conduct and accumulate relevant data to support the study, UniSA and IMT Atlantique worked together to create a virtual reality driving simulator. Seven AR visualisations were tested, which included

information about potential hazards and obstacles, speed limits and navigational directions. This also included incoming vehicle alerts and pedestrians, and notifications for potential points of interest, such as cafes.

This real-time information was displayed through a headset, onto the windshield, for the 28 participants (18 males and 10 females), aged between 22-50.

The technology uses sensors to deliver the data, ensuring that drivers stay focused on the road while accessing critical information.

RESULT AND FUTURE

Upon reviewing the results, researchers discovered that trust in autonomous vehicles was significantly increased thanks to the use of AR.

A standout quality was the effectiveness of AR to add or change driving-related information, tailoring visual cues based on a driver’s preference, attention patterns and stress levels, as Tran explains.

“The AR visuals helped participants understand the autonomous vehicle’s decision-making process, which is especially

important in complex traffic scenarios,” she says.

Tran says that while autonomous vehicles may be an intimidating concept, it’s important to understand the benefits they can present.

“Despite autonomous vehicles being generally safer than human drivers in routine conditions, there is a global reluctance to fully embrace them, but augmented reality might be able to change that,” she says.

Just one of the associated challenges is informing and educating drivers of all ages, as Walsh explains.

“One of the big issues that we’re going to have to face is the generational divide when it comes to the adoption and comfort with this technology,” he says. “The generation that’s coming through, that’s used to using ChatGPT, is inherently going to have a lot more trust in this technology than, say, someone’s grandparents.

“Theoretically, autonomous vehicles could be a superior transport method if they’re not susceptible to fatigue and can cause fewer fatalities. But the ethics around the technology and emotional component around its use are very real.”

Another challenge is the potential distractions presented by an AR interface. But as Walsh explains, this is barely a unique aspect of technology such as this.

“As with anything, once you’ve got a tool, it can either be used in a beneficial or detrimental manner. That’s where we have to weigh up the information displayed versus the additional cognitive load,” he says.

Walsh adds that the participation of car manufacturers and designers will likely be key for the effective and successful rollout of autonomous technology.

“I think the best experiences, and the most impactful are going to be where it’s integrated by the manufacturers as part of the car. The average car age on Australian roads is about 10 years, so there’s inevitably going to be a lag between when the technology comes out and when we see widespread adoption.”

In the short term, further testing will also be required to evaluate how these technologies can be beneficial for drivers, while also supporting broader adoption and acceptance.

“The next thing that I’d love to see is to run this in a real car, in some form or way. It’s important that we try and replicate the real-world experience as best we can,” Walsh says.

Image: stock.adobe.com/Have a nice day

The study evaluated the effectiveness of augmented reality in increasing confidence and comfortability for drivers.

Autonomous vehicles are set to transform the transport landscape globally.

Image: stock.adobe.com/Lee

Converge Expo brings together industry leaders across the municipal, civil and commercial construction sectors who are change makers shaping Australia’s future infrastructure.

17–18 SEPTEMBER 2025 Melbourne Convention & Exhibition Centre Australia’s hub for civil, commercial, and municipal solutions

FUEL EFFICIENCY

A GUARANTEE

with Cat VisionLink™ enabled – to a parts credit if their new machine consumes more fuel per hour on average than the committed Fuel Consumption Threshold during the first 12 months.

Eligible Cat machines will have their fuel consumption monitored by Cat dealers, and a report and letter will be sent quarterly to show how the average fuel

consumption in litres per hour compares to the threshold given at delivery. If the machine has consumed more, a parts credit will apply at the agreed value per litre over the threshold. It’s that simple. Cat has identified the Fuel Consumption Threshold as the rate of fuel consumption (expressed as litres per hour) considered to be representative of the expected fuel burn or consumption rate (in typical Australian operating conditions) for that model.

The productivity and efficiency of Cat’s new models are critical to finishing jobsites on time and with proper margins. Importantly, less fuel burn also means 2 (carbon dioxide) emissions. Give your business an edge with the Cat Fuel Edge Program.

