The Merlo Roto 50.26S and Westtech Woodcracker CS750

TIME IS MONEY.

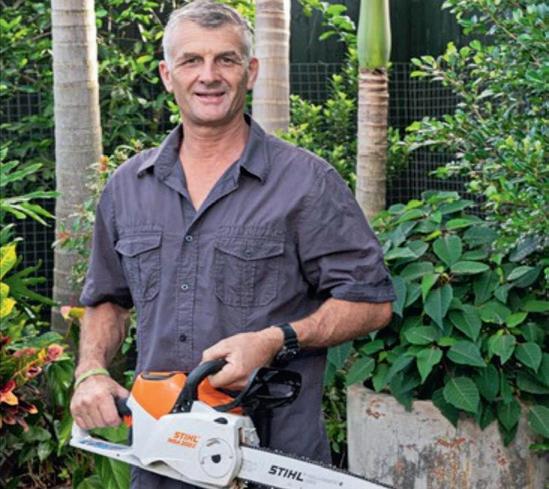

Buy STIHL Tools online 24/7 and harness your most valuable resource: your time.

Shop online, collect in-store, and keep working without downtime 24/7 quick collection ready to work

The Merlo Roto 50.26S and Westtech Woodcracker CS750

Buy STIHL Tools online 24/7 and harness your most valuable resource: your time.

Shop online, collect in-store, and keep working without downtime 24/7 quick collection ready to work

In general, we all place a lot of emphasis on history. If something has happened one way or at one time consistently in the past, we tend to expect it will happen again. Storm season is a good example. In Australia it’s understood to run from roughly November to April.

That’s fair enough, especially in Australia’s north, where what’s called the monsoon in Asian countries has an effect. In Queensland it’s called cyclone season, and it creates a great deal of work for the arbor sector.

Unfortunately, the work usually comes in a tsunami of destruction that leaves families in distress and arborists unable to cope with all the dangerous and difficult situations in need of professional attention.

It’s heartening on these occasions to see a huge volunteer response, not just from individual arborists but from large companies as well. The destruction of Cyclone Alfred last year was a great example. The number of companies and individuals who made themselves, their

knowledge and equipment available to help stricken Australians was truly breathtaking.

Just as an interesting aside, I’ve seen that community feeling more in the arbor world than anywhere else. Go to any climbing competition and you’ll see how competitors, even in the tightest pointscore struggles, will drop everything to help each other with equipment. The same competitors will jump around in glee, cheering for an opponent on a good run. Look around and see how small arbor outfits will club together to help each other tackle large contracts or share machinery.

It’s uplifting to see.

But getting back to history and planning for the future, over the past decade or so nature has made a mockery of ‘storm season’. It’s rained cats and dogs at all times of the year and all over the country, even in the outback, where history says it never rains.

What’s the lesson from this observation?

History does repeat, there’s no doubt

about that, and we all need to be ready to learn from past experience. But we need to remember ‘history’ is a very broad category. For sure the past decade has been wet, but look back to the 1990s and Australia suffered through a terrible drought. Midway through the 20th century weather patterns were similar to those we’re seeing now. The further back through history we look, the less defined Australia’s storm season becomes.

It may not be an exact science, but it’s still relevant. No matter how advanced the weather mapping and modelling become, no matter how convenient access to them is, nothing’s ever guaranteed with Australian weather. Storm season is kicking off as you read this. Be ready for the worst, make sure equipment and personnel are ready for emergency call-outs, and keep fingers crossed the most frightening thing we have to deal with for the next few weeks is an over-protective magpie or two.

Tom Foster Editor

The Australian Arbor Age is published bimonthly by Prime Creative Media Pty Ltd.

Chairman

John Murphy

CEO

Christine Clancy

Head of Sales

Andrew Morrison

Editor

Tom Foster

tom.foster@primecreative.com.au

Client Success Manager

Arianna Lucini

arianna.lucini@primecreative.com.au

Design

Caterina Zappia

Subscriptions

P. +61 3 9690 8766

subscriptions@primecreative.com.au

Website arborage.com.au

Copyright

The Australian Arbor Age magazine is owned by Prime Creative Media and published by John Murphy. All material in The Australian Arbor Age magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in The Australian Arbor Age magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2025

Articles

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766

info@primecreative.com.au www.primecreative.com.au

Sydney Office

Suite 11.01, 201 Miller Street North Sydney, NSW. 2060. Australia

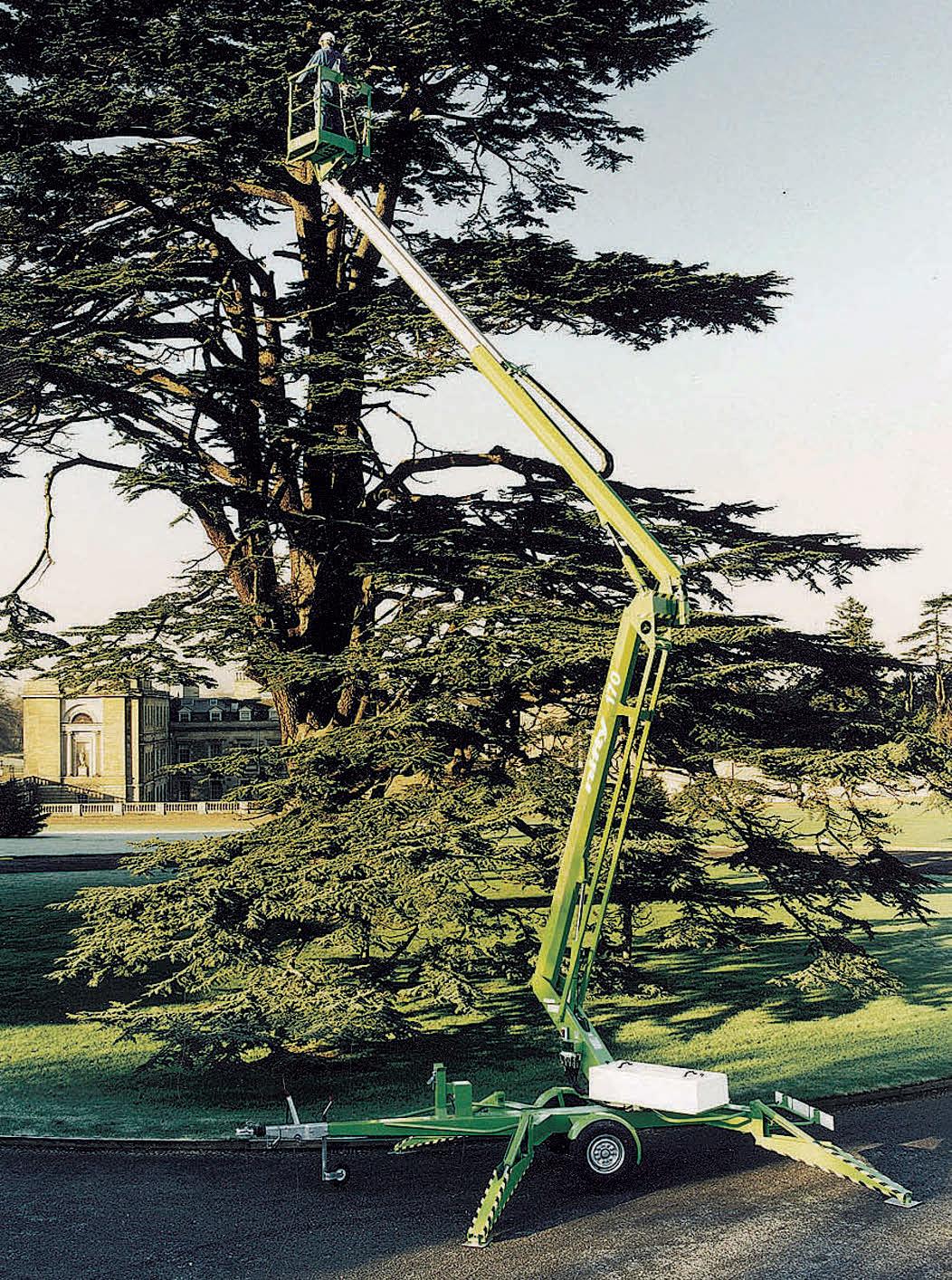

The Merlo Roto 50.26S telehandler and Westtech Woodcracker CS750.

Jim McArdle

B.Ed. Sc (Sydney), Dip. Arb. (Ryde), VTRA@QTRA qualifications. Director at McArdle Arboricultural Consultancy and TCAA President, Jim’s career spans across almost 40 years and focuses on consulting and reporting in tree risk

Beautiful – at a distance.

Steam Cone Story/stock.adobe.com

The Floss Silk Tree (Ceiba speciosa) is native to South America. It’s known by several colloquial names depending on its location, but strangely, we’re the only ones we can find who call it ‘Flossy’.

It’s deciduous, a relative of the baobab and kapok, and one of its most notable features is a trunk covered in nasty, sharp protrusions thought to discourage animals from inhabiting the branches.

Flossy grows fast and can reach heights of 25 metres. Its trunk is often green due to a high chlorophyll content, which allows photosynthesis and contributes to the plant’s health.

