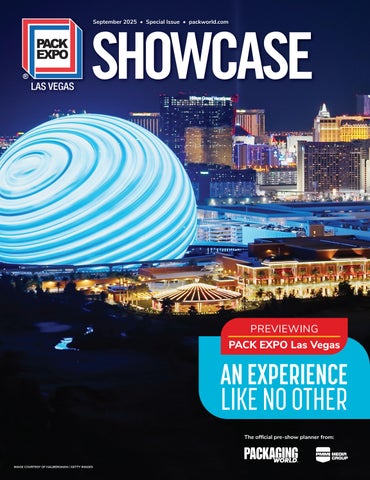

This year’s show is truly something special. Not just because of the technology, the scale, or the packed agenda, but because we’re celebrating 30 years of PACK EXPO Las Vegas.

Since its start in 1995, this show has grown from a regional gathering into the most comprehensive packaging and processing event of the year. And if you think you’ve seen this play before, think again; this year’s show is the most expansive to date. Surpassing 1 million net sq ft of exhibit space for the rst time, housing 2,300 exhibitor across over 40 vertical markets, there’s no shortage of ground to cover or conversations to start.

This issue of the PACK EXPO Las Vegas Showcase is here to help you make the most of it. Inside, you’ll nd a detailed Show Preview (p.8) to point you toward key pavilions and exhibitors, educational offerings, student activities, and networking events. If you’re short on time, ip to our two-page Quick Facts section (p.4) for a streamlined guide of the most essential show features. We’ve also included a QR directory to make your educational experience at the show even easier; just ip to p.22 and scan to see up-to-date session lists for each educational stage.

In a massive and famously nonuniform industry like packaging, it’s a relief that PACK EXPO includes focused destinations, bringing order to complexity. Need sustainable packaging solutions? Head to the Containers and Materials Pavilion, or the Reusable Packaging Pavilion, sponsored by the Reusable Packaging Association. Wrestling with supply chain challenges? The Logistics Pavilion is an essential visit. The Healthcare Packaging Pavilion offers state-of-the-art solutions covering pharma, biologics, nutraceuticals, and medical devices. Food and beverage producers will feel right at home in The Processing Zone or The Confectionery Pavilion, sponsored by the National Confectioners Association. And you can even stop by the Education and Workforce Development Pavilion for insights on strengthening your personnel and building the next generation of packaging pros.

While you’re out there, don’t forget to visit one of the seven educational stages scattered across the show oor. More than 100 informative sessions will touch on the industry’s hottest topics and trends, including sustainable packaging solutions, Extended Producer Responsibility (EPR), circularity, automation, AI, food safety, reusable packaging, and more. These sessions are your chance to learn directly from industry experts, thought leaders, and innovators in your eld. You might even discover fresh perspectives to spark innovation within your own company.

With such a vast expanse to explore, it helps to have an industry insider guide you toward what matters most. That’s why PMMI Media Group is producing an all-new feature for this show, a set of expert-led, curated show oor tours. The PACK EXPO Discovery Tours, sponsored by Lantech on Monday and Formic on Tuesday, are speci cally designed for senior decision-makers and rst-time buyers of packaging and processing automation. If sustainability is your main priority, check out the Sustainable Packaging Show Floor Tour, sponsored by Anchor Packaging and focused on cutting-edge solutions that reduce environmental impact. Flip to p.26 to learn more and apply for a spot.

You’ll also want to check out this year’s Technology Excellence Award nalists, where you can vote for your favorite technology among a host of standout innovations never-before displayed at a PACK EXPO show. It’s a great way to discover the companies truly pushing boundaries at the show, and a good reason to visit their booths to see the technologies up close.

Of course, this 30th anniversary celebration is about more than what’s new. It’s also a moment to re ect on the staying power of this industry and the people who drive it forward. As you walk the show oor, keep an eye out for the 30-Year Legacy Exhibitor logos; these mark the companies who were part of the inaugural 1995 show and continue to exhibit today.

There’s so much to see, learn, and experience at the show in Las Vegas. To help you on your way, download the PACK EXPO Las Vegas Mobile App, sponsored by ProMach, Inc., for a whole host of tools and resources, like an exhibitor search, personal agenda tool, interactive map, and more. Thanks for joining us for this milestone year. We hope you leave the show feeling energized, informed, and ready to take on whatever comes next.

Dave and I are looking forward to seeing you there. PW

PMMI Media Group’s David Newcorn and Matt Reynolds welcome you to the milestone 30th year of PACK EXPO Las Vegas and share useful tips about show features and resources to help you maximize your time.

Short on time? This two-page section offers a quick-start guide to PACK EXPO Las Vegas 2025, covering the essential show features and highlights.

Get the full scope of what PACK EXPO Las Vegas has to offer. Find information on show staples like the Technology Excellence Awards, industry-specific pavilions, the Industry Speaks stage and other educational sessions, networking events, student programs, and useful resources.

Scan the Exhibitor List QR Code for an alphabetical list of exhibitors with booth numbers included.

Scan QR codes to access updated session lists for all free show floor education opportunities.

Find an editor-curated rundown of the most innovative solutions unveiled at PACK EXPO International 2024 across categories including sustainable packaging, robotics, digital transformation, and more. Sign up for first access to the PACK EXPO Las Vegas 2025 Innovations Reports, capturing the breakthroughs that could transform your operations.

Advertisers in this issue have new technologies and innovations to show you at PACK EXPO Las Vegas. Find out where they’ll be on the show floor.

This unique advertising section profiles PACK EXPO exhibitors. Get a sneak preview of the leading firms you’ll see at the show.

Matt Reynolds, Chief Editor

Anne Marie Mohan, Senior Editor

Sean Riley, Senior News Editor

Casey Flanagan, Associate Editor

Tracey Labovitz, Editorial Operations Coordinator

Cam Franko, Audience Engagement Manager

Kim Overstreet, Director of Content

Kathy Travis, Art Director

David Bacho, Creative Director

sales@pmmimediagroup.com

Courtney Nichols, Director, Client Success & Development cnichols@pmmimediagroup.com

Lara Krieger, Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano, Financial Services Manager

David Newcorn, President

Elizabeth Kachoris, Vice President, Digital

Trey Smith, Senior Director, Events

Jen Krepelka, Director, Digital Media

Amber Miller, Director of Marketing

Joan Jacinto, Director, Ad Tech and Search

Joseph Angel, Founding Partner and Executive Vice President, Industry Outreach, PMMI

PMMI Media Group

500 W. Madison, Suite 1000, Chicago, IL 60661

Web: www.packworld.com

PMMI The Association for Packaging and Processing Technologies

12930 Worldgate Dr., Suite 200, Herndon VA, 20170

Phone: 571/612-3200 • Fax: 703/243-8556

Web: www.pmmi.org

Looking to discover what’s new in packaging and processing?

This at-a-glance guide gives you the essential details of what’s happening at PACK EXPO Las Vegas 2025, the ultimate packaging and processing event this year.

9:00 A.M. – 5:00 P.M. MONDAY, TUESDAY

9:00 A.M. – 3:00 P.M. WEDNESDAY

PACK EXPO Las Vegas is a massive showcase of cutting-edge technology and solutions. Targeted industry pavilions help attendees easily zero in on the solutions that fit their needs. For more pavilion information and to find exhibitors within every pavilion at PACK EXPO Las Vegas, visit pwgo.to/8803.

The Logistics Pavilion

Dive into the latest in warehousing, fulfillment, distribution, logistics, and transportation services — everything needed to move products faster, smarter, and more efficiently. With the current boom in e-commerce, the Logistics Pavilion will be the place to meet the moment. Find it in the North Hall

The Healthcare Packaging Pavilion

Explore state-of-the-art packaging innovations for pharmaceuticals, biologics, nutraceuticals, and medical devices. Precision, safety, and innovation converge at this top destination for life sciences companies. Located in the North Hall

PLAN AHEAD WITH THE PACK EXPO LAS VEGAS MOBILE APP

Navigate the show like a pro with the free PACK EXPO Las Vegas Mobile App, sponsored by ProMach, Inc.

The Processing Zone

Discover the latest food and beverage processing innovations, see the latest equipment in action, and explore advancements shaping the industry’s future at the Processing Zone. Find frontof-the-line solutions including homogenizing, heat treating, forming and sizing, and coating. Discover solutions to help increase efficiency, achieve total system integration, and ensure employee safety. Visit the Processing Zone in the North Hall.

Get hands-on with groundbreaking innovations in paperboard, glass, metal, flexible, and resealable solutions designed to captivate consumers and boost sustainability. This pavilion is a onestop-shop for attendees looking for new packaging to refresh, enhance, or differentiate their brand, add functionality, or improve sustainability. Find it in the South Lower Hall

Head to the Confectionery Pavilion, sponsored by the National Confectioners Association, to see the latest confectionery technology in action, from high-tech aeration and batch refining to innovative shaping and cluster production. Explore the sweet science behind the latest candy-making trends. Located in the South Upper Hall

• Search exhibitors, products and educational sessions

• Access your My Show Planner

• Navigate the show with new GPS-style directions

• Locate concessions and view transportation options

• Join the Scavenger Hunt

• Vote in the 2025 Technology Excellence Awards

Take time to network, recharge, and gain valuable insights at the Candy Bar Lounge, hosted by the National Confectioners Association and sponsored by Syntegon. Find it within the Confectionery Pavilion at booth SU-26000

The Reusable Packaging Pavilion

Sponsored by the Reusable Packaging Association, discover reusable packaging solutions that reduce waste, drive down costs, and supercharge supply chain efficiency, all while supporting the planet. Located in the South Upper Hall

The Association Partner Pavilion

This pavilion houses associations from the PACK EXPO Partner Program, which connects attendees to leading associations from all segments of packaging and processing. Find them in the West Hall. For a full list of participating associations, visit pwgo.to/8804

The Education and Workforce Development Pavilion

Explore PMMI U’s array of offerings, including sought-after training workshops. Colleges and universities from across the country will showcase their mechatronics and packaging and processing programs, while companies will have the opportunity to engage with students interested in pursuing careers in the industry. Located in the North Hall Lobby

Beyond the exhibits, PACK EXPO Las Vegas offers more than 100 free educational sessions right on the show floor. These sessions deliver expert insights on a wide range of topics, from automation, AI, and sustainability to navigating tariffs, reusable packaging, food safety, and more.

PMMI U is offering its popular training workshops in Las Vegas to coincide with PACK EXPO Las Vegas.

Risk Assessment Workshop: September 27-28, 2025.

Learn more at pwgo.to/8805

Certified Trainer Workshop: September 29-30, 2025. Learn more at pwgo.to/8806

Field Service Essentials: September 29-30, 2025.