CONTACT CAT DEALERS NOW FOR MORE INFORMATION OR ISIT CAT.COM/FUEL-EDGE-AU

WesTrac 1300 881 064

William Adams 1300 923 267

Western Australia WesTrac 1300 881 064

Hastings Deering 131 228

South Australia Cavpower 08 8343 1600

TERRA 0800 93 39 39

Images: Caterpillar

Cat’s innovations continue to improve on fuel efficiency and capacity.

SPECIALISED, FOR A REASON

SPECIALISED ROADING EQUIPMENT IS ANSWERING THE GROWING CALL FOR EMULSION EQUIPMENT IN AUSTRALIA, WITH A CONSTANTLY IMPROVING AND EXPANDING RANGE OFFERING IMPROVED VERSATILITY AND QUALITY.

Emulsion has long been in the DNA of Australia’s road construction sector. It’s first use can be tracked back to more than 100 years ago, with Shell chemist Hugh Alan McKay formulating what’s regarded as the first modern iteration of bitumen emulsion in 1923.

Regardless, a lack of specialised emulsion equipment in the subsequent years within Australia stagnated progress on the efficient delivery of projects involving emulsion.

Shortly after first venturing into the emulsion space in a serious way in 2017-18, bitumen sprayer and road maintenance equipment manufacturers Specialised Roading Equipment (SRE) saw great potential in creating a more sophisticated emulsion product line, beyond just basic pipe and pump fittings.

This push, originally in the New Zealand market, aimed to tackle what was – and

still is – a safety challenge. That is, that traditional pressure vessel systems can carry significant safety risks, with incidents highlighting the potential impacts and risks associated with explosions and other safety hazards.

“That’s what drove us to develop a much safer, more user friendly, and a more reliable solution,” Mark Wansbrough, Managing Director – SRE says.

With pumps that operate at only 3.5 bar pressure, a non-pressurised tank design, welded (rather than screw) fittings, as well as mechanical seals that can handle emulsion temperatures up to 80 degrees, SRE’s solution offers much greater risk prevention compared to conventional units. Each of these features help to eliminate the safety risk by preventing dangerous pressure build up, while also minimising the chances of human error thanks to a simplified design.

It’s Wansbrough’s belief that a lack of specialised equipment was a major contributing factor to these safety incidents, giving SRE motivation to answer the call.

“At the time, no one was really specialising in this area, and it was a

Specialised Roading Equipment’s range of emulsion equipment continues to grow.

says. “It was done on a very ad-hoc basis.”

The result: significant waiting times, reliance on local and in-house workshops to develop new solutions, as well as the use of outdated equipment. All contributing factors to the previously mentioned safety risks.

And safety is just one challenge that SRE has set out to solve. The other – a mainstay of SRE’s patented equipment –is reliability.

PERFORMANCE AND RELIABILITY

Consistent and predictable performance is always the goal during the development and delivery of SRE’s units.

Aided by simple and clear operational instructions, as well as minimal maintenance requirements, each emulsion

being said, if any issues were to arise, SRE has a comprehensive support and maintenance service, capable of delivering remote support and parts in a timely fashion.

As Chris Kaelin, Specialised Roading Equipment (SRE) Technical Manager explains, no news is usually good news.

“When you hear nothing, it’s usually a good sign,” he says. “Rarely do we hear issues pop up, and when they do, we’re quick to help.”

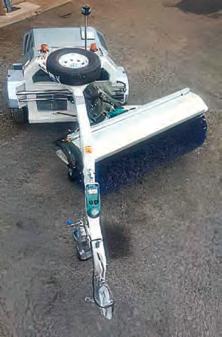

Among SRE’s popular units is its asphalt tack coater, sporting a 2.2-metre fixed spray bar and nine metre hand lance. Or SRE’s demountable tack coat sprayer, capable of being fitted to a wide variety of host vehicles, such as ‘utes’ or trucks. Another is its 800-litre emulsion trailers.

This is as well as SRE’s newly introduced 3.8-metre fixed wing emulsion sprayer, ideal for smaller sealing and tack coating jobs. This marks the latest development from the company, with a 3500-5000-litre tank size the direct result of industry and customer feedback for their emulsion needs.

SRE also offers kit options for customers who wish to conduct their own customised assembly and can even work with third party unit body builders, to successfully integrate the solution of choice. These units are highly customisable, depending on

Safety and usability were primary concerns during design and testing of

thanks in part to a modular design, with customers able to have direct input on deck size, required tank capacity, spray bar configuration, heating options and more.

