Driving Sustainable Transformation

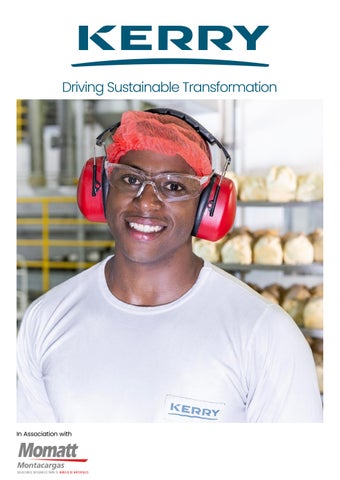

As Chief Operating Officer for Kerry Latin America, Fabio Figueiredo leads one of the region’s most dynamic supply chain transformations, anchored in digital innovation, sustainability, and customer-centric growth. Over three decades, Kerry has evolved from a regionally focused food and beverage solutions provider to a global leader in sustainable nutrition.

In this exclusive interview, Fabio discusses how Kerry is leveraging advanced technologies such as AI, predictive analytics, and integrated planning platforms to build a more agile, resilient, and environmentally responsible supply chain. He also highlights the company’s commitment to local sourcing, supplier collaboration, and operational excellence, ensuring that Kerry continues to deliver value, reliability, and sustainability across its Latin American network.

Kerry has marked 30 years of operations in Latin America. How has the supply chain evolved over this period, and what have been the key drivers of transformation in the region?

Over the past three decades, Kerry’s supply chain in Latin America has undergone a remarkable transformation, driven by digitalisation, operational resilience, and a deep commitment to sustainability. What began as a largely manual and localised network has evolved into a highly connected, data-driven ecosystem powered by technologies such as AI, machine learning, and advanced analytics. These tools have strengthened demand forecasting, optimised inventory management, and improved network design, making the supply chain more agile and responsive to market dynamics.

Key drivers of this transformation include the integration of digital tools for real-time visibility, robust risk management frameworks to navigate complex regulations, and a customer-centric approach that aligns supply chain decisions with business priorities. Kerry has also expanded its regional footprint through new warehouses and distribution centers, improving service levels and reducing lead times.

Sustainability remains at the heart of this transformation. Initiatives focused on responsible sourcing, waste reduction, and efficient resource use have created a more resilient and environmentally conscious supply chain. By combining technology, local expertise, and a sustainability-first mindset, Kerry continues to build a supply chain that is efficient, adaptive, and aligned with the evolving needs of the Latin American market.

With the integration of AI and machine learning in logistics, how is Kerry utilising these technologies to enhance supply chain operations and meet the growing demands of the Latin American market?

Kerry is strategically leveraging Artificial Intelligence (AI) and machine learning to drive measurable improvements across its end-to-end supply chain operations in Latin America. These technologies are applied from sourcing and procurement through to internal processes and customer fulfillment, optimising key functions such as inventory management, demand forecasting, and network planning. By analysing vast amounts of structured and unstructured data, AI and machine learning models can detect emerging market trends, anticipate potential disruptions, and recommend proactive mitigation strategies. This data-driven approach strengthens agility and resilience, enabling Kerry to respond swiftly to market shifts and evolving customer expectations.

Beyond operational efficiency, AI-powered analytics also support Kerry’s sustainability goals by reducing waste, optimising resource use, and enhancing transport planning to cut emissions. These initiatives reflect Kerry’s wider strategy of embedding innovation and responsibility across its operations.

The result is a supply chain that is smarter, faster, and more adaptive, one that combines advanced technology with sustainability to meet the dynamic demands of the Latin American market and deliver lasting value to customers.

Kerry has been expanding its presence in Latin America, including new warehouses and distribution centers. How do these developments align with Kerry’s overall supply chain strategy in the region?

Kerry’s expansion across Latin America aligns directly with its commitment to better serve customers through a deeper understanding of local market needs. This strategic growth enhances Kerry’s ability to deliver innovative solutions efficiently, ensuring faster and more reliable service to meet increasing regional demand.

By optimising its physical footprint through new warehouses and distribution centers, Kerry can manage inventory more effectively, reduce lead times, and improve service levels, all while supporting local market growth. These facilities also allow Kerry to better respond to evolving consumer expectations around authentic taste, functionality, and nutrition.

Moreover, this expansion reinforces Kerry’s commitment to sustainability. Each development integrates environmentally conscious practices, enhancing operational efficiency while advancing the company’s broader goal of embedding sustainability throughout its supply chain and customer partnerships.

Sustainability is a core focus for Kerry. How are supply chain operations in Latin America contributing to Kerry’s global sustainability goals, particularly in terms of reducing environmental impact?

Kerry’s supply chain operations in Latin America are central to advancing the company’s global sustainability objectives, particularly around reducing environmental impact and driving long-term efficiency. The region has become a model for how technology, innovation, and local collaboration can create a more responsible and resilient supply chain.