The Spanish call it a ‘drunken stick’ tree, and while there’s no reason given as to why that is, it may be because it looks so attractive at a distance.But up close…well…let’s just say it puts the ‘sting’ in ‘distinguishing feature’.

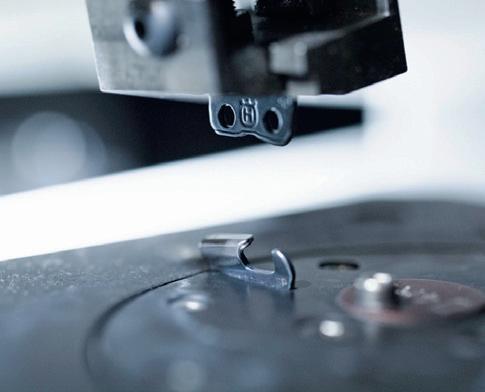

For generations, Husqvarna has set the standard in chainsaw technology, continually evolving to meet the needs of professionals and enthusiasts alike. Central to this enduring legacy is the Husqvarna X-Cut® saw chain, a product synonymous with proven reliability and high performance in the field.

Husqvarna’s decision to manufacture its own saw chain stems from a longstanding philosophy to prioritise the chainsaw user’s productivity and results above all. Decades of research and refinement have shaped the X-Cut® chain, reflecting Husqvarna’s unwavering dedication to customer satisfaction and efficient output.

This commitment is deeply ingrained in the brand’s identity, securing its position as one of the world’s most respected names in chainsaws.

The dream of creating an original Husqvarna saw chain has guided the company’s direction for years. With meticulous planning, advanced research, and a strategic approach, Husqvarna has established the X-Cut® chain as a trusted companion for demanding users. The launch of any Husqvarna product is never left to

The dream of creating an original Husqvarna saw chain has guided the company’s direction for years “

chance. Each innovation is built on decades of accumulated expertise and insight. Users have come to rely on Husqvarna’s reputation for efficiency and outstanding results, knowing every product is a testament to the brand’s rigorous standards and dedication.

The X-Cut® chain is crafted at Husqvarna’s state-of-the-art chain factory in Huskvarna, Sweden, neighbouring the original chainsaw factory and standing as a symbol of the brand’s heritage. Advanced manufacturing technology and winding production lines underpin every stage of the process. From raw steel to the finished chain, each step occurs within Husqvarna’s own facility. Rigorous testing, including on-site sawmill trials, ensures every chain meets the exacting demands of professionals worldwide.

Husqvarna’s approach to chain design is rooted in a deep understanding of arboriculture and forestry work. By focusing on maximising cubicmetre output, the X-Cut® chain was developed with the essential features, optimal manufacturing techniques, and superior materials required by industry experts. Every detail, from heat treatment to material selection,

Husqvarna’s approach to saw-chain design is rooted in a deep understanding of arboriculture and forestry work.

reflects Husqvarna’s commitment to long-term performance and reliability.

The X-Cut® chain undergoes extensive laboratory and field testing across diverse environments, upholding Husqvarna’s rigorous quality standards. Years of fine-tuning and professional collaboration have established the X-Cut® chain as a mainstay for

continuous cutting in challenging conditions. Its enduring design delivers consistent power and efficiency, making it the clear choice for those who demand excellence.

Today, the Husqvarna X-Cut® chain stands as an integral part of Husqvarna’s storied tradition. Established through persistent

innovation and attention to detail, it’s ready for the toughest tasks and trusted by professionals worldwide.

The X-Cut® chain exemplifies Husqvarna’s ongoing commitment to quality, reliability, and user satisfaction. It’s a benchmark that endures, season after season.

Log on to husqvarna.com/au/ to learn more.

All the trade fairs one of the world’s leading EWP brands will be attending until the end of 2025.

he fourth quarter of 2025 promises to be full of international events for Italian specialist EWP manufacturer CMC. The company will cover every corner of the globe and every key sector, from lifting to construction and from landscaping to electrical infrastructure

CMC’s constant presence at trade fairs is not only an opportunity to showcase its products, but to strengthen direct dialogue with customers, partners and all operators in the sector at a global level. Here is the complete and updated list of trade fairs in which CMC will be participating from October to December 2025. Each one represents a strategic opportunity for the company to showcase the quality and the innovation of its aerial platforms, consolidate its presence on the global market, and to gain isight for the

Whether it’s construction, green maintenance, industrial cleaning, infrastructure or digital technologies, CMC is always present, just like its commitment to ensuring safety, versatility and reliability in every

To see CMC’s range of MEWPs, log on to

he Utility Expo – October 7-9 –

This is the largest event in North America dedicated to public services, infrastructure and electrical safety. The training program is packed with a focus on innovation, safety and reliability. CMC and CMC NORTH AMERICA will be there to meet end users of facility management in the United States. These are the customers who choose the CMC brand to reach new heights every day, making it the market leader in the segment of tracked aerial platforms in the US.

3rd Assodimi National Congress –October 16-17 – Martina Franca (TA),

Organised by ASSODIMI/Assonolo, this national professional rental event has a

2025 promises to be another year full of international events for Italian specialist EWP manufacturer CMC. Images: CMC

central theme of promoting innovation in rental to generate value.

CMC, with its Italian sales network, will be present in the dual role of exhibitor (with the CMC S23 and CMC S20) and as the main sponsor of the event. CMC believes in ASSODIMI and has been an active member of this important organisation in the Italian MEWP rental sector for over 10 years.

• APEX Asia – October 28-31 – Shanghai, China.

CMC and its Asian dealers will be present at Asia’s most important trade fair for the aerial-access sector.

• Access + Handling Confex – October 29 – Dubai, UAE.

CMC will showcase its S32 spider for ‘large operations’. With a working height of 32m and a lateral outreach of 16m, the S32 is well-suited to the big projects with which the Gulf countries are redefining their infrastructure. CMC is also a Silver Sponsor, with live demos and a focus on access and handling solutions.

This event also serves as an international hub for manufacturers, experts and suppliers in the Middle East.

• TCI Expo – November 6-8 – St. Louis, USA. CMC stand: 921-1, 1303.

The world’s leading event for professional arboriculture, with exhibitors and visitors from all over the world, the TCI Expo is an unmissable event for those involved

in tree care and green-maintenance equipment and safety.

CMC will be present as a market leader in the arboriculture industry in North America.

• Excon 2025 – December 9-13 –Bengaluru, India.

South Asia’s largest exhibition for construction machinery and industrial technologies, Excon 2025 is organised by the Confederation of Indian Industry (CII), with a growing international participation.

CMC’s presence at trade fairs is not only an opportunity to showcase its products, but to strengthen dialogue with customers, partners and operators.

With multiple units available across Australia, our cutting-edge Sennebogens are a game-changer, delivering up to 5x times greater efficiency compared to traditional methods. By removing the need for manual handling and simplifying even the most complex clearing tasks, these Sennebogens are setting a new standard for safety, speed and precision in vegetation management.

With over four decades of experience, we stand as Australia’s foremost infrastructure partner, proudly Australian-owned and operating across 45 strategically located depots. We deploy the most comprehensive, in-house maintained fleet in the country, offering integrated vegetation management for grounds maintenance, arborist services, vegetation management and mechanical clearing across Road, Rail, Power & Water Utilities, as well as Local Government and Defence environments.

Reach out to Russell Warner on 0420 402 011 for all enquiries or simply scan the QR code to discover how our mechanical clearing expertise is shaping the future of vegetation management.