“The beauty of the whole system is that it’s so customisable to whatever is required,” Wansbrough says.

“It allows us to create these one-off opportunities, ultimately for whatever the customer wants.”

Kaelin says it’s all about providing peace of mind to the customer and involved stakeholders.

“Whether it’s the customer or the body builder, some don’t want to deal with emulsion components because they expect it to be more difficult to deal with,” he says.

“What we can do is get everything ready and hand over a package that just needs to be bolted on. After that, they’re ready to go.”

Wansbrough believes the company’s commitment to working with clients on an individual basis, to provide the best possible solution, is what’s set it up for success in the emulsion space. And there’s zero plans to change now.

“For us, it’s about reliability, adaptability and ultimately, availability,” he says.

“People were crying out for a solution but didn’t really know that one existed. Well now, they know.”

Images: Specialised Roading Equipment

Specialised Roading Equipment’s emulsion equipment.

Emulsion is far from a new space for Specialised Roading Equipment, but the company has now re-affirmed its focus and range of solutions.

THE BEST POSSIBLE FOUNDATION

CRUSHER SCREEN SALES & HIRE’S PM1200-20TB PUGMILL IS PROVIDING QUARRY AND MATERIAL SUPPLIERS WITH EXTREME PRECISION, RIGHT DOWN TO THE GRAM. FIND OUT HOW AND WHY THE UNIT HAS EMERGED AS AN INDUSTRY FAVOURITE.

It goes without saying that materials form the literal bedrock of construction and infrastructure projects. They’re often the primary concern for project managers, who determine the type, volume and contents of each material component.

But who supplies, designs and makes them, and how?

Crusher Screen Sales & Hire is just one company that’s providing the equipment needed to produce adequate quality and volume of materials for some of the country’s largest transport projects.

As the IMS (Irish Manufacturers) distributors for Australia, Crusher Screen Sales & Hire has caught the eye of many within the roads and transport sectors, with its portfolio of equipment and plant helping to make a difference in the very foundation of Australia’s’ transport network.

Crusher Screen Sales & Hire works closely with IMS to develop pugmills and

blenders, along with other plant, for the Australian market.

According to Crusher Screen Sales & Hire Manager John Andersen, the company offers the largest selection of pug mills and blenders in Australia, each with unique capabilities.

Just one, is the PM1200-20TB pugmill, which includes two five-metre-long feed hoppers, each capable of holding 12 cubic metres of material. These hoppers are equipped with separate conveyors and belt scales, enabling precise material addition, particularly for road base applications.

The PM1200-20TB’s dual powder hopper system allows operators to either blend two different powders simultaneously or manage high-cement content materials like RCC (Roller Compacted Concrete).

During high-cement content operations, one hopper can extract material while the other refills, improving

The PM1200-20TB pugmill, with twin high production powder hoppers and three bulk silos, on site at a major infrastructure project.

mixing accuracy and product consistency.

“It’s the only pugmill around that has two belt feeders on each hopper, that’s also able to produce accurately,” Andersen says.

Greater versatility is also provided by an enlarged pug box, which is specifically designed to accommodate higher cement percentages, addressing industry needs for more complex material blending.

While traditional road base mixes might use 0.5-2 per cent cement, this model can handle mixes with 7-10 per cent cement, ensuring thorough and uniform blending of materials.

“Some people will take the pugmills out to the roading project and cut the raw material and blend it on-site, to get a more accurate and constant mix,” Andersen says.

All these features and more have been developed directly off the back of industry feedback and requirements, as Andersen explains.

“It’s the beneficiary of years of experience and knowledge, as well as our interactions with our clients,” he says. “Those same clients have units that have lasted 10 to 15 years.”

INTEGRATED CONTROL

Through its development and adoption of different technologies, Crusher Screen Sales & Hire aims to deliver a

solution that’s highly adaptable and customisable, defending on project and material requirements.

Just one example is its PLC (Programmable Logic Controller), a control system that manages and m onitors the entire material mixing and loading process. It acts as the brain of the machine, controlling everything from raw material input to final product output.

The PLC tracks and records precise details of each mixing operation, including the exact percentages of raw materials used, water content, and powder additions.

It can generate real-time graphs comparing programmed material amounts against actual quantities used, providing detailed documentation for each batch.