Through the use of advanced technologies such as AI and machine learning, Kerry optimises resource utilisation, minimises food and packaging waste, and enhances route planning to cut fuel consumption and carbon emissions. These digital tools not only improve operational performance but also support Kerry’s mission to operate with minimal environmental impact.

Sustainability is embedded across every stage of the supply chain, from responsible sourcing of raw materials and water conservation to recycling initiatives and waste reduction. A standout example is Kerry’s Dairy Supply Pool initiative, which partners with local suppliers near key manufacturing sites to reduce transportation emissions while strengthening local economies.

All these efforts align with Kerry’s broader ambition to deliver sustainable nutrition to two billion people. By embedding sustainability into every link of the supply chain, Kerry is building an operation that is efficient, responsible, and future-ready, supporting both global goals and the communities it serves across Latin America.

With a diverse supplier base across Latin America, how does Kerry ensure consistency, quality, and compliance in its supply chain operations?

Kerry ensures a robust, reliable, and compliant supplier network through a combination of rigorous standards, continuous monitoring, and strong collaborative partnerships. The company enforces strict quality protocols and certification requirements, complemented by regular audits to verify that every supplier meets Kerry’s global standards.

Each supplier undergoes comprehensive evaluation, covering end-to-end processes, quality management systems, regulatory compliance, and social responsibility practices, to ensure full alignment with Kerry’s values and operational expectations. Through its supplier collaboration programme, Kerry builds transparent, long-term relationships, offering guidance and training to help partners continuously improve their performance.

Sustainability is the foundation of Kerry’s approach. Suppliers are encouraged and supported to adopt responsible practices such as reducing waste, optimising resources, and cutting emissions. To maintain compliance, Kerry employs robust monitoring systems that track adherence to both local and international regulations, proactively managing market and regulatory risks.

By integrating these strategies, Kerry maintains consistency, quality, and compliance across its diverse supplier base, ensuring that every partnership contributes to the company’s vision of sustainable growth and operational excellence in Latin America.

Operating across multiple countries in Latin America presents regulatory challenges. How does Kerry manage compliance and mitigate risks associated with varying regulations in the region?

Kerry manages the region’s regulatory complexity through a comprehensive compliance management framework that integrates proactive monitoring, local expertise, and advanced digital tools. This approach ensures full alignment with both global and country-specific regulatory requirements across Latin America.

An integrated compliance system enables daily horizon scanning, continuous regulatory intelligence gathering, and automated documentation workflows. Country-specific requirements are centrally tracked and regularly updated, while local compliance specialists ensure operational alignment and rapid response to regulatory changes. Automated platforms manage certifications, audit trails, and reporting, reducing manual intervention and significantly lowering compliance risks. Recognising the growing importance of cybersecurity and ESG compliance, Kerry has invested in robust data protection systems to safeguard its digitalised supply chain, while complementing internal controls with SEDEX and SMETA audit frameworks in key geographies to uphold ethical, environmental, and human rights standards.

Regular internal and supplier audits, combined with dynamic risk assessments, help identify and mitigate non-compliance early. Through proactive engagement with regulatory authorities and continuous optimisation of processes, Kerry ensures both operational continuity and strong governance across its Latin American operations.

Enhancing Customer Service Through Supply Chain Excellence: Customer satisfaction is closely tied to supply chain performance. What initiatives has Kerry implemented to ensure high service levels and responsiveness to customer needs in Latin America?

Kerry’s supply chain strategy in Latin America is built on three pillars, end-to-end operational excellence, technology enablement, and local market alignment, with customer satisfaction at its core. The company has established customer care centres of excellence, strategically located manufacturing facilities, and optimised distribution networks across the region. This integrated network, supported by a robust S&OP process, enables Kerry’s supply chain teams to work closely with commercial partners, fostering deep market understanding, improving order fulfilment, and ensuring rapid response to shifts in customer demand.

Advanced data analytics and predictive modelling further enhance performance by strengthening demand forecasting, capacity planning, and inventory optimisation. These tools allow Kerry to anticipate market fluctuations, minimise disruptions, and maintain exceptional service levels. Collaboration with local suppliers and logistics partners also reinforces agility and reliability throughout the value chain.

Customer-centric KPIs, focused on responsiveness and on-time, in-full delivery, are embedded within supply chain objectives to ensure service excellence remains a measurable priority. Continuous feedback loops with customers and commercial teams enable agile adaptation to evolving requirements, solidifying Kerry’s reputation for reliability, innovation, and customer focus across Latin America.

MOMATT is a strategic ally that drives industrial growth across Mexico. With strategically located distribution centers and a highly trained technical team, it supports industries seeking greater efficiency and productivity. Through its Training Center, CECAM, it prepares certified professionals who strengthen the country’s operational capacity. MOMATT’s dedication to quality, innovation, and excellence reinforces its role as a company of great strength—one that moves materials, progress, and opportunity for every collaborator and partner.