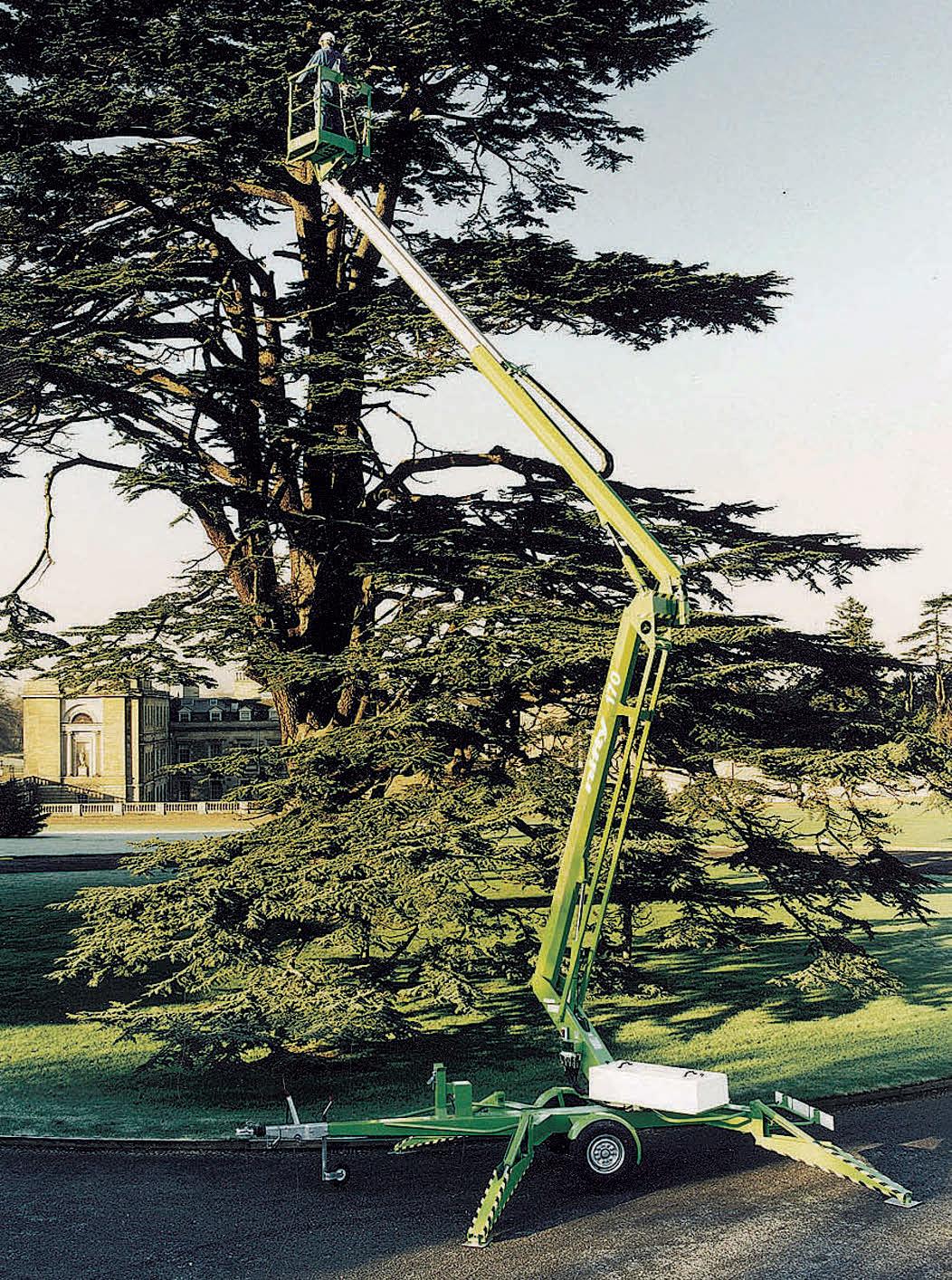

Scared and injured koalas rush to the top of trees, and this one had a major scare and climbed high.

Once a frightened koala is up at the highest point of a tree, it’s difficult to recover. They’re certainly not keen to give up what they believe to be a lofty point of safety.

After an attack by dogs at Brandy Hill, an area close to Newcastle in NSW, one injured marsupial sought refuge in the nearest, tallest canopy.

The frightened creature was injured

and needed attention, so Aaron and Ben from nearby Port Stephens Koala Hospital used a Nifty 120T EWP to effect a rescue. The Niftylift, a generous donation from Niftylift Australia, does service in rescues and cutting leaves for the animals in the sanctuary’s care

Koalas at the hospital are usually named after their rescuers, so this little feller became ‘Aaron’ and joined many

other koalas being cared for at the establishment, including staff favourite ‘Nifty’.

Ron Land from the sanctuary said, “It was a difficult and stressful rescue of a badly injured koala in which we deployed the EWP donated by Niftylift.”

“We’re all engaged in one of the toughest commitments anyone can make, wildlife care. We’re lucky to have a great team as we tackle life-and-death issues for the priceless wildlife that comes into our care. Aaron suffered terrible injuries in the dog attack, but we’ll pull him through.”

Soon after treatment, Aaron was eating food supplement and his injured arm and mouth looked set for recovery.

If you’d like to support Port Stephens koalas and assist with the costs of medical treatment, food and lodging for Aaron, Nifty and other rescued animals, please visit portstephenskoalas.com.au.

For information on the Niftylift range of elevating work platforms, go to niftylift.com.au

Nifty elevating work platforms are safe, environmentally conscious, high-performing and reliable.

Leguan’s new range of elevating work platforms is designed and built to deliver reliability, advanced technology, and selfpropelled off-road capability. Just what an arborist needs.

Leguan EWPs are made in Finland, and given the climate in that country, it’s no surprise Leguan machinery has a reputation for durability. It’s also well known to be user-friendly and capable of handling very tough terrain.

Now the new Terrain range of Leguans has just been unveiled in Australia, and all three include the best of these features to an outstanding degree.

Engineered for speed and built for safety and efficiency, the Leguan 195 excels in even the toughest environments, thanks to its robust track platform and exceptional driving capabilities. It’s the fastest lift to set up on the market, with unrivalled boom speeds that take the operator to maximum working height in just 55 seconds.

An advanced boom design ensures impressive side reach, even at greater heights, while the intuitive joystick control offers seamless, precise movements, allowing for easy operation in any situation.

A shielded boom structure protects the spider lift’s key components from external damage, making it an ideal choice for arboriculture. For navigating tight spaces or tackling complex tasks at height, the Leguan 195 offers performance, reliability, and safety.

• 19.7m maximum working height

• 9.9m maximum side reach

• 250kg maximum lift capacity.

A high-profile track platform and fast driving speeds make the nextgeneration Leguan 225 a first-rate choice for even the most challenging situations. The boom is designed to maximise side reach even at high working heights, while an intuitive user interface guarantees quick and smooth movements.

Thanks to user-friendly joystick controls, boom operation remains steady, and simultaneous movements become second nature. The Leguan 225’s intelligent features minimise

malfunctions and boost efficiency, allowing the operator to focus on the task at hand. Additionally, the boom is protected from external impacts, falling branches, and sawdust, making the 225

an excellent choice for arborists and tree-care professionals.

• 22.5m maximum working height

• 11.2m maximum side reach

• 250kg maximum lift capacity.

As the fastest 27-metre spider lift in the world, the Leguan 265 takes just one minute and 35 seconds to reach maximum working height. Its rugged track system, unrivalled ground clearance, and the market’s lowest centre of gravity provide exceptional stability and mobility, even in the most demanding conditions.

Engineered for versatility, the 265 features a lightweight design and a compact length, ensuring effortless manoeuvrability in confined spaces. Speed and efficiency are at the heart of the machine’s design, allowing operators to complete more projects in less time, driving greater productivity and profitability.

As the fastest 27-metre spider lift in the world, the Leguan 265 takes just one minute and 35 seconds to reach maximum working height.

• 26.5m maximum working height

• 13.6m maximum side reach

• 250kg maximum lift capacity.

Leguan is available in Australia through Monitor Group. See the entire Leguan range and Monitor’s extensive range of arbor and tree-care machinery at monitor.net.au.

Engineered for speed, built for safety and efficiency, the

195 excels in even the toughest environments. Images: Monitor

For backyard tree removal, tightaccess pruning, off-road terrain, or uneven ground, spider boom lifts are a game-changer.

When it comes to working at height in arboriculture, selecting the right elevated work platform (EWP) is critical for productivity, site access, and crew safety. For professional arborists, the two most popular access solutions are spider lifts and truck-mounted EWPs. But depending on the job type, location, and access requirements, one may outperform the other.

Whether you’re an arborist, contractor, or EWP hire buyer, here are some important considerations when comparing spider lifts and truckmounted lifts for tree work.

If the work involves backyard tree removal, tight-access pruning, offroad terrain, or uneven ground, spider boom lifts are a game-changer. These compact, tracked EWPs are built for narrow access, low ground pressure, and difficult terrain, making them a favourite among tree-care professionals.

Some of the main reasons arborists choose spider lifts include:

• quick setup – usually less than 10 minutes, with Leguan offering the world’s fastest spider-lift set up at between two and five minutes

• lightweight design – as low as 1.8T, reducing damage to lawns, gardens and pavers

• access –can generally pass through standard 900mm gates, with some models packing down to 780mm wide.

• handling slopes – can operate on gradients up to 25°

• flexible power options – diesel, electric, and hybrid models available,

suitable for residential tree jobs.

• impressive reach – working heights from 12m to 54m.

• premium features – auto-leveling outriggers, non-marking tracks and radio remote controls.

Spider lifts improve safety and ergonomics compared to climbing, reducing strain and fatigue during tree pruning, removals, and elevated chainsaw work.

For council contractors, line-clearing crews, or anyone doing multiple stops in a day, truck-mounted EWPs are the go-to choice. They’re fast, efficient, and ideal for roadside tree work.

Road-registered truck-mounted EWPs provide excellent mobility and efficiency when jumping between street trees, verge pruning, and utility work.

Top benefits of truck-mounted lifts include:

• fast setup – usually between two and five minutes

• good reach – 13m to 36m working heights

• versatile – well suited to powerline clearance, roadside pruning, council maintenance, and utility work

• drive-on convenience – no trailer needed, just drive to the site

• diesel-powered

• ute-mounted 14-20m EWP option – no truck license is required, making it ideal situation for small arbor teams and businesses.

The downside? Truck-mounted EWPs require solid ground and good access, so they’re less effective in tight residential spaces, sloped backyards, or soft-ground conditions.

Choosing between a spider lift and truckmounted EWP depends on the worksite conditions, job frequency, and access requirements.

If you’re focused on residential tree pruning, confined-space removals, or soft-ground sites, a spider lift offers unmatched access and control, making it

the most versatile EWP option.

