TMHA power zero operating emissions operations.

ALLRACK APPOINTED

NSW DISTRIBUTOR

Strengthening BHD’s NSW presence.

GETTING SYSTEM INTEGRATION RIGHT

NEOS aligns systems and strategy.

Growing demand and constraints of outdated facilities meant South West Healthcare needed a new approach to meet the region’s supply chain needs and future-proof operations, ensuring uninterrupted delivery of essential medical supplies, linen, and equipment to hospitals across Southwest Victoria.

Dematic provided an AutoStore solution that signi cantly increases storage capacity, improves order accuracy, and reduces the time to process orders. South West Healthcare can now deliver vital orders faster and has more space to dedicate to other important functions. Learn

at dematic.com/southwesthealthcare

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

Chairman: John Murphy

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Editor: Phillip Hazell

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Danielle Harris, Jacqueline Buckmaster

Client Success Manager: Caitlin Pillay

FOR ADVERTISING OPTIONS

Contact: William Jenkin

william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST) 1yr (11 issues) for $99.00 2yrs (22 issues) for $179.00

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The first half of 2025 has shown that Australia’s industrial, logistics, and trade sectors are not standing still, even against a backdrop of global uncertainty. Recent developments highlight the willingness of industry leaders to invest, adapt, and innovate in the face of turbulence.

In Sydney’s southwest, Charter Hall Group’s agreement with Jennmar Australia marks a milestone in the transformation of Smeaton Grange. The new 31,000sqm facility will consolidate 15 smaller sites into one purpose-built hub, enhancing operational efficiency while embedding sustainability measures such as rooftop solar, rainwater harvesting, and EV charging.

Australia Post’s opening of its Blacktown parcel delivery centre is another example of long-term planning meeting immediate operational needs. With capacity to process up to 48,000 parcels a day during peak periods, the facility improves turnaround times and positions the organisation to meet rising eCommerce demand while advancing its 5 Star Green Star ambitions.

Meanwhile, ISPT’s proposed $1.1 billion industrial estate in Melbourne’s southeast would deliver one of the nation’s largest industrial offerings, balancing large-scale capability with environmental responsibility. Native tree retention, recycled materials, and embedded renewable infrastructure are all part of the planned development.

On the global stage, Emirates’ expansion of its Courier Express service into Australia aims to address long-standing gaps in cross-border eCommerce. By leveraging its high-frequency passenger flight network, the carrier seeks to bypass traditional bottlenecks and offer faster, more predictable delivery to and from international markets.

The message from these stories is clear: while challenges are reshaping the way we move, store, and deliver goods, those prepared to rethink, reinvest, and retool will define the next era of logistics and supply chain in Australia.

This edition also launches the MHD Software Showcase, a new feature designed to provide readers with an overview of supply chain software solutions available in the Australian market.

Happy reading!

Phillip Hazell

At Toyota, we’re proud to be at the forefront of innovative material handling energy solutions including electric, lithium ion, hydrogen fuel cell*, and also o er our exclusive I_Site forklift telematics system helping to track and reduce energy usage. With a comprehensive range starting from pallet jacks right up to eight tonne counter-balance models, make the switch to Toyota’s electric forklifts built with quality top of mind, and that’s just part of the Toyota Forklift Advantage.

08 TMHA equipment boosts ef ciency for Drake Group

11 NEOS drives integration success by aligning systems.

48 Geotab s upgraded cold chain solution.

54 RE E turns demand volatility into opportunity.

23 eli deepens Australian ties.

27 inde s leet OCUS advances safety.

30 ungheinrich launches A E compact electric pallet truck.

14 Vanderlande builds safer service culture in automation.

17 D strengthens NS presence through AllRack partnership.

20 Addverb delivers uni ed robotics.

33 Swisslog s Syn uni es warehouse operations.

44 rcher launches advanced scrubbers.

46 NA launches Aerobot in Australia.

50 Con uest expands into industrial vehicles.

52 aperless boosts warehouse ef ciency with cloud tools

56 The RIC Group delivers tailored S for mid-tier growth

Drake

Charter Hall Group has secured a 15-year pre-lease agreement with global manufacturing company Jennmar Australia for a new 31,000sqm facility at its Smeaton Grange Logistics Hub in Sydney’s southwest.

The deal marks a major milestone in the redevelopment of the 16.71hectare brownfield site at 80 Hartley Road, which previously housed a Coles warehouse. The original facility, constructed in 1998, is currently being demolished to make way for a new state-of-the-art logistics estate.

Australia Post has officially opened a new 18,360m2 parcel delivery centre in Blacktown, aimed at strengthening its delivery capabilities across Sydney’s north-west and meeting rising demand driven by eCommerce.

The future-ready facility is designed to handle up to 30,000 parcels per day, with peak capacity reaching 48,000 during busy periods such as Christmas. It boasts the largest parcel van capacity in the national network, able to accommodate close to 400 vans servicing suburbs including Parramatta and the Windsor–Richmond growth corridor.

Replacing older sites at Seven Hills and Horsley Park, the new centre provides expanded space for loading operations, enabling faster turnaround times and greater operational efficiency.

Upon completion, the revitalised site will comprise three warehouse and office facilities totalling 78,000sqm of gross lettable area (GLA). Jennmar’s commitment accounts for nearly 45 per cent of the site’s total footprint and will enable the business to consolidate 15 smaller facilities from across the Smeaton Grange area into one custom-built warehouse, with room for future growth via an additional 6,000sqm of expansion space.

Charter Hall Industrial & Logistics

CEO Richard Stacker said the redevelopment reflects the Group’s strategy of transforming underutilised industrial land into sustainable precincts designed to meet the evolving needs of occupiers.

“Smeaton Grange continues to attract demand from high-quality tenant customers like Jennmar,” Stacker

said. “This new facility will allow them to scale operations efficiently, with excellent access to major arterial routes and the future Western Sydney Airport.”

Targeting a 4 Star Green Star rating, the new estate will feature rooftop solar, EV charging, rainwater harvesting, drought-tolerant landscaping and smart metering systems.

Jennmar Australia Managing Director Gareth King said the facility will create major operational efficiencies for the business.

“This move consolidates our local manufacturing and distribution operations into a modern facility, while allowing us to maintain our presence in the region,” he said.

Further leasing opportunities remain at the site, ranging from 6,000sqm to 38,000sqm. ■

Australia Post General Manager

Divisional North – NSW/ACT & QLD, Khaled Elkhatib, said the investment reflects Australia Post’s commitment to improving service for both delivery teams and customers.

“By bringing our teams closer to their delivery areas, we’re able to improve turnaround times and ensure parcels reach customers’ doorsteps faster,” Elkhatib said. “The additional space is also helping us manage growing parcel volumes and better support eCommerce retailers.”

To cater for future demand, the site includes an extra 5,000m2 of warehouse space to support long-term growth in parcel volumes.

In line with Australia Post’s sustainability targets, the facility is aiming for a 5 Star Green Star rating.

It incorporates a 398kW rooftop solar system, 81kWh of battery storage, electric vehicle charging stations, and a rainwater harvesting system — initiatives expected to reduce annual carbon emissions by more than 250 tonnes.

The new Blacktown centre strengthens Australia Post’s position in one of the nation’s most important logistics regions and supports the broader transformation of its parcel delivery network. ■

Toll Group is transitioning to an all-electric Toyota forklift fleet to cut emissions and boost safety.

One of Australia’s largest logistics providers is lowering the emissions of its material handling equipment fleet utilising Toyota Material Handling Australia’s (TMHA) range of battery electric equipment.

That goal has taken its next step towards completion with the addition of two new pieces of battery electric Toyota machinery at Toll’s Eagle Farm facility including a 9FBMT counterbalance unit capable of lifting up to eight tonnes.

The new 9FBMT unit and batteryelectric reach forklift join three other zero-tailpipe-emission Toyota machines at the Eagle Farm facility, meaning the warehouse in Brisbane’s east now exclusively uses battery electric material handling equipment.

Toll Global MHE Fleet Manager Neil Walters, and TMHA Corporate Key Account Manager Gareth Conlan, have

worked together to manage Toll’s Toyota fleet of more than 400 machines across the country and transition each of those to battery-electric equipment.

Neil says Toyota’s range of battery electric equipment has helped Toll contribute to its decarbonisation goals.

“We had a plan within Toll to transition all internal-combustion engine (ICE) trucks up to eight tonnes in capacity to battery electric,” he says. “The latest delivery we’ve taken is another step forward in that transition, and we’re on target to achieve that by the end of 2025.”

Toyota’s eight-tonne trucks in battery electric format has allowed Toll Group to work towards its goal, with the 9FBMT unit offering a maximum lift height of seven metres and a 1240Ah battery capacity.

Choosing Toyota battery-electric forklifts has made it easier for Toll Group to improve on-site safety,

with an additional directive to fit a sophisticated pedestrian alert system (PAS) on all equipment. Neil explained that electric trucks are better suited to the fitment of accessories such as the PAS system.

“One of the reasons (PAS fitment) is more effective on electrics is it’s built into the controller so it sends an electrical impulse and slows the machine down, whereas if it was an engine truck we’d have to put some electronic control in there and it would get very expensive, very quickly,” he says. “This way, the transition to battery-electric not only improves our overall footprint and damage we do on the environment, but we can use that in tandem with a PAS to achieve a much safer operating environment for our staff.”

TMHA is helping Toll Group to ensure all machinery, whether new or existing, gets fitted with the PAS To improve

safety for all forklift operators and warehouse workers.

Along with the ability to provide Toll Group with a range of battery electric machinery options, another reason for the logistics provider to partner with Toyota on a fleet of more than 400 machines is the service network and team of experienced service technicians who can ensure any downtimes are

kept to a minimum.

It is imperative to Toll Group’s business that its material handling equipment is kept up and running to ensure freight is delivered on time, and the quick callouts and reliability of TMHA makes that goal simple.

“In addition to the quality of the product, what is particularly noteworthy is the level of support

our account manager Gareth, and the service team and technicians have provided,” Neil says. “Toyota’s service network and their responsiveness are crucial and were key factors in selecting them as one of our preferred suppliers.