With over 50 years of experience and a forward-looking vision, MOMATT stands as Mexico’s benchmark in operational efficiency, reliability, and specialized service. Its philosophy is clear: deliver precise solutions backed by technology, expertise, and a strong commitment to each client’s logistical needs.

The company integrates every part of the process—from sales, rental, and maintenance of forklifts to technical training and spare-parts supply—ensuring continuity, safety, and high performance in demanding operations.

The global supply chain landscape has faced significant disruptions in recent years. How has Kerry’s supply chain in Latin America adapted to these challenges to maintain resilience and continuity?

Kerry’s supply chain in Latin America has implemented a multi-layered risk mitigation strategy to safeguard resilience and ensure uninterrupted operations amid global disruptions. Diversifying the supplier base across multiple geographies has reduced single-source dependencies and mitigated both geopolitical and sanitary risks. Advanced inventory management practices, supported by Kerry’s extensive global manufacturing footprint, enable dynamic safety stock calculations and real-time visibility across facilities. This ensures optimal stock levels, balancing working capital efficiency with the ability to respond rapidly to demand fluctuations and supply interruptions.

On the logistics front, Kerry employs multimodal transport planning and flexible routing algorithms to navigate bottlenecks and maintain service continuity. Scenario-based contingency planning and integrated S&OP (Sales & Operations Planning) cycles further enable swift, data-driven decisions in response to capacity constraints or market shifts. Through strategic partnerships with local suppliers and third-party logistics providers, Kerry has strengthened regional agility and response capabilities. Continuous monitoring of market, logistics, and regulatory conditions, combined with digital control towers for end-to-end visibility, allows proactive exception management and rapid issue resolution. This comprehensive and digitally enabled approach ensures Kerry’s Latin American supply chain remains resilient, adaptive, and capable of sustaining high service levels, even in the face of global volatility.

Effective supply chain management often requires cross-functional collaboration. How does Kerry foster collaboration between supply chain, procurement, and other departments to drive success in Latin America?

Kerry promotes cross-functional collaboration in Latin America through agile communication, integrated digital platforms, and a culture of transparency and shared accountability. These enablers connect functions such as supply chain, procurement, manufacturing, quality, RD&A, regulatory, and commercial teams, ensuring alignment across every stage of the value chain.

Real-time collaboration tools provide visibility across workflows, enabling fast information sharing, issue resolution, and decision-making. Cross-functional project teams are established for critical initiatives such as S&OP, innovation, and continuous improvement, ensuring synchronisation between demand planning, sourcing, and production scheduling.

Regular interdepartmental meetings, performance reviews, and workshops foster knowledge exchange and best-practice sharing, while shared KPIs and performance dashboards align all teams around common business objectives, customer priorities, and compliance standards.

Joint training programmes and capability-building sessions further embed a collaborative mindset, empowering teams to work seamlessly across functions. This integrated approach enhances agility, end-to-end visibility, and operational reliability, key elements in Kerry’s continued success and customer satisfaction across the Latin American region.

Looking ahead, what are the key trends and opportunities you foresee for Kerry’s supply chain operations in Latin America, and how is the company preparing to capitalise on them?

Looking ahead, Kerry’s supply chain strategy in Latin America is guided by three key pillars: customer centricity, digital transformation, and network resilience. Each of these drivers reflects the company’s focus on creating a more agile, sustainable, and technology-enabled supply chain capable of meeting the region’s evolving market demands.

Customer centricity remains central to Kerry’s approach. Understanding the unique needs of diverse Latin American markets allows the company to design tailored solutions that deliver authenticity, reliability, and innovation, strengthening relationships and enhancing service excellence. Sustainability continues to shape decision-making across every function. Kerry’s initiatives focus on reducing food waste, lowering carbon emissions, transitioning to eco-friendly packaging, and prioritising responsible sourcing. These efforts not only support global sustainability goals but also align with the expectations of environmentally conscious customers and partners.

Digital transformation will be a major enabler of this strategy. The adoption of advanced technologies, including artificial intelligence, predictive analytics, and integrated planning platforms, will enhance demand forecasting, scenario planning, and responsiveness to market shifts. This ensures improved speed to market and service performance.

To bolster resilience, Kerry is expanding local manufacturing and sourcing capabilities while diversifying its supplier base. This reduces reliance on distant suppliers, shortens lead times, and lowers transportation-related emissions.

Through continuous investment in technology, sustainability, and local expertise, Kerry is positioning its Latin American supply chain to remain agile, compliant, and customer-focused, well-equipped to capitalise on emerging opportunities and drive long-term growth across the region.

Kerry Group is a global leader in taste and nutrition, offering innovative food-, beverage- and functional-ingredient solutions across Latin America. With a deep commitment to sustainable nutrition and local communities, Kerry helps brands deliver healthier, better-tasting products while making a positive impact on people and planet. Their LATAM operations span multiple countries from Mexico to Brazil, leveraging global expertise and local insight.

Fabio Figueiredo Chief Operating Officer