However, for high-volume roadside tree maintenance, council contracts or multisite work, a truck-mounted lift provides the speed and ease to make the work safe and efficient.

For anyone looking to buy, hire, or compare spider or truck-mounted EWPs in Australia, Monitor Industries has the expertise and range to match the operator with the right solution – fast.

Log on to monitor.net.au to see Monitor’s range, or call 1800 025 024 for advice from an industry expert.

The machine’s design makes it suited for clearing projects in rail corridors, roadsides, utility easements and storm-recovery works.

Images: ETS Infrastructure Management

ETS Infrastructure Management (ETS) has supported Australia’s essential infrastructure with safe, efficient and reliable services for more than four decades. Today, the company’s strength lies in the size and capability of its specialised fleet, enabling the safe delivery of large-scale vegetation management, arborist services and mechanical clearing with precision.

Akey component of ETS’s success is its fleet, one of the largest privately owned in Australia. With more than 1500 road-registered vehicles and machines, including insulated and electrically tested elevating work platforms, tippers, chippers, mulchers and tree handlers, the company is equipped to tackle the nation’s toughest jobs.

This fleet is supported by a network of more than 40 in-house workshops and technicians who provide maintenance, servicing and complete rebuilds. This ensures every vehicle and machine is kept in peak operating condition, ready for rapid deployment. It’s a capability that allows ETS not just to respond, but to lead in delivering high standards of safety, reliability, and performance for clients across Australia.

Within its fleet, ETS operates a range of specialised machinery designed for challenging vegetation management

situations. The Energreen ILF Alpha Hedger, with its four-wheel steering, multiple traction modes and frontmounted mulcher for debris disposal and other mulching tasks, provides safe and consistent clearing on uneven or off-road terrain. Complementing this are Jarraffs, Mega Mulchers, whole-tree chippers and Hi-Rail equipment. Together, these

assets enable crews to deliver efficient vegetation management across complex environments.

Among the most powerful assets in the specialised fleet are the Sennebogen 718 E Tree Handlers, machines transforming

how large-scale vegetation works are delivered across Australia.

Compact yet powerful, these handlers combine reach, strength and precision, enabling crews to manage complex clearing tasks safely and efficiently. With multiple units available, they’re strategically located to support clients nationwide.

With a telescopic stick that extends up to 15 metres and an operating weight of 22 tonnes, the Sennebogen is built for heavy-duty performance. Its hydraulic cab elevation gives operators a superior vantage point, while the grapple-saw attachment enables trees to be grasped, cut, and placed in a single controlled motion. This machine can also attach grooming and stump-grinding heads for a multitude of tasks. The result is faster, safer clearing with reduced manual handling, a key advantage in today’s challenging operating environments.

The machine’s design makes it suited for clearing projects in rail corridors, roadsides, utility easements and stormrecovery works where speed, precision and safety are paramount. Earlier this year, during cyclone recovery operations in Queensland, the Sennebogen was deployed to safely remove collapsed trees from powerlines. Its extended reach and remote cutting ability allowed crews to restore access and protect the surrounding network without compromising operator or community safety.

The machine’s capability extends beyond emergency response. In urban and rural roadside settings, the Sennebogen

delivers high-volume vegetation clearing while maintaining strict safety controls around traffic and infrastructure. From maintaining visibility for road users to supporting asset protection, it ensures consistent outcomes while minimising disruption.

When working around sensitive environments, including areas with native wildlife, the Sennebogen can pair with qualified Fauna Spotters to ensure habitats are respected and protected.

Russell Warner, Manager Strategic Partnerships, highlighted the machine’s value: “The Sennebogen increases both safety and productivity, enabling us to handle complex, large-scale jobs efficiently. Both our Sennebogens are in high demand for major clearing projects,” he said.

Backed by the expertise of trained operators and supported by a national network, the Sennebogen is a prime example of how the right equipment, combined with planning and environmental focus, can deliver safe, efficient and responsible outcomes in even the most complex situations.

ETS’s specialised fleet and skilled

operators enable safe, efficient and reliable outcomes. Supported by in-house maintenance and a strong national presence, every project is approached with safety, precision and environmental responsibility. From vegetation management and mechanical clearing to emergency response, ETS works alongside clients and communities to provide tailored solutions that protect essential networks. Above all, ETS is guided by its purpose of ‘Working together to make communities safer’ and setting the benchmark for infrastructure and vegetation management across Australia.

For further information contact Russell Warner on 0420 402 011 or email russell. warner@ets.com.au

To learn more about ETS, visit ets.com.au or scan the QR Code.

Posting performance metrics for employees ignites their competitive spirit and enables them to see their improvements.

We all want to maximise the time we spend on activities we like and limit time we spend on tasks we don’t. The best way to do this is to improve efficiency.

Take grocery shopping, for example. If you plan your route through the store in advance (minimisng the back and forth between aisles), your travel time is streamlined, resulting in a reduced ‘cycle time’. The time you save can then be spent on the things you like to do.

A logging operation is no different. The key to improving your bottom

line is efficiency – reducing cycle times and streamlining tasks that are necessary but don’t add to profit. For example, with a feller buncher, the value-added task is cutting trees, while maintenance, fuelling and travel times are costs, not value-added functions.

Here’s how to get a handle on the efficiency of your operation:

• document your typical day and time your tasks (e.g. leave house, stop

at fuelling station, arrive on site, start machine, fill machine, grease machine, travel, cut, etc)

• group each task into a handful of categories (e.g. commute, daily maintenance, harvesting, skidding, loading, etc)

• write down how long it takes to perform the tasks in each bucket. Let’s say you find that daily maintenance on your loader takes

an average 45 minutes: 15 to grease, 10 to clean windows, 10 to blow out radiator, five minutes to check oil levels and five minutes for a general inspection

• look at areas for improvement. Maybe you find that if you added a power grease gun, kept it in the cab and greased just after lunch when the grease and the machine were warm, you could save five minutes a day. And you bring spares of high-risk hoses to the woods, and that saves you 15 minutes a week. These incremental changes can make a considerable difference by the end of the year. Just saving five minutes a day over 50 five-day work weeks

equals about 21 hours of increased production time. Now add in the time saved by having spare hoses (12.5 hours) and you’ve got 33.5 hours of increased production.

You don’t think of five minutes as significant until you look at a whole year and see you’re adding almost a week of production.

The same goes for the harvesting process. Once you’ve broken down the cycle times for bunching, skidding and loading, analyse them and look for ways to reduce them.

Here are some tips to consider for improving machine cycle times.

• Look at travel times for harvesting equipment, especially machines on tracks. Unnecessary travel time is very expensive due to undercarriage replacement costs and lost production time.

• Plan your cut ahead of time. Take a few minutes to walk the plot. You can assess the ground conditions and terrain much better on foot.

• Avoid unnecessary trips for fuelling. If you’re cutting close to the landing and have half a tank, fill up. If you don’t, you’ll need fuel when you’re cutting further away, and you’ll have to track all the way back to refuel and then return to where you were cutting.

• The harvesting machine should be

Affordable

working about a day ahead of the skidders in order to keep the wood flowing out steadily and everyone working productively. If there’s no wood on the ground and the skidders ‘catch up’ with the harvesting machine, you lose efficiency. For example, if you’re cutting in a mixed stand, there may not be enough of a particular species to fill a truck. With the truck driver waiting, the harvester operator has to find and cut more of the same species to finish the load instead of harvesting trees systematically.

• Always keep cutting tools sharp. Dull cutting tools prolong cut cycle times, can damage saw discs and increase fuel consumption. A dull saw disc on a feller buncher can increase fuel consumption as much as 15 per cent.

• Invest in appropriate equipment. For example, tyre chains can help reduce skidder and feller-buncher cycle times. Chains increase traction and

reduce the need for the feller buncher to move trees to a place accessible to a skidder without chains.

• The quickest way to the landing is not always a straight line. The fastest way is likely the path of least resistance. For example, you’re the skidder operator on the front face of a really steep hill, and the landing is at the top. You could claw and grab your way to the top, or you could go down the hill and around to an area less steep, traveling further but getting to the landing quicker.

• Optimise skid distances to eliminate unnecessary loader moves and road building, but know at what point a move is more efficient. Know your cycle times. When skid distances reach a certain point, you’ll know you can make up the time lost by moving the landing because skidder cycle times will be faster.

• Post performance metrics for employees. Keep score. This ignites their competitive spirit and enables thems to see their improvements.

• Use technology. In the past, cycle times, machine down time and production levels were measured manually with stop watches, weigh scales and tape measures. Today there are affordable telemetric systems that can provide most of this information through onboard computer systems. Having this information at your fingertips is worth the investment.

Contact your local Cat dealer for more information

NSW/ACT WesTrac 1300 881 064

VIC/TAS William Adams 1300 923 267

Western Australia WesTrac 1300 881 064

QLD/NT Hastings Deering 131 228

South Australia Cavpower 08 8343 1600

• Have appropriate maintenance tools on site, as well as replacement fluids and parts for components more likely to fail (hoses and seal kits).