Learn more at pwgo.to/8807

Multiple stages throughout the show floor serve specific learning interests, including the Innovation Stages, Processing Innovation Stage, Sustainability Central, Industry Speaks, and the Reusable Packaging Learning Center. Whether you’re looking to explore emerging technologies or gain practical strategies for your operation, there’s something for everyone. Flip to p.22 to scan QR codes and access the most up-to-date session listings for each stage.

The Attendee Resource Center on the PACK EXPO Las Vegas website is an online gateway with information and resources to help you maximize your time at the show. Use it to access the My Show Planner tool to mark your “must-see” interests and schedule meet-

ings in advance, learn about the PACK Match 1:1 free consultation service, download the Attendee ROI Guide, use the justification letter template, and much more. Find it at pwgo.to/8826

The Technology Excellence Awards are back at PACK EXPO Las Vegas 2025, and it’s up to you to vote for the winner. The awards recognize exhibitor’s brand-new innovations never-before displayed at a PACK EXPO trade show. All registered attendees are eligible to vote for favorites among the finalists across four categories: Food & Beverage, General Packaging & Processing, Personal Care & Pharma, and Sustainability.

Voting will begin on September 22 and continue onsite until Tuesday, September 30 at noon. There are three ways to vote: onsite, on the official show mobile app, and online. The winner of each category will be announced via social media and a press release Tuesday afternoon. While you’re at the show, be sure to check out the finalists and winners at their booths! For a complete description of the finalists’ technologies, visit the Technology Excellence Awards page at pwgo.to/8808 or flip to p.10.

The Packaging & Processing Women’s Leadership Network (PPWLN) fosters growth, knowledge sharing, and networking opportunities for women in packaging and processing. Each year at PACK EXPO Las Vegas, PPWLN hosts a networking breakfast to share experiences, build meaningful connections, and hear from influential voices in leadership and workforce development.

This year’s featured speaker, Alison Fragale, an organizational psychologist and professor at the University of North Carolina-Chapel Hill, is a nationally recognized negotiation, communication, and workplace dynamics expert. Her keynote at the PPWLN Breakfast will offer attendees new perspectives and tools to grow personally and professionally.

The PPWLN Breakfast is open to all PACK EXPO Las Vegas attendees, regardless of gender, and is designed to welcome everyone who supports the development of a diverse and inclusive industry.

The Networking Breakfast takes place September 30, from 7:30 a.m. to 9:00 a.m., in Room N-247 at the Las Vegas Convention Center. Register to attend at pwgo.to/8818. Admission is free but an RSVP is recommended, as space is limited, and interest remains high.

The PPWLN breakfast is proudly sponsored by PPWLN Gold Sponsors: Morrison Container Handling Solutions and ProMach, Inc. ; PPWLN Breakfast Sponsors: BW Packaging, Emerson Discrete Automation Group, Plexpack Corp., Septimatech Group Inc., SMC Corporation of America, and Smurfit Westrock PW

s s or -15080 TO SCO CL , F ST FILLI I CTI

Discover thousands of innovations and unmatched learning opportunities at the most comprehensive packaging and processing event of 2025, now celebrating 30 years of industry impact.

September 29 - October 1, 2025

9:00 a.m. - 5:00 p.m. Monday, Tuesday 9:00 a.m. - 3:00 p.m. Wednesday

Las Vegas Convention Center

Las Vegas, Nevada

Registration Pricing: Don’t miss the largest gathering of packaging and processing professionals of the year at PACK EXPO Las Vegas. Attendee registration is open now at packexpolasvegas.com. Registration $130. Why Register? PACK EXPO Las Vegas registration brings exceptional value. Your badge gives you access to:

• All three days of the largest packaging and processing event of the year, with 2,300 exhibitors across over 1 million net sq ft of space.

• Over 100 educational sessions taking place directly on the show floor, covering the latest industry trends, technological advancements, and best practices.

• The PACK Match program for end-users: A one-on-one virtual consultation with a non-biased industry expert to find the right suppliers and solutions ahead of the show.

• New Show Floor Tours: Attend the PACK EXPO Discovery Tours, sponsored by Formic, or the PACK EXPO Sustainability Tour, sponsored by Anchor Packaging, for an expert led tour of the show. Participation is free, but space is limited. Apply at pwgo.to/8801

• Networking on the show floor and at select events, including the Young Professionals Networking Reception sponsored by Beckhoff Automation LLC at The Cove Bar & Arcade, a private performance of Mystère by Cirque du Soleil® at PACK gives BACK™ sponsored by Rockwell Automation, and more.

Please note: No one under the age of 14 is permitted on the show floor.

Unlock your next breakthrough at PACK EXPO Las Vegas 2025 (Sept. 29-Oct. 1; Las Vegas Convention Center), the ultimate packaging and processing event this year. An estimated 35,000 attendees will gather in Las Vegas to explore 2,300 exhibitors and thousands of cutting-edge solutions.

Produced by PMMI, this biennial event reliably showcases the most innovative technologies and facilitates invaluable networking opportunities, making it essential to stay informed on the industry’s latest developments. Explore game-changing advancements for over 40 vertical markets, from food and beverage to pharmaceuticals, e-commerce, and more. You can discover crossover solutions you won’t see at vertically targeted events, expanding what’s possible for your business.

In 2025, PACK EXPO Las Vegas marks 30 years as one of North America’s most influential packaging and processing events. From its 1995 launch as a regional event to its current form as an international powerhouse, the show has expanded dramatically in size, scope, and impact. The show reaches another new milestone this year, surpassing 1 million net sq ft of exhibition space for the first time, making even more room for new solutions and innovations.

The packaging and processing industry never stands still, and neither does PACK EXPO Las Vegas. Whether it’s the Sustainability Central stage and Logistics Pavillion added in 2023 to address these vital topics, or the Industry Speaks learning stage where thought leaders from the PACK EXPO Las Vegas Partner Program share valuable insights, this show remains a step ahead of the biggest trends and technologies shaping the future.

To commemorate this milestone year, PMMI proudly honors its PMMI Member Companies that were part of the inaugural show and continue to exhibit today with a 30-Year Legacy Exhibitor logo. Find the list of Legacy Exhibitors at pwgo.to/8802

But the focus of PACK EXPO Las Vegas remains firmly on what’s next: AI, automation, workforce development, digital transformation, and sustainability. The show continues to actively engage members, partners, and emerging leaders to shape the next decades of innovation, collaboration, and industry impact.

To enhance the PACK EXPO Las Vegas experience for attendees, the show floor features several specialty pavilions, all of which have expanded from 2023. For more pavilion information and to find exhibitors within every pavilion at PACK EXPO Las Vegas, visit pwgo.to/8803

Dive into the latest in warehousing, fulfillment, distribution, logistics, and transportation services — everything needed to move products faster, smarter, and more efficiently. With the current boom in e-commerce, the Logistics Pavilion will be the place to meet the moment. Find targeted solutions related to the supply chain, including warehousing, fulfillment, distribution logistics services, and transportation providers. Find it in the North Hall

Explore state-of-the-art packaging innovations for pharmaceuticals, biologics, nutraceuticals, and medical devices. Precision, safety, and innovation converge at this top destination for life sciences companies. Located in the North Hall

Discover the latest food and beverage processing innovations, see the latest equipment in action, and explore advancements shaping the industry’s future at the Processing Zone. This pavilion supports the integration of processing and packaging, a key function in the manufacturing environment. Search for front-of-the-line solutions including homogenizing, heat treating, forming and sizing, and coating. Discover solutions to help increase ef ciency, achieve total system integration, and ensure employee safety. Visit the Processing Zone in the North Hall

THE TECHNOLOGY EXCELLENCE AWARDS are back at PACK EXPO Las Vegas 2025, recognizing exhibitors’ brand-new innovations never-before displayed at a PACK EXPO trade show. All registered attendees are eligible to vote for favorites among the finalists across four categories: Food & Beverage, General Packaging & Processing, Personal Care & Pharma, and Sustainability.

Voting will begin on September 22 and continue onsite until Tuesday, September 30 at noon. There are three ways to vote: onsite, on the official show mobile app, and online. Your vote counts!

The winner of each category will be announced via social media and press release Tuesday afternoon. While you’re at the show, be sure to check out the finalists and winners at their booths! To learn more, visit pwgo.to/8808

The Technology Excellence Awards 2025 Finalists are as follows:

• HyperBarrier ® Paper. Replaces multilayer plastics with a single-layer nanocomposite barrier coating on paper, for recyclable high-barrier food packaging. COPAR SMART PACKAGING, Booth SU-30098A

• Senzani U-Seal. Cold-sealing technology that enables the creation of fully recyclable cardboard packs in a variety of shapes from flat blanks. Senzani Brevetti SPA, Booth SU-26041

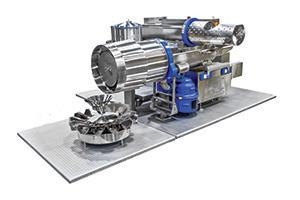

• Efficient Agitation (EA) Retort. This technology allows for more versatile packaging options in retort processing, using a patented trapezoidal motion for greater mix energy and shorter stroke length during sterilization. JBT Corporation, Booth N-8612

• HaiPick Climb. Hai Robotics says this is the first robot of its kind, capable of climbing warehouse racks and operating in lowprecision environments. Hai Robotics USA, Booth SU-25090

• Volta All-Electric Adhesive Jetting Head. This adhesive applicator uses an all-electric design and features integrated pattern control for direct programming on the head itself. Robatech USA, Inc., Booth N-8447

• MAG-B Horizontal Form Fill and Seal. This HFFS machine features magnetic track motion, pitch-less operation, and rapid changeover capabilities. Bartelt Packaging, Booth W-1130

Care & Pharma Finalists

• PR-12 and PR-24 Syringe Plunger Rod Insertion and Labeling Machine. High-speed, high-control plunger rod insertion and syringe labeling in one compact unit. WLS, Booth W-1152

• MLD Advanced. This syringe filling system features 100% in-process control and gentle, no-glass-to-glass-contact handling. Syntegon, Booth N-5244

• BK-4 Precision Belt Capper with EM-980 Torque Tester. A capper with a four-belt clutched cap tightening system for gentle, consistent torque across cap styles, and an inline torque monitor. Kaps-All Packaging Systems, Inc., Booth W-820

• ZeCycle Recycling Program. This closed-loop program allows for recycling of VCI film and LDPE poly films, processing them into PCR resin for use in new VCI film, and creating a measurable environmental impact. ZERUST Corrosion & Cleaning Solutions, Booth SU-25054

• Machine Stretch Film with 30% PCR Content. Thin, strong films with 30% PCR content and a baled film collection program to support circularity. Trioworld, Booth SU-34018

• Comprex North America, LLC. This chemical-free CIP system uses compressed air and minimal water to clean piping systems. Floco Process, Booth N-6760