“If there’s a problem, they get to the job and fix it. They service the machinery when needed, and from an account management perspective, Gareth makes sure we get the right equipment at the right price, in a timely fashion.”

Neil and Gareth share a strong working relationship with regular contact to ensure the fleet is running smoothly and any issues are dealt with in a prompt manner.

“We’d probably talk every second day but have a dedicated meeting every week,” Gareth says. “If (Neil) needs help with anything he’ll come to me direct, and if there are any site issues he needs escalated, he’ll push them across to me and I’ll work with our branch network to resolve the issue. It would be uncommon for us not to talk every 48-72 hours.”

Toll Group is currently on track to have a fully battery electric material handling equipment fleet by the end of 2025. ■

For more information freecall Toyota Material Handling Australia on 1800 425 438 or visit www. toyotamaterialhandling.com.au

Automated sortation enhances multiple stages of the supply chain by enabling:

> Efficient unloading of inbound containers

> Streamlined cross-docking for rapid distribution to retail outlets

> Cost-effective order picking

> Fast and precise shipping sortation

Vanderlande provides a variety of line sorters, including sliding shoe and pusher sorters, as well as loop sorters such as cross-belt and tilt-tray sorters, tailored to meet your speci c needs. Our sortation systems are designed to support customers at any stage of their automation journey, whether they are just beginning or already highly experienced.

Learn more at www.vanderlande.com/warehousing/systems/sortation

NEOS’ David Bissett says integration success depends on aligning systems, people, processes and long-term strategy.

Argon & Co stresses integration success depends on people, not technology. Image: Oulaphone/stock.adobe.com

In today’s supply chain environment, technology is often seen as the answer to every operational challenge. But according to David Bissett, Partner at Argon & Co and head of its systems integration arm NEOS, successful transformation goes well beyond the technology layer.

Integration, he says, should not be treated as a standalone IT project. Instead, it must be viewed as a broader business initiative that brings together systems, people and processes into a unified, future-ready operating model.

“The biggest mistake businesses make is assuming integration is just

about plugging in a new system,” David explains. “In reality, it’s about how that system fits into the broader way of working, and how ready the organisation is to adopt and sustain the change.”

While new software platforms often promise seamless end-to-end functionality, David has seen many implementations fail not because the technology was flawed, but because the business wasn’t ready.

He points to common issues such as unclear business objectives, insufficient

data health, under-resourced teams, and a lack of stakeholder engagement before going live.

“It’s not unusual for businesses to skip the planning phase, rush into system selection, and hope it all comes together during implementation,” he says. “But any issues you don’t resolve early will reappear during delivery, often with greater consequences.”

NEOS encourages businesses to begin with a structured readiness assessment that considers operating model design, data quality, change impacts and investment appetite. The goal is to identify and close critical gaps before

vendors or system integrators are brought in. Without this, integration efforts often become reactive, with project teams scrambling to retrofit processes or align roles midstream.

When it comes to selecting platforms, David argues that businesses should focus less on short-term convenience and more on long-term suitability. Rather than defaulting to generic off-the-shelf systems, he advises organisations to prioritise best-fit solutions that can align with their strategy, scale with growth, and integrate cleanly into their architecture.

“The question is not which system has the most features, but which system delivers the right capabilities in the right way for your specific needs,” he says.

He encourages clients to stresstest vendor claims through use case demonstrations, reference checks and, where appropriate, small-scale proofof-concepts. A system that looks good in a presentation may not always suit the operational realities of a particular business.

David also notes the importance of budgeting for the total cost of integration, including the effort required to prepare data, manage change and sustain the solution over time.

“One of the best pieces of advice I received from a CEO was to choose the solution you won’t regret in ten years,” he says. “Don’t optimise for short-term cost. Optimise for long-term value.”

People and process are central to success

Technology may enable transformation, but David maintains that people and processes determine whether it succeeds. He highlights the need for businesses to engage early with internal stakeholders, define clear governance models, and prepare staff for what new systems will require of them.

“You can’t bolt a new system onto an old operating model and expect results,” he says. “Change has to be embedded across the organisation, not

just in the IT function.”

This includes training that goes beyond system functionality. Scenariobased learning, rooted in actual job roles and workflows, is more effective than classroom sessions focused on screens and menus. David also stresses the importance of internal ownership.

While vendors and systems integrators play key roles, they rarely take responsibility for broader business change. Organisations need to lead that themselves.

“Vendors won’t redesign your business model,” he says. “They’ll deliver what you ask for. If you haven’t done the groundwork, you’ll get a technically sound system that may not work operationally.”

Among the recurring pitfalls David sees is the belief that integration ends at go-live. In reality, sustaining and improving a new platform is an ongoing task. Without postimplementation support, continuous development and internal capability building, the initial investment can quickly lose momentum.

Another misstep is expecting external partners to resolve internal misalignment. A vendor can configure a system, but they cannot fix unclear workflows, siloed data or unprepared teams.

“Integration is a business capability, not a one-off project,” he says. “It has to be planned, resourced and owned by the organisation.”

NEOS frequently supports clients not only during the selection and delivery phase, but also as they transition to managing the system themselves. This includes helping to define future roadmaps, embed governance, and build internal centres of excellence.

As supply chains face increasing volatility, the ability to adapt and scale becomes critical. David says architectural planning is often the missing link that prevents businesses from evolving their platforms over time.

“Many businesses implement new

systems without understanding how those systems will interact with others, or how they’ll support emerging technologies like AI,” he says.

Modular architectures, he argues, provide a more agile foundation than monolithic systems. They allow businesses to plug in new capabilities as needed, whether for automation, analytics or advanced planning.

Given the growing importance of data-driven decision-making, he also sees data health and integration maturity as critical enablers of technologies such as machine learning and predictive intelligence.

“If your data isn’t well structured, governed and accessible, you won’t get the benefit from new technologies,” he adds.

NEOS positions itself as a partner that blends business consulting with technical understanding. Rather than leading with platforms or features, David says the team focuses on aligning systems to business outcomes.

“We’re not here to sell software,” he says. “Our job is to help clients achieve operational change in a way that is sustainable, measurable and strategically sound.”

With integration increasingly viewed as a long-term capability, not a one-off investment, businesses that take the time to align strategy, systems and people are better placed to respond to disruption and scale their operations effectively.

“Doing integration right is not about doing more, it’s about doing the right things in the right order,” David says. “And that begins with being prepared.” ■

Vanderlande’s Asia Pacific Service Director, Tarang Shah, shares how the company’s customer-first, people-driven approach is reshaping service for automated material handling systems across Australia and New Zealand.

Walk into any automated warehouse and the first thing you’ll notice is the machinery: conveyors moving in synchrony, robotic arms lifting with precision, sensors flashing in rhythm. But behind the seamless choreography of automation lies a different kind of engineering –one that Vanderlande believes is just as critical as the technology itself.

It’s the engineering of service. For Vanderlande, service is not just about keeping equipment running; it’s about creating a resilient operational culture around it. At the core of that culture are two things: safety and people. With a global team of more than 11,000 colleagues, Vanderlande brings scale and staying power to every customer. In Australia and

New Zealand, the company’s service business is growing at a rapid rate – now with almost 200 specialists highly trained service professionals embedded within customer operations. Some work on-site 24/7, assuming full responsibility for running and maintaining complex automation systems. Others provide scheduled support in line with customer peak periods or maintenance windows. But the shape of the service model, whether resident or remote, is never one-sizefits-all.

“Flexibility is the key,” says Tarang, Vanderlande’s Service Director for Warehousing in Asia Pacific.

The company tailors each engagement based on customer maturity, in-house capability, and

operational scale. A grocery giant may rely on full-time technical support and system operations, while a smaller site might only require quarterly maintenance and emergency support during seasonal surges. The approach is fluid, but the objective remains constant: maximise uptime, minimise risk, and support performance.

Tarang stresses that this isn’t just about being responsive; it’s about being predictive. Vanderlande’s service strategy is grounded in data, and the team deploys a suite of tools and sensors to gather insight from systems in real time. These are not just used for dashboards and reporting. They drive decision-making.

At one customer site – a major Australian grocery distribution centre

– the service team was alerted to a behavioural anomaly in a key asset. Using predictive analytics and on-site diagnostics, they were able to isolate the issue before it became disruptive. The proactive intervention saved an estimated 48 hours of potential downtime, a scenario that could have had a ripple effect across the retailer’s national supply chain.

“The systems we designed for a customer two or three years ago often need adjusting to reflect how their business has changed,” Tarang explains. “Operational demand shifts, end-consumer habits evolve, and we use data to keep the systems optimised accordingly.”

What emerges is a vision of service that goes well beyond repairs. It’s about partnership. Tarang and his team operate with a long-term view of system health, and their philosophy centres on continuous improvement, both technical and human.

Nowhere is this more evident than in Vanderlande’s workforce development. From day one, new hires undergo structured onboarding not just to learn their technical responsibilities, but to absorb the company’s broader cultural priorities. Safety is not introduced as a module – it’s the very first item on the agenda.

“We don’t view safety as a KPI or a compliance box,” Tarang says. “It’s the foundation. Nothing comes before it.”

Daily review meetings, referred to internally as DRMs, open with safety updates – a practice institutionalised across the region. Team members are actively encouraged to raise near misses or potential hazards, not just report incidents. Dedicated health and safety business partners work exclusively with service teams to reinforce standards, provide hands-on support, and act as escalation points. It’s a full-time job because safety isn’t a passive commitment – it’s an operating principle.

This approach, Tarang believes, is one of Vanderlande’s key differentiators in the Australian market. He’s reluctant to speak about competitors, but emphatic about Vanderlande’s stance.

“Whether you’re a technician or a site manager, every conversation here starts with safety,” he says.

And it shows in the numbers. Internal surveys consistently highlight the onboarding experience and safety culture as reasons why new hires choose to stay. Tarang describes the culture as highperformance but inclusive and believes that retaining skilled professionals depends as much on how they’re treated as on how they’re trained.

Every role, from flow controllers and process analysts to control specialists and mechanical technicians, is framed around the customer outcome. This, he says, helps maintain consistency across teams and sites.