NZ TERRA 0800 93 39 39

TCM’s new work bays have been equipped to ensure machinery continues to receive the servicing and attention it needs.

The Sydney branch of one of Australia’s most respected and longserving suppliers of arbor machinery has moved. The service and expertise are still there though, same as always.

Tree Care Machinery Pty. Ltd. (TCM) began servicing the South Australian tree-care industry over 30 years ago, providing a range of machinery and arborist equipment to make the care of trees more efficient and profitable.

Joining the EEA Group in 2023 allowed Tree Care Machinery, the home of Bandit chippers and stump grinders, Hansa chippers and Cast

loaders, to expand its range of products and service all Australian states and territories.

After a few years in Glendenning on Sydney’s western edge, the Sydney office of TCM now has a new home in Seven Hills. On September 01, the new headquarters opened its doors at 15 Stanton Road, Seven Hills.

All other TCM branches are still up and running, including Melbourne, Adelaide, Brisbane, Newcastle and Perth.

The TCM parts team has worked tirelessly to make the relocation as seamless as possible. The new office and warehouse are set up and ready to go for anyone needing parts for

chippers. The work bays have also been equipped to ensure chippers and stump grinders continue to receive the servicing and attention they need, and any breakdowns are dealt with quickly and efficiently to ensure minimum downtime.

To get in touch with TCM, call 1800 681 733, or use the contact tab at treecaremach.com.au.

There’s a new headquarters for Bandit chippers and stump grinders in Sydney.

Morbark and Rayco equipment offer complete solutions for vegetation processing and land clearing.

Managing vegetation, whether through routine tree care, largescale land clearing, or biomass fuel production, requires rugged, dependable equipment designed to maximise productivity and safety. Morbark, along with its affiliate Rayco, offers a full line of industrial and tree-care machinery that helps customers efficiently process wood, brush, and stumps while turning organic debris into valuable end products.

For arborists, municipalities, and contractors, Morbark brush chippers are essential tools for day-to-day tree care. These machines are built to handle everything from small residential jobs to heavy-duty commercial clearing. With powerful infeed systems and reliable chip throwers, Morbark brush chippers reduce bulky limbs and branches into manageable chips that are easy to haul, recycle, or repurpose as mulch. Compact and manoeuvrable models serve residential crews, while larger towable or track units provide the power and versatility required for demanding clearing projects.

When the scale of work increases, Morbark horizontal grinders are the solution for transforming large volumes of wood waste into usable products.

Designed for green-waste recycling facilities, land-clearing operations, and mulch producers, these grinders efficiently process logs, brush, and

other woody debris. Operators benefit from consistent, high-quality output, whether producing mulch, boiler fuel, or biomass feedstock. With innovative features that reduce maintenance downtime and maximise throughput, Morbark horizontal grinders provide unmatched performance in even the toughest applications.

Completing the land-clearing process requires addressing stumps and dense brush. Rayco stump grinders are built to

efficiently remove stumps of all sizes, from backyard jobs to commercialscale projects. Their designs emphasise operator safety, visibility, and ease of use, enabling faster job completion.

In addition, Rayco forestry mulchers provide powerful solutions for brush clearing and vegetation management. These mulchers effectively grind brush and small trees into mulch, leaving cleared land ready for use. They are especially valuable for right-of-way maintenance, wildfire prevention, and habitat restoration projects where ground-level clearing is essential.

What sets Morbark and Rayco apart is their ability to offer a complete suite of vegetation-management equipment. From initial tree felling and brush chipping to grinding, mulching, and stump removal, customers can find purpose-built machines tailored to their needs. By providing innovative, durable, and efficient equipment solutions, Morbark and Rayco empower customers across industries – tree care, land clearing, recycling, and biomass production – to process vegetation safely, sustainably, and profitably. Together, they deliver the tools necessary to turn challenges into opportunities amid growing demand for land management and renewable resources.

When it’s time to hand over a sizable wedge of cash for a new machine, a buyer wants reassurance on a few things. One is the machine being capable of doing the work required. Another is support from the manufacturer which will ensure the machine’s viability. GDE Mulching Services found what it was looking for with Vermeer and the SC70TX Stump Grinder.

The Vermeer SC70TX is a wellthought-out, robust stump cutter. It’s a narrow 129.5cm wide when it’s ready to transport, its diesel punches out a hefty 67 horsepower, and it runs a 23" cutting wheel. Safety features are top notch, and an optional remote control allows working in hard-to-access areas ßwhile the operator is sited in a safe position to monitor and control the machine. A 30-tooth cutter wheel spins at 880rpm and, overall, it’s ideally sized for a wide range of both commercial and residential work.

Graham

Dewitt, owner and Managing Director of GDE Mulching Services

in Brisbane’s south, has many years of experience with different types of machines. While he expected the Vermeer to be a good candidate for his next purchase, the decision wasn’t a foregone conclusion.

Shopped around

“I’m a bit of a veteran,” said the goodhumoured Dewitt.

“I’ve owned a fair bit of Vermeer gear over the years – around 20 chippers and at least a dozen stump grinders.”

But things moved on and Graham, an arborist by profession, sold the arbor business and went into land clearing

– roadsides, estates and so forth – and recently had a job come up where, mathematically, it made sense to buy a stump grinder rather than hire one.

Graham is currently running a sizable fleet of heavy machinery, including an excavator and horizontal grinders, so he phoned some suppliers and requested a demo of suitable stump grinders. He found most suppliers weren’t keen on the idea.

“I told them if they brought one up, and it did what they said it would do, I’d buy it on the spot,” he said. “The standard response was, ‘Oh, we’re not doing that’.”

After a few years away from the Vermeer arbor equipment, Graham decided to give the company a try.

Vermeer was happy to accept the challenge.

“I told them the same as the others,” he explained to The Australian Arbor Age. “If it does what you say it will do, I’ll buy it.”

The SC70TX must’ve delivered on the promise, because Graham went ahead with the purchase and has been running the Vermeer for around four months.

How has he found the support from Vermeer itself?

“We had a couple of little teething issues,” said the Queenslander, “and they were straight out to the site and fixed them up. They’ve been really good. No problem.”

The machine itself has won Graham over as well.

“Its power, size and, so far, reliability have been excellent,” he said. “Being on tracks, having a remote control

An optional remote control allows working in hard-to-access areas.

available…you can stand a few metres away, or even 10 metres away, and grind on to your heart’s content in safety.”

While the SC70TX is clearly fulfilling GDE Mulching Services’ needs, Graham is firm in his assertion it was Vermeer’s service which secured his custom over similarly

rated machinery from other brands.

“The reason I went back to Vermeer is how helpful the staff were in getting the deal done, and so far, four months into ownership, the after-sales service has been good.”

Discover the whole range on VermeerAustralia.com.au.

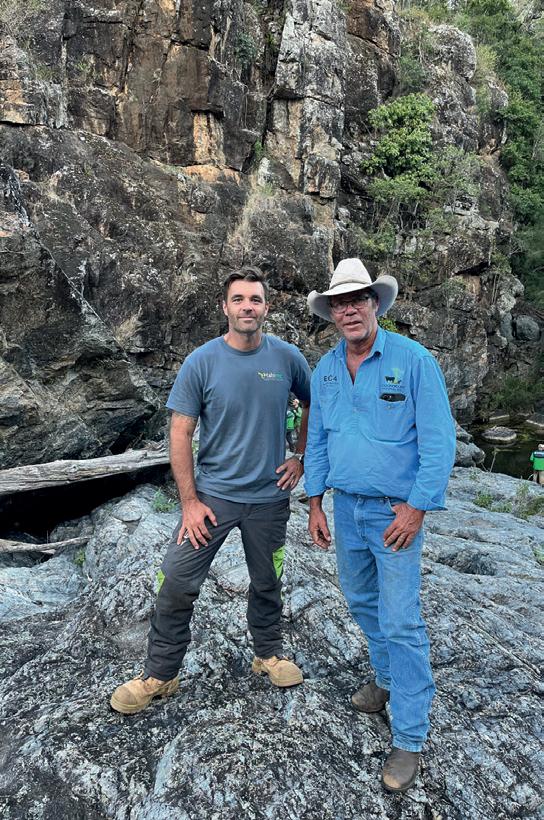

Queensland’s Bush and Beach Tree Services has moved to a Merlo telehandler and Westtech Woodcracker CS750 Smart grapple saw. The company is convinced it’s the way of the future.

The hinterland to the west of Queensland’s Sunshine Coast sounds like an idyllic location for an arbor business. The scenery is magnificent and the potential for tree work is just as good.

But for a successful and hardworking arbor outfit, the area possibly has a drawback or two.

“Being one hour inland from the coast has its disadvantages,” said Luke Maher, who, along with partner Arna, owns and operates Bush and Beach Tree Services. “With competition from employers on the coast it can be difficult to get groundies and climbers to travel out here for work.”

Luke and Arna are both arborists. Luke

is Level 3 and Arna Level 5, and Bush and Beach Tree Services offers a wide range of services to clients throughout the Sunshine Coast, Noosa and Gympie. Typically, Bush and Beach will tackle all types of tree work, stump removal, storm clean-up and a much more. Recently, Luke’s been looking for a way to cope with a common problem.