Sponsored by the Reusable Packaging Association, discover reusable packaging solutions that reduce waste, drive down costs, and supercharge supply chain efficiency, all while supporting the planet. Located in the South Upper Hall

This pavilion houses associations from the PACK EXPO Partner Program, which connects attendees to leading associations from all segments of packaging and processing. Find them in the West Hall. For a full list of participating associations, visit pwgo.to/8804

Get hands-on with groundbreaking innovations in paperboard, glass, metal, flexible, and resealable solutions designed to captivate consumers and boost sustainability. This pavilion is a one-stopshop for attendees looking for new packaging to refresh, enhance, or differentiate their brand, add functionality, or improve sustainability. Find it in the South Lower Hall

Head to the Confectionery Pavilion, sponsored by the National Confectioners Association, to see the latest confectionery technology in action, from high-tech aeration and batch refining to innovative shaping and cluster production. Located in the South Upper Hall

Take time to network, recharge, and gain valuable insights at the Candy Bar Lounge, hosted by the National Confectioners Association and sponsored by Syntegon. Find it within the Confectionary Pavilion at Booth SU-26000

Sponsored by Smurfit Westrock, this attendee favorite will display award-nominated packaging solutions. Find it on the concourse between the North and West Buildings

PACK EXPO Las Vegas serves as the ultimate resource hub for strengthening the existing workforce and nurturing the future workforce. Explore PMMI U’s array of offerings, including sought-after training workshops. Colleges and universities from across the country will showcase their mechatronics and packaging and processing programs, while companies will have the opportunity to engage with students interested in pursuing careers in the industry. Located in the North Hall Lobby.

PMMI U is offerings its popular training workshops in Las Vegas to coincide with PACK EXPO Las Vegas, including:

Risk Assessment: September 27-28, 2025

• This workshop provides engineers, safety officers, and operations managers valuable insights into industry standards, the machine risk assessment process, identification of health and safety hazards, and effective mitigation of risks. Learn more at pwgo.to/8805

Certified Trainer: September 29-30, 2025

• The Certified Trainer workshops will give attendees strategies and tactics to train across all employee skill levels, including service technicians, service and training managers, maintenance technicians, internal trainers, line supervisors, and any employee tasked with training fellow employees or customers. Learn more at pwgo.to/8806

Field Service Essentials: September 29-30, 2025

• This two-day workshop explores the non-technical knowledge and skills needed to be a great technician. Through demonstrations and role-play exercises, attendees will learn about customer service, troubleshooting, environmental issues, safety, training, and service call follow-up. A PMMI Member Exclusive. Learn more at pwgo.to/8807

Searching for a specific company or solution?

Visit the online exhibitor list to easily discover exhibitors and locate them on the show floor. Find detailed descriptions of each exhibitor and filter by product category, vertical market, and more to find the right solution for your company.

Beyond the exhibits, PACK EXPO Las Vegas offers over 100 free educational sessions right on the show floor. These sessions cover various topics, including the latest industry trends, technological advancements, and best practices. Attendees gain valuable knowledge that can be directly applied to their operations, fostering innovation and efficiency. Scan QR codes on p.22 to access updated session lists for each stage

Presented by Packaging World and sponsored by Dow, Sustainability Central is your first stop to stay on top of what is arguably the biggest, most multifaceted challenge the packaging industry is currently facing. Expert-led sessions will help you navigate the complexities of sustainability and what it means for your brand. Session topics will include sustainable packaging solutions, Extended Producer Responsibility and other legislation, circularity, and much more. This is a vital destination for anyone looking to understand and implement sustainable practices in packaging and processing. Find it in the South Upper Hall, Booth SU-35000. For more information, flip to p.20 or visit pwgo.to/8809

Sponsored by Anchor Packaging, this industry expert-led tour will provide a curated experience designed for first-time attendees and senior decision-makers who are actively seeking sustainable solutions. Flip to p.26 for more information and apply at pwgo.to/8810

Sponsored by Lantech on Monday; Formic on Tuesday, the PACK EXPO Discovery Tours are a curated experience that simplifies the show for busy professionals. They are designed for senior-level decision-makers and first-time buyers of packaging and processing automation. Led by seasoned industry experts, each tour delivers valuable insights and context, helping attendees make the most of their time on the floor. Flip to p.26 for more information and apply at pwgo.to/8811

Catch free, 30-minute seminars on breakthrough technologies and best practices, presented across three stages each day by suppliers and subject matter experts. Session topics include cobots, automation, AI, navigating tariffs, thermal inkjet (TIJ) technology, and more. Located in the West Hall, Booths W-4300, W-4310, W-4318 Learn more at pwgo.to/8812

Experts from the PACK EXPO Partner Program, covering multiple industry verticals, will address the latest hot topics and industry trends such as sustainability, remote access, supply chain solutions, augmented reality, and operational efficiency. Located in the West Hall, Booth W-4324. To learn more, visit pwgo.to/8814

This stage focuses on advancements in food & beverage processing technologies, offering insights into improving efficiency and product quality. Session topics include food safety, sustainability, food processing, AI, and more. Find it in the North Hall, Booth N-9100. For more information, visit pwgo.to/8813

Sponsored by the Reusable Packaging Association, hear from experts on strategies to implement a reusable packaging system that can improve material-handling performance, reduce operating costs, create new economic values, and lower the environmental impacts of a brand’s supply chain. Located within the Reusable Packaging Pavilion in the South Upper Hall, Booth SU-34000 For more information, visit pwgo.to/8815

Take advantage of the numerous networking events designed to connect professionals across various sectors at PACK EXPO Las Vegas. These events provide opportunities to exchange ideas, discuss challenges, and build relationships leading to future collaborations and business growth. For an online rundown of all networking and special events, visit pwgo.to/8816.

SPONSORED BY:

Sponsored by Beckhoff Automation LLC, the Young Professionals Networking Reception at PACK EXPO Las Vegas offers up-andcoming leaders an opportunity to socialize with their peers in a fun and relaxed environment, perfect for making new connections in the industry. Attend the event at The Cove Bar & Arcade September 29 at 7:00 p.m. to 9:00 p.m. Free with registration; RSVP required. Learn more and register at pwgo.to/8819

Sponsored by Rockwell Automation, step out on the town with an exclusive, private performance of Mystère by Cirque du Soleil® — a special event just for PACK EXPO Las Vegas participants! From gravity-defying feats to whimsical comedy and stunning visuals, this unforgettable experience promises thrills at every turn. Best of all, proceeds from this annual event will support the PMMI Foundation, providing financial support for packaging and processing education throughout the U.S. and Canada.

See the performance on Sunday, September 28, at Treasure Island Las Vegas. Doors open at 6:15 p.m., with the performance at 7:00 p.m. Tickets are $95 each, or buy nine and get the 10th free. Take advantage of the 10-tickets-for-the-price-of-nine deal to treat customers or business partners to the show.

Don’t miss this extraordinary night of entertainment for a great cause! To buy tickets and find more information, visit pwgo.to/8817.

In this exclusive lounge for first-time attendees, you can get assistance on how to navigate the show, access product locators, talk to experienced show staff, get access to a special networking breakfast on September 30, or simply relax and recharge to help maximize your time at the show. Don’t miss the special sessions on How to Navigate the Show Floor taking place Monday and Tuesday at 8:30 a.m. and Simplify Supplier Sourcing with ProSource, MondayWednesday at 12:30 pm. The Lounge and Networking Breakfast are both sponsored by ProMach, Inc. Learn more at pwgo.to/8887

SPONSORED

BY:

THE PACKAGING & PROCESSING WOMEN’S LEADERSHIP NETWORK (PPWLN) fosters growth, knowledge sharing, and networking opportunities for women in packaging and processing. Each year at PACK EXPO Las Vegas, PPWLN hosts a networking breakfast to share experiences, build meaningful connections, and hear from influential voices in leadership and workforce development.

Explore the future of packaging and processing in these immersive forums designed to facilitate conversation and build business strategy. Industry visionaries will discuss emerging trends, sustainability, and technological advancements shaping the industry for the next decade. Designed exclusively for CPGs and PMMI members in operations, plant managers, and engineers, these sessions promise actionable strategies to elevate your business. Learn about topics and session scheduling and register in advance at pwgo.to/8888.

This year’s featured speaker, Alison Fragale, an organizational psychologist and professor at the University of North Carolina-Chapel Hill, is a nationally recognized negotiation, communication, and workplace dynamics expert. As a speaker, author, and educator, Fragale is known for blending research with relatable

stories that help professionals better understand power, confidence, and leadership. Her keynote at the PPWLN Breakfast will offer attendees new perspectives and tools to grow personally and professionally.

The PPWLN Breakfast is open to all PACK EXPO Las Vegas attendees, regardless of gender, and is designed to welcome everyone who supports the development of a diverse and inclusive industry.

The Networking Breakfast takes place September 30, from 7:30 a.m. to 9:00 a.m., in Room N-247 at the Las Vegas Convention Center. Register to attend at pwgo.to/8818. Admission is free but an RSVP is recommended, as space is limited.

The PPWLN breakfast is proudly sponsored by PPWLN Gold Sponsors: Morrison Container Handling Solutions and ProMach Inc.; PPWLN Breakfast Sponsors: BW Packaging, Emerson Discrete Automation Group, Plexpack Corp., Septimatech Group Inc., SMC Corporation of America, and Smurfit Westrock.

Today’s students are tomorrow’s industry leaders. That’s why PACK EXPO Las Vegas offers programs and activities aimed at getting students excited about careers in packaging and processing. For information on all student opportunities, visit pwgo.to/8820

Robotics teams from Las Vegas area high schools will bring the robots they’ve designed and built to showcase them in action. Each team’s high school receives a $500 grant from the PMMI Foundation to support their participation. Come watch these fun demonstrations and feel free to ask questions. Find it in the North Hall Lobby, NL-1.

Sponsored by Emerson Discrete Automation Group, teams of engineering students from colleges, trade schools, and universities across the U.S. will race around the PACK EXPO Las Vegas show floor, completing tasks and solving problems at the booths of participating exhibitors. Students can explore the cutting-edge world of packaging and processing and compete for cash prizes, while companies can connect with the future workforce by participating as a race destination. The race takes place Wednesday, October 1, beginning at 9:00 a.m. Learn more at pwgo.to/8821

This exciting, real-world, end-to-end competition challenges teams of students to design and build working packaging machinery and compete against other schools at PACK EXPO International in Chicago. The winning team from PACK EXPO International 2024, Spruce Packaging, will showcase their winning design at the show in Las Vegas. Be sure to check it out in the North Hall, N-6100.