“People need to know not just what they do, but why it matters,” he adds. That sense of purpose becomes even more important as the company adopts new tools and technologies. Artificial intelligence is already being trialled to enhance maintenance forecasting and operational planning, with further integration expected in coming months. But Tarang is quick to clarify: the aim isn’t to replace human decision-making – it’s to empower it.

“When our people have better tools, they make faster, better decisions,” he says. “That benefits them and it benefits the customer.”

Vanderlande’s approach reflects a broader shift in the industry. As automation becomes more ubiquitous, customers are no longer looking only at hardware specs or system speed. They’re evaluating reliability, longevity, and support – not just in technology, but in the teams behind it. In that context, service has become a competitive edge.

Tarang believes that more customers are beginning to view service as a value generator rather than a cost centre. With automation often representing a large capital investment, ongoing system performance is critical to ROI. A wellmaintained, well-supported system delivers measurable results, especially in sectors like grocery, parcel, and general merchandise, where downtime has outsized consequences.

Still, service remains an area where many organisations underinvest, or view as an afterthought. Vanderlande’s goal is to flip that script.

“The most advanced automated system in the world is only as good as the team keeping it running,” Tarang says. “Our job is to make sure that team is supported, equipped, and safe.”

As the industry continues to evolve, Vanderlande’s challenge ¬– and opportunity – is to scale that service model without losing what makes it distinctive. For Tarang, that means doubling down on culture, clarity, and continuous feedback.

“We have the technology,” he says. “But it’s the people and culture that drives the outcome.” ■

Cantilever racking provides flexible storage for bulky and long materials. Images: BHD

BHD’s partnership with storage specialist AllRack is helping bring high-quality racking systems closer to customers in New South Wales. Here’s how.

BHD’s focus on building a strong local distribution network is paying dividends in New South Wales, where Sydney-based AllRack now serves as its state distributor.

The family-owned business, founded in the 1980s by David Wiggins and his brother, began by supplying a range of warehouse equipment – from trolleys and plastic bins through to pallet racking and mezzanine systems – to customers across Sydney. Over time, the company has established itself as a trusted provider of storage solutions in the warehousing sector.

Michael Wiggins, a director at AllRack, says the decision to join the BHD network came after positive recommendations from within the distributor base.

“We’d had some disappointments

with other product lines we were distributing,” Michael says. “We had a relationship with one of the Victorian BHD distributors, and after chatting with them, they suggested we give John Harrison at BHD a call to see if he needed a distributor for New South Wales. We did that, and the rest is history.”

AllRack’s role as BHD’s NSW distributor centres on two main product lines: selective pallet racking and cantilever racking.

“They’re definitely the highest quality Asian-Manufactured racking products on the market,” Michael says. “BHD is known mainly for its cantilever racking system for a very good reason. A lot of other racking

companies use BHD cantilever racking – even large competitors that are not part of the BHD network buy BHD cantilever due to its superiority. That’s definitely their core product.”

The proven track record of these products in the market, particularly in cantilever systems, has made them a competitive option for a range of warehouse and industrial applications in New South Wales.

Michael says having a local distributor is critical to reducing transport costs and improving responsiveness for customers.

“The price of freight between Melbourne and Sydney – and then even north of Sydney – is very expensive these days,” he says. “If you can have a local warehouse and stock the product locally, that’s an

immediate saving and brings the product closer to the end user.”

AllRack’s local presence also allows the business to provide faster service and better on-the-ground support.

“We’ve got knowledgeable staff, boots on the ground, people who can go out and check on racking systems, do racking audits, and provide quick service when someone needs a quote,” Michael says. “We could be out there the next day, rather than waiting a week for someone to come up from Melbourne.”

According to David, New South Wales operators are increasingly moving towards specialised racking solutions rather than relying solely on standard selective systems.

“The price of land has gone up so much that gone are the days of just filling a warehouse with low-density standard selective racking,” he says. “People are wanting to limit wasted space in their warehouse but also look at automation as a way of increasing storage density and pick efficiency.”

This shift towards optimised layouts and automation-ready systems has influenced how BHD and AllRack position their offerings in the market, with an emphasis on tailored solutions to match operational needs.

As part of its long-term strategy, AllRack is looking to grow its physical footprint across New South Wales.

“We already have a warehouse in Newcastle,” Michael says. “We think we’re going to need a warehouse in Western Sydney and an office there as well. Part of our five-year plan is to have satellite offices in some regional areas we think are growing.”

The expansion will allow the company to better serve customers in growth corridors while reducing lead times for delivery and installation.

Michael says being part of the BHD distributor network offers customers access to a consistent product range, backed by local expertise and service.

“BHD’s cantilever systems are a

known quantity in the industry,” he says. “When you’re supplying something that a lot of people already trust, it makes it easier to deliver solutions with confidence.”

The partnership ensures that customers benefit from both BHD’s manufacturing capabilities and AllRack’s understanding of the local market.

Michael sees the relationship between BHD and AllRack continuing to strengthen as customer needs evolve and the company’s expansion plans take shape.

“Our focus is on making sure

customers in New South Wales can get the right product, when they need it, backed by people who understand their business,” he says. “That’s what having a local BHD distributor is all about.”

With a strong foundation, an established reputation in the storage solutions sector, and a clear plan for growth, AllRack is positioned to play an increasingly important role in BHD’s national network – ensuring that customers in New South Wales have ready access to high-quality racking systems, supported by local knowledge and service. ■

Key features include:

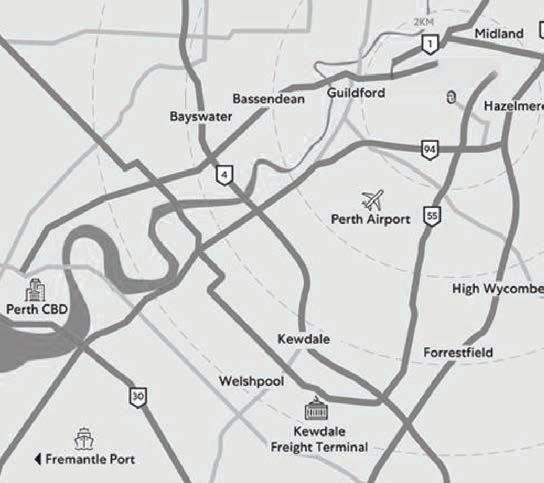

Storage Type and Capacity

Hazelmere, Western Australia Opening in November 2025

• Controlled ambient - 5,475 pallets

• Cool room (+2 to +8°C) - 500 pallets

• Secure storage zones for high-value medications and therapies, as well as controlled drugs

• Tailored for compliance with TGA, cGxP, and ISO standards

• Dedicated healthcare facility to meet all storage requirements and statewide transport and distribution

Sustainability and Resilience

• 100% solar powered via rooftop panels

• 40,000L rainwater tanks for irrigation and greywater use

• Energy-smart lighting systems reduce consumption

• Backup power: Diesel generators ensure operational continuity

Strategic Impact

• Part of Toll’s A$100M Asia-Pacific healthcare logistics investment

• Strengthens Toll’s 3PL/4PL capabilities in ANZ

• Creates local jobs and increases supply chain resilience across WA

Addverb’s autonomous mobile robots streamline warehouse operations. Images: Addverb

Addverb delivers unified robotics and software to simplify, scale, and future-proof modern warehouse automation globally.

As warehouses around the world confront increasing pressures, rising costs, labour shortages, growing SKU complexity, the call for automation has shifted from a nice-to-have to an operational imperative. But amid this urgency, one challenge remains: how to deploy automation that’s not fragmented, but unified. Addverb, a global robotics and automation company, has built its foundation on answering that very challenge.

Addverb refuses to rely on external systems – every robot, shuttle, and software platform is engineered in-house to ensure total control and performance. The result? A unified robotics ecosystem designed to support more coordinated and efficient supply chain operations.

The power of vertical integration

Addverb’s approach to automation is based on vertical integration, with both hardware and software conceived, developed, and produced in-house. This structure allows the company to maintain oversight across development

and delivery, supporting coordination, quality control, and deployment efficiency.

From ASRS systems to AMRs, robotic picking arms and intelligent sorting, each piece of equipment is designed to synchronise with Addverb’s in-house software suite, which includes Warehouse Control Systems (WCS), Warehouse Execution Systems (WES), and AI-powered orchestration platforms. This coordination enables businesses to orchestrate warehouse operations with precision, ensuring that software isn’t just a dashboard, but the brain behind the machinery.

At the heart of this ecosystem lies Addverb’s modular software suite, which provides the digital backbone to its physical infrastructure. Designed to be flexible and hardwareagnostic, Addverb’s software stack can be deployed independently or as a unified layer, offering unprecedented scalability. It enables intelligent synchronisation across

diverse warehouse assets, automated and manual through advanced data orchestration, visualisation dashboards, and real-time control.

With deep learning and AI at its core, the system predicts bottlenecks, optimises workflows, and supports intelligent decision-making. Whether it’s streamlining multi-robot coordination, visualising KPIs via interactive dashboards, or managing resource allocation dynamically, Addverb’s software ensures that the entire warehouse operates as one cohesive unit.

Since entering the Australian market, Addverb has introduced its global automation technologies to support warehousing, manufacturing, and logistics operations across the region. Drawing on its international experience, the company has worked to adapt its solutions to meet the specific regulatory, operational, and workforce conditions present in Australia. This approach reflects a broader effort to

align automation strategies with the practical challenges and expectations of local industry.

Peter Zann, National Sales Manager at Addverb Australia, shares his perspective.

“Australian businesses are increasingly looking for solutions that are agile, scalable, and digitally connected,” Peter says. “What we offer at Addverb is a single, cohesive platform that integrates robotics, software, and support, ensuring that our customers can future-proof their operations without the headache of managing multiple vendors. This flexibility is proving to be a gamechanger for our partners here in Australia.”

Addverb’s integration of robotics and software into a unified platform reflects an effort to address the operational challenges facing businesses in a rapidly changing environment. Its approach supports scalability, flexibility across multiple sites, and improved data visibility to help businesses adapt and remain efficient.