After climbing for 20 years or more, he’s looking for a way to deal with a common climbing problem.

“Like any climber who’s been doing it so long, the body has started to play up,” he told The Australian Arbor Age. I don’t recover as well as I used to.

“The weekends aren’t long enough anymore,” he said with a chuckle.”

It wasn’t just himself Luke was thinking of. He has a loyal group of employees and he wanted to ensure they were looked after as well.

“We have an ageing crew and we want to keep them employed,” he said. “The industry’s always hard, there’s no doubt about it. We’re trying to prolong the working lives of our people.”

With an eye on increasing the effectiveness and longevity of the business and its employees, Luke and Arna did some research, and in April 2025 took delivery of a Merlo Roto 50.26S and Westtech Woodcracker CS750 grapple saw.

The effect on business and the Bush and Beach personnel has been marked.

“From the safety side of it, there’s a major difference,” said Luke. “We’ve reduced our climbing by about 75 per cent, and it’s reduced the number of staff we need and lot of the heavy lifting they have to do. Things come down gently in a controlled manner with the Merlo and Woodcracker.”

The Australian Arbor Age had a good

look at the Merlo Roto 50.26S and Woodcracker CS750 Smart grapple saw in the August/September 2025 issue. But to jog the memory, or for anyone who may have missed it, the Merlo Roto 50.26S telehandler has a five-tonne maximum load capacity and 26-metre maximum lifting height. It’s ideal for accessing tall trees, elevated worksites, and remote-canopy areas. It’s also compact and agile, built for challenging

The industry’s always hard, there’s no doubt about it. We’re trying to prolong the working lives of our people “ ”

terrain and confined spaces, while state-of-the-art load-management and stability systems ensure operator safety, even when working at full extension. A spacious ROPS/ FOPS-certified cab is equipped with ergonomic controls, and other features include a hydrostatic transmission, reduced fuel consumption, and reliable performance.

The Woodcracker CS750 Smart is

The Woodcracker gets the material clear of the tree and on the ground.

a little trickier to describe because it doesn’t fit neatly into the category of grapple saw or felling saw. It’s a little of both: a robust grapple-saw package that excels in safely taking larger tree sections to the ground, thanks to a combination of strong gripping and rotator holding force.

Housed under the CS750 grapple is an advanced Hultdins saw unit with automatic chain tensioning, greasetype chain lubrication and a 75cmdiameter maximum cut capacity.

It’s designed for tasks where site access and drop-zone space permit cutting larger and heavier tree sections. The Woodcracker gets the material clear of the tree and on the ground where it can be further processed.

An easy transition

Luke has plenty of experience operating heavy machinery and found the transition to the Merlo and Woodcracker not too challenging.

“I have my civil tickets for excavators and other machinery, and I can certainly operate most things,” he said. “The

Merlo/Woodcracker combo seemed a little daunting to start with, but it just needed hours in the seat. Now we’ve learned the machine, our productivity in tree removals has probably quadrupled.

“We’ve done some very big days, and the machinery doesn’t complain after six hours of hard work. It can still do another two hours of removals, where for a climber, six or seven hours of big removals is quite taxing.”

Luke pointed out the operator can make a huge difference to a machine’s overall performance, and Bush and Beach Tree Services has an ace up its sleeve.

“I can drive it and operate the Merlo,” said Luke. “I’m steady with it.”

Then, with a glint in his eye, he went on to say, “But Arna’s 21-year-old son, Kalani, is gifted when it comes to machines, and he’s exceptional on this machine.”

Luke and Arna didn’t take the acquisition of the Merlo and Woodcracker lightly. It was a big financial commitment, but

Luke found the mathematics made sense.

“It’s certainly not something everyone can just race out and buy,” he said. “But when we calculated what we’d be paying for a good contract climber for a week, and compared that to the repayments on the Merlo and Woodcracker, there’s not a great deal of difference. This way, at the end of the financing term, we end up owning a substantial asset.”

Luke and Arna bought the Merlo and Woodcracker from EEA Group. EEA went to Rey Kell at Forest Centre to import and supply the Woodcracker, and Luke and Arna couldn’t be happier with the service during and since the purchase.

“Both companies have been fantastic,” said Luke.

“Ben at EEA Group probably calls once a week or once a fortnight just to touch base and see how things are going and if there’s anything we need.

“The Woodcracker came from Forest Centre, and that’s how we got to know Rey Kell.

“I’d had a bit to do with Rey through friends in the forestry game as well, and he provides them with all their saw heads and other equipment, so I knew he had a very high reputation. Since we’ve taken on the Woodcracker, we talk regularly. He’s prompt and he’s straight down the line.

“The whole process has been fantastic.”

Luke’s convinced he and Arna have made a sensible and cost-effective move for Bush and Beach Tree Services, but they also believe they’re just the first of many arbor businesses that will follow in years to come.

“It’s the new way of tree handling for the future,” said Luke with some conviction.

“We’re one of the early adopters in Australia, but I can see in a few years these Merlo/Woodcracker combinations are going to be a common sight.

“Once people see what they’re capable of and the speed they work at, there’s going to be a lot more of them getting about.”

The Australian Arbor Age magazine headed north to The Sunshine State for the Queensland Arboricultural Association’s freestyle climbing competition. It was well worth the trip.

As long as the climber was deemed to be acting safely they were free to adopt whatever style they felt worked best.

As the sun rose over the Mount Tamborine showground on the last weekend of July a hardy group of climbers made their way to the work tree and sign-on area manned by staff and volunteers from the Queensland Arboricultural Association (QAA).

It was the day of the freestyle climbing comp, and while it wasn’t exactly gloomy weather, there was no need for a touch of the ol’ slip, slop, slap either. It was overcast with rain threatened for later in the day.

As a sizable crane from Davo’s Crane Hire was eased into position and bells were hung, competitors went through sign-on and briefing and the stage was set.

The tree was the same one used for the state championship earlier in the year, and under the guidance of QAA president Jamie Boston, the indefatigable secretary Bec Dalton, and a contingent of volunteers and helpers, things got underway. The climber began attaching his or her harness to the crane to be lifted safely but swiftly to the predetermined start station.

From there the climber was timed to strike the bells hung at various vantage points around the tree as is seen in competitions everywhere.

Ah. But this was a freestyle event.

With some of the more rigorous parameters of a ‘normal’ climbing event relaxed, as long as the climber was deemed to be acting safely they were free to adopt whatever style they felt would have the bells rung in the shortest possible time.

And there sure were some interesting styles.

When you choose the BVR Brush Chippers from Morbark, LLC, you’re not just investing in a machine — you’re investing in decades of innovation, quality, and craftsmanship. These chippers are designed to stand the test of time and make your toughest jobs easier and more profitable.

Don’t settle for less. Choose the chipping power of the BVR Brush Chippers and experience the difference that Morbark’s legendary performance can bring to your business.

Unlock Powerful Performance with the BVR Line of Wood Chippers from Morbark.

When you choose a BVR Wood Chippers, you’re not just investing in a machine — you’re investing in decades of innovation, quality, and craftsmanship. These chippers are designed to stand the test of time and make your toughest jobs easier and more profitable. Don’t settle for less. Choose the chipping power of BVR Wood Chippers and experience the difference that Morbark’s legendary performance can bring to your business. To find a Dealer in your neck of the woods, go to https://dealers.morbark.com

Monitor Industries - Australia

Ph: +61 1800 025 024

www.monitor.net.au

Stevens Group - New Zealand

Ph: +64 09 275 0443

www.stevensgroup.co.nz

To learn more about the complete line of BVR Wood Chippers, scan the QR Code with your mobile camera

®

highlight of

Ella was a novice and a clear favourite with the crowd. She worked her way around the bells with the occasional slip or miscalculation and the cheering and support grew louder and more strident as her climb progressed. Then, as she approached the bell nearest the spectators, the support began to swell, until, at full stretch, the young climber lunged out to headbutt the target bell.

The place went crazy with people jumping and hallooing and bellowing their support. Ella-Beth’s grin must’ve been clearly visible from at least as far

away as Brisbane as she worked her way around the remaining bells.

Another huge roar of approval went to Eban Weaver-Wampl. In his first-ever comp Eban climbed his way to the semifinals.

Although the support for Ella-Beth was strong and very vocal, one of the most overwhelming impressions of the whole event was the incredible camaraderie among the climbers. Everyone cheered and boosted everyone else, whether it was their nearest competitor or someone they’d only just met, and climbers awaiting their turn helped

those before them stow ropes and pack away. That resulted in the pace of the competition being nearly as fast as the climbers in the tree.

That was a good thing, because with organisers gazing anxiously at the Bureau of Meteorology website on their phones, it was obvious there was some rough weather headed toward Mt Tamborine.

Thanks to swift and decisive action from the organiser, and a determination not to allow the event to be interrupted, the competition was completed in time.

Not by much, for sure, but in time enough. Nobody had to miss a climb and no one had to climb in conditions where safety had been compromised.

As the first raindrops began to patter down on awnings and gazebos, the results were tallied and winners announced.