Sponsored by Visionary Benefactor Schneider Electric, the student lounge will be open for students to come and meet with HR professionals to discuss career opportunities, receive resume writing tips, and attend interview workshops. Visit it at N-237.

THE PMMI FOUNDATION provides financial support for packaging and processing education throughout the U.S. and Canada. Since its inception, the PMMI Foundation has given more than $5.4 million to strengthen the industry’s workforce. Enjoy the following events, with proceeds benefiting the Foundation.

The PMMI Foundation Golf Tournament:

Held the day before PACK EXPO Las Vegas (Sunday, September 28), this annual charity event brings packaging and processing professionals together for a morning of golf, networking, and giving back. The 2025 event takes place at Bali Hai Golf Club and welcomes players of all skill levels. More than just a fun outing, proceeds support scholarships, student travel, and workforce development programs through the PMMI Foundation. In 2023 alone, the tournament raised over $40,000 to help close the industry’s talent gap. Learn more and register to play at pwgo.to/8823

Silent Auction: Featuring entertainment, sports, and historical memorabilia, this Silent Auction will take place Monday through Wednesday of the show. All bidding will occur virtually, and items will be displayed in the West Hall Lobby. Proceeds will go to benefit the PMMI Foundation.

Students attending PACK EXPO Las Vegas are invited to attend the PPWLN Breakfast, followed by a tour given by members of the PPWLN Executive Council. To find more information on the breakfast and register to attend, visit pwgo.to/8822. Student tours are also available beyond the PPWLN tour. PMMI staff will conduct tours of the show floor daily at 10:00 a.m. and 2:00 p.m. Contact Kate Torrence at kate@pmmi.org for more information.

Attendees have access to a host of tools and resources to help them make the most of their time at PACK EXPO Las Vegas.

My Show Planner allows you to create a personalized collection of “must-sees,” and your key means of tracking your interests before, during, and after the show. It includes a personalized resource planning tool and director, appointment scheduling capabilities. Add exhibitors and sessions of interest and even schedule meetings in advance, maximizing your time at the show. To get started, visit pwgo.to/8824

This complimentary program offers registered end-user attendees a one-on-one virtual consultation with a non-biased industry expert, helping to find the right suppliers and solutions to address their needs before they arrive at PACK EXPO Las Vegas. Upon completing the consultation, the attendee will receive a list of relevant exhibitors they can visit during the show, curated to provide solutions to their challenges. This service is only available to end-user buyers of packaging, processing, or related solutions who have registered to attend PACK EXPO Las Vegas. The deadline to register and schedule an appointment is September 16. Consultations with PACK Match Advisors take place September 8-25. To learn more and register, visit pwgo.to/8825.

The Ask the Experts program is an additional attendee resource offered onsite at PACK EXPO Las Vegas, serving as an extension of the PACK Match program. Ask the Experts will be staffed by experienced packaging or processing industry executives. Get expert guidance on finding the right packaging or processing solutions to address your specific challenges. Find them in the South Building and West Building Lobbies.

Navigate the show like a pro with the free PACK EXPO Las Vegas Mobile App, sponsored by ProMach, Inc.

• Search exhibitors, products, and educational sessions

• Access your My Show Planner and add to your personal agenda

• NEW! Turn-by-Turn Navigation helps you find anything with improved GPSstyle directions

• Get in the know on transportation & dining options, meeting rooms, FAQ’s and more

• Engage in the Scavenger Hunt and vote in the Technology Excellence Awards

This is your onsite destination for industry advice and show planning tools. Get one-on-one guidance, map your route, and print your itinerary using product locators. Find them in the West Building Lobby.

This is an online gateway with information and resources to help attendees maximize their time and get more ROI from attending the show. Download the Attendee ROI Guide, use the justification letter template, explore additional search tools to find the best solutions at the show, and much more. To access it, visit pwgo.to/8826

The PMMI Booth showcases all that the organization offers to its members and the packaging and processing industry. Learn about PMMI business drivers including Business Intelligence, Workforce Development, Industry Services, and more. Get acquainted with the PMMI Media Group and the PACK EXPO brand of trade shows. Stop by to discover how PMMI can make a difference in your business, career, and community. Find it in the West Hall Lobby

The Insider Advantage Program at PACK EXPO Las Vegas 2025 is designed exclusively for leading national and multinational CPG buying groups seeking a more strategic and productive show experience. This upgraded experience offers an unmatched combination of convenience, comfort, and connectivity offering a lounge with Wi-Fi, product locators, refreshments, and semi-private meeting space access available to reserve on a first-come, first-served basis. For groups bringing 10+ employees, private meeting space is available to hold executive-level discussions, host strategic partners, or regroup with your team. Space is limited and reserved on a first-come, firstserved basis. To join, fill out the interest form at pwgo.to/8827 or contact Claire Morrell at cmorrell@pmmi.org

Sustainability is no longer optional—it’s mission-critical. At Sustainability Central, you’ll find free, expert-led education that empowers you to meet evolving regulatory, environmental, and consumer demands head-on.

Across three full days of programming, discover the latest in:

• Sustainable packaging materials and design strategies

• Extended Producer Responsibility (EPR) and circularity

• Reducing carbon footprints and water consumption

• E-commerce packaging innovation

• Legislation and compliance readiness

• Data and AI for efficiency and energy savings

Each session is designed to help brands and suppliers alike align sustainability goals with business outcomes, efficiency improvements, and customer expectations.

Whether you’re leading your company’s sustainability strategy or looking for new ideas to get started, this is your destination to engage, learn, and take action.

LOCATION

South Upper Hall | Booth SU-35000

DATES

Monday–Wednesday, Sept. 29–Oct. 1

Explore the full schedule and learn more at pwgo.to/8894

Free education. Real impact. A more sustainable future starts here.

Located in the South Upper Hall at SU-35000

At PACK EXPO Las Vegas’ Sustainability Central, get different takes on sustainability from industry experts and gain insight on making your brand more sustainable for the future.

MONDAY, SEPTEMBER 29

10:00 AM - 10:30 AM Advancing the Circular Economy with Breakthrough Material Identification Technology

Peter Chauvel, Strategy & Operations Lead at Google X, The Moonshot Factory

Jill Martin, Senior R&D/TS&D Fellow at The Dow Chemical Company

11:00 AM - 11:30 AM A Supplier’s Role in Creating a Sustainable Value Chain

Nate Pajka, Sustainability Manager at Metsä Board

12:00 PM - 12:30 PM Sustainable Packaging Impact on Consumer Behavior

Caitlin Boyd, Client Engagement Manager at NielsenIQ

John Robinson, Global Director at NielsenIQ

1:00 PM - 1:30 PM Streamlining Operations with Right-Sized Packaging Solutions for a Sustainable Future

Jack Smith, Director, Business Development at Packsize

2:00 PM - 2:30 PM Packaging Waste, Circularity, and the EPR Mandate to Create ROI

Gary Brinkman, Chief Revenue Officer at Sebright Products, Inc.

3:00 PM - 3:30 PM EPR & EPS: What's Next for Transport Packaging?

Joe Grzyb, Director of Sustainability at EFP, LLC

4:00 PM - 4:30 PM How PPWR Will Shape EPR: A Future Look at Packaging Policy

Philippe Blank, Head of Sustainable Design & Circular Economy – Packaging Adhesives & Consumer Goods at Henkel Corporation

TUESDAY, SEPTEMBER 30

10:00 AM - 10:30 AM Tape Smarter: Rethinking Packaging Tape to Eliminate Virgin Plastic

Bradley Dunlap, Director of Product Marketing - Industrial Packaging at Shurtape Technologies, LLC

11:00 AM - 11:30 AM Building the Business Case for Sustainability

John Garnett, Senior Vice President, Technical, Sustainability at Charter Next Generation

12:00 PM - 12:30 PM Legislation is Here—Is Your Packaging Ready?

Curt Cozart, Chief Operating Officer at Association of Plastic Recyclers (APR)

1:00 PM - 1:30 PM Evolving E-Commerce Packaging Materials

Bradley McLeod, Business Development Director – Packaging Materials Innovation at Henkel Corporation

2:00 PM - 2:30 PM Driving Sustainable Savings & Circularity in Packaging

Ricardo Cardoso, CEO and President Trioworld North America at Trioworld

3:00 PM - 3:30 PM Who Really Cares About Sustainable Packaging?

Christopher Davidson, Vice President, Sustainability Engagement at Smurfit Westrock

4:00 PM - 4:30 PM What Your Business Needs to Know About Preventing Plastic Resin Loss

Charlotte Dreizen, Director, Sustainability & Environment at Plastics Industry Association

WEDNESDAY, OCTOBER 1

10:00 AM - 10:30 AM Driving Efficiency in Compressed Air with Data & AI

Amit Patel, Director Intelligent Automation at Emerson

11:00 AM - 11:30 AM EPR Developments Shaping the U.S. Landscape: What You Need to Know

Jason Bergquist, Vice President - US at RecycleMe

12:00 PM - 12:30 PM Rethinking Cold Chain: Sustainability and Smart Freezing Solutions

Keith Baechle, Chief Commercial Officer at Nordic Cold Chain Solutions

Ben Shore, Chief Product Officer at Nordic Cold Chain Solutions

Scan these QR codes for updated schedules on all the educational stages listed below.

Catch free, 30-minute seminars on breakthrough technologies and best practices, presented across three stages each day by suppliers and subject matter experts. Session topics include cobots, automation, AI, navigating tariffs, thermal inkjet (TIJ) technology, and more.

This stage focuses on advancements in processing technologies, offering insights into improving efficiency and product quality. Session topics include food safety, sustainability, food processing, AI, clean-label products, and more. These sessions are targeted to food and beverage manufacturers.

Experts from the PACK EXPO Partner Program, covering multiple industry verticals, will address the latest hot topics and industry trends such as sustainability, remote access, supply chain solutions, augmented reality, and operational efficiency.

Presented by Packaging World and sponsored by Dow, this is your first stop to stay on top of what is arguably the biggest, most multifaceted challenge in the packaging industry today. Expert-led sessions will help you navigate the complexities of sustainability and what it means for your brand. Session topics will include sustainable packaging solutions, Extended Producer Responsibility and other legislation, circularity, and much more.

Sponsored by the Reusable Packaging Association, hear from experts on strategies to implement a reusable packaging system that can improve material-handling performance, reduce operating costs, create new economic values, and lower the environmental impacts of a brand’s supply chain.

We hope this Resource Guide will help you find the supplier for your next project. But chances are good that you will also be checking out potential vendors online. If you have ever tried to search for packaging machinery online you were likely overwhelmed by the sheer number of results. For example, a search for “cartoning equipment” on Google is returning about 36 million results.

What if you could connect to your next supplier by searching online through a curated, vetted list of the leading suppliers of packaging and processing machinery, materials and services? Now you can. PMMI ProSource is the online directory of PMMI members, representing the top suppliers in our industry who are experts in packaging and processing.