Addverb’s in-house capabilities reflect a commitment to sustainability and responsible innovation. This aspect of their approach goes beyond mere compliance; it embodies a vision for a future that prioritises environmental stewardship. The company’s manufacturing operations fully comply with RoHS (Restriction of Hazardous Substances) standards, ensuring that their products do not contain harmful materials that could jeopardise human health or the environment.

Additionally, many of Addverb’s products are thoughtfully engineered to minimise energy consumption, thereby contributing to lower operational costs for businesses and supporting broader environmental goals. In the Australian

context, Addverb is actively working to strengthen supply chains and expand its support network. By focusing on regionally adapted solutions, the company not only reduces its carbon footprint but also ensures the ability to deliver responsive and timely service to its customers.

This approach fosters a spirit of collaboration with ecosystem partners, helping to build a sustainable and resilient framework capable of meeting the demands of modern logistics. These initiatives reflect Addverb’s overarching commitment to not merely participating in the Australian market, but to taking a proactive role in driving sustainable transformation and innovation within the industry.

One of the standout features of Addverb’s innovative technology lies in its remarkable interoperability. This capability allows Addverb’s systems to integrate with a wide array of existing Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS) platforms, and various third-party software applications.

The integration process is designed with user-friendliness in mind, offering a plug-and-play adaptability that reduces market entry barriers and facilitates a more cohesive operational environment. By eliminating operational silos that often hinder efficiency and collaboration, Addverb empowers businesses to streamline their processes and enhance overall productivity. Addverb incorporates artificial intelligence (AI) and machine learning across its solutions, supporting ongoing system optimisation and adaptation as business needs evolve.

For instance, the incorporation of vision-enabled robotic picking systems enhances precision and speed in

warehousing, reducing the likelihood of errors associated with manual picking. The predictive analytics feature allows businesses to anticipate demand fluctuations and optimise inventory levels, which enhances responsiveness to market changes.

“At Addverb, our mission extends well beyond merely supplying automation products; we are dedicated to fostering long-term partnerships that stand the test of time,” says Peter. “This commitment to collaboration and relationship-building not only distinguishes us in the industry but also ensures that we truly understand and meet the unique needs of each client we serve.

“Our in-house capabilities are a vital component of our service offering –this means that we are deeply involved with our clients at every stage of the process, from the initial design phase, where we collaborate closely to ensure that concepts align with their goals, all the way through to delivery and implementation.”

Real-time performance tuning is another aspect of Addverb’s offerings, ensuring that the systems are not only operational but also consistently improving over time. This strategic approach enables businesses to evolve alongside their technological infrastructure, allowing them to harness insights gathered from data and make informed decisions that can drive growth and efficiency. As a result, Addverb’s solutions are not static; they are designed for dynamic evolution, perfectly aligning with the rapid pace of change in today’s business landscape.

As automation continues to reshape global supply chains, Addverb is taking a consolidated approach – bringing together hardware, software, AI, deployment, and support within a single ecosystem. This model aims to reduce complexity, accelerate implementation, and support longterm operational adaptability. In an environment where integration and responsiveness are increasingly vital, Addverb’s unified robotics ecosystem offers a coordinated pathway toward warehouse modernisation. ■

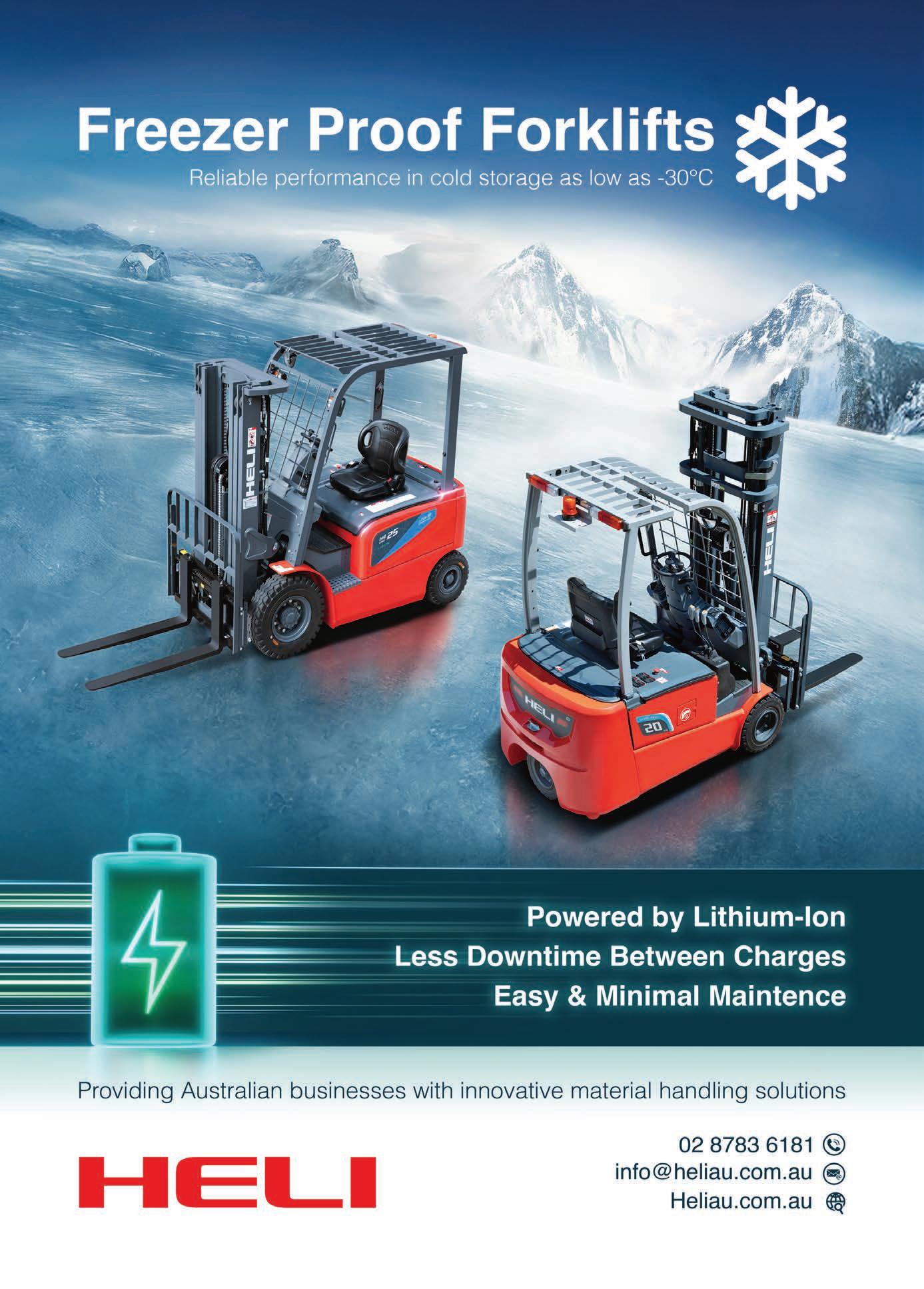

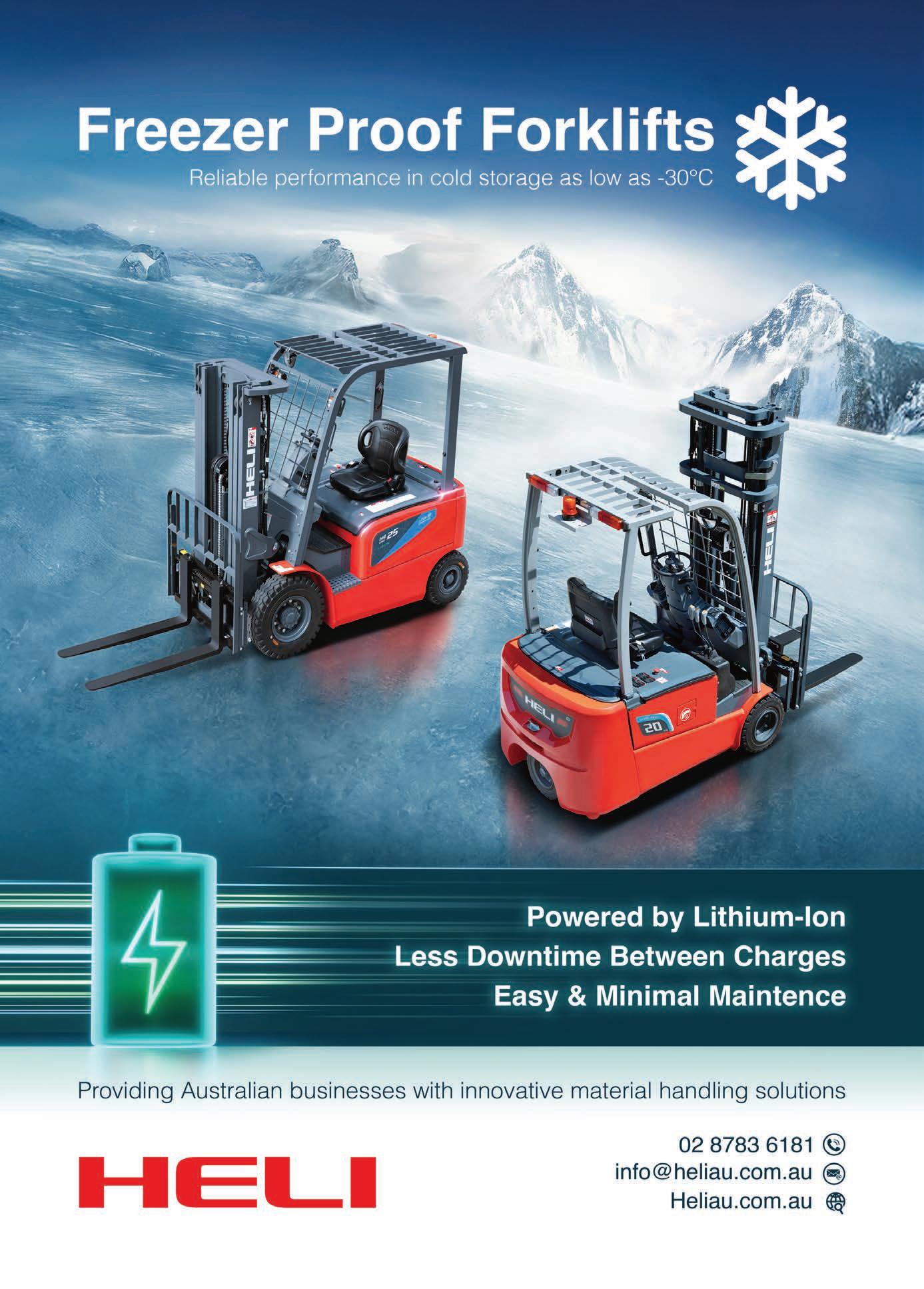

Heli strengthens Australian presence with an open day, showcasing lithium forklifts and deepening dealer partnerships.