It was a well-run day with incredible support from and for everyone, and The Australian Arbor Age felt privileged to be on hand to enjoy the experience. It was the second QAA climbing competition we’ve attended this year, and they’ve both been brilliant. We’re looking forward to a big year spectating at QAA events in 2026.

Any discussion which includes female climbers in Australia is very likely to include Jess Hamer. Jess is a strong competitor and popular personality at events both locally and internationally.

Just as we were tidying up this issue and uploading it to the printer the results from the Queensland Tree Climbing Championship were gazetted showing yet another victory for female climber Jess Hamer.

The Australian Arbor Age had grabbed Jess for a quick catch up between climbs and found the Queenslander, as always, cheerful and inspirational.

Jess’ career started in horticulture, and while she enjoyed that line of work, there was one aspect of the industry that caught her attention.

“I started off in gardens,” she said. “Then I thought it’d be cool to learn about trees. I started studying trees and really enjoyed doing that, so then I went full time into tree care.

“I’ve been doing climbing work for 10 years now.”

Despite her obvious climbing success, Jess believes good fortune has played its part in her progression in arboriculture.

“I’ve been pretty fortunate,” she said.

“I’ve had a lot of experiences, positive and negative, and I’ve had a lot of good people around me to get me through it all.

“I do have my Level 5 now and I’ve had it for quite a long time. I did my Cert 3 then my Cert 5 straight after.

“I’m enjoying doing both. It’s another new experience for me.”

Jess’ win at the Queensland state championships was hot on the heels of a victory at the QAA freestyle event a few weeks earlier. Jess had not only won the freestyle event, but was among the most vocal and supportive in what was already an enthusiastic crowd.

We wondered what someone who climbed competitively at an international level enjoyed so much about freestyle climbing.

“I like to look at freetsyle as a

‘fun’ kind of comp, she said. “It’s no-pressure training, that kind of thing, and there are very few rules.

“Obviously we stay safe – we’re professionals. But even with the safety front of mind it’s good fun, swing-around-and-smash-somebells climbing.”

While Jess is an experienced, professional arboriculturalist, she’s continually growing and evolving. Right now she’s looking forward to the next phase of life, which includes

Inspirational and international climbing competitor Jess

a move into more consulting work.

“I’ve only just started doing consulting work in the past couple of months to start dialling back on the contract climbing,” she said. “I’m giving the body a bit of a break, and my partner and I have started trying for a baby, so I’m safeguarding myself with some consulting work.”

What about the future? Does Jess expect to continue working with and caring for trees?

“Absolutely,” she beamed. “I wouldn’t know what else to do or where else to go.”

A good result at the recent Asia Pacific Tree Climbing Championships earned Isobel Watson a place at the International Tree Climbing Championship in New Zealand. Nobody was more surprised than Izzy herself.

Ididn’t realise I’d qualified for the Worlds straight away,” the irrepressible Isobel – Izzy – told The Australian Arbor Age. “Steph Dryfhout from New Zealand, an amazing climber and an amazing person, finished in front of me in Masters at the Asia Pacifics. Everyone was congratulating me for getting into the Worlds, and I was like, ‘No, no. Steph won’. And they said, “She’s returning champion. You qualify because she’s already got her Worlds’ ticket.”

“I was like, ‘Oh’.

Grounded

A Level 3 arborist with an adventurous spirit and the most pleasant kind of outgoing personality, Izzy studied arboriculture and began her career in England, where, at that time, it wasn’t always easy being a female tree-care professional.

After two years of college, a keen young Izzy went searching for work, and wasn’t ready to take ‘No,’ for an answer.

“When I started in England there was

a fair bit of misogyny. It was accepted that ‘girls don’t climb’. I was kept on the ground for the best part of two years of my career, and I really struggled to get any work. I’d email people and phone and text...I was persistent.”

Despite the effort and searching, there

wasn’t a lot of work sent Izzy’s way, and the work she did find kept her on the ground.

“My climbing was actually put back by a good two years, even though I had my qualifications and tickets,” she lilted with the tiniest trace of an English accent.

When I was training in England I was so against competition climbing. I don’t know why “ ”

Izzy’s determination to climb saw her subcontracting to other arborists, mostly smaller outfits with, as she described it: “…one-man bands who had a six-inch chipper and a Land Rover Defender type set up”. Some of the business owners preferred to stay on the ground and that gave Izzy the climbing opportunities she was after, allowing her to upskill until she became the lead climber of several small companies.

“That was literally how I learned,” smiled the English ex-pat.

After three years of climbing in England, Izzy packed up and flew to Australia. Unfortunately, it was 2020, and unknown to Izzy – and everyone else – COVID was about to hit.

“I did a year here,” she recalled thoughtfully. “I did my first lot of crane work, climbed between 50m and 70m Mountain Ash which was three times the height of anything I’d climbed before, and at the end of 2020 my visa was running out and the COVID situation meant it was a very unsure time.

“I went back to England and carried on contracting there, and for 2021 just moved around the country.”

In 2022 Izzy worked her way around America, Switzerland, Germany and other parts of Europe before heading back to Australia and, just three days after landing, fronted her first climbing competition.

Izzy’s future holds a vista of exciting possibilities. Image: Cameron Rogers

“I had jet lag,” chuckled the now Victorian-based arborist. “I had no idea about comp climbing. I’d never even looked at the rules. It’s very different to work climbing.

“One of my friends, Beaver, who’s a big part of team Australia – coach, moral support, bag carrier and more – just signed me up for this competition. I somehow came second in the Masters and I’ve just kept competing since.”

While climbing was Izzy’s work goal for many years, competition climbing hadn’t figured much in her aspirations.

“It’s funny,” she mused. “When I was training in England I had no interest in competition climbing. I don’t know why. I was quite narrow-minded. Even though I have a passion for the industry, it’s my job and I preferred to have other hobbies outside of my work.

In 2022 Izzy worked her way around America, Switzerland, Germany and other parts of Europe before heading back to Australia. Image: Dan Dass

“I didn’t want to be climbing trees seven days a week.

“I did fire breathing and horse riding back home,” she casually revealed. “My cup was half full with different hobbies. But since I’ve been in Australia I haven’t been able to travel because of my visa sponsorship, so it’s become more about trees for me now.

“I wouldn’t say I’m all about comp climbing. I climb five days a week at work, and I’ve been doing it for 10 years. In terms of training, I do it all at work, because I’m already there. I have my gear out, I have to climb trees anyway because that’s what I’m being paid to do, so I integrate the training into that.”

Currently working for McLeod Trees in Mordiallic, and looking forward to permanent residency in 2027, Izzy’s now bubbling over at the thought of the ITCC – ‘the Worlds’ – but it’s not the

I’m really lucky to be climbing with the world’s best climbers – which I never thought I’d do – and to be put in the same bracket as them is just a bit surreal to me. “ ”

be all and end all for anyone with Izzy’s bold vision. Her future is still very much a vista of exciting possibilities.

“It honestly depends how this Worlds competition goes for me,” she said with a thoughtful look.

“I’m really lucky to be climbing with the world’s best climbers – which I never thought I’d do – and to be put in the same bracket as them is just a bit surreal to me. I don’t believe it. I think that’s a massive kick for me to actually really get my head down and start training. There’ll be 30 to 40 women at that competition from all over the world, and if I get through to

the Masters I think that’ll really shoot my confidence up, and I’ll keep going until hopefully I can get top spot.

“If I don’t do too well at the worlds, I can either use that as motivation to train harder, or I could keep bumbling along and enjoying the atmosphere and social side of it, keeping it stress free.

“And in terms of my work climbing career, I’m hoping, at some point in the future, I can go back to travelling and contracting.

“Eventually I’ll slow down, but in the short term it’ll really depend how I go in this year’s Worlds.

The National Industry Awards, hosted annually by Arboriculture Australia, are the highest honour in the arbor profession. More than trophies, they symbolise peer recognition, celebrate excellence, and encourage higher standards across the arboriculture industry.

Arboriculture Australia (Arb Aus), the peak national body representing the industry, relies on the passion and expertise of professionals and volunteers. The National Industry Awards not only recognise individual and organisational achievement but also serve as a reminder of the power of giving back to the profession. Volunteering, whether through local organisations, field days, competitions, or mentoring, enriches the arboriculture community and strengthens the industry for future generations.

That’s why Arb Aus encourages everyone to start thinking now about nominations for the 2026 National Industry Awards, to be presented at the gala dinner of the National Arboriculture Conference in Hobart, 12–14 April, 2026.

Nominating a peer, colleague, or organisation is one of the most meaningful ways to celebrate their contribution. It shines a light on often unseen hard work and motivates others to follow the example. Categories include advocacy, diversity and inclusion, and invaluable volunteer service, ensuring plenty of scope to acknowledge the many amazing things people are achieving in the arbor industry.

Nominations are now open via the Arboriculture Australia website. The process is simple:

• visit trees.org.au (navigate to News & Events > Awards)

• select the award category

• provide details about the nominee and their contribution

• submit the entry online before the closing date.

Taking a few minutes to nominate helps strengthen the profession and ensure outstanding achievements within the arbor community receive the recognition they deserve.

At the 2025 National Arboriculture Conference gala dinner held at the National Arboretum in Canberra, three outstanding individuals were recognised for their remarkable contributions.