PMMI ProSource is a robust online directory with more than one way to navigate.

Start at Prosource.org and click through to the specific category you need. PMMI ProSource features illustrations and category definitions to help guide you through to the right solution.

Carton Erect/Load/Seal

Equipment Category

• 54 Companies

Carton Erectors/Formers

Equipment Category

• 31 Companies

Equipment Category

• 9 Companies

Gabletop Cartoning Equipment

Cartoning Equipment

See all Cartoning equipment categories

At the top right of ProSource.org is a powerful search bar. AI tools, auto complete function, and common synonyms are loaded into the search to help you find your solution faster.

Use the Package Type tool on the left hand side of PMMI ProSource to search for equipment by the packaging it runs: bags, bottles, cartons and more. Search results will display the suppliers who told PMMI their machines can handle those package types.

PMMI ProSource quickly connects you to your next supplier. How?

• Focused on our industry. Browse hundreds of categories of validated suppliers in key areas of machinery, materials and services, such as vertical form/fill/seal equipment, liquid fillers and conveyors.

• Authoritative. All companies listed are members of PMMI, the leading global association of packaging and processing that produces the PACK EXPO shows and this magazine. PMMI sta validate category listings.

• Less scrolling, more finding. Rather than spending hours scrolling through search engine results online, go to PMMI prosource.org for a curated experience that connects you faster to the packaging and processing specialists who have the specific solutions you need.

Use PMMI ProSource’s filters during your search to sort through packaging solutions as you research, similar to the consumer sites you love.

• Say you are a start-up salsa company looking for your first machine. Once you are in the Liquid Fillers section, you can sort results to find suppliers that specialize in entry-level/budget models or hot fill machines machines using the panel on the left.

• Or, if you are a snack company looking specifically for stick pack machines, go to the Vertical Form/Fill/Seal section and select Stick Pack under the Bag Style section.

In addition to the directory listings, PMMI ProSource also offers many helpful howto articles to help you solve typical problems in the facility. Recent articles have included “Palletizing 101: An Overview of the Basics” and “Common Ways Labeling Projects Can Fail.”

When you find a supplier that you are interested in, click on the preview blurb to be taken to their profile page. There, you can get an overview of the PMMI member supplier, their specialties, equipment categories and contact information.

Congratulations—rather than spending precious time digging through endless results on a search engine, you have just made a connection with a new potential supplier. And you did it all for free!

Try out PMMI ProSource today and send us your feedback. We are always looking for ways to improve the site. Drop us a line at prosource@pmmi.org.

New for PACK EXPO Las Vegas, these expert-guided walking tours help you maximize your time and investment with a focused, insider’s look at the technologies and supplierstransforming packaging and processing.

Space is limited. Learn more and plan your experience at pwgo.to/8893

Designed for first-time attendees and senior decision-makers, this curated experience connects you with innovative suppliers who specialize in first-time automation and transformative solutions. You’ll get valuable insights, a strategic overview of key technologies, and face time with exhibitors who can drive your business forward.

• Monday, Sept. 29 | 1:30–3:00 p.m. – West & North Halls

Meet at West Lobby Attendee Resource Center

• Tuesday, Sept. 30 | 9:30–11:00 a.m. – South Halls

Meet at South Lower Lobby Attendee Resource Center

Sponsored by Lantech on Monday; Formic on Tuesday

For professionals focused on reducing environmental impact, this tour highlights cutting-edge sustainability solutions across the show floor. Led by an industry expert, the experience includes:

• Introductions and tour briefing

• Visits to eight forward-thinking exhibitors

• Custom game plan to guide continued exploration

• Refreshment break with snacks and networking

• Tuesday, Sept. 30 | 1:30–3:00 p.m.

• Meet at Sustainability Central (Booth SU-35000)

Sponsored by Anchor Packaging

PMMI Media Group editors scoured the PACK EXPO International 2024 show floor in Chicago, capturing video of the latest innovations in action. What follows is a carefully curated, categorized look at nearly 300 booth visits, each one selected for showcasing something both new and genuinely innovative. Drawing on decades of editorial experience covering PACK EXPO, our team identified the technologies, materials and machinery that pushes the boundaries of packaging and processing.

While others fumble through generic sustainability reports, get the insider’s playbook to packaging’s most disruptive sustainable innovations. Find new technologies that could redefine green packaging standards. This isn’t surfacelevel coverage; it’s the strategic intelligence that separates sustainability leaders from followers.

The age of human-only packaging lines is ending, and smart companies are already building their robotic advantage. Collaborative robots, autonomous systems, and AI-powered solutions that will redefine what’s possible in packaging operations. While others cling to outdated processes, take this opportunity to engineer the future of efficient production.

The packaging innovations unveiled at PACK EXPO Las Vegas 2025 will create tomorrow’s competitive advantages. Be among the first to access our next Innovations Reports covering every breakthrough that could transform your operations.

Outdated case packing lines can hemorrhage efficiency, and every minute of downtime means lost revenue. This report identifies the automation breakthroughs that eliminate the pain points slowing case packing operations. Case and tray erector and packer innovations bring benefits like small footprint, fast changeovers, and operator-friendly design. These aren’t just upgrades, they’re production line game changers that transform your biggest headaches into streamlined efficiency.

Suppliers of digital tools for packaging and processing are building advantages in OEE tracking, supply chain traceability, quality control, machine maintenance, product inspection, and more. This report identifies the digital transformation tools pushing the future of connected operations.

Today’s e-commerce landscape demands packaging that moves faster, wastes less, and still delivers a great unboxing experience. This report explores how innovators are stepping up with smarter automation, flexible formats, and materials designed to balance speed, protection, and sustainability.

Want the inside track on how flexible packaging is evolving? This report highlights breakthroughs in paper-based, bio-based, and monolayer materials. It also dives into equipment like form/fill/seal systems, flow wrappers, and bagging machines that offer small footprints, rapid changeovers, energy efficiency, and more. Whether you’re focused on sustainability, food safety, or consumer convenience, this report shows where flexible packaging is headed next.

Inspection and detection technologies safeguard product quality and keep lines moving. This report covers combination checkweigher/metal detector solutions, metal detectors with intuitive touch HMIs, AI-powered inspection systems, and more. Designed to detect contaminants and other errors at full production speed, these systems help manufacturers protect consumers, ensure compliance, and minimize downtime.

Beverage packaging is evolving fast to meet demands for greener materials and flexible equipment. Find innovations like paperboard ring carrier applicators, small-footprint wraparound labelers, and aluminum coffee pods designed for sustainability without sacrificing performance.

New medical packaging machinery combines small footprints with high-speed automation and operator-friendly features to streamline production. Innovations include vision inspection for IV bags and vacuum sealers with adjustability for varied applications. On the materials side, recycle-ready HDPE pouches and custom thermoformed designs reduce plastic use while ensuring product protection and integrity.

Conveying systems are evolving with smarter automation, modular designs, and improved integration with robotics and IoT. This report features innovations like direct drive belts with low tension, space-saving curved belt conveyance, and a spiral design that accommodates lighter loads. Accumulation innovations include adding single-filing or multi-laning functions. As conveyors play a growing role in OEE, these upgrades boost both line performance and flexibility.

Looking for the newest innovations in a space not listed above?

There’s plenty more where these came from. Visit pwgo.to/#### to find more Innovations Reports covering:

• Cartoning

• Dairy Food & Beverage

• Filling & Capping

• Fruits & Vegetables

• Liquid Foods

• Pharmaceutical Traceability & Inspection

• Prepared Foods

• Proteins

Found value in these insights?

Don’t let the momentum stop there.

The next wave of packaging breakthroughs is just around the corner. Stay in the loop by signing up to be among the first to receive our PACK EXPO Las Vegas 2025 Innovations Reports. Get a front-row seat to the technologies shaping what’s next in packaging and processing.

Coding, marking, and labeling are evolving to meet demands for speed, precision, and sustainability. This report covers innovations like eco-conscious printing, QR-enabled traceability, and high-speed labeling systems. It also includes RFID breakthroughs, from full e-commerce line tracking to RFID tags on digital seals, to boost supply chain visibility and compliance. Whether it’s reducing waste, enhancing shelf appeal, or enabling smart packaging, these advances are helping CPGs meet rising consumer and regulatory expectations.

Baking and snack packaging is advancing with automation and ease of use at the forefront. This report highlights innovations like HMI-enabled flow wrappers, dust-reducing seasoning systems, and vision-guided robots that gently handle delicate products.

This report features ultra-compact palletizers, cobot solutions for safe human-machine collaboration, and systems that let operators adjust footprints directly from the HMI. With a growing emphasis on safety, energy efficiency, and sustainability, these innovations bring precision, flexibility, and efficiency to the end of the line.

New pharma packaging technologies are tackling speed, precision, and compliance. Innovations in this report include a digital printer that customizes sealed blisters in small batches, a blister machine redesigned for reliable use with eco-friendly materials, and a rotary filler adaptable to include a combination scale or auger filler. These solutions help manufacturers protect drug integrity, streamline production, and meet evolving industry standards.

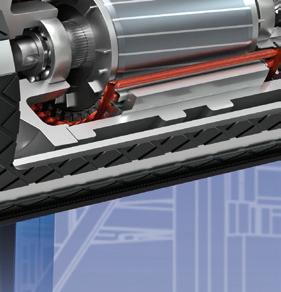

Packaging machinery controls and components are getting faster, smarter, and more adaptable. Cybersecuritycertified controllers and advanced safety fieldbus modules boost protection, while durable, high-torque belts improve efficiency and reliability. These upgrades give operations the flexibility to adapt to new products, meet changing demands, and keep lines running at peak performance.