Heli Oceania hosted an open day at its Sydney facility, inviting local dealers and suppliers to experience its expanding range of material handling solutions and reinforcing its presence in the Australian market.

The event marked nearly two years since Heli established a local warehouse in Australia, with the company using the milestone to highlight its lithiumpowered forklifts, new telehandlers, and commitment to long-term partnerships in the region.

Yang Anguo, Chairman of Anhui Heli Forklift Group, said the open day was more than just a product showcase – it was an opportunity to bring key

stakeholders together and reaffirm Heli’s investment in Australia.

“We’ve been in the Australian market for less than two years,” said Yang. “The open day gave us a chance to deepen our relationships with our customers and dealers. At the same time, we’re able to present new products like our telehandlers and lithium technology to the market.”

Local support builds confidence

Heli’s Australian facilities has allowed the company to provide faster access to spare parts, technical support, and training, which Yang said has built dealer confidence and helped position the brand as a serious player in a

competitive market.

“Since we established the warehouse, our partners in Australia have seen greater support – not only in parts but in technical assistance,” he says. “That’s made a difference. It gives them the confidence to work with us as long-term partners.”

This commitment has been critical for dealers such as Allied Forklifts, which supplies Heli equipment to customers across Western Australia. Wayne Adams, Managing Director at Allied, said the partnership has strengthened significantly in recent years.

“Heli originally sold small quantities of forklifts to Allied under a non-

exclusive dealer arrangement,” says Wayne. “Since 2018, our dealings improved once we pledged 100 per cent allegiance to Heli. Both parties have since shared great success in Western Australia.”

Wayne says the level of service and support from Heli had been instrumental.

“The spare parts and service support has improved turnaround times,” he says. “We communicate effectively with the Heli Oceania support team and this has reduced the time taken to resolve issues. Our customers benefit and Allied’s support team are under less pressure.”

He added that Allied’s own experience running Heli forklifts had given customers confidence.

“The Heli has performed well and we can say to our clients that they are as good as most other new forklifts on the market,” Wayne says. “We have been running these in our hire fleet since 2010 – you do not make money in hire if you are spending too much on repairs.”

One of the central themes of the open day was electrification. As industries look to lower emissions and adopt more sustainable solutions, Heli has doubled down on developing lithium-powered forklifts and other ‘new energy’ equipment. Yang believes Australia is a suitable market for this technology.

“Australia has a mature industrial vehicle market and is very open to new energy products,” he says. “That’s why we’re bringing our latest lithium-ion battery technology here.”

These new energy models – designed to meet the needs of both indoor and outdoor applications – offer a quieter, cleaner alternative to traditional internal combustion forklifts. Yang said Heli’s lithium-powered range had been well received by Australian dealers and end-users alike.

“It’s encouraging to see so much interest,” he added. “Our lithium products are not only environmentally friendly – they’re also very competitive when it comes to performance and reliability.”

Wayne says there was a shift towards battery-electric solutions, albeit a gradual one in Western Australia.

“We have seen a shift towards lithium forklifts,” he says. “We expect to see a big improvement in this market over the coming years.”

15-year partnership pays off Heli’s growing reputation in Australia has also been shaped by its relationship with Allied Forklifts, one of its longeststanding partners in Australia. The two companies have worked together since 2010, with Allied initially offering Heli as a second-tier brand before making it their primary product line in 2018.

“There is always a cheaper brand on the market,” Wayne says. “But the support we provide, in partnership with Heli, offers far greater benefits to the client. That commitment is frustrating the competition and building our reputation.”

Yang added that these kinds of collaborations were essential for building a strong foundation in international markets.

“The product is just one part of the relationship,” he says. “The service, the understanding, the local support –those are equally important.”

Beyond commercial partnerships, Yang says the company was also invested in cultural and community exchange between China and Australia. He pointed to Heli’s recent sponsorship of a local race car at the Bathurst 6-Hour Race as one example of the company’s desire to build broader relationships.

“It’s not just about forklifts,” he

says. “We’re also supporting cultural activities, sponsoring sports – these are ways we can connect with people, learn about Australia’s amazing culture, and share a little of ours as well.”

Yang says he sees Australia as a key market not just for sales, but for longterm engagement.

“We think the manufacturing industries of China and Australia are very compatible,” he says. “We believe this is just the beginning of a deeper relationship – one that’s not just about products but also about shared values and mutual respect.”

With the open day now behind them, both Heli and its dealer network are energised about what’s ahead. The company has clear ambitions to expand its presence in Australia, not only by introducing new models but by strengthening local support infrastructure and building closer ties with the people who sell and operate its equipment.

Wayne says Allied Forklifts was optimistic about future opportunities. “More recently, Heli Oceania are looking at these national companies to see how the Heli dealer network can work together and bid for large fleets,” he says.

“This is a great opportunity for Allied as the doors open to supply many more new forklifts here in WA.”

As Heli continues to expand its new energy portfolio and develop local partnerships, Yang remains optimistic.

“We’re here for the long term,” he says. “This is just the start.” ■

Powering Australia’s future of automation — one value chain at a time.

For over 70 years, KNAPP has delivered intelligent automation that transforms fulfilment. From robotics and shuttles to software and AI, we design solutions that adapt — not just automate.

Our latest innovation, AeroBot, landed in Australia fresh from winning Best Product at LogiMAT Europe. Built for flexibility and scalability, it’s set to reshape fulfilment for businesses of every size.

Because the right automation partner doesn’t just install systems — they grow with you.

2 out of 3 warehouses today face unreliable connectivity as a key challenge

Ericsson Private 5G meets current needs for secure, uninterrupted connectivity while enabling the future of Logistics 4.0. With impressive scalability, low and predictable latency, and fast data transfer, it eliminates Wi-Fi dead zones, makes real-time communications and inventory management seamless, and enables autonomous vehicles and robotics. Private 5G connectivity is helping industry leaders like CJ Logistics address dead zones and achieve productivity gains from day one.

Transform your warehouse operations with Ericsson Private 5G. Ericsson.com/logistics