Dave Crispin received the Arboriculture Advocacy Award, presented to an individual or business that has contributed to raising awareness and understanding of issues in the arboriculture industry.

“It’s not often I’m lost for words, but this was one of those occasions,” said Dave. “Advocacy is championing something you truly believe in. I truly believe in our association, ArbWest, the arboriculture industry and what we stand for.

“ArbWest has achieved several positive outcomes these past few years, including managing to turn our arboricultural traineeship into an apprenticeship, so those who finish the three years achieve a trade qualification.

“Working closely with local governments to help combat Polyphagous Shot Hole Borer (PSHB) and running a two-day seminar at the prestigious WACA ground for over 100 delegates were just a couple of the projects we’ve tackled. This award speaks to all the hard work our committee has put in. I was fortunate

enough to have my name put forward.”

The award recognised Dave’s outstanding influence on the arboriculture community through his work with community groups, his advocacy for urban canopy cover, and his inspiring role at school career

events. His most significant contribution, however, has been his research into the devastating PSHB (Euwallacea fornicatus) and his leadership in working with the Department of Primary Industries to combat the pest in Western Australia.

As Vice Chair of the Tasmanian Arboricultural Organisation (TAO), Rach Denholm, recipient of the Invaluable Volunteer Service Award, has been a driving force since 2018, leading events such as the Annual Tree Climbing Competition and Arb Field Day. Her advocacy for professionalism, inclusivity, and mental-health awareness in arboriculture has made a lasting impact.

“It’s a huge recognition of the work volunteers do across the country and the work I’ve done in Tasmania,” Rach said.

“Why do I bother to volunteer when I already have a business to run and a busy life?

“Because there are so many people calling themselves arborists without adequate training and it’s important to support the people who are working professionally.”

Rach also spoke about an issue close to her heart. “The suicide rate in Australia is too high, especially among men, and this is a male-dominated industry. I want

to support bringing people together to network, have fun and talk about mental health. Suicide happens when people feel disconnected, lose hope, and lose their connection to the community, and of course there are many other issues like finances and job satisfaction. That’s why it’s so important for everyone in our industry to feel connected and included.”

The Diversity and Inclusion Award is presented to an individual or business that has championed diversity and inclusion in the arboriculture industry and contributed to positive change.

Tyla Bickley played a leading role in organising the 2024 Women’s Climbing Workshop, which empowered female arborists across Australia. Her award recognised the event’s success in building skills, confidence, and networks, while also celebrating her ongoing dedication to diversity in the industry.

From securing sponsors to managing logistics and coordinating trainers and attendees, Tyla’s dedication ensured the event’s success. The workshop empowered female climbers by providing them with the confidence, skills, and support to take their abilities to the next level. Seven participants went on to compete in the local ACT Tree Climbing Competition, and the 2025 Australian Tree Climbing Championship boasted a record number of female entrants.

Tyla said, “I feel very honoured. Being the one to receive this award feels like evidence of all the hard work some very inspiring women have done in the past couple of decades for the Australian arboriculture industry. It’s their mentorship and dedication to building community that enabled me to begin, and see through, an apprenticeship three years ago. Hosting the Women in Arb climbing workshop last year was a reflection of how impactful their support has been for me.”

The next National Arboriculture Conference will take place in Hobart, Tasmania, 12 - 14 April, 2026. The National Industry Award winners will be announced at the gala dinner on Monday.

This premier industry event is themed ‘Enhancing Tree Biomechanics and Effective Canopy Management’ and will feature international and local presenters, networking opportunities, the ATCC, the New Arborist of the Year event, tree tours and, of course, the celebration of the 2026 Award winners.

Attending industry conferences and events is one of the most valuable investments arborists can make in their professional growth. These gatherings provide access to the latest research, techniques, and innovations shaping arboriculture. Just as importantly, they bring people together, creating space for networking, collaboration, and the sharing of ideas across regions and specialties.

Mark your calendar and visit the Arboriculture Australia website (trees.org.au) to register for the 2026 conference and start preparing your nomination for the 2026 National Industry Awards.

The TTIA’s Brian Beecroft underlines some important points regarding ‘employee choice about casual employment’ and the Right to Disconnect which now apply.

As of August 26, 2024, the statutory Right to Disconnect and the casual ‘employee choice pathway’ apply. Image: Pinklife/stock.adobe.com

The new Right to Disconnect and changes to casual conversion introduced as part of the Fair Work Legislation Amendment (Closing Loopholes No.2) Act 2024 (the Loopholes No. 2 Act) started applying to employers other than small businesses from August 26, 2024.

As of August 26, 2025, the statutory Right to Disconnect and the casual ‘employee choice pathway’ (dealing with conversion from casual to full time or part-time employment) apply to small-business employers and their employees. A recap of these entitlements and obligations is provided as follows:

• casual conversion provisions previously in the NES have now been replaced with the new ‘employee choice about casual employment’ provisions.

• Casual employees who have worked with their small-business employer for 12 months, and who believe their employment relationship no longer meets the (new) definition of ‘casual employee’ in the Fair Work Act may give their employer written notice that they choose to become full-time or part-time. If the employer receives this notice from an employee, the employer must first consult with the employee and then provide them a

written response either accepting or rejecting the notification within 21 days.

An employer may choose not to accept the notification if:

• having regard to the (new) definition of casual employment and the employee’s current employment relationship with the employer, the employee still meets the requirements of that definition.

• there are fair and reasonable operational grounds for not accepting it – such as that it would require substantial changes to the way work is organised or that substantial changes to the employee’s terms

and conditions would be reasonably necessary to ensure compliance with full-time or part-time provisions in the applicable Fair Work instrument.

• accepting the notification would result in the employer not complying with a recruitment or selection process required by or under a law of the Commonwealth or a state or a territory.

If the employer doesn’t accept the notification, the written response is required to specify the reasons for the employer’s decision.

If the employer accepts the notification, the written response is required to specify whether the employee is changing to full-time or part-time employment, the hours of work that will apply after the change takes effect, and the day the change takes effect (which will by default the first full pay period after the employer’s response is given unless the employer and employee agree to another day).

An employee cannot give their employer written notification to convert to full-time or part-time employment if they have already received a

If there’s a dispute between an employer and employee about the Right to Disconnect, a party may refer the dispute to the FWC. Image: Fokasu Art/stock.adobe.com

response from the employer rejecting a notification within the previous six months.

The ‘employee choice about casual employment’ provisions do not:

• require an employee to change to fulltime or part-time employment

• permit an employer to require an

While the Right to Disconnect provides an employee the right to refuse afterhours contact, it doesn’t make unlawful an employer’s contact or attempted contact. Image: Centric/stock.adobe.com

employee to change to full-time or part-time employment

• require an employer to increase the hours of work of an employee who gives a notification to change to fulltime or part-time employment.

If there is a dispute between the employer and an employee who has provided a notification and attempts to resolve the dispute at the workplace

An employee’s role will need to be considered, along with personal circumstances. Image: rh2010/stock.adobe.com

level have occurred but have been unsuccessful, a party may refer the dispute to the Fair Work Commission (FWC). Where the FWC has resolved a dispute about a notification, the employee cannot, within the next six months, provide their employer with another notification.

An employer must not do any of the following in an attempt to avoid any right or obligation under the ‘employee choice about casual employment’ provisions:

• reduce or vary an employee’s hours of work

• change the employee’s pattern of work

• terminate an employee’s employment.

The Right to Disconnect includes the following:

• an employee may refuse to monitor, read or respond to contact, or attempted contact, from an employer outside of the employee’s working hours, unless the refusal is unreasonable

• an employee may refuse to monitor, read or respond to contact, or attempted contact, from a third party if the contact or attempted contact relates to their work and is outside of the employee’s working hours unless the refusal is unreasonable.

In determining whether a refusal as noted above is unreasonable, the following are to be taken into account:

• the reason for the contact or attempted contact

• how the contact or attempted contact is made and the level of disruption the contact or attempted contact causes the employee

• the extent to which the employee is compensated (including nonmonetarily) to remain available to perform work during the period in which the contact or attempted contact is made; or for working additional hours outside of the

employee’s ordinary hours of work. The nature of the employee’s role and the employee’s level of responsibility should also be considered, as should the employee’s personal circumstances (including family or caring responsibilities).

While Right to Disconnect provides an employee the right to refuse to monitor, read or respond to contact or attempted contact, it does not make unlawful an employer’s contact or attempted contact of an employee (unless such contact or attempted contact occurs in breach of an order by the FWC).

Modern awards now also contain Right to Disconnect clauses. Some modern awards include clarification about circumstances in which an employer is not prevented from requiring an employee to monitor, read or respond to contact or attempted contact, such as (depending on the modern award) when the employee is being paid standing by time.

If there is a dispute between the employer and an employee about the Right to Disconnect and attempts to resolve the dispute at the workplace level have occurred but have been unsuccessful, a party may refer the dispute to the FWC. The FWC can make orders in resolution of a dispute where either or both of the following apply:

• an employee has unreasonably refused to monitor, read or respond to contact or attempted contact and

there is a risk the employee will continue to do so;