For loading operations, the PLC can automatically manage truck loading, tracking specific weight limits, registering truck and client details, and ensuring precise material distribution. It can handle multiple trailers and program specific loading sequences.

One of its most significant features is remote monitoring capability, allowing Crusher Screen’s technicians to access the machine’s system remotely.

“If a client has a problem and they’re 2000 kilometres away, we can

The PM1200-20TB has a longer threemetre pugbox to ensure a quality mix when blending high percentages of powder – like roller-compacted concrete.

actually go into the PLC on the pugmill and see what’s happening. And if there’s a problem, rectify it or fix it,”

Andersen says.

The system is highly customisable, enabling engineers to program specific mix designs remotely and adapt the controller to unique client requirements.

Designed to be user-friendly, the PLC offers preset programs to further minimise potential human error in material mixing, as well as during the loading process.

PASSING BENEFITS ON

For Crusher Screen Sales & Hire, the next steps are all focused on further educating the sector on the benefits of the equipment. Also, helping customers to tackle their ongoing challenges, such as the persistent skills shortage.

Andersen says it’s technologies like PLC that will help to dilute the potential impacts of changing operators.

“The biggest issue we’ve got within the industry is a shortage of operators and staff,” he says.

“It’s challenges such as this where customers can benefit, because we’re a small and nimble company that has the ability to react to people’s needs.

“There’s few around that can cater for the constantly evolving needs of our customers, but we’re one of them.”

MAKING SAFETY STICK FOR TOMORROW’S WORKFORCE

SAFETY IS AT THE FOREFRONT OF KOMATSU’S CONCERNS AS A COMPANY. A KEY REASON WHY ITS DEDICATED SAFETY WEEK PROGRAM IS LEADING TO GREATER OUTCOMES.

Creating a strong safety culture starts from the very beginning of a career with Komatsu, which is why each year the company runs a dedicated Safety Week for first- and third-year apprentices across all trades that deliver practical, engaging training that goes beyond the basics.

The aim is to equip apprentices with the tools, knowledge and mindset to make safety a core part of how they work, not just during their apprenticeship, but throughout their careers.

Kate Pemberton, Komatsu’s National Apprentice Development Manager, says Safety Week is a key investment in people.

“Safety Week allows us to deliver essential safety concepts in a way that’s interactive, relatable and most importantly, memorable. We want safety to be something our apprentices live and breathe – not just something they tick off a checklist,” she says.

First-year apprentices take part in a comprehensive program that blends foundational safety skills with broader wellbeing and behavioural training. This includes mental health and wellbeing, safe

ALL UNDER CONTROL

QUALITY FABRICATION & ENGINEERING

(QFEAUS) IS ON A MISSION

TO

PRACTICE SAFETY, DURABILITY, VERSATILITY, AND INNOVATION IN ITS OPERATIONS, ALL OF WHICH CAN BE FOUND IN ITS NEW CONTROL SYSTEM.

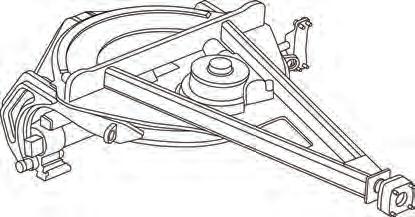

Quality Fabrication & Engineering (QFEAUS), among the leading Australian manufacturers of aggregate spreaders, has unveiled its nextgeneration control system – a purpose-built solution that redefines ease of use, safety, and repairability in roadwork machinery.

The control system is featured on the Road Ant ™, a dual-controlled forward moving aggregate spreader, created to increase safety on spray sealing projects across the road network.

After years of innovation and feedback from operators, the system is already making waves across South Australia, Victoria, New South Wales, and Queensland.

Existing systems, which the QFEAUS’ team believes were overcomplicated and outdated, laid the foundation for the new control system.

Adam Wernicke, Auto Electrical Technician for QFEAUS was instrumental in the development of the control system, saying there is always room for improvement. “We thought we could bring something unique

to the market, so we built an expandable, growth-focused system,” he says.

One major driver for the development of the system was creating an ease of repairability for the spray seal machine.

“I wanted to build a system that could be fixed on the side of the road, if necessary, with really basic tools,” says Wernicke.

SAFETY IS PARAMOUNT