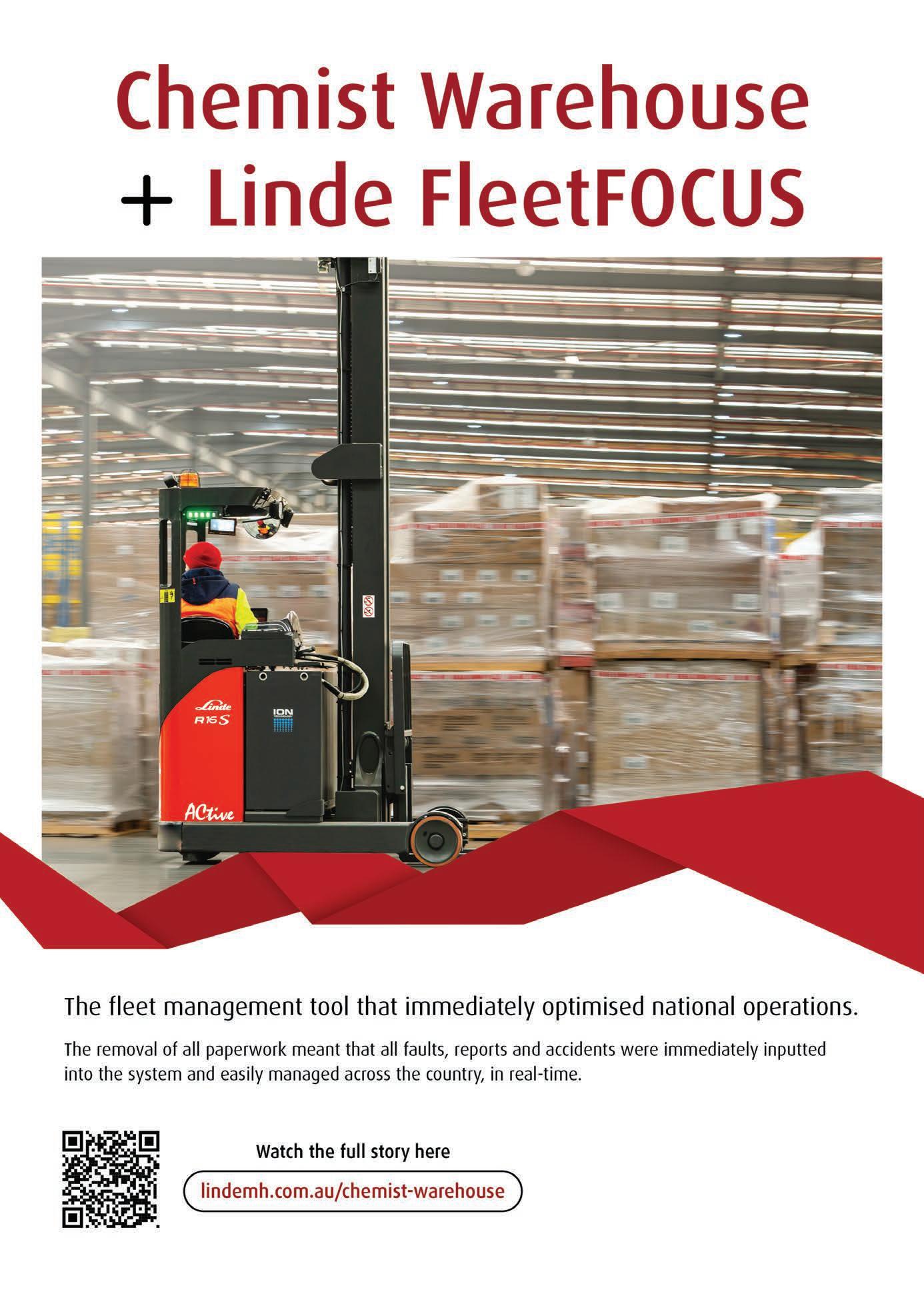

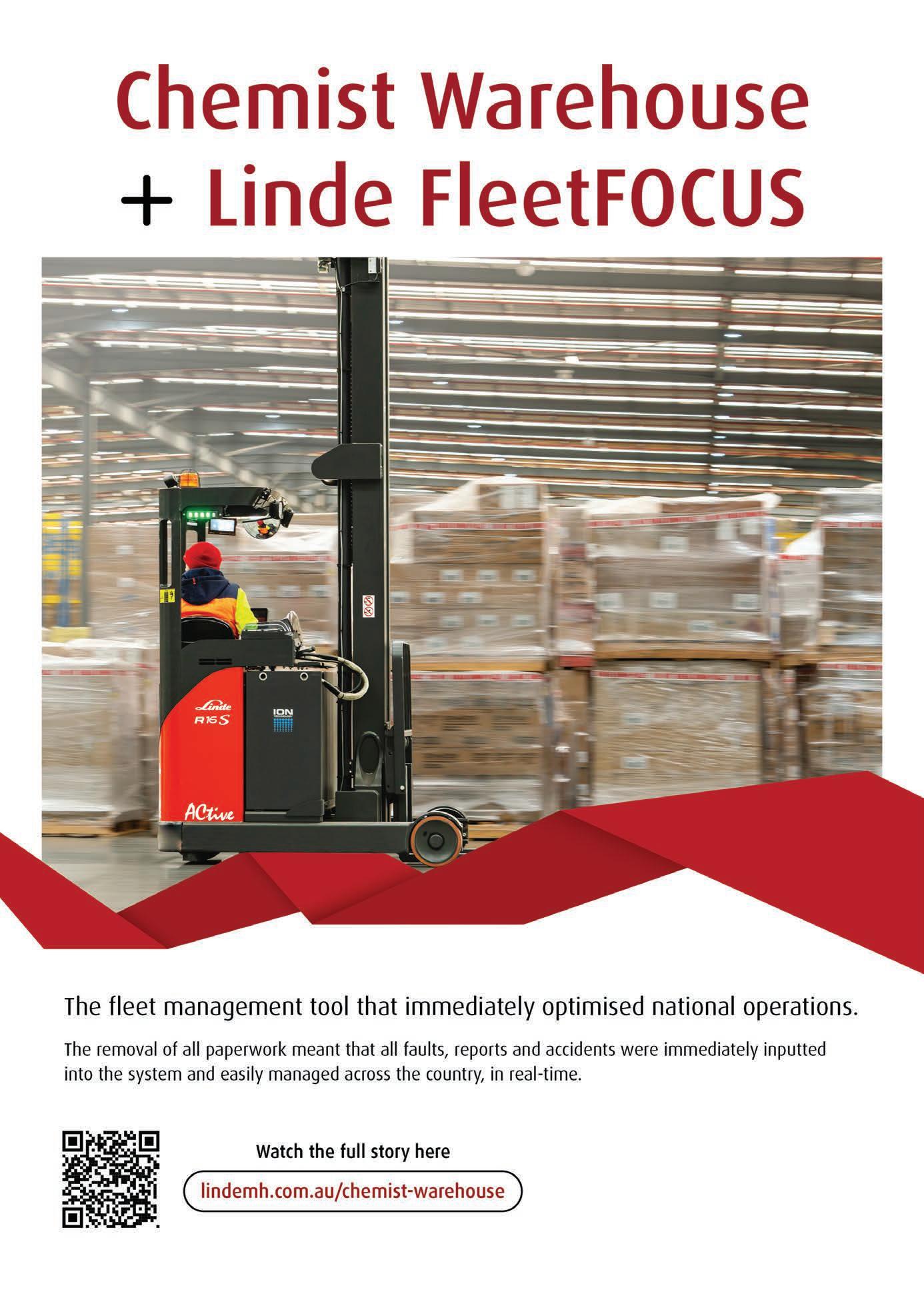

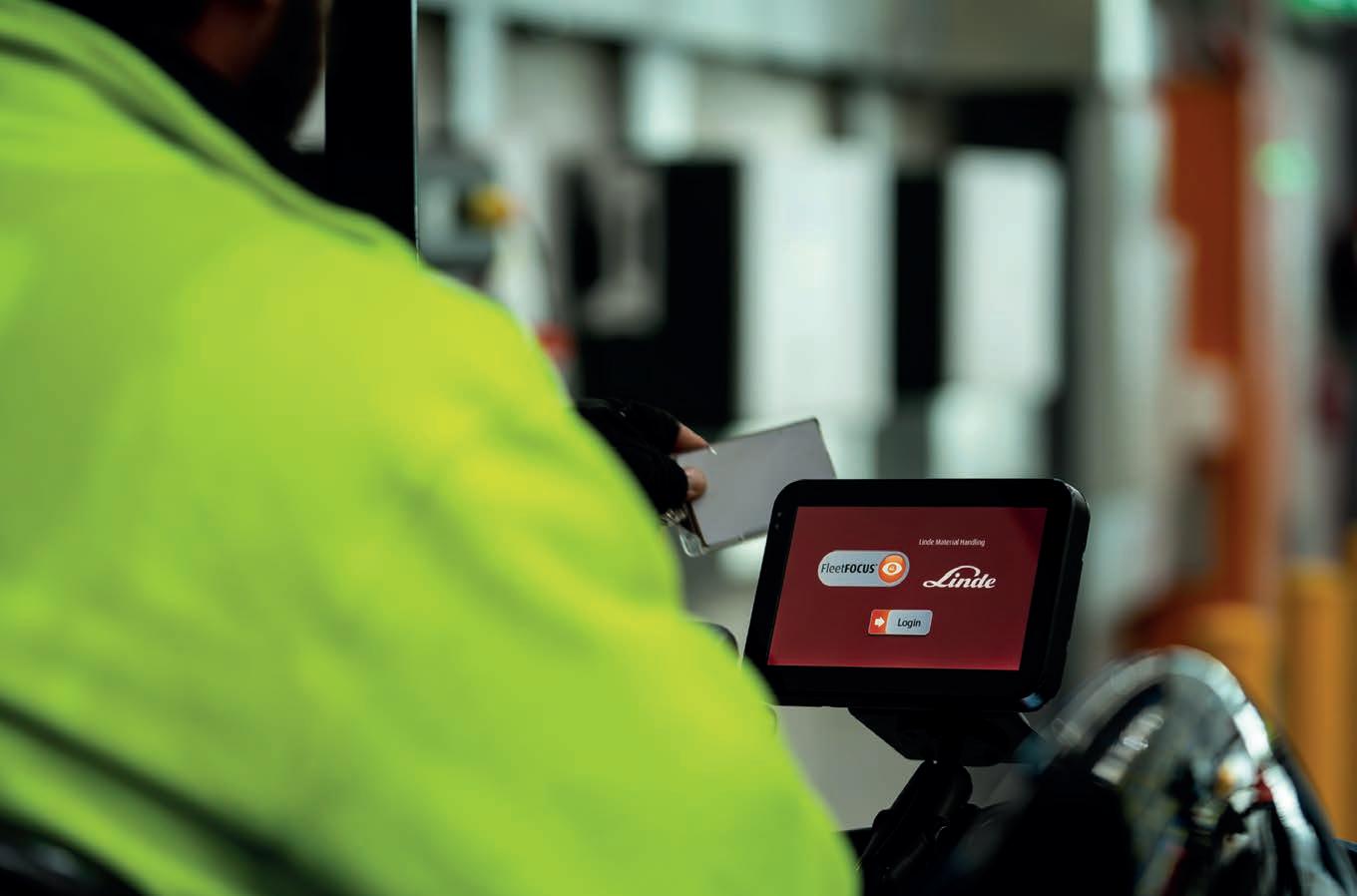

Linde Material Handling’s FleetFOCUS system is continuing to advance, with new features, customer-driven improvements, and a growing role in multi-site fleet management.

National Fleet Contracts Manager Stuart Hitchens shares the latest updates.

Businesses across Australia are continuing to lean on digital tools to sharpen their material handling operations. As automation and connected equipment become standard in warehouses and logistics hubs, fleet management systems are moving beyond basic monitoring to deliver proactive safety, cost control, and operational insights.

Linde Material Handling’s FleetFOCUS platform is one such system. Designed to provide real-time visibility and control over forklifts and other equipment, FleetFOCUS has become a central tool for businesses seeking to optimise utilisation, boost safety compliance, and act on data-driven insights.

According to Stuart Hitchens, National Fleet Contracts Manager at Linde MH, recent updates to the system have focused on both functionality and user experience.

“We consistently release firmware updates every two to three months, adding new features and refining performance so our customers always have a cutting-edge fleet management solution,” he says.

Linde MH’s approach to FleetFOCUS development has been shaped by end-user feedback. Stuart says many of the system’s refinements come

directly from client recommendations.

“Over the past year we’ve implemented at least 10 customer suggestions,” he explains. “When we see a request that benefits our entire user base, we take it on, refine it, and roll it out in future releases.”

Recent updates include streamlined pre-operational checks to speed up the process for operators, a new highlighting feature for critical safety questions, and driver name displays on in-cab screens to improve accountability. Backend performance optimisation has also been a focus, with the aim of making the system run as smoothly as possible in busy, highdemand environments.

Safety remains one of FleetFOCUS’s strongest value points. The system enforces pre-operational checks, monitors driver behaviour, and can limit vehicle access to authorised personnel only. Shock reporting automatically places a truck into reduced-speed ‘limp’ mode after a significant impact until a supervisor resets it, ensuring WHS compliance and accountability.

From a compliance perspective, Stuart notes that FleetFOCUS gives customers a complete safety management framework.

“The system enforces thorough pre-operational checks, highlights critical safety points, and monitors driver behaviour to prevent incidents before they happen,” he says. “It’s designed to support businesses in meeting – and in some cases exceeding – current WHS obligations.”