ADHESIVE APPLICATION

BAUMER HHS W-4156

VALCO MELTON W-3730

BAG/POUCH FILL/SEAL (PRE-MADE BAGS)

ALLIEDFLEX TECHNOLOGIES, INC. SL-15021

CAM PACKAGING SYSTEMS W-3952

FORMOST FUJI CORPORATION W-2916

MASSMAN COMPANIES W-2722

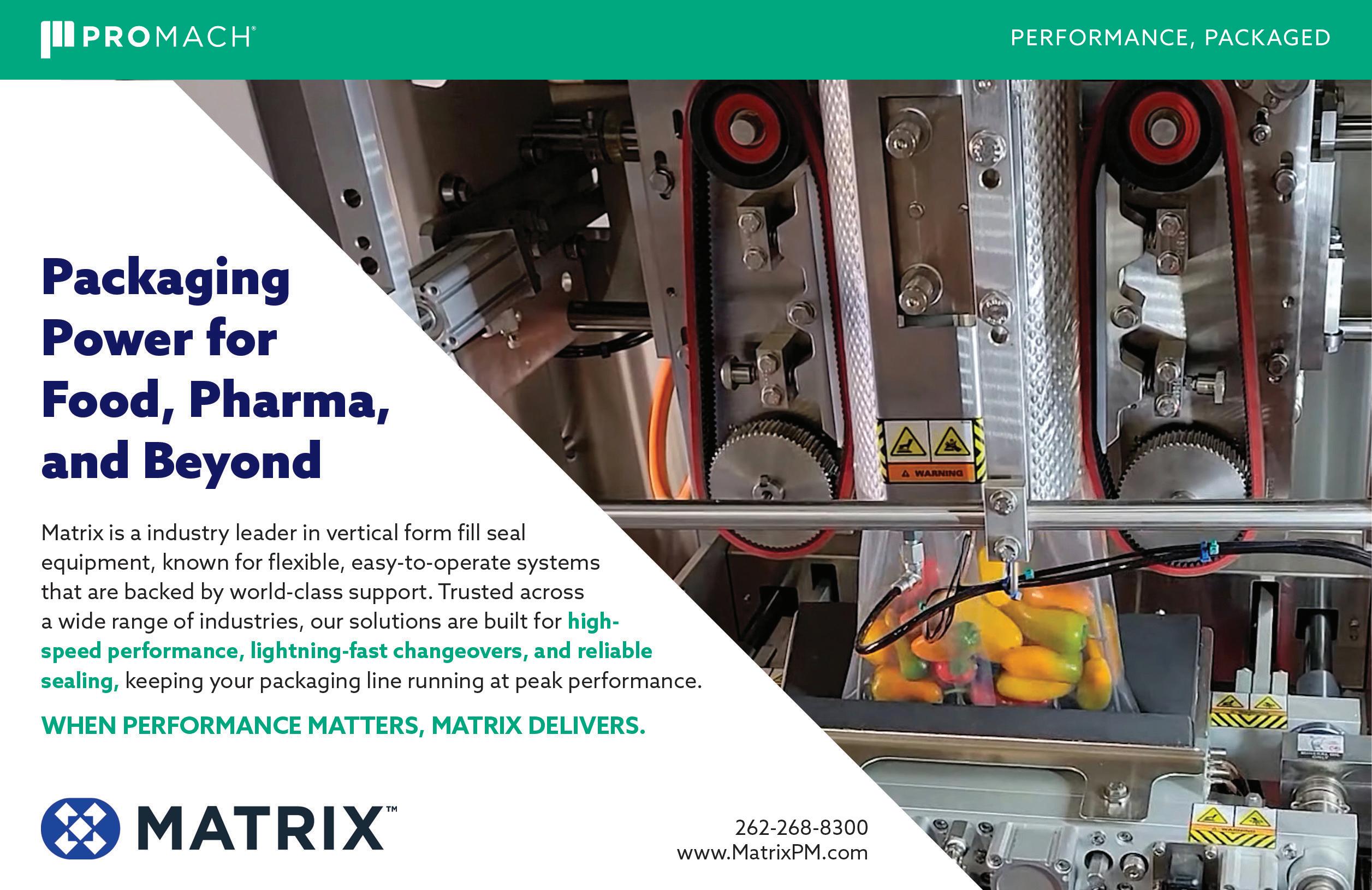

MATRIX PACKAGING MACHINERY, INC.

SU-28056

TRIANGLE PACKAGE MACHINERY CO. W-2200

BLISTERS/CLAMSHELLS/SKIN PACKAGING

HAVER & BOECKER USA, INC. SL-15015

BULK HANDLING/FILLING EQUIPMENT

HAVER & BOECKER USA, INC. SL-15015

VAC-U-MAX SU-26032

CARTONING

BLUEPRINT AUTOMATION (BPA) W-2230

CAMA NORTH AMERICA W-3452

ECONOCORP, INC. W-2522

JLS AUTOMATION SL-15018

MARCHESINI GROUP USA INC. N-5820

PMI KYOTO W-3308

SERPA PACKAGING SOLUTIONS W-1148

TRIANGLE PACKAGE MACHINERY CO. W-2200

CASE ERECT/SEAL

BAUMER HHS W-4156

EASTEY W-3628

ECONOCORP, INC. W-2522

EOL GROUP - STANDARD-KNAPP W-2110

FOCKE & CO W-2210

CASE/TRAY PACKING

BLUEPRINT AUTOMATION (BPA) W-2230

CAMA NORTH AMERICA W-3452

ECONOCORP, INC. W-2522

EOL GROUP - STANDARD-KNAPP W-2110

FOCKE & CO W-2210

JLS AUTOMATION SL-15018

MARCHESINI GROUP USA INC. N-5820

MASSMAN COMPANIES W-2722

PMI KYOTO W-3308

PROSYS FILL LLC. W-2552

SERPA PACKAGING SOLUTIONS W-1148

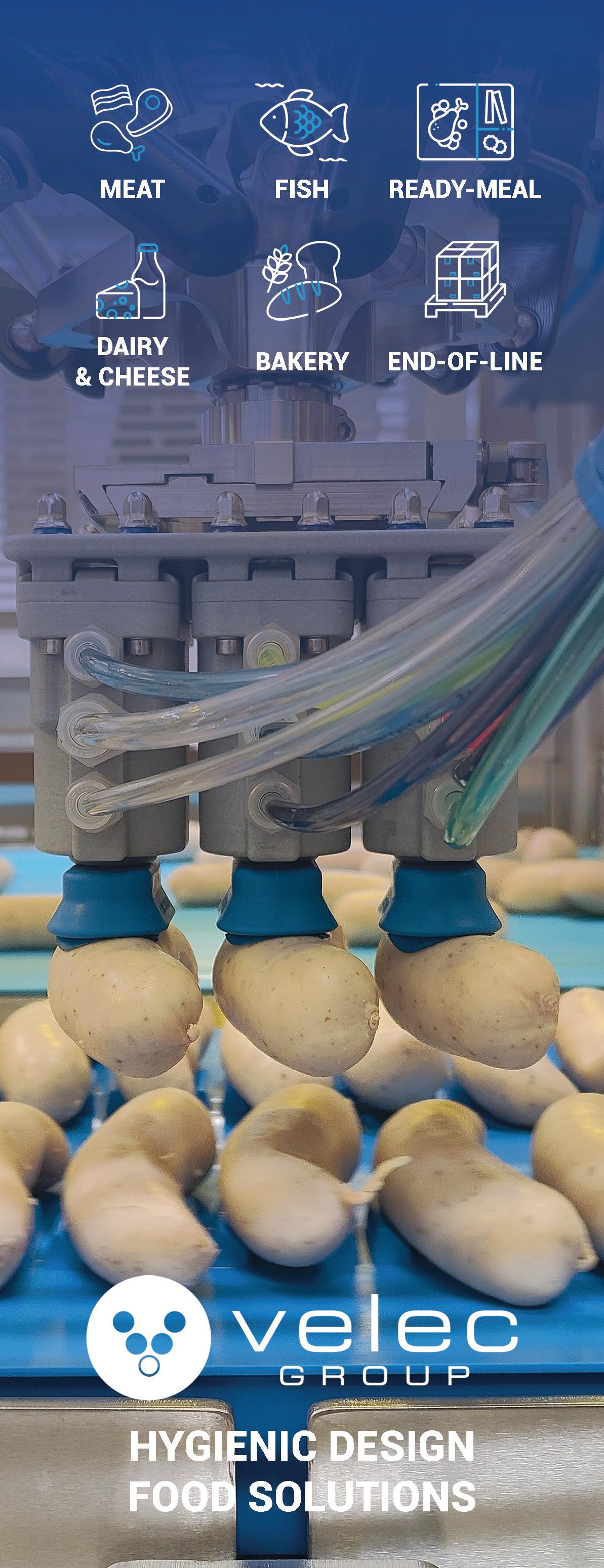

VELEC SYSTEMS W-3550

CODING/MARKING

LEIBINGER N-9262

SQUID INK MANUFACTURING, INC. W-3628C

WEBER PACKAGING SOLUTIONS, INC. W-2544

CONTROLS & MACHINE COMPONENTS

BECKHOFF AUTOMATION LLC SL-15047

SLEEVE SEAL W-3924

NERCON CONVEYOR SYSTEMS W-3300

VDG (VAN DER GRAAF) N-8258

CONVEYING & ACCUMULATION

CAM PACKAGING SYSTEMS W-3952

EOL GROUP - STANDARD-KNAPP W-2110

HEAT AND CONTROL, INC. W-2506

MODULAR CONVEYOR EXPRESS W-3300

NERCON CONVEYOR SYSTEMS W-3300

SPAN TECH, LLC SL-13009

VAC-U-MAX SU-26032

VDG (VAN DER GRAAF) N-8258

VELEC SYSTEMS W-3550

CUP/TRAY FILLING/DEPOSITING/SEALING

VELEC SYSTEMS W-3550

FEEDING/INSERTING/UNSCRAMBLING

MODULAR CONVEYOR EXPRESS W-3300

NITA LABELING SYSTEMS W-3268

FILLING/CAPPING, DRY

SPEE-DEE PACKAGING MACHINERY, INC. W-1916

YAMATO CORPORATION SL-11033

FILLING/CAPPING, LIQUID & VISCOUS

HAVER & BOECKER USA, INC. SL-15015

MARCHESINI GROUP USA INC. N-5820

MATRIX PACKAGING MACHINERY, INC. SU-28056

PROSYS FILL LLC. W-2552

VELEC SYSTEMS W-3550

FLOW WRAPPING

FORMOST FUJI CORPORATION W-2916

FORM/FILL/SEAL - HORIZONTAL

FORMOST FUJI CORPORATION W-2916

FORM/FILL/SEAL -VERTICAL

ALLIEDFLEX TECHNOLOGIES, INC. SL-15021

HEAT AND CONTROL, INC. W-2506

MATRIX PACKAGING MACHINERY, INC. SU-28056

TRIANGLE PACKAGE MACHINERY CO. W-2200

INSPECT/ DETECT/ CHECK WEIGH/ X-RAY

NITA LABELING SYSTEMS W-3268

SPEE-DEE PACKAGING MACHINERY, INC. W-1916

VALCO MELTON W-3730

LABELING

AMERICAN FILM & MACHINERY W-3628B

LEIBINGER N-9262

MARCHESINI GROUP USA INC. N-5820

NITA LABELING SYSTEMS W-3268

QUADREL LABELING SYSTEMS W-3600

SLEEVE SEAL W-3924

WEBER PACKAGING SOLUTIONS, INC. W-2544

MATERIAL HANDLING

MODULAR CONVEYOR EXPRESS W-3300

NERCON CONVEYOR SYSTEMS W-3300

SPAN TECH, LLC SL-13009

MULTIPACKING/SHRINK BUNDLING/BANDING

CAMA NORTH AMERICA W-3452

EASTEY W-3628

EOL GROUP - STANDARD-KNAPP W-2110

PALLETIZING/DEPALLETIZING

COLUMBIA MACHINE, INC. W-2364

COLUMBIA/OKURA LLC W-2364

EOL GROUP - STANDARD-KNAPP W-2110

FOCKE & CO W-2210

HAVER & BOECKER USA, INC. SL-15015

MARCHESINI GROUP USA INC. N-5820

VELEC SYSTEMS W-3550

ROBOTICS

AGILOX NORTH AMERICA N-6116

BLUEPRINT AUTOMATION (BPA) W-2230

COLUMBIA/OKURA LLC W-2364

JLS AUTOMATION SL-15018

MASSMAN COMPANIES W-2722

PMI KYOTO W-3308

VELEC SYSTEMS W-3550

SHRINK WRAPPING

EASTEY W-3628

STRETCH WRAPPING/PALLET LOAD STABILIZATION

COLUMBIA/OKURA LLC W-2364

TAMPER-EVIDENT MACHINERY

AMERICAN FILM & MACHINERY W-3628B

SLEEVE SEAL W-3924

THERMOFORM/FILL/SEAL

MARCHESINI GROUP USA INC. N-5820

MULTIVAC GROUP N-7630

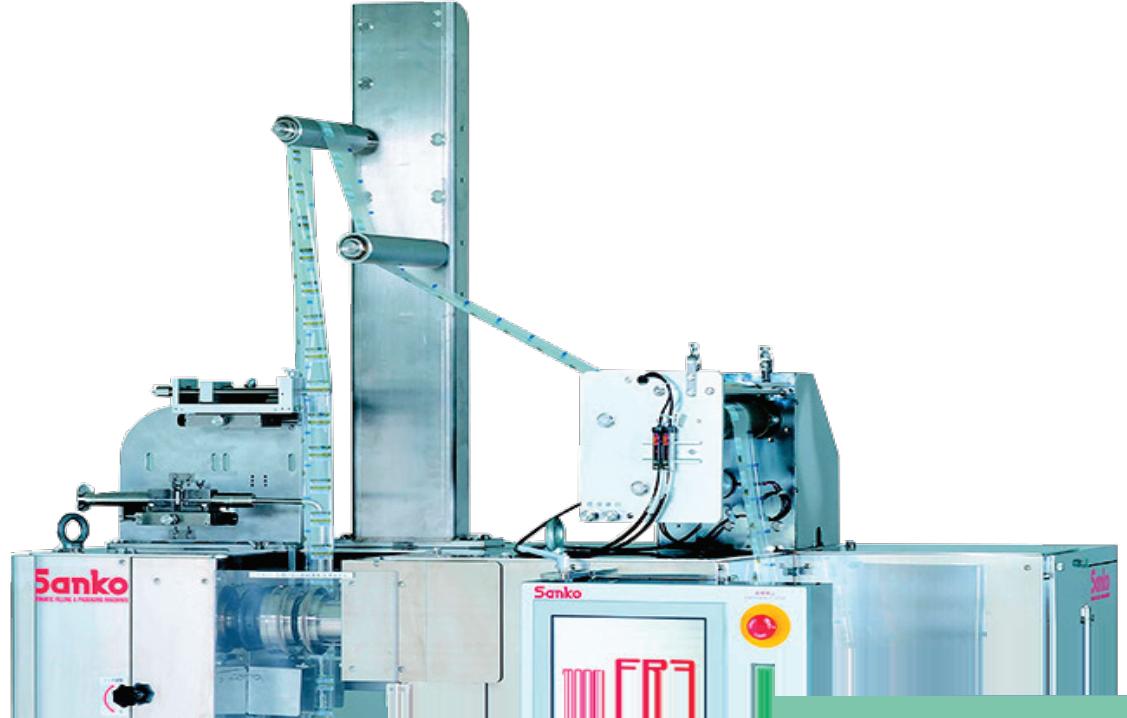

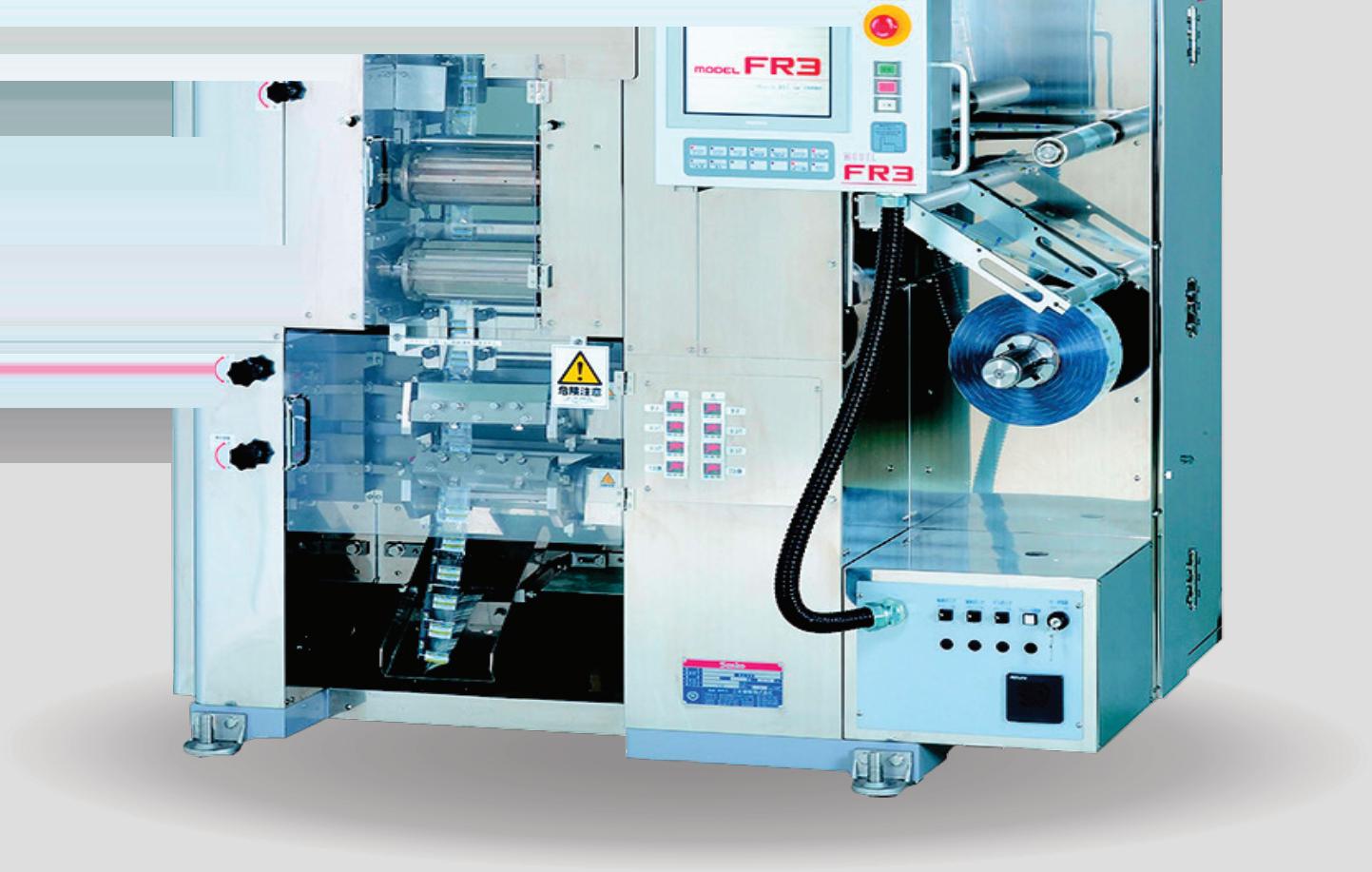

THEM/SANKO NORTH AMERICA SL-15080

WEIGHING/COMBINATION SCALES

CAM PACKAGING SYSTEMS W-3952

HEAT AND CONTROL, INC. W-2506

YAMATO CORPORATION SL-11033

ADDITIVES, COATINGS & INKS

SQUID INK MANUFACTURING, INC. W-3628C

FLEXIBLE PACKAGING

ALLIEDFLEX TECHNOLOGIES, INC. SL-15021

MULTIVAC GROUP N-7630

SPAN TECH, LLC SL-13009

LABELS

AMERICAN FILM & MACHINERY W-3628B

CONTRACT PACKAGING

SPAN TECH, LLC SL-13009

SPEE-DEE PACKAGING MACHINERY, INC. W-1916

THEM/SANKO NORTH AMERICA SL-15080

E-COMMERCE

LEIBINGER N-9262

PACKAGING LINE INTEGRATION

EOL GROUP - STANDARD-KNAPP W-2110

MULTIVAC GROUP N-7630

SPAN TECH, LLC SL-13009

THEM/SANKO NORTH AMERICA SL-15080

YAMATO CORPORATION SL-11033

SUSTAINABILITY

SERPA PACKAGING SOLUTIONS W-1148

Phone: +1 (678) 926-9659 5775

Email: us.sales@agilox.net

www.agilox.net

AGILOX is a leading manufacturer of Autonomous Mobile Robots (AMRs), offering innovative material handling solutions across a wide range of industries—including packaging and logistics. *Current Vehicle lineup Left to Right: AGILOX ODM, OCF, OFL (To be Debuted at PACK EXPO), and the ONE.

Driven by a mission to revolutionize the world of AMRs, AGILOX focuses on ease of use and scalability. Their solutions allow customers to seamlessly integrate new vehicles and adapt workflows—often with just the click of a button.

AGILOX AMRs transport loads autonomously, intelligently navigating warehouse environments and optimizing routes in real time. Unlike centralized systems, AGILOX uses a decentralized approach, powered by its proprietary X-Swarm Technology—an AI-based software that enables robots to communicate and coordinate their movements and statuses dynamically.

All AGILOX components—including hardware, software, and the extremely intuitive HMI—are developed in-house to deliver the most reliable and user-friendly experience possible.

Founded in Austria in 2009, AGILOX now operates globally, with customers across Europe, North America, and Asia. The U.S. headquarters is located in Atlanta, Georgia.