The role of data in operational decision-making

FleetFOCUS is as much an analytics platform as it is a monitoring tool. By collecting detailed usage data from equipment, it enables businesses to spot inefficiencies and adjust resources accordingly.

“FleetFOCUS allows businesses to see exactly how their fleet is being used,” Stuart says. “If you’re using a high-cost reach truck for a task that could be handled by a pallet jack, that’s an immediate cost-saving opportunity. Likewise, if equipment is only used seasonally, you can right-size the fleet to match actual demand.”

The system provides up to 30 different real-time reports covering utilisation, battery consumption, operator licensing, and hardware condition. These insights help companies balance workloads, plan maintenance, and avoid unnecessary capital expenditure.

Looking ahead, Linde MH is investigating how artificial intelligence (AI) and machine learning could add new capabilities to FleetFOCUS. One area of interest is refining driver behaviour analysis.

“AI has the potential to identify patterns that might lead to accidents and then provide targeted coaching to the driver to reduce risk,” Stuart says. “This kind of predictive insight could be a real step change in safety.”

While the system does not yet directly integrate with Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) platforms, Stuart says this is firmly on the roadmap.

“We know the value of creating a unified view of fleet data alongside other operational data, and we’re actively exploring the security and logistical factors that need to be addressed to make that possible.”

FleetFOCUS is already being used across multi-site operations in Australia and New Zealand, with testing and implementation underway in broader Asia. For businesses operating across regions, the platform provides a single, consistent view of the fleet, regardless of location.

“Our goal is to make it seamless for global operators to track and manage every vehicle,” Stuart explains. “That means consistent data, consistent reporting, and the ability to apply the same safety and efficiency standards across all sites.”

Rolling out a fleet management system involves more than installing hardware. Linde MH takes a structured approach to onboarding, starting with a pre-deployment consultation to configure units and portal settings before equipment arrives on site.

“We provide free, mandatory training to all website users before they receive their units, so they’re confident using the system from day one,” Stuart says. “We also run three refresher training sessions every month, and customers can join at no cost. Ongoing support is critical to making sure FleetFOCUS delivers maximum value.”

Connectivity is central to any realtime fleet management system, and FleetFOCUS was the first Australian

solution to offer dual Wi-Fi and GPRS (3G/4G) connectivity. This ensures uninterrupted communication between trucks and the central platform, even in complex environments. A memory card backup stores data during outages, automatically updating the system once the connection is restored.

For decision-makers, this reliability means that operational data is always available – whether they’re checking equipment impacts, monitoring battery charge, or reviewing operator pre-start check compliance.

Alongside safety and efficiency, FleetFOCUS supports sustainability goals. By enabling smarter fleet allocation, it helps avoid unnecessary asset purchases and ensures that existing equipment is used efficiently. Monitoring driver behaviour and battery use can also extend asset life and reduce energy consumption.

“Optimising resources isn’t just about cost,” Stuart notes. “It’s about reducing waste and making sure every piece of equipment is delivering maximum value for as long as possible.”

Because FleetFOCUS is developed locally, Linde MH can act quickly on customer feedback and release updates without long lead times. All changes made by Linde MH, or its fleet management partner, are deployed free of charge to all users.

“We’re committed to ensuring that FleetFOCUS evolves alongside our customers’ needs,” Stuart says. “Technology moves quickly in this space, and we want our users to always feel they’re working with one of the most advanced fleet management systems on the market.”

From enforcing safety protocols to uncovering hidden efficiency gains, FleetFOCUS continues to expand its capabilities. With AI-driven insights on the horizon and growing adoption across multi-site and international operations, Linde MH’s fleet management platform is positioning itself not just as a monitoring tool, but as an integral part of modern warehouse and logistics strategy. ■

An operator uses Jungheinrich’s AME Series electric pallet truck to move goods efficiently.

Jungheinrich’s AME series offers compact, efficient Class 3.1 electric pallet trucks for diverse applications.

Jungheinrich has launched its new AME series, a Class 3.1 electric pallet truck designed to meet changing material handling needs.

MHD sat down with Martin Strogilakis, Head of Product Management at Jungheinrich Australia, to explore what makes this new series notable in the market.

“The AME series is designed with modern material handling challenges in mind,” says Martin. “It’s compact, highly manoeuvrable, and equipped with features that make it ideal for production areas, backof-store operations, and logistics environments.”

The new AME series is Jungheinrich’s latest electric pallet truck, introduced

under Class 3.1 – a category defined by a maximum weight of 250 kg.

Martin says that this makes it suited for tail lifts, mezzanine floors, and other space-restricted or elevated environments. Fully electric and built for efficiency, the AME series offers an alternative to manual pallet jacks, especially for customers who don’t require the heavier Class 3.2 models, which exceed the 250 kg threshold.

In space-constrained environments, the AME’s compact design and manoeuvrability make it well-suited to operations.

“In production lines or retail backrooms, space is often limited,” Martin says. “The AME can navigate narrow aisles and tight corners with

ease, allowing operators to move goods quickly and safely.”

Operator comfort is another area where the AME series excels. Ergonomic tiller heads, controls, and features like storage compartments and a smooth ride contribute to reduced fatigue and increased productivity during long shifts.

The AME series is powered by a maintenance-free lithium-ion battery, offering longer runtimes, faster charging, and zero battery maintenance hassles.

“It’s a huge advantage,” says Martin. “Less downtime means more time moving goods.”

Adding to its versatility is the option for an integrated charger,

allowing users to plug the truck into any standard outlet. Ideal for dynamic environments like retail and logistics where dedicated charging stations may not be feasible.

With load capacities ranging from 1,500 to 2,000 kg and compatibility with both Euro and Australian pallet dimensions, the AME series is built to meet diverse operational needs. Whether in production, retail, or logistics, Martin says that the AME series delivers performance, reliability, and value.

A smart investment in productivity and safety

“The new AME series isn’t just an electric pallet truck. It’s a smart investment in productivity and safety,” he says. “It offers the perfect balance of performance, affordability, and quality for customers looking to move away from manual pallet jacks without stepping up to a heavier Class 3.2 truck.”

Jungheinrich invites customers across Australia to experience the AME series firsthand through live demonstrations at their branches. With the AME series, electric pallet trucks are evolving to deliver greater efficiency – and they’re here now. ■

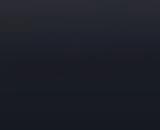

An operator uses Swisslog SynQ interface to monitor processes and inventory. Images: Swisslog

Swisslog’s SynQ software unifies warehouse systems for smarter, scalable, and data-driven warehouse automation.

Swisslog has developed a unified software platform, SynQ, to help warehouses manage growing operational complexity, labour shortages, and rising throughput demands.

Short for Synchronisation and Intelligence Quotient, SynQ combines warehouse management (WMS), control (WCS), and material flow (MFS) capabilities in a single system. The modular platform integrates with ERP and e-commerce systems, providing end-to-end coordination and visibility across automated and manual processes. Designed to improve transparency and support faster decision-making, SynQ is aimed at operators seeking

a more adaptable and data-driven approach to warehouse optimisation.

“SynQ is best-in-class end-to-end software designed for everything within the four walls of a warehouse,” explains Dan Ulmamei, Managing Director at Swisslog Australia and New Zealand.

SynQ sets itself apart from traditional warehouse software by delivering intelligence across the entire operational stack – from business systems through to the physical movement of goods. It acts as the nerve centre of the warehouse, managing inventory, controlling automation, and

providing the insights needed to run facilities more efficiently.

“At its core, SynQ doesn’t just manage warehouse operations; it synchronises them,” Dan says.

Its built-in visualisation and monitoring capabilities provide live oversight of warehouse processes through a SCADA-style interface, allowing operators to not only observe performance but also directly intervene in real-time.

“You can ‘click’N’run’ directly from the 3D visualisation,” Dan explains. “An operator can access any pallet within the automated warehouse and make changes directly – like sending it to a reject station if something doesn’t

look right. That kind of responsiveness is invaluable.”

One of the software’s greatest strengths is its configurability. SynQ isn’t a one-size-fits-all solution. Instead, it is deployed and customised based on each client’s unique processes and operational goals.

“Our role is to understand and tailor a system to the customer’s needs,” says Dan.

The software suite includes industryspecific modules developed from Swisslog’s decades of experience in automation, covering everything from item picking and replenishment to returns and labour management. With over 500 software experts globally contributing to development, and more than 100 years of warehouse innovation behind it, Swisslog ensures SynQ remains responsive to evolving industry demands.

“Nothing works without software today,” Dan says. “You have to operate within it – and with SynQ, we’re helping warehouses do that more intelligently.”

In today’s market, automation is no longer optional; it’s a competitive imperative. But for many businesses, deploying automation across existing operations can be daunting. This is where SynQ delivers critical value: it provides a unified platform that scales with the business.

Whether supporting high-volume retail fulfilment or complex multiclient 3PL operations, SynQ can coordinate automation assets such as ASRS (Automated Storage and Retrieval Systems), AMRs (Autonomous Mobile Robots), conveyors, and shuttles –all while interfacing with business intelligence tools for performance tracking and continuous improvement.

“SynQ aligns warehouse hardware with business processes,” says Dan.

The software’s modularity means it can be expanded in phases as operational needs evolve. Many Swisslog customers, Dan notes, begin with foundational capabilities and grow their SynQ installation over time.

Swisslog has deployed SynQ across a broad range of industries, from retail and FMCG to pharmaceuticals and 3PL. Locally, brands such as Linfox, Coca-Cola, and Jaycar have already adopted the platform, gaining enhanced visibility and control over their warehouse operations.

“Linfox is a great example of how we’ve built long-term partnerships in Australia,” says Dan. “We’ve been working closely with them to help bring efficiency and transparency to their automated operations. The feedback has been very positive, particularly around usability and the power of the data that SynQ provides.”

This level of insight ranges from the operator screen in small warehouses

to full-scale control rooms in major facilities. No matter the size, SynQ enables customers to see their entire operation live, at a glance.

While many companies are still exploring the possibilities of AI, Swisslog is already putting it into practice. Dan notes that SynQ is built to support machine learning tools and AI-enabled robotics, including Swisslog’s nextgeneration item picking systems.

By embedding AI tools into core warehouse software, Swisslog is helping customers unlock automation strategies that are not only scalable but also self-improving.

“We’re not just delivering automation hardware and software – we’re delivering intelligence,” Dan says.

Beyond the initial deployment, Swisslog’s commitment to continuous improvement ensures SynQ remains future-ready. With long-term service and upgrade paths, the software is built to deliver lasting value across decades of use.

“We have machines running for over five years and still going strong, and they’ll be there for another 20 years if maintained well,” Dan says. “That speaks to the strength of our servicing model and the reliability of our entire automation ecosystem, including software.”

Swisslog’s support model includes ongoing upgrades and performance tuning, allowing customers to evolve their systems in step with market changes and internal growth strategies.

As eCommerce accelerates, order profiles become more unpredictable, and labour markets tighten, warehouses are being asked to do more with less. Software like SynQ is making that possible – not through brute force, but through intelligence.

With its integrated WMS, WCS, and MFS capabilities, real-time visualisation, and business intelligence tools, SynQ is more than a product; it’s a strategic platform for modern, datadriven warehousing.

“SynQ helps our customers work smarter, not harder,” Dan says. “And in today’s environment, that makes all the difference.” ■

Discover innovative platforms transforming logistics, warehousing and transport management in the 2025 MHD Software Showcase

MHD ’s Software Showcase highlights leading supply chain software solutions driving efficiency, visibility, and resilience across logistics.

he logistics and supply chain sector increasingly relies on software to drive efficiency, accuracy, and customer satisfaction. From streamlining warehouse operations to managing the complexities of final-mile delivery, technology is changing the way goods move from production lines to end customers. The right digital tools can improve fulfilment speed, reduce costs, and help businesses build more resilient operations.

MHD’s Software Showcase recognises the top-performing companies developing solutions in critical categories, including Warehouse Management Systems (WMS), Transport Management Systems (TMS), last-mile delivery platforms, demand planning software, and Enterprise Resource Planning (ERP) systems. Together, these tools form an interconnected digital ecosystem driving the modern supply chain.

efficiently based on operational demand. Leading providers in this space include Infor WMS, CartonCloud, Katana Cloud Inventory, and Odoo.

A TMS manages the movement of goods beyond the warehouse, covering route planning, carrier selection, scheduling, freight tracking, and delivery performance. By improving shipment visibility, reducing transport costs, and ensuring compliance with delivery requirements, it streamlines both outbound and inbound logistics. Top solutions include Blue Yonder TMS, CargoWise, Freight2020, and LogiNext. When integrated, WMS and TMS platforms create a seamless flow of information, bridging internal operations with external transport activities.

A WMS focuses on optimising activities within the warehouse –from receiving and storing goods to order picking, packing, and dispatch. It enhances stock visibility, streamlines workflows, improves order accuracy, and allocates resources

better decision-making by forecasting customer demand with precision, using historical sales data, market trends, and seasonal patterns. This allows businesses to align inventory, production schedules, and supply chain resources with actual demand, reducing stockouts and avoiding excess inventory. Industry leaders here include RELEX Solutions, Microsoft Dynamics 365, GMDH Streamline, and Logility.

Last-mile delivery solutions address the most complex and costly stage of the delivery process – getting goods from a distribution centre or local hub to the end customer. These platforms optimise routes, enable real-time tracking, speed up delivery, and enhance customer communication, all while minimising operational costs and environmental impact. Notable offerings include Drive Yello, OptimoRoute, Track-POD, and Radaro. Demand planning software supports

ERP systems integrate core business processes – from finance and procurement to sales, HR, and inventory management – into a centralised platform. In logistics, ERP enables smooth coordination across purchasing, production, warehousing, and transport, ensuring every part of the supply chain is aligned and informed. Standout systems include Oracle NetSuite ERP, Epicor, TechnologyOne, and MYOB Acumatica. When combined, these systems give businesses end-to-end visibility and control: demand planning ensures the right products are ready, ERP allocates the resources to move them, WMS and TMS manage their flow through the network, and last-mile delivery technology guarantees they reach the customer quickly and reliably. ■

Esendex Australia

Opturion Pty Ltd

Glenvern Group Pty Ltd

o9 Solutions

John Galt Solutions

Ramco

Mobiledock

Kinaxis

365 ERP PTY LTD

Trace Consultants

b2wise

The RIC Group

JAIX Logistics Software Pty Ltd

Blue Yonder

Softeon

RELEX Solutions Infor

nConnect Group Pty Ltd

Demand Management Systems Pty Ltd Inventory Optimization Real-Time Plan Updates Automated Replenishment Multi-SourceIntegration Data CollaborativeManagement Workflow Customizable&Analytics Reporting Purchase Planning Order& Exception Alerts Stockout& AccurateModels Forecasting

Esendex Australia

Glenvern Group Pty Ltd

CartonCloud

Linde Material Handling

Infocomm Software

John Galt Solutions

Ramco

Mobiledock

Distribution Technologies

365 ERP PTY LTD

3DLogistiX

Paperless Warehousing

Trace Consultants

BISCIT Pty Ltd

The RIC Group

JAIX Logistics Software Pty Ltd

Blue Yonder

Infios

Softeon

Infor

EDDA Design & Development Pty Ltd

nConnect Group Pty Ltd

Thomax

Automation-readyBarcode/RFIDsupportCloud-basedsystem

Cycle counting tools Enterprise-readyERP/TMSintegration Mobile device access

Optimised picking/packing Real-timeinventoryReturnsmanagementScalable/multi-siteSME-friendly

TRANSPORT MANAGEMENT SYSTEM (TMS)

Esendex Australia

Opturion Pty Ltd

Fluent Cargo

Nash

CartonCloud

FreightExchange

Infocomm Software

John Galt Solutions

Ramco

Mobiledock

Cario

Frontier Force Technology

Kinaxis

365 ERP PTY LTD

3DLogistiX

Radaro Australia Pty Ltd

Origin by Sandfield

Paperless Warehousing

BISCIT Pty Ltd

The RIC Group

JAIX Logistics Software Pty Ltd

Blue Yonder

Slipstream Infios

Softeon

nConnect Group Pty Ltd

ANZ Case Studies

API/EDI integration CarriermanagementCloud-basedsystem Dispatch automation Freight auditandpay Freight quoting/rating LoadconsolidationMulti-modalsupport ProofofdeliveryReal-timetracking Route optimisation Scales with business

ENTERPRISE RESOURCE PLANNING (ERP) ANZ Case Studies

Esendex Australia

Glenvern Group Pty Ltd

John Galt Solutions

Ramco

Mobiledock

Unbound Systems

365 ERP PTY LTD

3DLogistiX

Origin by Sandfield BISCIT Pty Ltd

The RIC Group

JAIX Logistics Software Pty Ltd

Softeon

Infor

Esendex Australia

Opturion Pty Ltd

Nash

CartonCloud

FreightExchange

Infocomm Software

John Galt Solutions

Ramco

Cario

Frontier Force Technology

365 ERP PTY LTD

Radaro Australia Pty Ltd

Origin by Sandfield

BISCIT Pty Ltd

The RIC Group

JAIX Logistics Software Pty Ltd

Adiona TechPty Ltd

Blue Yonder

Tarot Analytics Pty Ltd

nConnect Group Pty Ltd

Thomax

Automated Dispatching

Proofof Delivery (POD) Dynamic Rerouting Analytics& Reporting Customer Support Interface Fleet& Carrier Integration Pricing& Billing Automation ANZ Case Studies

Real-TimeGPS Tracking Route&Optimization Planning Customer&Communication Notifications OrderManagement &Delivery

Kärcher introduces new industrial scrubbers, enhancing cleaning efficiency, safety, and adaptability for warehouses and logistics.

With efficiency and smart systems now critical to operations, Kärcher offers two solutions suited to the transport and logistics industry: the KIRA B 50, a fully autonomous floor scrubber designed to deliver consistent cleaning results, and the B 260 RI Bp, a ride-on floor scrubber built for deep cleaning in large-scale environments.

Warehousing and logistics operations often face persistent challenges, including dusty yards and floors, splinters from wooden pallets, slippery surfaces, and poor site presentation. Dust on floors, inventory, and machinery can affect health and safety, contribute to contamination risks, create inefficiencies, and reduce the value of stored goods. Kärcher’s machines are designed to address these issues by providing thorough cleaning that reduces airborne dust, removes hazards, and improves the overall presentation of facilities.

Big spaces. Big advantages

The B 260 RI Bp is designed for large,

high-dust environments, with a highpowered scrubbing system capable of lifting compacted grime, oil residues, and dust from busy warehouse floors. Operating at speeds of up to 10 km/h, it features a steering angle sensor that automatically reduces speed when turning to improve safety. A 260-litre fresh water tank with an automatic fill function and a DOSE cleaning detergent system supports cleaning at scale. The machine’s dual turbine suction system and squeegee leave floors dry and ready to use immediately after cleaning. Efficiency features include the DOSE cleaning system, improved servicing access, the KIK intelligent control system, and an eco!efficiency mode that reduces power usage while extending battery run time by up to 40 per cent. These measures help reduce downtime while maintaining cleaning performance.

Consistent results, every day

A common challenge with manual cleaning is inconsistency, with factors such as fatigue, time pressure, and staff

turnover affecting outcomes. Kärcher’s autonomous cleaning robot, the KIRA B 50, is designed to deliver the same standard of cleaning on every cycle.

Suitable for medium to large spaces, it combines hardware and software to automate cleaning tasks. When paired with the optional docking station, it can recharge, drain, rinse, and refill without operator involvement. Its multi-sensor system – incorporating an integrated laser scanner, 3D and ultrasonic sensors, and an onboard computer – provides 360° environmental detection. This enables it to identify obstacles, people, and hazards such as drop-offs or glass.

Using this sensor data, the KIRA B 50’s software plans cleaning routes, avoids collisions, and navigates around blockages without halting the process. Certified for operation in public spaces, it can work safely in areas with pedestrian traffic.

A web portal allows for remote monitoring, with access to cleaning reports, device status, and other operational data, helping to meet