780 Apex Rd, Sarasota, FL 34240

Phone: 941/923-1181

www.alliedflex.com

Email: dfc@alliedflex.com

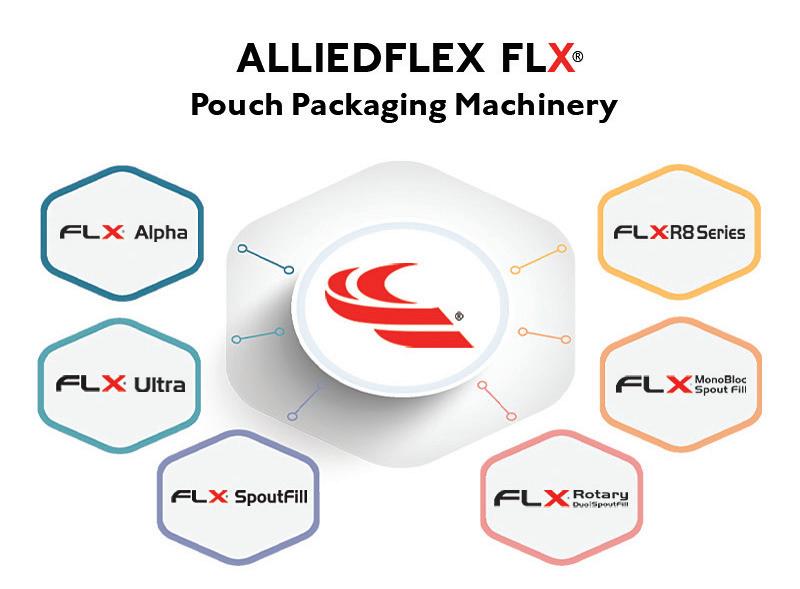

ALLIEDFLEX® THE AUTHORITY in STAND-UP POUCH PACKAGING & MACHINERY

ALLIEDFLEX® is a leading North American supplier of Global Standup Pouch Packaging Machinery and Turnkey System Provider for a variety of food and non-food applications. We also provide integrated systems for Pouch Processing (Pasteurization, Cooling) & Automated Pouch Packaging including Robotic Flex Top Load, Multi Pack Cartoning, Collating, and Case Packing Systems.

ALLIEDFLEX® specializes in Pouch & Bag Packaging Machinery for Standup Pouch and a variety of Flexible Packaging Formats.

Zipper or "slider" styles, retort pouch, spouted pouch, die cut shaped pouch, side gusseted, stick pack, stand-up pouch, standing pouch and aseptic pouch machinery. Intermittent and continuous motion vertical form fill seal VFFS machinery technologies from the most respected suppliers in the world.

We offer: Fill Seal (pre-made), Fill through Spout, and Form Fill Seal (roll stock) HFFS Machinery Technologies, Horizontal Pouch Packaging, Vertical Pouch Packaging, Turnkey Robotic Automation for Pouch Processing and End of Line Secondary Packaging Systems, Semi & Automated Pouch Leak Detection Machinery to suit your present and future needs.

Markets Served: Beverage, Applesauce, Fruit Puree, Baby Food, Candy, Snacks, Dried Fruit, Meal Kits, Processed Foods, Wine, Sauces, Cereal, Detergent Pods, Pet Treats, Pet Food, Shredded Cheese, Dairy Foods, Bakery Products, Cookies, Croutons, Coffee, Health & Beauty, Oil, Granola, Rice, Pasta, Yogurt, Ice Cream, Dairy, Poultry, Frozen Foods, Beverages, Personal Care, Home Care, Chocolate, Protein Powder, Nutraceuticals, Spices, Pharmaceuticals.

Our Global Machinery Partners include:

VELTEKO | NEXES Control | HDG Packaging Machinery | IMA FILLSHAPE | ARANOW Stick Pack Machinery | SCALDOPACK Spouted Pouch Machinery | Umbra Large Bag Machinery.

We also manufacture our own line of Pouch Packaging Machinery under our exclusive registered FLX® Brand Packaging Machinery. These FLX® machines include Pilot Plant Models and our popular FLX® R8 Rotary Fill Seal Models providing moderate output systems to get you in the market quickly and economically. ASK ALLIEDFLEX!

See us at booth #SL-15021

10570 Success Lane, Dayton, OH 45458

Phone: 937-886-3160

Email: sales.usa@baumerhhs.com

www.baumerhhs.com/applications/end-of-line

For PackExpo Las Vegas, Baumer hhs plans to feature our Tesla electrically-activated hot melt application technology, our PX-1000 cold glue applicator, DF char-resistant hot melt hoses, X-Grip manual hot melt handgun and our pallet stabilization swirled-hot melt solution to reduce the use of stretch wrap. All these products promote more efficient and sustainable operations, promoting the reduction or elimination of compressed air, non-recyclable stretch wrap, and the number of spare parts used over the life of the applicators. Visit us in booth W-4156 and find out how you can enjoy more sustainable, stable and satisfying application solutions with Baumer hhs.

See us at booth #W-4156

13130 Dakota Ave, Savage, MN 55378

Phone: 952/890-0000

Email: beckhoff.usa@beckhoff.com

www.beckhoff.com/packexpo

Go smart, modular, and cabinet-free this year at PACK EXPO Las Vegas! Visit the Beckhoff booth to explore how our cutting-edge automation solutions can transform your packaging machines. From boosting throughput to enabling smarter control systems, we’re here to help you automate what's next in packaging.

With pluggable IPC, I/O and drive technology modules, the machine mounted MX-System delivers maximum space and time savings for packaging machine builders and end users. The modular, IP67-rated control cabinet replacement can be decentralized on machines and conveyance systems as needed.

As our next step in mechatronics technology, XTS NCT turns Beckhoff’s popular linear transport system into a low-profile robot with contact-free power and communication to movers with directly attached effectors.

And with the cost-effective XTS EcoLine motor modules, users enjoy 95% of the performance at just 55% cost—fully compatible with existing XTS components. Reliable, and ideal for scalable, intelligent product handling in diverse applications, XTS EcoLine opens up intelligent product transport to countless new packaging machines.

Other must-see highlights:

• No-code TwinCAT 3 Machine Learning Creator for real-time deployment of AI models

• XPlanar flying motion technology for adaptive automation in packaging

• Beckhoff Smart System Diagnosis (B/SSD) for predictive maintenance in servo systems

7041 Boone Ave N., Brooklyn Park, MN 55428

Phone: 800-877-5658

www.afmsleeves.com

Email: info@afmsleeves.com

AFM’s shrink sleeve applicators are designed for middle, full body, and full body and cap applications. The LX-150 is designed for moderate production rates up to 300 pieces per minute and is an ideal solution for industries including food and beverage, pharmaceutical, nutraceutical, health and beauty, and other manufactured goods.

Shrink Tunnels for shrink sleeve labels and tamper-evident band application from American Film & Machinery are designed for middle, full body, combo packs, and full body and cap shrink applications. Our tunnels are a perfect addition to shrink labeling lines in manufactured goods industries, including food and beverage, pharmaceutical, nutraceutical, health, and beauty, consumer goods, and chemical products.

Shrink sleeves are an ideal solution for marketing your products to make them stand out on the shelf. Shrink sleeve labels cover your container from top to bottom and can be designed with 360 degrees of full-color graphics, text, and even unique finishes. With full reverse print capabilities, our shrink sleeves are the perfect solution for stimulating shelf appeal to your entire product line, even when using the same container for all of your products.

Tamper-evident shrink bands are a fast and easy way to secure your containers and add value and protection to your products. Shrink bands are used in a variety of industries, from personal care products, cosmetics, foods, and pharmaceuticals. Our shrink bands are available in a variety of colors and can include perforation for easy removal.

American Film & Machinery (AFM), headquartered in Brooklyn Park, Minnesota, is a singlesource supplier of all of your Shrink Sleeve Labeling needs. We successfully introduced the first generation of rotary shrink sleeve labelers over 57 years ago. Since then, through our commitment to research and development, constant innovation, and implementation of the latest technology, and the wealth of knowledge and experience of our highly qualified and motivated workforce, we have evolved far beyond our original role as a manufacturer of specialty machinery. Today, AFM is a dynamic partner for our customers, creating a harmonious marriage of shrink sleeve labelers, heat shrink tunnels, full-body labels, tamper-evident seals, contract labeling, and packaging services.

See us at booth #W-3628

Make your products jump from the shelf with complete coverage of your product container.

Economical

With over 40 years of experience in shrink labeling, AFM offers a complete line of shrink sleeve labeling and tamper evident band applicators, tunnels, shrink sleeve labels, and tamper bands. Supplying both the machines and the material, AFM provides a single source that works together seamlessly and maximizes uptime. For more information, visit www.afmsleeves.com or call 714-974-9006 for an Authorized

804/520-5400

www.blueprintautomation.com

BPA is a world leader in end-of-line packaging automation. With a diverse and innovative team of experts, BPA designs, develops and manufactures primary and secondary packaging solutions for QSR, food service and retail products. You make it. We pack it.

• Vision Guided Robotics: Applying vision and robots to solve difficult solutions not meant for more mechanical solutions. Our systems pick both unpackaged (naked) and packaged items whether loading directly to a flow wrapper, H/F/F system, cartoning, or case packing.

• Case and Tray Packing: Packing solutions to load flexible bags, cartons and more into case formats such as RSC, wrap around, shelf ready, pallet display, tray, master bag and more. Providing both vertical and horizontal pack solutions.

To give you more options, BPA has designed the EasyD shelf ready case with a no tear front that allows for easy loading and no per box fee!

• Turnkey Packaging Systems: Taking total control of your packaging line from the end of processing, your F/F/S or flow wrapper through palletizing!

www.camagroup.us

For over 40 years Cama has been an international leader in the engineering and production of high technology secondary packaging systems. We offer complete integrated packaging lines – from primary packages to final packaging, including robotics, cartoning, case packing and sleeving.

Cama proudly serves a diverse customer base with industry expertise in Food, Beverage, Bakery, Confectionery, Coffee, Ice Cream, Dairy, Ready Meals, Non-Food including Personal, Health & Home Care, Pet Food, Pharmaceutical and more.

Cama serves the North American and Global market providing local engineering, manufacturing and aftermarket services, including technical service, programming and parts.

Cama prides itself in long term customer partnerships through our consultative approach to provide customized systems using proven modular state of the art technology.

Ready to learn more? Be sure to add Cama to your list of "must see exhibitors" and contact us today if you would like to schedule a consultation with one of our specialists.

Phone: 360/694-1501

www.palletizing.com

Email: pallsales@colmac.com

As a complete systems integrator providing high speed, high level infeed, floor level and robotic palletizing solutions combined with systems engineering and turnkey installation capabilities, Columbia Machine has a solution to meet the needs of virtually any palletizing application.

With expertise in Food, Beverage, Tissue Towel, Personal Care, Chemical, Bakery, Dairy, Snack Foods and more, you will not find a palletizing solutions provider offering more flexibility than Columbia Machine. Put us on your list of “must see exhibitors” to learn more about Columbia’s sustainability initiatives, the easiest palletizer changeover available, and see why we have become the largest palletizing solutions provider in North America.